Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

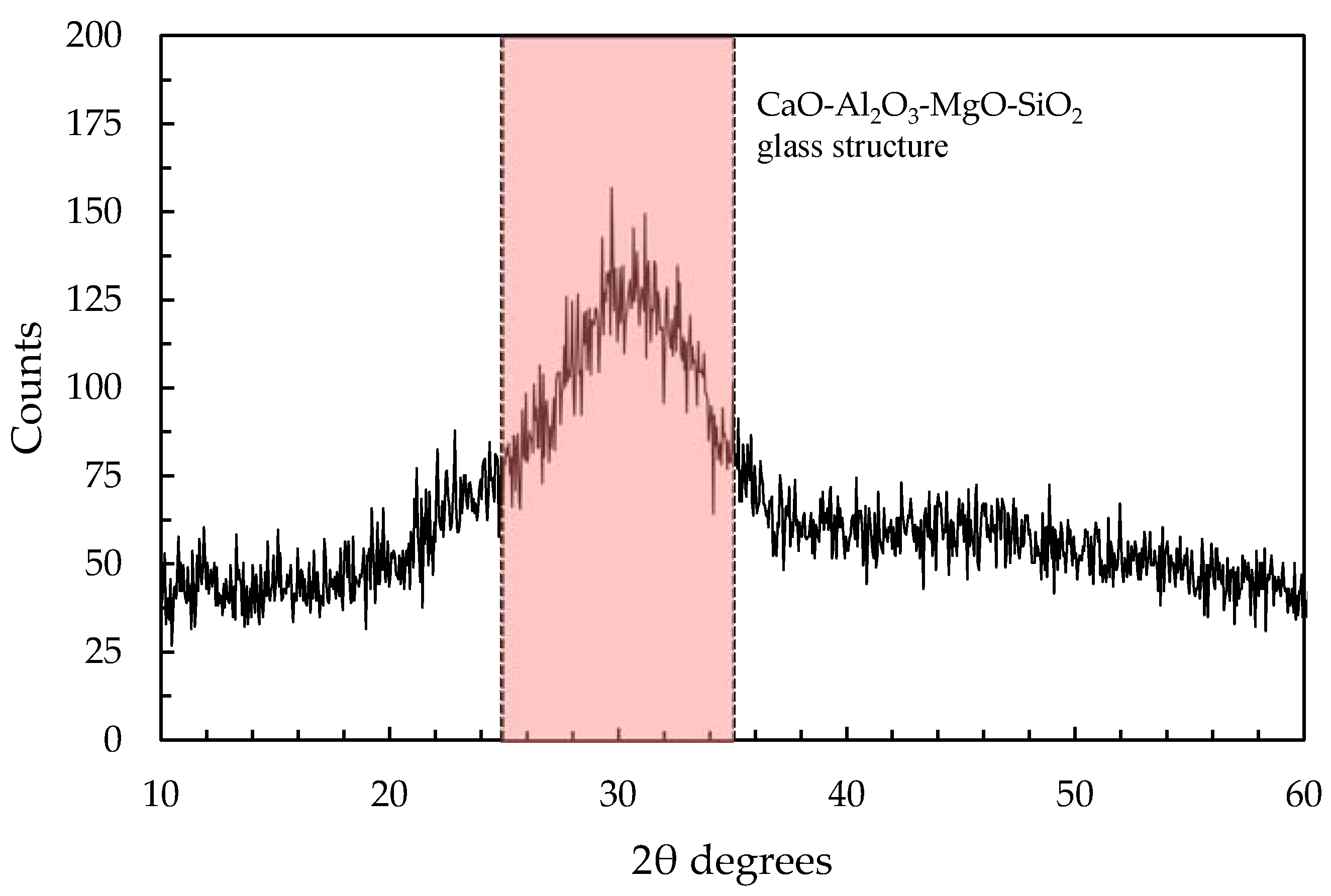

2.1.1. Matrix

2.1.2. Fillers

2.2. Mix Design

2.3. Sample Preparation

- (i)

- Ground granulated blast furnace slag, alkali activator in powder or flakes and deionized water are placed into the steel bowl;

- (ii)

- The mixer starts at low speed (140 rpm for the revolving action, 62 rpm for the planetary action) for 30 s;

- (iii)

- The mixing proceeds at high speed (285 rpm for the revolving action, 125 rpm for the planetary action) for 60 s;

- (iv)

- The mixing stops for 90 s;

- (v)

- The mixer completes the procedure with a further 60 s at high speed.

2.4. Experimental Setup

3. Results and Discussion

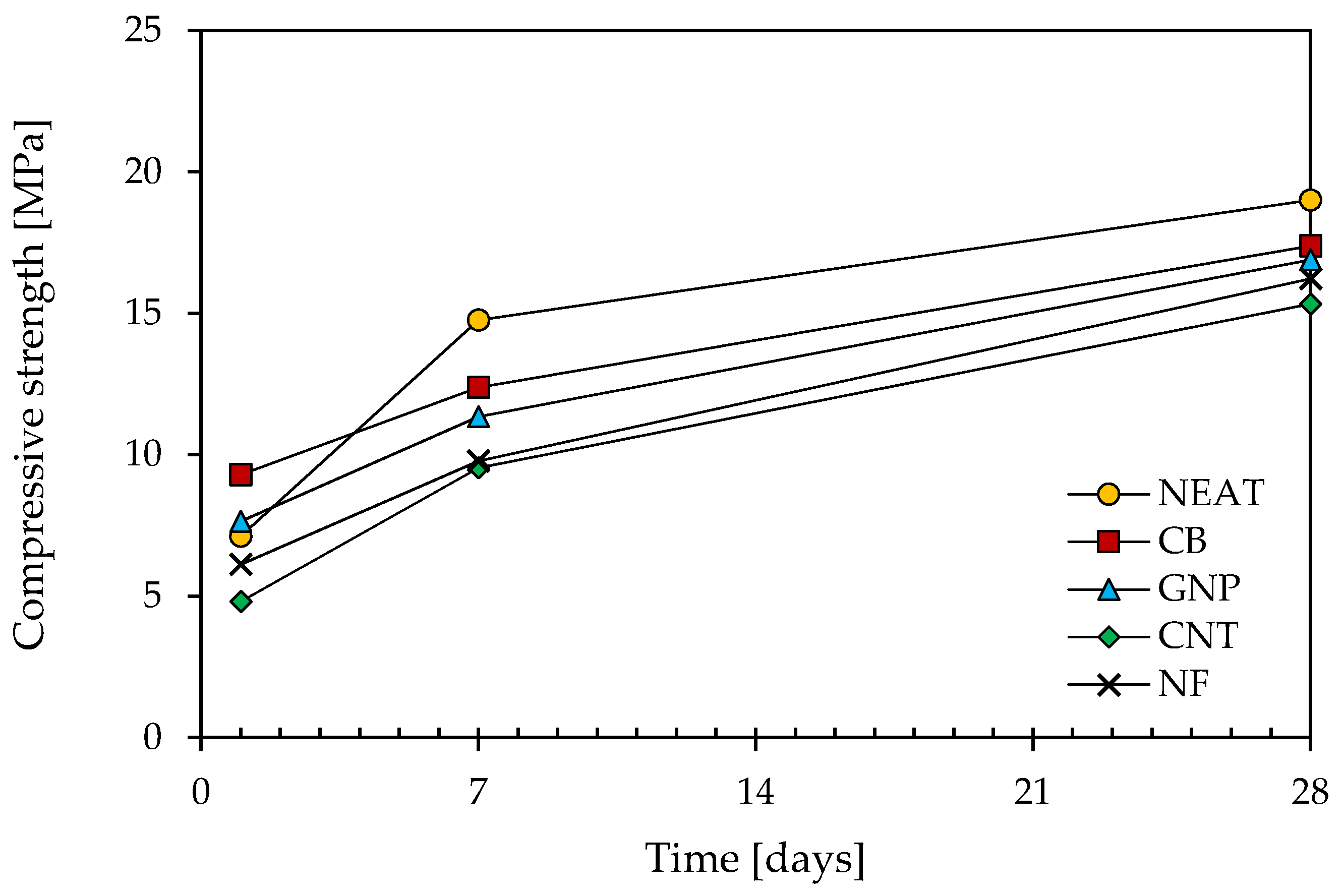

3.1. General Characterization of Mortars

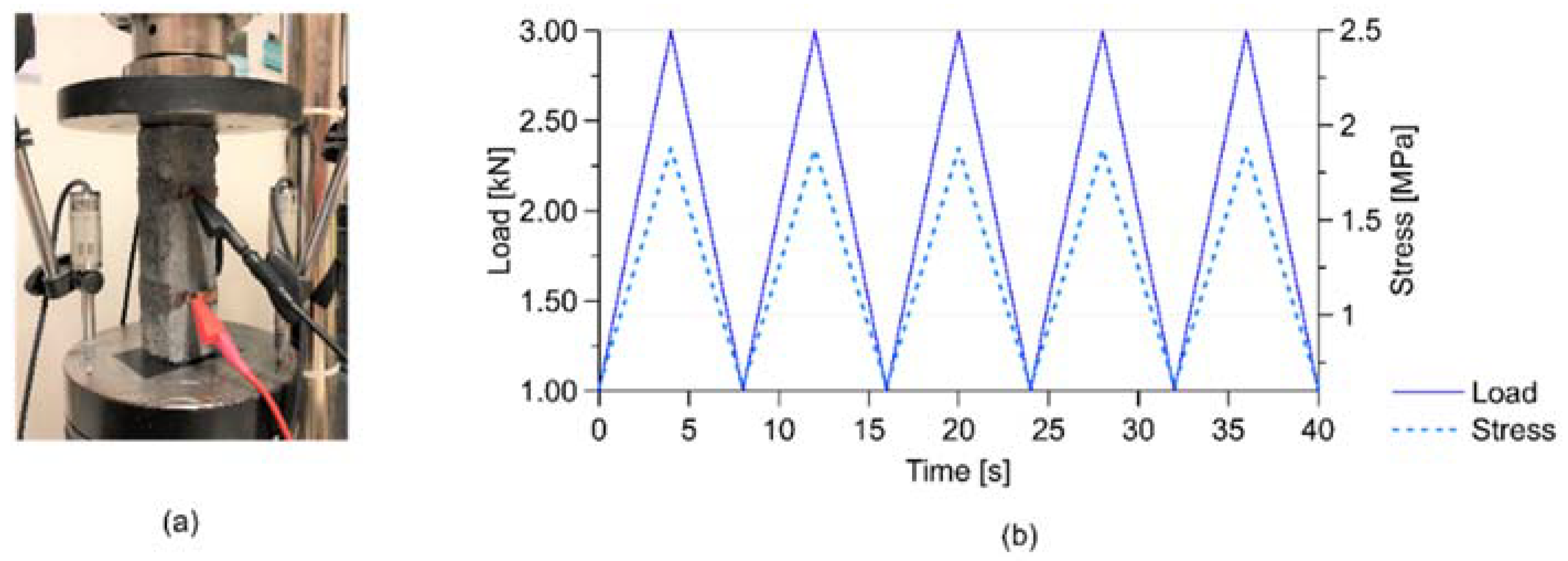

3.2. Electrical Tests

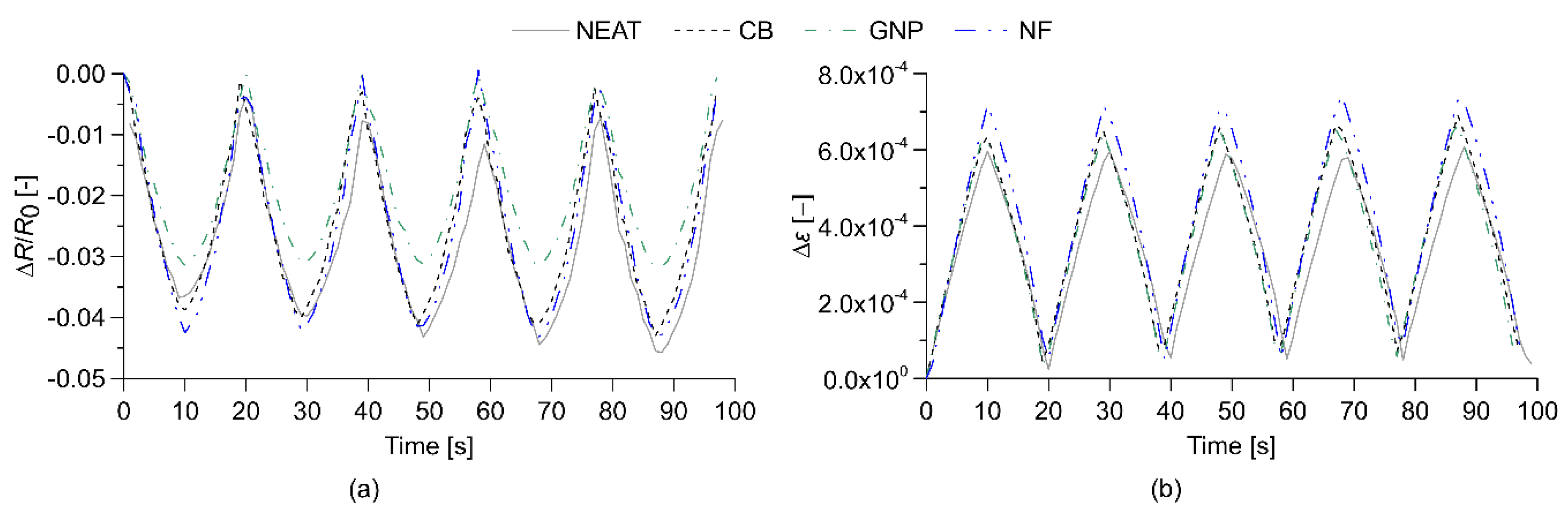

3.3. Sensing Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Miller, S.A. Supplementary cementitious materials to mitigate greenhouse gas emissions from concrete: Can there be too much of a good thing? J. Clean. Prod. 2018, 178, 587–598. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Schneider, M. The cement industry on the way to a low-carbon future. Cem. Concr. Res. 2019. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. 2010. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Habert, G.; Billard, C.; Rossi, P.; Chen, C.; Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 2010, 40, 820–826. [Google Scholar] [CrossRef]

- Miller, S.A.; Myers, R.J. Environmental Impacts of Alternative Cement Binders. Environ. Sci. Technol. 2020, 54, 677–686. [Google Scholar] [CrossRef]

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Tataranni, P.; Besemer, G.M.; Bortolotti, V.; Sangiorgi, C. Preliminary Research on the Physical and Mechanical Properties of Alternative Lightweight Aggregates Produced by Alkali-Activation of Waste Powders. Materials (Basel Switz.) 2018, 11, 1255. [Google Scholar] [CrossRef] [Green Version]

- Coppola, L.; Coffetti, D.; Crotti, E. Pre-packed alkali activated cement-free mortars for repair of existing masonry buildings and concrete structures. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Thomas, R.J.; Peethamparan, S. Alkali-activated concrete: Engineering properties and stress–strain behavior. Constr. Build. Mater. 2015, 93, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. The durability of one-part alkali activated slag-based mortars in different environments. Sustainability 2020, 12, 3561. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The combined use of admixtures for shrinkage reduction in one-part alkali activated slag-based mortars and pastes. Constr. Build. Mater. 2020, 248. [Google Scholar] [CrossRef]

- Habert, G.; D’Espinose De Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of “green concrete”. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- He, J.; Bu, X.; Bai, W.; Zheng, W.; Gao, Q.; Wang, Y. Preparation and properties of self-compacting alkali-activated slag repair mortar. Constr. Build. Mater. 2020, 252, 119034. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Marini, A.; Passoni, C.; Pastore, T. Lightweight cement-free alkali-activated slag plaster for the structural retrofit and energy upgrading of poor quality masonry walls. Cem. Concr. Compos. 2019, 104, 103341. [Google Scholar] [CrossRef]

- Manjunath, R.; Narasimhan, M.C.; Umesha, K.M. Studies on high performance alkali activated slag concrete mixes subjected to aggressive environments and sustained elevated temperatures. Constr. Build. Mater. 2019, 229, 116887. [Google Scholar] [CrossRef]

- Coppola, B.; Tardivat, C.; Richaud, S.; Tulliani, J.-M.; Montanaro, L.; Palmero, P. Alkali-activated refractory wastes exposed to high temperatures: Development and characterization. J. Eur. Ceram. Soc. 2020, 40, 3314–3326. [Google Scholar] [CrossRef]

- Horvat, B.; Ducman, V. Influence of particle size on compressive strength of alkali activated refractory materials. Materials (Basel) 2020, 13, 2227. [Google Scholar] [CrossRef] [PubMed]

- Virendra, K.; Amit, K.; Brajkishor, P. Influence of elevated temperature on alkali-activated ground granulated blast furnace slag concrete. J. Struct. Fire Eng. 2019, 12, 2040–2317. [Google Scholar]

- Khan, H.A.; Khan, M.S.H.; Castel, A.; Sunarho, J. Deterioration of alkali-activated mortars exposed to natural aggressive sewer environment. Constr. Build. Mater. 2018, 186, 577–597. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Donnini, J.; Bellezze, T.; Corinaldesi, V. Mechanical, electrical and self-sensing properties of cementitious mortars containing short carbon fibers. J. Build. Eng. 2018, 20, 8–14. [Google Scholar] [CrossRef]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F. Commercial and recycled carbon/steel fibers for fiber-reinforced cement mortars with high electrical conductivity. Cem. Concr. Compos. 2020, 109, 103569. [Google Scholar] [CrossRef]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F.; Cachim, P. Evaluating the self-sensing ability of cement mortars manufactured with graphene nanoplatelets, virgin or recycled carbon fibers through piezoresistivity tests. Sustainability 2018, 10, 4013. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.M.; Nam, I.W.; Yang, B.; Yoon, H.N.; Lee, H.K.; Park, S. Carbon nanotube (CNT) incorporated cementitious composites for functional construction materials: The state of the art. Compos. Struct. 2019, 227, 111244. [Google Scholar] [CrossRef]

- Camacho-Ballesta, C.; Zornoza, E.; Garcés, P. Performance of cement-based sensors with CNT for strain sensing. Adv. Cem. Res. 2016, 28, 274–284. [Google Scholar] [CrossRef] [Green Version]

- D’Alessandro, A.; Ubertini, F.; García-Macías, E.; Castro-Triguero, R.; Downey, A.; Laflamme, S.; Meoni, A.; Materazzi, A.L. Static and dynamic strain monitoring of reinforced concrete components through embedded carbon nanotube cement-based sensors. Shock Vib. 2017, 2017, 3648403. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Corazza, F. Electrical properties of carbon nanotubes cement composites for monitoring stress conditions in concrete structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar] [CrossRef] [Green Version]

- Meoni, A.; D’alessandro, A.; Downey, A.; García-Macías, E.; Rallini, M.; Materazzi, A.L.; Torre, L.; Laflamme, S.; Castro-Triguero, R.; Ubertini, F. An experimental study on static and dynamic strain sensitivity of embeddable smart concrete sensors doped with carbon nanotubes for SHM of large structures. Sensors (Switzerland) 2018, 18, 831. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, H.M.; Park, S.M.; Lee, S.M.; Shon, I.J.; Jeon, H.; Yang, B.J. Automated generation of carbon nanotube morphology in cement composite via data-driven approaches. Compos. Part B Eng. 2019, 167, 51–62. [Google Scholar] [CrossRef]

- Kim, G.M.; Park, S.M.; Ryu, G.U.; Lee, H.K. Electrical characteristics of hierarchical conductive pathways in cementitious composites incorporating CNT and carbon fiber. Cem. Concr. Compos. 2017, 82, 165–175. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Damage monitoring of cement paste by electrical resistance measurement. Cem. Concr. Res. 2000, 30, 1979–1982. [Google Scholar] [CrossRef]

- Downey, A.; D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Geiger, R. Biphasic DC measurement approach for enhanced measurement stability and multi-channel sampling of self-sensing multi-functional structural materials doped with carbon-based additives. Smart Mater. Struct. 2017, 26, 65008. [Google Scholar] [CrossRef] [Green Version]

- Candamano, S.; Sgambitterra, E.; Lamuta, C.; Pagnotta, L.; Chakraborty, S.; Crea, F. Graphene nanoplatelets in geopolymeric systems: A new dimension of nanocomposites. Mater. Lett. 2019, 236, 550–553. [Google Scholar] [CrossRef]

- MacKenzie, K.J.D.; Bolton, M.J. Electrical and mechanical properties of aluminosilicate inorganic polymer composites with carbon nanotubes. J. Mater. Sci. 2009, 44, 2851–2857. [Google Scholar] [CrossRef]

- Rovnaník, P.; Míková, M.; Kusá, K. Electrical properties of alkali-Activated slag composite with combined graphite/CNT filler. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Comparison of electrical and self-sensing properties of Portland cement and alkali-activated slag mortars. Cem. Concr. Res. 2019, 118, 84–91. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Electrical and self-sensing properties of alkali-activated slag composite with graphite filler. Materials (Basel) 2019, 12, 1616. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vilaplana, J.L.; Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Self-sensing properties of alkali activated blast furnace slag (BFS) composites reinforced with carbon fibers. Materials (Basel) 2013, 6, 4776–4786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.D.; Scrivener, K.L.; Pratt, P.L. Factors affecting the strength of alkali-activated slag. Cem. Concr. Res. 1994, 24, 1033–1043. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. Hydration products of alkali activated slag cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Page, M.M.; Laurent, P.; Havel, M.; Roger, C. Arkema graphistrength multi-walled carbon nanotubes. In Proceedings of the 2008 NSTI Nanotechnology Conference and Trade Show, Boston, MA, USA, 1–5 June 2008; pp. 47–50. [Google Scholar]

- Bayuaji, R.; Yasin, A.K.; Susanto, T.E.; Darmawan, M.S.; Darmawan, S. A review in geopolymer binder with dry mixing method (geopolymer cement). AIP Conf. Proc. 2017, 1887, 20042. [Google Scholar] [CrossRef] [Green Version]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Rallini, M.; Materazzi, A.L.; Kenny, J.M. Strain Sensitivity of Carbon Nanotube Cement-based Composites for Structural Health Monitoring. In Proceedings of the SPIE—The International Society for Optical Engineering, Las Vegas, NV, USA, 21–24 March 2016; Volume 9803, p. 980319. [Google Scholar]

- D’Alessandro, A.; Meoni, A.; Ubertini, F.; Luigi Materazzi, A. Strain Measurement in a Reinforced Concrete Beam Using Embedded Smart Concrete Sensors, Lecture Notes in Civil Engineering. In Proceedings of the Conference on Italian Concrete Days, Lecco, Italy, 14–15 June 2018; pp. 289–300. [Google Scholar]

| Component | CaO | SiO2 | Al2O3 | MgO | TiO2 | SO3 | K2O | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| wt.% | 45.6 | 32.9 | 10.4 | 6.4 | 2.3 | 1.6 | 0.7 | 0.2 |

| Min/Max Size [mm] | Specific Mass [g/cm3] | Water Absorption s.s.d. [%] | Dosage [%] |

|---|---|---|---|

| <0.25 | 2.40 | 0.20 | 25 |

| 0.25/0.50 | 2.70 | 0.76 | 30 |

| 0.50/1.00 | 2.58 | 0.77 | 25 |

| 1.00/1.50 | 2.63 | 0.93 | 10 |

| 1.50/2.50 | 2.62 | 1.02 | 10 |

| Carbon Filler | SEM Image | Property | |

|---|---|---|---|

| CNT |  | Apparent density | 50–150 kg/m3 |

| Length | 0.1–10 µm | ||

| Specific surface | ~210 m2/g | ||

| NF |  | Density | 1000 kg/m3 |

| Diameter | 150 nm | ||

| Specific surface | 20–30 m2/g | ||

| CB |  | Density | 1800 kg/m3 |

| Particle size | 30 nm | ||

| Specific surface | ~1000 m2/g | ||

| GNP |  | Density | 1800 kg/m3 |

| Diameter | 15 µm | ||

| Specific surface | 100 m2/g | ||

| Composition [g] | NEAT | CB | GNP | CNT | NF |

|---|---|---|---|---|---|

| GGBFS | 1000 | 1000 | 1000 | 1000 | 1000 |

| Activator | 160 | 160 | 160 | 160 | 160 |

| Sand s.s.d. | 3000 | 3000 | 3000 | 3000 | 3000 |

| Water | 650 | 650 | 650 | 650 | 650 |

| Carbon black | 10 | ||||

| Graphene nanoplatelets | 10 | ||||

| Carbon nanotubes | 10 | ||||

| Carbon nanofibers | 10 |

| NEAT | CB | GNP | CNT | NF | |

|---|---|---|---|---|---|

| Workability [mm] | 240 | 210 | 220 | 200 | 190 |

| Specific mass at fresh state [kg/m3] | 2200 | 2095 | 1925 | 1770 | 1770 |

| 28-day specific mass [kg/m3] | 1980 | 1920 | 1840 | 1690 | 1670 |

| 1-day compressive strength [MPa] | 7.1 | 9.3 | 7.6 | 4.8 | 6.1 |

| 7-day compressive strength [MPa] | 14.8 | 12.4 | 11.3 | 9.5 | 9.8 |

| 28-day compressive strength [MPa] | 19.0 | 17.4 | 16.9 | 15.3 | 16.2 |

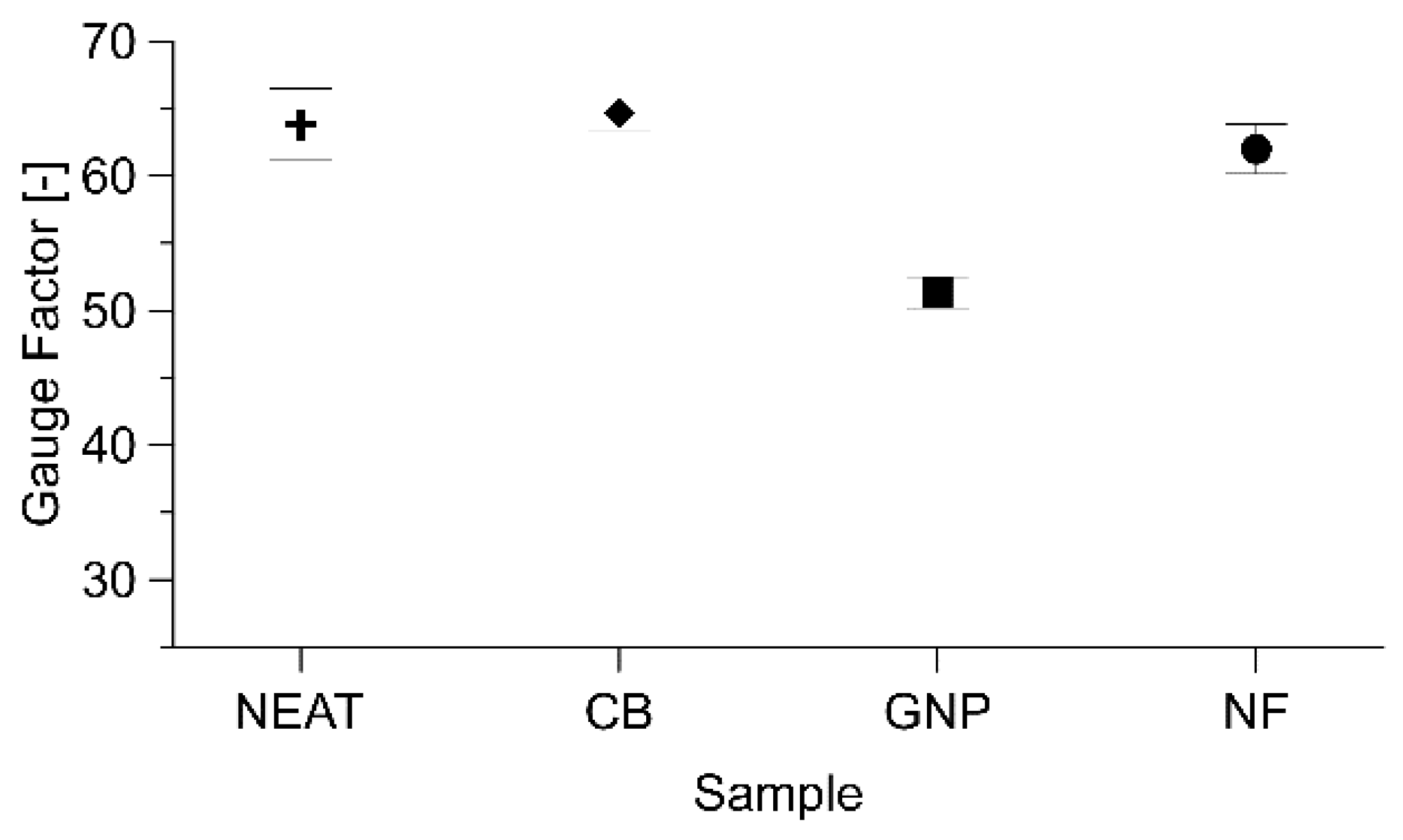

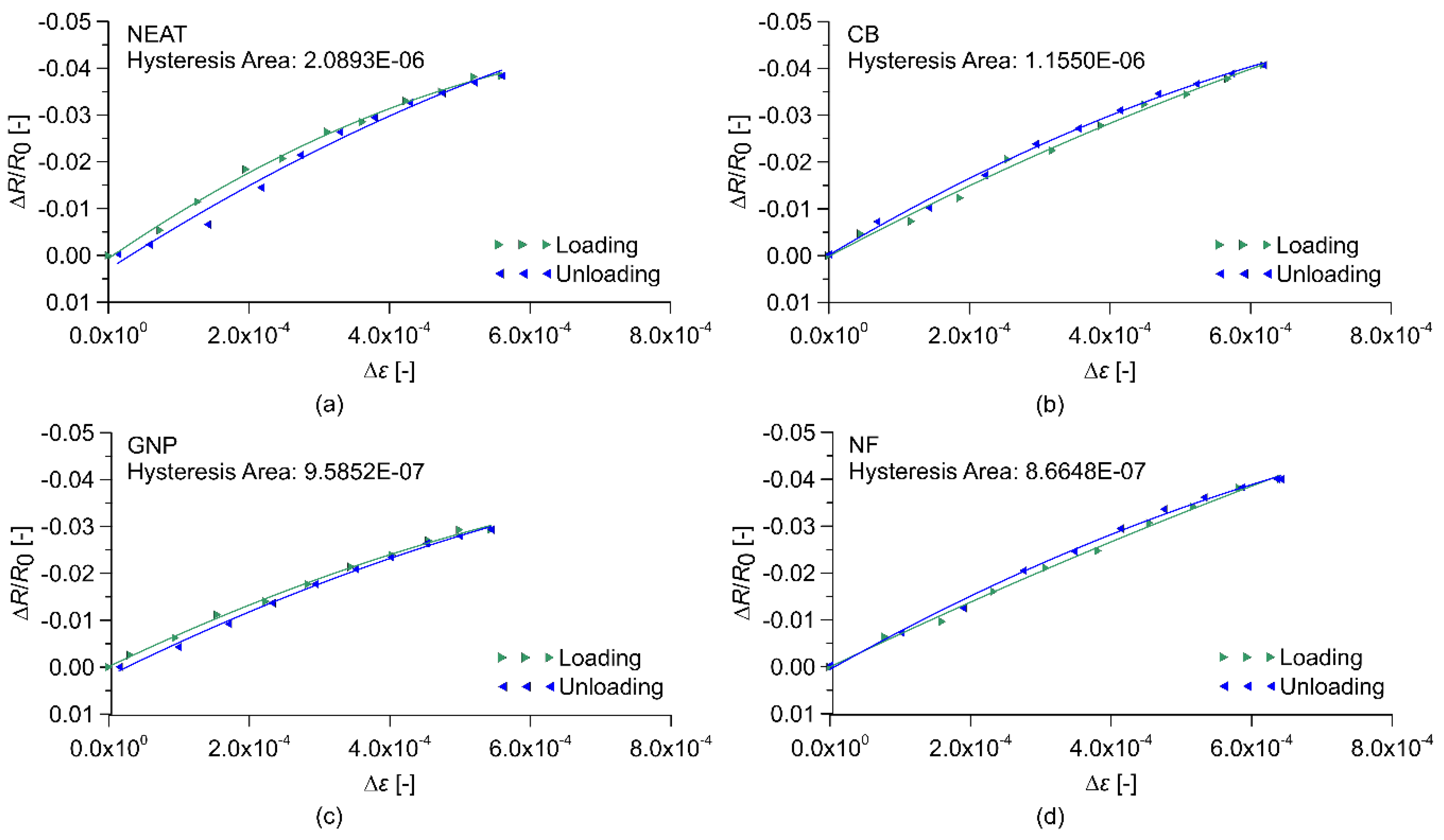

| Sample | R0 [Ω] | GF | S [Ω] | R2 [-] |

|---|---|---|---|---|

| NEAT | 3.02 × 105 | 64 | 1.93 × 107 | 0.8577 |

| CB | 2.21 × 105 | 65 | 1.43 × 107 | 0.9852 |

| GNP | 2.55 × 105 | 39 | 0.98 × 107 | 0.9636 |

| NF | 2.36 × 105 | 62 | 1.46 × 107 | 0.9825 |

| Sample | R2 [-] |

|---|---|

| NEAT | 0.8577 |

| CB | 0.9852 |

| GNP | 0.9636 |

| NF | 0.9825 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Alessandro, A.; Coffetti, D.; Crotti, E.; Coppola, L.; Meoni, A.; Ubertini, F. Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions. Sustainability 2020, 12, 9916. https://doi.org/10.3390/su12239916

D’Alessandro A, Coffetti D, Crotti E, Coppola L, Meoni A, Ubertini F. Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions. Sustainability. 2020; 12(23):9916. https://doi.org/10.3390/su12239916

Chicago/Turabian StyleD’Alessandro, Antonella, Denny Coffetti, Elena Crotti, Luigi Coppola, Andrea Meoni, and Filippo Ubertini. 2020. "Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions" Sustainability 12, no. 23: 9916. https://doi.org/10.3390/su12239916

APA StyleD’Alessandro, A., Coffetti, D., Crotti, E., Coppola, L., Meoni, A., & Ubertini, F. (2020). Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions. Sustainability, 12(23), 9916. https://doi.org/10.3390/su12239916