1. Introduction

Nowadays, the visible consequences of environmental degradation and the prediction of future environmentally catastrophic scenarios require drastic solutions for environmental conservation. Among them is the integrated management of solid wastes, in which a set of actions is proposed in order to promote sustainability and the preservation of natural resources through three main actions: reducing consumption, reusing consumed materials, and recycling generated waste.

The use of alternative materials in the civil engineering construction industry aiming to reduce the production of wastes or the use of previously generated wastes has become indispensable. In the context of the reduction of natural resource use in civil construction, such as soils, different materials appear as alternative options to compose soil-mixtures: synthetic or natural fibers, construction and demolition wastes, ashes or tire fibers. Another sustainable alternative is the addition of polymers, using previously generated wastes, such as plastic strips.

The study entitled “Fast facts about plastic pollution” by National Geographic written by Laura Parker [

1] exposes the worrying situation of plastic in the world, showing the growing need for recycling and reusing this material. According to the study, 40% of plastic produced is packaging, used only once and then discarded. Worldwide, 448 million tons of plastic have been produced since the beginning of this materials manufacturing, of which 44% has been made since 2000. Currently, less than a fifth of all plastic is globally recycled. In Europe, plastic recycling rates are higher than 30 percent, while in China, the rate of plastic recycling is 25 percent. In the United States, plastic recycling is only 9 percent of total plastic trash.

After numerous studies indicating a high potential for the application of polymeric fiber reinforced-composites in improving the mechanical properties of soils, recent studies started to evaluate the influence of using polymeric strips as soil reinforcement materials, e.g., References [

2,

3,

4,

5,

6].

The main difference between the two types of inclusions is in the shape of the materials. While polymeric fibers are very thin and elongated materials, such as filaments, polymeric strips are materials of greater width and thickness, usually cut from existing plastic structures. The use of Polyethylene Terephthalate (PET) strips as soil improvement has several advantages, such as the possibility of reusing plastic waste to increase soil strength without the need of a recycling process, as in the case of synthetic fibers.

Sivakumar Babu and Chouksey [

2] evaluated the effect of including strips 12 mm long and 4 mm wide, in quantities of 0.50%, 0.75% and 1.0% in a sandy soil through unconfined strength tests and triaxial tests (consolidated and not drained). The authors noted significant increases in the soil shear strength parameters (cohesion and internal friction angle), which were greater for greater amounts of strips added. In addition, unconfined strength tests indicated an increase in ductility, proportional to the inclusion of strips. Soltani-Jigheh [

3] studied the inclusion of plastic strips 4 mm wide and 8 mm long in quantities of 0.25; 0.50; 0.75; 1.0; 1.5 and 2% in relation to the mass of a clayey soil by performing triaxial tests (consolidated and not drained). The results showed a small increase in the shear strength of the soil. In general, changes obtained in the shear strength of soils were also small, resulting, in general, in an increase of cohesion and decrease of the friction angle.

Studies have also addressed the use of cement or lime to improve soil properties. The large number of studies that evaluated the use of soil-cement mixtures may be justified by the characteristics obtained with this composite, which presents a significant increase in natural soil strength and stiffness [

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17]. Although cement is considered a high-environmental-impact material, these studies aim to obtain a material with high strength and durability from the inclusion of small amounts of cement, reducing the use of other polluting materials. Specht et al. [

9] suggest that a cement-treated soil usually shows an increase in soil strength and stiffness, turning this mixture into an ideal material for several geotechnical applications, such as the base of shallow foundations, slope protection and base/sub-base of flexible pavements. However, great brittleness and high cracking potential have discouraged the use of such material in pavement engineering. In this sense, the addition of fibers and strips in a soil-cement composite can provide a material with high strength and more ductile behavior.

Specht [

9] studied the behavior of soil-cement-fiber mixtures submitted to static and dynamic loads aiming at paving. The author stated that the influence of the inclusion of polypropylene fibers on the properties of the composite essentially depends on the fiber and matrix. Still, according to Specht [

9], more flexible fibers showed a more pronounced effect on post-peak behavior, increasing ductility, toughness, and resistance to fatigue, while fibers with greater stiffness pronounced the effect of increasing peak strength. In addition, longer fibers were more effective.

Guedes [

14] analyzed the mechanical performance of a soil-cement micro reinforced with synthetic polypropylene fibers for use as a primary coating on unpaved roads. The study incorporated fibers of 6 and 24 mm lengths into the soil-cement in proportions of 0.25%, 0.50%, and 0.75%. The incorporation of fibers into the composite proved to be satisfactory, increasing the peak strength and the drop in strength after the peak. Other factors that were significantly affected by the inclusion are the increase in break deformations, decrease in stiffness, increase in elastic and plastic deformations, and reduction in deformability modules and strength to compaction. The 24 mm fiber incorporated into the soil at 0.75% content proved to be the most influential combination.

Girardello [

15] studied the behavior of pullout tests of embedded plates in soil-cement-fiber layers using polymeric polypropylene fibers. The results indicated an increase in the strength required for the removal of the embedded sand-cement, sand-cement-fiber, and sand-fiber plates when compared to the removal of the embedded sand plates. Changes were observed in the form of soil rupture when reinforced with fibers and/or cement.

Cristelo et al. [

12] analyzed microscopic images of the soil in its pure state, with the addition of fibers, cement, and with the addition of cement and fibers together. The authors observed the soil structure and concluded that there is an increase in the void index with the addition of fibers, which are responsible for a loss of mechanical strength, resulting from the friction between the particles. The addition of cement, unlike what occurs with the addition of fibers, is responsible for decreasing the void index of the composite, since it acts as a binder. In the case of the mixture of soil, cement and fibers, cement acts by reducing voids and increasing the bond strength at the soil-fiber interface, providing improvement in the mechanical strength of the mixture.

Regarding the inclusion of strips, Olutaiwo and Ezegbunem [

16] evaluated the effect of cement and PET bottle strips in a lateritic soil using Modified Proctor and CBR tests. The amount of cement varied between 0%, 1%, 3%, 5%, and 7%, and the number of strips (5 mm wide and 10 mm long) in 0%, 5%, 10%, 15% and 20%. Results showed a decrease in the optimum humidity and an increase in the maximum dry density, which were shown to be greater in the inclusion of 10% of strips for all the cement quantities. As for the CBR tests, all cement-strip combinations evaluated increased the soil’s bearing capacity. In all cement inclusions, the inclusion of 10% of strips generated the greatest increase in strength. The most effective inclusion was 7% cement with 10% strips, generating a 326.8% increase in soil support capacity. Overall, the addition of the strips to the soil-cement presented a beneficial alternative to the environment, in addition to being economical when compared to the single addition of cement.

Tang et al. [

17] evaluated the inclusion of natural fiber reinforcements within cemented soils and found an increase in UCS and changes on the brittle behavior of cemented soil to a more ductile behavior. Olgun et al. [

18] evaluated the effect of polypropylene (PP) fibers inclusion on the strength of cement-fly ash stabilized clay soil and found that the main advantage of fiber reinforcement was the improvement in material ductility, particularly above 0.5% fiber content, and with increased fibers length.

Therefore, the present study aims to expand the understanding of the shear strength and deformability behavior of a cement-treated lateritic soil mixture with recycled polymeric strips. Considering the high cost of the cement and the polluting potential of these materials, the recycled strips were added to a cement-treated soil seeking a low-cost material with high strength, ductility and a highly sustainable alternative. This practice seeks to assess how much strength can increase with the addition of the recycled strips in order to maximize their use and minimize the use of cement. Unconfined compression and direct shear tests were conducted using soil-strip, soil-cement, and soil-strip-cemented mixtures. A lateritic sandy soil was used in the present study for the evaluation of the effect of recycled strips and cement inclusion in soils found in tropical zones.

2. Materials and Methods

Sandy soil samples were collected from the experimental campus of the São Paulo State University (UNESP) at Bauru, in Sao Paulo State, Brazil. Soil samples were characterized according the following recommendations: particle size analysis—ABNT NBR 7181 [

19], liquidity limit—ABNT NBR 6459 [

20], plasticity limit—ABNT NBR 7180 [

21], specific density of solids—ABNT NBR 6458 [

22], unconfined compression strength—ABNT NBR 6457 [

23] and ABNT 7182 [

24], and direct shear—ASTM D3080 [

25]. The soil was classified as a medium to fine, reddish brown, clayey sand, according to the classification adopted by ABNT NBR 6502 [

26]. These materials are residual soils formed in humid tropical regions with a predominance of weathering. Lateritic soils are characterized in their formation by the intense migration of particles under the action of infiltrations and evaporations, giving rise to a porous surface horizon, remaining almost exclusively the most stable minerals (quartz, magnetite, illite and kaolinite). In these soils, the presence of aggregated clay and silt particles is common owing to the action of iron and aluminum oxides and hydroxides, which gives these soils characteristics of mechanical and hydraulic behavior not consistent with their texture. Lateritic fine-grained soils have superior properties when compacted; however, they can show unfavorable properties such as cracks, shrinkage, water sensitivity and irregular distribution [

27,

28,

29,

30].

Table 1 illustrates soil properties obtained in tests for characterization of this soil.

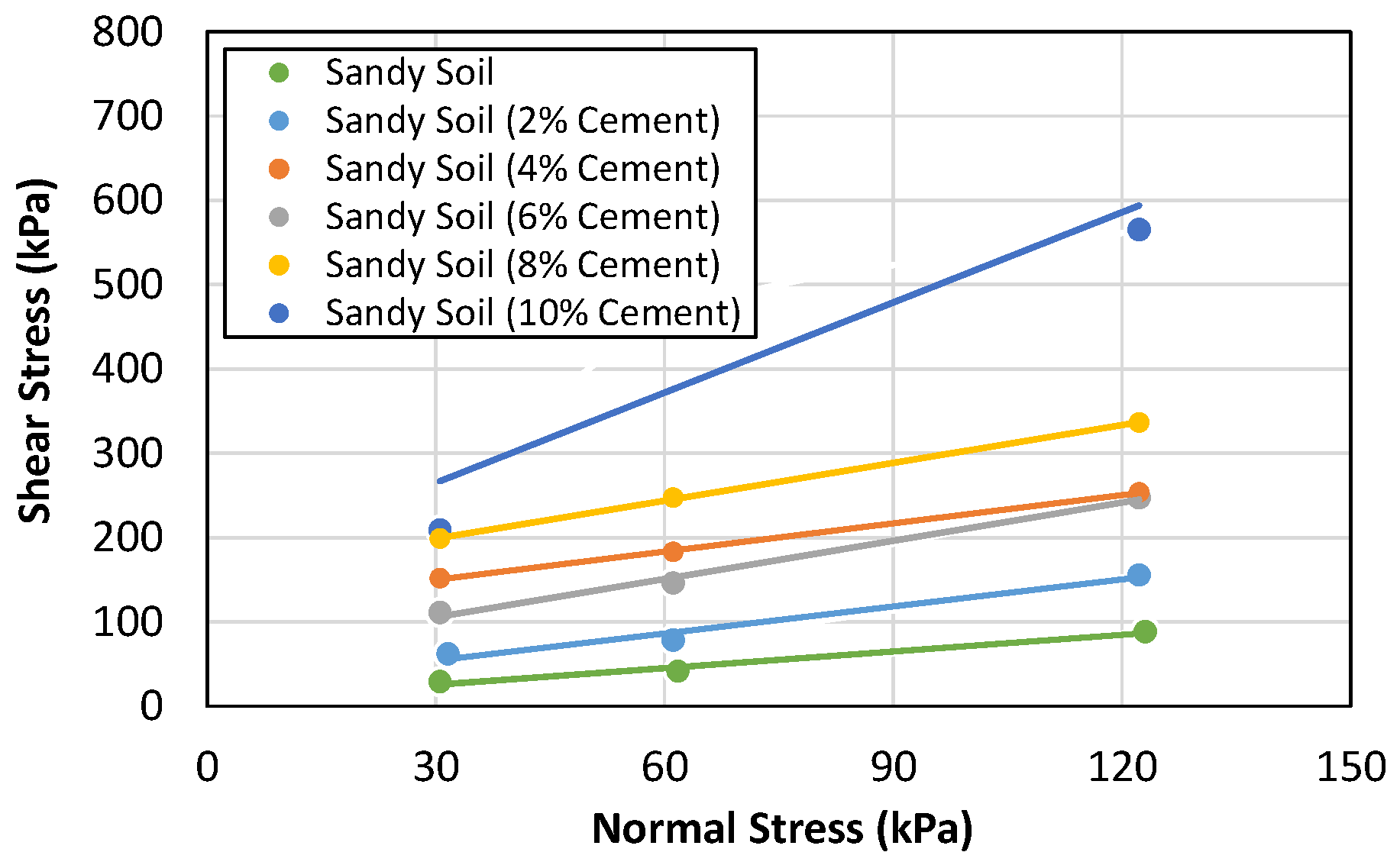

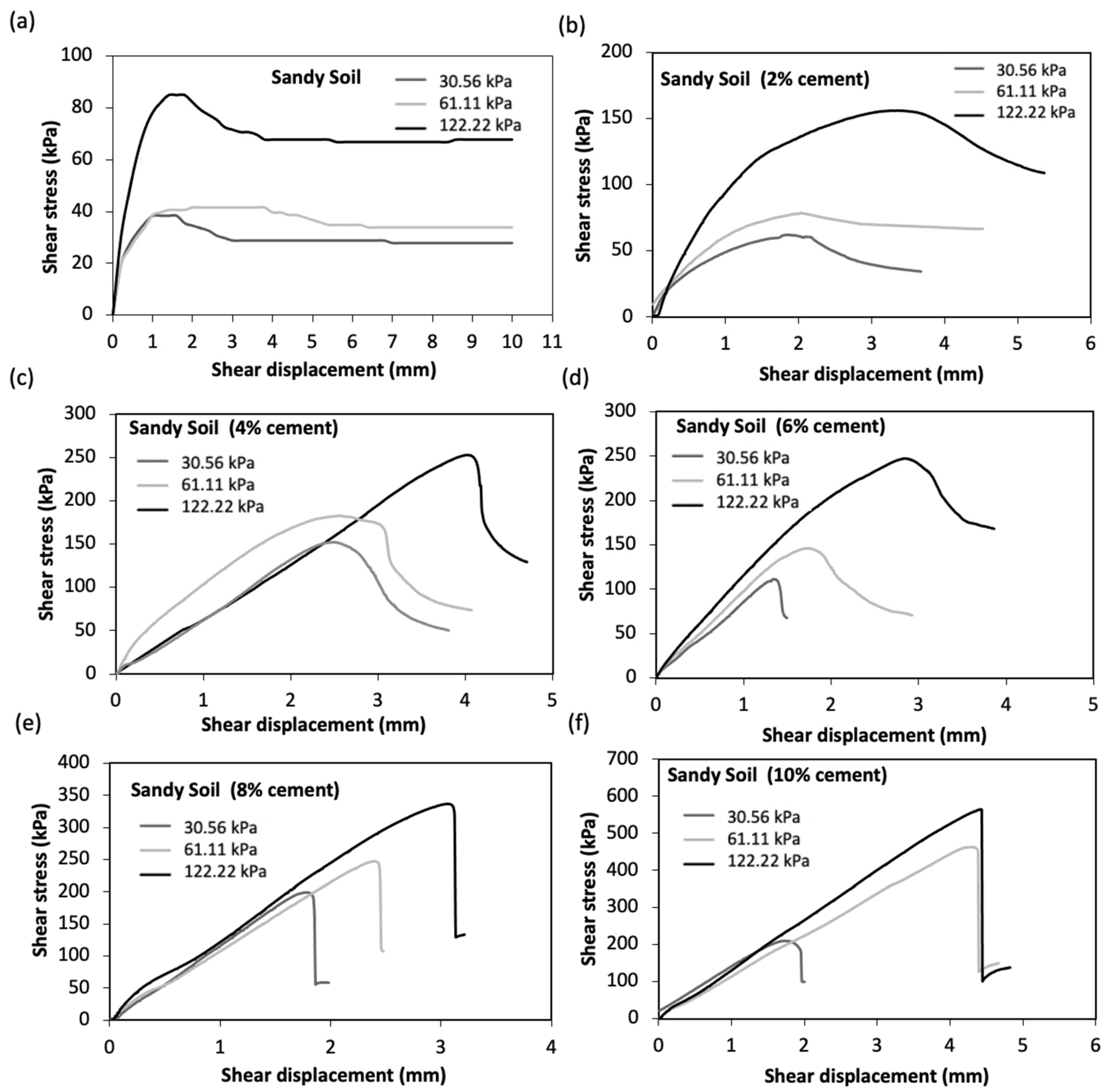

The Portland cement used in this research is type CP II-F-32, manufactured by CSN (Brazil). This cement was chosen, according to Brazilian Portland Cement Association (ABCP), due to its wide availability in Brazil. The cement was added to soil in percentages of 2, 4, 6, 8 and 10%.

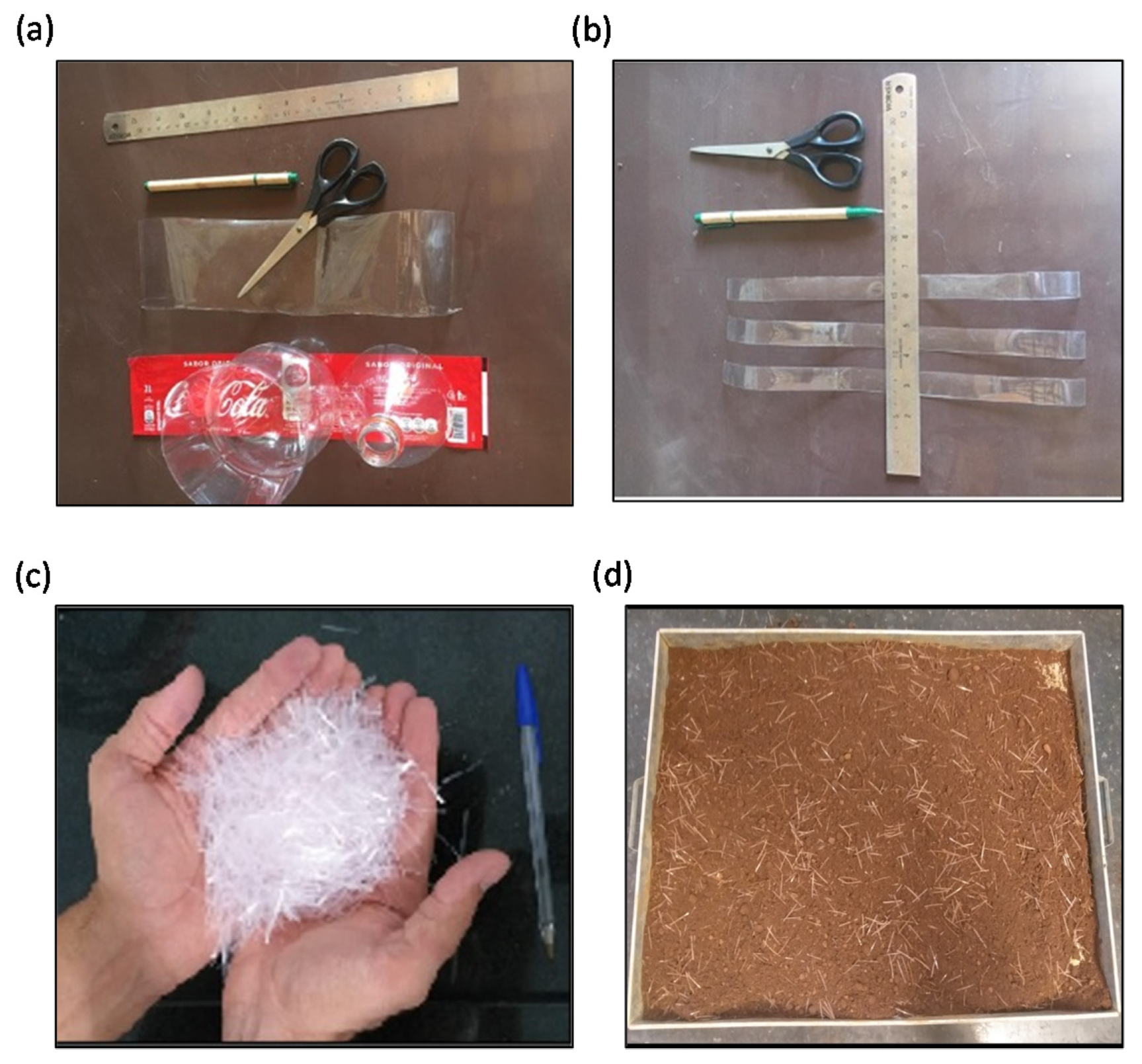

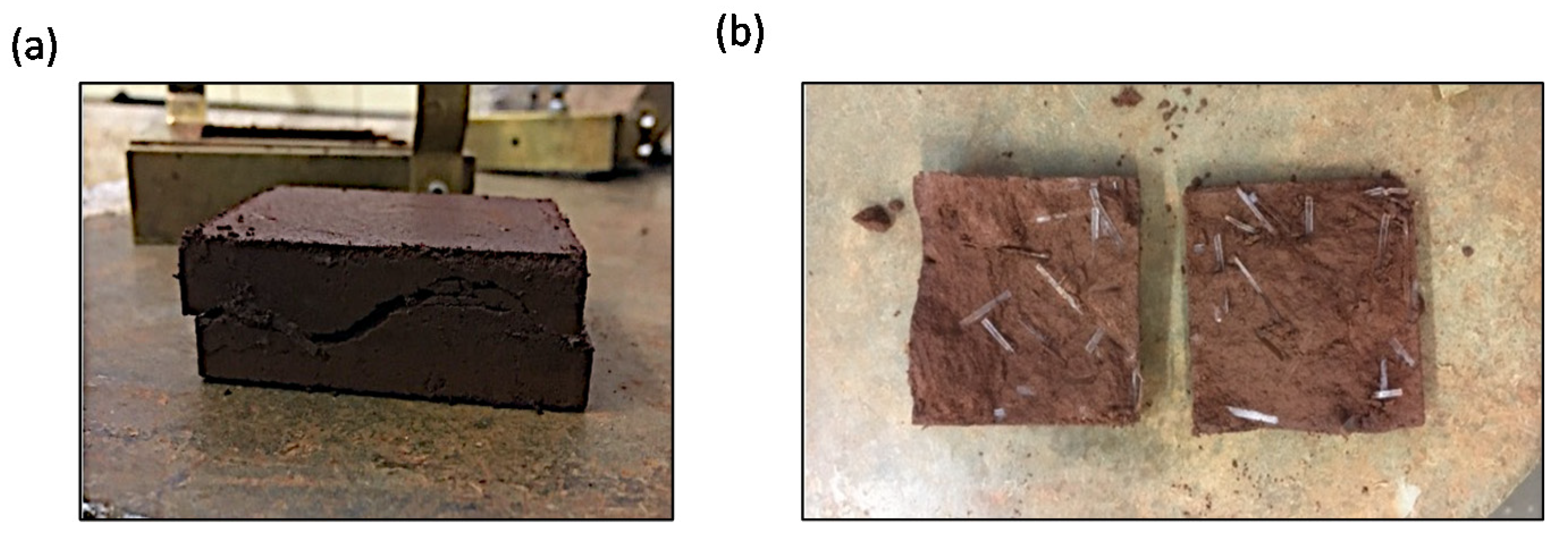

Plastic wastes used in this research were composed by PET bottle. Strips were cut from Coca-Cola

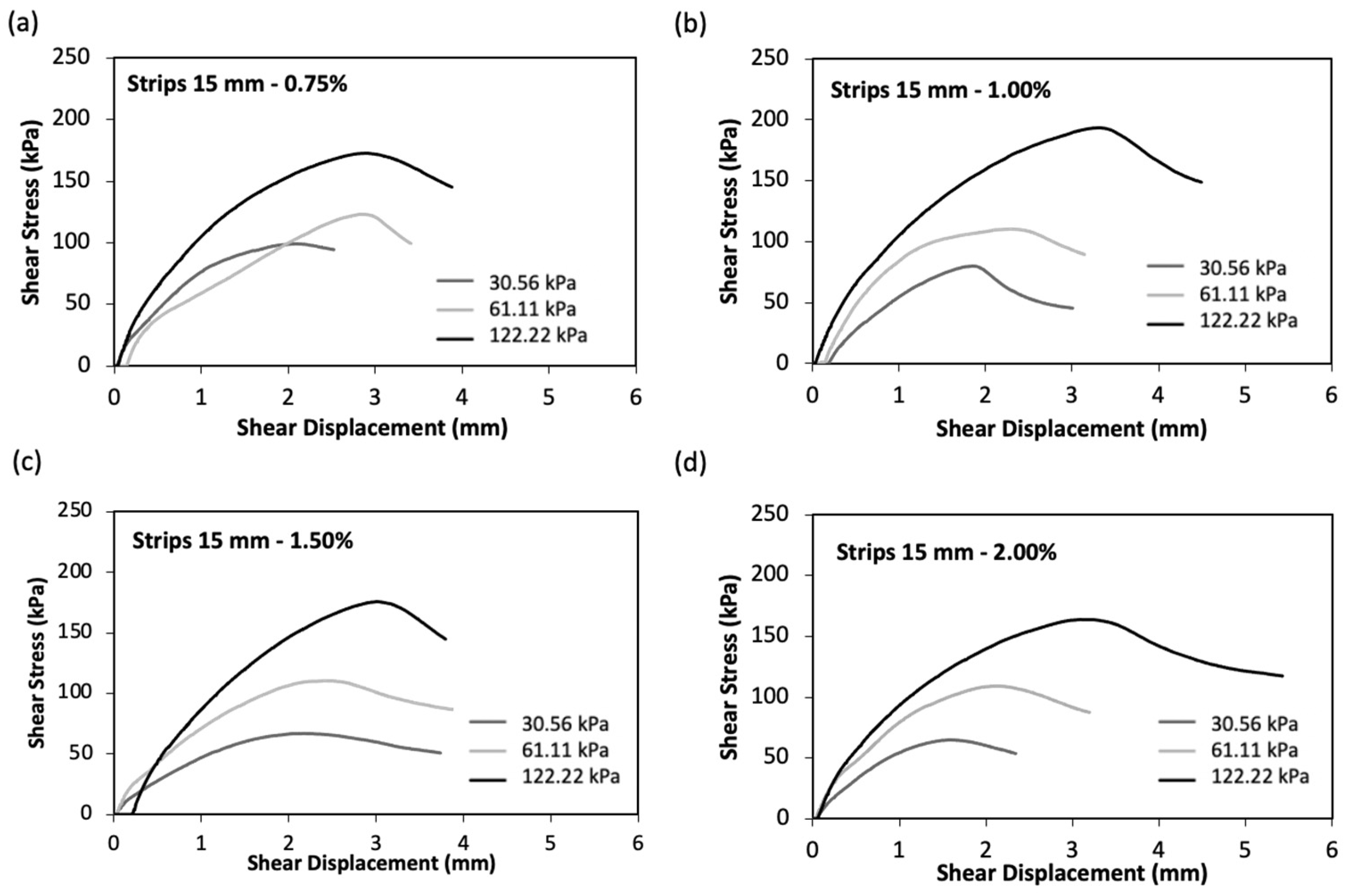

® plastic bottles and randomly distributed in the soil. Bottles were previously sanitized under running water. After this process, a portion of the bottle in which the label was placed was cut and separated from the rest of the packaging to form the strip sample. The sample was cut into strips with 1.5 mm width by 10, 15, 20, and 30 mm length. The percentual of strips (0.0, 0.25, 0.5, 0.75, 1.0, 1.5, and 2%) was added to soils in relation to the mass of dry soil (

Figure 1). The PET strips have a specific mass of 1.30 g/cm

3, a tensile strength of 1000 MPa, and a tensile modulus of 15.0 GPa. The aspect ratio (AR) for the strips having a length of 10 mm, 15 mm, 20 mm, and 30 mm are 20, 30, 40, and 60, respectively. The cutting process of the PET strips, the final shape of the strips, and an example of soil mixed with strips are shown in

Figure 1.

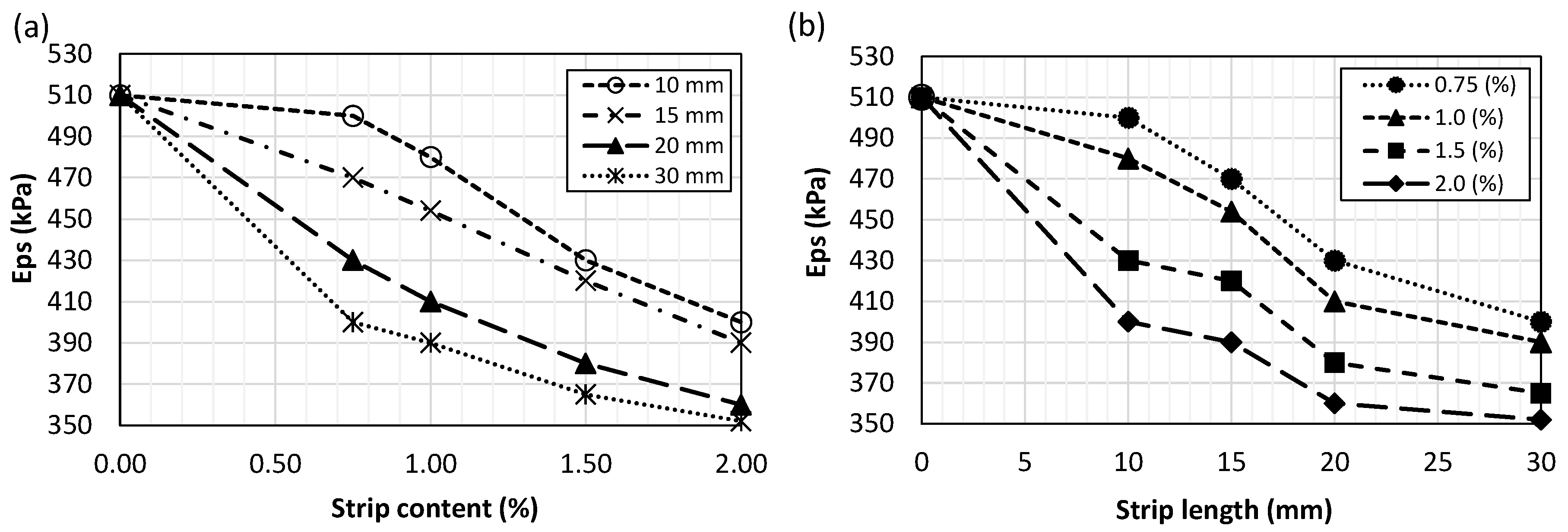

Standard Proctor tests—ABNT NBR 7182 [

24] were conducted with the addition of strips to the soil in order to evaluate the effect of including different sizes and percentages of strips to the soil compaction parameters (maximum dry density and optimum moisture content). Proctor tests with the addition of cement—ABNT NBR 12,023 [

31] were also conducted in percentages of 2% and 10% to obtain the optimal parameters for the soil-cement mixture.

Unconfined compression tests—ABNT NBR 12,770 [

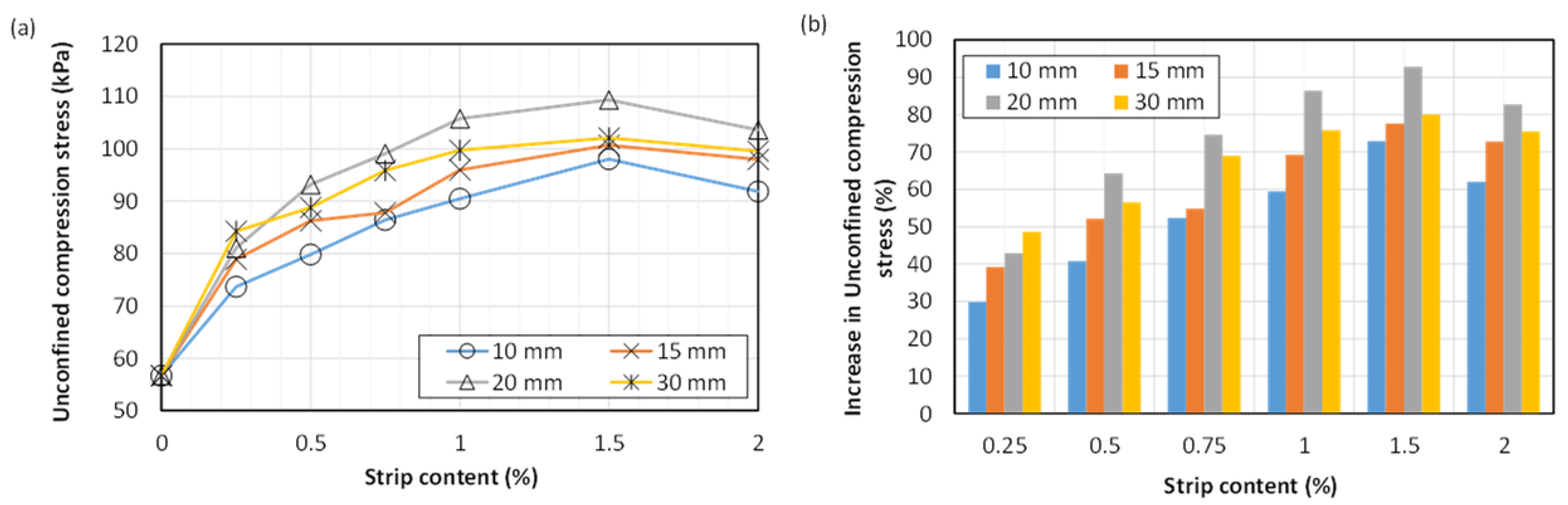

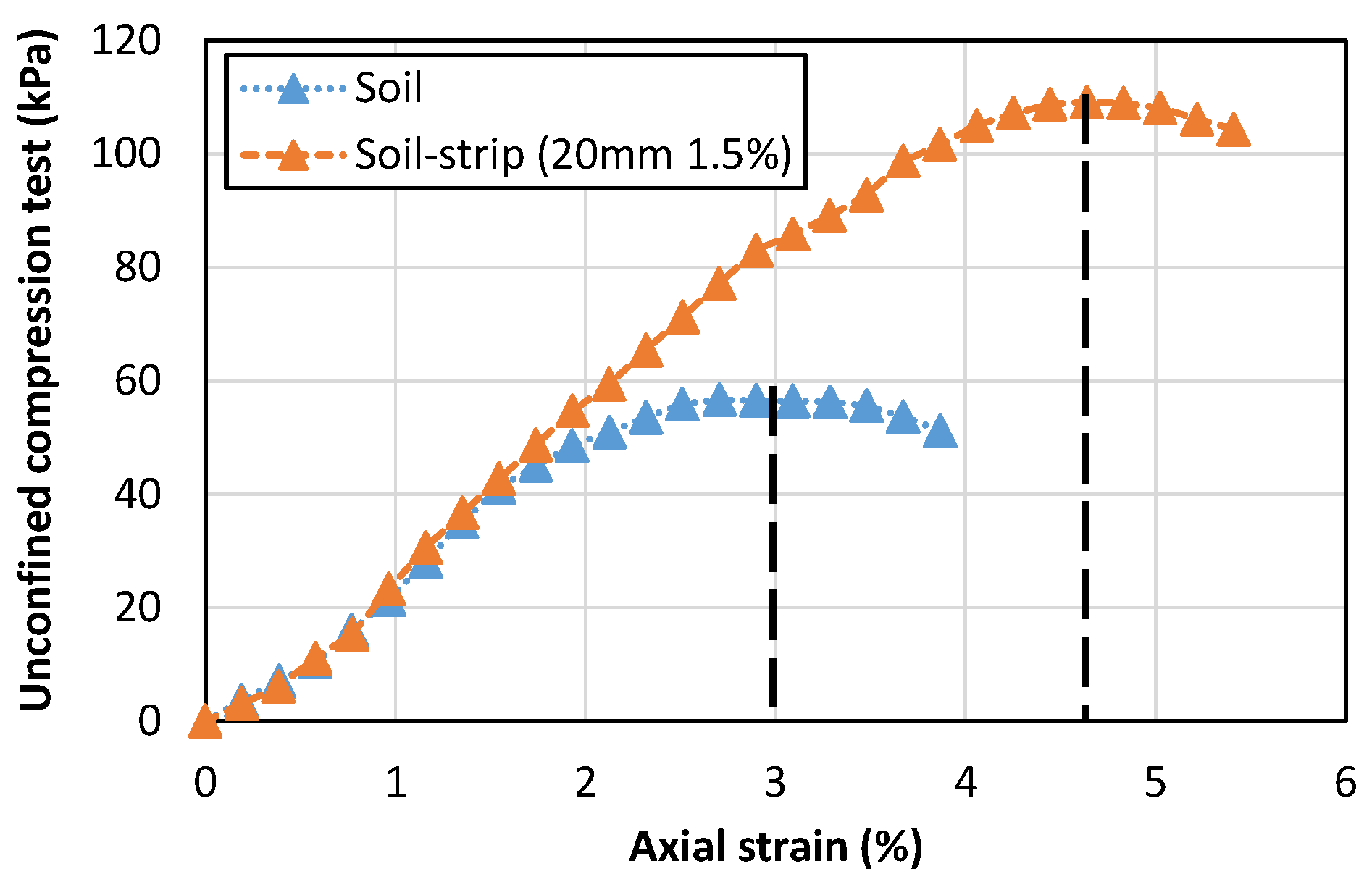

32] were also conducted for natural soil and soil-strip mixtures. Due to the small variations obtained with the inclusion of strips in the compaction parameters (see item 3.1.1), a natural soil compaction curve was adopted for the molding of the specimens, which were compacted in the optimum moisture (±0.5) and with a 100% degree of compaction, with an acceptable variation of 3%. UCS tests were performed with 3 specimens for each length and respective strips content, totalizing 24 unconfined compression strength tests, allowing an analysis of the effect of the inclusion of strips in the soil in terms of strength improvement and variability.

The direct shear tests were conducted according to ASTM D3080 [

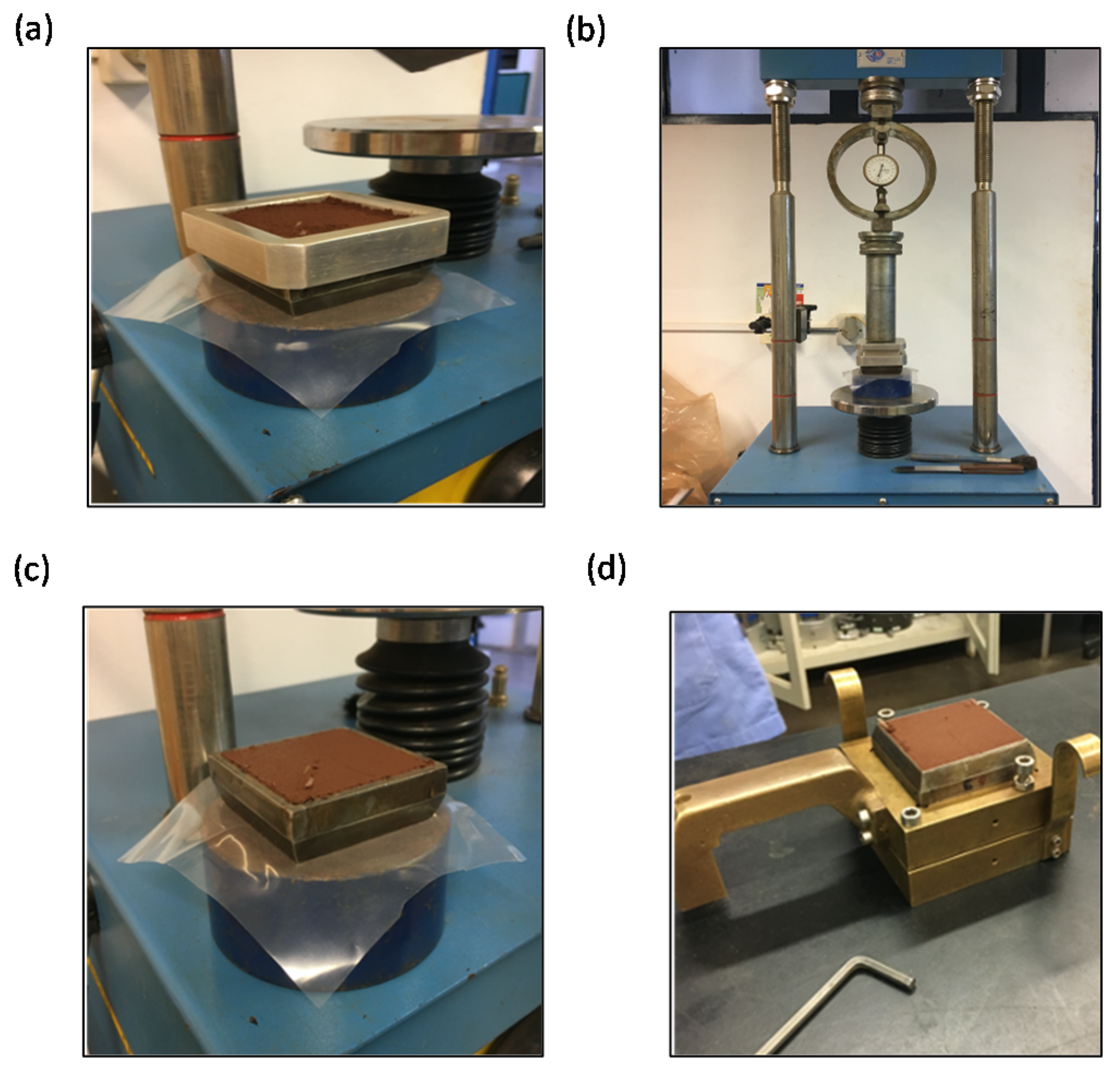

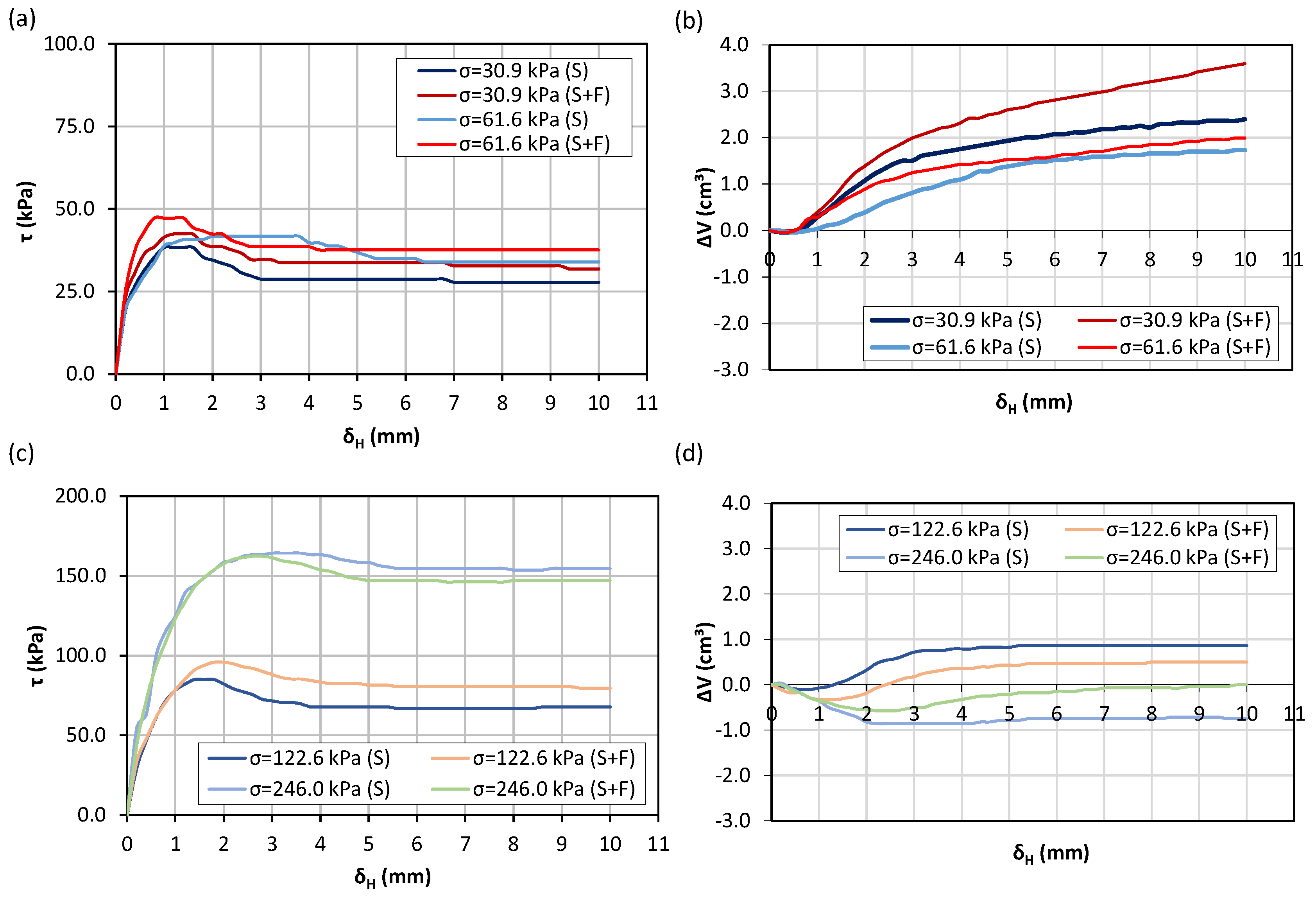

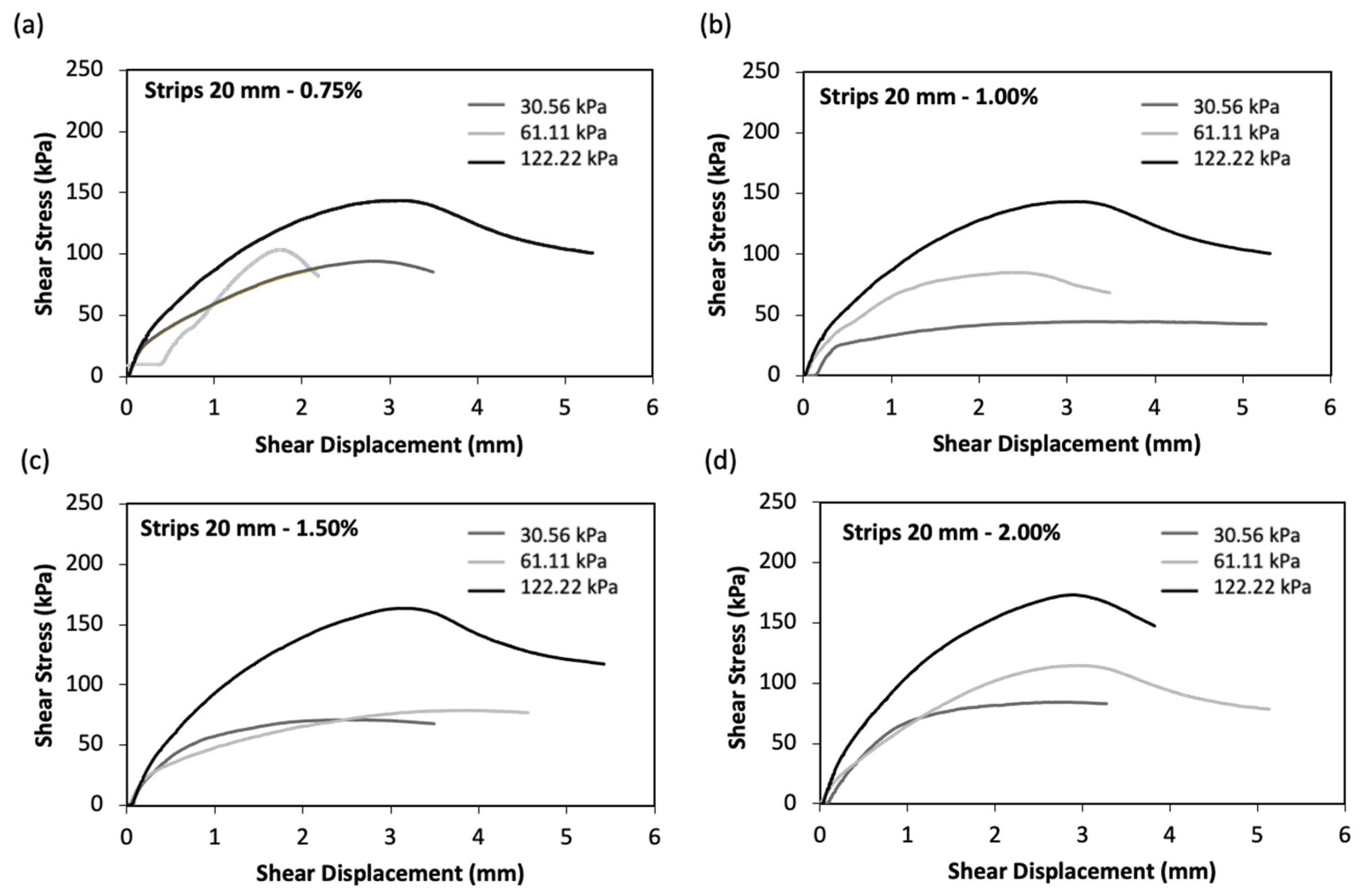

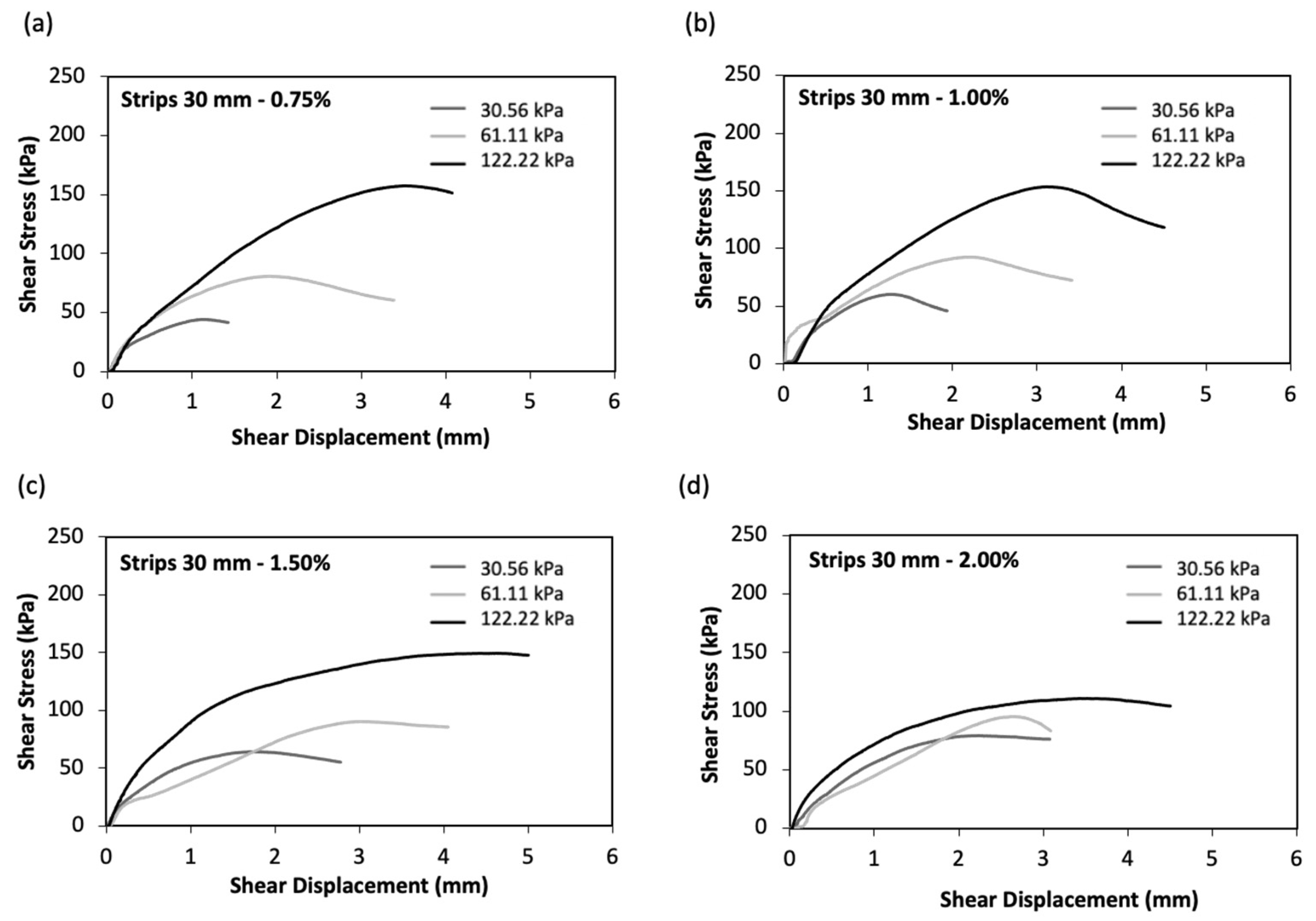

25] with the addition of cement to soil in percentages of 2, 4, 6, 8, and 10%. In addition to the soil-cement tests, soil-cement-strips tests were also performed. The direct shear tests were performed with the molding of the specimens in the optimum soil content, using a previously calculated mass of soil or soil-cement according to the volume of each mold and the maximum density of the composite. The sought degree of compaction was 95% for the tests with the soil-cement and soil-cement-strip. For the tests with the soil-strip the degree of compaction of 100% was adopted for comparison with the unconfined compression test (UCS) results. The static compaction procedure was adopted, in which a metal plunger was attached to the same simple compression equipment and introduced into the metal mold of direct shear test at a constant speed, compacting the amount of soil, strip, and water previously calculated, weighed with a resolution of 0.01 gf, and homogenized to obtain maximum dry density and optimal moisture content according to compaction degree (

Figure 2a,b). The specimens were then placed inside a capsule that was attached to the direct shear machine to initiate the shearing (

Figure 2c,d). The specimens were densified with the use of loads of 1, 2 and 4 kg, which resulted in normal stresses of 30.56, 61.11, and 122.22 kPa, respectively. In the execution of tests with the use of soil-cement and soil-cement-strip composites, curing was carried out by placing the specimens in a humid chamber, with constant wetting for periods of 7, 14, and 28 days. The tests were carried out with the specimens of 7 days due to similarity with the results obtained considering the periods of 14 and 28 days.

Considering the high cost of cement and the potential pollutant of the material, the strips were added to the sandy matrix composites with 2% cement, looking for a low-cost material, with high strength, ductility and high sustainable potential, seeking to assess how much the strength could increase with the addition of the strips so to maximize their use and minimize the use of cement. The analysis of the results was based on the analysis of the shear strength soil parameters (cohesion and internal friction angle) and the stress-displacement curves taking into account the soil, the soil-cement, and the soil-cement-strip.