How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance

Abstract

1. Introduction

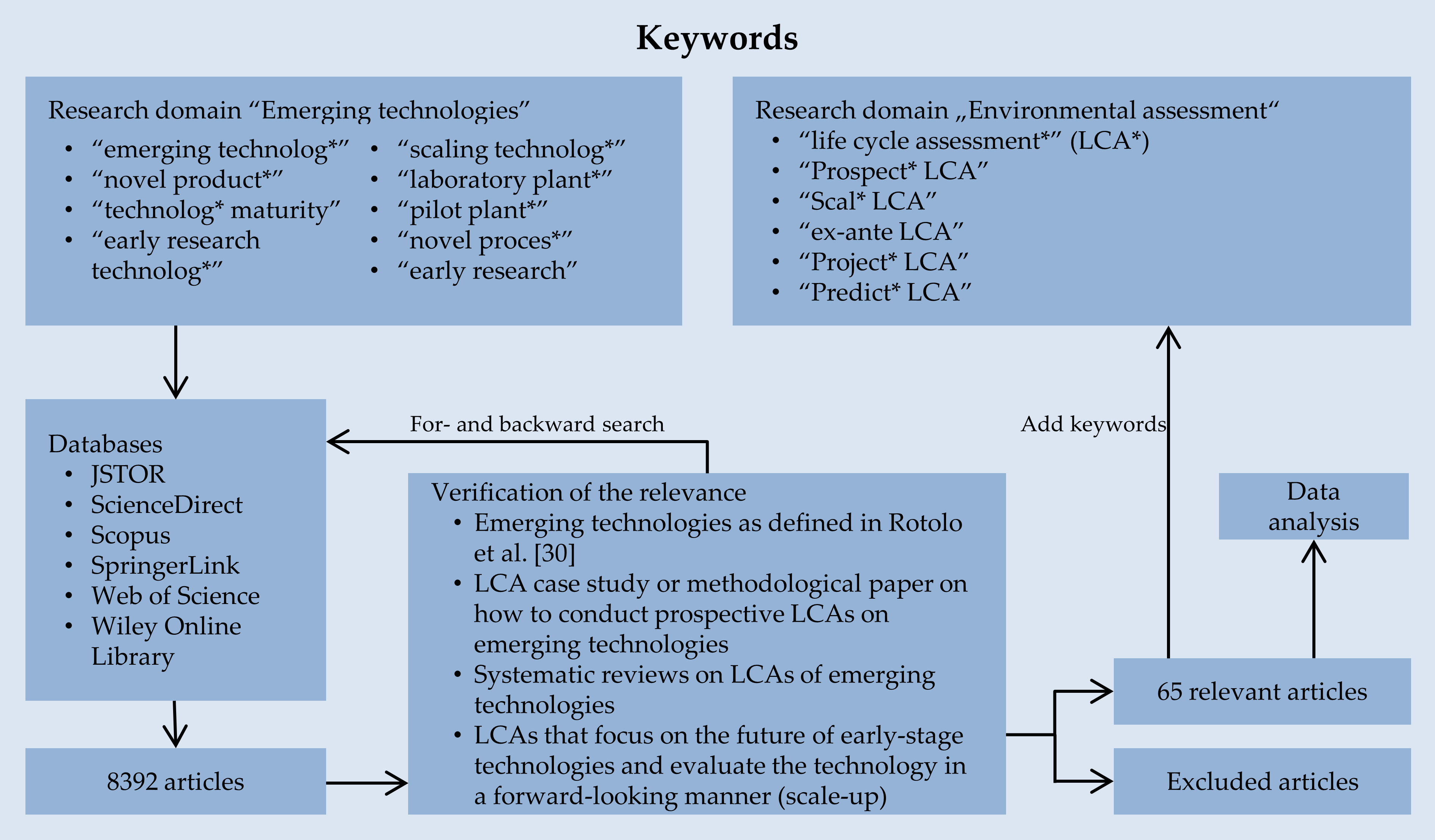

2. Methodology

- Emerging technologies defined in Rotolo et al. [30] as “a relatively fast-growing and radically novel technology characterized by a certain degree of coherence persisting over time and with the potential to exert a considerable impact on the socio-economic domain(s) which is observed in terms of the composition of actors, institutions, and the patterns of interactions among those, along with the associated knowledge production processes.”

- An LCA case study or methodological paper on how to conduct prospective LCAs on emerging technologies or systematic reviews on LCAs of emerging technologies.

- LCAs that are focused on the future of early-stage technologies and evaluate the emerging technology in a forward-looking manner (scale-up).

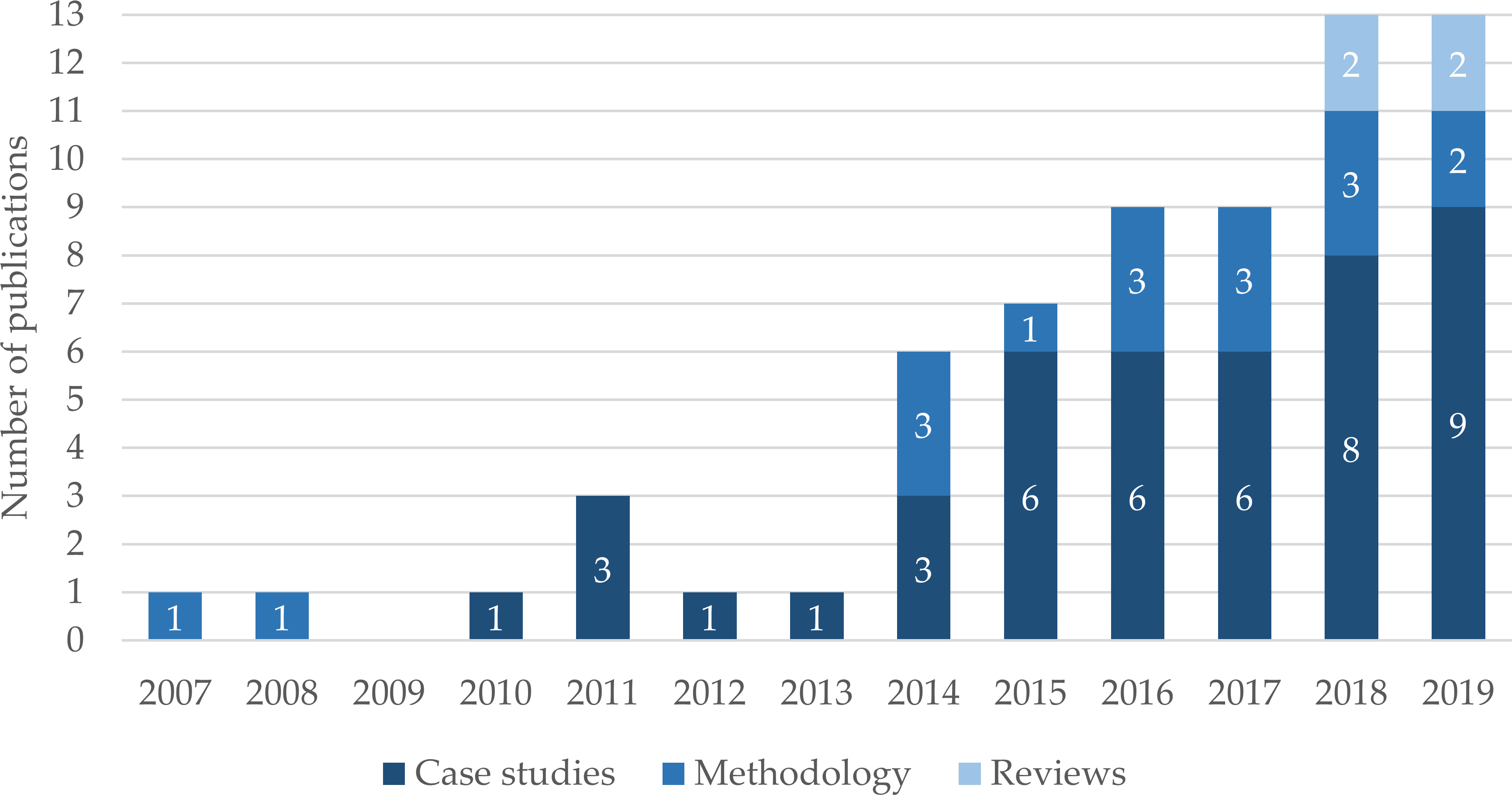

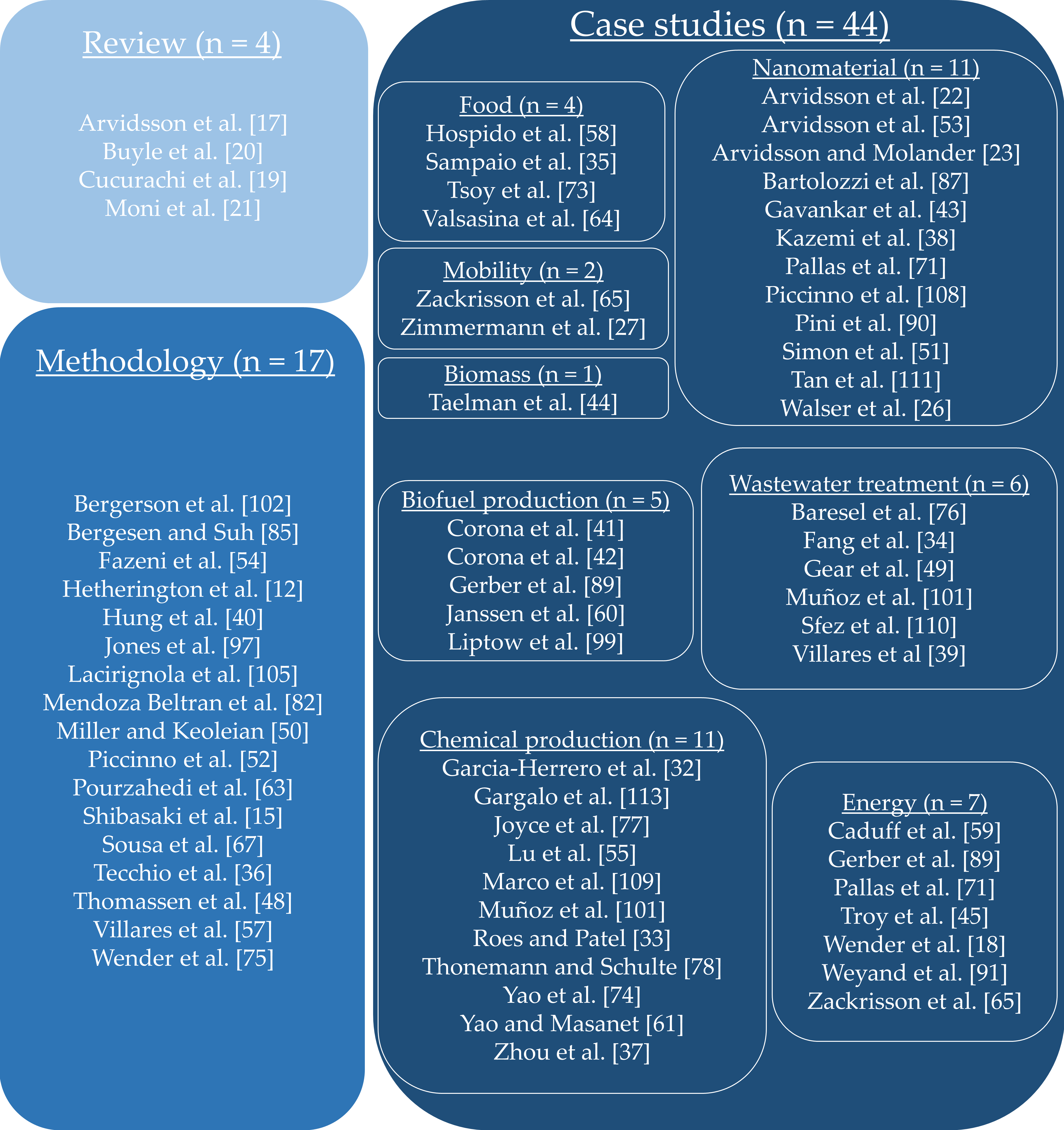

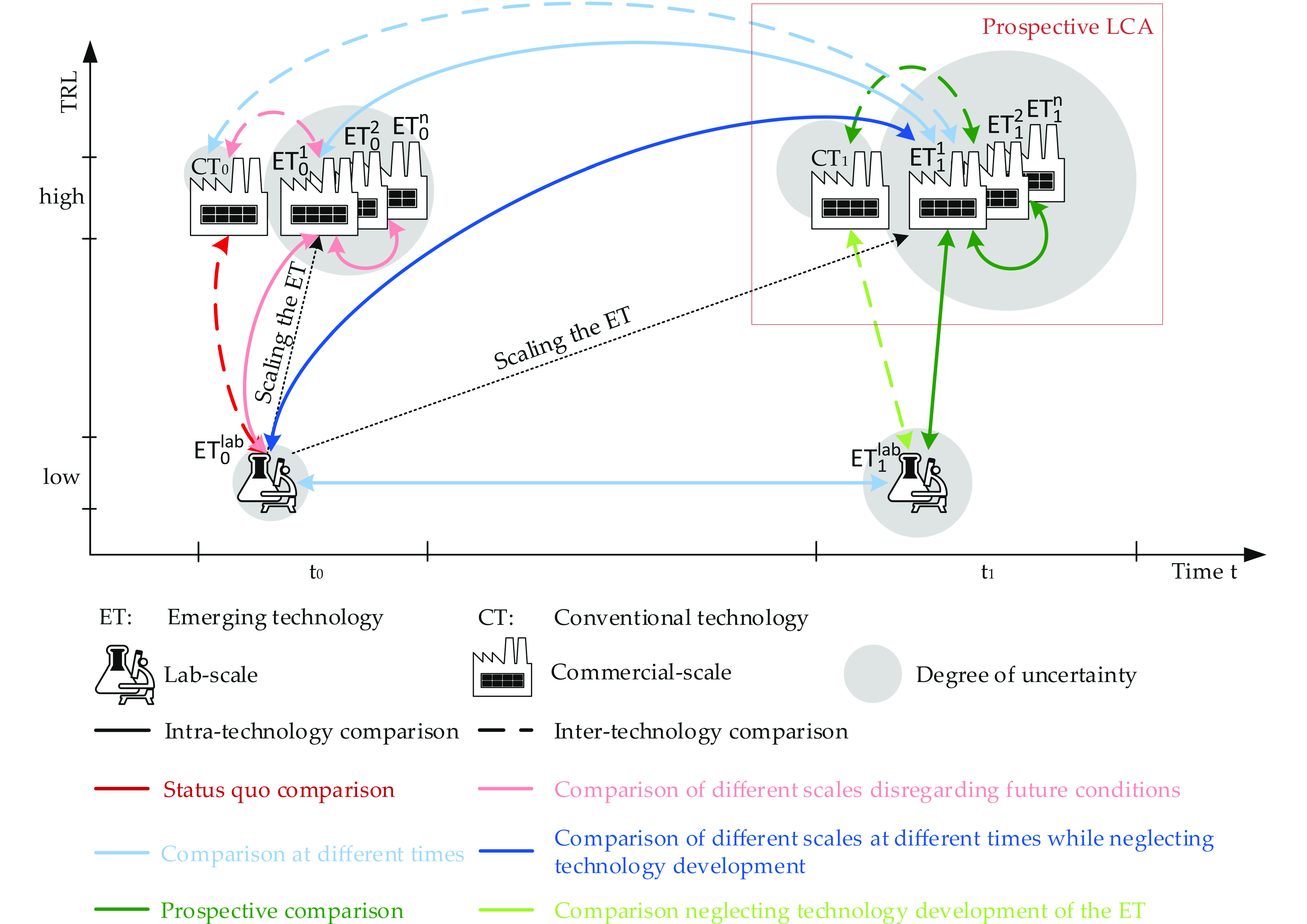

3. Results and Discussion

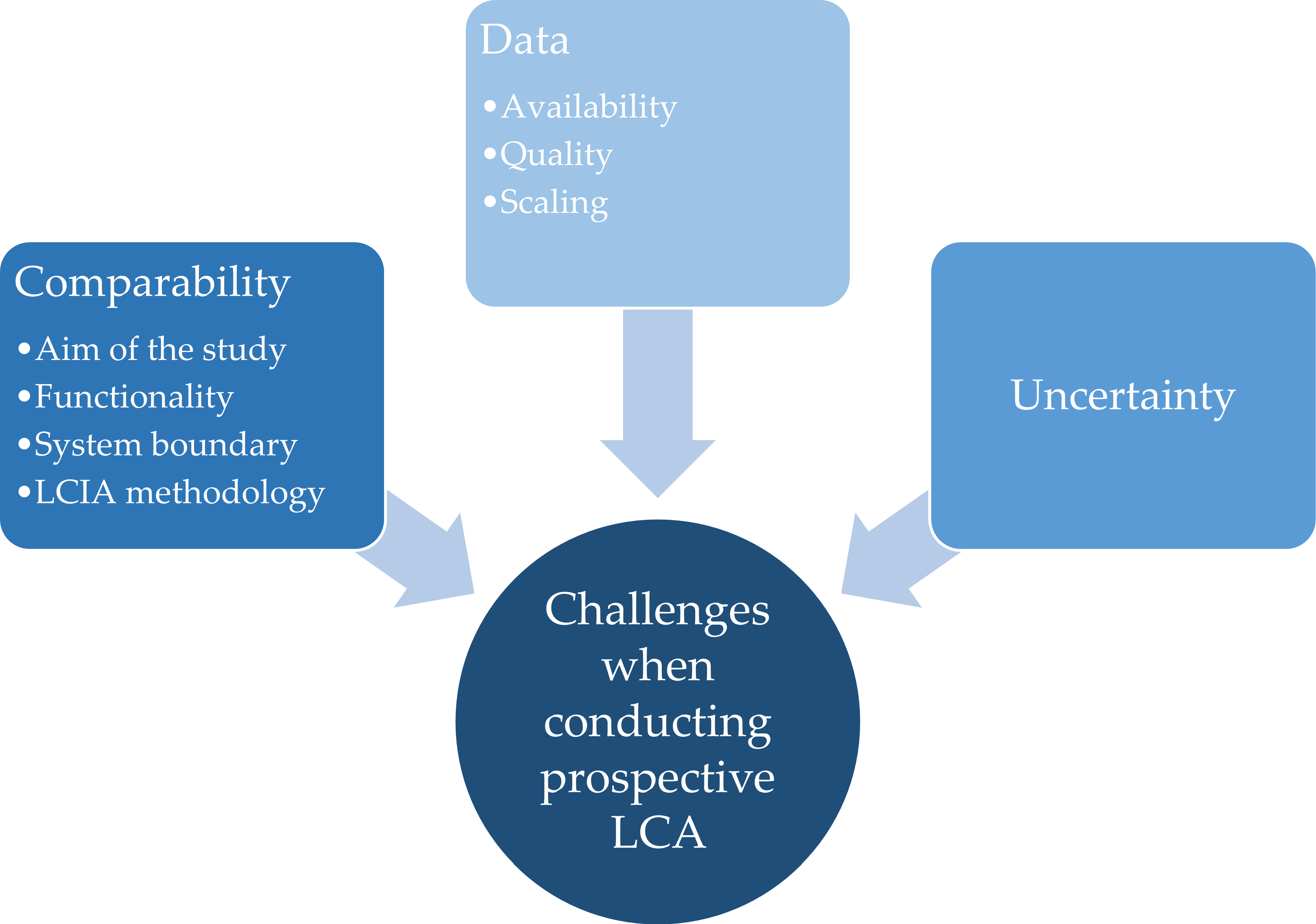

3.1. Challenges in the Application of Prospective Life Cycle Assessments

3.1.1. Comparability

Aim of the study

Functionality

System boundary

Life Cycle Impact Assessment Methodology

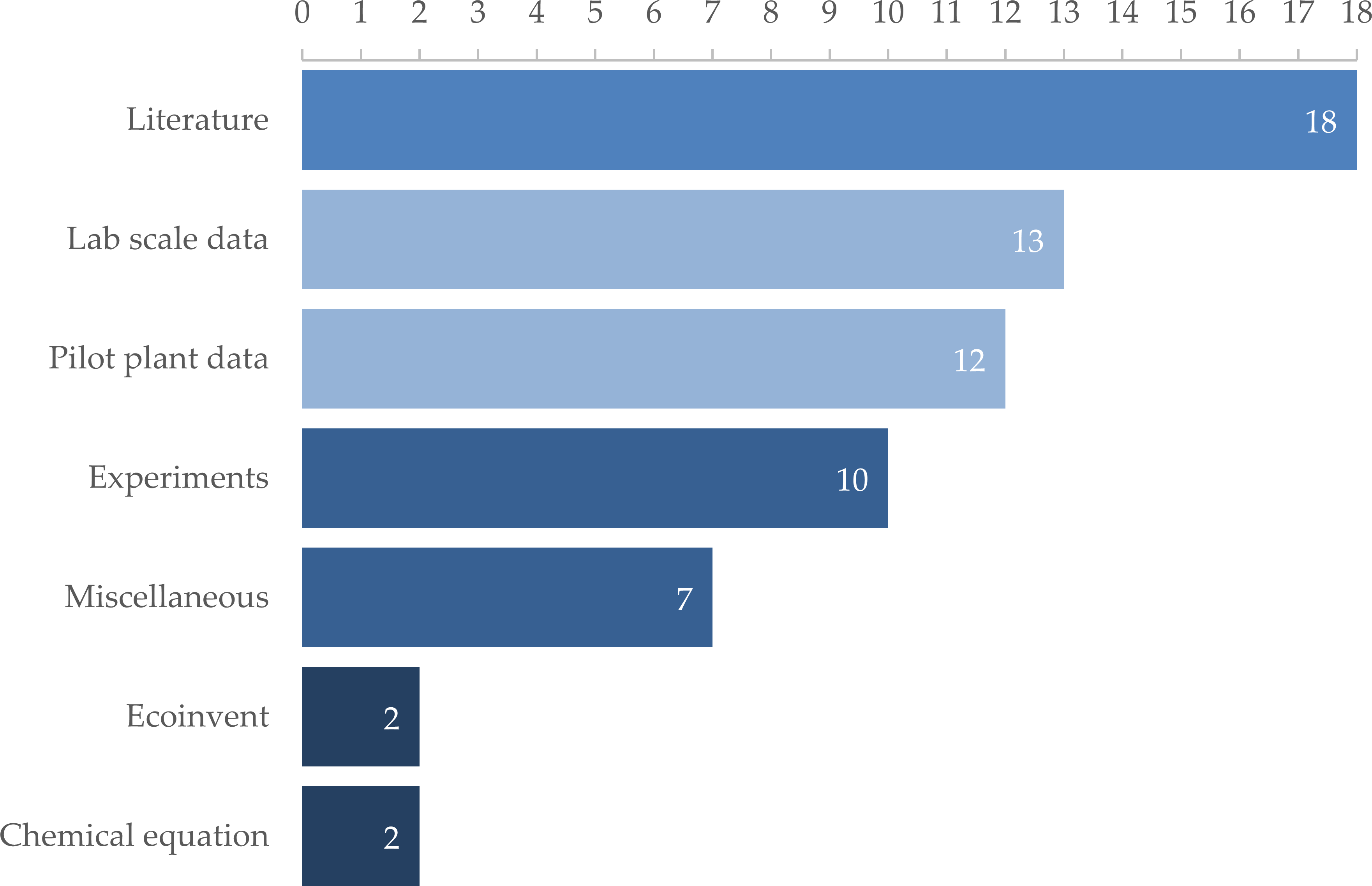

3.1.2. Data

Availability

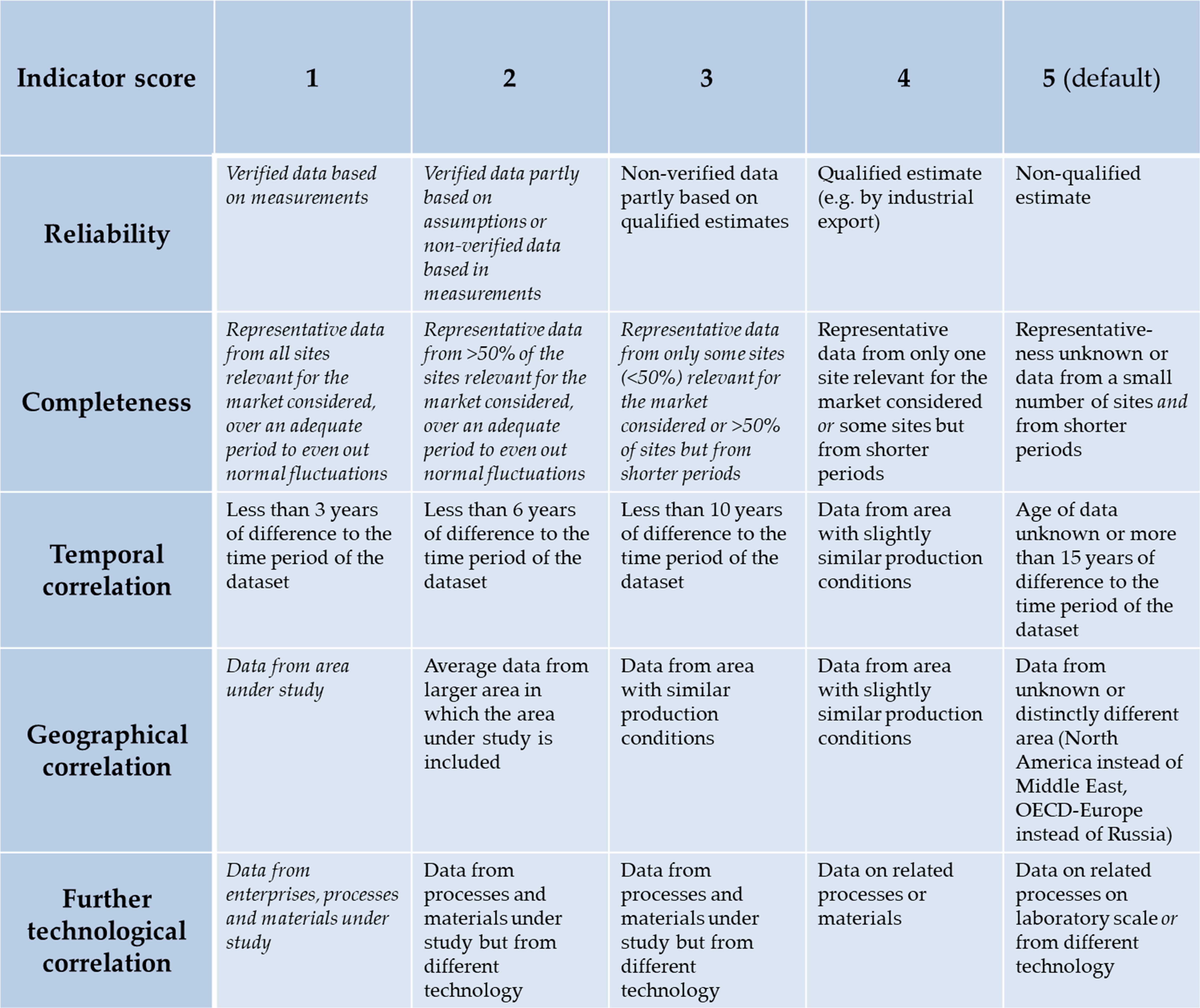

Quality

Scaling

3.1.3. Uncertainty

3.1.4. Integrated Overview of the Examined Challenges

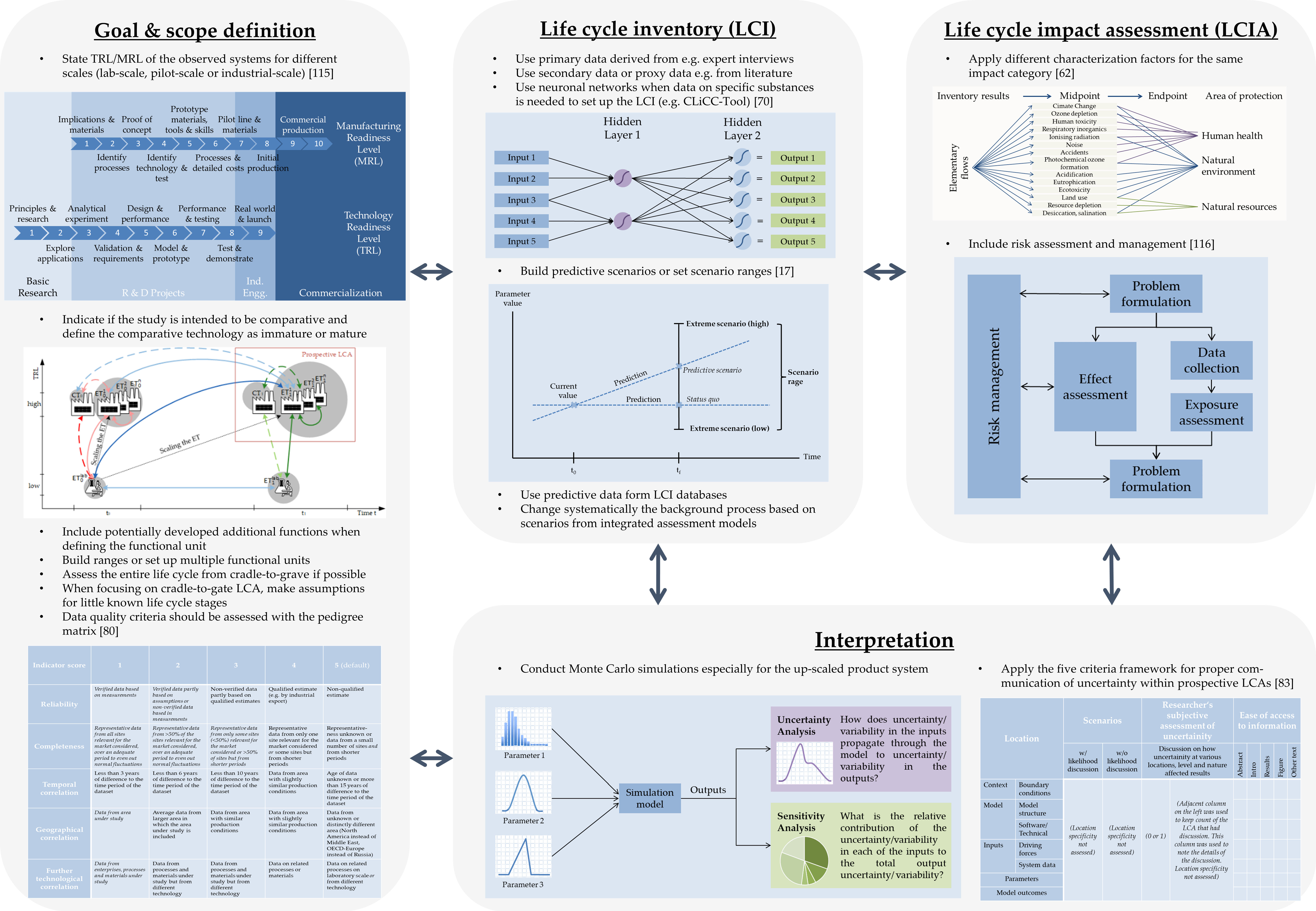

3.2. Framework for the Application of Prospective LCAs

4. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Zamagni, A. Life cycle sustainability assessment. Int. J. Life Cycle Assess. 2012, 17, 373–376. [Google Scholar] [CrossRef]

- Daylan, B.; Ciliz, N. Life cycle assessment and environmental life cycle costing analysis of lignocellulosic bioethanol as an alternative transportation fuel. Renew. Energy 2016, 89, 578–587. [Google Scholar] [CrossRef]

- Falcone, P.M.; González García, S.; Imbert, E.; Lijó, L.; Moreira, M.T.; Tani, A.; Tartiu, V.E.; Morone, P. Transitioning towards the bio-economy: Assessing the social dimension through a stakeholder lens. Corp. Soc. Responsib. Environ. Manag. 2019, 26. [Google Scholar] [CrossRef]

- Falcone, P.; Imbert, E. Social Life Cycle Approach as a Tool for Promoting the Market Uptake of Bio-Based Products from a Consumer Perspective. Sustainability 2018, 10, 1031. [Google Scholar] [CrossRef]

- Rafiaani, P.; Kuppens, T.; Van Dael, M.; Azadi, H.; Lebailly, P.; Van Passel, S. Social sustainability assessments in the biobased economy: Towards a systemic approach. Renew. Sustain. Energy Rev. 2018, 82, 1839–1853. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- ISO. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.-J.; Hendriks, A.J. Power-law relationships for estimating mass, fuel consumption and costs of energy conversion equipments. Environ. Sci. Technol. 2011, 45, 751–754. [Google Scholar] [CrossRef] [PubMed]

- Caduff, M.; Huijbregts, M.A.J.; Koehler, A.; Althaus, H.-J.; Hellweg, S. Scaling Relationships in Life Cycle Assessment. J. Ind. Ecol. 2014, 18, 393–406. [Google Scholar] [CrossRef]

- Gasafi, E.; Weil, M.R. Approach and application of life cycle screening in early phases of process design: Case study of supercritical water gasification. J. Clean. Prod. 2011, 19, 1590–1600. [Google Scholar] [CrossRef]

- Hetherington, A.C.; Borrion, A.L.; Griffiths, O.G.; McManus, M.C. Use of LCA as a development tool within early research: Challenges and issues across different sectors. Int. J. Life Cycle Assess. 2014, 19, 130–143. [Google Scholar] [CrossRef]

- Hellweg, S.; Milà i Canals, L. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- McKone, T.E.; Nazaroff, W.W.; Berck, P.; Auffhammer, M.; Lipman, T.; Torn, M.S.; Masanet, E.; Lobscheid, A.; Santero, N.; Mishra, U.; et al. Grand challenges for life-cycle assessment of biofuels. Environ. Sci. Technol. 2011, 45, 1751–1756. [Google Scholar] [CrossRef] [PubMed]

- Shibasaki, M.; Fischer, M.; Barthel, L. Effects on Life Cycle Assessment—Scale up of processes. In Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses—Proceedings of the 14th CIRP Conference on Life Cycle Engineering; Springer: London, UK, 2007. [Google Scholar]

- Shibasaki, M.; Albrecht, S.; Kupfer, T. Small Scale and Large Scale Plants—Effect on Life Cycle Assessment. In 17th European Symposium on Computer Aided Process Engineering—ESCAPE17; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Wender, B.A.; Foley, R.W.; Prado-Lopez, V.; Ravikumar, D.; Eisenberg, D.A.; Hottle, T.A.; Sadowski, J.; Flanagan, W.P.; Fisher, A.; Laurin, L.; et al. Illustrating anticipatory life cycle assessment for emerging photovoltaic technologies. Environ. Sci. Technol. 2014, 48, 10531–10538. [Google Scholar] [CrossRef] [PubMed]

- Cucurachi, S.; Van der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; Van Passel, S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability 2019, 11, 5456. [Google Scholar] [CrossRef]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life cycle assessment of emerging technologies: A review. J. Ind. Ecol. 2019, 1. [Google Scholar] [CrossRef]

- Arvidsson, R.; Kushnir, D.; Sandén, B.A.; Molander, S. Prospective Life Cycle Assessment of Graphene Production by Ultrasonication and Chemical Reduction. Environ. Sci. Technol. 2014, 48, 4529–4536. [Google Scholar] [CrossRef]

- Arvidsson, R.; Molander, S. Prospective Life Cycle Assessment of Epitaxial Graphene Production at Different Manufacturing Scales and Maturity. J. Ind. Ecol. 2017, 21, 1153–1164. [Google Scholar] [CrossRef]

- Krishna Manda, B.M.; Worrell, E.; Patel, M.K. Prospective life cycle assessment of an antibacterial T-shirt and supporting business decisions to create value. Resour. Conserv. Recycl. 2015, 103, 47–57. [Google Scholar] [CrossRef]

- Spielmann, M.; Scholz, R.; Tietje, O.; Haan, P.D. Scenario Modelling in Prospective LCA of Transport Systems. Application of Formative Scenario Analysis (11 pp). Int. J. Life Cycle Assess. 2005, 10, 325–335. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective environmental life cycle assessment of nanosilver T-shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, B.M.; Dura, H.; Baumann, M.J.; Weil, M.R. Prospective time-resolved LCA of fully electric supercap vehicles in Germany. Integr. Environ. Assess. Manag. 2015, 11, 425–434. [Google Scholar] [CrossRef] [PubMed]

- Fink, A. Conducting Research Literature Reviews. From the Internet to Paper, 4th ed.; SAGE: Los Angeles, CA, USA, 2014; ISBN 1452259496. [Google Scholar]

- Zumsteg, J.M.; Cooper, J.S.; Noon, M.S. Systematic Review Checklist: A Standardized Technique for Assessing and Reporting Reviews of Life Cycle Assessment Data. J. Ind. Ecol. 2012, 16, S12–S21. [Google Scholar] [CrossRef] [PubMed]

- Rotolo, D.; Hicks, D.; Martin, B.R. What is an emerging technology? Res. Policy 2015, 44, 1827–1843. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Inhaltsanalyse. Grundlagen und Techniken, 12th, ed.; Beltz: Weinheim, Germany, 2015; ISBN 3407257309. [Google Scholar]

- Garcia-Herrero, I.; Cuéllar-Franca, R.M.; Enríquez-Gutiérrez, V.M.; Alvarez-Guerra, M.; Irabien, A.; Azapagic, A. Environmental Assessment of Dimethyl Carbonate Production: Comparison of a Novel Electrosynthesis Route Utilizing CO2 with a Commercial Oxidative Carbonylation Process. ACS Sustain. Chem. Eng. 2016, 4, 2088–2097. [Google Scholar] [CrossRef]

- Roes, A.L.; Patel, M.K. Ex-ante environmental assessments of novel technologies—Improved caprolactam catalysis and hydrogen storage. J. Clean. Prod. 2011, 19, 1659–1667. [Google Scholar] [CrossRef]

- Fang, L.L.; Valverde-Pérez, B.; Damgaard, A.; Plósz, B.G.; Rygaard, M. Life cycle assessment as development and decision support tool for wastewater resource recovery technology. Water Res. 2016, 88, 538–549. [Google Scholar] [CrossRef]

- Sampaio, A.P.C.; De Men Sá, M.; Castro, A.L.A.; De Figueirêdo, M.C.B. Life cycle assessment from early development stages: The case of gelatin extracted from tilapia residues. Int. J. Life Cycle Assess. 2017, 22, 767–783. [Google Scholar] [CrossRef]

- Tecchio, P.; Freni, P.; Benedetti, B.; De Fenouillot, F. Ex-ante Life Cycle Assessment approach developed for a case study on bio-based polybutylene succinate. J. Clean. Prod. 2016, 112, 316–325. [Google Scholar] [CrossRef]

- Zhou, Y.; Lee, C.K.; Sharratt, P. Bridging the Gap from Pilot Plant Experimental Records to Life Cycle Inventory. Ind. Eng. Chem. Res. 2017, 56, 10393–10412. [Google Scholar] [CrossRef]

- Kazemi, A.; Bahramifar, N.; Heydari, A.; Olsen, S.I. Life cycle assessment of nanoadsorbents at early stage technological development. J. Clean. Prod. 2018, 174, 527–537. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; Mendoza Beltran, A.; Guinee, J. Applying an ex-ante life cycle perspective to metal recovery from e-waste using bioleaching. J. Clean. Prod. 2016, 129, 315–328. [Google Scholar] [CrossRef]

- Hung, C.R.; Ellingsen, L.A.-W.; Majeau-Bettez, G. LiSET: A Framework for Early-Stage Life Cycle Screening of Emerging Technologies. J. Ind. Ecol. 2018, 41, 105. [Google Scholar] [CrossRef]

- Corona, A.; Ambye-Jensen, M.; Vega, G.C.; Hauschild, M.Z.; Birkved, M. Techno-environmental assessment of the green biorefinery concept: Combining process simulation and life cycle assessment at an early design stage. Sci. Total Environ. 2018, 635, 100–111. [Google Scholar] [CrossRef] [PubMed]

- Corona, A.; Parajuli, R.; Ambye-Jensen, M.; Hauschild, M.Z.; Birkved, M. Environmental screening of potential biomass for green biorefinery conversion. J. Clean. Prod. 2018, 189, 344–357. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Taelman, S.E.; Meester, S.; De Roef, L.; Michiels, M.; Dewulf, J. The environmental sustainability of microalgae as feed for aquaculture: A life cycle perspective. Bioresour. Technol. 2013, 150, 513–522. [Google Scholar] [CrossRef]

- Troy, S.; Schreiber, A.; Reppert, T.; Gehrke, H.-G.; Finsterbusch, M.; Uhlenbruck, S.; Stenzel, P. Life Cycle Assessment and resource analysis of all-solid-state batteries. Appl. Energy 2016, 169, 757–767. [Google Scholar] [CrossRef]

- Hischier, R.; Salieri, B.; Pini, M. Most important factors of variability and uncertainty in an LCA study of nanomaterials—Findings from a case study with nano titanium dioxide. NanoImpact 2017, 7, 17–26. [Google Scholar] [CrossRef]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Int. J. Life Cycle Assess. 2008, 13, 290–300. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Dael, M.; Van Passel, S.; You, F. How to assess the potential of emerging green technologies? Towards a prospective environmental and techno-economic assessment framework. Green Chem. 2019, 21, 4868–4886. [Google Scholar] [CrossRef]

- Gear, M.; Sadhukhan, J.; Thorpe, R.; Clift, R.; Seville, J.; Keast, M. A life cycle assessment data analysis toolkit for the design of novel processes—A case study for a thermal cracking process for mixed plastic waste. J. Clean. Prod. 2018, 180, 735–747. [Google Scholar] [CrossRef]

- Miller, S.A.; Keoleian, G.A. Framework for analyzing transformative technologies in life cycle assessment. Environ. Sci. Technol. 2015, 49, 3067–3075. [Google Scholar] [CrossRef]

- Simon, B.; Bachtin, K.; Kiliç, A.; Amor, B.; Weil, M. Proposal of a framework for scale-up life cycle inventory: A case of nanofibers for lithium iron phosphate cathode applications. Integr. Environ. Assess. Manag. 2016, 12, 465–477. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Arvidsson, R.; Nguyen, D.; Svanström, M. Life cycle assessment of cellulose nanofibrils production by mechanical treatment and two different pretreatment processes. Environ. Sci. Technol. 2015, 49, 6881–6890. [Google Scholar] [CrossRef]

- Fazeni, K.; Lindorfer, J.; Prammer, H. Methodological advancements in Life Cycle Process Design: A preliminary outlook. Resour. Conserv. Recycl. 2014, 92, 66–77. [Google Scholar] [CrossRef]

- Lu, J.; Kumagai, S.; Ohno, H.; Kameda, T.; Saito, Y.; Yoshioka, T.; Fukushima, Y. Deducing targets of emerging technologies based on ex ante life cycle thinking: Case study on a chlorine recovery process for polyvinyl chloride wastes. Resour. Conserv. Recycl. 2019, 151. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System Boundary Selection in Life-Cycle Inventories Using Hybrid Approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; Van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA: A case study on an emerging technology for metal recovery from E-Waste. Int. J. Life Cycle Assess. 2017, 22, 1618–1633. [Google Scholar] [CrossRef]

- Hospido, A.; Davis, J.; Berlin, J.; Sonesson, U. A review of methodological issues affecting LCA of novel food products. Int. J. Life Cycle Assess. 2010, 15, 44–52. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.-J.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef] [PubMed]

- Janssen, M.; Tillman, A.-M.; Cannella, D.; Jørgensen, H. Influence of high gravity process conditions on the environmental impact of ethanol production from wheat straw. Bioresour. Technol. 2014, 173, 148–158. [Google Scholar] [CrossRef][Green Version]

- Yao, Y.; Masanet, E. Life-cycle modeling framework for generating energy and greenhouse gas emissions inventory of emerging technologies in the chemical industry. J. Clean. Prod. 2018, 172, 768–777. [Google Scholar] [CrossRef]

- EC-JRC. International Reference Life Cycle Data System (ILCD) Handbook. General Guide for Life Cycle Assessment: Detailed Guidance; EUR: Luxembourg, 2010. [Google Scholar]

- Pourzahedi, L.; Pandorf, M.; Ravikumar, D.; Zimmerman, J.B.; Seager, T.P.; Theis, T.L.; Westerhoff, P.; Gilbertson, L.M.; Lowry, G.V. Life cycle considerations of nano-enabled agrochemicals: Are today’s tools up to the task? Environ. Sci. Nano 2018, 5, 1057–1069. [Google Scholar] [CrossRef]

- Valsasina, L.; Pizzol, M.; Smetana, S.; Georget, E.; Mathys, A.; Heinz, V. Life cycle assessment of emerging technologies: The case of milk ultra-high pressure homogenisation. J. Clean. Prod. 2017, 142, 2209–2217. [Google Scholar] [CrossRef]

- Zackrisson, M.; Jönsson, C.; Johannisson, W.; Fransson, K.; Posner, S.; Zenkert, D.; Lindbergh, G. Prospective Life Cycle Assessment of a Structural Battery. Sustainability 2019, 11, 5679. [Google Scholar] [CrossRef]

- Gasafi, E.; Meyer, L.; Liselotte, S. Using Life-Cycle Assessment in Process Design: Supercritical Water Gasification of Organic Feedstocks. J. Ind. Ecol. 2004, 7, 75–91. [Google Scholar] [CrossRef]

- Sousa, I.; Wallace, D.; Eisenhard, J.L. Approximate Life-Cycle Assessment of Product Concepts Using Learning Systems. J. Ind. Ecol. 2008, 4, 61–81. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Thinkstep. GaBi Software-System and Database for Life Cycle Engineering. 2016. Available online: http://www.gabi-software.com/deutsch/index/ (accessed on 29 April 2016).

- Song, R.; Keller, A.A.; Suh, S. Rapid Life-Cycle Impact Screening Using Artificial Neural Networks. Environ. Sci. Technol. 2017, 51, 10777–10785. [Google Scholar] [CrossRef] [PubMed]

- Pallas, G.; Vijver, M.G.; Peijnenburg, W.J.G.M.; Guinée, J. Life cycle assessment of emerging technologies at the lab scale: The case of nanowire-based solar cells. J. Ind. Ecol. 2019, 8, 733. [Google Scholar] [CrossRef]

- Smetana, S.; Palanisamy, M.; Mathys, A.; Heinz, V. Sustainability of insect use for feed and food: Life Cycle Assessment perspective. J. Clean. Prod. 2016, 137, 741–751. [Google Scholar] [CrossRef]

- Tsoy, N.; Prado, V.; Wypkema, A.; Quist, J.; Mourad, M. Anticipatory Life Cycle Assessment of sol-gel derived anti-reflective coating for greenhouse glass. J. Clean. Prod. 2019, 221, 365–376. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, M.; Di Maio, F.; Cucurachi, S. Life cycle assessment of 3D printing geo-polymer concrete: An ex-ante study. J. Ind. Ecol. 2019. [Google Scholar] [CrossRef]

- Wender, B.A.; Foley, R.W.; Hottle, T.A.; Sadowski, J.; Prado-Lopez, V.; Eisenberg, D.A.; Laurin, L.; Seager, T.P. Anticipatory life-cycle assessment for responsible research and innovation. J. Responsible Innov. 2014, 1, 200–207. [Google Scholar] [CrossRef]

- Baresel, C.; Dahlgren, L.; Almemark, M.; Lazic, A. Municipal wastewater reclamation for non-potable reuse—Environmental assessments based on pilot-plant studies and system modelling. Water Sci. Technol. 2015, 72, 1635–1643. [Google Scholar] [CrossRef]

- Joyce, P.J.; Hertel, T.; Goronovski, A.; Tkaczyk, A.H.; Pontikes, Y.; Björklund, A. Identifying hotspots of environmental impact in the development of novel inorganic polymer paving blocks from bauxite residue. Resour. Conserv. Recycl. 2018, 138, 87–98. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A. From Laboratory to Industrial Scale: A Prospective LCA for Electrochemical Reduction of CO2 to Formic Acid. Environ. Sci. Technol. 2019, 53, 12320–12329. [Google Scholar] [CrossRef]

- Weidema, B.P.; Wesnæs, M.S. Data quality management for life cycle inventories—An example of using data quality indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Ciroth, A.; Muller, S.; Weidema, B.; Lesage, P. Empirically based uncertainty factors for the pedigree matrix in ecoinvent. Int. J. Life Cycle Assess. 2016, 21, 1338–1348. [Google Scholar] [CrossRef]

- Muller, S.; Lesage, P.; Ciroth, A.; Mutel, C.; Weidema, B.P.; Samson, R. The application of the pedigree approach to the distributions foreseen in ecoinvent v3. Int. J. Life Cycle Assess. 2016, 21, 1327–1337. [Google Scholar] [CrossRef]

- Mendoza Beltran, A.; Cox, B.; Mutel, C.; Van Vuuren, D.P.; Font Vivanco, D.; Deetman, S.; Edelenbosch, O.Y.; Guinée, J.; Tukker, A. When the Background Matters: Using Scenarios from Integrated Assessment Models in Prospective Life Cycle Assessment. J. Ind. Ecol. 2018, 99, 111. [Google Scholar] [CrossRef]

- Gavankar, S.; Anderson, S.; Keller, A.A. Critical Components of Uncertainty Communication in Life Cycle Assessments of Emerging Technologies. J. Ind. Ecol. 2015, 19, 468–479. [Google Scholar] [CrossRef]

- Shibasaki, M.; Warburg, N.; Eyerer, P. Upscaling effect and Life Cycle Assessment. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 61–64. [Google Scholar]

- Bergesen, J.D.; Suh, S. A framework for technological learning in the supply chain: A case study on CdTe photovoltaics. Appl. Energy 2016, 169, 721–728. [Google Scholar] [CrossRef]

- Rubin, E.S.; Azevedo, I.M.L.; Jaramillo, P.; Yeh, S. A review of learning rates for electricity supply technologies. Energy Policy 2015, 86, 198–218. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Daddi, T.; Punta, C.; Fiorati, A.; Iraldo, F. Life cycle assessment of emerging environmental technologies in the early stage of development: A case study on nanostructured materials. J. Ind. Ecol. 2019, 2, 1010. [Google Scholar] [CrossRef]

- Haupt, G. Learning from experts: Fostering extended thinking in the early phases of the design process. Int. J. Technol. Des. Educ. 2015, 25, 483–520. [Google Scholar] [CrossRef]

- Gerber, L.; Gassner, M.; Maréchal, F. Systematic integration of LCA in process systems design: Application to combined fuel and electricity production from lignocellulosic biomass. Comput. Chem. Eng. 2011, 35, 1265–1280. [Google Scholar] [CrossRef]

- Pini, M.; Cedillo González, E.; Neri, P.; Siligardi, C.; Ferrari, A. Assessment of Environmental Performance of TiO2 Nanoparticles Coated Self-Cleaning Float Glass. Coatings 2017, 7, 8. [Google Scholar] [CrossRef]

- Weyand, S.; Wittich, C.; Schebek, L. Environmental performance of emerging photovoltaic technologies: Assessment of the status quo and future prospects based on a meta-analysis of life-cycle assessment studies. Energies 2019, 12, 4228. [Google Scholar] [CrossRef]

- Pesonen, H.-L.; Ekvall, T.; Fleischer, G.; Huppes, G.; Jahn, C.; Klos, Z.S.; Rebitzer, G.; Sonnemann, G.W.; Tintinelli, A.; Weidema, B.P.; et al. Framework for scenario development in LCA. Int. J. Life Cycle Assess. 2000, 5, 21–30. [Google Scholar] [CrossRef]

- Sharp, B.E.; Miller, S.A. Potential for Integrating Diffusion of Innovation Principles into Life Cycle Assessment of Emerging Technologies. Environ. Sci. Technol. 2016, 50, 2771–2781. [Google Scholar] [CrossRef]

- Cox, B.; Mutel, C.L.; Bauer, C.; Mendoza Beltran, A.; Van Vuuren, D.P. Uncertain Environmental Footprint of Current and Future Battery Electric Vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef] [PubMed]

- Gibon, T.; Wood, R.; Arvesen, A.; Bergesen, J.D.; Suh, S.; Hertwich, E.G. A Methodology for Integrated, Multiregional Life Cycle Assessment Scenarios under Large-Scale Technological Change. Environ. Sci. Technol. 2015, 49, 11218–11226. [Google Scholar] [CrossRef] [PubMed]

- Van der Voet, E.; Van Oers, L.; Verboon, M.; Kuipers, K. Environmental Implications of Future Demand Scenarios for Metals: Methodology and Application to the Case of Seven Major Metals. J. Ind. Ecol. 2019, 23, 141–155. [Google Scholar] [CrossRef]

- Jones, C.; Gilbert, P.; Raugei, M.; Mander, S.; Leccisi, E. An approach to prospective consequential life cycle assessment and net energy analysis of distributed electricity generation. Energy Policy 2017, 100, 350–358. [Google Scholar] [CrossRef]

- Sandén, B.A.; Karlström, M. Positive and negative feedback in consequential life-cycle assessment. J. Clean. Prod. 2007, 15, 1469–1481. [Google Scholar] [CrossRef]

- Liptow, C.; Tillman, A.-M.; Janssen, M. Life cycle assessment of biomass-based ethylene production in Sweden—Is gasification or fermentation the environmentally preferable route? Int. J. Life Cycle Assess. 2015, 20, 632–644. [Google Scholar] [CrossRef]

- Sandén, B.A.; Jonasson, K.M.; Karlström, M.; Tillman, A.-M. LCA of Emerging Technologies: A Methodological Framework. In Proceedings of the LCM 2005—Innovation by Life Cycle Management, International Conference, Barcelona, Spain, 5–7 September 2005. [Google Scholar]

- Muñoz, I.; Portillo, F.; Rosiek, S.; Batlles, F.J.; Martínez-Del-Río, J.; Acasuso, I.; Piergrossi, V.; De Sanctis, M.; Chimienti, S.; Di Iaconi, C. Prospective environmental and economic assessment of solar-assisted thermal energy recovery from wastewater through a sequencing batch biofilter granular reactor. J. Clean. Prod. 2019, 212, 1300–1309. [Google Scholar] [CrossRef]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.S.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R.; et al. Life cycle assessment of emerging technologies: Evaluation techniques at different stages of market and technical maturity. J. Ind. Ecol. 2019, 33, 101. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Gilijamse, W.; Ragas, A.D.M.J.; Reijnders, L. Evaluating Uncertainty in Environmental Life-Cycle Assessment. A Case Study Comparing Two Insulation Options for a Dutch One-Family Dwelling. Environ. Sci. Technol. 2003, 37, 2600–2608. [Google Scholar] [CrossRef] [PubMed]

- Cooper, D.R.; Gutowski, T.G. Prospective Environmental Analyses of Emerging Technology: A Critique, a Proposed Methodology, and a Case Study on Incremental Sheet Forming. J. Ind. Ecol. 2018, 219, 239. [Google Scholar] [CrossRef]

- Lacirignola, M.; Blanc, P.; Girard, R.; Pérez-López, P.; Blanc, I. LCA of emerging technologies: Addressing high uncertainty on inputs’ variability when performing global sensitivity analysis. Sci. Total Environ. 2017, 578, 268–280. [Google Scholar] [CrossRef] [PubMed]

- Marini, C.; Blanc, I. Towards Prospective Life Cycle Assessment: How to Identify Key Parameters Inducing Most Uncertainties in the Future? Application to Photovoltaic Systems Installed in Spain. In Computational Science and Its Applications—ICCSA 2014; Murgante, B., Misra, S., Roch, A.M.A.C., Torre, C., Rocha, J.G., Falcão, M.I., Taniar, D., Apduhan, B.O., Gervasi, O., Eds.; Springer: New York, NY, USA, 2014; pp. 691–706. [Google Scholar]

- Ravikumar, D.; Seager, T.P.; Cucurachi, S.; Prado, V.; Mutel, C. Novel Method of Sensitivity Analysis Improves the Prioritization of Research in Anticipatory Life Cycle Assessment of Emerging Technologies. Environ. Sci. Technol. 2018, 52, 6534–6543. [Google Scholar] [CrossRef] [PubMed]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. Predicting the environmental impact of a future nanocellulose production at industrial scale: Application of the life cycle assessment scale-up framework. J. Clean. Prod. 2018, 174, 283–295. [Google Scholar] [CrossRef]

- De Marco, I.; Iannone, R.; Miranda, S.; Riemma, S. An environmental study on starch aerogel for drug delivery applications: Effect of plant scale-up. Int. J. Life Cycle Assess. 2017, 303, 1818. [Google Scholar] [CrossRef]

- Sfez, S.; Van den Hende, S.; Taelman, S.E.; De Meester, S.; Dewulf, J. Environmental sustainability assessment of a microalgae raceway pond treating aquaculture wastewater: From up-scaling to system integration. Bioresour. Technol. 2015, 190, 321–331. [Google Scholar] [CrossRef]

- Tan, L.; Mandley, S.J.; Peijnenburg, W.J.G.M.; Van der Waaijers Loop, S.L.; Giesen, D.; Legradi, J.B.; Shen, L. Combining ex-ante LCA and EHS screening to assist green design: A case study of cellulose nanocrystal foam. J. Clean. Prod. 2018, 178, 494–506. [Google Scholar] [CrossRef]

- Clavreul, J.; Christensen, T.H.; Baumeister, H. LCA of Waste Management Systems: Development of Tools for Modeling and Uncertainty Analysis; DTU Environment: Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Gargalo, C.L.; Cheali, P.; Posada, J.A.; Carvalho, A.; Gernaey, K.V.; Sin, G. Assessing the environmental sustainability of early stage design for bioprocesses under uncertainties: An analysis of glycerol bioconversion. J. Clean. Prod. 2016, 139, 1245–1260. [Google Scholar] [CrossRef]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The ecoinvent Database: Overview and Methodological Framework (7 pp). Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Fernandez, J.A. Contextual Role of TRLs and MRLs in Technology Management; Sandia National Lab-CRF: Livermore, CA, USA, 2010.

- Barberio, G.; Scalbi, S.; Buttol, P.; Masoni, P.; Righi, S. Combining life cycle assessment and qualitative risk assessment: The case study of alumina nanofluid production. Sci. Total Environ. 2014, 496, 122–131. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. https://doi.org/10.3390/su12031192

Thonemann N, Schulte A, Maga D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability. 2020; 12(3):1192. https://doi.org/10.3390/su12031192

Chicago/Turabian StyleThonemann, Nils, Anna Schulte, and Daniel Maga. 2020. "How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance" Sustainability 12, no. 3: 1192. https://doi.org/10.3390/su12031192

APA StyleThonemann, N., Schulte, A., & Maga, D. (2020). How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability, 12(3), 1192. https://doi.org/10.3390/su12031192