Structural Performance of Damaged Open-Web Type SRC Beam-Columns after Retrofitting

Abstract

:1. Introduction

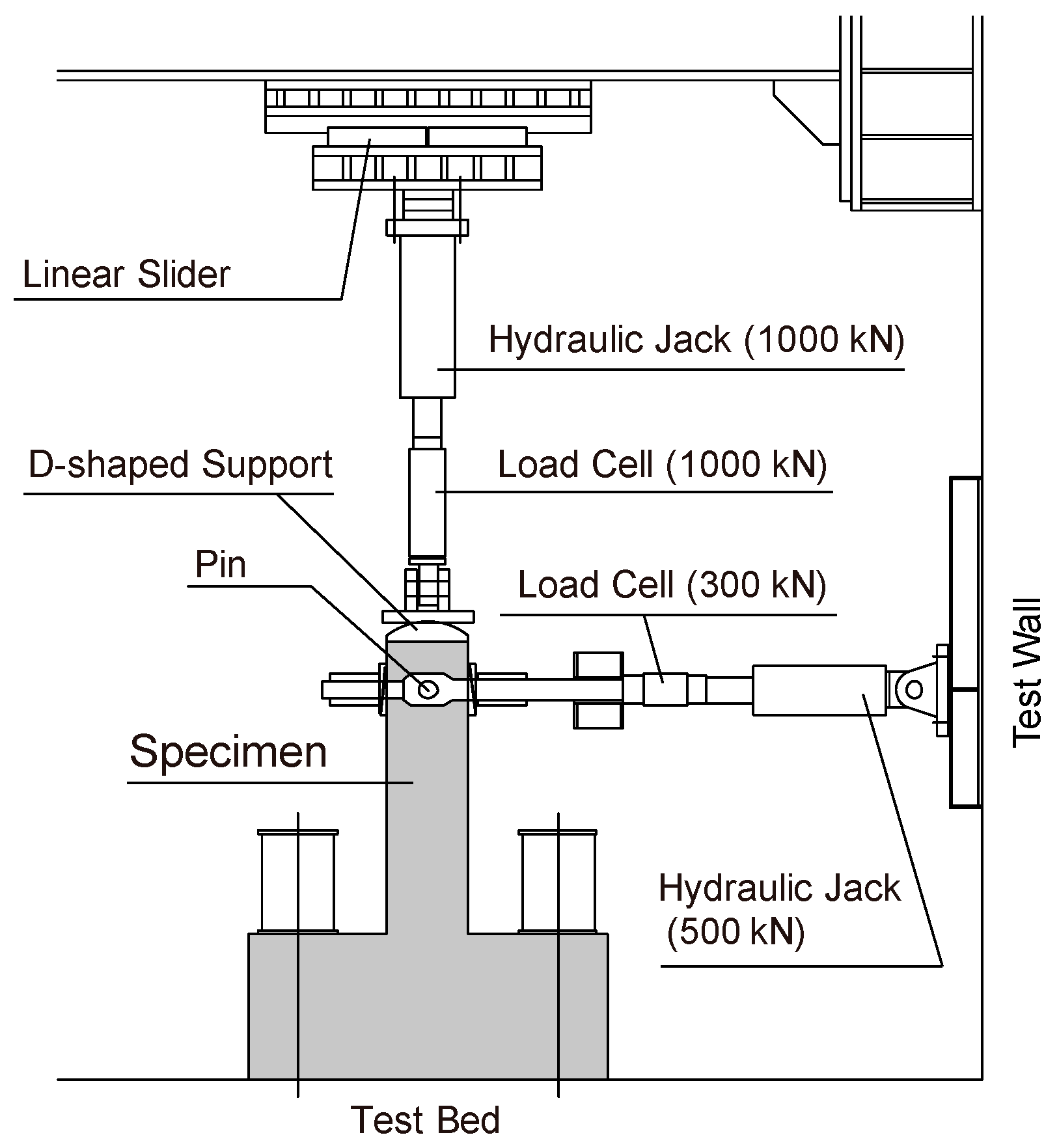

2. Experiment of Open-Web Type SRC Beam-Columns

2.1. Outline of Experiment

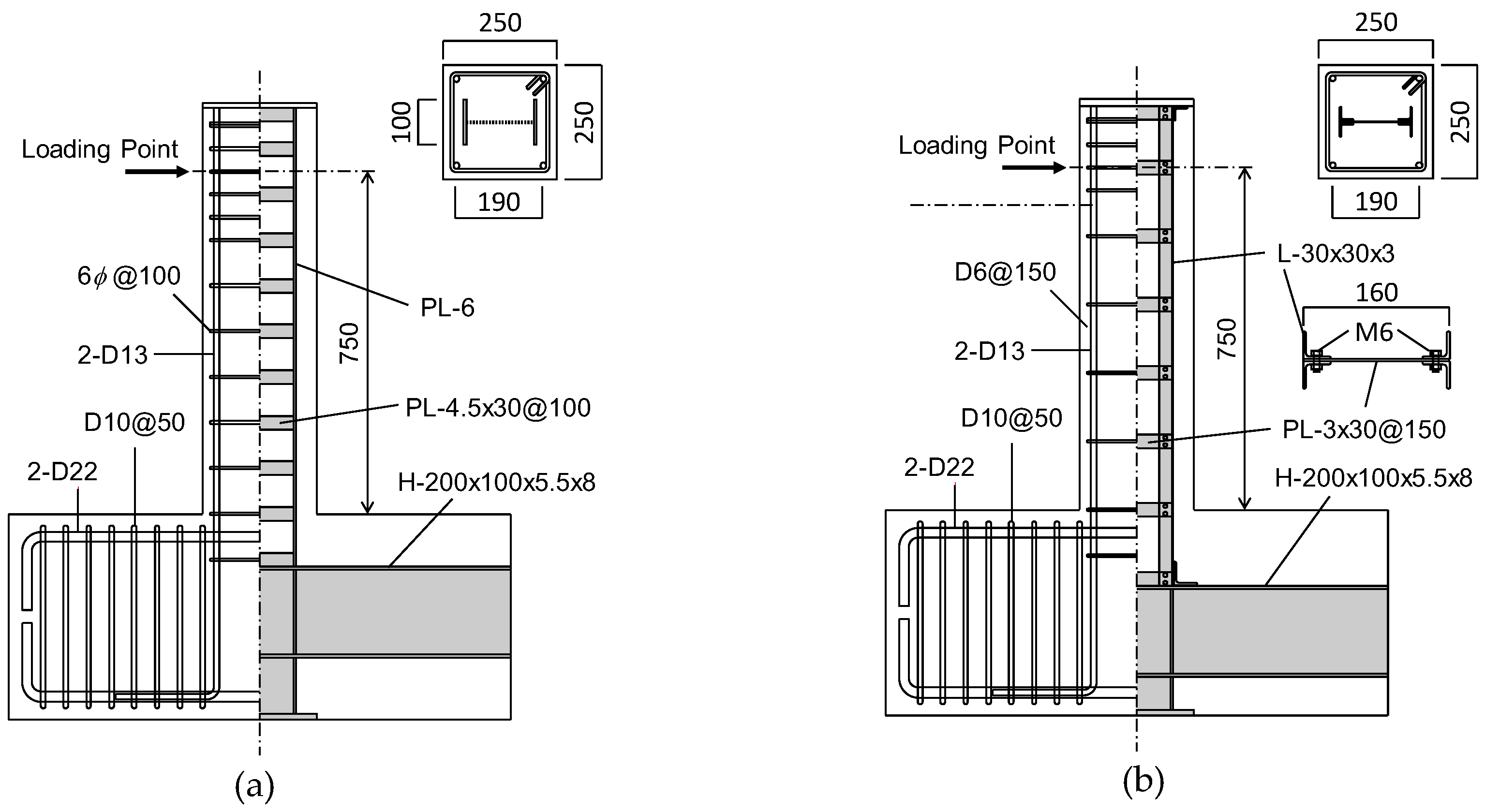

2.2. Specimen

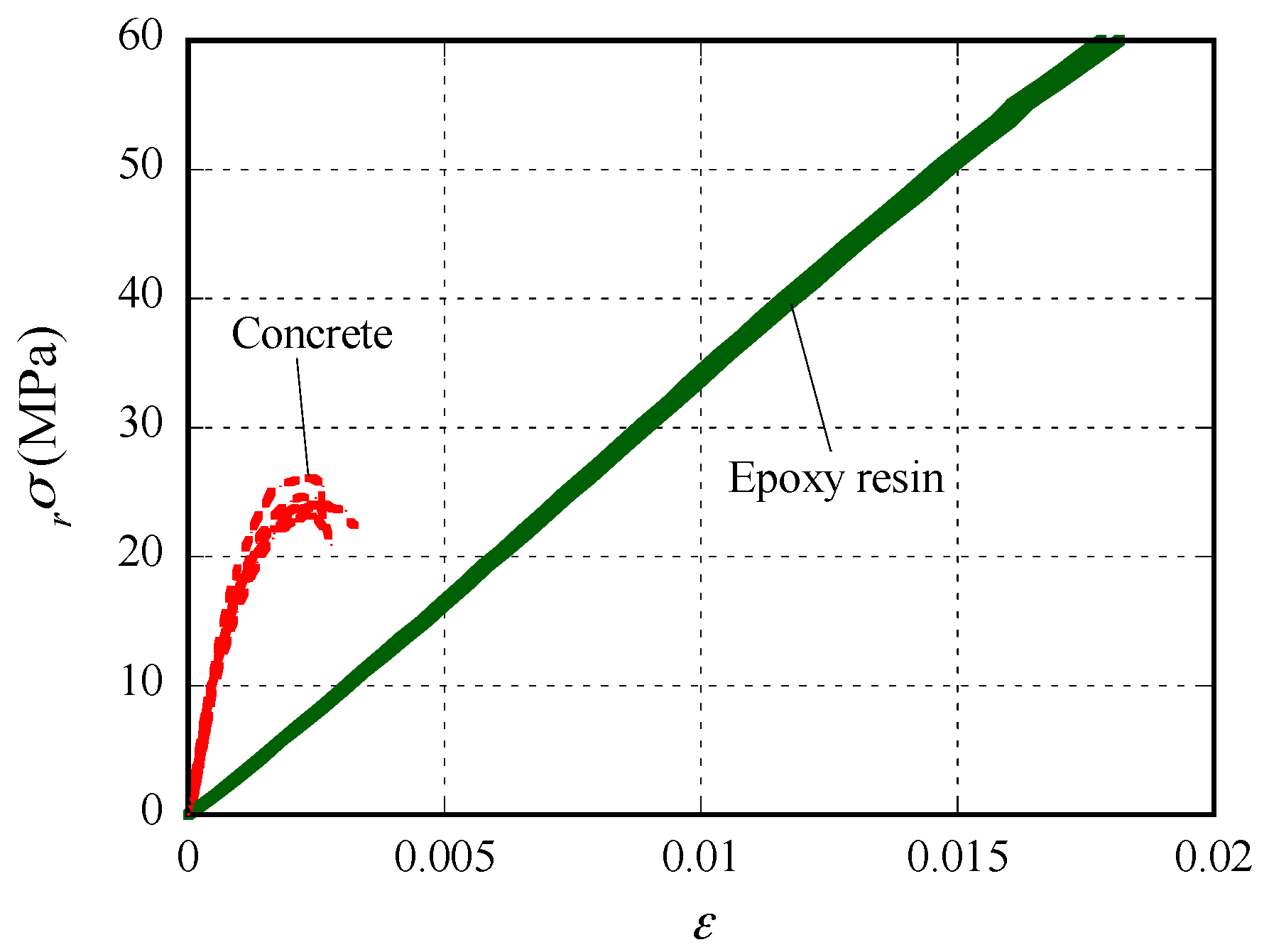

2.3. Material Propeties

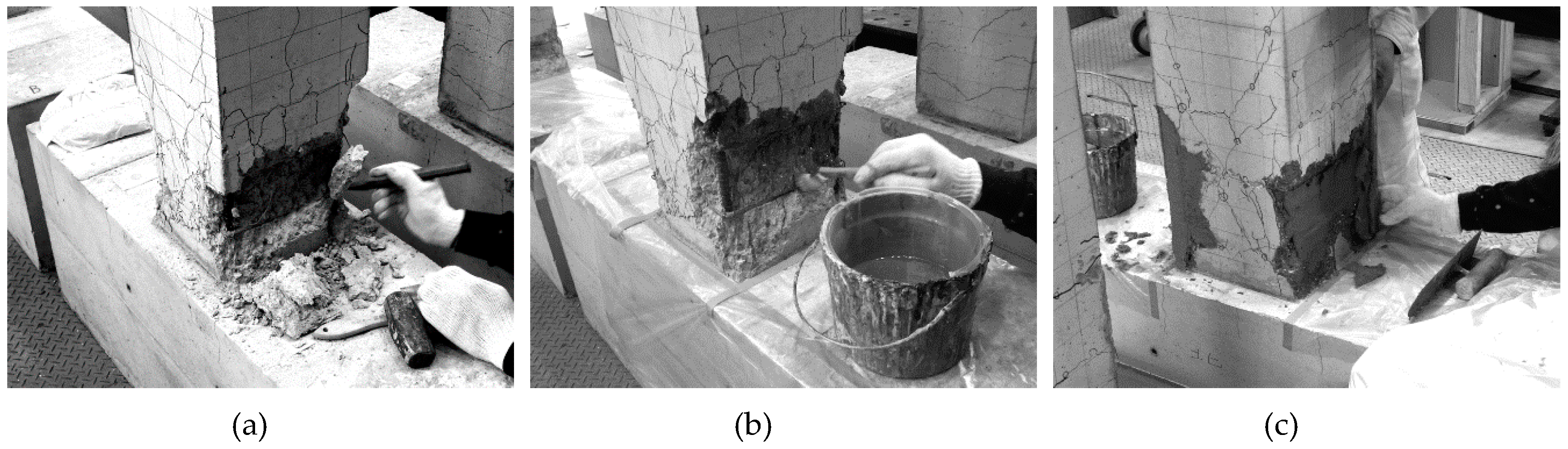

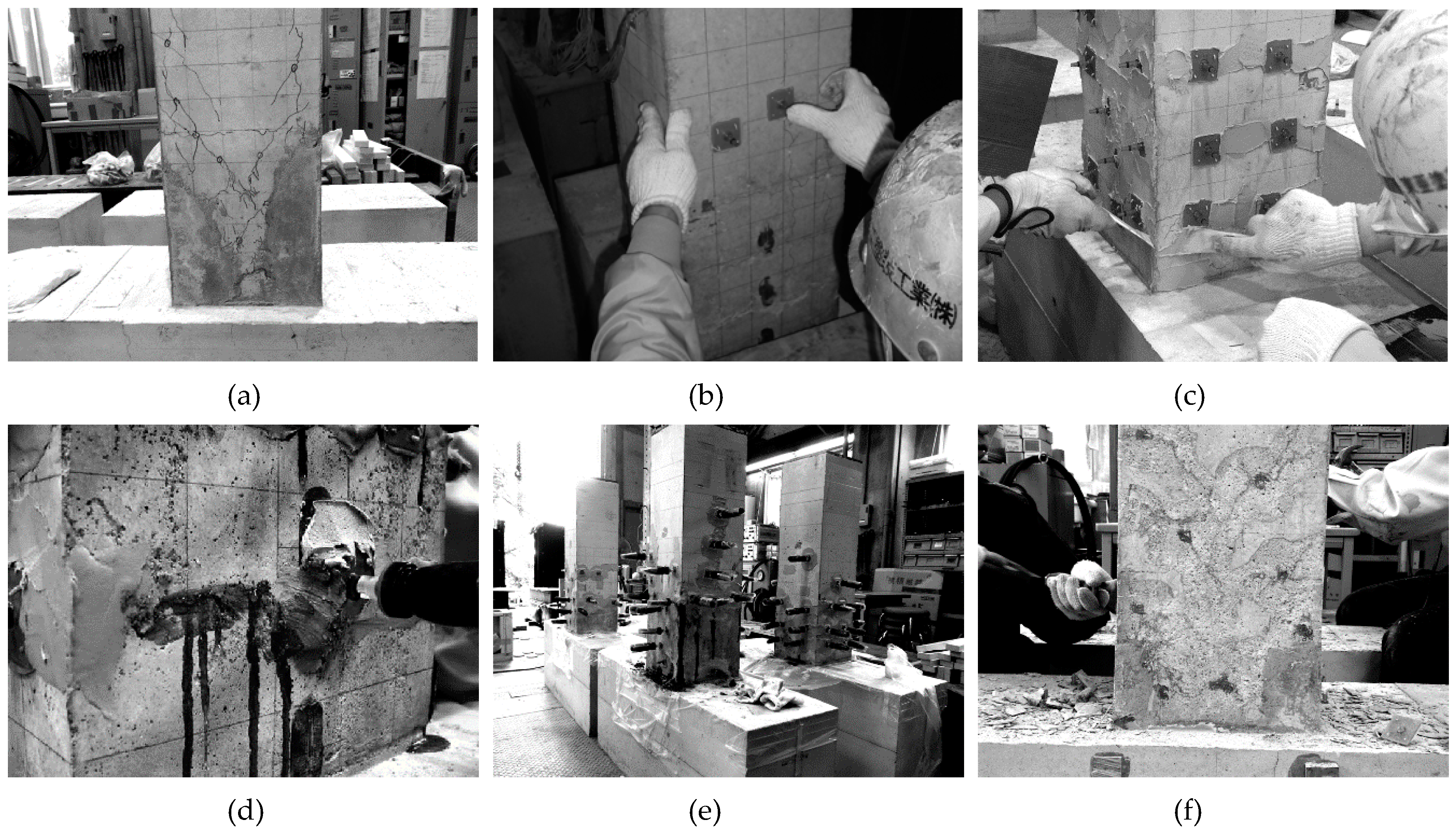

2.4. Method of Retrofitting

3. Experimental Results

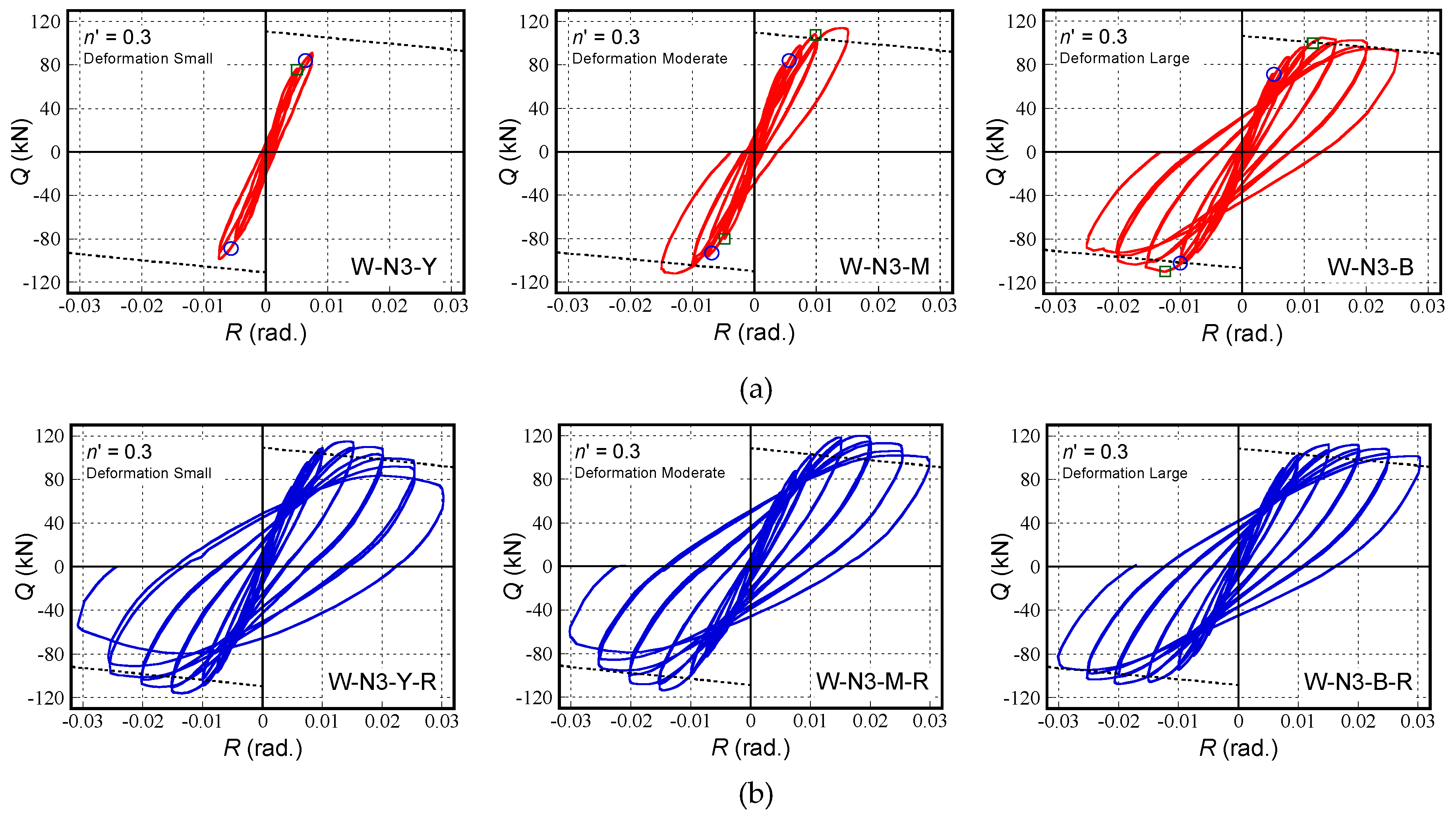

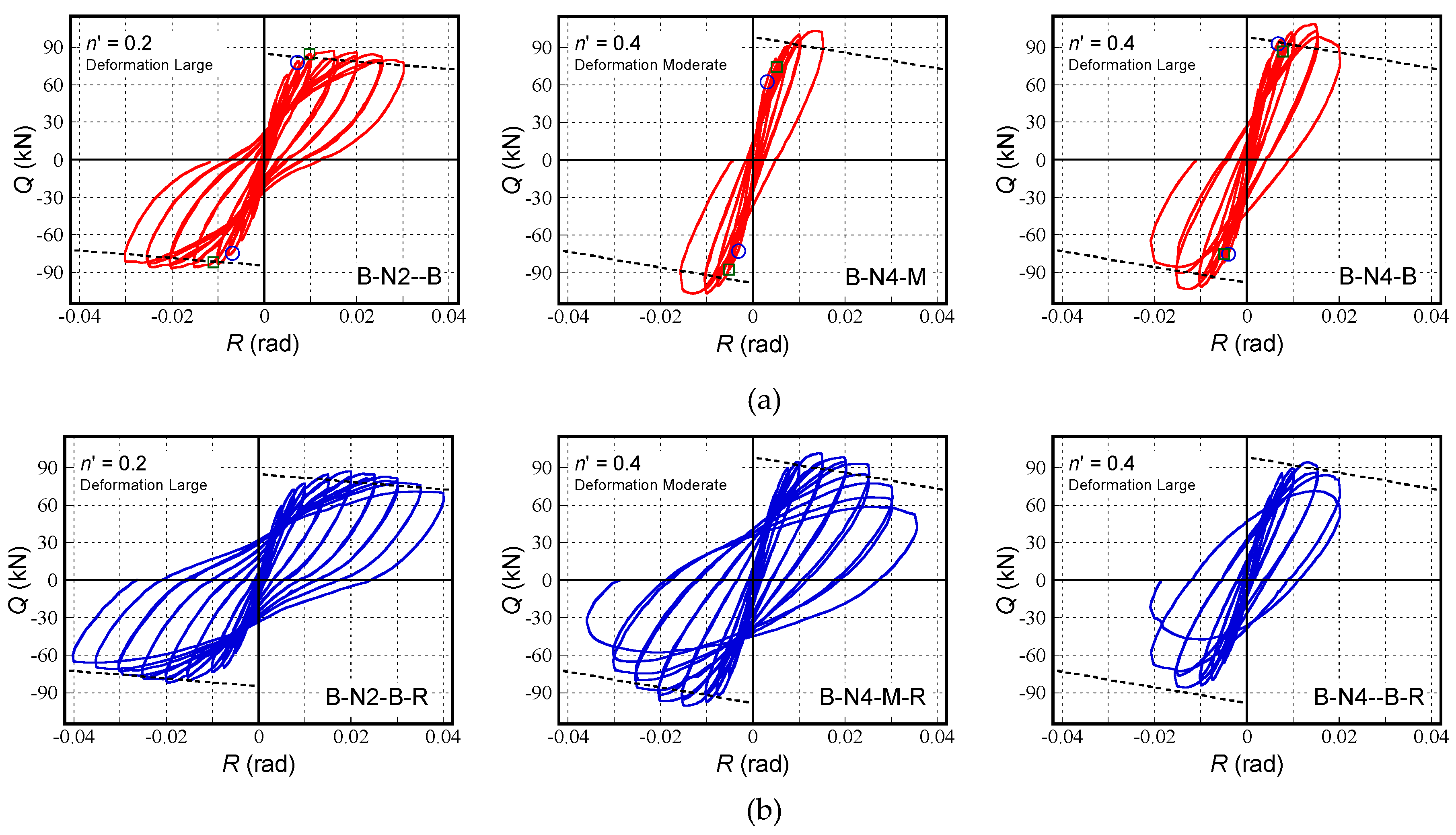

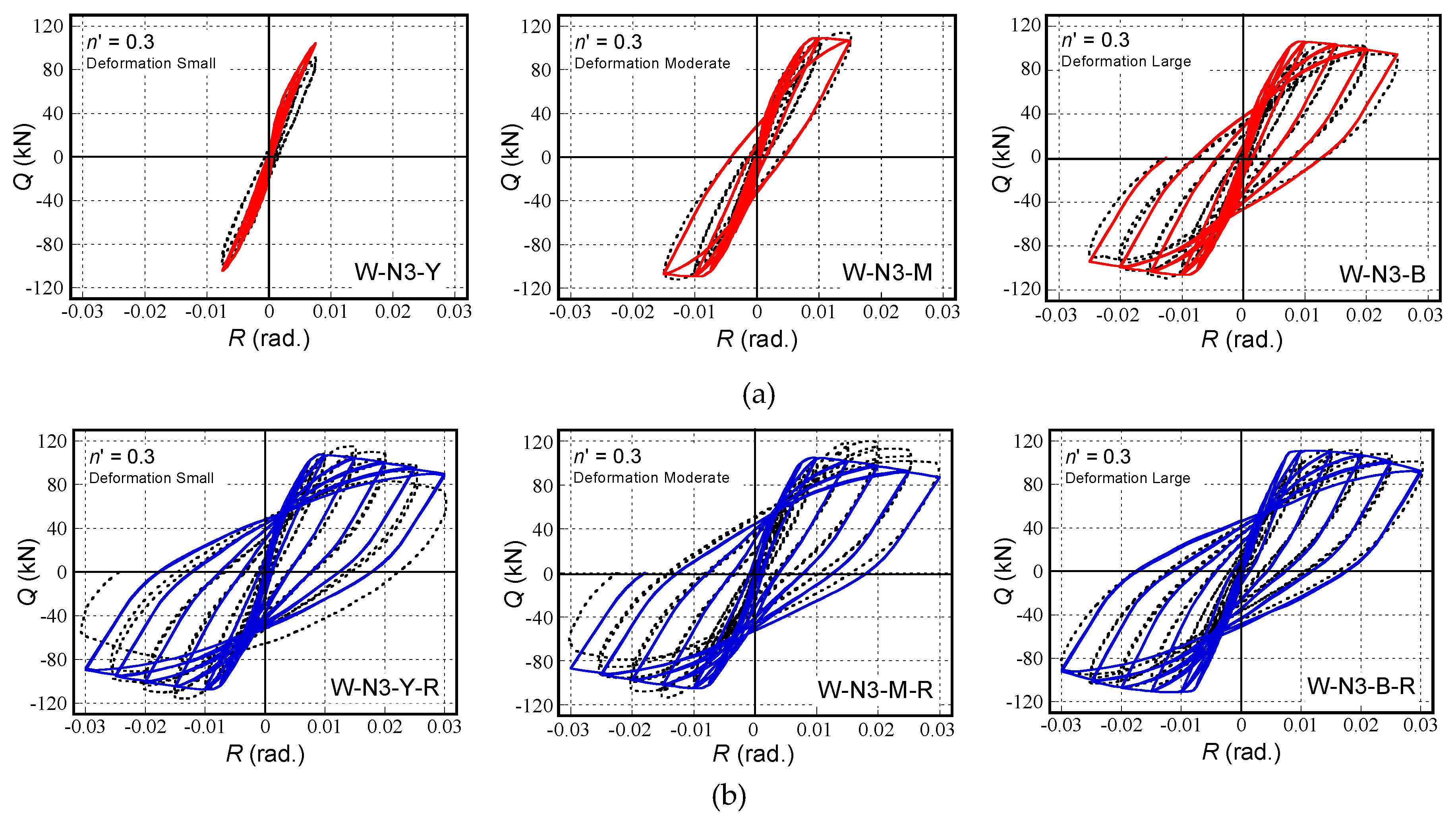

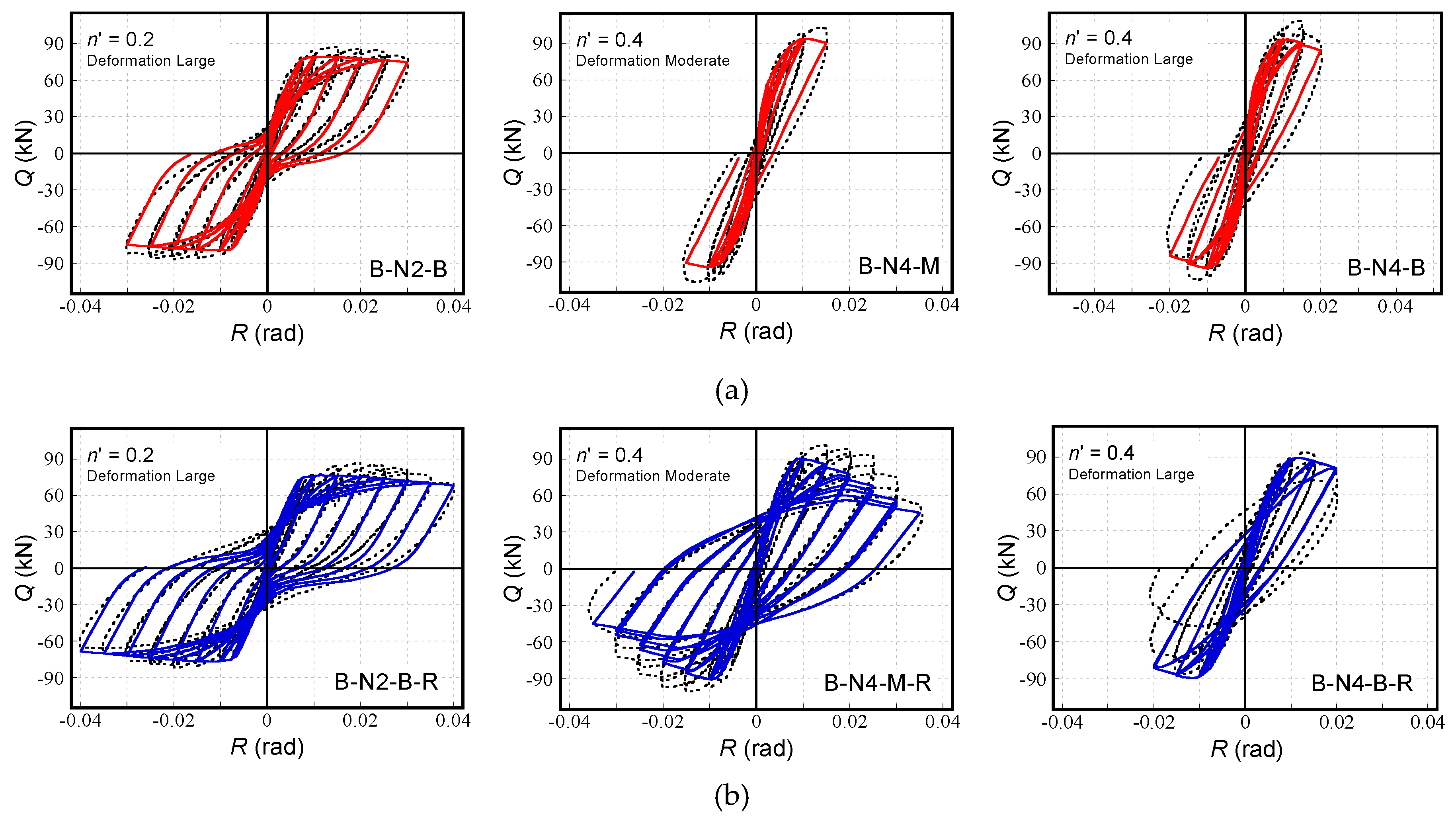

3.1. Horizontal Load–Drift Ratio Relation

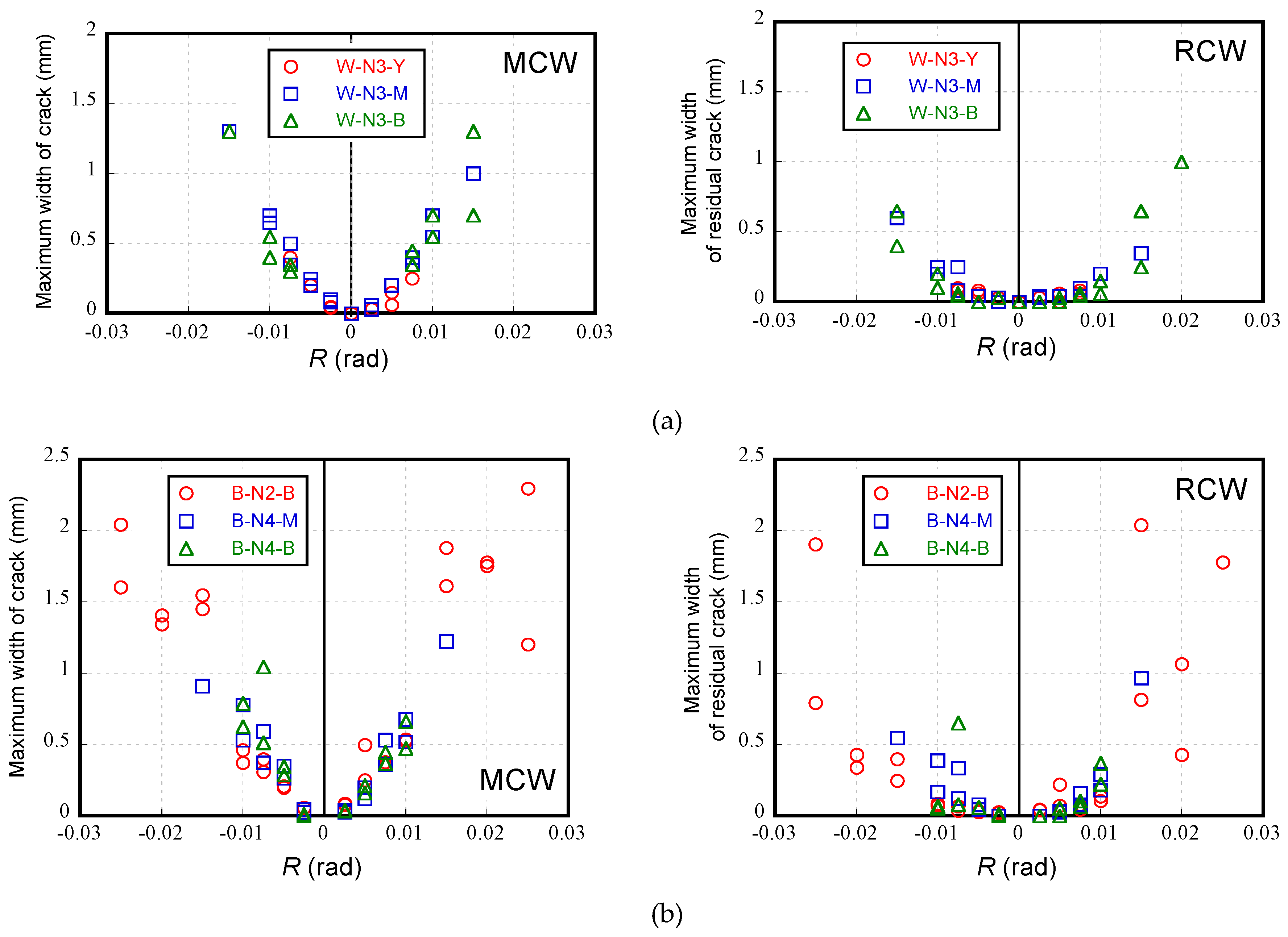

3.2. Width of Flexural Cracks

4. Evaluation of Structural Performance

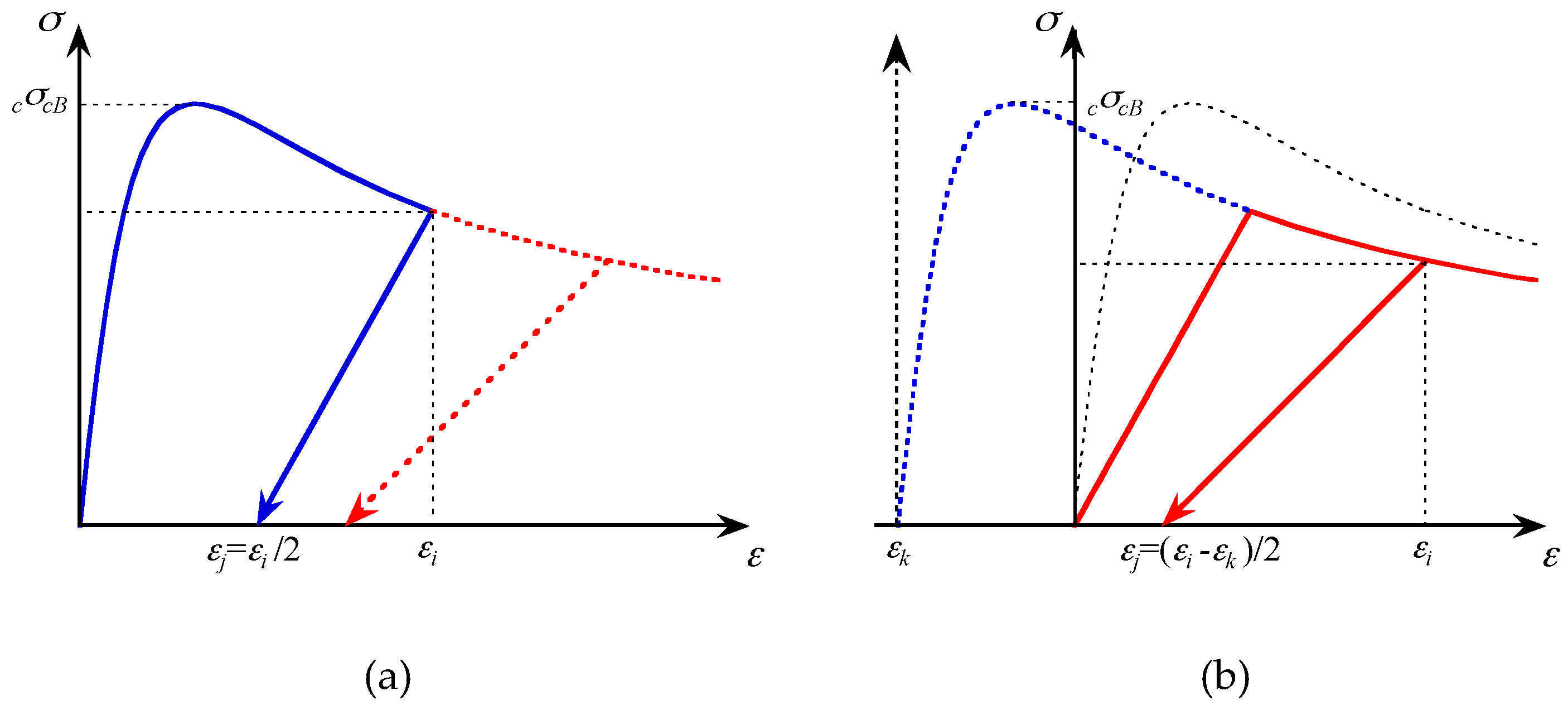

4.1. Numerical Analysis

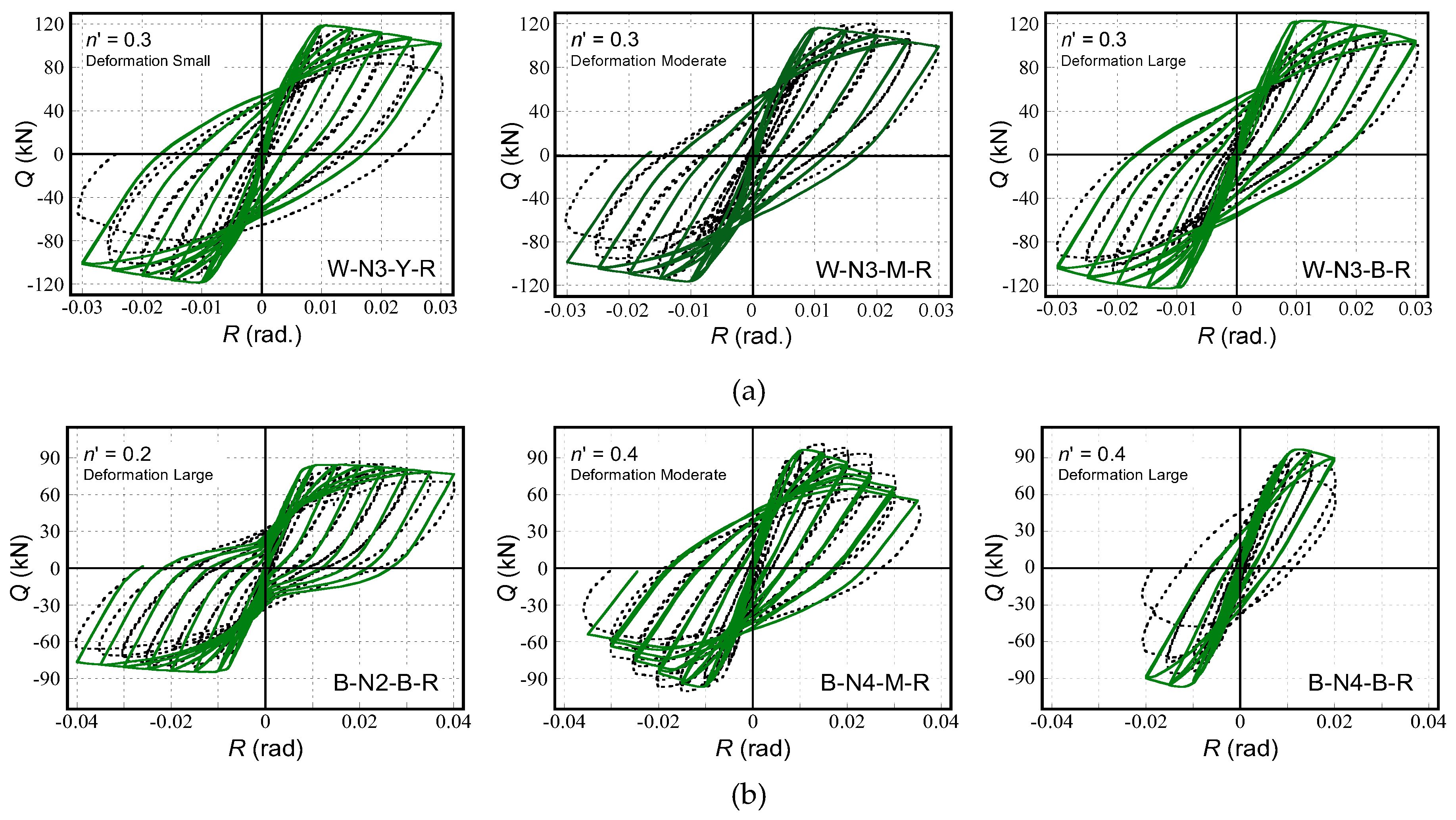

4.2. Comparison with the Experimentally Obtained Results

5. Conclusions

- (1)

- The initial stiffness of the retrofitted columns was lower than the initial ones. The lower stiffness might be attributed to the deterioration of the concrete rigidity, low rigidity of the resin and the polymer cement mortar, in addition to the imperfect injection of the resin.

- (2)

- The retrofitted SRC columns showed a higher load carrying capacity in case of weld-connected specimens, while the experienced displacement in each column differed. The higher load carrying capacity can be attributed to the effect of the strain aging and strain hardening of the steels. In the case of the bolt-connected specimen, the retrofitted columns showed approximately the same capacities as the initial columns. The effect of the buckling of the longitudinal reinforcing bars was observed in the column that experienced the larger displacement and higher axial load.

- (3)

- Analytical results predicted the stiffness reduction ratio and the experimental behaviors fairly well. However, for retrofitted beam-columns, the analytical results underestimate the experimental behavior.

- (4)

- Analytical results considering the increment of 20% of the yield stress of the steel due to strain aging and hardening predicted the experimental behaviors well, which implies the validity of the analytical method presented in this paper for the evaluation of the structural performance of retrofitted SRC columns.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Approach for Reduction of CO2 and Waste Emission through Life Cycle of Buildings. Available online: http://www.nilim.go.jp/lab/bcg/siryou/tnn/tnn0267pdf/ks0267011.pdf (accessed on 2 February 2020).

- American Concrete Institute. Concrete Repair Guide; ACI Committee 546: Farmington Hills, MI, USA, 1996. [Google Scholar]

- Japan Concrete Institute. Practical Guideline for Investigation, Repair and Strengthening of Cracked Concrete Structures 2009; Japan Concrete Institute: Tokyo, Japan, 1998. [Google Scholar]

- French, C.W.; Thorp, G.A.; Tsai, W.J. Epoxy Repair Techniques for Moderate Earthquake Damage. ACI Struct. J. 1990, 87, 416–424. [Google Scholar]

- Ekenel, M.; Myers, J.J. Durability performance of RC beams strengthened with epoxy injection and CFRP fabrics. Constr. Build. Mater. 2007, 21, 1182–1190. [Google Scholar] [CrossRef]

- Balsamo, A.; Colombo, A.; Manfredi, G.; Negro, P.; Prota, A. Seismic behavior of a full-scale RC frame repaired using CFRP laminates. Eng. Struct. 2005, 27, 769–780. [Google Scholar] [CrossRef]

- Editorial Committee for the Report on the Hanshin-Awaji Earthquake Disaster. Report on the Hanshin-Awaji Earthquake Disaster; Architectural Institute of Japan: Tokyo, Japan, 1998. [Google Scholar]

- Sakino, K.; Sun, Y. Stress–Strain Curve of Concrete Confined by Rectilinear Hoop. J. Struct. Constr. Eng. AIJ 1994, 461, 95–104. [Google Scholar] [CrossRef] [Green Version]

- Kato, B.; Akiyama, H.; Yamauchi, Y. Cyclic stress–strain relations for steel based on experimentally obtained results. In Proceedings of the Summaries of Technical Papers of Annual Meeting; AIJ: Tokyo, Japan, 1973; pp. 937–938. [Google Scholar]

- Sakai, J.; Matsui, C. Hysteresis Characteristic of Steel Reinforced Concrete Beam-Columns. J. Struct. Constr. Eng. AIJ 2000, 534, 183–190. [Google Scholar] [CrossRef] [Green Version]

- Fujinaga, T.; Sun, Y. Structural Performance of Damaged Open-web Type SRC Beam-columns after Retrofitting. In Proceedings of the 15th World Conference of Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

| Specimens | Connection of Batten Plates | Axial Load Ratio n = N/N0 1 | Method of Retrofitting | Young’s Modulus of Concrete cE (GPa) | Compressive Strength of Concrete fc’ (MPa) | |

|---|---|---|---|---|---|---|

| 1st loading | W-N3-Y | Weld-connected | 0.30 | - | 22.4 | 24.1 |

| W-N3-M | - | 21.0 | 23.6 | |||

| W-N3-B | - | 21.3 | 22.2 | |||

| 2nd loading | W-N3-Y-R | 0.31 | Injection of epoxy | 21.2 | 23.4 | |

| W-N3-M-R | 20.0 | 23.1 | ||||

| W-N3-B-R | 0.29 | Section repair Injection of epoxy | 19.3 32.3 2 | 22.7 28.8 2 | ||

| 1st loading | B-N2-B | Bolt-connected | 0.20 | - | 21.6 | 24.5 |

| B-N4-M | 0.40 | - | 22.7 | 24.3 | ||

| B-N4-B | - | 23.8 | 24.1 | |||

| 2nd loading | B-N2-B-R | 0.20 | Section repair Injection of epoxy | 23.8 10.2 2 | 26.3 20.1 2 | |

| B-N4-M-R | 0.40 | 21.8 8.83 2 | 24.5 20.6 2 | |||

| B-N4-B-R | 22.8 10.1 2 | 25.0 21.2 2 | ||||

| Young’s Modulus sE (GPa) | Yield Strength fy (MPa) | Tensile Strength fu (MPa) | Yield Ratio | Elongation (%) | |||

|---|---|---|---|---|---|---|---|

| Steel | Flange /chord | W Series | 205 | 313 | 436 | 0.716 | 30.7 |

| B Series | 201 | 354 | 473 | 0.748 | 31.5 | ||

| Batten plate (Web) | W Series | 202 | 340 | 473 | 0.720 | 35.5 | |

| B Series | 212 | 382 | 520 | 0.735 | 26.4 | ||

| Reinforcement | Main rebar D13 | W Series | 193 | 349 | 497 | 0.702 | 25.3 |

| B Series | 183 | 355 | 496 | 0.715 | 23.6 | ||

| Hoop ϕ 6 | W Series | 206 | 678 1 | 724 | 0.937 | 11.2 | |

| B Series | 189 | 391 1 | 515 | 0.758 | 25.7 | ||

| Young’s Modulus rE (GPa) | Compressive Strength rfc (MPa) | Splitting Tensile Strength rft(MPa) | |

|---|---|---|---|

| W Series | 3.05 | 88.1 | 23.8 |

| B Series | 3.20 | 73.0 | - |

| Specimens | Initial Stiffness (kN/mm) | Stiffness Reduction Ratio (%) 1 | Maximum Strength (kN) | Deformation Ratio at max. Strength (rad) | |||

|---|---|---|---|---|---|---|---|

| + | - | ||||||

| 1st loading | W-N3-Y | 29.6 | - | 95.0 | - | (0.0075) | (−0.0075) |

| W-N3-M | 28.6 | - | 112.9 | - | 0.0143 | -0.0131 | |

| W-N3-B | 24.9 | - | 107.2 | - | 0.0128 | −0.0125 | |

| 2nd loading | W-N3-Y-R | 24.5 | 82.6 | 115.4 | 1.08 | 0.0146 | −0.0135 |

| W-N3-M-R | 22.8 | 79.7 | 116.9 | 1.04 | 0.0189 | −0.0147 | |

| W-N3-B-R | 19.6 | 78.8 | 109.8 | 1.03 | 0.0151 | −0.0201 | |

| 1st loading | B-N2-B | 32.9 | - | 86.9 | - | (0.015) | (−0.020) |

| B-N4-M | 37.2 | - | 104.8 | - | 0.014 | −0.013 | |

| B-N4-B | 34.4 | - | 105.9 | - | 0.015 | −0.012 | |

| 2nd loading | B-N2-B-R | 24.4 | 74.2 | 84.5 | 0.97 | 0.020 | −0.020 |

| B-N4-M-R | 31.8 | 85.5 | 100.9 | 0.96 | 0.014 | −0.014 | |

| B-N4-B-R | 24.6 | 71.4 | 90.2 | 0.85 | 0.013 | −0.013 | |

| Stiffness Reduction Ratio | Strength Prediction Ratio (Exp./Ana.) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1.0fy | 1.2fy | |||||||||

| Exp. | Analysis (Exp./Ana.) | max. | 0.005 rad | 0.01 rad | 0.02 rad | max. | 0.005 rad | 0.01 rad | 0.02 rad | |

| W-N3-Y-R | 0.814 | 0.909 (0.895) | 1.074 | 0.910 | 1.013 | 1.072 | 0.971 | 0.910 | 0.919 | 0.961 |

| W-N3-M-R | 0.797 | 0.814 (0.979) | 1.112 | 0.863 | 0.955 | 1.139 | 1.004 | 0.863 | 0.865 | 1.018 |

| W-N3-B-R | 0.787 | 0.905 (0.870) | 0.987 | 0.821 | 0.885 | 1.024 | 0.895 | 0.821 | 0.804 | 0.925 |

| B-N2-B-R | 0.742 | 0.765 (0.970) | 1.101 | 0.983 | 0.991 | 1.051 | 0.997 | 0.983 | 0.904 | 0.947 |

| B-N4-M-R | 0.855 | 0.669 (1.278) | 1.118 | 1.101 | 1.056 | 1.255 | 1.042 | 1.101 | 0.992 | 1.127 |

| B-N4-B-R | 0.714 | 0.617 (1.157) | 1.007 | 1.073 | 0.982 | 0.893 | 0.930 | 1.073 | 0.935 | 0.808 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujinaga, T.; Sun, Y. Structural Performance of Damaged Open-Web Type SRC Beam-Columns after Retrofitting. Sustainability 2020, 12, 1381. https://doi.org/10.3390/su12041381

Fujinaga T, Sun Y. Structural Performance of Damaged Open-Web Type SRC Beam-Columns after Retrofitting. Sustainability. 2020; 12(4):1381. https://doi.org/10.3390/su12041381

Chicago/Turabian StyleFujinaga, Takashi, and Yuping Sun. 2020. "Structural Performance of Damaged Open-Web Type SRC Beam-Columns after Retrofitting" Sustainability 12, no. 4: 1381. https://doi.org/10.3390/su12041381

APA StyleFujinaga, T., & Sun, Y. (2020). Structural Performance of Damaged Open-Web Type SRC Beam-Columns after Retrofitting. Sustainability, 12(4), 1381. https://doi.org/10.3390/su12041381