A Procedure to Support Systematic Selection of Leading Indicators for Sustainability Performance Measurement of Circular Economy Initiatives

Abstract

1. Introduction

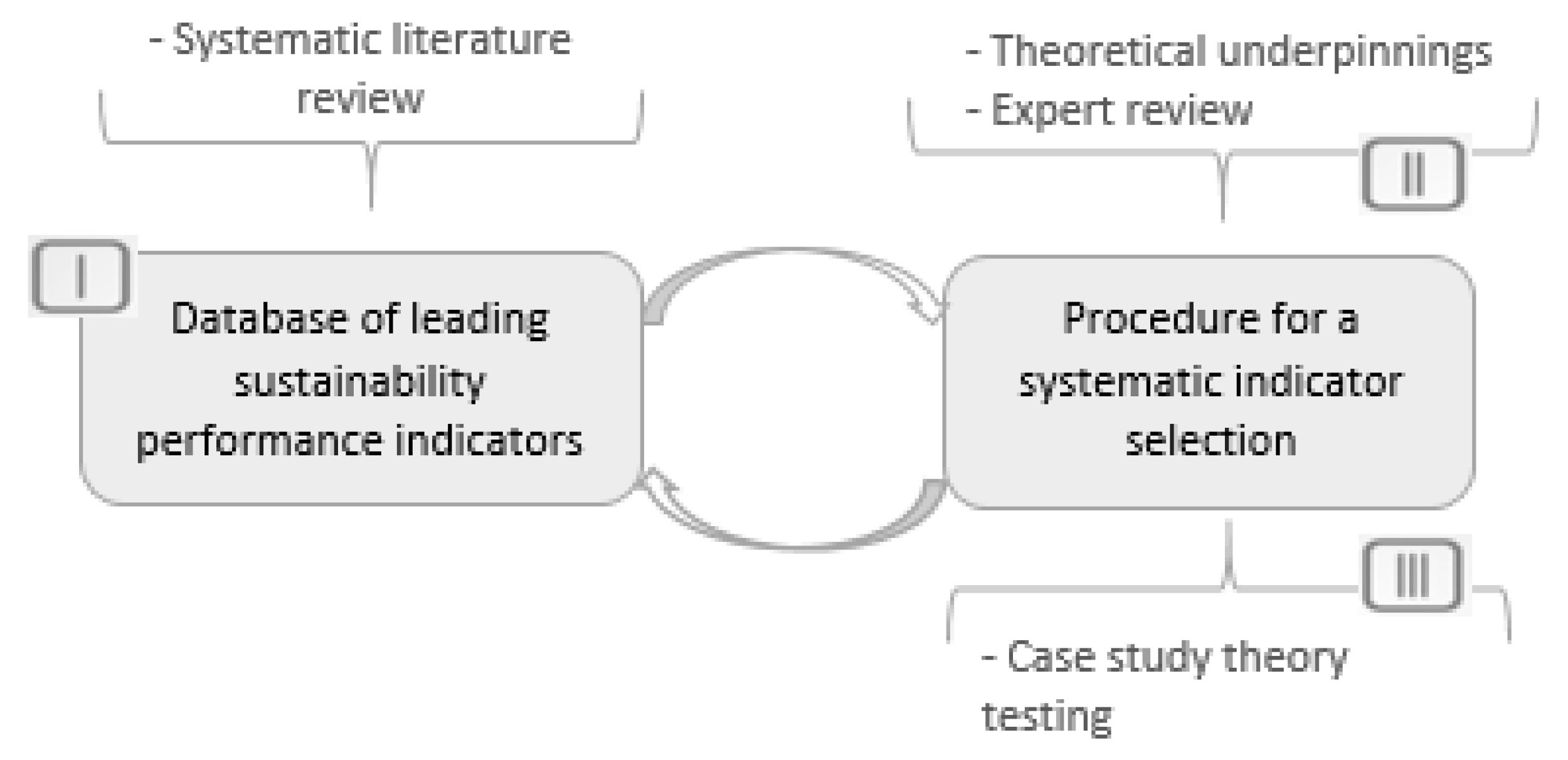

2. Research Methods

2.1. Research Approach

2.1.1. Case Study for Theory Testing

2.1.2. Case Study Set-Up: Case Selection, Data Collection and Analysis

2.2. Conceptual Framing

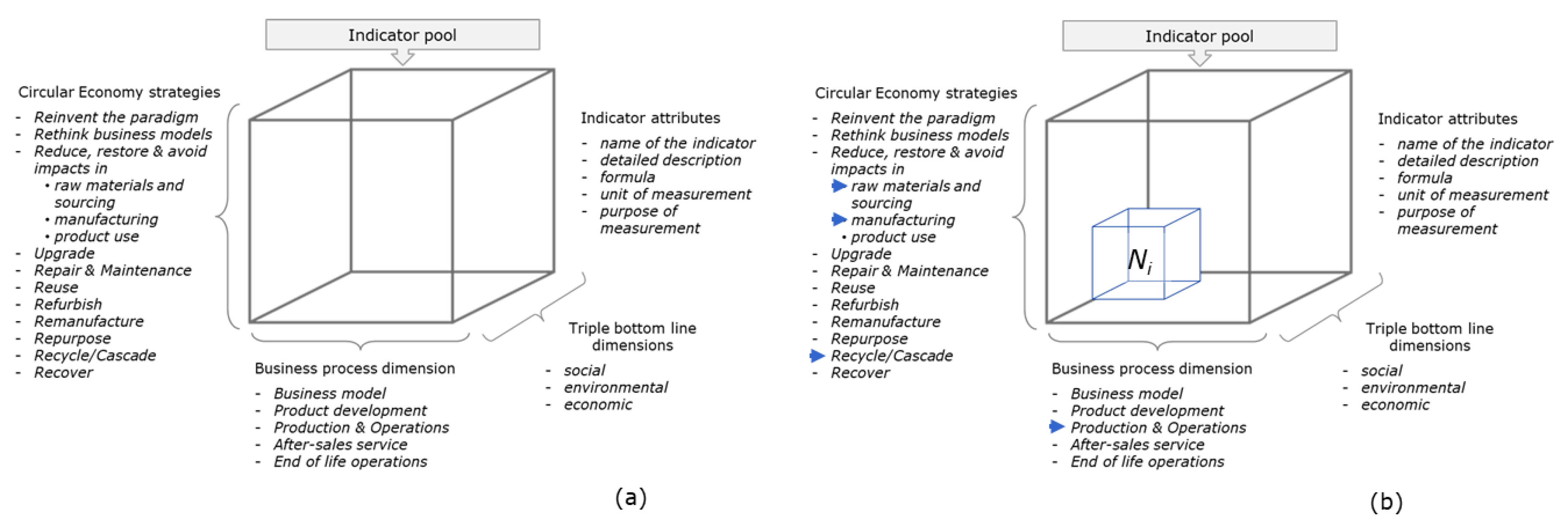

2.2.1. Leading Performance Indicator Database

2.2.2. Procedure Development in the Context of Sustainability Assessment

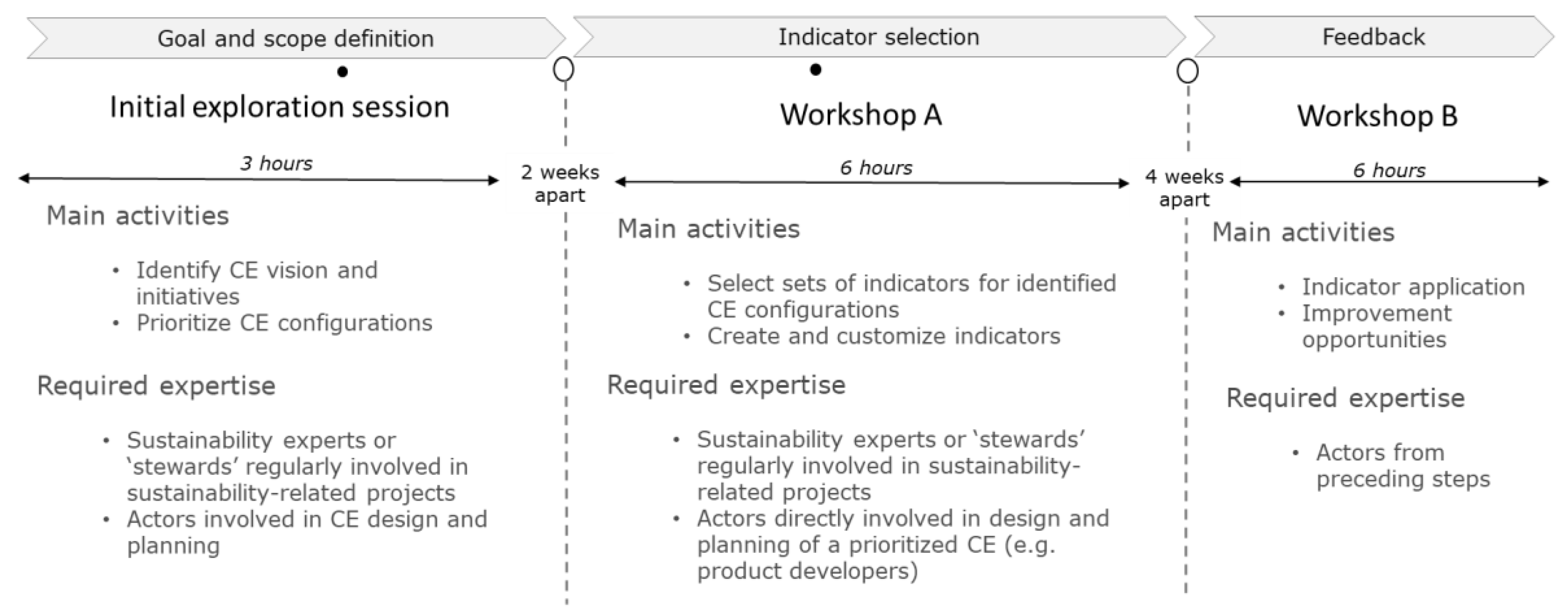

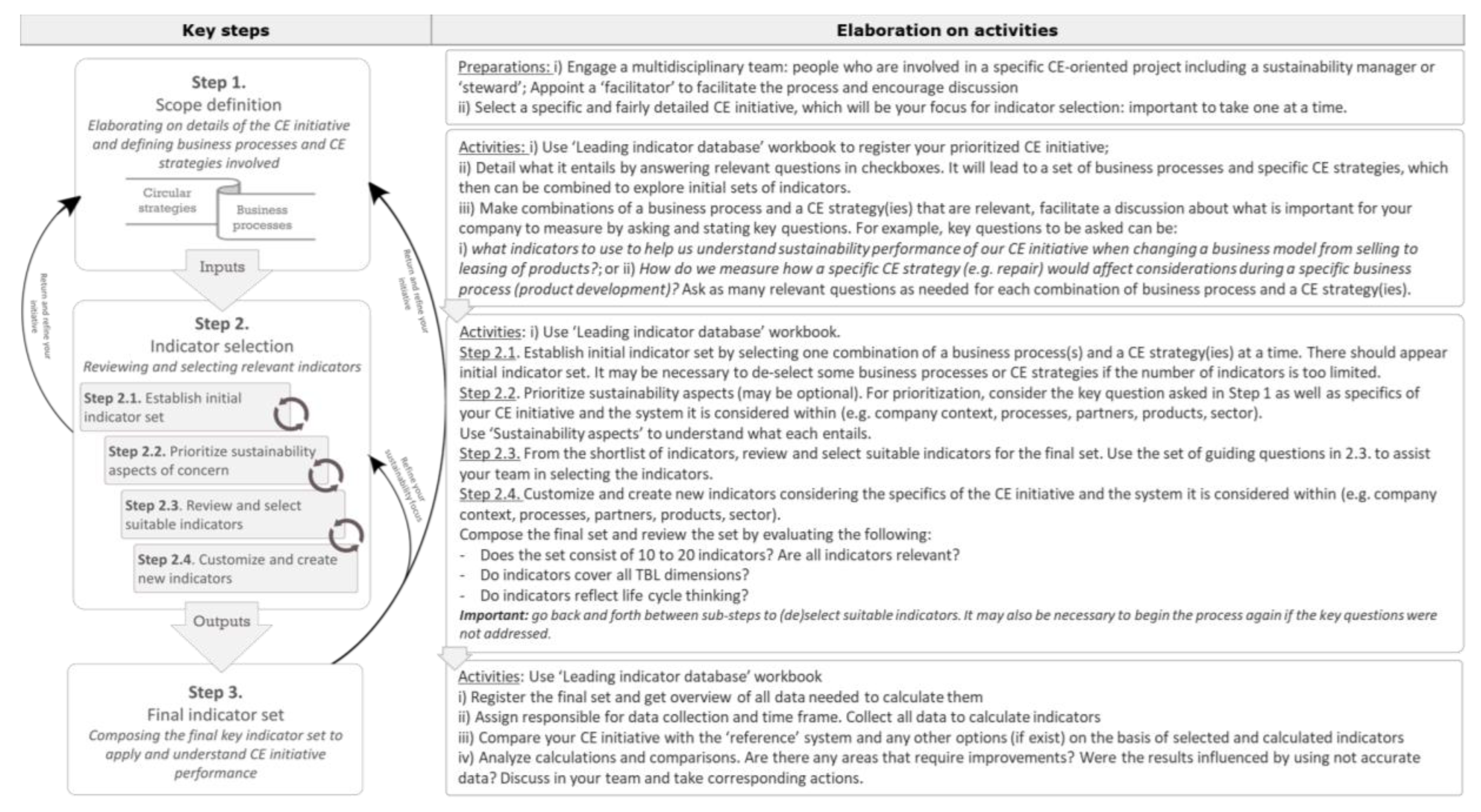

3. Results: A Step-by-Step Procedure for A Systematic Indicator Selection

3.1. Step 1: Scope Definition—Elaborating on a CE Initiative

3.1.1. Overview and Preparations

3.1.2. Activities

3.2. Step 2: Reviewing and Selecting Relevant Indicators

3.2.1. Overview and Preparations

3.2.2. Activities

- How much data is required to measure the indicator and how big is the uncertainty of data collection?

- Does data collection involve significant costs or time?

- Is the indicator easy-to-use and understand?

- Does the use of the indicator require experts?

3.3. Step 3: Composing the Final Indicator Set

- Does the set consist of 10 to 20 indicators?

- Are all indicators relevant?

- Do indicators cover all TBL dimensions?

- Do indicators reflect life cycle thinking?

Implementing the Final Set of Indicators

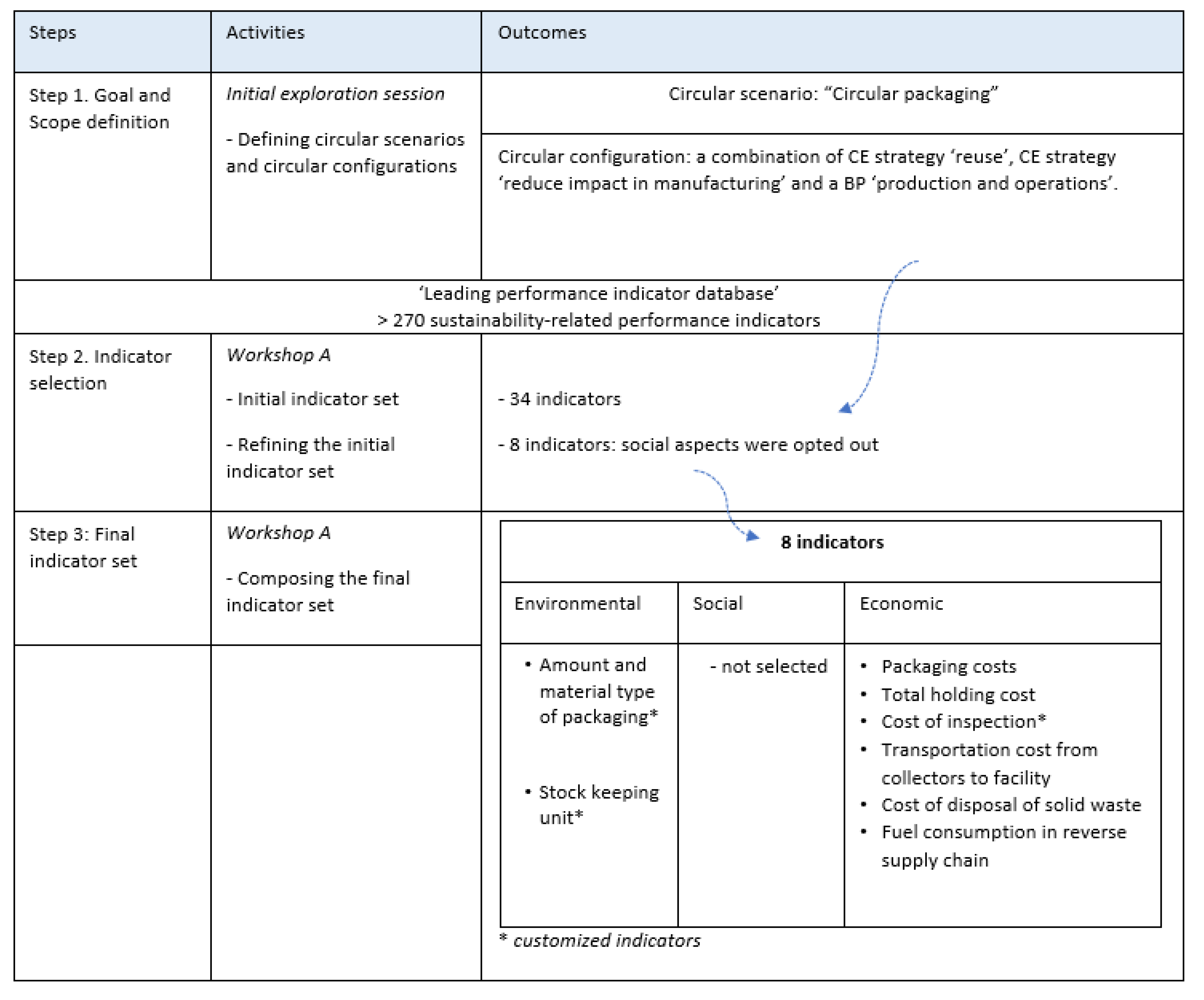

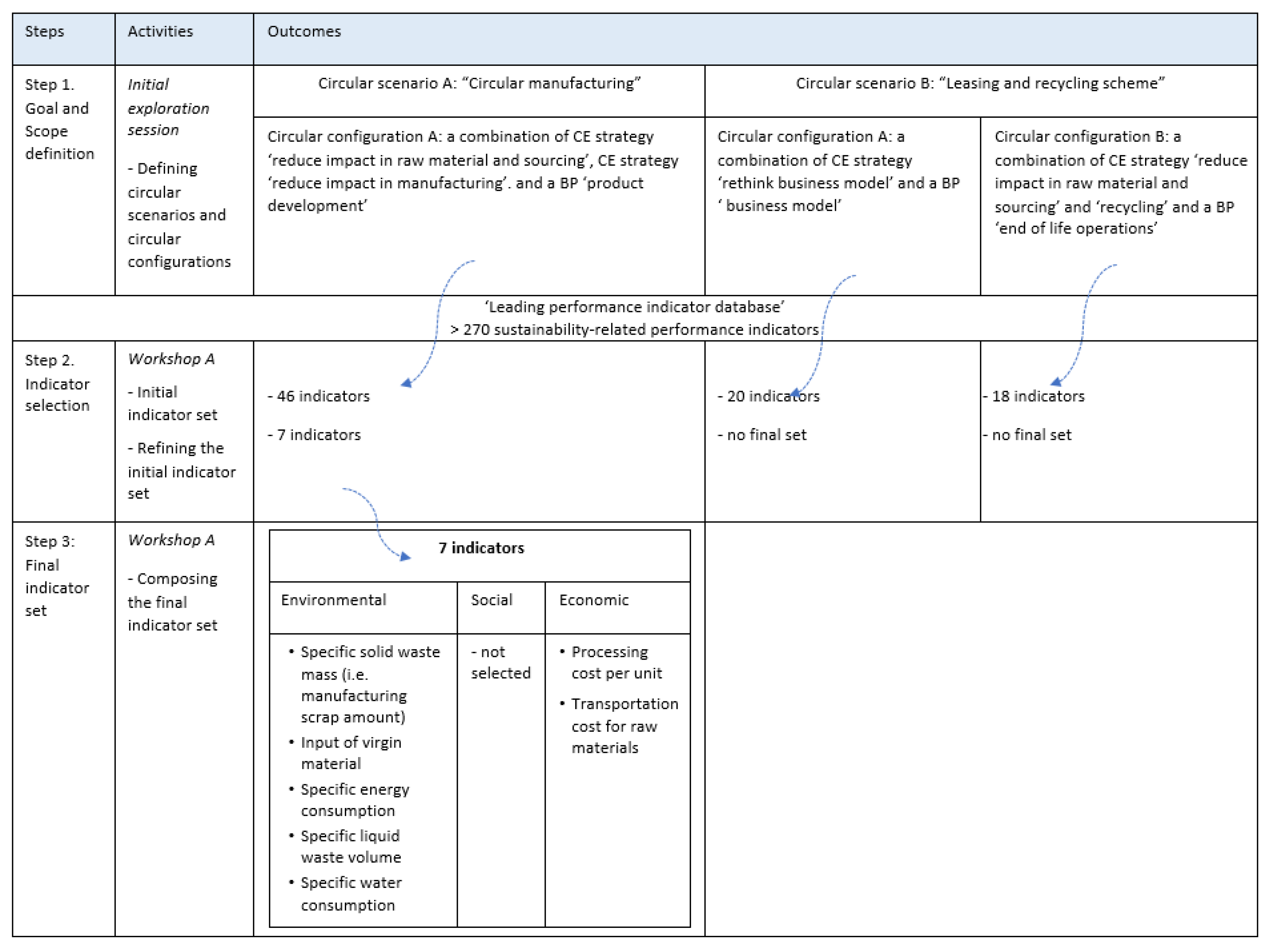

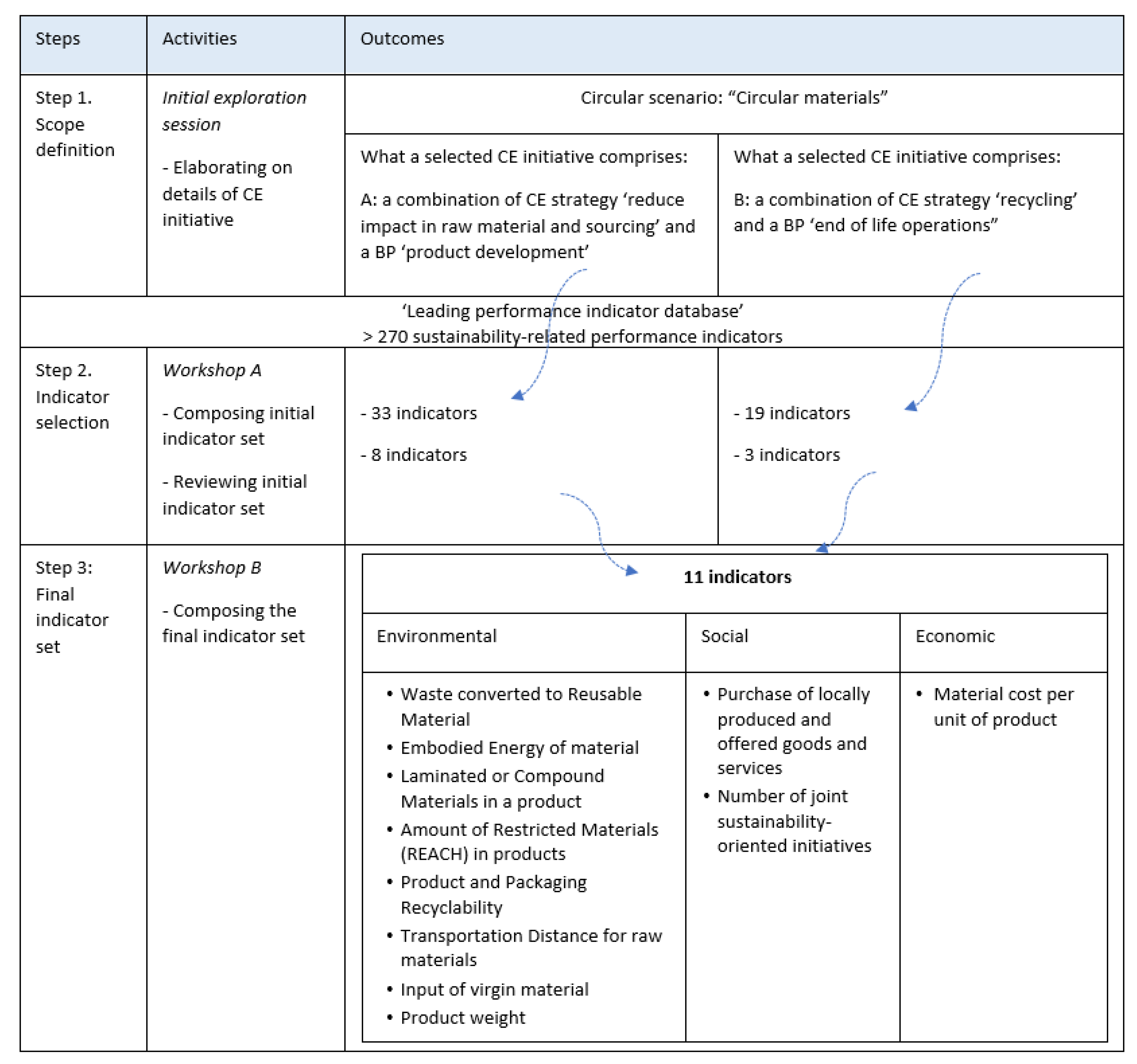

4. Empirical Application in Case Study Settings

4.1. Summary of Insights from the Case Studies

5. Discussion

- it is essential to set the scope for indicator selection by outlining a CE initiative and elaborating on its details by explicating what corporate decisions it affects (e.g., business process orientation) and what specific CE focus it has (e.g., CE strategy view) prior indicator selection process,

- it is necessary to set a baseline scenario, upon which a CE initiative scenario can be compared,

- it is important to involve a multidisciplinary team to support the selection of suitable indicators, including a sustainability ‘steward’ to facilitate the interpretation of indicators and an expert team who is engaged in the development of the CE initiative into focus (e.g., product designers, after-sale managers),

- availability of indicator attributes, such as formulae, units and purpose of measurement, eases the interpretation of each indicator, which facilitates the selection process. This is important especially for SMEs, which might not have a sustainability manager to support indicator interpretation, similarly, availability of elaborations on sustainability aspects and what they entail facilitates their interpretation and prioritization,

- it can be beneficial to work with indicators from one sustainability dimension at a time, however, a final set should comprise a balanced number of TBL indicators,

- the iterative selection procedure seems to help in arriving at suitable indicators, the suitability of which is judged by the users who are to operate with indicators and relate to their results.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B Application of Indicator Selection Procedure in Company 2 and Company 3

Appendix B.1. Company 2

Appendix B.2. Company 3

Appendix C

| Company 1 | |||

|---|---|---|---|

| “The process of indicator selection should start with the aligning or defining the organizational sustainability vision and objectives. It is very important to make a company aware of why selection of indicators is important and what indicators can be used for. It is important to connect the final set of indicators to the corporate values”. | “Make the tool user-friendly for those, who may not have an expertise in sustainability assessments, but have passion to work with indicators to make good”. “.. the procedure requires the facilitator with sustainability expertise to facilitate the team and aid the interpretation of each indicator” (authors: thus making it challenging for (smaller) companies to use the database and select the ‘right’ indicators in a time-efficient manner). | “It is good to have gradual steps in the database (different excel sheets) to obtain the initial set of indicators and then to select the most suitable indicators for the final set using the guiding questions. It gives a good overview of the whole process of the indicator selection, as well as tracks what indicators have been removed from the final set, but initially comprised the initial set”. | “.. (guiding questions) they are very helpful, because they “force” the user to think of each single indicator and reflect on it. Also, the indicator review step helped to understand the internal processes and what matters the most and what are the gaps”. |

| Company 2 | |||

| Important to have a circular scenario ready to be used as an input for the selection process, “… to make filtering meaningful and to be able further narrow down the set of selected indicators”. | ‘Broadness’ of the indicators in comparison to, for instance, life cycle assessment methodology, in that, the screening tool accounts for different business processes and allows to select indicators that cover all three dimensions of sustainability. | “Some indicators can be used to improve existing performance measurement systems, for instance, the environmental management system, because the majority of the company’s factories are certified according to ISO 14001”. | Importance of having boundaries during the indicator evaluation process, “so not to select too many, too few or too ‘biased’ indicators by trying to avoid trade-offs” and that “there might be ‘risks’ associated with operating with a ‘limited’ number of indicators or contradictory indicators”. |

| Company 3 | |||

| “Looking at the final set, as a product developer, I am already aware of some key performance indicators … and could easily use them without the need for the database. On the other hand, some indicators (e.g., energy related) can be very difficult to analyze and interpret due to the lack of (my) knowledge of that area”. | “What competencies the user should have in order to work in the database”. “When is it appropriate to use the tool, i.e., in what part of the decision-making process does it bring the most value to”. | “… there is (‘in industrial world’ – authors) a lot of confusion with circular economy as a concept, therefore, the practitioners need more help in understanding what circular opportunities are there for a specific sector or specific company; … and then to focus on how to create a ‘good’ impact”. | |

References

- Hart, S.L. A Natural-Resource-Based View of the firm. Acad. Manag. Rev. 1995, 20. [Google Scholar] [CrossRef]

- Rademaekers, K.; Asaad, S.S.Z.; Berg, J. Study on the Competitiveness of the European Companies and Resource Efficiency. In Proceedings of the Final Report, Rotterdam, The Netherlands, 6 July 2011. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Contet, P.; Konig, U. Guide to Resource Efficiency in Manufacturing. Greenovade Belgium Energy Regulatory Commission (ERC) (2012). Legal Notice No. 102. Energy Act (No. 12 of 2006). Government of Kenya. Nairobi. Kenya Energy Regulatory Commission (ERC) (2014). Statement on Local Petroleum Pump Prices. Available online: https://erc.go.ke/index.php?option=com_content&view=article&id=21 6:erc-statement-on-local-petroleum-pumpprices&catid=98&Itemid=579 (accessed on 11 November 2019).

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.; Hildenbrand, J.; Kristinsdottir, A.R.; Kristoffersen, E.; Shabazi, S.; Nielsen, K.D.; Jönbrink, A.-R.; et al. Developing a circular strategies framework for manufacturing companies to support circular economy oriented innovation. J. Clean. Prod. 2019, 241. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Configuring new business models for circular economy: From patterns and design options to action. In Proceedings of the 4th International Conference on New Business Models: New Business Models for Sustainable Entrepreneurship, Innovation, and Transformation, Berlin, Germany, 1–3 July 2019; pp. 74–89. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Evans, S. The Cambridge Business Model Innovation Process. Procedia Manuf. 2017, 8, 262–269. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A conceptual framework for circular design. Sustainability 2016, 8. [Google Scholar] [CrossRef]

- Bakker, C.; den Hollander, M.; van Hinte, E.; Zijlstra, Y. Products that Last—Product Design for Circular Business Models; TU Delft Library: Delft, The Netherlands, 2014. [Google Scholar]

- Blomsma, F.; Pigosso, D.C.; McAloone, T.C. A Theoretical Foundation for Developing a Prescriptive Method for the Co-Design of Circular Economy Value Chains. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 3141–3150. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Rashid, A.; Asif, F.M.A.; Krajnik, P.; Nicolescu, C.M. Resource conservative manufacturing: An essential change in business and technology paradigm for sustainable manufacturing. J. Clean. Prod. 2013, 57, 166–177. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain—Policy Report; PBL Netherlands Environ Assess Agency: AV Den Haag, The Netherlands, 2017; p. 42. [Google Scholar]

- Azevedo, S.; Godina, R.; Matias, J. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef]

- EMF. Circularity Indicators: An Approach to Measuring Circularity. Ellen MacArthur Found 2015, 12. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Asif, F.M.A.; Lieder, M.; Rashid, A. Multi-method simulation based tool to evaluate economic and environmental performance of circular product systems. J. Clean. Prod. 2016, 139, 1261–1281. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C. A Robust Indicator for Promoting Circular Economy through Recycling. J. Environ. Prot. (Irvine Calif.) 2015, 6, 1095–1104. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. Towards the ex-ante sustainability screening of Circular Economy initiatives in manufacturing companies: Consolidation of leading. J. Clean. Prod. 2019, 118318. [Google Scholar] [CrossRef]

- Waas, T.; Hugé, J.; Block, T.; Wright, T.; Benitez-Capistros, F.; Verbruggen, A. Sustainability assessment and indicators: Tools in a decision-making strategy for sustainable development. Sustainability 2014, 6, 5512–5534. [Google Scholar] [CrossRef]

- Keeble, J.J.; Topiol, S.; Berkeley, S. Using Indicators to Measure Sustainability Performance at a corporate and Project Level. J Bus. Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Shareef, R. Want better business theories? Maybe karl popper has the answer. Acad. Manag. Learn. Educ. 2007, 6, 272–280. [Google Scholar] [CrossRef]

- Minnameier, G. The Logicality of Abduction, Deduction and Induction. In Ideas in Action: Proceedings of the Applying Peirce Conference; Nordic Pragmatism Network: Helsinki, Finland, 2010; pp. 239–251. [Google Scholar]

- Zaidah, Z. Case study as a research method. J. Kemanus. 2007, 9, 1–6. [Google Scholar]

- Yin, R.K. Case Study Research—Design and Methods. Clin. Res. 2006, 2, 8–13. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Shenton, A.K. Strategies for ensuring trustworthiness in qualitative research projects. Educ. Inf. 2004, 22, 63–75. [Google Scholar] [CrossRef]

- Baxter, P.; Jack, S. Qualitative Case Study Methodology: Study Design and Implementation for Novice Researchers. Qual. Rep. 2008, 13, 544–559. [Google Scholar]

- Pojasek, R.B. Using Leading Indicators to Drive Sustainability Performance. Environ. Qual. Manag. 2009. [Google Scholar] [CrossRef]

- Pavlov, A.; Bourne, M. Explaining the effects of performance measurement on performance: An organizational routines perspective. Int. J. Oper. Prod. Manag. 2011, 31, 101–122. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. An integrated sustainability decision-support framework Part I: Problem structuring. Int. J. Sustain. Dev. World Ecol. 2005, 12, 98–111. [Google Scholar] [CrossRef]

- Gibson, R.B. Sustainability. In Tools, Technology Approaches Sustainanbility; Sheate, W.R., Ed.; World Scientific Publishing: Singapore, 2010; pp. 389–410. [Google Scholar]

- Issa, I.I.; Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Leading product-related environmental performance indicators: A selection guide and database. J. Clean. Prod. 2015, 108, 321–330. [Google Scholar] [CrossRef]

- Rahdari, A.H.; Anvary Rostamy, A.A. Designing a general set of sustainability indicators at the corporate level. J. Clean. Prod. 2015, 108, 757–771. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9. [Google Scholar] [CrossRef]

- Shields, D.J.; Šolar, S.V.; Martin, W.E. The role of values and objectives in communicating indicators of sustainability. Ecol. Indic. 2002, 2, 149–160. [Google Scholar] [CrossRef]

- Arena, M.; Ciceri, N.D.; Terzi, S.; Bengo, I.; Azzone, G.; Garetti, M. A state-of-the-art of industrial sustainability: Definitions, tools and metrics. Int. J. Prod. Lifecycle Manag. 2009, 4, 207. [Google Scholar] [CrossRef]

- Muthu, S.S. Handbook of Sustainable Apparel Production; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- O’Connor, M.P.; Zimmerman, J.B.; Anastas, P.T.; Plata, D.L. A strategy for material supply chain sustainability: Enabling a circular economy in the electronics industry through green engineering. ACS Sustain. Chem. Eng. 2016, 4, 5879–5888. [Google Scholar] [CrossRef]

- Fernandes, P.T.; Canciglieri Júnior, O.; Sant’Anna, Â.M.O. Method for integrated product development oriented to sustainability. Clean Technol. Environ. Policy 2017, 19, 775–793. [Google Scholar] [CrossRef]

- EC. Internal Market, Industry, Entrepreneurship and SMEs. Eur. Comm. 2019. Available online: https://ec.europa.eu/growth/smes/business-friendly-environment/sme-definition_en (accessed on 11 November 2019).

- McAloone, T.C. Industry Experiences of Environmentally Conscious Design Integration: An Exploratory Study. Ph.D. Thesis, Cranfield University, Bedford, England. Academic Year 1998.

- EC. Regulation (EC) No. 2037/2000 of the European Parliament and of the Council of 29 June 2000 on Substances that Deplete the Ozone Layer; European Parliament: Brussels, Belgium, 2000; pp. 1–24. [Google Scholar]

- Veleva, V.; Hart, M.; Greiner, T.; Crumbley, C. Indicators of sustainable production. Clean. Prod. 2001, 9, 447–452. [Google Scholar] [CrossRef]

- ISO 14033. Environmental Management—Quantitative Environmental Information—Guidelines and Examples; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- Mesa, J.; Esparragoza, I.; Maury, H. Developing a set of sustainability indicators for product families based on the circular economy model. J. Clean. Prod. 2018, 196, 1429–1442. [Google Scholar] [CrossRef]

- Grimaud, G.; Perry, N.; Laratte, B. Decision Support Methodology for Designing Sustainable Recycling Process Based on ETV Standards. Procedia Manuf. 2017, 7, 72–78. [Google Scholar] [CrossRef]

- Badurdeen, F.; Shuaib, M.A.; Lu, T.; Jawahir, I.S. Sustainable Value Creation in Manufacturing at Product and Process Levels: A Metrics-Based Evaluation. In Handbook of Manufacturing Engineering and Technology; Springer: London, UK, 2015; pp. 3343–3375. [Google Scholar] [CrossRef]

- Gibson, R.B.; Hassan, S.; Holtz, S.; Tansey, J.; Whitelaw, G. Sustainability Assessment: Criteria, Processes and Applications; Earthscan: London, UK, 2005. [Google Scholar]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sustain. Eng. 2017, 10, 289–298. [Google Scholar] [CrossRef]

- Stewart, R.; Niero, M. Circular economy in corporate sustainability strategies: A review of corporate sustainability reports in the fast-moving consumer goods sector. Bus. Strateg. Environ. 2018, 27, 1005–1022. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

| Recommendations | References | Explanation | Adopted Feature |

|---|---|---|---|

| Reduce uncertainty of what has be measured | [25] | Establish a pool of indicators suitable for the exact assessment scope | The procedure entails application of the ‘Leading performance indicator database’, where each indicator is classified according to various circular economy strategies, business processes and TBL aspects |

| Dynamic and reflective process | [26,37,38] | Support dynamic and open-ended selection process, focusing on the process rather than on results | The procedure encourages the user to work with indicator selection in an iterative way, by encouraging to define a scope, select indicators, review indicators, and align the selection with the scope |

| Support review of indicators | [38] | Provide guidance for the review of individual indicators | The guiding questions have been developed to support the procedure of indicator review, evaluation, creation and customization |

| Indicator number | [39,40] | Ensure indicator set is manageable yet provides a solid basis for decision-making | The procedure leads the user to defining the final set of indicators that is relevant for the screening scope yet limited to the key indicators that can support decisions |

| Indicator application | [36] | Ensure the information about indicator is sufficient to apply and interpret it | The procedure entails application of the ‘Leading performance indicator database’, where each indicator has a formula, units and purpose of measurement registered |

| Recommendations | Case Company | Explanation | Adopted Feature | ||

|---|---|---|---|---|---|

| C1 | C2 | C3 | |||

| Strategic consideration | √ | Ensure alignment of lower level performance indicators with corporate sustainability objectives | Not adopted in the current procedure | ||

| Scope definition | √ | √ | Ensure the scope is defined before proceeding to the indicator selection | Introduction to the procedure highlights the importance of having a defined CE initiative prior indicator selection process. Furthermore, practical examples on how to construct CE configurations for selected CE initiatives are given in Step 1 | |

| Baseline identification | √ | √ | √ | Ensure identification and explanation of a baseline scenario | The recommendation to define the baseline scenario in order to encourage scenario comparison on the basis of the selected indicators is given is Step 1 |

| Multidisciplinary team | √ | √ | Ensure the experts with relevant expertise are involved in the indicator selection and evaluation process | Introduction to the procedure highlights involvement of actors with relevant expertise for indicator selection, evaluation and customization process | |

| Triple bottom line aspect navigation | √ | √ | √ | Support flexible (de)selection of relevant triple bottom line aspects to reduce complexity | The recommendation in Step 2 was introduced to allow for prioritization of sustainability aspects, thus reducing the complexity by simultaneously operating with too many indicators and sustainability aspects |

| Indicator number | √ | √ | √ | Provide a recommendation about the number of indicators in the final set | Step 3 indicates the recommended number of indicators to be included in the final set |

| Account trade-offs | √ | √ | Provide a recommendation about how to address trade-offs between indicators | Not adopted in the current procedure | |

| Reference | Considers all dimensions of sustainability | Considers a variety of circular economy strategies | Considers a variety of business processes | Considers a life cycle perspective | Encourages a dynamic indicator selection process | Presents a practical application in industry |

| Present research | √ | √ | √ | - * | √ | √ |

| [51] | - Only environmental | √ | - Only product development | - | - | √ |

| [52] | √ | - Limited to recycling | - Only end of life process | - | - | - |

| [38] | - Only environmental | - | - Only product development | √ | √ | √ |

| [53] | √ | - | - Only product development and manufacturing process | √ | - | √ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. A Procedure to Support Systematic Selection of Leading Indicators for Sustainability Performance Measurement of Circular Economy Initiatives. Sustainability 2020, 12, 951. https://doi.org/10.3390/su12030951

Kravchenko M, Pigosso DCA, McAloone TC. A Procedure to Support Systematic Selection of Leading Indicators for Sustainability Performance Measurement of Circular Economy Initiatives. Sustainability. 2020; 12(3):951. https://doi.org/10.3390/su12030951

Chicago/Turabian StyleKravchenko, Mariia, Daniela C. A. Pigosso, and Tim C. McAloone. 2020. "A Procedure to Support Systematic Selection of Leading Indicators for Sustainability Performance Measurement of Circular Economy Initiatives" Sustainability 12, no. 3: 951. https://doi.org/10.3390/su12030951

APA StyleKravchenko, M., Pigosso, D. C. A., & McAloone, T. C. (2020). A Procedure to Support Systematic Selection of Leading Indicators for Sustainability Performance Measurement of Circular Economy Initiatives. Sustainability, 12(3), 951. https://doi.org/10.3390/su12030951