A Graphical Tool to Estimate the Air Change Efficiency in Rooms with Heat Recovery Systems

Abstract

1. Introduction

2. Materials and Methods

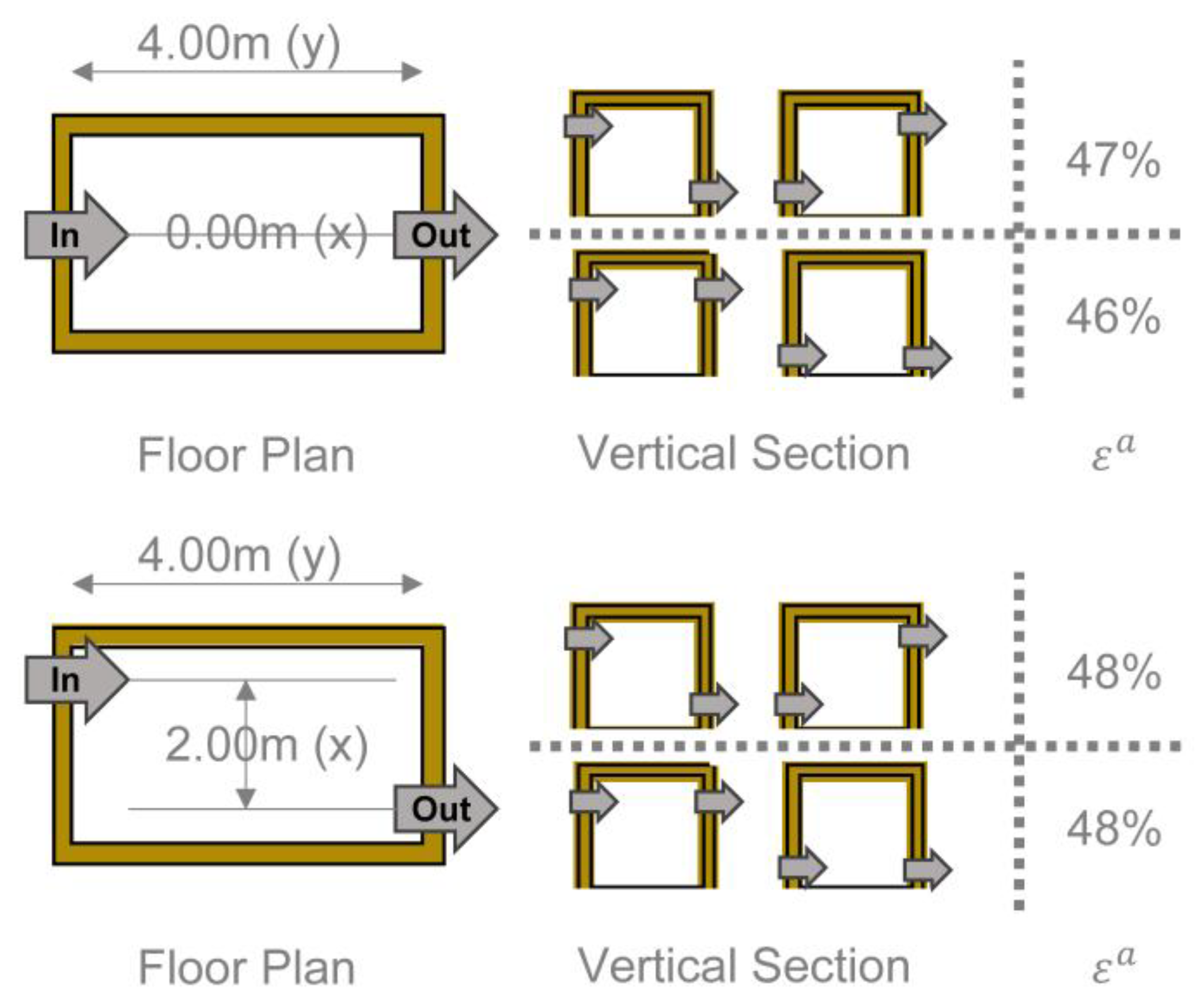

- The relative location of the inlet and exhaust air openings;

- The supply of positively or negatively buoyant air;

- The envelope airtightness;

- The momentum of the jet;

- The discharge Archimedes number; and

- The magnitude and location of the contaminant sources.

- The effects of buoyancy and Archimedes number result in a temperature gradient between the outdoor and indoor air that is minimised in rooms with an air inlet by high-efficiency heat recovery systems. In circulation areas and rooms with an air exhaust, the air flow acquires the temperature of the indoor air, adopting an isothermal behaviour;

- Energy-efficient buildings have construction systems that avoid uncontrolled air flow through the envelope. This can be verified if there is compliance with strict infiltration limits by means of onsite pressurization tests [19];

- A high ventilation jet velocity ensures the mixing of the indoor air. However, the loss of velocity caused by air mixing does not affect the overall efficiency of the system [15];

- The use of the air change efficiency parameter, , is recommended in the literature [20] to characterize rooms where the location of the contaminating source is not specified and, at the same time, an adequate IAQ is desired in the entire volume of the room.

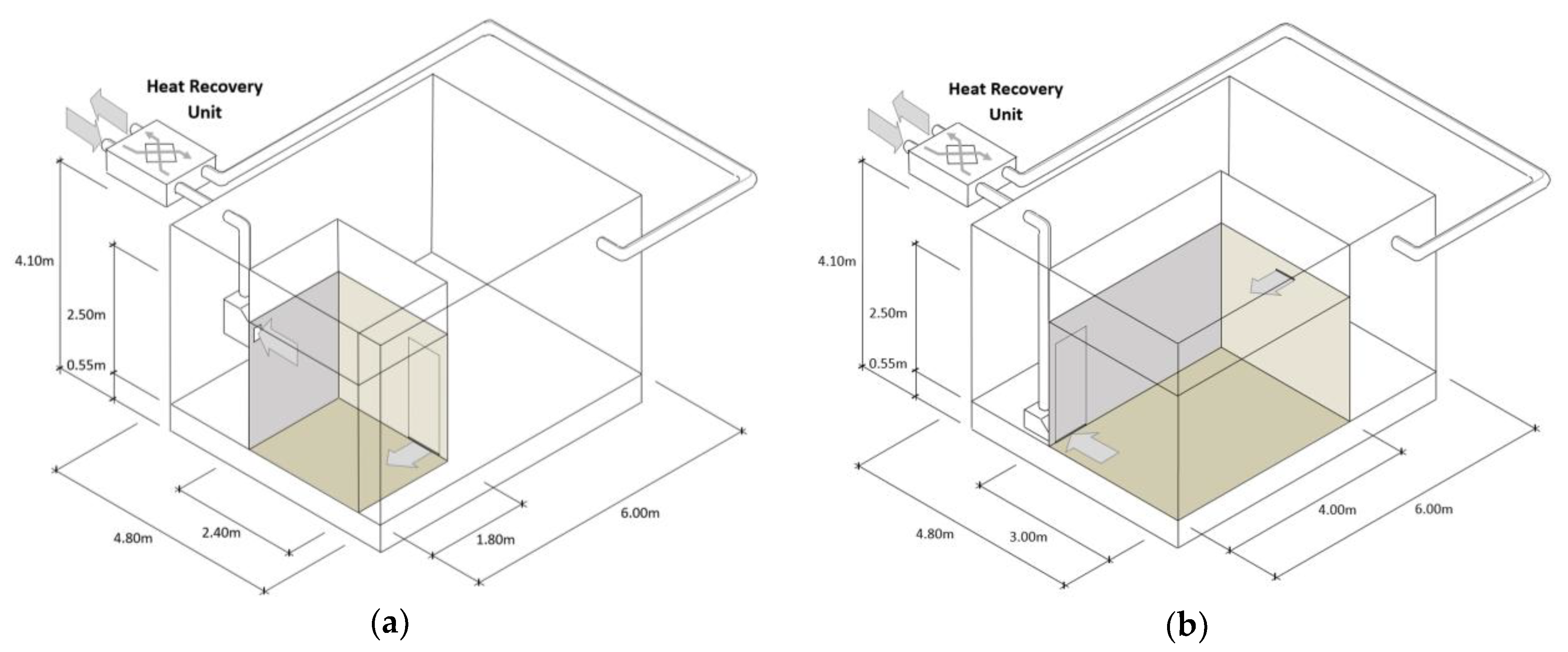

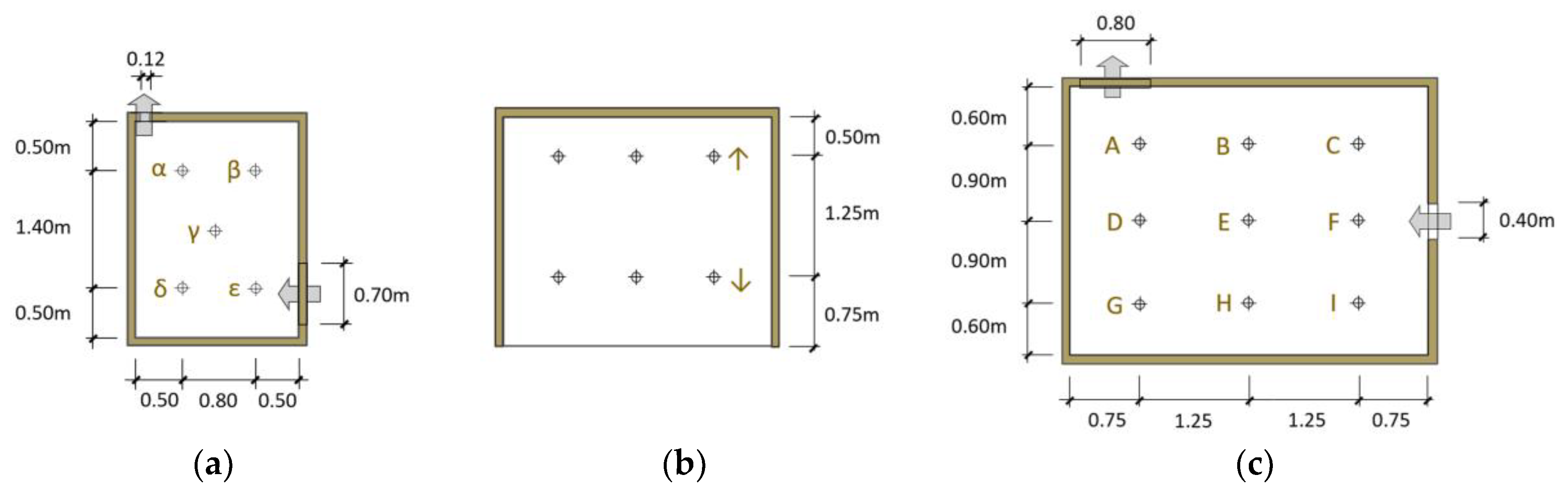

2.1. Basis for the Experimental Study

- The opening of doors, windows, or any other factor that could cause a non-steady regime were not considered. The objective was to analyze the efficiency complying with the minimum ventilation conditions without the impact of the occupants’ behavior;

- Incompressible flow: the Mach number reached an approximate value of 0.00734, with a higher velocity around the air jet. The density variation due to the pressure gradient was negligible;

- The local mean age of the air in the inlet was set to zero;

- The air flow through the openings was perpendicular to the envelope. The inlet had no moving parts or obstacles that could cause a variation of the air flow through them;

- Constant air flow velocity was set, depending on the type of air inlet, between 1.25 and 2.50 m/s, (that is, air flow rates between 10 and 15 l/s, respectively). It was verified that a variation in the jet velocity and in the global volumetric ventilation flow does not have an impact on the overall value of , as a previous experimental research had already demonstrated [16];

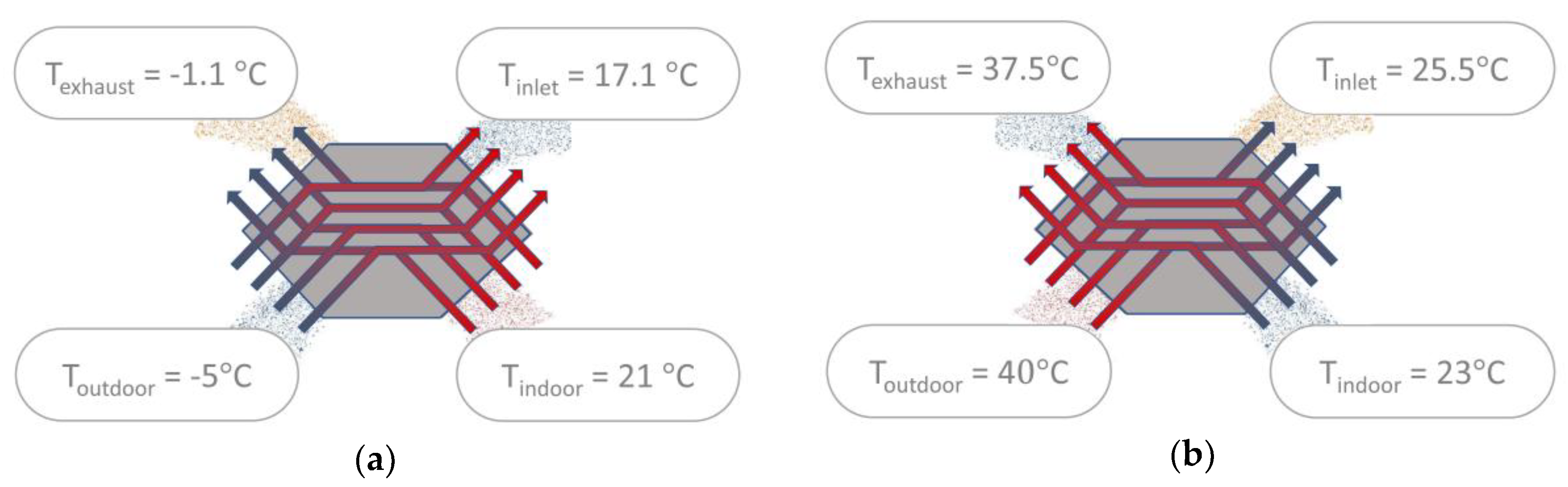

- The turbulence intensity considered was 5% and the length of the inlet scale 0.01 m [14];

- The outdoor air supply was thermally conditioned by a heat recovery device. Efficiency values of the heat recovery system between 81% and 86% were obtained, depending on the outdoor/indoor temperature difference from May to February. Due to the efficiency of the heat recovery system, the obtained temperature gradient between the outdoor air supply and the indoor comfort temperature was in the range of + 2.88 and −3.10 °C in all the tests. The surfaces of the volume were considered smooth and isothermal regarding the comfort indoor air temperature (23 °C).

2.2. Basis for the Numerical Study

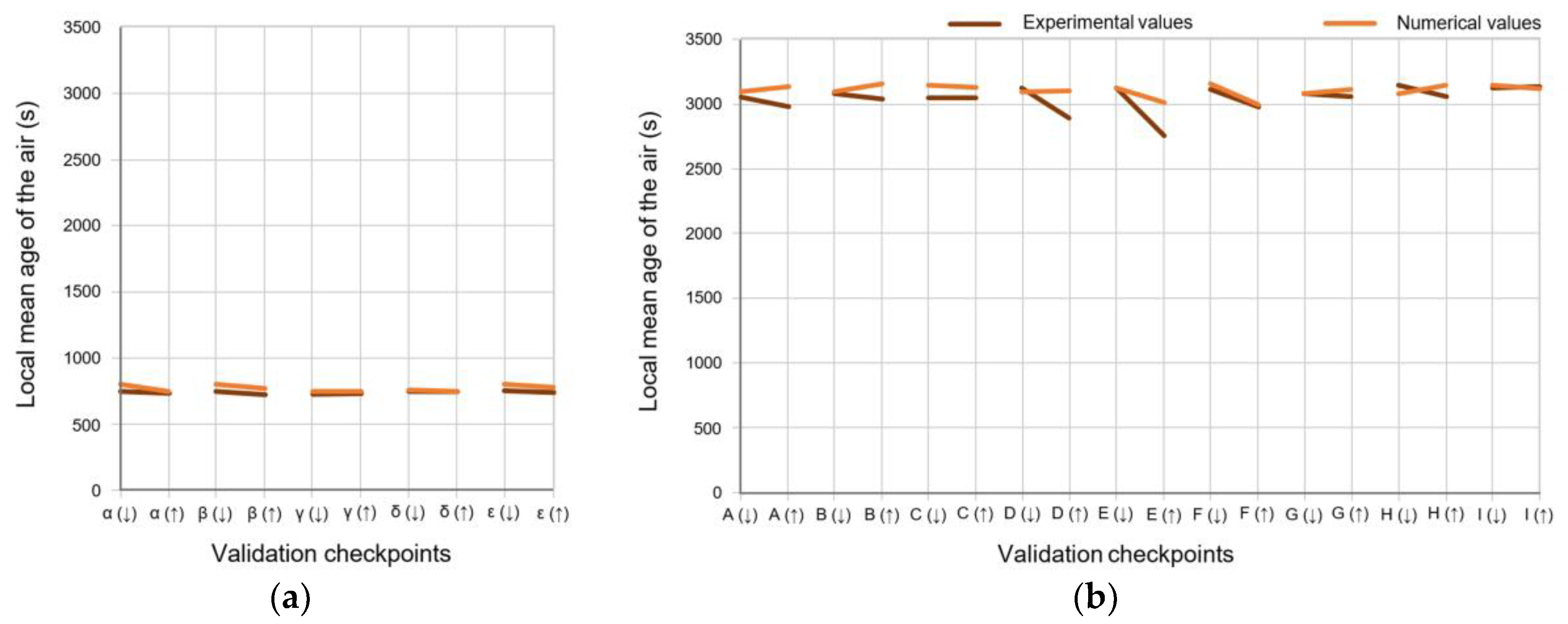

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| air change efficiency | |

| room average age of the air | |

| local mean age of the exhaust air | |

| average time of exchange of air | |

| local mean age of the air | |

| turn-over time | |

| CFD | computational fluid dynamics |

| CI | confidence interval |

| IAQ | indoor air quality |

| UDF | user-defined functions |

| dimensionless wall distance |

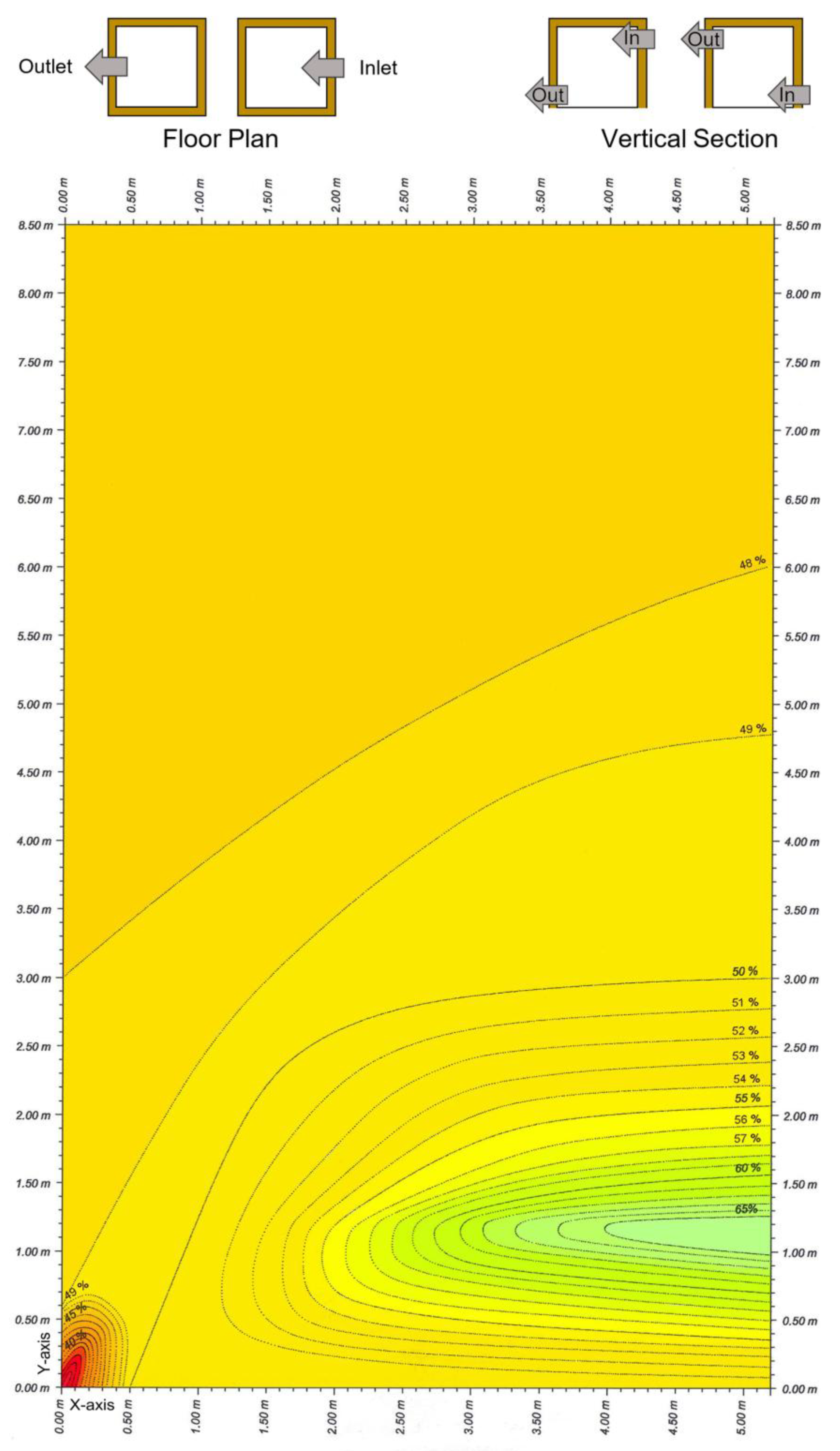

Appendix A. Example of Application

References

- Wargocki, P. Ventilation, Indoor Air Quality, Health, and Productivity. In Ergonomic Workplace Design for Health, Wellness, and Productivity, 1st ed.; Hedge, A., Ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Eurostat. Final Energy Consumption by Sector (2017 Data). Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00124/default/table?lang=en (accessed on 1 December 2019).

- National Institute for Health and Welfare (THL). HealthVent Health-Based Ventilation Guidelines for Europe Project; Deliverable 8: Report on the impact of guideline implementation on health and energy; National Institute for Health and Welfare: Kuopio, Finland, 2012.

- Guillén-Lambea, S.; Rodríguez-Soria, B.; Marín, J.M. Review of European ventilation strategies to meet the cooling and heating demands of nearly zero energy buildings (nZEB)/Passivhaus. Comparison with the USA. Renew. Sustain. Energy Rev. 2016, 62, 561–574. [Google Scholar] [CrossRef]

- Mikola, A.; Simson, R.; Kurnitski, J. The impact of Air Pressure Conditions on the Performance of Single Room Ventilation Units in Multi-Story Buildings. Energies 2019, 12, 2633. [Google Scholar] [CrossRef]

- Kwon, K.-S.; Lee, I.-B.; Han, H.-T.; Shin, C.-Y.; Hwang, H.-S.; Hong, S.-W.; Bitog, J.P.; Seo, I.-H.; Han, C.-P. Analysing ventilation efficiency in a test chamber using age-of-air concept and CFD technology. Biosyst. Eng. 2011, 110, 421–433. [Google Scholar] [CrossRef]

- Ameen, A.; Cehlin, M.; Larsson, U.; Karimipanah, T. Experimental Investigation of Ventilation Performance of Different Air Distribution Systems in an Office Environment-Heating Mode. Energies 2019, 12, 1835. [Google Scholar] [CrossRef]

- Dijkstra, H.A. Ventilation Efficiency in an L-Shaped Room. Master’s Thesis, University of Technology, Eindhoven, The Netherlands, 18 June 2015. [Google Scholar]

- Rabanillo-Herrero, M.; Padilla-Marcos, M.A.; Feijó-Muñoz, J.; Gil-Valverde, R.; Meiss, A. Ventilation efficiency assessment according to the variation of opening position in L-shaped rooms. Build. Simul. 2020, 13, 213–221. [Google Scholar] [CrossRef]

- Hormigos-Jiménez, S.; Padilla-Marcos, M.A.; Meiss, A.; González-Lezcano, R.A.; Feijó-Muñoz, J. Computational fluid dynamics evaluation of the furniture arrangement for ventilation efficiency. BSERT 2018, 39, 557–571. [Google Scholar] [CrossRef]

- Mundt, E.; Mathisen, H.M.; Nielsen, P.V.; Moser, A. Ventilation Effectiveness. Guidebook nº2, 1st ed.; Mundt, E., Ed.; Federation of European Heating and Ventilation Association REHVA: Helsinki, Finland, 2004. [Google Scholar]

- Davidson, L.; Olsson, E. Calculation of age and local purging flow rate in rooms. Build. Environ. 1987, 22, 111–127. [Google Scholar] [CrossRef]

- Sandberg, M. What is ventilation efficiency? Build. Environ. 1981, 16, 123–135. [Google Scholar] [CrossRef]

- Sandberg, M.; Sjöberg, M. The use of moments for assessing air quality in ventilated rooms. Build. Environ. 1983, 18, 181–197. [Google Scholar] [CrossRef]

- Etheridge, D.; Sandberg, M. Building Ventilation. Theory and Measurement, 1st ed.; John Wiley & Sons Ltd.: Baffins Lane, UK, 1996. [Google Scholar]

- Meiss, A. Study of the Air Change Efficiency in Dwellings from Architectural Design Parameters. Ph.D. Thesis, Universidad de Valladolid, Valladoid, Spain, 2009. [Google Scholar]

- Meiss, A.; Feijó-Muñoz, J.; García-Fuentes, M.A. Age-of-the-air in rooms according to the environmental condition of temperature: A case study. Energy Build. 2013, 67, 88–96. [Google Scholar] [CrossRef]

- Rabanillo-Herrero, M.; Padilla-Marcos, M.A.; Feijó-Muñoz, J.; Meiss, A. Effects of the radiant heating system location on both the airflow and ventilation efficiency in a room. Indoor Built Environ. 2019, 28, 372–383. [Google Scholar] [CrossRef]

- Šadauskienė, J.; Paukštys, V.; Šeduikytė, L.; Banionis, K. Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania. Energies 2014, 7, 4972–4987. [Google Scholar] [CrossRef]

- Roos, A. On the Effectiveness of Ventilation, 1st ed.; Rutten, P., Mattheij, R.M.M., ter Morsche, H.G., Eds.; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 1999. [Google Scholar]

- Sherman, M.H. Tracer-gas techniques for measuring ventilation in a single zone. Build. Environ. 1990, 25, 365–374. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN-ISO 9972:2015. Thermal Performance of Buildings. Determination of Air Permeability of Buildings. Fan Pressurization Method; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Sherman, M.H. Uncertainty in air flow calculations using tracer gas measurements. Build. Environ. 1989, 24, 347–354. [Google Scholar] [CrossRef][Green Version]

- Nielsen, P.V.; Allard, F.; Awbi, H.B.; Davidson, L.; Schälin, A. A Computational Fluid Dynamics in Ventilation Design Guidebook nº10, 1st ed.; Nielsen, P.V., Ed.; Federation of European Heating and Ventilation Association REHVA: Helsinki, Finland, 2007. [Google Scholar]

- Gilani, S.; Montazeri, H.; Blocken, B. CFD simulation of stratified indoor environment in displacement ventilation: Validation and sensitivity analysis. Build. Environ. 2016, 95, 299–313. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modelling for CFD, 2nd ed.; Wilcox, D.C., Ed.; DCW Industries Inc.: Palm Drive, Beverly Hills, CA, USA, 1994. [Google Scholar]

- Murakami, S.; Kato, S. Numerical and experimental study on room airflow–3-D predictions using the k-e turbulence model. Build. Environ. 1989, 24, 85–97. [Google Scholar] [CrossRef]

- Richtmyer, R.D.; Morton, K.W. Difference Methods for Initial-Value Problems, 2nd ed.; Richtmyer, R.D., Ed.; Krieger Pub. Co.: Krieger Lane, FL, USA, 1994. [Google Scholar]

- Campano Laborda, M.Á.; Acosta García, I.; Fernández-Agüera, J.; Sendra, J.J. Towards finding the optimal location of a ventilation inlet in a roof monitor skylight, using visual and thermal performance criteria, for dwellings in a Mediterranean climate. J. Build. Perform. Simul. 2015, 8, 226–238. [Google Scholar] [CrossRef]

| y+ (dimensionless wall distance) | 30 |

| d (distance to the first node near a wall) | 0.01 m |

| Maximum proportion of cell | 1:4 |

| Maximum growing rate | 1.10 (10%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meiss, A.; Padilla-Marcos, M.Á.; Poza-Casado, I.; Álvaro-Tordesillas, A. A Graphical Tool to Estimate the Air Change Efficiency in Rooms with Heat Recovery Systems. Sustainability 2020, 12, 1031. https://doi.org/10.3390/su12031031

Meiss A, Padilla-Marcos MÁ, Poza-Casado I, Álvaro-Tordesillas A. A Graphical Tool to Estimate the Air Change Efficiency in Rooms with Heat Recovery Systems. Sustainability. 2020; 12(3):1031. https://doi.org/10.3390/su12031031

Chicago/Turabian StyleMeiss, Alberto, Miguel Ángel Padilla-Marcos, Irene Poza-Casado, and Antonio Álvaro-Tordesillas. 2020. "A Graphical Tool to Estimate the Air Change Efficiency in Rooms with Heat Recovery Systems" Sustainability 12, no. 3: 1031. https://doi.org/10.3390/su12031031

APA StyleMeiss, A., Padilla-Marcos, M. Á., Poza-Casado, I., & Álvaro-Tordesillas, A. (2020). A Graphical Tool to Estimate the Air Change Efficiency in Rooms with Heat Recovery Systems. Sustainability, 12(3), 1031. https://doi.org/10.3390/su12031031