Analysis of China’s Manufacturing Industry Carbon Lock-In and Its Influencing Factors

Abstract

1. Introduction

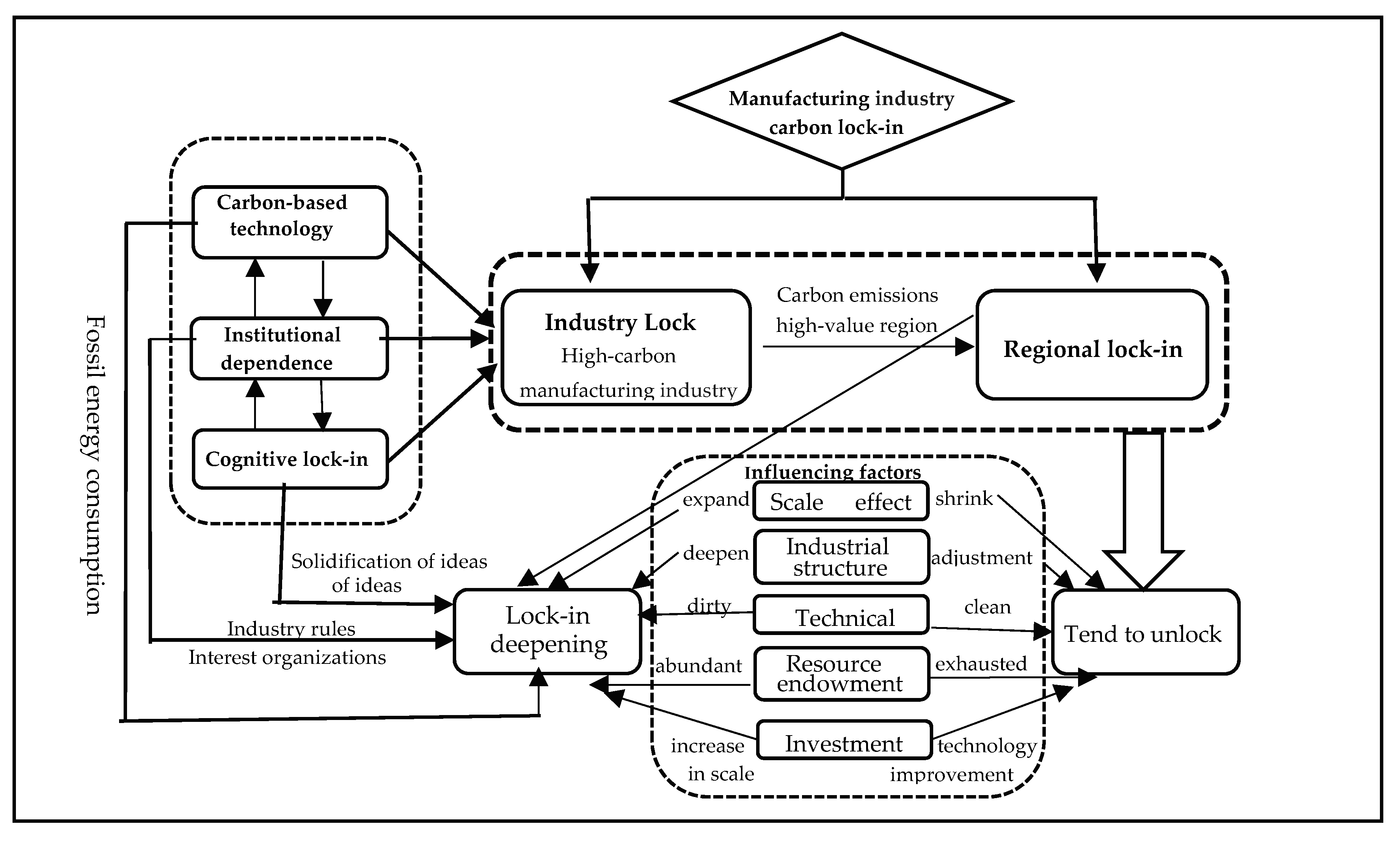

2. Analysis Framework

2.1. Carbon Lock-In of High-Carbon Manufacturing Industry

2.2. Carbon Lock-In of High-Carbon Regional and Influencing Factors

3. Research Methods and Selection of Variables

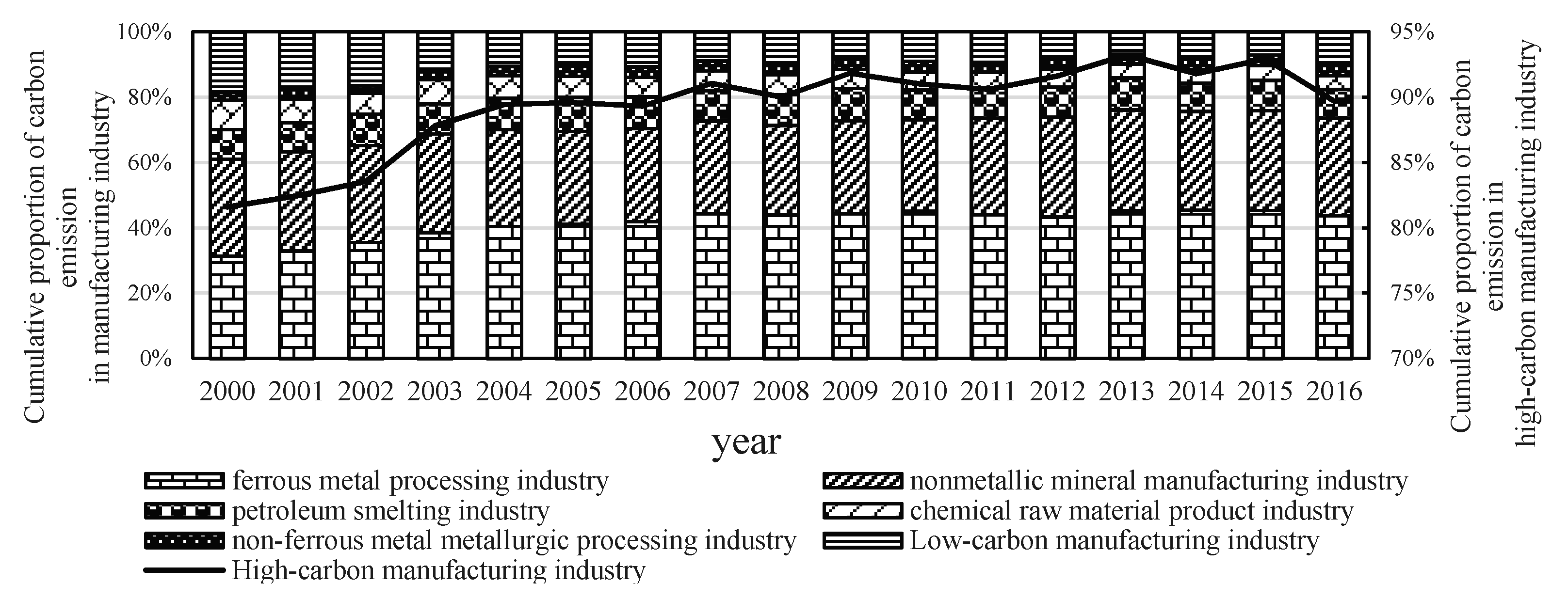

3.1. High-Carbon Industry Lock-In

3.2. GTWR Model

3.3. Index Selection of Carbon Emissions Influencing Factors

4. Results and Analysis

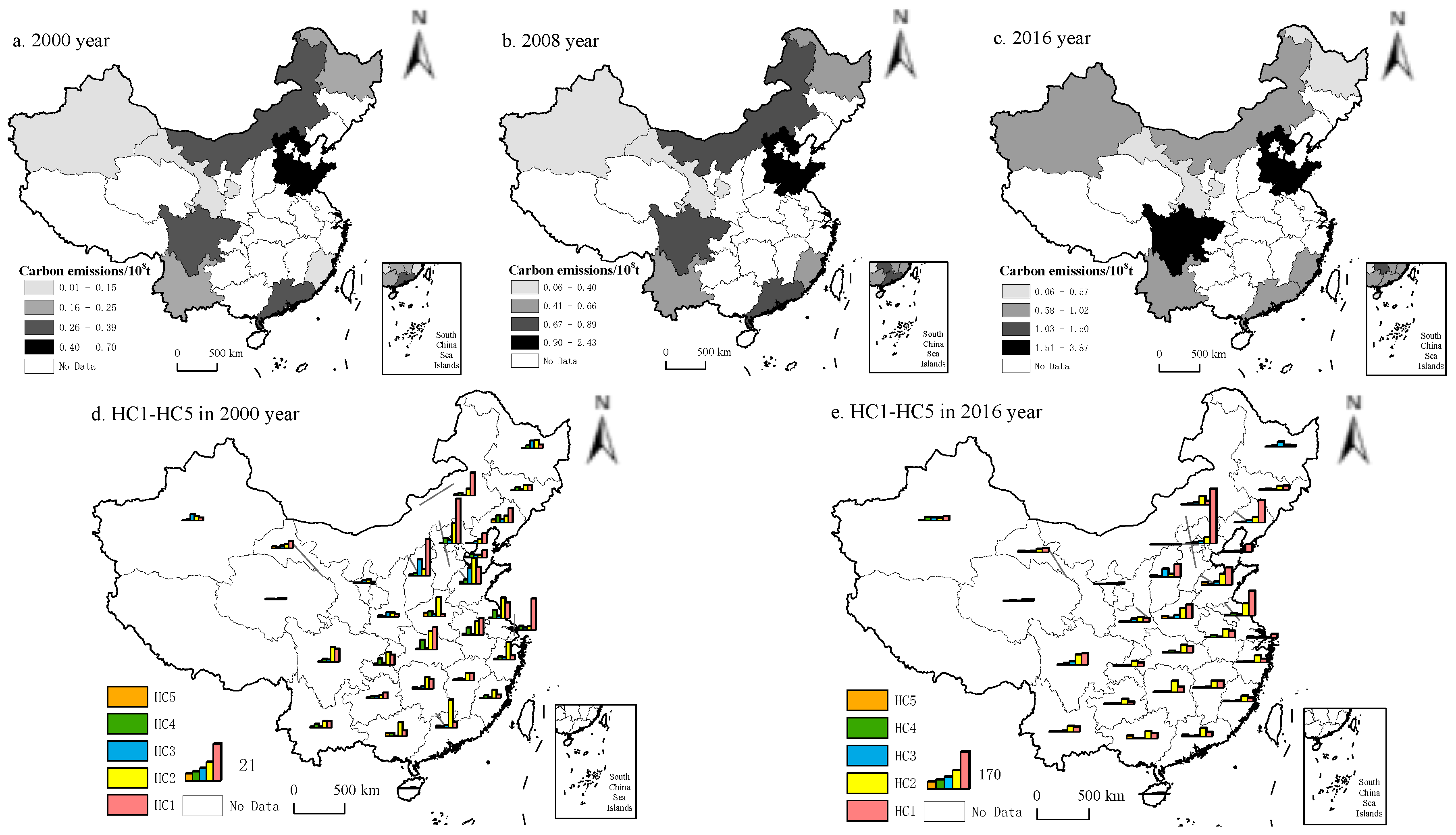

4.1. Spatial–Temporal Differentiation and Regional Lock-In in Carbon Emissions of High-Carbon Manufacturing Industry

4.2. Analysis of Determinants in Carbon Emissions of High-Carbon Manufacturing Industry

4.2.1. Model Selection of Determinants and Data Preprocessing

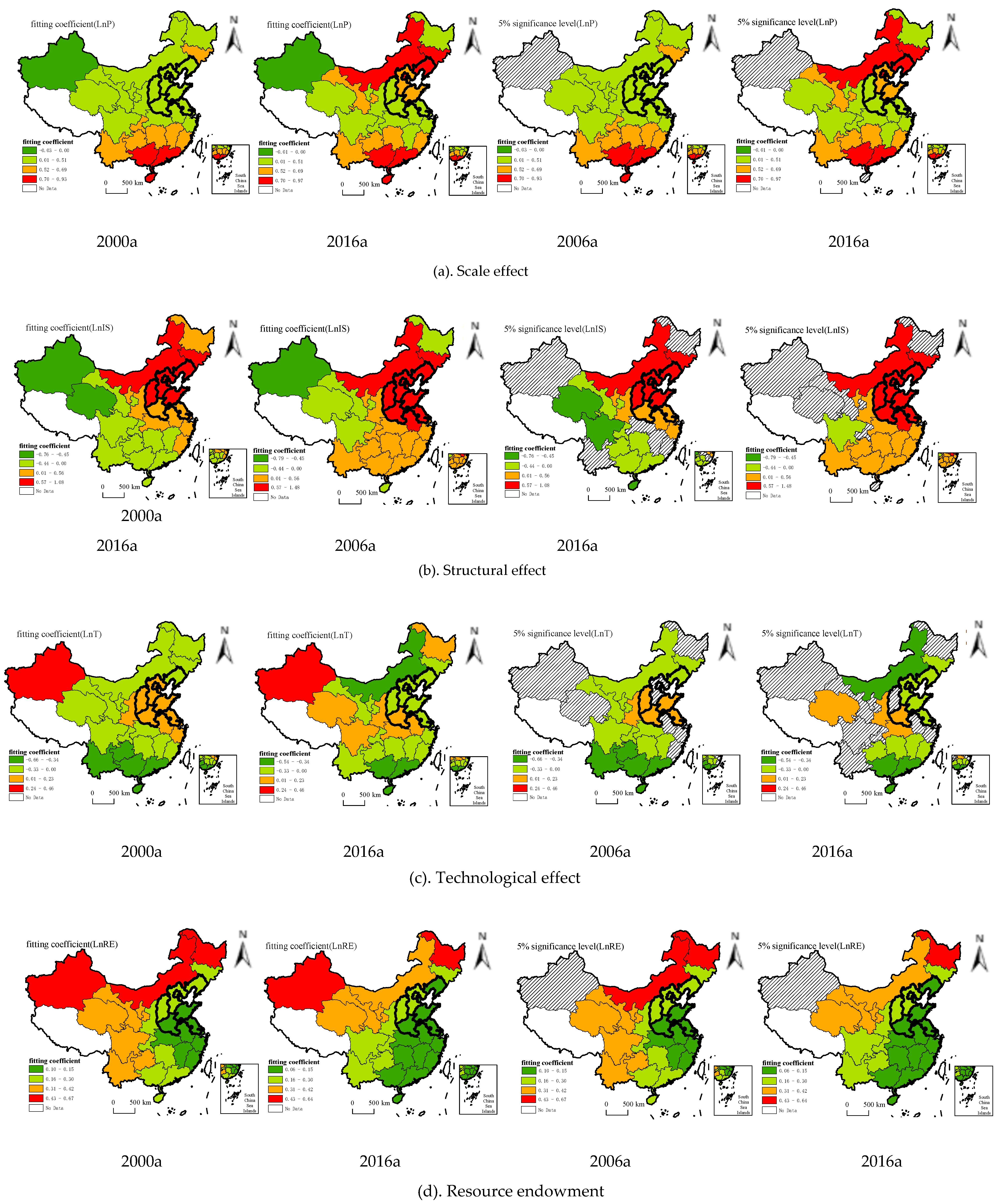

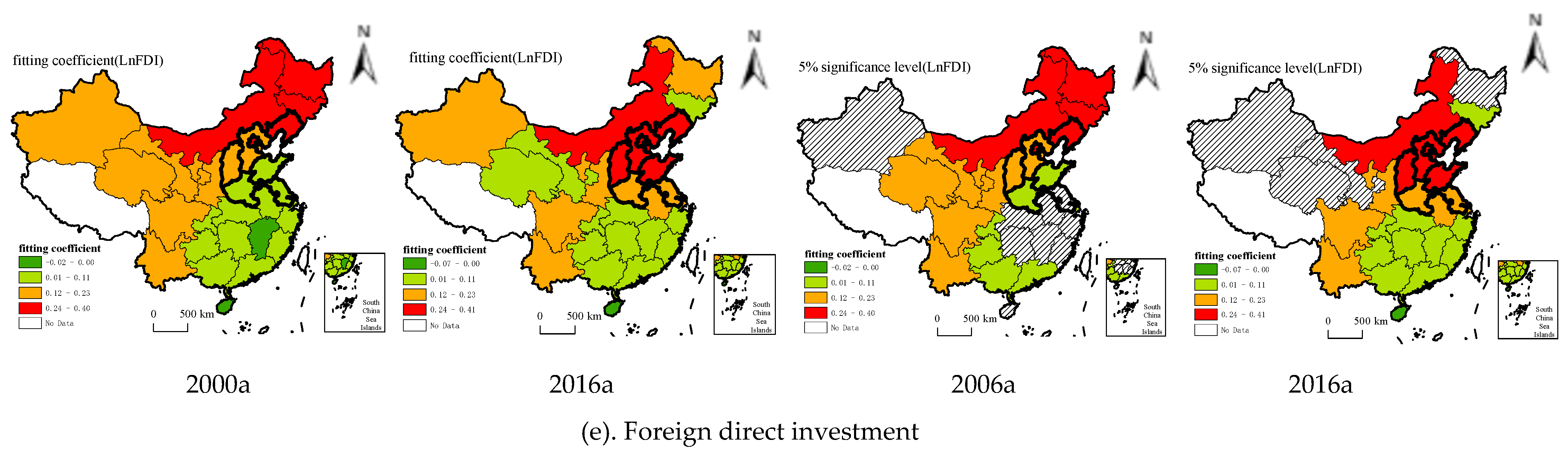

4.2.2. Spatial–Temporal Differentiation of Carbon Emissions Influencing Factors

5. Conclusions and Implication

Author Contributions

Funding

Conflicts of Interest

References

- National Statistical Bureau of the People’s Republic of China. China Statistical Yearbook; Statistical Publishing House: Beijing, China, 2000–2016.

- Hammond, G.P.; Norman, J.B. Decomposition analysis of energy-related carbon emissions from UK manufacturing. Energy 2012, 41, 220–227. [Google Scholar] [CrossRef]

- Kopidou, D.; Tsakanikas, A.; Diakoulaki, D. Common trends and drivers of CO2 emissions and employment: A decomposition analysis in the industrial sector of selected European Union countries. J. Clean. Prod. 2016, 112, 4159–4172. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mandaraka, M. Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energy Econ. 2007, 29, 636–664. [Google Scholar] [CrossRef]

- Clara Inés Pardo Martínez. Energy efficiency developments in the manufacturing industries of Germany and Colombia 1998–2005. Energy Sustain. Dev. 2009, 13, 89–101. [Google Scholar]

- Chang, N.; Lahr, M.L. Changes in China’s production-source CO2 emissions: Insights from structural decomposition analysis and linkage analysis. Econ. Syst. Res. 2016, 28, 224–242. [Google Scholar] [CrossRef]

- Lee, M.; Zhang, N. Technical efficiency, shadow price of carbon dioxide emissions, and substitutability for energy in the Chinese manufacturing industries. Energy Econ. 2012, 34, 1492–1497. [Google Scholar] [CrossRef]

- Huw, M.K. China as a Global Manufacturing Powerhouse: Strategic Considerations and Structural Adjustment. China World Econ. 2010, 18, 1–32. [Google Scholar]

- Lin, B.; Liu, K. How efficient is China’s heavy Industry? A perspective of inputeoutput analysis. Emerg. Mark. Financ. Trade 2016, 52, 2546–2564. [Google Scholar] [CrossRef]

- Unruh, G.C. Understanding carbon lock-in. Energy Policy 2000, 28, 817–830. [Google Scholar] [CrossRef]

- Unruh, G.C. Escaping carbon lock-in. Energy Policy 2002, 30, 317–325. [Google Scholar] [CrossRef]

- Chang, C.L.; McAleer, M.; Zuo, G. Volatility Spillovers and Causality of Carbon Emissions, Oil and Coal Spot and Futures for the EU and USA. Sustainability 2017, 9, 1789. [Google Scholar] [CrossRef]

- Chen, H.; He, L.; Chen, J. Impacts of Clean Energy Substitution for Polluting Fossil-Fuels in Terminal Energy Consumption on the Economy and Environment in China. Sustainability 2019, 11, 6419. [Google Scholar] [CrossRef]

- Yang, X.M.; Jiao, F.H. The Path, Evolution and Mechanism of the Industry Structure Locking-in for the Coal Resource-based City: A Case Study of Huai Be. Sci. Geogr. Sin. 2015, 35, 1256–1264. [Google Scholar]

- Wei, Y.D.; Li, W.; Wang, C. Restructuring industrial districts, scaling up regional development: A study of the Wenzhou model, China. Econ. Geogr. 2007, 83, 421–444. [Google Scholar] [CrossRef]

- Yin, Y.M.; Liu, Z.G.; Liu, W.D. Review on the progress of path dependence theory. Foreign Econ. Manag. 2011, 33, 1–7. [Google Scholar]

- Tian, Y.S.; Xiong, S.Q.; Ma, X.M. Structural Path Decomposition of Carbon Emission: A Study of China’s Manufacturing Industry. J. Clean. Prod. 2018, 193, 563–574. [Google Scholar] [CrossRef]

- De Oliveira Junior, V.B.; Pena, J.G.C.; Salles, J.L.F. An improved plant-wide multiperiod optimization model of a byproduct gas supply system in the iron and steel-making process. Appl. Energy 2016, 164, 462–474. [Google Scholar] [CrossRef]

- Moreno, B.; da Silva, P.P. How do Spanish polluting sectors’ stock market returns react to European Union allowances prices? A panel data approach. Energy 2016, 103, 240–250. [Google Scholar] [CrossRef]

- Wei, J.; Huang, K.; Yang, S. Driving forces analysis of energy-related carbon dioxide (CO2) emissions in Beijing: An inputeoutput structural decomposition analysis. J. Clean. Prod. 2016, 163, 58–68. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Harrell, G.; Schreck, B. Moving beyond equipment and to systems optimization: Techno-economic analysis of energy efficiency potentials in industrial steam systems in China. J. Clean. Prod. 2016, 120, 53–63. [Google Scholar] [CrossRef]

- Xu, R.; Lin, B. Why are there large regional differences in CO2 emissions? Evidence from China’s manufacturing industry. J. Clean. Prod. 2017, 140, 1330–1343. [Google Scholar] [CrossRef]

- Xu, B.; Lin, B. Reducing CO2 emissions in China’s manufacturing industry: Evidence from nonparametric additive regression models. Energy 2016, 101, 161–173. [Google Scholar] [CrossRef]

- Wang, Y.P.; Yan, W.Y.; Ma, D. Carbon Emissions and Optimal Scale of China’s Manufacturing Agglomeration under Heterogeneous Environmental Regulation. J. Clean. Prod. 2018, 176, 140–150. [Google Scholar] [CrossRef]

- Jiang, S.; Yang, C.; Guo, J. Uncovering the Driving Factors of Carbon Emissions in an Investment Allocation Model of China’s High-Carbon and Low-Carbon Energy. Sustainability 2017, 9, 1021. [Google Scholar] [CrossRef]

- Diao, B.D.; Ding, L.; Su, P.D. Study on Spatiotemporal Heterogeneity of Industry Driving Factors in PM2.5 Concentration in China. China Popul. Resour. Environ. 2018, 28, 52–62. [Google Scholar]

- Stewart Fotheringham, A.; Charlton, M.; Brunsdon, C. The geography of parameter space: An investigation of spatial non-stationarity. Int. J. Geogr. Inf. Sci. 1996, 10, 605–627. [Google Scholar] [CrossRef]

- Huang, B. Geographically and Temporally Weighted Regression for Modeling Spatio-temporal Variation in House Prices. Int. J. Geogr. Inf. Sci. 2010, 24, 383–401. [Google Scholar] [CrossRef]

- He, Q.Q.; Huang, B. Satellite-based High-resolution PM2.5 Estimation over the Beijing-Tianjin-Hebei region of China Using an Improved Geographically and Temporally Weighted Regression Model. Environ. Pollut. 2018, 236, 1027–1037. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, Y.Y. Increased CO2 Emissions Because of Energy Consumption in Beijing Based on Three-Level Nested I-O Structural Decomposition Analysis. Resour. Sci. 2013, 35, 275–283. [Google Scholar]

- Zhang, K.; Wang, D.F. The Interaction and Spatial Spillover between Agglomeration and Pollution. Chin. Ind. Econ. 2014, 315, 70–82. [Google Scholar]

- Li, T.; Song, Y.; Shen, J. Clean Power Dispatching of Coal-Fired Power Generation in China Based on the Production Cleanliness Evaluation Method. Sustainability 2019, 11, 6778. [Google Scholar] [CrossRef]

- Shi, M.J.; Feng, R.; Zheng, D. Influence of Comparative Advantage and Competitive Advantage on Regional Manufacturing Transfer. Econ. Geogr. 2017, 37, 108–115. [Google Scholar]

- Wang, S.J.; Su, Y.X.; Zhao, Y.B. Regional Inequality, Spatial Spillover Effects and Influencing Factors of China’s City-Level Energy-Related Carbon Emissions. Acta Grogr. Sin. 2018, 73, 414–428. [Google Scholar]

- Li, Q. Environmental Decentralization and Firm TFP: Evidence from the Data of Chinese Manufacturing Enterprises. J. Clean. Prod. 2017, 43, 133–145. [Google Scholar]

- Liu, H.L.; Li, B.T.; Tang, W.H. Manufacturing Oriented Topology Optimization of 3D Structures for Carbon Emissions Reduction in Casting Process. J. Clean. Prod. 2019, 225, 755–770. [Google Scholar] [CrossRef]

| Signs | Meaning | Interpretation | Unit |

|---|---|---|---|

| C | Carbon emissions | Carbon emission in the high-carbon manufacturing industry | 1 million tons |

| P | Scale effect | Sales value in the high-carbon manufacturing industry | 10,000 persons |

| IS | Structural effect | Proportion of employees of the high-carbon manufacturing industry in the total manufacturing industry | % |

| T | Technological effect | Internal R&D expenses of the high-carbon manufacturing industry | 100 million yuan |

| RE | Resource endowment | Total production and sales volume of the mining industry | 100 million yuan |

| FDI | Foreign direct investment | FDI to the high-carbon manufacturing industry | 100 million yuan |

| Year | Moran’s I | Year | Moran’s I | Year | Moran’s I |

|---|---|---|---|---|---|

| 2000 | 0.263 *** | 2006 | 0.324 *** | 2012 | 0.236 ** |

| 2001 | 0.287 *** | 2007 | 0.378 *** | 2013 | 0.223 ** |

| 2002 | 0.292 *** | 2008 | 0.333 *** | 2014 | 0.207 ** |

| 2003 | 0.298 *** | 2009 | 0.320 *** | 2015 | 0.216 ** |

| 2004 | 0.321 *** | 2010 | 0.274 *** | 2016 | 0.227 ** |

| 2005 | 0.321 *** | 2011 | 0.254 *** |

| Province | Liaoning | Hebei | Shandong | Shanxi | Henan | Jiangsu | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Factor | 2000 | 2016 | 2000 | 2016 | 2000 | 2016 | 2000 | 2016 | 2000 | 2016 | 2000 | 2016 | |

| LnP | 0.50 * | 0.66 * | 0.40 * | 0.46 * | 0.45 * | 0.47 * | 0.35 * | 0.36 * | 0.43 * | 0.39 * | 0.44 * | 0.45 * | |

| LnIS | 0.76 * | 1.04 * | 0.91 * | 1.16 * | 0.58 * | 0.94 * | 0.72 * | 0.91 * | 0.41 * | 0.58 * | 0.33 * | 0.50 * | |

| LnT | −0.06 * | −0.18 * | 0.03 | −0.02 * | 0.07 * | −0.01 * | 0.08 * | 0.06 * | 0.06 * | 0.08 * | 0.05 * | 0.01 * | |

| LnRE | 0.25 * | 0.16 * | 0.25* | 0.18 * | 0.13 * | 0.10 * | 0.23 * | 0.19 * | 0.11 * | 0.10 * | 0.09 * | 0.08 * | |

| LnFDI | 0.27 * | 0.24 * | 0.20* | 0.28 * | 0.06 * | 0.19 * | 0.17 * | 0.25 * | 0.04 * | 0.12 * | 0.02 | 0.12 * | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhang, L.; Qin, Y.; Zhang, J. Analysis of China’s Manufacturing Industry Carbon Lock-In and Its Influencing Factors. Sustainability 2020, 12, 1502. https://doi.org/10.3390/su12041502

Wang X, Zhang L, Qin Y, Zhang J. Analysis of China’s Manufacturing Industry Carbon Lock-In and Its Influencing Factors. Sustainability. 2020; 12(4):1502. https://doi.org/10.3390/su12041502

Chicago/Turabian StyleWang, Xia, Lijun Zhang, Yaochen Qin, and Jingfei Zhang. 2020. "Analysis of China’s Manufacturing Industry Carbon Lock-In and Its Influencing Factors" Sustainability 12, no. 4: 1502. https://doi.org/10.3390/su12041502

APA StyleWang, X., Zhang, L., Qin, Y., & Zhang, J. (2020). Analysis of China’s Manufacturing Industry Carbon Lock-In and Its Influencing Factors. Sustainability, 12(4), 1502. https://doi.org/10.3390/su12041502