Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents

Abstract

:1. Introduction

- the warm bituminous mixtures or half-warm bituminous mixtures that are produced with different processes at a reduced temperature compared with classical hot mixtures [6];

2. Experimental Procedures and Materials

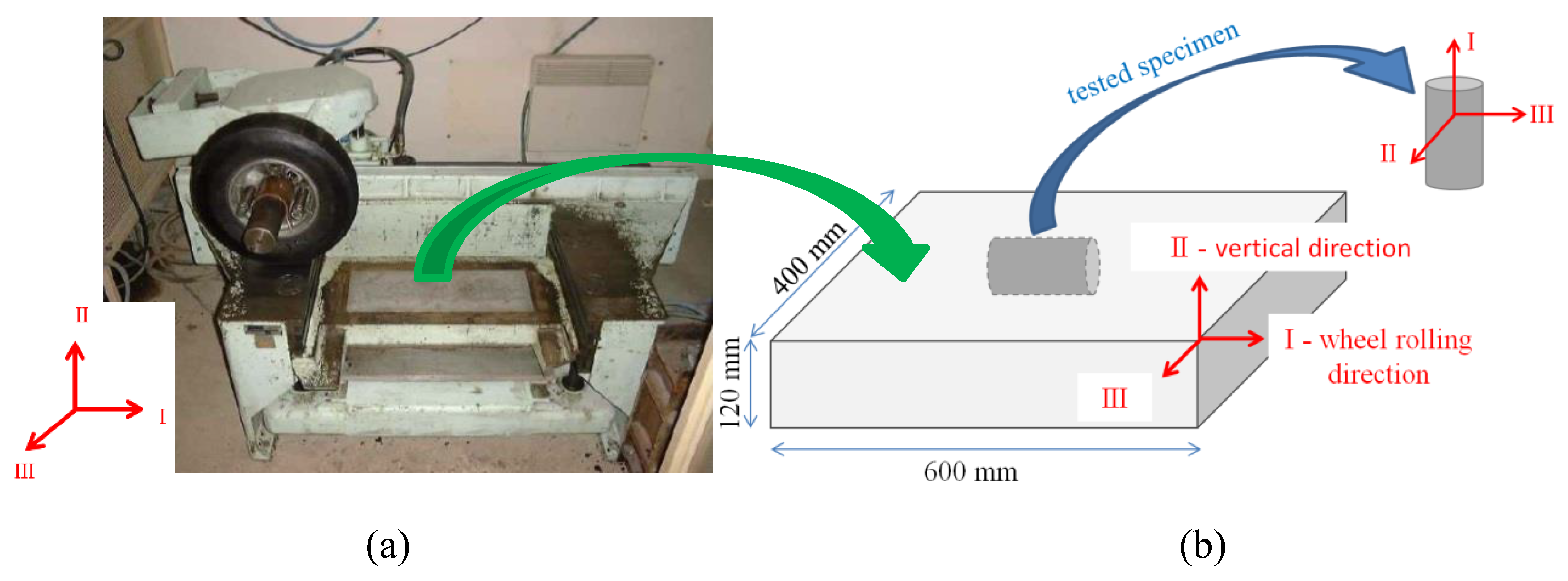

2.1. Test Equipment

2.2. Test Procedures

2.2.1. Fatigue Test

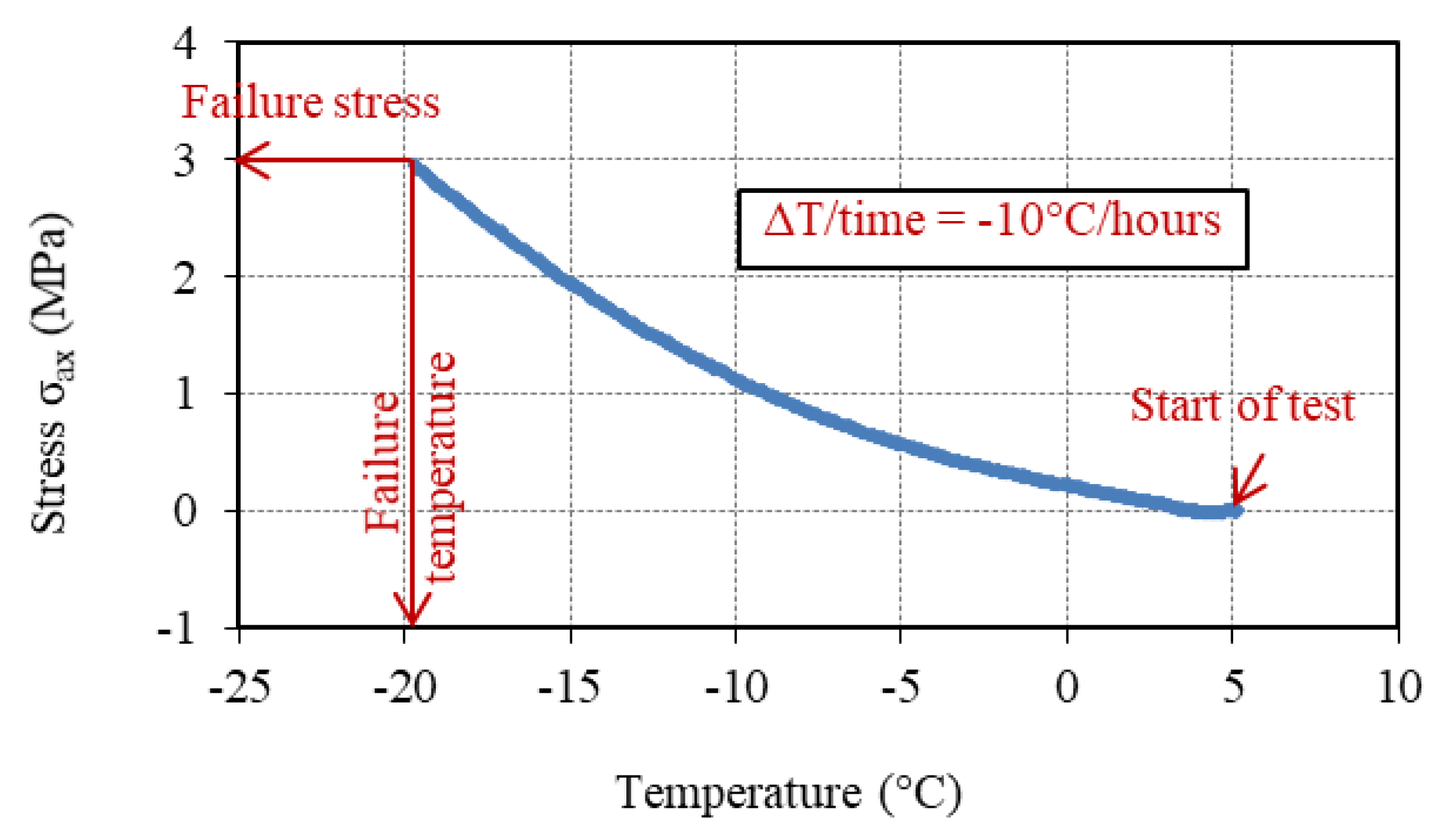

2.2.2. TSRST

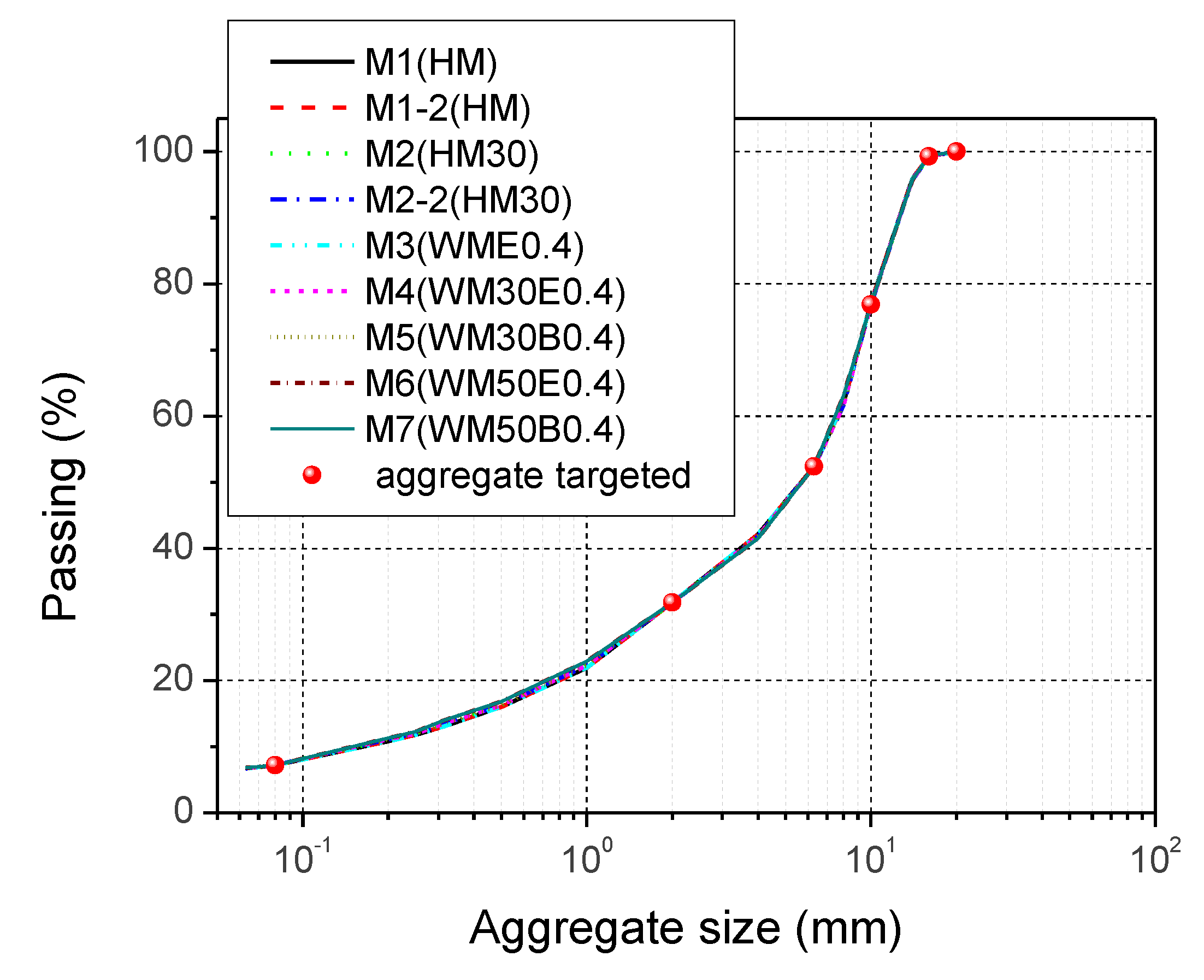

2.3. Tested Materials

3. Fatigue Test Results and Analysis

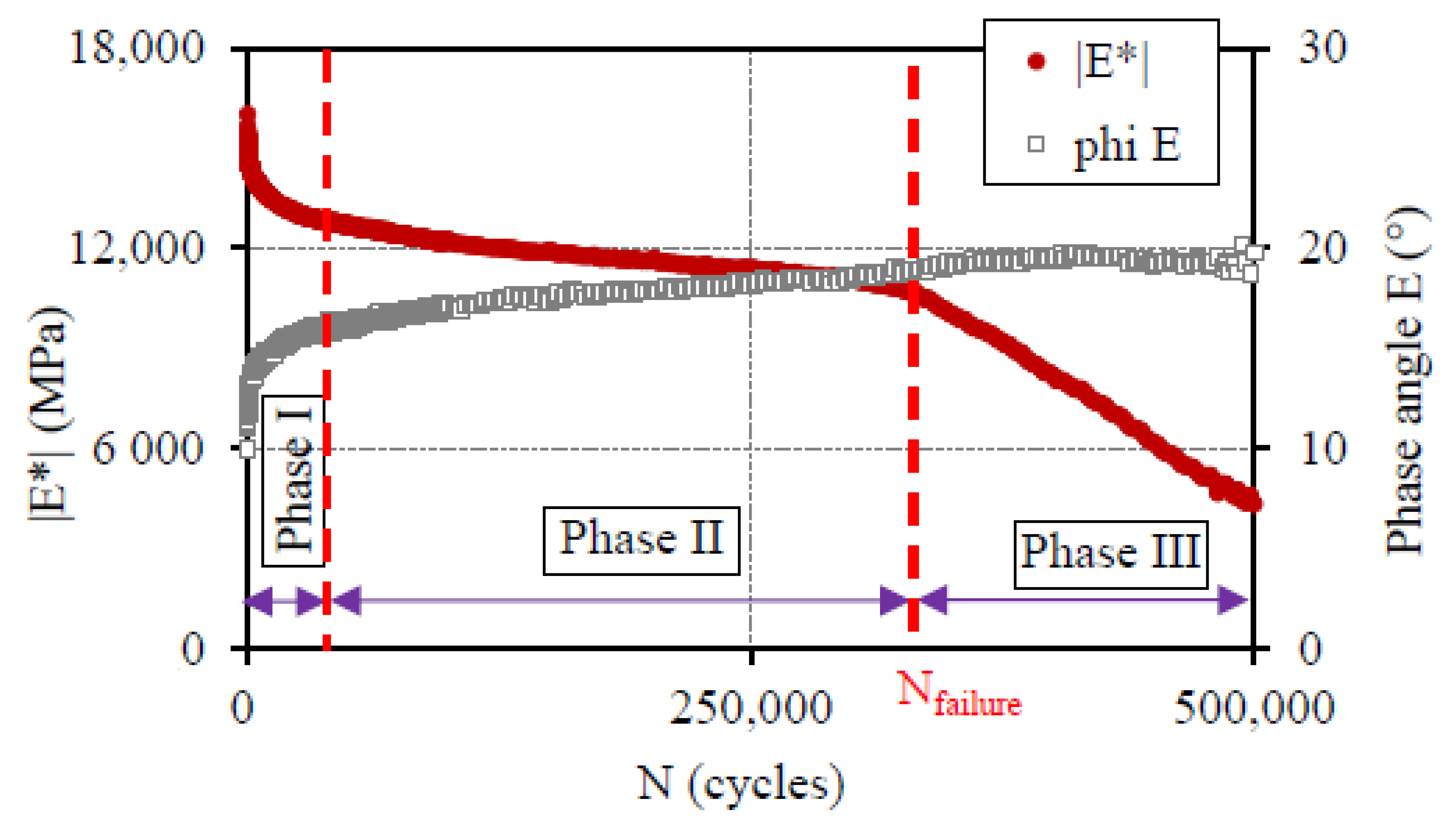

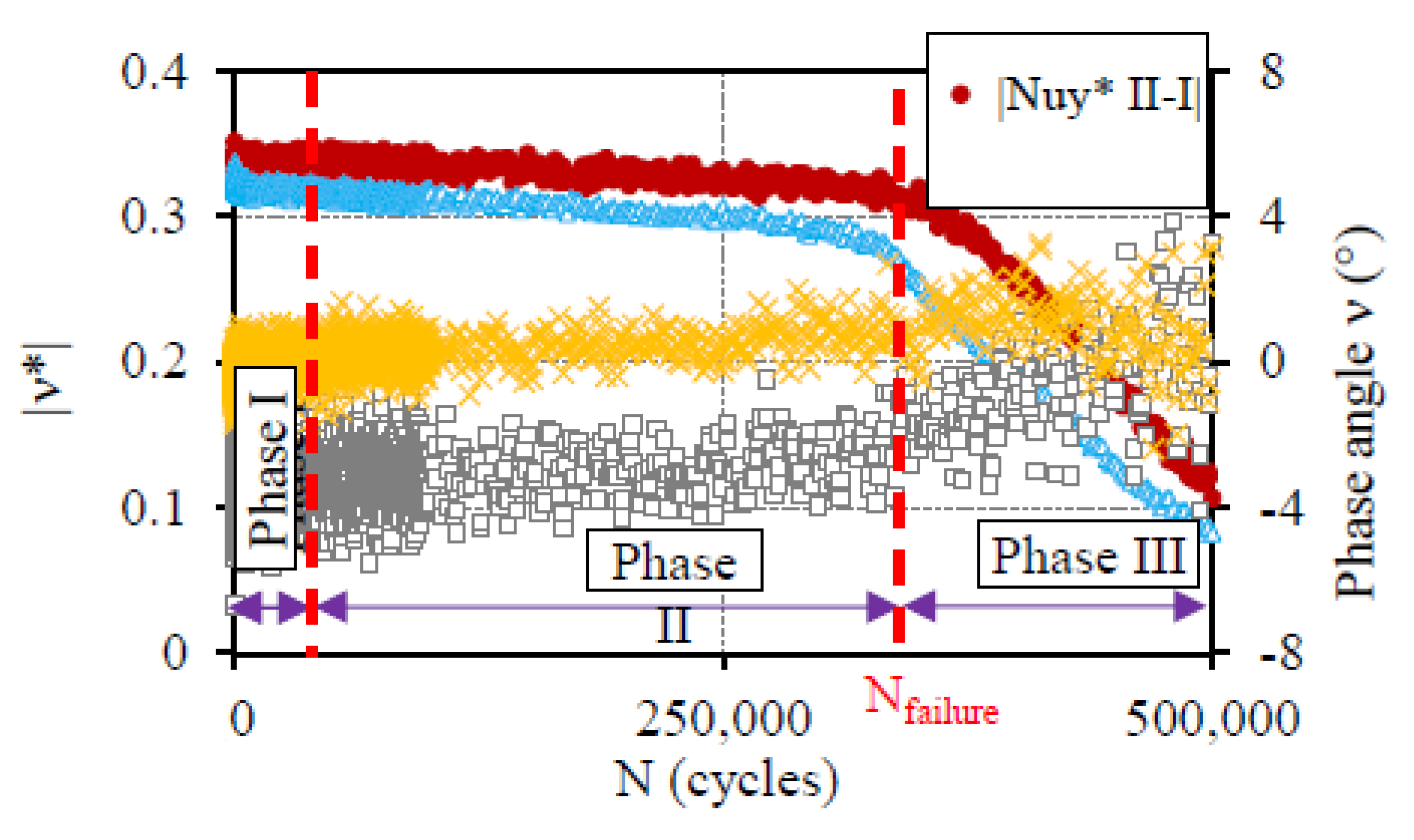

3.1. Example of Fatigue Test Results

3.2. Fatigue Criteria

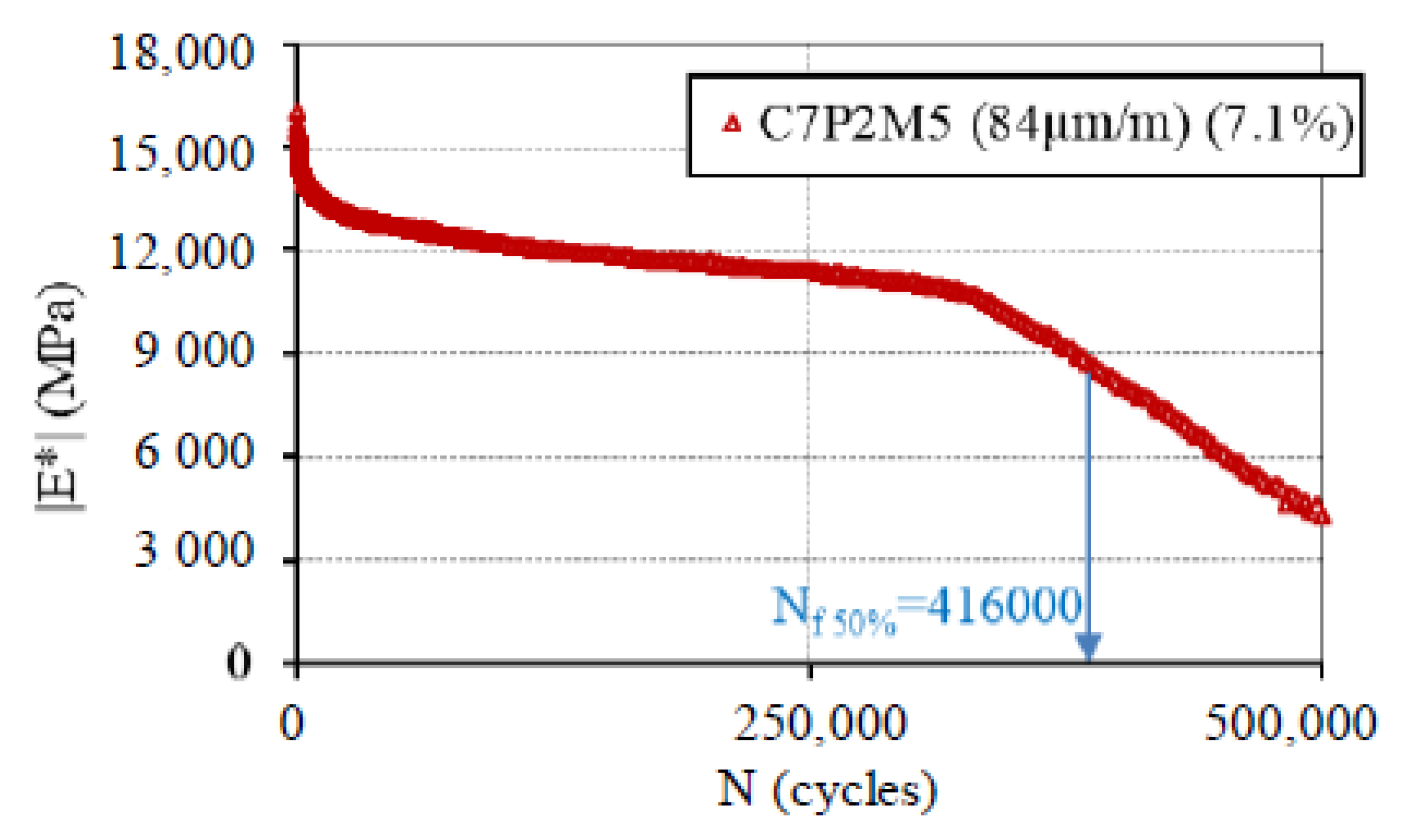

- Criterion based on modulus decrease: The classical fatigue criterion, used in the French pavement design method, is based on an arbitrary relative decrease in the complex modulus of 50%. The fatigue life (Nf50%) is then defined as the number of cycles when the modulus reaches 50% of its initial value (Figure 6).

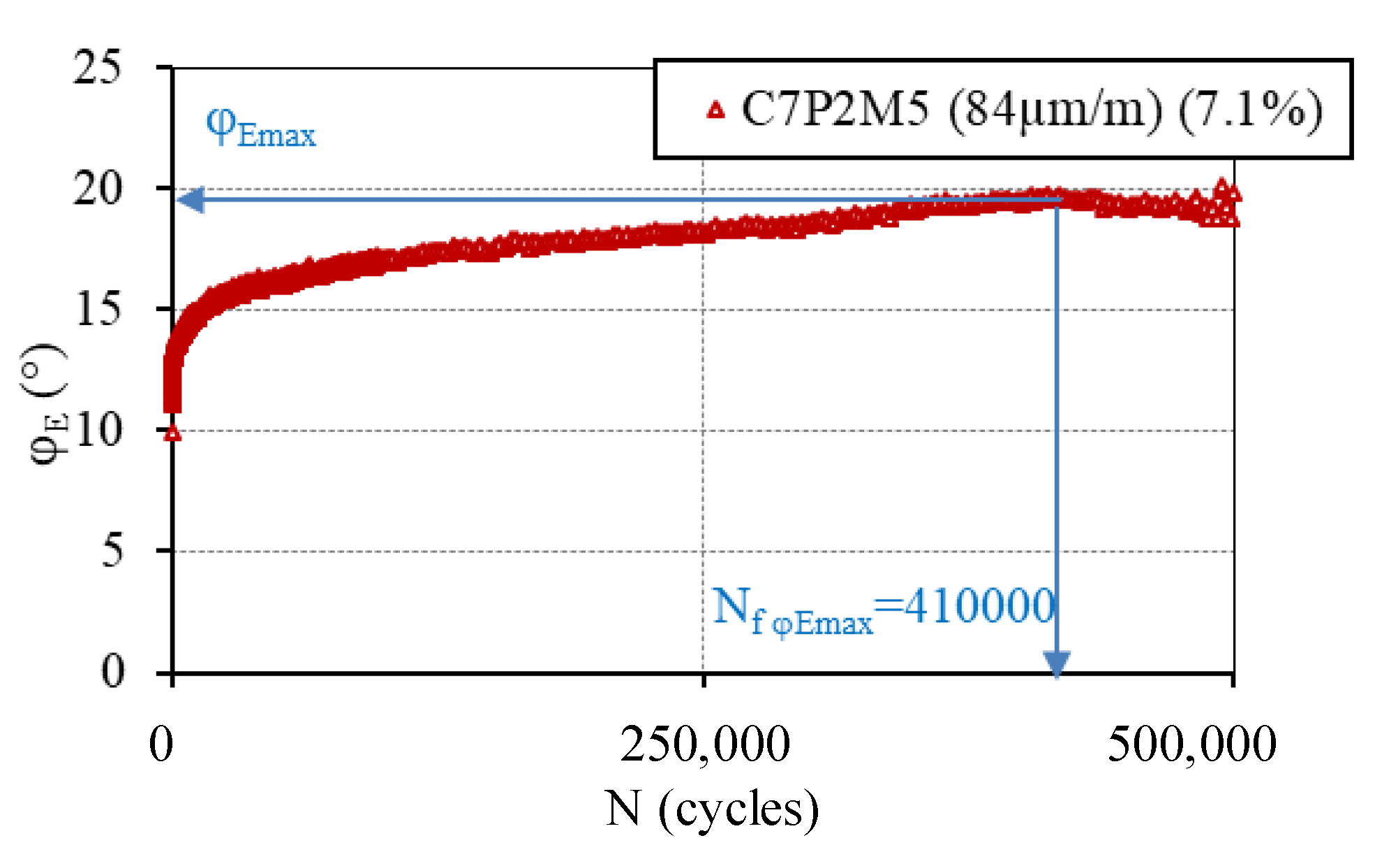

- Criterion based on the phase angle of the complex modulus evolution: the fatigue life (Nfmaxφ) is defined as the number of cycles corresponding to the highest value of the phase angle (Figure 7).

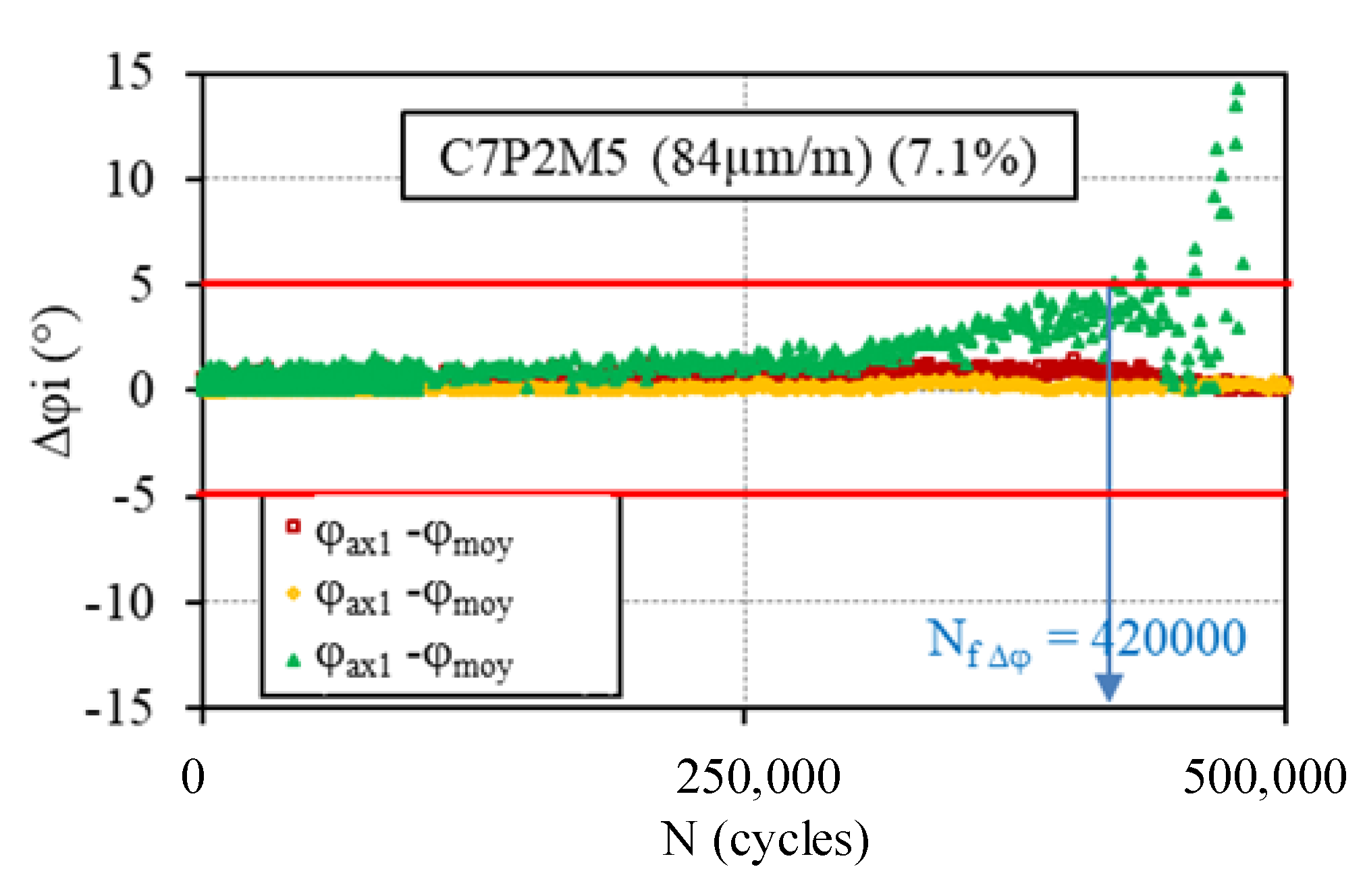

- Criterion obtained from the analysis of the specimen homogeneity from the phase angles values provided by each of the three axial extensometers φεiax: NfΔφ is defined as the number of cycles at which the value Δφi = φεiax − φE reaches 5° for one of the extensometers (where φεiax is the phase angle between the signal from extensometer i and the axial stress, with i = 1, 2 or 3) (Figure 8).

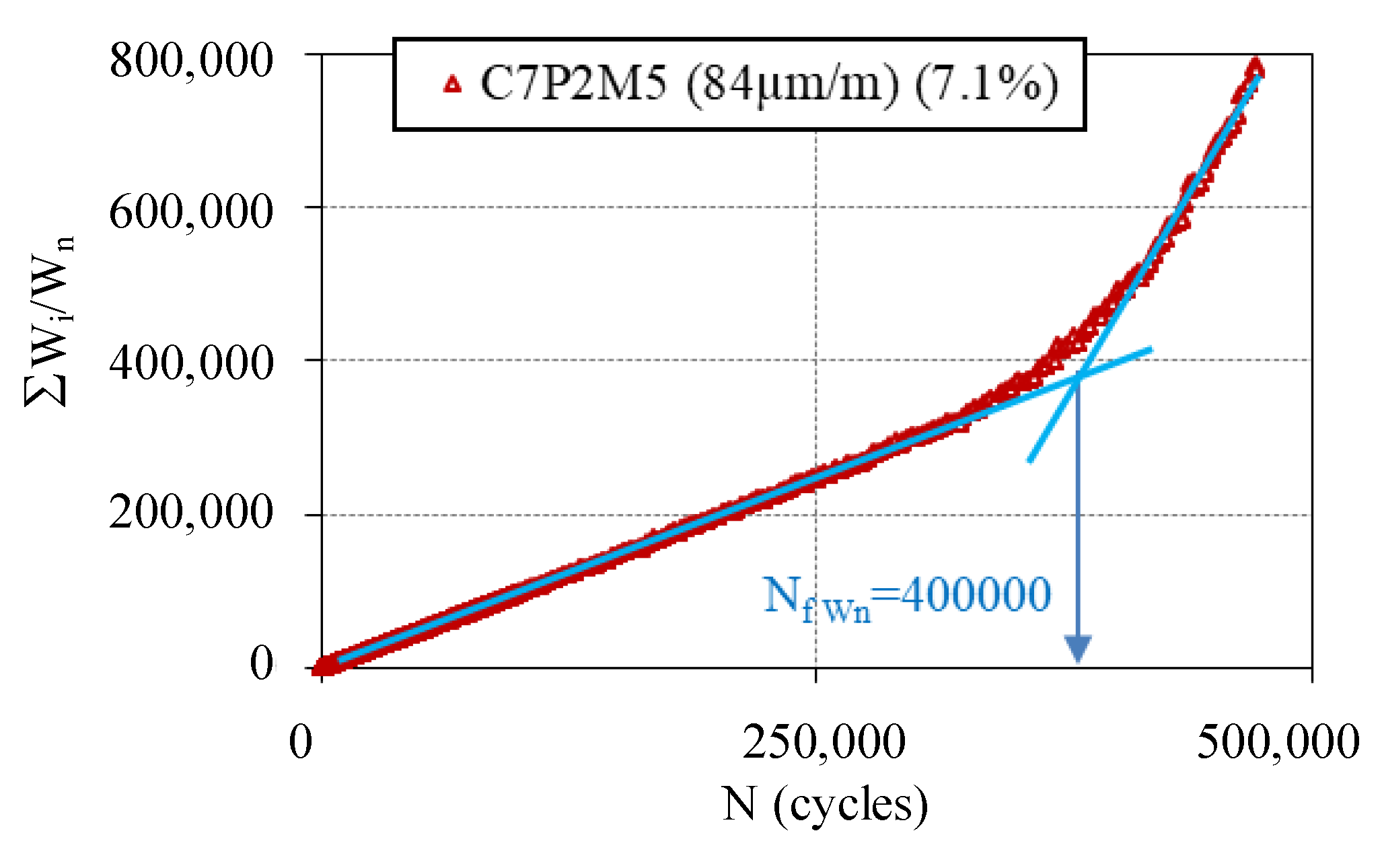

- Viscous dissipated energy criterion: the fatigue life (NfWN) is obtained from the analyses of the evolution of the dissipated energy ratio, DER, given by Equation (9).

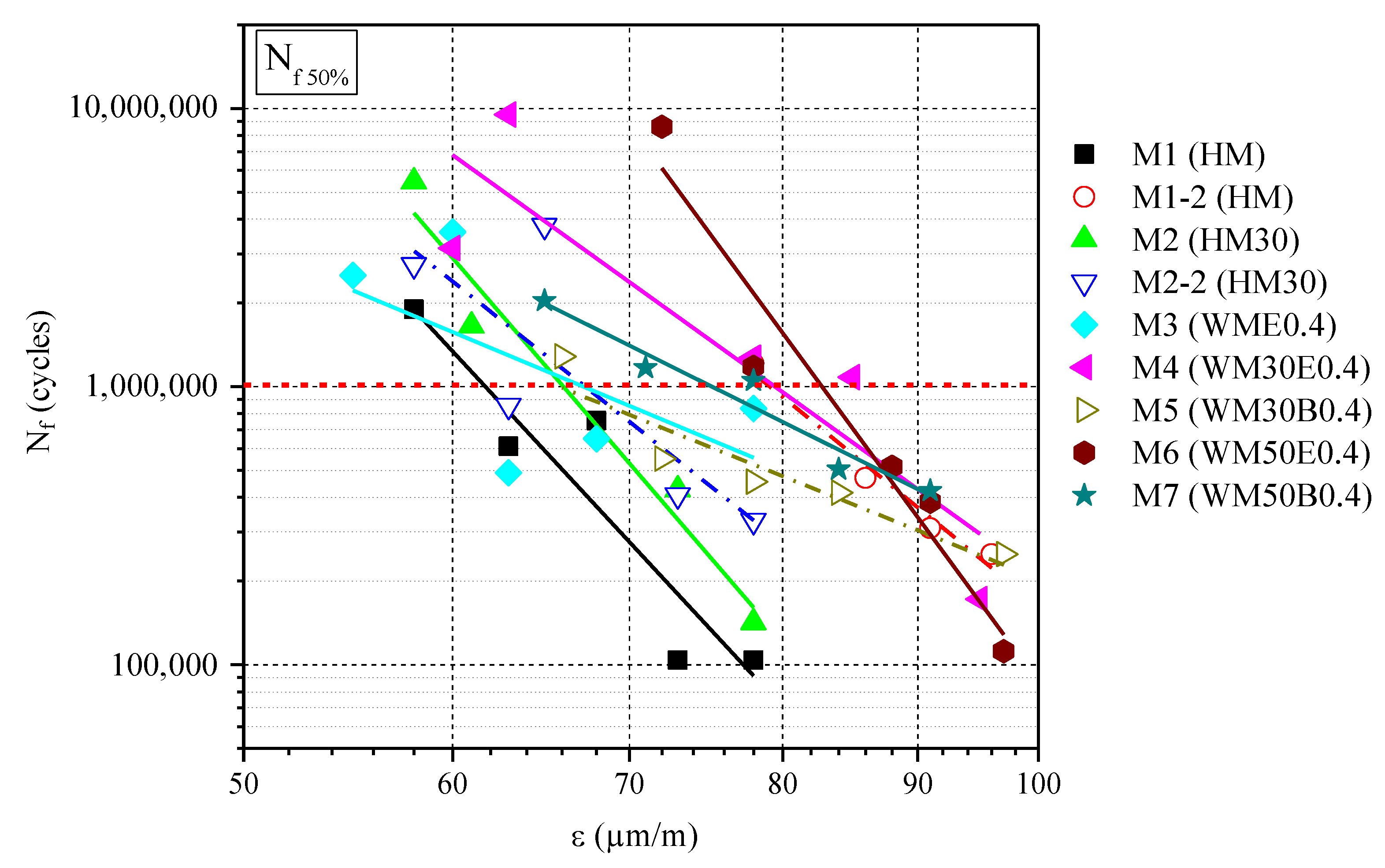

3.3. Wöhler Curves for Tested Materials

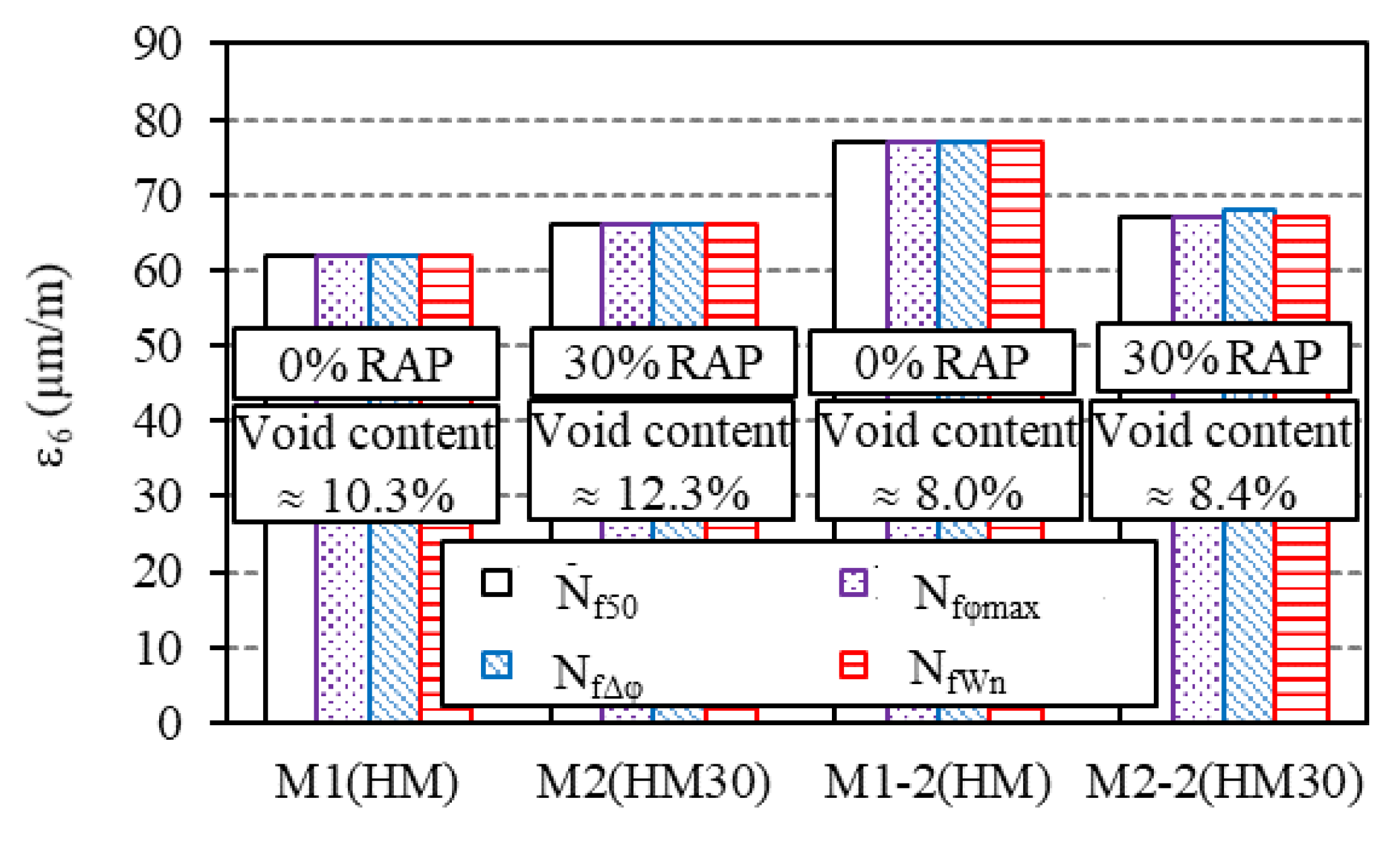

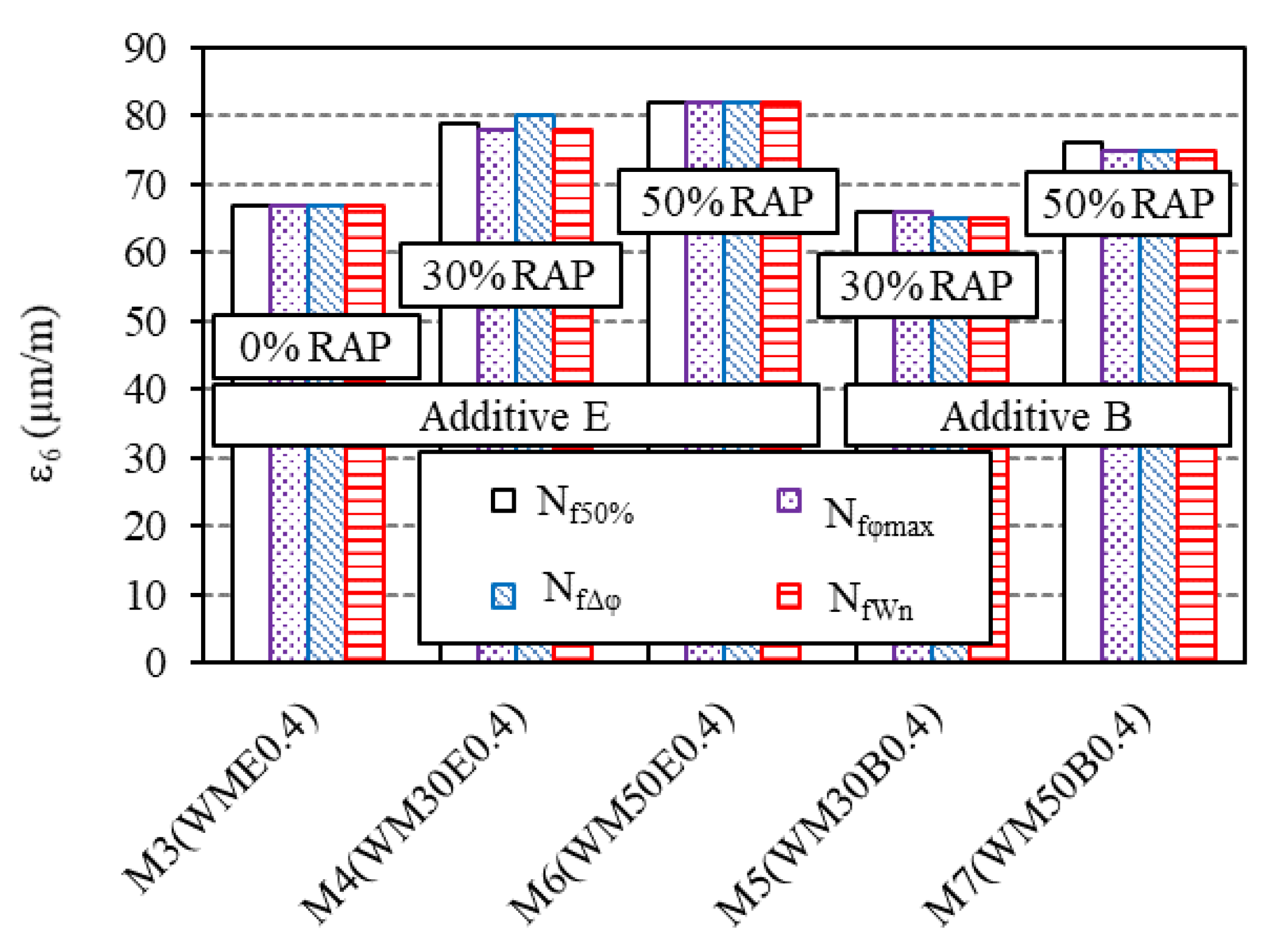

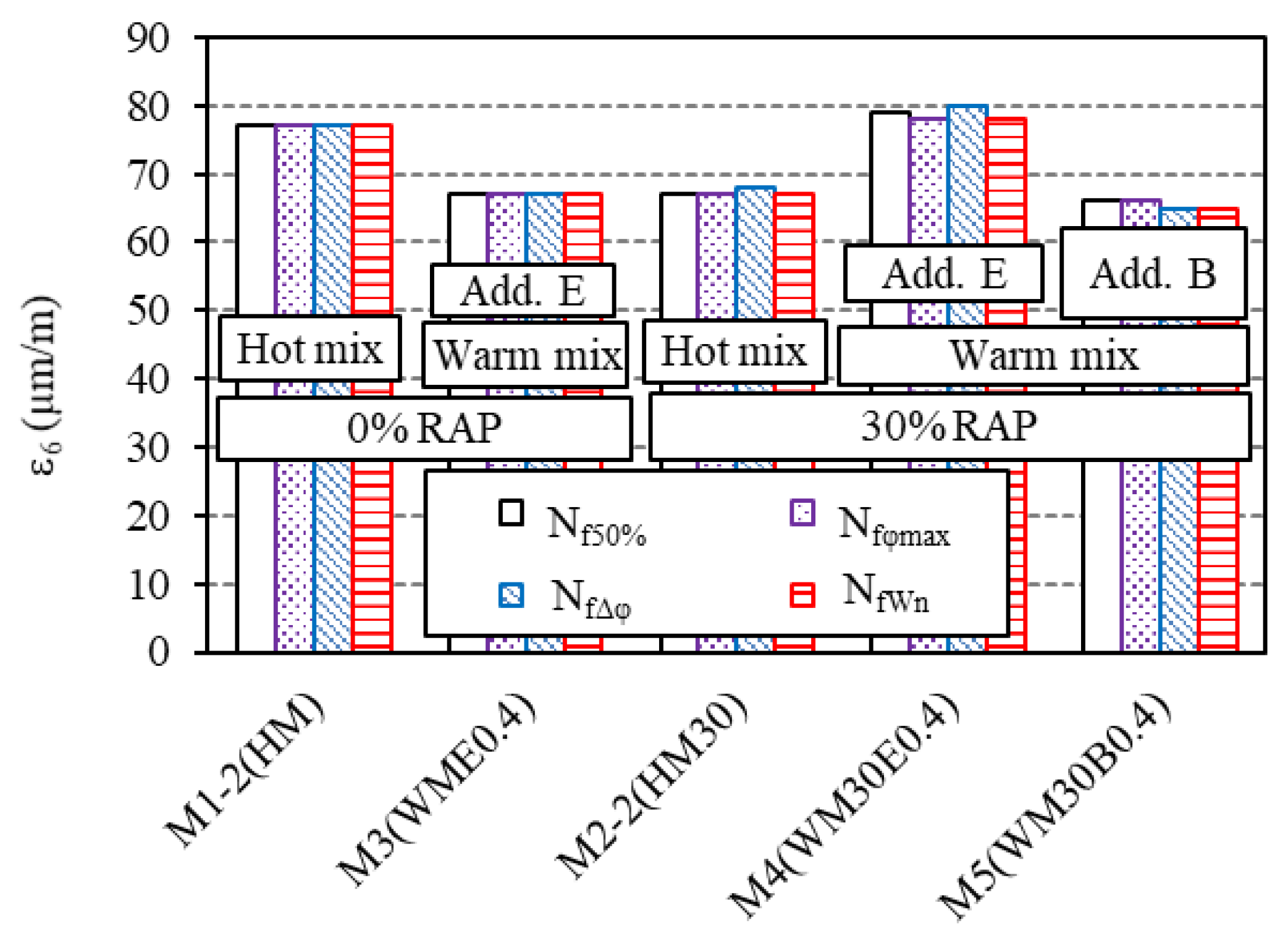

3.4. Influence of Mix Design and Void Content on ε6

3.4.1. Influence of Voids Content

3.4.2. Influence of RAP Content

3.4.3. Influence of the Type of Additive

3.4.4. Influence of Manufacturing Process

4. Thermal Stress Restrained Specimen Test (TSRST)

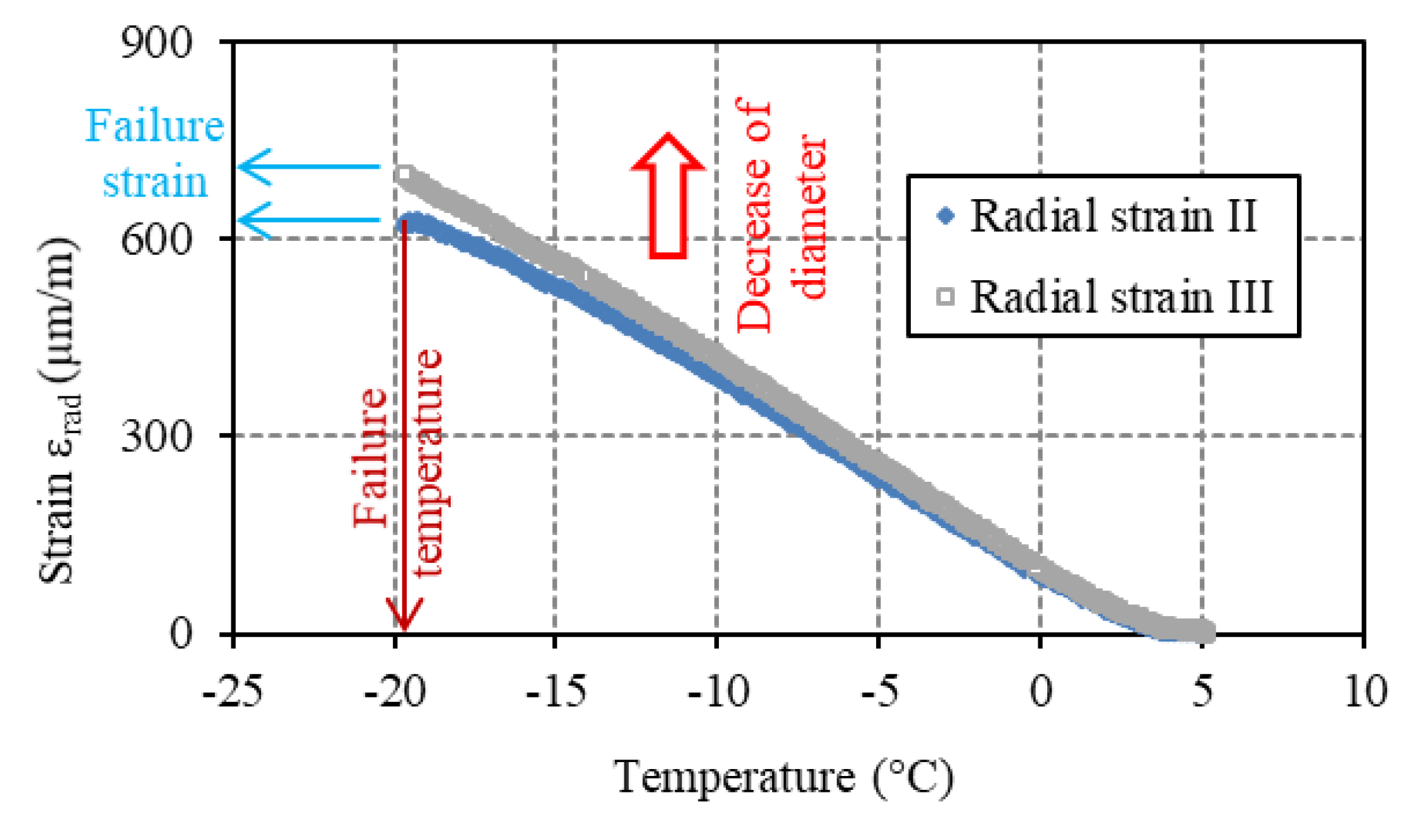

4.1. Example of TSRST Results

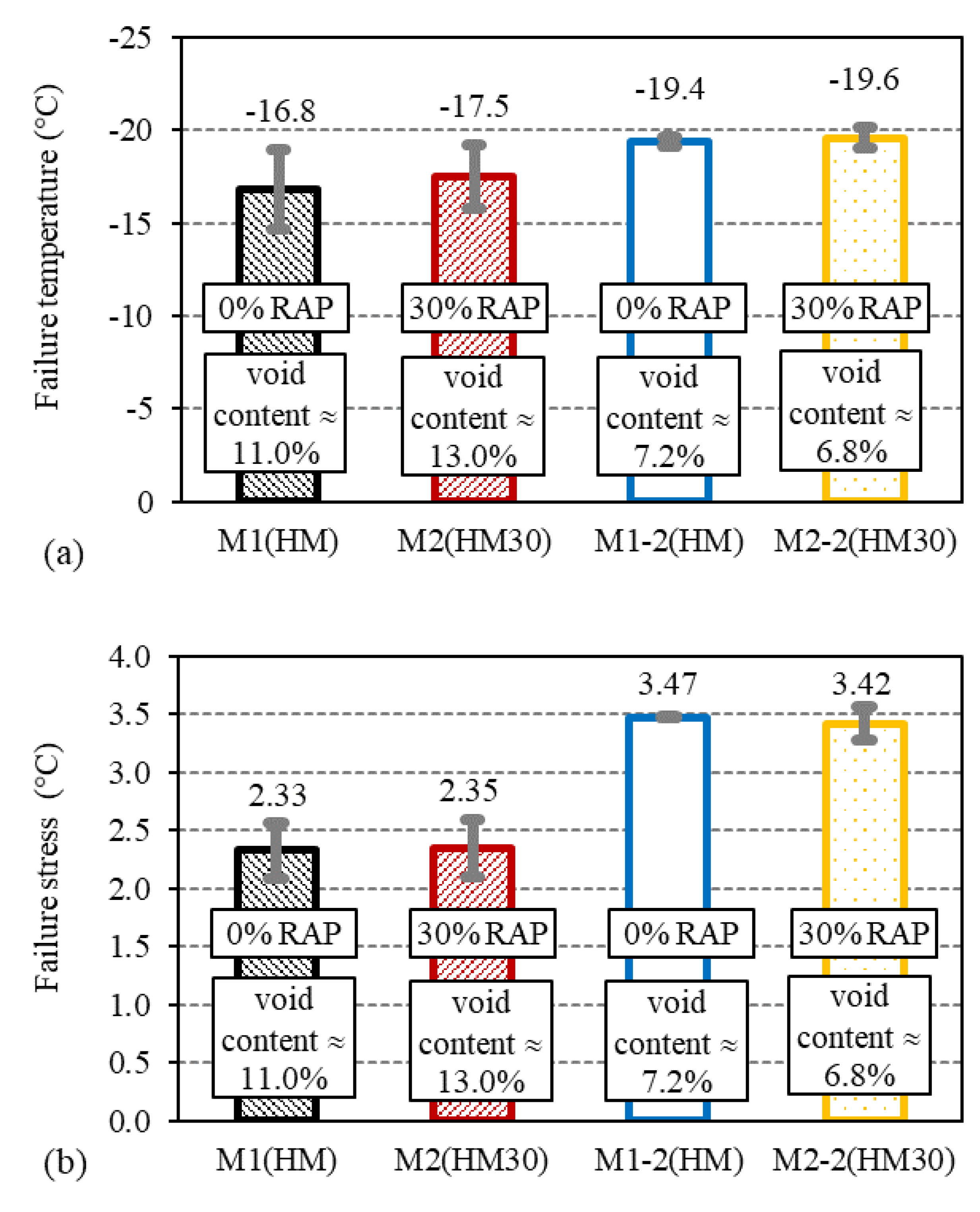

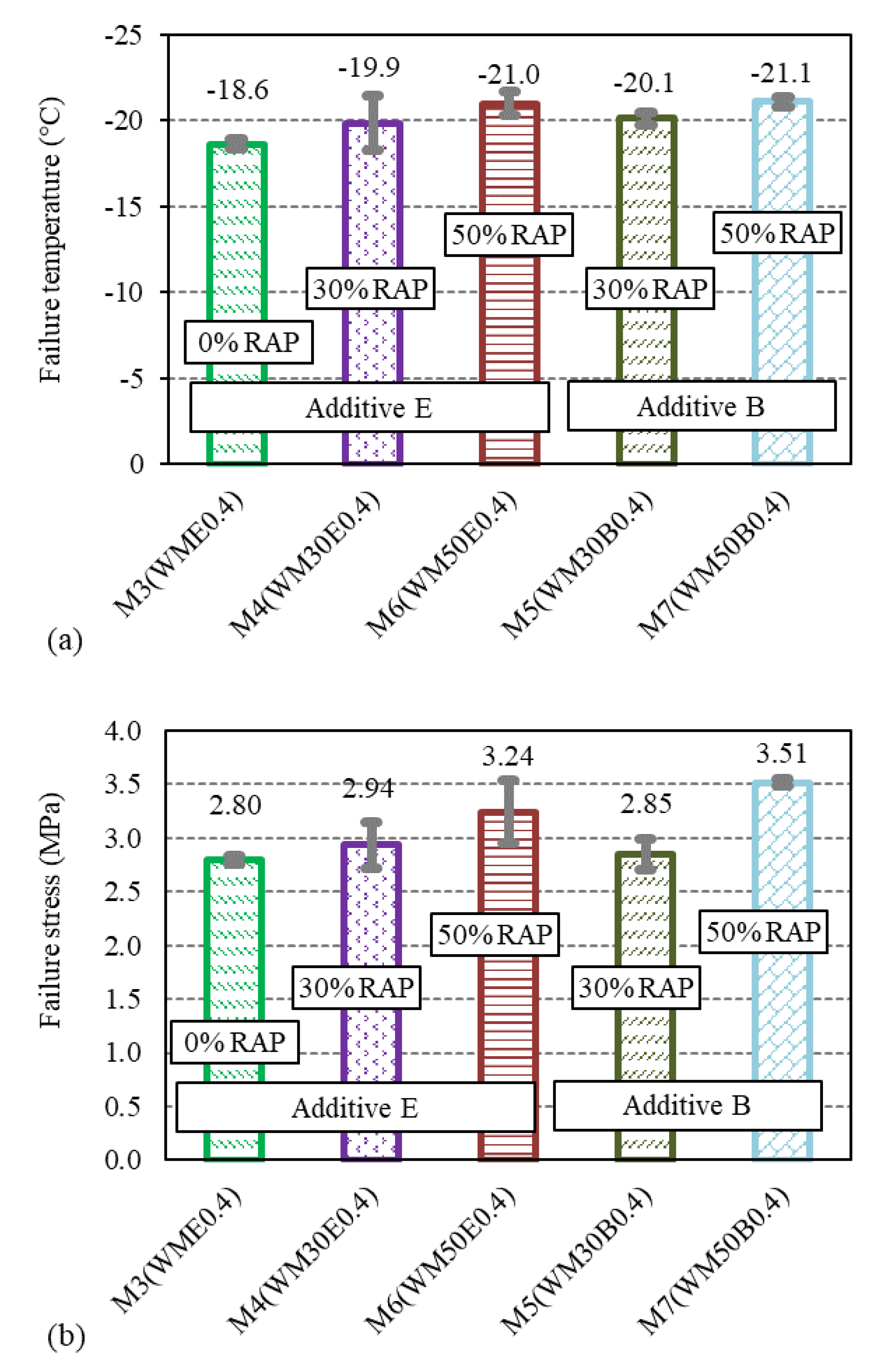

4.2. Results of the Tested Materials

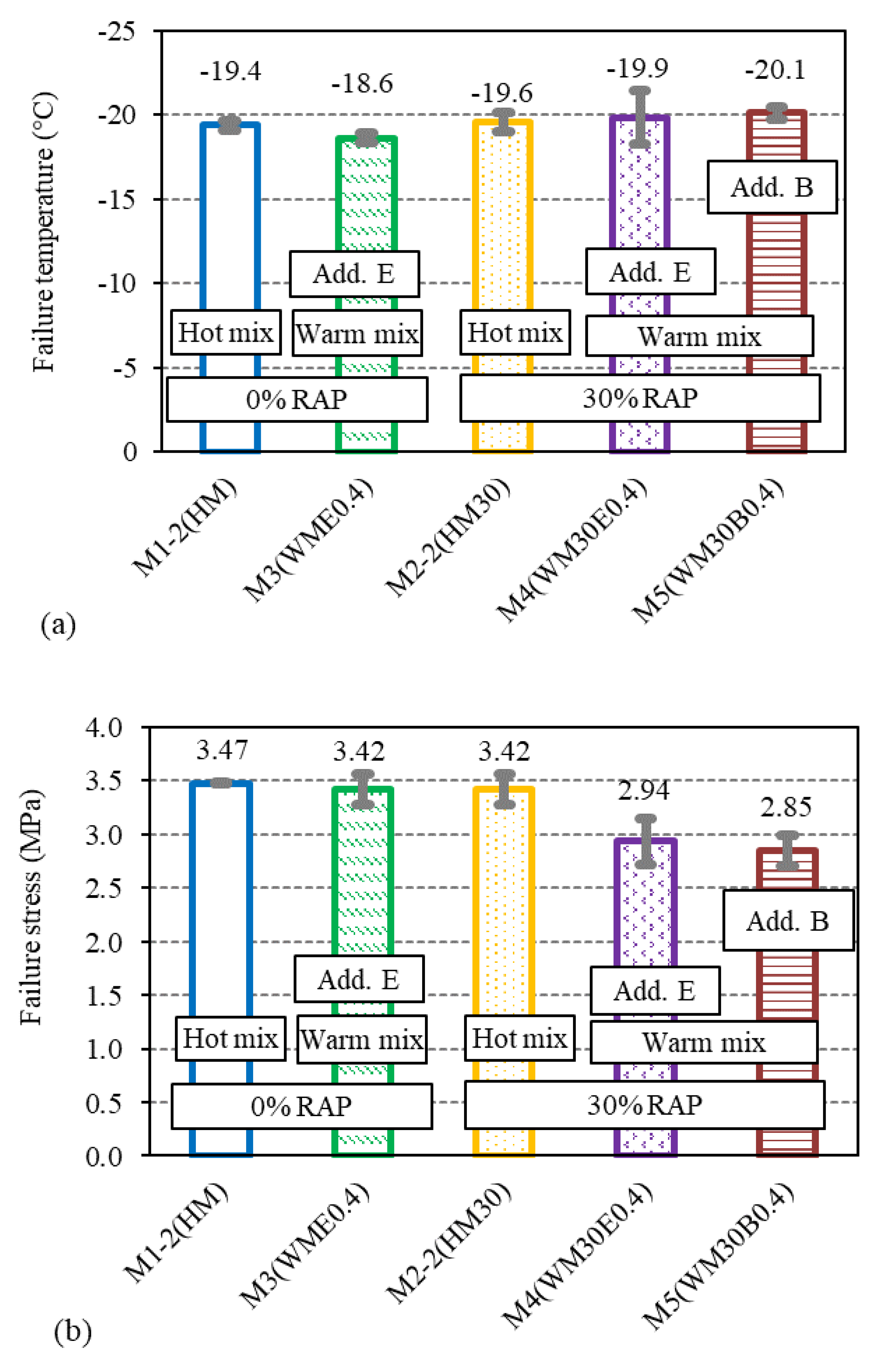

4.3. Analysis of Stress and Temperature Results at Failure

4.3.1. Influence of Void Content

4.3.2. Influence of RAP Content

4.3.3. Influence of Type of Additive

4.3.4. Influence of Manufacturing Process

5. Conclusions

- The performed tests were improved thanks to measurement of the radial strain in two directions. It gives information on the multi-axial behaviour of the materials, which needs to be further investigated to better understand the bituminous mixtures’ behaviour This is absolutely essential to improve the modelling and design of road structures.

- Four criteria were applied to determine the fatigue life of the tested materials and gave similar results.

- The repeatability of the TSRST was good, based on the temperature failure, stress failure and radial strain failure values.

- A decrease in the voids content improves the fatigue and TSRS tests’ performance.

- The influence of the manufacturing process (hot or warm), RAP content and type of used additive for the warm process have been evaluated for both types of test. Overall, warm bituminous mixtures with RAP exhibit comparable performances with hot bituminous mixtures and even better performances, in some cases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Fatigue Test | TSRST | ||||

|---|---|---|---|---|---|

| Material | Specimen | Strain Amplitude (Average) µm/m | %Voids | Specimen | %Voids |

| M1 (HM) | C8P1M1 | 78 | 9.9 | B1P1M1 | 11.7 |

| C1P1M1 | 73 | 11.2 | B2P1M1 | 11.2 | |

| C6P1M1 | 68 | 10 | B5P1M1 | 11.3 | |

| C5P1M1 | 63 | 10.8 | |||

| C7P1M1 | 58 | 9.7 | |||

| M1-2 (HM) | C1P2M1-2 | 96 | 7.2 | B1P2M1-2 | 7.2 |

| C4P2M1-2 | 91 | 8.3 | B4P2M1-2 | 7 | |

| C2P2M1-2 | 86 | 7.7 | B5P2M1-2 | 7.3 | |

| C5P1M1-2 | 78 | 7.5 | |||

| M2 (HM30) | C3P1M2 | 78 | 12.4 | B1P2M2 | 12.9 |

| C5P1M2 | 73 | 11.8 | B2P2M2 | 13 | |

| C6P2M2 | 61 | 12.4 | B5P2M2 | 13 | |

| C7P2M2 | 58 | 12.6 | |||

| M2-2 (HM30) | C4P2M2-2 | 78 | 8.4 | B2P2M2-2 | 6.4 |

| C5P1M2-2 | 73 | 8.4 | B3P2M2-2 | 6.9 | |

| C1P1M2-2 | 65 | 8.4 | B4P2M2-2 | 7.2 | |

| C1P2M2-2 | 63 | 8.3 | |||

| C8P2M2-2 | 58 | 8.3 | |||

| M3 (WME0.4) | C3P2M3 | 78 | 7.8 | B2P2M3 | 7.2 |

| C5P2M3 | 68 | 7.9 | B3P2M3 | 7.1 | |

| C1P2M3 | 63 | 8.3 | B4P2M3 | 7.6 | |

| C6P2M3 | 60 | 6.7 | |||

| C6P1M3 | 55 | 7.8 | |||

| M4 (WM30E0.4) | C4P1M4 | 95 | 7.9 | B2P2M4 | 7.5 |

| C5P2M4 | 85 | 7.2 | B3P2M4 | 7.3 | |

| C8P2M4 | 78 | 7.5 | B4P2M4 | 7.6 | |

| C7P2M4 | 63 | 7.1 | |||

| C6P2M4 | 60 | 7.1 | |||

| M5 (WM30B0.4) | C6P1M5 | 97 | 7.2 | B2P2M5 | 7.1 |

| C7P2M5 | 84 | 7.1 | B3P3M5 | 7.5 | |

| C8P2M5 | 78 | 7.6 | B4P3M5 | 7.7 | |

| C1P2M5 | 72 | 8.3 | |||

| C6P2M5 | 66 | 7 | |||

| M6 (WM50E0.4) | C3P2M6 | 97 | 7.1 | B3P2M6 | 6.9 |

| C5P1M6 | 91 | 7 | B4P2M6 | 7 | |

| C8P2M6 | 88 | 6.8 | B5P2M6 | 7.2 | |

| C3P1M6 | 78 | 6.7 | |||

| C6P2M6 | 72 | 6.7 | |||

| M7 (WM50B0.4) | C8P1M7 | 91 | 7.1 | B1P2M7 | 7.4 |

| C3P2M7 | 84 | 7.2 | B3P2M7 | 7 | |

| C8P2M7 | 78 | 6.8 | B4P2M7 | 7.3 | |

| C5P2M7 | 71 | 7.1 | |||

| C6P2M7 | 65 | 6.7 | |||

| Material | Nf 50% | Nf φ max | Nf Δφ | Nf Wn | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ε6 (µm/m) | 1/b | R2 | ε6 (µm/m) | 1/b | R2 | ε6 (µm/m) | 1/b | R2 | ε6 | 1/b | R2 | |

| M1(HM) | 62 | 10.2 | 0.86 | 62 | 10.2 | 0.86 | 62 | 10.1 | 0.87 | 62 | 9.9 | 0.85 |

| M1-2(HM) | 77 | 7.8 | 0.97 | 77 | 6.9 | 0.97 | 77 | 7.3 | 0.89 | 77 | 7.5 | 0.98 |

| M2(HM30) | 66 | 11.0 | 0.96 | 66 | 11.0 | 0.96 | 66 | 11.0 | 0.96 | 66 | 10.4 | 0.97 |

| M2-2(HM30) | 67 | 7.5 | 0.66 | 67 | 7.7 | 0.66 | 68 | 7.5 | 0.47 | 67 | 7.7 | 0.65 |

| M3(WME0.4) | 67 | 4.0 | 0.36 | 67 | 3.0 | 0.15 | 67 | 4.0 | 0.35 | 67 | 4.0 | 0.35 |

| M4(WM30E0.4) | 79 | 6.8 | 0.81 | 78 | 7.4 | 0.82 | 80 | 6.6 | 0.80 | 78 | 7.1 | 0.80 |

| M5(WM30B0.4) | 66 | 3.8 | 0.88 | 66 | 3.8 | 0.86 | 65 | 3.5 | 0.86 | 65 | 3.7 | 0.89 |

| M6(WM50E0.4) | 82 | 13.0 | 0.94 | 82 | 13.0 | 0.94 | 82 | 12.9 | 0.93 | 82 | 12.8 | 0.94 |

| M7(WM50B0.4) | 76 | 4.7 | 0.95 | 75 | 4.7 | 0.95 | 75 | 4.5 | 0.98 | 75 | 4.9 | 0.92 |

| Material | Specimen | Voids (%) | Failure Radial Strain in Direction II (µm/m) | Failure Radial Strain in Direction III (µm/m) | ||||

|---|---|---|---|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | |||||

| M1 (HM) | B1P1M1 | 11.7 | 600 | 637 | 35 (5.5%) | - | - | - |

| B2P1M1 | 11.2 | 670 | - | |||||

| B5P1M1 | 10.1 | 640 | - | |||||

| M1-2 (HM) | 570 | 597 | 6 (1.0%) | 700 | 700 | 10 (1.4%) | ||

| B1P2M1-2 | 7.2 | 600 | 690 | |||||

| B4P2M1-2 | 7.0 | 640 | 710 | |||||

| M2 (HM30) | B5P2M1-2 | 7.3 | 590 | 603 | 35 (5.8%) | - | - | - |

| 600 | - | |||||||

| B1P2M2 | 12.9 | 600 | - | |||||

| M2-2 (HM30) | B2P2M2 | 13.0 | 710 | 703 | 6 (0.8%) | - | 795 | 7 (0.9%) |

| B5P2M2 | 13.0 | 700 | 790 | |||||

| B2P2M2-2 | 6.4 | 700 | 800 | |||||

| M3 (WME0.4) | B3P2M2-2 | 6.9 | 580 | 603 | 21 (3.5%) | 660 | 730 | 66 (9.0%) |

| B4P2M2-2 | 7.2 | 620 | 740 | |||||

| B2P2M3 | 7.2 | 610 | 790 | |||||

| M4 (WM30E0.4) | B3P2M3 | 7.1 | 730 | 693 | 35 (5.1%) | 700 | 663 | 32 (4.8%) |

| B4P2M3 | 7.6 | 660 | 650 | |||||

| B2P2M4 | 7.3 | 690 | 640 | |||||

| M5 (WM30B0.4) | B3P2M4 | 7.5 | 630 | 663 | 29 (4.4%) | 700 | 710 | 17 (2.4%) |

| B4P2M4 | 7.6 | 680 | 700 | |||||

| B2P2M5 | 7.1 | 680 | 730 | |||||

| M6 (WM50E0.4) | B3P3M5 | 7.5 | 660 | 657 | 6 (0.9%) | 700 | 713 | 23 (3.2%) |

| B4P3M5 | 7.7 | 660 | 740 | |||||

| B3P2M6 | 6.9 | 650 | 700 | |||||

| M7 (WM50B0.4) | B4P2M6 | 7.0 | 760 | 740 | 35 (4.7%) | 850 | 760 | 85 (10.4%) |

| B5P2M6 | 7.2 | 760 | 730 | |||||

| B1P2M7 | 7.4 | 700 | 700 | |||||

| All tests | 655 | 53 (8.1%) | 721 | 53 (7.3%) | ||||

References

- Tapsoba, N.; Sauzéat, C.; Di Benedetto, H.; Baaj, H.; Ech, M. Behaviour of asphalt mixtures containing reclaimed asphalt pavement and asphalt shingle. Road Mater. Pavement Des. 2014, 15, 330–347. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J. Performance properties of rubberized stone matrix asphalt mixtures produced through different processes. Constr. Build. Mater. 2016, 104, 230–234. [Google Scholar] [CrossRef]

- Al-Qadi, I.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review (Research Report FHWA-ICT-07-001); Illinois Center for Transportation: Urbana, IL, USA, 2007. [Google Scholar]

- McDaniel, R.S.; Shah, A.; Huber, G.A.; Copeland, A. Effects of reclaimed asphalt pavement content and virgin binder grade on properties of plant produced mixtures. Road Mater. Pavement Des. 2012, 13, 161–282. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Fini, E.; Goh, S.W.; Colbert, B. Evaluation of low-temperature binder properties of warm-mix asphalt, extracted and recovered RAP and RAS, and bioasphalt. J. Mater. Civ. Eng. 2011, 23, 1569–1574. [Google Scholar] [CrossRef]

- Hajj, E.; Souliman, M.; Alavi, M.; Salazar, L.G.L. Influence of hydrogreen bioasphalt on viscoelastic properties of reclaimed asphalt mixtures. Transp. Res. Rec. 2013, 2371, 13–22. [Google Scholar] [CrossRef]

- Pouget, S.; Loup, F. Thermo-mechanical behaviour of mixtures containing bio-binders. Road Mater. Pavement Des. 2013, 14 (Suppl. 1), 212–226. [Google Scholar] [CrossRef]

- Hong, F.; Prozzi, J.A. Evaluation of recycled asphalt pavement using economic, environmental, and energy metrics based on long-term pavement performance sections. Road Mater. Pavement Des. 2018, 19, 1816–1831. [Google Scholar] [CrossRef]

- Braham, A.; Lynn, T.; Steger, R.; Pyle, R. Characterizing Compactability of High RAP and Warm Mix Asphalt Mixtures in the Superpave Gyratory Compactor. J. Test. Eval. 2015, 43, 535–543. [Google Scholar] [CrossRef]

- Doyle, J.D.; Howard, I.L. Thermal Cracking Potential of High RAP-WMA Evaluated with Bending Beam Rheometer Mixture Beam Test. J. Test. Eval. 2013, 41, 236–246. [Google Scholar] [CrossRef]

- Olard, F.; Le Noan, C.; Bonneau, D.; Dupriet, S.; Alvarez, C. Very high recycling rate (>50%) in hot mix and warm mix asphalts for sustainable road construction. In Proceedings of the 4th Eurasphalt Eurobitume Congress, Copenhagen, Denmark, 21–23 May 2008. [Google Scholar]

- Sun, Y.; Wang, W.; Chen, J. Investigating impacts of warm-mix asphalt technologies and high reclaimed asphalt pavement binder content on rutting and fatigue performance of asphalt binder through MSCR and LAS tests. J. Clean. Prod. 2019, 219, 879–893. [Google Scholar] [CrossRef]

- Eddhahak-Ouni, A.; Dony, A.; Colin, J.; Mendez, S.; Navaro, J.; Drouadaine, I.; Bruneau, D. Experimental investigation of the homogeneity of the blended binder of a high rate recycled asphalt. Road Mater. Pavement Des. 2012, 13, 566–575. [Google Scholar] [CrossRef]

- Mangiafico, S.; Di Benedetto, H.; Sauzeat, C.; Olard, F.; Pouget, S.; Dupriet, S.; Planque, L.; Van Rooijen, R. Statistical analysis of the influence of RAP and Mix Composition on Viscoelastic and Fatigue Properties of Asphalt Mixes. Mater. Struct. 2015, 48, 1187–1205. [Google Scholar] [CrossRef]

- Mangiafico, S.; Sauzéat, C.; Di Benedetto, H. Comparison of different blending combinations of virgin and RAP-extracted binder: Rheological simulations and statistical analysis. Constr. Build. Mater. 2019, 197, 454–463. [Google Scholar] [CrossRef]

- Noferini, L.; Simone, A.; Sangiorgi, C.; Mazzotta, F. Investigation on performances of asphalt mixtures made with Reclaimed Asphalt Pavement: Effects of interaction between virgin and RAP bitumen. Int. J. Pavement Res. Technol. 2017, 10, 322–332. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Forton, A.; Mangiafico, S.; Sauzéat, C.; Di Benedetto, H.; Marc, P. Properties of blends of fresh and RAP binders with rejuvenator: Experimental and estimated results. Constr. Build. Mater. 2020, 236, 117555. [Google Scholar] [CrossRef]

- Podolsky, J.H.; Saw, B.; Elkashef, M.; Williams, C.; Cochran, E.W. Rheology and mix performance of rejuvenated high RAP field produced hot mix asphalt with a soybean derived rejuvenator. Road Mater. Pavement Des. 2020. [Google Scholar] [CrossRef]

- Baaj, H.; Ech, M.; Tapsoba, N.; Sauzeat, C.; Di Benedetto, H. Thermomechanical characterization of asphalt mixtures modified with high contents of asphalt shingle modifier (ASM®) and reclaimed asphalt pavement (RAP). Mater. Struct. 2013, 46, 1747–1763. [Google Scholar] [CrossRef]

- Hajj, E.; Sebaaly, P.E.; Shrestha, R. Laboratory evaluation of mixes containing recycled asphalt pavement (RAP). Road Mater. Pavement Des. 2009, 10, 495–517. [Google Scholar] [CrossRef]

- Hong, F.; Chen, D.; Mikhail, M. Long-term performance evaluation of recycled asphalt pavement results from Texas: Pavement studies category 5 sections from the long-term pavement performance program. Transp. Res. Rec. 2010, 2180, 58–66. [Google Scholar] [CrossRef]

- Hong, F.; Guo, R.; Zhou, F. Impact of recycled asphalt pavement material variability on pavement performance. Road Mater. Pavement Des. 2014, 15, 841–855. [Google Scholar] [CrossRef]

- Huang, S.C.; Pauli, A.T.; Grimes, R.W.; Turner, F. Ageing characteristics of RAP binder blends—What types of RAP binders are suitable for multiple recycling? Road Mater. Pavement Des. 2014, 15, 113–145. [Google Scholar] [CrossRef]

- Lakshmi Roja, K.; Masad, E.; Mogawer, W. Performance and blending evaluation of asphalt mixtures containing reclaimed asphalt pavement. Road Mater. Pavement Des. 2020. [Google Scholar] [CrossRef]

- Mangiafico, S.; Di Benedetto, H.; Sauzéat, C.; Olard, F.; Pouget, S.; Planque, L. New method to obtain viscoelastic properties of bitumen blends from pure and reclaimed asphalt pavement binder constituents. Road Mater. Pavement Des. 2014, 15, 312–329. [Google Scholar] [CrossRef]

- Mangiafico, S.; Sauzéat, C.; Di Benedetto, H.; Pouget, S.; Olard, F.; Planque, L. Quantification of biasing effects during fatigue tests on asphalt mixes: Non-linearity, self-heating and thixotropy. Road Mater. Pavement Des. 2015, 16, 73–99. [Google Scholar] [CrossRef]

- Mensching, D.J.; Sias Daniel, J.; Bennert, T.; Medeiros, M.S., Jr.; Elwardany, M.D.; Mogawer, W.; Hajj, E.Y.; Alavi, M.Z. Low temperature properties of plant-produced RAP mixtures in the Northeast. Road Mater. Pavement Des. 2014, 15, 1–27. [Google Scholar] [CrossRef]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Pedraza, A.; Di Benedetto, H.; Sauzéat, C.; Pouget, S. 3D Linear viscoelastic behaviour of bituminous mixtures containing high content of multi-recycled RAP. Road Mater. Pavement Des. 2019. [Google Scholar] [CrossRef]

- Sias Daniel, J.; Gibson, N.; Tarbox, S.; Copeland, A.; Andriescu, A. Effect of long-term ageing on RAP mixtures: Laboratory evaluation of plant-produced mixtures. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 173–192. [Google Scholar] [CrossRef]

- Zhou, F.; Hu, S.; Das, G.; Scullion, T. High RAP Mixes Design Methodology with Balanced Performance (Report No. FHWA/TX-11/0-6092-2). Available online: https://static.tti.tamu.edu/tti.tamu.edu/documents/0-6092-2.pdf (accessed on 11 November 2020).

- Baaj, H.; Di Benedetto, H.; Chaverot, P. Effect of binder characteristics on fatigue of asphalt pavement using an intrinsic damage approach. Road Mater. Pavement Des. 2005, 6, 147–174. [Google Scholar] [CrossRef]

- Di Benedetto, H.; De La Roche, C.; Baaj, H.; Pronk, A.; Lundström, R. Fatigue of Bituminous Mixtures. Mater. Struct. 2004, 15, 202–216. [Google Scholar] [CrossRef]

- Di Benedetto, H.; Nguyen, Q.T.; Sauzeat, C. Nonlinearity, Heating, Fatigue and Thioxotropy during cyclic loading of Asphalt Mixtures. Road Mater. Pavement Des. 2011, 12, 129–158. [Google Scholar] [CrossRef]

- Lundström, R.; Di Benedetto, H.; Isacsson, U. Influence of asphalt mixture stiffness on fatigue failure. J. Mater. Civ. Eng. 2004, 16, 516–525. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Di Benedetto, H.; Sauzéat, C. Determination of thermal properties of asphalt mixtures as another output from cyclic tension-compression test. Road Mater. Pavement Des. 2012, 13, 85–103. [Google Scholar] [CrossRef]

- Shen, S.; Sutharsan, T. Quantification of Cohesive Healing of Asphalt Binder and its Impact Factors Based on Dissipated Energy Analysis. Road Mater. Pavement Des. 2011, 12, 525–546. [Google Scholar] [CrossRef]

- Tapsoba, N.; Sauzeat, C.; Di Benedetto, H. Analysis of fatigue test for bituminous mixtures. J. Mater Civ. Eng. 2013, 25, 701–710. [Google Scholar] [CrossRef]

- Zhang, J.; Sabouri, M.; Guddati, M.N.; Kim, Y.R. Development of a failure criterion for asphalt mixtures under fatigue loading. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 1–15. [Google Scholar] [CrossRef]

- Kandhal, P.S.; Koehler, W.C. Effect of rheological properties of asphalts on pavement cracking. Asph. Theol. Relatsh. ASTM STP 1987, 941, 99–117. [Google Scholar]

- Sauzéat, C.; Di Benedetto, H.; Chaverot, P.; Gauthier, G. Low temperature behaviour of bituminous mixes: TSRS tests and acoustic emission. In Characterization of Pavement and Soil Engineering Materials; Loizos, S., Scarpas, A., Al-Qadi, I., Eds.; Taylor Francis Group: London, UK, 2007. [Google Scholar]

- Moon, K.H.; Falchetto, A.C.; Marasteanu, M.O. Rheological modelling of asphalt materials properties at low temperatures: From time domain to frequency domain. Road Mater. Pavement Des. 2013, 14, 810–830. [Google Scholar] [CrossRef]

- EN 13108-8:2016 Standard. Bituminous Mixtures—Part 8: Reclaimed Asphalt; AFNOR: La Plaine Saint-Denis, France, 2016. [Google Scholar]

- NF EN 12697-33+A1. Mélange Bitumineux—Méthodes d’essai pour Mélange Hydrocarboné à Chaud—Partie 33: Confection d’éprouvettes au Compacteur de Plaque; Norme Européenne—Norme Française AFNOR: La Plaine Saint-Denis, France, 2007. [Google Scholar]

- NF P 98-086. Chaussées—Terrassements—Dimensionnement des Chaussées Routières—Détermination des Trafics Routiers pour le Dimensionnement des Structures de Chaussée; French Standard AFNOR: La Plaine Saint-Denis, France, 2019. [Google Scholar]

- Pham, N.H.; Sauzéat, C.; Di Benedetto, H.; Gonzalez-Leon, J.A.; Barreto, G.; Nicolai, A.; Jakubowski, M. Reclaimed asphalt pavement and additives’ influence on 3D linear behaviour of warm mix asphalts. Road Mater. Pavement Des. 2015, 16, 569–591. [Google Scholar] [CrossRef]

- Pham, N.H.; Sauzéat, C.; Di Benedetto, H.; Gonzalez-Leon, J.A.; Barreto, G.; Nicolai, A.; Jakubowski, M. Analysis and modeling of 3D complex modulus tests on hot and warm bituminous mixtures. Mech. Time Depend. Mater. 2015, 19, 167–186. [Google Scholar] [CrossRef]

- Tapsoba, N.; Sauzéat, C.; Di Benedetto, H.; Baaj, H.; Ech, M. Three dimensional analysis of fatigue tests on bituminous mixtures. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 730741. [Google Scholar] [CrossRef]

| Number of Cycles (N) | Recording Period | Number of Recorded Cycles |

|---|---|---|

| Cycle 1 to 1000 | All cycles | 1000 |

| Cycle 1000 to 10,000 | 2 cycles every 20 cycles | 900 |

| Cycle 10,000 to 100,000 | 2 cycles every 200 cycles | 900 |

| Cycle 100,000 to 1,000,000 | 2 cycles every 2000 cycles | 900 |

| After one million | 2 cycles every 5000 cycles | --- |

| Material number | M1/M1-2 | M2/M2-2 | M3 | M4 | M5 | M6 | M7 |

| Material name | HM | HM30 | WME0.4 | WM30E0.4 | WM30B0.4 | WM50E0.4 | WM50B0.4 |

| Production process | Hot | Hot | Warm | Warm | Warm | Warm | Warm |

| %RAP | - | 30 | - | 30 | 30 | 50 | 50 |

| Type of additive | - | - | add. E | add. E | add. B | add. E | add. B |

| %Additive | - | - | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Material | Specimen | Voids (%) | Failure Temperature (°C) | Failure Stress (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | |||||

| M1 (HM) | B1P1M1 | 11.7 | −18.4 | −16.8 | 2.1 | 2.43 | 2.33 | 0.24 (10.1%) |

| B2P1M1 | 11.2 | −14.4 | 2.06 | |||||

| B5P1M1 | 10.1 | −17.6 | 2.50 | |||||

| M1−2 (HM) | B1P2M1−2 | 7.2 | −19.6 | −19.4 | 0.3 | 3.48 | 3.47 | 0.01 (0.2%) |

| B4P2M1−2 | 7.0 | −19.5 | 3.47 | |||||

| B5P2M1−2 | 7.3 | −19.1 | 3.47 | |||||

| M2 (HM30) | B1P2M2 | 12.9 | −15.7 | −17.5 | 1.8 | 2.07 | 2.35 | 0.25 (10.6%) |

| B2P2M2 | 13.0 | −17.6 | 2.43 | |||||

| B5P2M2 | 13.0 | −19.2 | 2.55 | |||||

| M2−2 (HM30) | B2P2M2−2 | 6.4 | −19.6 | −19.6 | 0.6 | 3.58 | 3.42 | 0.14 (4.2%) |

| B3P2M2−2 | 6.9 | −19.0 | 3.30 | |||||

| B4P2M2−2 | 7.2 | −20.1 | 3.38 | |||||

| M3 (WME0.4) | B2P2M3 | 7.2 | −18.7 | −18.6 | 0.3 | 2.78 | 2.80 | 0.04 (1.4%) |

| B3P2M3 | 7.1 | −18.9 | 2.84 | |||||

| B4P2M3 | 7.6 | −18.3 | 2.77 | |||||

| M4 (WM30E0.4) | B2P2M4 | 7.3 | −21.7 | −19.9 | 1.6 | 3.14 | 2.94 | 0.22 (7.4%) |

| B3P2M4 | 7.5 | −19.1 | 2.96 | |||||

| B4P2M4 | 7.6 | −18.8 | 2.71 | |||||

| M5 (WM30B0.4) | B2P2M5 | 7.1 | −19.7 | −20.1 | 0.4 | 2.95 | 2.85 | 0.14 (4.9%) |

| B3P3M5 | 7.5 | −20.3 | 2.91 | |||||

| B4P3M5 | 7.7 | −20.4 | 2.69 | |||||

| M6 (WM50E0.4) | B3P2M6 | 6.9 | −21.5 | −21.0 | 0.7 | 2.92 | 3.24 | 0.29 (9.0%) |

| B4P2M6 | 7.0 | −21.3 | 3.49 | |||||

| B5P2M6 | 7.2 | −20.2 | 3.32 | |||||

| M7 (WM50B0.4) | B1P2M7 | 7.4 | −20.9 | −21.1 | 0.3 | 3.54 | 3.51 | 0.03 (0.9%) |

| B3P2M7 | 7.0 | −21.4 | 3.52 | |||||

| B4P2M7 | 7.3 | −21.0 | 3.48 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, N.H.; Sauzéat, C.; Di Benedetto, H.; González-León, J.A.; Barreto, G.; Nicolaï, A. Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents. Sustainability 2020, 12, 9812. https://doi.org/10.3390/su12239812

Pham NH, Sauzéat C, Di Benedetto H, González-León JA, Barreto G, Nicolaï A. Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents. Sustainability. 2020; 12(23):9812. https://doi.org/10.3390/su12239812

Chicago/Turabian StylePham, Nguyen Hoang, Cédric Sauzéat, Hervé Di Benedetto, Juan A. González-León, Gilles Barreto, and Aurélia Nicolaï. 2020. "Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents" Sustainability 12, no. 23: 9812. https://doi.org/10.3390/su12239812

APA StylePham, N. H., Sauzéat, C., Di Benedetto, H., González-León, J. A., Barreto, G., & Nicolaï, A. (2020). Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents. Sustainability, 12(23), 9812. https://doi.org/10.3390/su12239812