1. Introduction

The readymade garment (RMG) industry is the single most foreign-currency-earning sector in Bangladesh [

1]. This sector is the biggest export earner, with a value of over 30.61 billion USD in the 2017–2018 financial year, which accounts for 81% of the total export earnings of the country Bangladesh Garment Manufacturers and Exporters Association (BGMEA) [

2]. The RMG industry is also the single largest sector, employing over four million workers—an estimated 55–60% of whom are women—coming mostly from insolvent family backgrounds. Currently, the BGMEA has 4500 registered members of factories. Knitwear and sweater manufacturers account for 40% of BGMEA member factories, and the other 60% are woven garment manufacturers. These factories account for 100% of the woven garment exports of the country. They also predominantly share 95% of the sweater exports, and approximately half of the light knitwear exports are made by them [

2]. Although the sector has enormous potential for further growth, it receives international concern due to the number of employee deaths due to building collapses and fire hazards in factories. Many industrial and commercial buildings in Bangladesh have not been constructed according to the Bangladesh National Building Code (BNBC) [

3]. Moreover, it is evident from several building collapses resulting from earthquake and fire incidents in RMG factory buildings that the structural design and preparedness measures are inadequate. For instance, the RMG building that collapsed on 24 April 2013 (known as the Rana Plaza collapse) killed over 1138 people [

4]. Under this prevailing condition, if an earthquake of moderate or stronger magnitude happens in Bangladesh, it will have a huge and catastrophic number of casualties and fatalities in RMG factory buildings. Despite there being much literature on workplace safety in RMG factory buildings in Bangladesh [

3,

5,

6], earthquake risk reduction in these buildings is a new concept. Among different measures (structural and nonstructural) of the idea, this research explores awareness, preparedness, and response in the RMG industry in Bangladesh.

In Bangladesh, each year, approximately 11,700 workers die from traumatic injuries, and a further 24,500 fatalities occur from work-related diseases across all sectors [

7]. Apart from the Rana Plaza fatalities in 2013, there have been over four hundred deaths associated with fire incidents in the last two decades [

7]. Following the Rana Plaza tragedy, several researchers (i.e., [

5,

7,

8,

9,

10]) investigated the types and causes of fire hazards and associated disasters (

Table 1). These studies identified the root causes of fire hazards and associated deaths in the RMG industry in Bangladesh. Ansary and Barua [

3] and Barua and Ansary [

6] discussed the processes of inspection of the structural integrity of the RMG buildings and the progress of building safety monitoring in Bangladesh. The column capacity, structural system, and construction materials of the RMG factory buildings are identified as the main three susceptibility factors for vertical loads [

4]. Some limited research has focused on disaster preparation and response concerning earthquake hazards in the RMG industry in Bangladesh (

Table 1). Despite this, experts continue to advocate that disaster governance should be based on informed knowledge derived from research [

11].

This research seeks to progress disaster risk reduction by asking: What is the current level of preparedness and response to earthquake hazards in the RMG industry? It conducts face-to-face interviews with workers, officials, senior executives, and owners in the RMG industry, as well as emergency management officials and policymakers who are dealing with preparedness within disaster risk governance in Bangladesh. The research questions are: What are the current levels of earthquake knowledge, risk perception, preparedness, and earthquake experience for implementing risk reduction practices in the RMG industry, and what are the challenges? How can the collaborative efforts of the government of Bangladesh (GoB), Bangladesh Garment Manufacturers and Exporters Association (BGMEA), and Bangladesh Knitwear Exporters Association (BKMEA) be used to implement preparedness and response for earthquake risk reduction in the Bangladeshi RMG industry?

In the following sections, earthquake hazards and risks, preparedness activities led by the GoB, and risk perception and preparedness are discussed. Next, the methods used for this research are outlined. In the subsequent sections, the results of this paper are presented, and, finally, the conclusions, discussion, and implications of this research are provided.

1.1. Earthquake Hazards and Risks in Bangladesh

Bangladesh is highly susceptible to earthquakes due to its proximity to active faults and geomorphology, and socio-political factors (i.e., limited preparedness, fragile building structures, and high population exposure). Furthermore, a multinational earthquake disaster risk index suggests that Dhaka is one of the top twenty seismic prone cities. Dhaka is defined within the top twenty due to the fragility of the built environment (i.e., buildings, roads, transport, water and power lines, etc.), high population density, inadequate emergency response and recovery capacity (Cardona et al. 1999) [

16]. Akhter [

17] provided a list of earthquakes from 1548 to 2009, originating between Sumatra and Bhutan, which affected Dhaka with varying degrees of intensity. Alam, et al. [

18] suggested that between 810BC and 2012, 562 earthquakes impacted the Bay of Bengal and Bangladesh region. Moreover, a hidden fault under Dhaka that is thought to be accruing stress [

17] could mean that the next earthquake results in catastrophic damage to Dhaka [

17,

19].

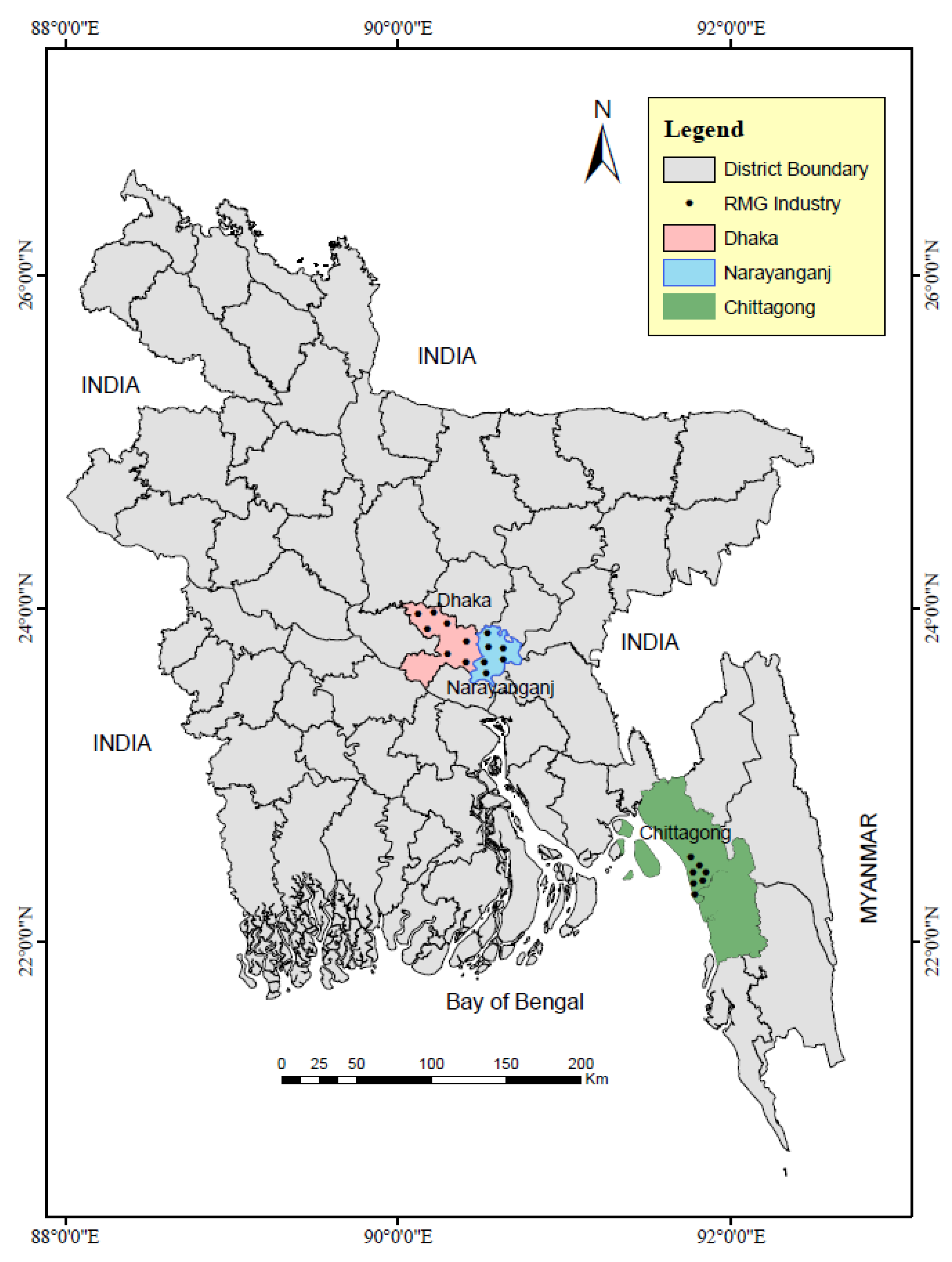

In both historical and recent times, the major cities, Dhaka and Chittagong (see

Figure 1 for location) have experienced ground-shaking with intensities between III and VIII on the modified Mercalli intensity (MMI) scale from local, regional and teleseismic earthquakes [

17,

18]. The earthquakes that occurred in 1897, 1934 and 1950 ruptured large areas adjacent to Bangladesh. The 1762 and 1897 earthquakes severely shook the Chittagong region and northern Bangladesh and caused landslides and liquefaction [

20,

21]. The 14 July 1885 Bengal earthquake (

Ms 7) originating within Bangladesh caused significant damage in Dhaka (Khan and Hossain, 2005) [

22]. Earthquakes in Bangladesh are low-frequency catastrophic events, and the vast majority of Bangladeshi have not experienced significant earthquakes in their lifetimes. Over the last three decades, the earthquakes that occurred in 1997, 1999, and 2003 caused substantial damage in Southeast (SE) Bangladesh [

23].

Earthquakes with a magnitude of at least six could significantly damage vulnerable infrastructure and cause human casualties in Dhaka (Stone, 2011) [

19]. A moderate earthquake (Mw 5.8) occurring in Assam, India, resulted in the cracking of five buildings in Dhaka on 25 April 2013. Furthermore, a recent survey suggests that residents in Chittagong perceived a very low-risk of earthquakes and had undertaken minimal preparedness for earthquakes in the future [

24]. Bangladeshi cities lack not only effective policy in disaster risk reduction but also an appropriate implementation of existing policies [

25].

1.2. Earthquake Preparedness Activities in Bangladesh

Following the 2004 Indian Ocean tsunami, the GoB has emphasized mitigating the effects of low -frequency earthquake hazards. This focused research on identifying areas that are prone to severe seismic effects in Bangladesh [

26]. The revised Standing Orders on Disasters (SOD), published by the Disaster Management Bureau (DMB) in 2010, emphasized the need for mapping areas liable to earthquake damage. The DMB (currently strengthened as the Department of Disaster Management), a technical division of the GoB, has attempted to increase public awareness to enhance preparedness for the pre and post-earthquake periods in Bangladesh. Awareness activities included the publication of preparedness manuals and the launching of the program in national broadcasting media, such as TV and radio [

27]. In 2009, the DMB published a manual that outlined pre-disaster measures and recommended activities that should be carried out during earthquakes [

27]. Although some measures have been adopted, there is no effective strategic plan for earthquake preparedness. Following the verdict of the High Court Division of Supreme Court in 2009, the GoB formed an Earthquake Preparedness and Awareness Committee. The committee was formed by members from 38 departments and agencies headed by the Minister of the Ministry of Disaster Management and Relief. The objective was to prepare the nation for earthquake risk management. The review of the work of the Ministry of Food and Disaster Management suggests that the GoB is still working towards identifying earthquake-prone areas and improving disaster risk reduction for earthquake-related hazards.

1.3. A Review on Studies about Disaster Risk Perception and Preparedness

In the following sections, earthquake hazard knowledge, risk perception and disaster preparedness, particularly important to this research, are explored. To mitigate the effects of natural hazards, it is essential to understand how people living in risk-prone areas perceive hazards and risks and their knowledge and preparedness to particular hazards [

28,

29]. Enhancement of earthquake hazard knowledge increases risk perception and preparedness actions [

30] and decreases vulnerability in the future. Russell, et al. [

31] identified that homeownership, income, education, marital status, number of children at home, living experience in the neighborhood and frequency of earthquakes determine preparedness level to earthquake hazards. In relation to volcanic hazards, Johnston, et al. [

32] suggest that only direct experiences may increase hazard knowledge and risk perception. Indeed, when people perceive hazards more, they are supposed to take more protective measures [

33]. This, however, may not necessarily lead to better preparedness (Johnston et al. 1999; Rüstemli and Karanci, 1999) [

32,

34]. Nevertheless, hazard knowledge and risk perception remain important components of risk mitigation approaches [

35]. It is unlikely that an individual will be motivated to take part in mitigation measures for natural hazards without a prior appreciation of the hazard and risk [

36]. However, cultural and cognitive variables have a significant impact on the communities’ response to earthquake risks, suggesting that education and information may influence developing their cognitive processes to earthquake preparedness [

37].

The residents in Chittagong were aware of the sudden onset of earthquake hazards that leave people with limited time to prepare and evacuate [

24]. The term,

Bhumikompo, is known by the residents and is the Bengali term for earthquake, consisting of two words:

Bhumi (land) and

kompo (shaking) [

24]. By conducting community consultation in Chittagong, Alam [

24] suggests that the residents have low-risk perception and have not taken any preparation in the absence of their direct experience of earthquakes. Paul, et al. [

38] conducted a quantitative survey of 444 residents of Dhaka to understand risk perceptions and preparedness about earthquakes. Over 75 percent of the population and 80 percent of the buildings in Dhaka are susceptible to earthquake hazards (Paul and Bhuiyan, 2010) [

38]. The findings suggest that 83 percent of the residents were not prepared for a major earthquake in the future. In Dhaka, vulnerability to earthquake and fire hazards are further heightened due to limited road networks, fragile buildings, the storage of flammable materials within the buildings, the existence of mixed land use, including residential and industrial buildings located together [

15]. Alam, et al. [

39] warned that the recurrence of the 1762 earthquake-like event would cause liquefaction, compaction, landslides and co-seismic subsidence, fatalities and morbidities in SE Bangladesh.

Previous research focused on understanding the morphology and seismic risk in Dhaka and Chittagong cities and Mymensingh town. Bangladesh is highly susceptible to earthquakes due to its proximity to active faults and geomorphology, and socio-political factors (i.e., limited preparedness, fragile building structures, and high population exposure). Although efforts were undertaken to improve building design and occupational health and safety, there is still a pressing need to understand earthquake risk reduction strategies in RMG industries in Bangladesh. This research attempts to fill this gap in knowledge by assessing institutional policies and factory owners and/or workers’ hazard knowledge, perception, disaster preparation and responses for earthquake hazards. The findings endeavor to help develop more effective response mechanisms and better prepare for future hazard events.

2. Methods and Materials

To fulfill the objectives, the research addresses and resolves several specific scientific and technical issues related to the diverse disciplinary fields of disaster preparedness and policy planning. This research aims to improve the institutional capacity to manage earthquake hazards and associated emergency response. To gain a better understanding of factory owners and/or workers’ perception of hazard and risk and their preparedness [

40,

41], both quantitative and qualitative methods were utilized in this research. With both approaches having their own limitations (Gregory et al. 2009) [

42], mixed methods serve to bring in a more robust evidence base than either qualitative or quantitative approaches provide when they are used separately [

43].

To understand the RMG work environment, hazard perception, disaster preparedness and challenges for workplace safety, it required visiting inside the factories and consulting the workers, executives and owners about workplace safety, earthquake preparedness and emergency response. When the investigators attempted to visit the factories for this research purpose, they did not have permission from the owners. Then, official letters mentioning the noble intention of the research were sent to the BGMEA and BKMEA in an attempt to collate a list of industries appropriate for the study. After a month of experiencing no response from both the BGMEA and BKMEA for the formal request, the author, along with data collecting assistants, randomly visited over 40 factories in Dhaka, Narayanganj and Chittagong, Bangladesh between March and May 2017 (

Figure 1). Following discussions with each industrial authority on the author’s academic affiliation, noble approaches of this research and humble request, 20 industrial authorities allowed access for the investigators to interview workers, officials and top executives on questions limited to the research objectives. To check the structural integrity of the buildings; Alliance (Alliance for Bangladesh Workers Safety), Accord (the Accord on Fire and Building Safety in Bangladesh) and National Tripartite Plan of Action (NTPA) inspected 6, 3 and 2 factories, respectively. The remaining nine factories were not inspected by any authority. After the Rana Plaza collapse on 13 June 2013, the Alliance, Accord and NTPA were also the three authorities that inspected the structural integrity of the RMG factory buildings between 2013 and 2018.

To assess RMG occupants’ knowledge, risk perception and preparedness for earthquake hazards, investigators administered a combination of semi-structured and open-ended questionnaires to workers of 20 RMG factories located in Dhaka, Narayanganj and Chittagong between March and May 2017. Seven factories were located in Dhaka, and seven in Chittagong. The remaining six were in Narayanganj. During each factory visit, one representative from the factory accompanied the data collectors to introduce workers to the purpose of the research. After the introduction, the workers willingly participated in answering the research questions. This study considered data from a sample of 178 workers: 63 from Dhaka and 63 from Narayanganj, and 52 interviews from Chittagong.

The questionnaire included two sections. The first section consisted of a series of questions designed to address the first objective of the research and included questions about general knowledge of earthquake hazards, past experiences of earthquakes, risk perception, emergency response, preparation and evacuation procedure for the workplace. The second section contained items to answer the second research objective, which aimed to strengthen effective earthquake preparation and response procedures in the RMG industry in Bangladesh. A total of 22 key informant interviews were conducted through participatory consultation with factory workers, particularly team leaders, owners, key executives, officers and administrators, to establish current earthquake preparation and response procedures of the RMG industries. These key informants possess expert knowledge about workplace safety, compliance procedures, disaster preparedness and emergency response within their factory. The questionnaire was pretested in the field to determine its adequacy, applicability and to address any deficiencies found. Throughout the research process, the norms of social science survey practice were rigorously applied, paying attention to concerns over the workers’ and participants’ rights during data collection.

The map of the study area was constructed using ArcGIS 10.3. Field survey data were first checked and collated for analysis. Statistical tools such as frequency and percent distributions, cross-tabulation and custom table were used to analyze the workers’ demographic characteristics and responses on aspects of disaster preparedness and emergency response and presented in tables by using MS-Excel 2017. Of these 178 workers, 119 were male, and 59 were female. Approximately 73 percent of the workers belong to the age group of 21–35 years. Only 3 percent of workers were above 45 years old, and 10 percent were below 20 years old. Approximately 33 percent of the workers were illiterate. 43 percent had not achieved secondary school certificate (SSC) education, 14 percent had their SSC, and 11 percent had attained their higher secondary certificate. The workers in RMG industries had an average service experience of 5.5 years, and 36.5 percent of the workers have between 4 and 7 years’ experience and, 10 percent have over ten years of work experience.

The research aimed at developing effective earthquake preparation procedures through a participatory consultation with factory workers, owners, fire services and civil defense officials, key executives, experts and administrators in Dhaka, Narayanganj and Chittagong. To meet this aim, the results from the field questionnaire surveys and key informant discussions were shared in a one day workshop at Zilla Parishad, Chittagong on 22 July 2017. The workshop involved factory workers, owners, fire services and civil defense officials, key executives, experts, administrators and representatives from the GoB, BGMEA and BKMEA. Fifteen people from the above stakeholders attended the workshop. The combined results of this research obtained through questionnaire surveys, key informant consultations and workshops were shared with a diverse group of academic, emergency management, disaster and health specialists using the Internet and personal contacts in Dhaka, Narayanganj and Chittagong.

3. Results

In the following sections, key findings are provided to inform the RMG industry, BGMEA and BKMEA about developing earthquake risk mitigation strategies and assisting the GoB to determine the appropriateness of its national preparedness strategy. The sections include findings of earthquake hazard knowledge and risk perception, previous experience of an earthquake at the workplace, the challenges faced within the factories during past events, knowledge about preparedness, evacuation problems, ownerships of RMG buildings and disaster preparedness, and suggestions to improve earthquake preparation.

3.1. Earthquake Knowledge, Risk Perception and Disaster Preparedness

Field data unveil real-life hazard knowledge, risk perceptions, obstacles for disaster preparation and disaster mitigation strategies in the RMG industry. These are discussed in the following sections.

3.1.1. Knowledge about Earthquake and Risk Perceptions

To mitigate the effects of natural hazards, it is essential to understand how people living in places at risk perceive hazards, their risk and their understanding and preparedness to particular hazards [

28,

29]. Enhancement of earthquake hazard knowledge may increase risk perception and preparedness actions [

30,

37] to reduce future vulnerability. In this research, of the 178 respondents, 76 respondents (42.7 percent) perceived that their workplace could be impacted by fire, and 97 respondents (54.5 percent) believed that they are at risk of both fire incidents and earthquakes. Only four respondents believe that they are only at risk of an earthquake. These four respondents trust that they are not at risk of a fire as they perceived that their factories are fire hazards compliant [

3]. The respondents suggest that they have all means of preparation and practice frequent drills in the buildings to minimize and control fire hazards. However, as earthquakes are an uncontrollable phenomenon, the industries remain at risk of this type of hazard. One respondent suggested that their workplace is not at risk of any hazard because the factory building structure is earthquake- resistant, and the workplace has an effective fire risk mitigation system in place.

The surveyed RMG industries appear to be compliant with workplace safety-related acts, rules, and policies, as train workers about both fire and earthquake. Key informant discussions suggest that these industries warn their workers of earthquakes, resulting in higher risk perception among workers. The industry owners allow workers to evacuate the building after an earthquake. The factories that are being inspected by Alliance for structural integrity and workplace safety have owners who mainly train workers in a fire hazard, and simultaneously, they inform workers about the possibility of earthquakes and what to do when they occur. Of the 178 respondents, 105 workers (59 percent) were mainly trained in fire hazards. The remaining 73 (41 percent) were trained in hazards for both earthquake and fire. Certain key informants suggest that workers have learned to shut off main switches in case of earthquakes. They informed that the risks associated with earthquakes depend on the number of floors of the RMG factory buildings. Factories located in one or two-storied buildings may have less-risk than those in multi-storied buildings.

3.1.2. Experience of Earthquake Occurrence at Workplace

In historical and recent times, the major cities, Dhaka and Chittagong (see

Figure 1 for location), have experienced ground shaking from local, regional and teleseismic earthquakes with intensities between III and VIII on the modified Mercalli intensity (MMI) scale. In this research, of the 178 participants, 147 workers suggested that they have experienced earthquakes at their workplace. The workers mainly faced smaller size earthquakes (

Ms 4.5 to 6), which only shake the ground slightly and finish before workers realize an earthquake has occurred. The workers suggested that no action is required because of their short duration and weak intensity. On several occasions, earthquakes finish even before the occupants have finished evacuating. The weak intensity of the earthquake may match the vibration from the sewing machines they work on, explaining why they may have a slow reaction or no reaction at all. During earthquakes, the workers’ responses depend on their knowledge, earthquake experience and training they have received from the employers. Both survey data and key informant discussions reveal that female workers become panicked and start running on the floor to evacuate when experiencing earthquakes. Conversely, some workers said that they maintain their post and position. Other workers have suggested that when experiencing tremors, they run towards the assembly area or take shelter under machines or tables.

The RMG industries that appear to be compliant with workplace safety train workers about earthquake preparedness within their fire safety training. They train workers to get down from the building and take refuge in an assembly area or to stay near stronger beams or underneath sturdy tables. Some RMG industries suggested they provide alarm sirens and open all gates to evacuate the building immediately. In these types of industries, the workers evacuate in a sequence and take shelter in an assembly area. Discussions with the top executives and owners of the RMG industries suggested that the person in charge of the floor provides direction and monitors workers through a safe evacuation. Following the earthquake, the site engineer and administrative officer inspect the building to check for any fault or damage. Later, management makes sure that all workers have safely returned to the workplace. Sharing of these findings with experts at workshops suggests that RMG owners should not train and allow workers to return to the building after evacuation because this will increase the chance of deaths and injuries during earthquakes and possible after-shocks.

3.1.3. Challenges Faced at Workplace during Past Earthquake Events

Field research suggests that the occupants of RMG factories did not face many challenges during past earthquakes. Qualitative data indicate that workers did not need to worry because there were enough staircases to evacuate the buildings quickly. Most workers usually go outside, but those who cannot evacuate manage to take shelter beside pillars or under strong tables. Workers who are very pious are found to sound Allah (God), Allah (God) and Allah (God). Although this does not happen widely, few workers become panicked during earthquakes and are prone to falling and sustaining injuries during evacuation, as evidenced in some cases. Other challenges include congestion and collisions among workers as they rush to evacuate. Some workers are found to shout when panicked, while others are uncertain and confused about what actions to take. Currently, some industrial authorities do not provide alarm sirens or allow workers to go outside of the premises. Perversely, owners may refuse to evacuate workers to maximize productive working hours. This indicates that RMG factories do not follow any standard procedure for earthquake risk reduction throughout the industry. Establishing standardization across the RMG industry creates another challenge to the aims of this research.

3.1.4. Knowledge about Earthquake Preparedness

In response to an earthquake at the workplace, about 79 percent of respondents state that they have general knowledge about earthquake preparation. These findings are contrary to the earlier research by Alam [

24], who conducted a field survey of Bangladeshi coastal communities, which found that none of the participants had any knowledge of what to do during an earthquake, nor had they undertaken any preparedness activities. Although Mulilis, et al. [

44] and Mulilis, et al. [

45] have suggested that a better understanding of hazards may not influence preparedness, this research explores that workers having prior knowledge of earthquake hazards possess the basic safety preparedness to hazards. Workplace safety training is an important component of disaster preparedness. Workers should receive workplace safety and hazard identification training before they start working in the RMG industry; however, about 47.2 percent of workers received training 28 days after joining the workplace. A total of 37.6 percent received training on the very first week, and the remaining 15.2 percent of the respondents had received training between 8 and 28 days after employment at the workplace. Of the industrial workers, 82 percent indicated that they were aware they should not be adjacent to metal elements/electric wires/gas oven, mirrors, glasses or other similar items during earthquakes (

Table 2). The participants learned about these risk elements from workplace training, coworkers, general discussions, and electronic and print media.

From the 178 participating workers, 79 percent know they may take safe refuge by standing along the side of strong beams and seeking cover underneath strong tables during an earthquake (

Table 3). This knowledge implies that the workers who have not experienced strong to extreme earthquakes in the past have learned about possible safety procedures to undertake during earthquakes. About 80 percent of workers know the location of the first aid kit in their workplace (

Table 3), and 90 percent of workers know emergency service numbers (

Table 3). The majority of workers, 94 percent, have knowledge of the location of exit/evacuation gates for any emergency event (

Table 2). The noncompliant RMG factories do not have demarcated assembly points identified for evacuation from the building. Although some RMG factories inspected by Alliance or Accord or NAP, have been labeled as compliant with industry standards, not all of these factories have demarcated assembly points. As such, only 45 percent of workers could identify the location of the assembly points following an emergency (

Table 2). Key learning from this research is that a compliant factory trains workers, supervisors, officials and top executives equally through formal and informal training initiatives about hazards, disaster preparedness and evacuation procedures

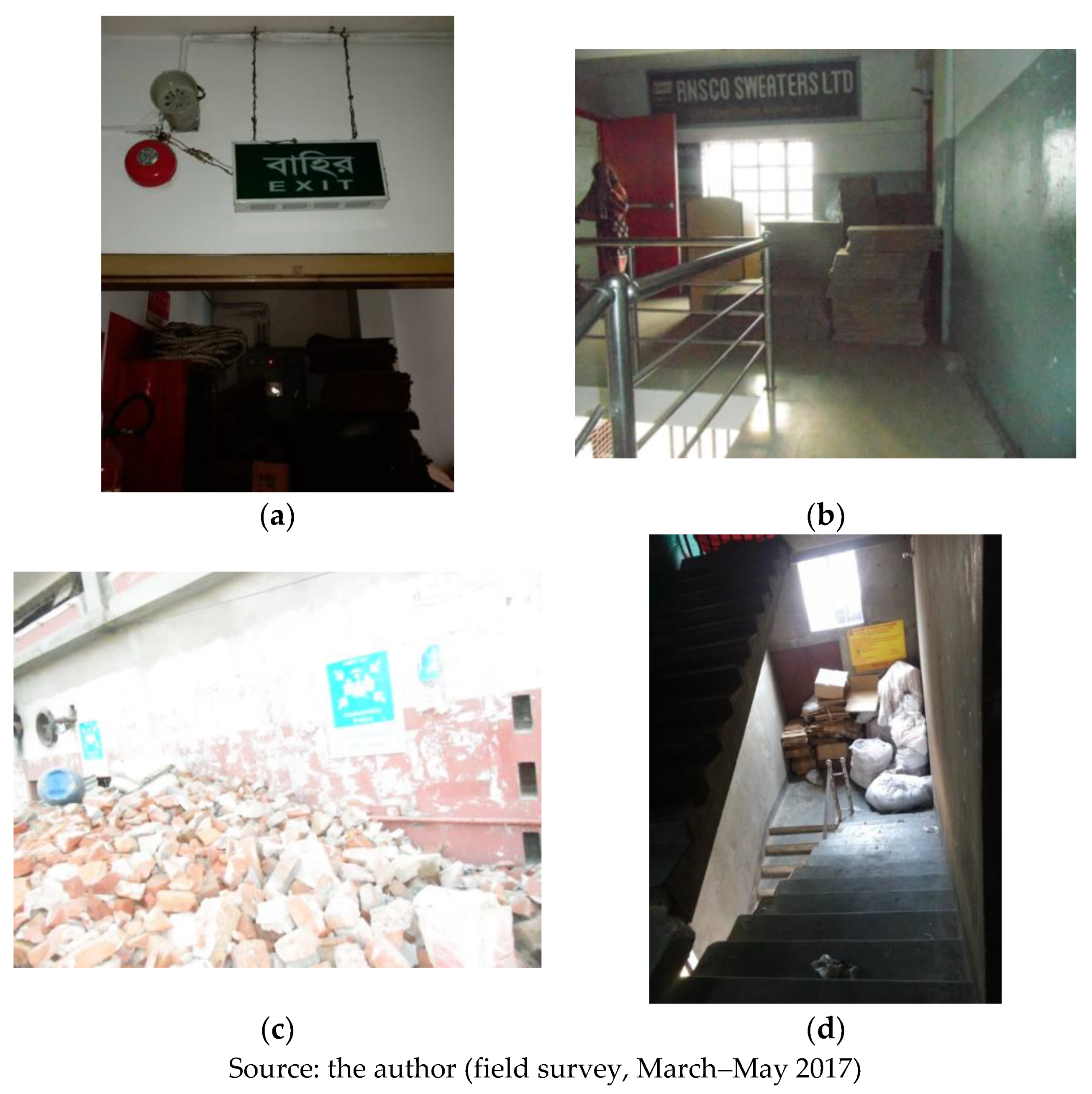

3.2. Evacuation Problems Following an Earthquake

It was noted that of the 20 factories inspected, one factory owner had never practiced evacuation at the workplace. Some factory management claimed they have high levels of preparedness to mitigate fire and earthquake hazards. Key informant discussions with senior executives and owners of the factories deemed compliant by compliance agencies suggest the structural design of the buildings and overall preparation have a zero-tolerance approach to hazards. Seven workers suggest that they could not understand the research question about evacuation because they had not received evacuation training in the workplace. The remaining 139 workers provided responses about evacuation challenges at their workplace (

Table 3). These include: (i) the provision of the main entrance and exit on the ground floor is not wide enough for the mobility of workers; (ii) a narrow exit gate; (iii) passages, aisles, corridors, stairways being obstructed by packages; (iv) no fire door installed; (v) no exit sign; (vi) blocked exit gate, etc. (

Figure 2).

3.3. Ownership of RMG Building and Disaster Preparedness

The ownership of buildings has a significant impact on hazard preparedness. Of the surveyed 20 factories, nine are rented buildings, while 11 are owned. Factories located in rental buildings experienced comparatively higher challenges to comply with structural integrity and disaster preparedness. The findings are consistent with Russell, Goltz and Bourque [

31], who suggest that homeownership is one of the determining factors to earthquake preparedness. Research with executives and owners of the RMG factories in rented buildings advises that approval from the owners is required to make any structural changes. It is unlikely that the owners will provide consent for such changes, even if it would strengthen the buildings. The owners fear that RMG management may leave the building after the agreed rental period, and the structure may become unfit for future occupants.

Conversely, most of the RMG factories in rental buildings think that it is inefficient to spend money on rental buildings because they may have to relocate at any time. Most rental buildings have stairs on two sides and two exit gates; preferably, the buildings should have stairs on all four sides and have four gates as per the International Labor Organisation (ILO). Some owners, who also operate factories in rental buildings, state that following an inspection by the NTPA, they attempted to increase exit gates, but they failed to receive approval from the building owners.

3.4. Suggestions to Improve Earthquake Risk Reduction Strategies

Field research proposes a list of activities that can be undertaken to improve earthquake preparation, prevent evacuation difficulties during an earthquake and how to improve occupational health and safety in RMG factories. These activities are discussed in the following sections.

3.4.1. Suggestions to Improve Earthquake Preparation

Although current practices and policies provide guidance for structural resistance of the RMG factory buildings, the policies remain silent on earthquake risk implementation strategies. As such, the first step in earthquake preparation recognizes earthquakes as a hazard for RMG factories because the region is located within and adjacent to active fault zones. It was noted that many industries did not include earthquake preparation in their hazard training manual. The GoB should develop appropriate policies and legislation to include hazard management and specifically to earthquakes into ongoing training activities. Qualitative data obtained through surveys and discussions with workers and key informants suggest several important steps to improve earthquake preparation. The strategies presented include launching awareness, training among workers and improving building design and allowing adequate space between buildings (

Table 4).

3.4.2. Suggestions to Improve Evacuation Following an Earthquake

Having a lack of unified action plans from the GoB, BGMEA and BKMEA, different RMG factories undertake varying types of evacuation procedures for their workplaces. Although some factories train and allow occupants to evacuate the buildings during earthquakes, experts suggest an increased likelihood of further deaths and injuries for such attempts. Instead, an improved evacuation option would depend on building structure, design, floor numbers, owning the building or occupying a rental building and the purpose of building construction, etc. Questionnaire surveys and discussions with workers provided valuable suggestions to improve evacuation procedures during an emergency (

Table 5). The strategies include introducing building space among workers, a sufficient number of gates for evacuation, provision of space between work stations, installation of rescue windows and clearing stairs and ground floors for clear access and free movement.

3.4.3. Future Plans and Strategies to Improve Earthquake Preparedness

The research provided the following plans to improve earthquake preparation. These plans are consistent with the GoB monitoring strategy and compliance procedure outlined by Alliance, Accord, NAP and Department of Inspection for Factories and Establishment (DIFE). The notable strategies suggested for future actions include compliance with ILO instructions for evacuation gates, the proportion of building size and number of workers, maintaining BNBC rules and guidelines for building design and construction materials, and executing drills and training (

Table 5).

4. Discussion and Conclusions

The applied value of the research is providing immediate practical solutions and feeding into policy on how effective people-centered earthquake risk reduction strategies and disaster governance could be developed and implemented for RMG industries in Bangladesh. It seeks to increase the disaster resilience of RMG industries by saving lives, reducing financial losses and developing safer working environments. It was noted that of the 178 workers, 76 respondents perceived that their workplace could be impacted by fire, and 97 respondents believed that they are at risk of both fire and earthquake. Because one industry appears to be compliant for fire hazards, four respondents felt that they are only at risk of an earthquake. The findings suggest that 105 workers (59 percent) were mainly trained on fire hazards, while the remaining 73 (41 percent) were trained for both earthquake and fire incidents. The majority of workers experienced light to moderate earthquakes (

Ms 4.5 to 6) at their workplace. Although Alam [

24] suggests that rural coastal communities in the SE coast of Bangladesh do not know how to respond during an earthquake, the majority of the RMG factory workers, over 80 percent, are aware that they should not to be adjacent to metal elements/electric wires/gas oven, mirrors, glasses or other similar items during the earthquake.

The majority of workers know the location of the workplace first aid kit, emergency evacuation gates, and phone numbers for emergency services, which are essential elements of earthquake preparedness. The factories located in a rental building faced comparatively higher challenges to comply with structural integrity and disaster preparedness. The respondents suggest that they have all means of preparation and practice frequent drills in the buildings to minimize and control fire hazards. However, the earthquake is an uncontrolled natural phenomenon, and the RMG industry remains at risk of this hazard. Following the Rana Plaza collapse in 2013, measures to update and strengthen workplace safety in RMG industries have occurred. However, it appears that these measures have mainly focused on fire hazards and safety. Key learning from this research is that a compliant workplace trains its workers, supervisors, officials and top executives equally through formal and informal training initiatives about hazards, disaster preparedness and safe evacuation if necessary.

The research may help to develop and rectify new policies and practices for emergency response and disaster governance. A combination of these activities will lead to the development of coordinated and people-centered earthquake-risk reduction strategies and disaster governance plans for the RMG industry in Bangladesh. To strengthen current disaster risk reduction (DRR) efforts in RMG industries, this research suggests heightened awareness about the scientific nature of earthquakes, training activities, how to remain calm during an earthquake to take refuge or evacuation, knowledge about building space and designing and constructing RMG buildings with complying structural integrity and workers’ occupational health and safety. Discussions with key informants, representatives from BGMEA, BKMEA and lessons identified from the dissemination of findings in workshops, suggest that key findings of this research are beneficial for RMG industries. The findings may help develop a sustainable business for readymade factory owners, entrepreneurs, executives and workers in Bangladesh. The findings, however, need to be disseminated to strategic government officials and ministers of the Ministry of Labor and Employment, Department of Inspection for Factories and Establishment (DIFE), Ministry of Disaster Management and Relief (MoDMR) and Ministry of Industries in order to develop implementation strategies. Emergency responses and earthquake risk reduction in RMG industries are still at an early stage; future research may explore the involvement of large-scale stakeholders from national to local levels, in which effective preparedness and emergency response can be developed and implemented within industrial, commercial and residential apartment complexes in Bangladesh.