Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles

Abstract

1. Introduction

2. Literature Review

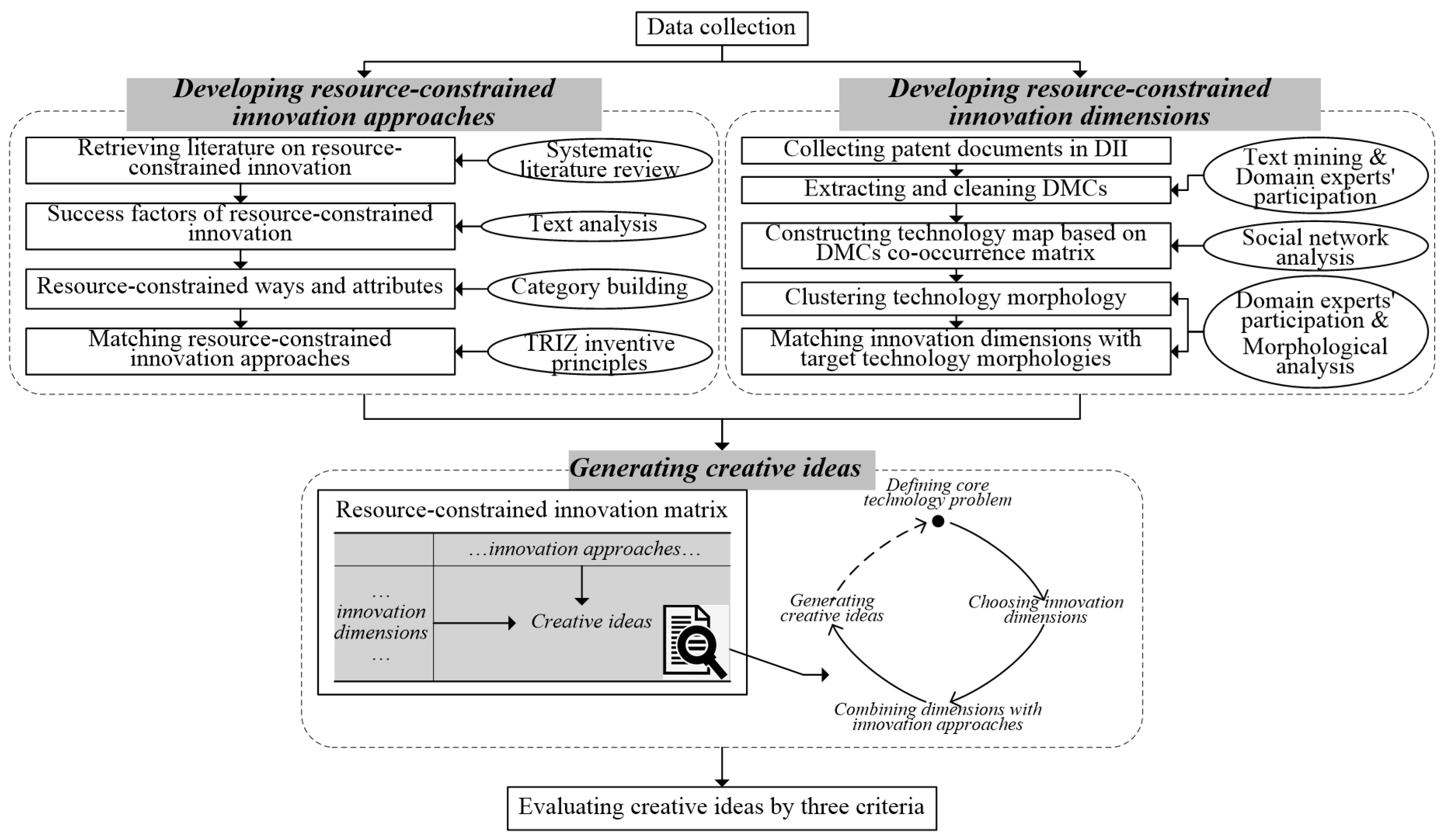

3. Proposed Method for Resource-Constrained Innovation

3.1. Research Concept

- ◆

- A method to lay emphasis on the savings of resource, time and cost in the process of product development under resource-constraints context and sustainability;

- ◆

- A method to focus on generating creative ideas for NPD;

- ◆

- A method to put emphasis on problem-solving of resource-constrained innovation by integrating the advantages of TRIZ and MA;

- ◆

- A structured method to develop innovation dimensions from existing patent documents and deduce creative ideas by means of resource-constrained innovation approaches.

3.2. Research Framework

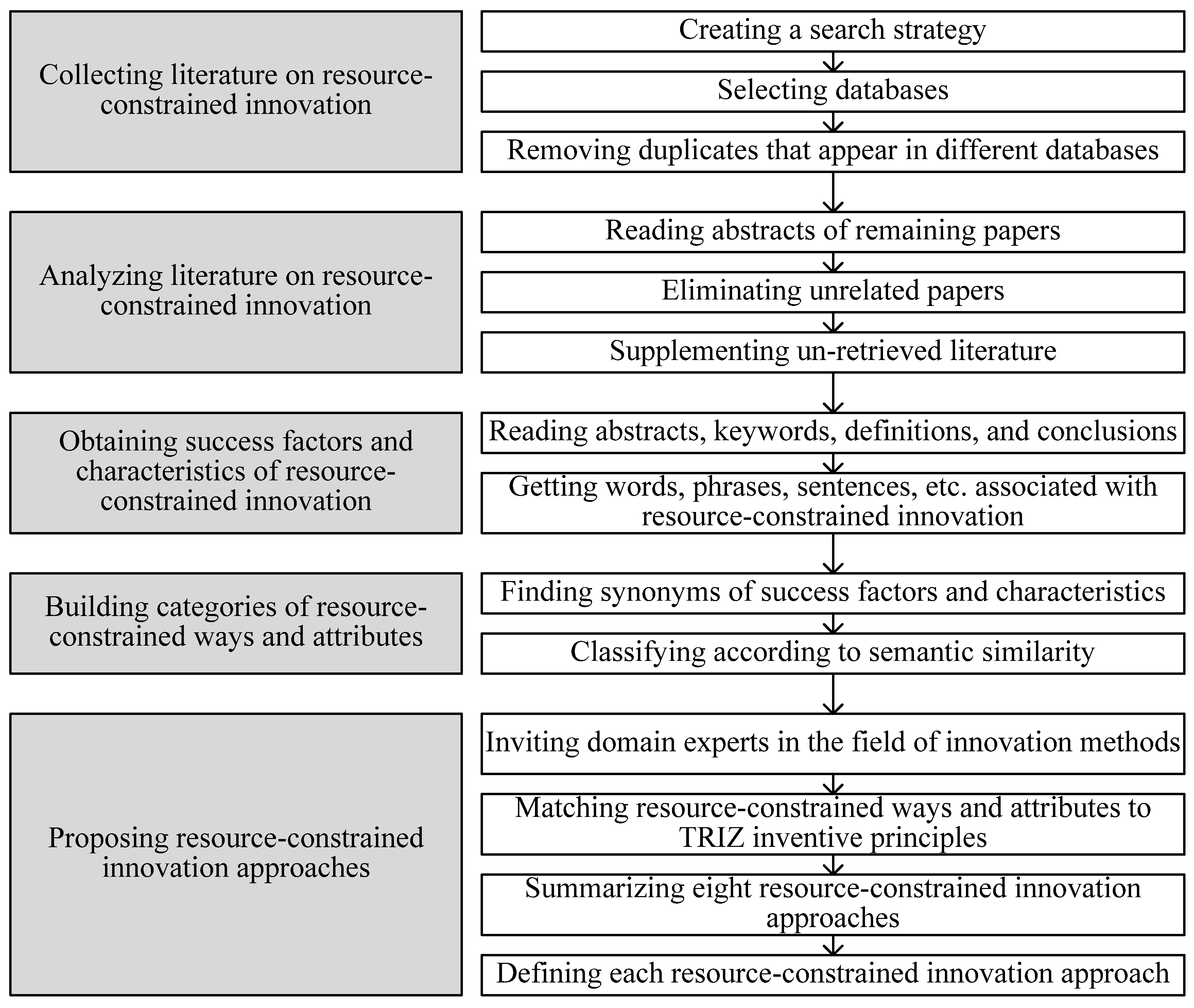

3.2.1. Module 1: Developing the Resource-Constrained Innovation Approaches

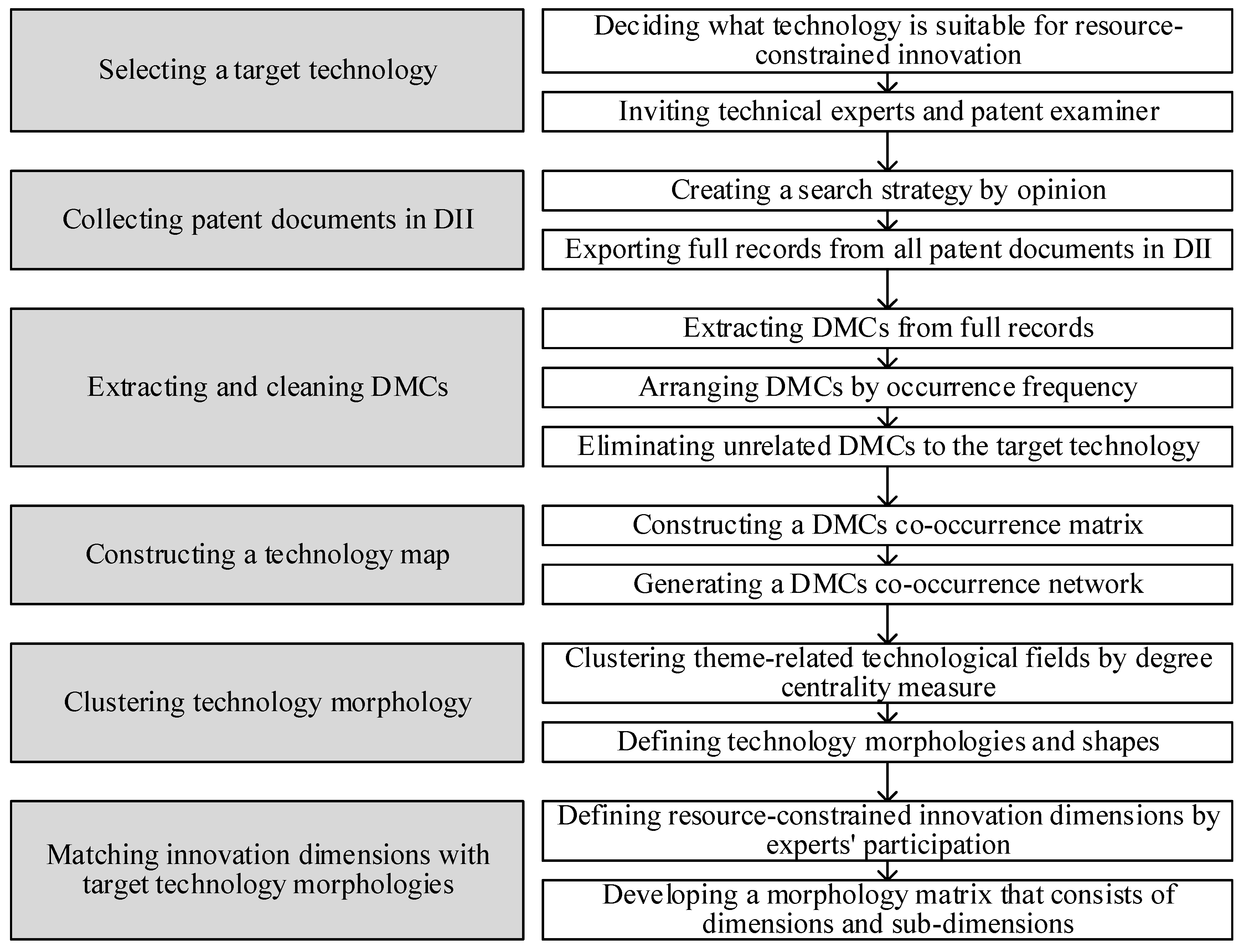

3.2.2. Module 2: Developing the Resource-Constrained Innovation Dimensions

3.2.3. Module 3: Generating Creative Ideas

4. Illustrative Example: Idea Generation for CBM Extraction Technology in China

4.1. Background

4.2. Patents Data Collection and Preprocessing

4.3. Technology Map Construction and Clustering

4.4. Defining the Resource-Constrained Innovation Dimensions

- ◆

- The mechanism dimension focuses on basic physical, chemical or biological effects that release pressure and gas in the coal-bed.

- ◆

- The material dimension includes solid states, liquid states and gas states.

- ◆

- The space dimension focuses on the location sub-dimension that represents the location from where the CBM extraction technology is carried out. The locations, including ground, coal reservoir, surrounding rock and tunnel above/below the coal-bed.

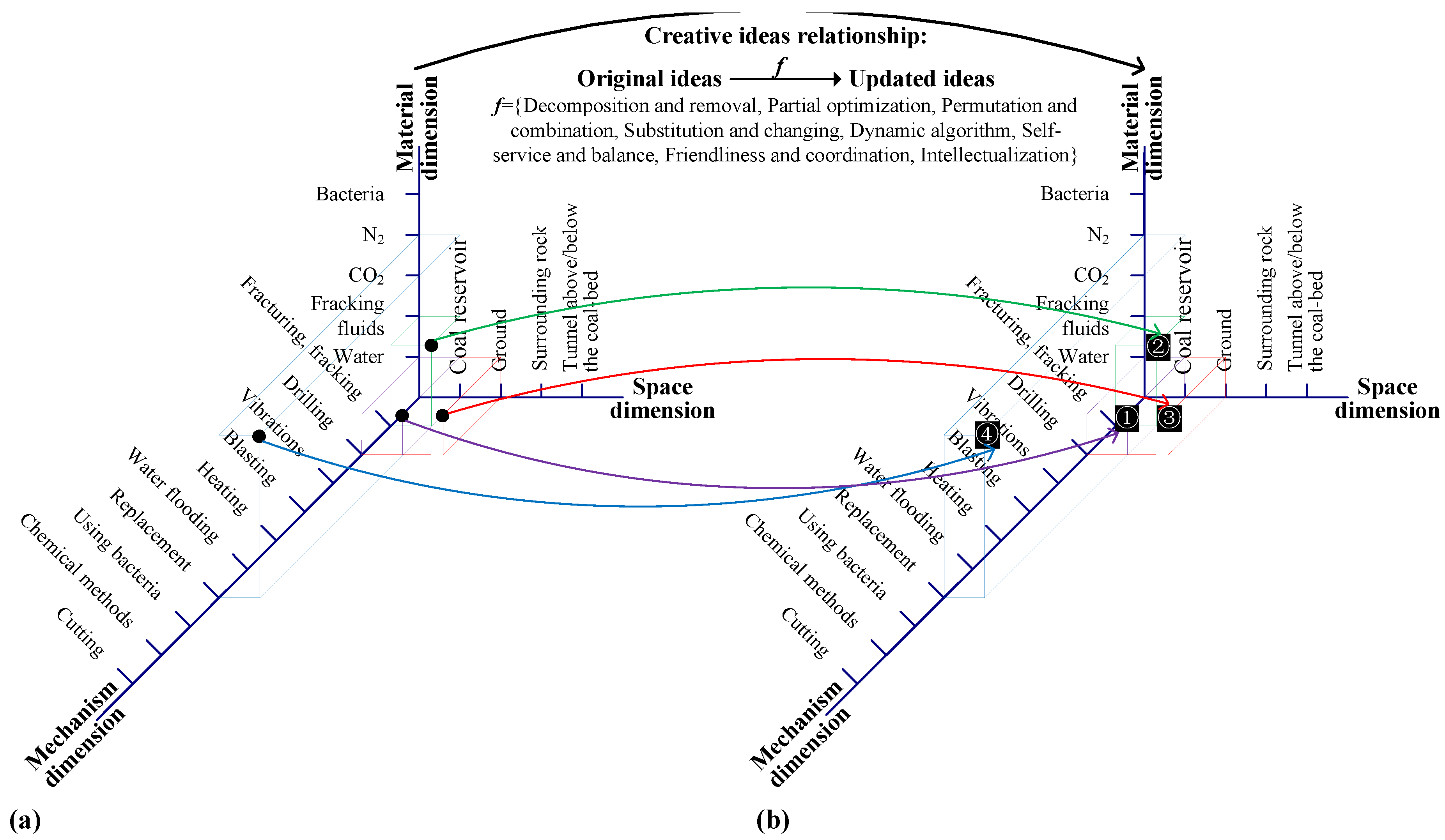

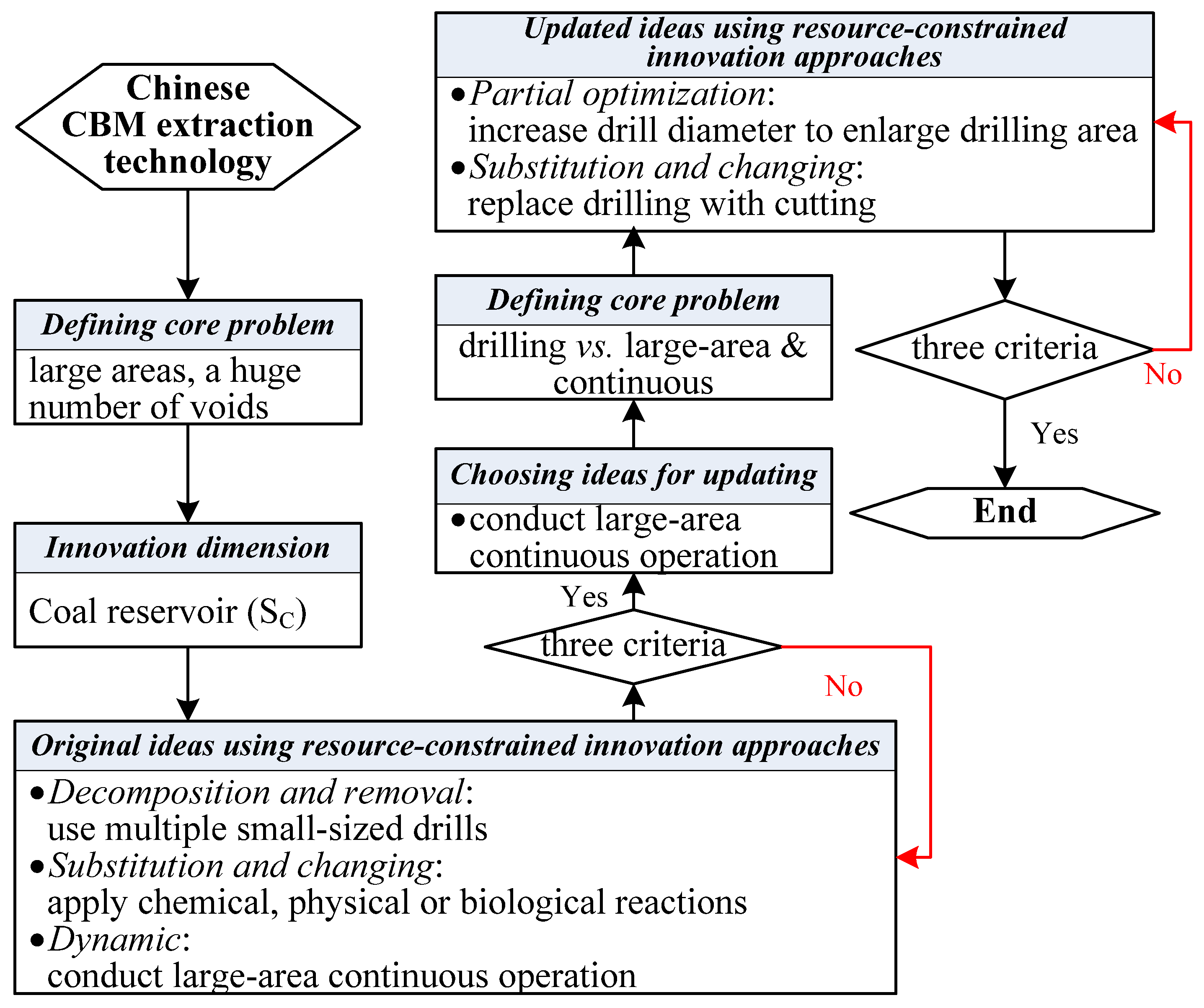

4.5. Generating Creative Ideas for CBM Extraction Technology

4.6. Validation in China

- ◆

- Using multiple small-sized drills to work at the same time. We combine the SC with the decomposition and removal approach. Thus, the segmentation principle divides an object into independent parts and makes it easy to disassemble. We can decompose the large-diameter drilling equipment into multiple small-sized drills to work at the same time. The small-sized drills mean compact and portable, easy to maintenance and replacement, ease to transportation [61]. This original idea is already a resource-constrained end-solution for Chinese CBM extraction technology. Using multiple small-sized drills can largely shorten the construction period and cut cost compared with the large-diameter drilling equipment. Resource-constrained innovation has been achieved. There is no analysis on developing the small-sized drilling equipment in this article.

- ◆

- Applying chemical, physical or biological reactions to make the coal-bed internal self-cracking. We combine SC with the substitution and changing approach. Thus, the theory substitution principle makes the coal-bed internal self-cracking by use of force field, electric field, magnetic field or mechanic field. These reactions change the pressure of coal-bed and release the gas. However, there is no existing technology to decompose CBM chemically or biologically. Resource-constrained innovation has not been achieved.

- ◆

- Conducting large-area continuous operating to replace drilling holes. We combine SC with a dynamic approach. Thus, the continuity of useful action principle advocates to work continuously and eliminate all idle or intermittent actions. We can carry on continuous operating to replace independent, one by one and intermittent drilling work. Conducting large-area continuous operating can fulfill one-time and continuous work by utilizing existing cutting equipment [62]. Savings of time and cost have achieved resource-constrained innovation. This original idea should be further discussed in the stage of updating ideas.

- ◆

- Increasing the drill diameter to enlarge the drilling area. We use the partial optimization approach. Thus, the local optimization principle overcomes the drilling equipment is weak and optimize them by increasing the drill diameter. Moreover, the super-large-diameter drilling equipment enlarges the drilling area. However, it may easily result in coal-bed collapse and lead to fatal gas accidents [52]. Resource-constrained innovation cannot be achieved this way.

- ◆

- Replacing drilling with cutting. We use the substitution and changing approach. The mechanics substitution principle changes operating mode for coal-bed from static to movable fields or from unstructured fields to those having structure. Thus, we can change the direction of voids from vertical to horizontal. The drilling is vertical, but the cutting is horizontal. The horizontal cutting can largely increase the operating area at one go-off, decrease project quantity and reduce construction cost. A new cutting system which is combined with existing cutting equipment of coal-bed will save the cost and time. Resource-constrained innovation can be achieved this way.

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Resource-Constrained Innovation Approaches | Resource-Constrained Ways and Attributes | Success Factors and Characteristics Used in Literature |

|---|---|---|

| Decomposition and removal approach | Minimizing | Keep it simple, cut corners [57]; Minimize the use of material and financial resources in the complete value chain [5]; Reducing the complexity, lean, minimize the use of extensive resources [73]; Minimize inessential costs, low input of resources [74]; Highly scalable products which have reduced functionalities, while reducing costs [75]; Avoiding obesity [76]; Simplification, minimalist features and functional requirements [1]. |

| Concentration on core functionalities | Cost innovation [17]; Cost engineering, the reduction of raw materials costs, as well as conversion and logistics in getting products into retail channels [77,78,79]; Good enough, limited features [67]; Bare essentials, eliminate unessential functions, reduce the complexity, tailored for less, provide insights into required features and functions, functional requirements of the user [78]; Core product modification [80]. | |

| Functional and focused on essentials | Decomposition of multipurpose machines by using established technology [81]; Eliminating unessential functions [74]; Provide the essential functions people need [82,83]; Strip the products down to their bare essentials rather than add ever more bells and whistles [84]. | |

| Compact design with a no frills structure | Unnecessary frills stripped out [85]; Basic no frills product to minimize unnecessary feature, swarms of low-cost simple products perform complex tasks in unison, small and compact products comprised of cheap parts [79]. | |

| Partial optimization approach | Modularity | Create families of parts that share common characteristics, reduce development costs for future generation of products and provide the innovator with speed to customize products [43,61,86,87,88,89,90]. |

| Process optimization | Manufacturing processes, process parameters, labor, supply-chain logistics and other relevant manufacturing variables that could be optimized for achieving lower costs [8]; Where expensive capital-intensive processes can be streamlined [17]; Rigorous design procedure [91]. | |

| Location | Developing markets, emerging markets, exploration of local needs, end to end localization, core value identification, proximity to the local markets [67]; Provides information on local operational conditions and infrastructure [80]; Use of local resources [1]. | |

| Permutation and combination approach | Architectural innovation | Mix and match [67]; Recombination of established technologies into a new product [81,91]; Reconfiguration of an established system to link together existing components in a new way without changing core technology or know-how [61,69]. |

| Bricolage | Combining existing materials at hand, leveraging existing innovation processes, using existing resources, use of limited raw materials [68,92,93]; Leveraging existing products, inputs and services [1]. | |

| Combining | Proven technologies from other industry domains [39]. | |

| Substitution and changing approach | Inventive analogies [94,95] | Within-industry analogies, cross-industry analogies, bionic analogies [96], transferring solutions from nature, transferring solution from one industry domain to the other field of physical, chemistry and biology. |

| Bricolage | Making do with resources at hand, easily available physical materials, non-material resources [92]. | |

| Instead of using good-enough or economical materials | Do not have sophisticated technological features [74]; Using homegrown or self-created technologies [97]; Meeting the desired objective with a good-enough, economical means [98,99]; Substitute cheaper materials for the expensive [17]; Use of cutting edge technology [8]; Careful consideration of the materials [78,79]; Reduces material use [4]. | |

| Dynamic approach | Re-use of existing components | Upcycling, remanufacturing, organic materials [91]; Reduce use of limited raw materials, reuse of existing components [8]. |

| Self-service and balance approach | Easy to repair and service | Products can be repaired and maintained at the local level [61]; Light and highly manufacturable, as well as robust and low maintenance [99]. |

| Self-service | Provide ways for customers to eliminate the need for expensive personal service without forgoing the value of the service [68]. | |

| Friendliness and coordination approach | User-friendly and easy to use | Lightweight: Portable for varying transportation options [1]; Human centric design [1]; Pleasing to the eye, easy to use, highly portable, and adaptable to an ever-growing range of accessories [78,79]; User-centric innovation; Eco-friendly [100]; Sustainable [23]; Green technologies: Powered by renewable resources [1]; Affordability and sustainability [101]; Draw sparingly on raw materials and minimize environmental impact [102]; Low carbon footprint [74,103]; Tailor made [47,97]; Reducing the use of scarce resources [9]; Factor of safety [91]. |

| Intellectualization approach | Mobile enabled solutions: Connectivity anytime, anywhere [1] |

References

- Basu, R.R.; Banerjee, P.M.; Sweeny, E.G. Frugal innovation: Core competencies to address global. J. Manag. Glob. Sustain. 2013, 1, 20. [Google Scholar] [CrossRef]

- Bhatti, Y.A.; Ventresca, M. How Can ‘Frugal Innovation’ Be Conceptualized?; Working paper. 2013. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2203552 (accessed on 30 August 2019).

- Hyvärinen, A.; Keskinen, M.; Olli, V. Potential and pitfalls of frugal innovation in the water sector: Insights from Tanzania to global value chains. Sustainability 2016, 8, 888. [Google Scholar] [CrossRef]

- Sharma, A.; Iyer, G.R. Resource-constrained product development: Implications for green marketing and green supply chains. Ind. Mark. Manag. 2012, 41, 599–608. [Google Scholar] [CrossRef]

- Tiwari, R.; Herstatt, C. Assessing India’s lead market potential for cost-effective innovations. J. Indian Bus. Res. 2012, 4, 97–115. [Google Scholar] [CrossRef]

- Zeschky, M.; Widenmayer, B.; Gassmann, O. Frugal innovation in emerging markets. Res. Technol. Manag. 2011, 54, 38–45. [Google Scholar] [CrossRef]

- Zeschky, M.; Widenmayer, B.; Gassmann, O. Organising for reverse innovation in Western MNCs: The role of frugal product innovation capabilities. Int. J. Technol. Manag. 2014, 64, 255–275. [Google Scholar] [CrossRef]

- Rao, B.C. How disruptive is frugal? Technol. Soc. 2013, 35, 65–73. [Google Scholar] [CrossRef]

- Radjou, N.; Prabhu, J.; Ahuja, S.; Roberts, K. Jugaad Innovation: Think Frugal, Be Flexible, Generate Breakthrough Growth; Jossey-Bass: San Francisco, CA, USA, 2012. [Google Scholar]

- Prabhu, J.; Jain, S. Innovation and entrepreneurship in India: Understanding jugaad. Asia Pac. J. Manag. 2015, 32, 843–868. [Google Scholar] [CrossRef]

- Rosca, E.; Arnold, M.; Bendul, J.C. Business models for sustainable innovation—An empirical analysis of frugal products and services. J. Clean. Prod. 2016, 162, s133–s145. [Google Scholar] [CrossRef]

- Hossain, M. Frugal innovation: A review and research agenda. J. Clean. Prod. 2018, 182, 926–936. [Google Scholar] [CrossRef]

- Cooper, R.G. A process model for industrial new product development. IEEE Trans. Eng. Manag. 1983, EM-30, 2–11. [Google Scholar] [CrossRef]

- Ernst, H. Success factors of new product development: A review of the empirical literature. Int. J. Manag. Rev. 2002, 4, 1–40. [Google Scholar] [CrossRef]

- Hird, A.; Mendibil, K.; Duffy, A.; Whitfield, R.I. New product development resource forecasting, New product development resource forecasting. R D Manag. 2016, 46, 857–871. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Mashelkar, R.A. Innovation’s holy grail. Harv. Bus. Rev. 2010, 88, 132–141. [Google Scholar]

- Williamson, P.J. Cost innovation: Preparing for a ‘value-for-money’ revolution. Long Range Plan. 2010, 43, 343–353. [Google Scholar] [CrossRef]

- Murphy, S.A.; Kumar, V. The front end of new product development: A Canadian survey. R D Manag. 1997, 27, 5–15. [Google Scholar] [CrossRef]

- Geum, Y.; Park, Y. How to generate creative ideas for innovation: A hybrid approach of WordNet and morphological analysis. Technol. Forecast. Soc. Chang. 2016, 111, 176–187. [Google Scholar] [CrossRef]

- Kim, J.; Wilemon, D. Focusing the fuzzy front-end in new product development. R D Manag. 2002, 32, 269–279. [Google Scholar] [CrossRef]

- Soukhoroukova, A.; Spann, M.; Skiera, B. Sourcing, filtering, and evaluating new product ideas: An empirical exploration of the performance of idea markets. J. Prod. Innov. Manag. 2011, 29, 100–112. [Google Scholar] [CrossRef]

- Mazieri, M.R.; Vils, L.; Queiroz, M.J.D. Frugal innovation beyond emerging countries: The key role of developed countries. J. Manag. Technol. 2017, 17, 232–257. [Google Scholar] [CrossRef]

- Weyrauch, T.; Herstatt, C. What is frugal innovation? Three defining criteria. J. Frugal Innov. 2017, 2, 1. [Google Scholar] [CrossRef]

- Hossain, M. Mapping the frugal innovation phenomenon. Technol. Soc. 2017, 51, 199–208. [Google Scholar] [CrossRef]

- Gibbert, M.; Hoegl, M.; Välikangas, L. In praise of resource constraints. MIT Sloan Manag. Rev. 2007, 49, 15–17. [Google Scholar]

- von Zedtwitz, M.; Corsi, S.; Søberg, P.; Frega, R. A typology of reverse innovation. J. Prod. Innov. Manag. 2014, 32, 12–28. [Google Scholar] [CrossRef]

- Smith, A.; Fressoli, M.; Thomas, H. Grassroots innovation movements: Challenges and contributions. J. Clean. Prod. 2014, 63, 114–124. [Google Scholar] [CrossRef]

- Osborn, A.F. Applied Imagination: Principles and Procedures of Creative Problem-Solving; Revised ed.; Scribner: New York, NY, USA, 1963. [Google Scholar]

- Shah, J.J.; Smith, S.M.; Vargas-Hernandez, N. Metrics for measuring ideation effectiveness. Des. Stud. 2003, 24, 111–134. [Google Scholar] [CrossRef]

- Zwicky, F. Discovery, Invention, Research-through the Morphological Approach; The Macmillan Company: New York, NY, USA, 1969. [Google Scholar]

- Li, X.; Qiu, S.; Ming, H.X.G. An integrated module-based reasoning and axiomatic design approach for new product design under incomplete information environment. Comput. Ind. Eng. 2019, 127, 63–73. [Google Scholar] [CrossRef]

- Altschuller, G.; Zlotin, B.; Zusman, A.; Filatov, V.I. Search for New Ideas: From Insight to Technology (Theory of Inventive Problem Solving); Kartya Moldovenyaska Publishing House: Kishinev, Moldova, 1989. [Google Scholar]

- Horowitz, R. From TRIZ to ASIT in 4 Steps. Available online: https://triz-journal.com/triz-asit-4-steps/ (accessed on 30 August 2019).

- Sickafus, E. Unified Structured Inventive Thinking: How to Invent; Ntelleck: Grosse Ile, MI, USA, 1997. [Google Scholar]

- Wissema, J.G. Morphological analysis: Its application to a company TF investigation. Futures 1976, 8, 146–153. [Google Scholar] [CrossRef]

- Moehrle, M.G. MorphoTRIZ—Solving technical problems with a demand for multi-smart solutions. Creat. Innov. Manag. 2010, 19, 373–384. [Google Scholar] [CrossRef]

- Ritchey, T. General Morphological Analysis: A General Method for Non-Quantified Modelling; Working paper. 2013. Available online: http://swemorph.com/pdf/gma.pdf (accessed on 30 August 2019).

- Porter, A.; Ashton, B.; Clar, G.; Coates, J.F.; Cuhls, K.; Cunningham, S.; Ducatel, K.; Duin, P.; Georgehiou, L.; Gordon, T.; et al. Technology futures analysis: Toward integration of the field and new methods. Technol. Forecast. Soc. Chang. 2004, 71, 287–303. [Google Scholar]

- Herstatt, C.; Tiwari, R. Lead Market India: Key Elements and Corporate Perspectives for Frugal Innovations; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar]

- Mulrow, C. Systematic reviews: Rationale for systematic reviews. BMJ (Clin. Res. Ed.) 1994, 309, 597–599. [Google Scholar] [CrossRef] [PubMed]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Agarwal, N.; Grottke, M.; Mishra, S.; Brem, A. A systematic literature review of constraint-based innovations: State of the art and future perspectives. IEEE Trans. Eng. Manag. 2017, 64, 3–15. [Google Scholar] [CrossRef]

- Pisoni, A.; Michelini, L.; Martignoni, G. Frugal approach to innovation: State of the art and future perspectives. J. Clean. Prod. 2018, 171, 107–126. [Google Scholar] [CrossRef]

- Wolter, B. It takes all kinds to make a world—Some thoughts on the use of classification in patent searching. World Pat. Inf. 2012, 34, 8–18. [Google Scholar] [CrossRef]

- Yoon, B.; Phaal, R.; Probert, D. Morphology analysis for technology roadmapping: Application of text mining. R D Manag. 2010, 38, 51–68. [Google Scholar] [CrossRef]

- Yoon, B.; Park, Y. Development of new technology forecasting algorithm: Hybrid approach for morphology analysis and conjoint analysis of patent information. IEEE Trans. Eng. Manag. 2007, 54, 588–599. [Google Scholar] [CrossRef]

- Yoon, B.; Park, Y. A systematic approach for identifying technology opportunities: Keyword-based morphology analysis. Technol. Forecast. Soc. Chang. 2005, 72, 145–160. [Google Scholar] [CrossRef]

- Duczynski, G. Morphological analysis as an aid to organisational design and transformation. Futures 2017, 86, 36–43. [Google Scholar] [CrossRef]

- Agarwal, N.; Brem, A. Frugal innovation-past, present, and future. IEEE Eng. Manag. Rev. 2017, 45, 37–41. [Google Scholar] [CrossRef]

- Peng, B.; Guo, D.; Qiao, H.; Yang, Q.; Zhang, B.; Hayat, T.; Alsaedi, A.; Ahmad, B. Bibliometric and visualized analysis of China’s coal research 2000–2015. J. Clean. Prod. 2018, 197, 1177–1189. [Google Scholar] [CrossRef]

- Burgherr, P.; Hirschberg, S. Assessment of severe accident risks in the Chinese coal chain. Int. J. Risk Assess. Manag. 2007, 7, 1157. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.-P.; Liu, H.-Y. An analysis of fatal gas accidents in Chinese coal mines. Saf. Sci. 2014, 62, 107–113. [Google Scholar] [CrossRef]

- Chen, H.-D.; Cheng, Y.-P.; Zhou, H.-X.; Li, W. Damage and permeability development in coal during unloading. Rock Mech. Rock Eng. 2013, 46, 1377–1390. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Guo, H. A case study of gas drainage to low permeability coal seam. Int. J. Min. Sci. Technol. 2017, 27, 687–692. [Google Scholar] [CrossRef]

- Wang, F.; Ren, T.; Tu, S.; Hungerford, F.; Aziz, N. Implementation of underground longhole directional drilling technology for greenhouse gas mitigation in Chinese coal mines. Int. J. Greenh. Gas Control 2012, 11, 290–303. [Google Scholar] [CrossRef]

- Lunarzewski, L.W. Gas emission prediction and recovery in underground coal mines. Int. J. Coal Geol. 1998, 35, 117–145. [Google Scholar] [CrossRef]

- Andel, T. Frugal price: Virtue or vice? Mater. Handl. Logist. 2013, 68, 4. [Google Scholar]

- Wang, L.; Cheng, Y.-P.; Ge, C.-G.; Chen, J.-X.; Li, W.; Zhou, H.-X.; Wang, H.-F. Safety technologies for the excavation of coal and gas outburst-prone coal seams in deep shafts. Int. J. Rock Mech. Min. Sci. 2013, 57, 24–33. [Google Scholar] [CrossRef]

- Yoon, B.; Park, I.; Coh, B.Y. Exploring technological opportunities by linking technology and products: Application of morphology analysis and text mining. Technol. Forecast. Soc. Chang. 2014, 86, 287–303. [Google Scholar] [CrossRef]

- Yuan, L. Control of coal and gas outbursts in Huainan mines in China: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 559–567. [Google Scholar] [CrossRef]

- Ray, S.; Kanta Ray, P. Product innovation for the people’s car in an emerging economy. Technovation 2011, 31, 216–227. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, S.; Sang, S.; Pan, Z.; Zhao, W.; Yang, Y.; Hu, Q.; Yang, Y. Characteristics and generation mechanisms of coal fines in coalbed methane wells in the southern Qinshui Basin, China. J. Nat. Gas Sci. Eng. 2016, 34, 849–863. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, J.; Zhang, Y.; Liu, Z.; Yue, Z.; Liu, P.; Feng, L.; Wu, H.; Yue, J. Linear Cutting Micro-Layer Mine Pressure Relief Out-Burst Eliminating Method, Involves Performing Bed Cutting Process, Forming Coal Dust during Cutting Action, and Conveying Coal Dust from Roadway by Using Lower Gate of Transporting Device. China Patent Application CN106468176-A, CN106468176-B, 13 November 2018. [Google Scholar]

- Feng, Y.; Zhang, Y.; Zhang, L.; Yue, Z.; Chen, M.; Wu, R.; Yao, L.; Geng, Y.; Feng, L.; Wang, Y.; et al. Coal Mine Pressure Relief and Coal Seam Gas Mining System Has Closed-Loop Linear Gear Cutting Belt Is Made to Pass through Outer Surfaces of Upper Rollers and Lower Rollers. China Patent Application CN106640180-A, CN106640180-B, 13 November 2018. [Google Scholar]

- Feng, Y.; Yue, Z.; Wu, H.; Wang, Y.; Wu, R.; Chen, M.; Zhang, L.; Hu, X.; Geng, Y.; Feng, L.; et al. Reciprocating Wire Cutting Coal Mine Pressure Relief and Seam Gas Mining System, Has Linear Cutting Rack Whose End is Connected with Motion Mechanism, Where Another End of Rack is Connected with Road That Is Fixed in Driving Device. China Patent Application CN106640181-A, CN106640181-B, 6 July 2011. [Google Scholar]

- Tiwari, R.; Kalogerakis, K. A Bibliometric Analysis of Academic Papers on Frugal Innovation; Working Papers; 2016. Available online: http://www.global-innovation.net/team/tiwari/PDF/working_paper_93.pdf (accessed on 30 August 2019).

- Agarwal, N.; Brem, A. In Frugal and reverse innovation—Literature overview and case study insights from a German MNC in India and China. In Proceedings of the 2012 18th International ICE Conference on Engineering, Technology and Innovation, Munich, Germany, 18–20 June 2012. [Google Scholar]

- Prabhu, G.; Gupta, S. Heuristics of Frugal Service Innovations. In Proceedings of the PICMET’14 Conference: Portland International Center for Management of Engineering and Technology, Kanazawa, Japan, 27–31 July 2014. [Google Scholar]

- Ray, P.K.; Ray, S. Resource-constrained innovation for emerging economies: The case of the Indian telecommunications industry. IEEE Trans. Eng. Manag. 2010, 57, 144–156. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, J.; Wang, J. Effects of the sharing economy on sequential innovation products. Complexity 2019, 3, 1–18. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, J.; Liu, B. Pricing and service level decisions under a sharing product and consumers’ variety-seeking behavior. Sustainability 2019, 11, 6951. [Google Scholar] [CrossRef]

- Feng, L.; Niu, Y.; Liu, Z.; Wang, J.; Zhang, K. Discovering technology opportunity by keyword-based patent analysis: A hybrid approach of morphology analysis and USIT. Sustainability 2020, 12, 136. [Google Scholar] [CrossRef]

- Barclay, C. Using frugal innovations to support cybercrime legislations in small developing states: Introducing the cyber-legislation development and implementation process model (CyberLeg-DPM). Inf. Technol. Dev. 2014, 20, 165–195. [Google Scholar] [CrossRef]

- Brem, A.; Wolfram, P. Research and development from the bottom up—Introduction of terminologies for new product development in emerging markets. J. Innov. Entrep. 2014, 3, 1–22. [Google Scholar] [CrossRef]

- Pawlowski, J.M. Towards born-Global innovation: The role of knowledge management and social software. In Proceedings of the European Conference on Knowledge Management, ECKM, Kaunas, Lithuania, 5–6 September 2013; Volume 2, pp. 527–534. [Google Scholar]

- Rao, B.C. Alleviating Poverty in the Twenty-First Century Through Frugal Innovations. Challenge 2014, 57, 40–59. [Google Scholar] [CrossRef]

- Yamashina, H.; Kubo, T. Manufacturing cost deployment. Int. J. Prod. Res. 2002, 40, 4077–4091. [Google Scholar] [CrossRef]

- Marion, T.J.; Meyer, M.H. Applying industrial design and cost engineering to new product development in early-stage firms. J. Prod. Innov. Manag. 2011, 28, 773–786. [Google Scholar] [CrossRef]

- Rao, B.C. Advances in science and technology through frugality. IEEE Eng. Manag. Rev. 2017, 45, 32–38. [Google Scholar] [CrossRef]

- Altmann, P.; Engberg, R. Frugal innovation and knowledge transferability. Res. Technol. Manag. 2016, 59, 48–55. [Google Scholar] [CrossRef]

- Winterhalter, S.; Zeschky, M.B.; Neumann, L.; Gassmann, O. Business models for frugal innovation in emerging markets: The case of the medical device and laboratory equipment industry. Technovation 2017, 66–67, 3–13. [Google Scholar] [CrossRef]

- Sehgal, V.; Dehoff, K.; Panneer, G. The importance of frugal engineering. Strategy Bus. 2010, 59, 20–37. [Google Scholar]

- Sehgal, V.; Dehoff, K.; Panneer, G. Back to basics. Mark. Lead. 2011, 1, 33–37. [Google Scholar]

- Wooldridge, A. First break all the rules: The charms of frugal innovation. Economist 2010. Available online: https://media.economist.com/news/special-report/15879359-charms-frugal-innovation-first-break-all-rules (accessed on 30 August 2019).

- Economist. Schumpeter: Asian innovation, frugal ideas are spreading from east to west. Economist 2012. Available online: http://www.economist.com/node/21551028 (accessed on 29 August 2019).

- Belkadi, F.; Buergin, J.; Gupta, R.K.; Zhang, Y.; Bernard, A.; Lanza, G.; Colledani, M.; Urgo, M. Co-definition of product sructure and production network for frugal innovation perspectives: Towards a modular-based approach. Procedia CIRP 2016, 50, 589–594. [Google Scholar] [CrossRef]

- Belkadi, F.; Gupta, R.K.; Vlachou, E.; Bernard, A.; Mourtis, D. Linking Modular Product Structure to Suppliers’ Selection Through PLM Approach: A Frugal Innovation Perspective. In Proceedings of the PLM 2016: Product Lifecycle Management for Digital Transformation of Industries, Columbia, SC, USA, 11–13 July 2016; Springer International Publishing: Cham, Switzerland, 2016; pp. 227–237. [Google Scholar]

- Belkadi, F.; Gupta, R.K.; Natalizio, S.; Bernard, A. Modular Architectures Management with PLM for the Adaptation of Frugal Products to Regional Markets. In Proceedings of the PLM 2017: Product Lifecycle Management and the Industry of the Future, Seville, Spain, 10–12 July 2017; Springer International Publishing: Cham, Switzerland, 2017; pp. 462–472. [Google Scholar]

- Belkadi, F.; Colledani, M.; Urgo, M.; Bernard, A.; Colombo, G.; Borzi, G.; Ascheri, A. Modular design of production systems tailored to regional market requirements: A Frugal Innovation perspective. IFAC-Pap. 2018, 51, 96–101. [Google Scholar] [CrossRef]

- Belkadi, F.; Vlachou, E.; Kumar-Gupta, R.; Zogopoulos, V.; Kaya, M.; Bernard, A.; Mourtzis, D.; Natalizio, S.; Buyukdigan, B.G.; Bayrak, I.T. Modularity as a support for frugal product and supplier network co-definition under regional market constraints: A mirroring hypothesis application. Int. J. Prod. Res. 2018, 56, 6575–6590. [Google Scholar] [CrossRef]

- Rao, B.C. Revisiting classical design in engineering from a perspective of frugality. Heliyon 2017, 3, e00299. [Google Scholar] [CrossRef] [PubMed]

- Linna, P. Bricolage as a means of innovating in a resource scarce environment: A study of innovator-entrepreneurs at the BOP. J. Dev. Entrep. 2013, 18, 1–23. [Google Scholar] [CrossRef]

- Baker, T.; Nelson, R.E. Creating something from nothing: Resource construction through entrepreneurial bricolage. Adm. Sci. Q. 2005, 50, 329–366. [Google Scholar] [CrossRef]

- Kalogerakis, K.; Lüthje, C.; Herstatt, C. Developing innovations based on analogies: Experience from design and engineering consultants. J. Prod. Innov. Manag. 2010, 27, 418–436. [Google Scholar] [CrossRef]

- Tiwari, R.; Kalogerakis, K.; Herstatt, C. Frugal Innovation and Analogies: Some Propositions for Product Development in Emerging Economies; Working Paper; 2014. Available online: http://www.global-innovation.net/publications/PDF/Working_Paper_84.pdf (accessed on 30 August 2019).

- Lim, C.; Yun, D.; Park, I.; Yoon, B. A systematic approach for new technology development by using a biomimicry-based TRIZ contradiction matrix. Creat. Innov. Manag. 2018, 27, 414–430. [Google Scholar] [CrossRef]

- Mandal, S. Frugal Innovations for Global Health—Perspectives for Students. IEEE Pulse 2014, 5, 3. [Google Scholar] [CrossRef]

- Soni, P.; Krishnan, R.T. Frugal innovation: Aligning theory, practice, and public policy. J. Indian Bus. Res. 2014, 6, 29–47. [Google Scholar] [CrossRef]

- Nocera, D.G. Can we progress from solipsistic science to frugal innovation? Daedalus 2012, 141, 45–52. [Google Scholar] [CrossRef]

- Ahuja, S. Cost vs. Value + empathy: A new formula for frugal science. Des. Manag. Rev. 2014, 25, 52–55. [Google Scholar]

- Randall, R.; Leavy, B. India: MNC strategies for growth and innovation. Strategy Leadersh. 2014, 42, 30–39. [Google Scholar]

- Dandonoli, P. Open innovation as a new paradigm for global collaborations in health. Glob. Health 2013, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Howard, M. Will frugal innovation challenge the west? Mark. Lead. 2011, 3, 53. [Google Scholar]

| Resource-Constrained Innovation Approaches | TRIZ Inventive Principles | Resource-Constrained Principles |

|---|---|---|

| Decomposition and removal approach | Segmentation | |

| Taking out | ||

| Universality | ||

| Partial optimization approach | Local quality | Local optimization principle which is defined to overcome a system’s weak links and optimize the system state by improving local components. |

| Asymmetry | ||

| Partial or excessive actions | ||

| Permutation and combination approach | Merging | |

| Nested doll | ||

| Preliminary anti-action | ||

| Intermediary | ||

| Substitution and changing approach | Copying | Cheaper substitution principle is defined to reduce time, materials and human effort by replacing with cheaper labour, materials and local services. Theory substitution principle is defined to optimize system efficiency by use of interchange of the light field, sound field, force field, electric field, magnetic field or mechanic field. |

| Cheap short-living objects | ||

| Mechanics substitution | ||

| Porous materials | ||

| Color changes | ||

| Parameter changes | ||

| Phase transitions | ||

| Thermal expansion | ||

| Strong oxidants | ||

| Inert atmosphere | ||

| Composite materials | ||

| Dynamic approach | Dynamics | Re-use principle which is defined to make full use of waste materials and energy or parts to provide service for the system itself so as to maximize the use of system resources. |

| Another dimension | ||

| Periodic action | ||

| Continuity of useful action | ||

| Skipping | ||

| Self-service and balance approach | Anti-weight | |

| Turn Lemons into Lemonade | ||

| Feedback | ||

| Self-service | ||

| Discarding and recovering | ||

| Friendliness and coordination approach | Spheroidality-curvature | Consistency principle which is defined to combine systematic characteristics, allocate system resources to maintain consistency and achieve best system efficiency. |

| Homogeneity | ||

| Intellectualization approach | Self-Analysis principle is defined to load data processing software into the system so that it can automatically analyze and process data to improve its decision-making speed. | |

| Sharing principle is defined to share R&D knowledge or information among innovators to control costs and accelerate product design cycle. |

| H01-B03B3 | H01-C03 | H01-D03 | ┄ | X25-E03 | ┄ | H01-D13 | ┄ | X25-L01A | |

|---|---|---|---|---|---|---|---|---|---|

| H01-B03B3 | 127 | 7 | 23 | 3 | 1 | 0 | |||

| H01-C03 | 7 | 87 | 10 | 1 | 0 | 0 | |||

| H01-D03 | 23 | 10 | 63 | 1 | 0 | 0 | |||

| ⋮ | |||||||||

| X25-E03 | 3 | 1 | 1 | 24 | 0 | 1 | |||

| ⋮ | |||||||||

| H01-D13 | 1 | 0 | 0 | 0 | 5 | ||||

| ⋮ | |||||||||

| X25-L01A | 0 | 0 | 0 | 1 | 0 | 1 |

| Example | Updated Ideas | Resource-Constrained Approaches | Original Ideas |

|---|---|---|---|

| (1) | substitute MeD with MeC + SC | Dynamic, Substitution, Removal | MeD + MaW + SC |

| (2) | combine MeF with MeU + mix environment-friendly MaB in MaF + SG | Combination, Friendliness | MeF + MaF + SG |

| simultaneous MeF in adjacent Wells + MaF + SG | Self-service | ||

| (3) | MeD with remote intelligent monitoring system + MaW + SG | Intellectualization | MeD + MaW + SG |

| MeD horizontal Wells in SC and MeD vertical Wells from SG + MaW + SC, SG | Partial optimization, Combination | ||

| (4) | MeR + material is partially optimized to liquid N2 + SC | Partial optimization | MeR + MaN + SC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Feng, J.; Wang, J. Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles. Sustainability 2020, 12, 917. https://doi.org/10.3390/su12030917

Liu Z, Feng J, Wang J. Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles. Sustainability. 2020; 12(3):917. https://doi.org/10.3390/su12030917

Chicago/Turabian StyleLiu, Zhenfeng, Jian Feng, and Jinfeng Wang. 2020. "Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles" Sustainability 12, no. 3: 917. https://doi.org/10.3390/su12030917

APA StyleLiu, Z., Feng, J., & Wang, J. (2020). Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles. Sustainability, 12(3), 917. https://doi.org/10.3390/su12030917