Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs

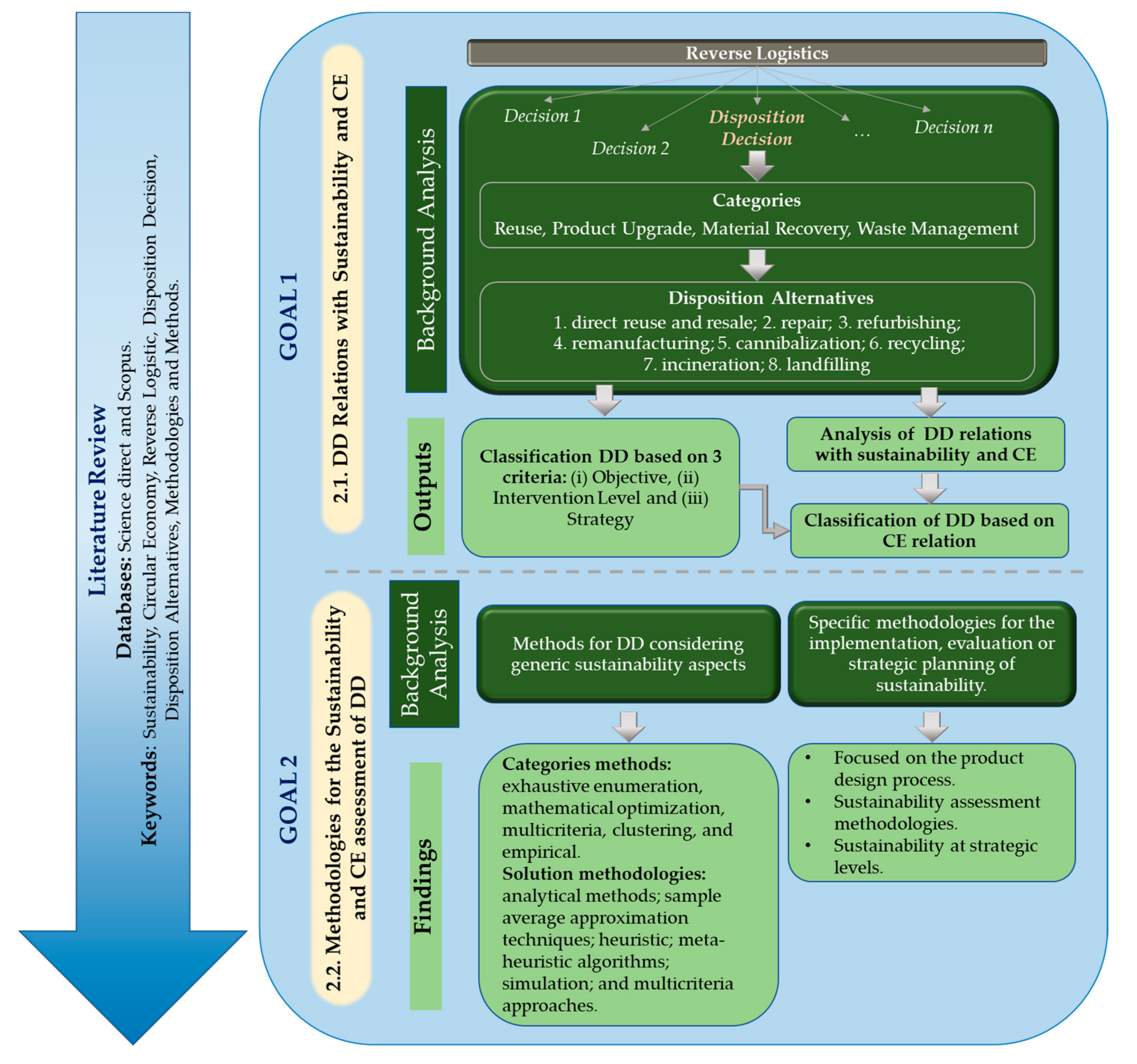

Abstract

1. Introduction

2. Background

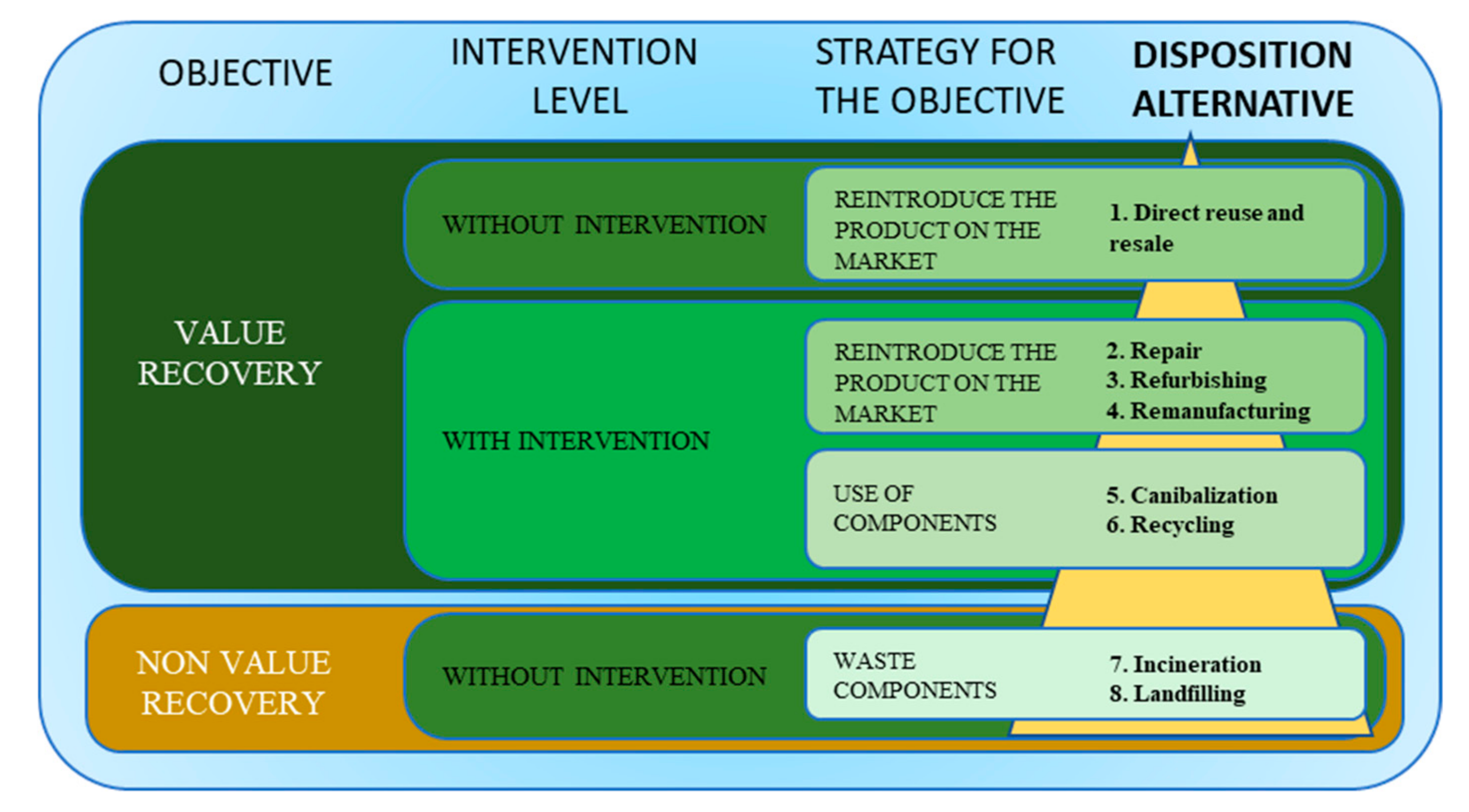

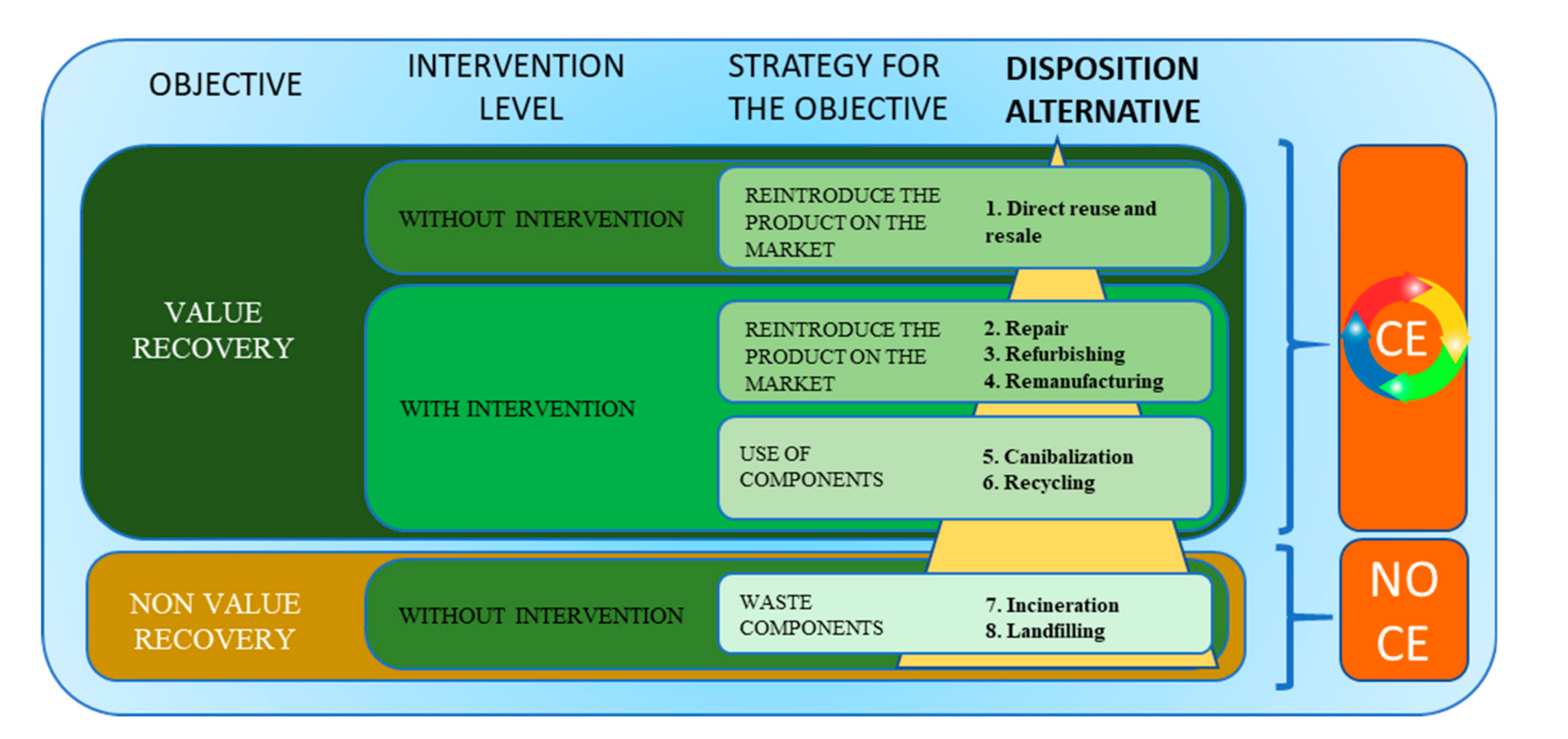

2.1. DD Relations with Sustainability and CE

2.2. Methodologies for the Sustainability and CE Assessment of DD

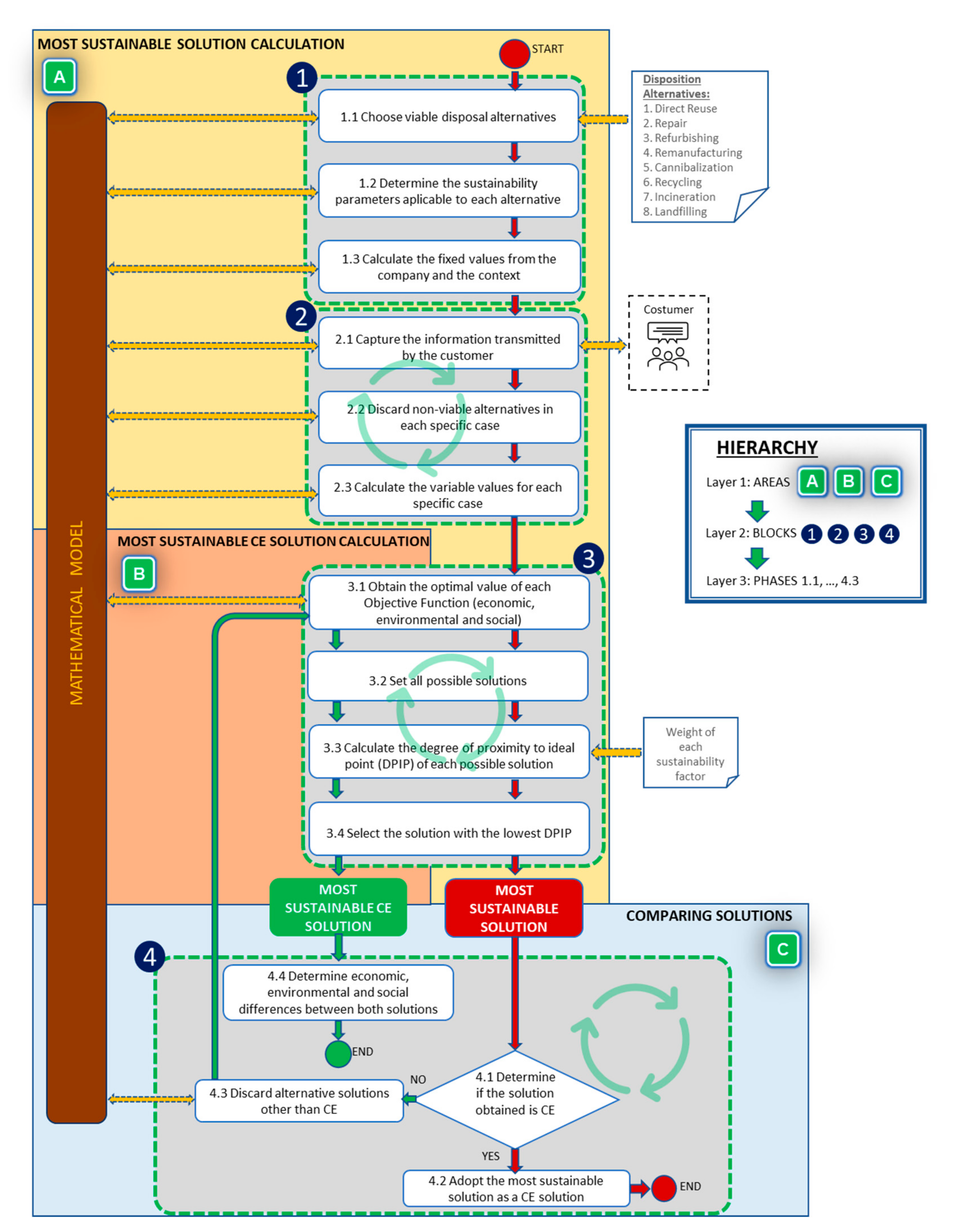

3. Methodology for Sustainable and CE Disposition Decision-Making

3.1. Layer 1

3.2. Layer 2

- Block 1. MM adaptation and introducing fixed values

- Block 2. Preparing the MM for its execution in each specific case

- Block 3. Solution process execution

- Block 4. Comparing solutions

3.3. Layer 3

- Phase 1.1 Choose viable disposition alternatives

- Phase 1.2 Determine the sustainability parameters applicable to each alternative

- Phase 1.3 Calculate the fixed values from the company and the context

- Phase 2.1 Capture the information transmitted by customers

- Phase 2.2 Discard non-viable alternatives in each specific case

- Phase 2.3 Calculate the variable values for each specific case

- Phase 3.1 Obtain the optimal value of each of (economic, environmental, social)

- Phase 3.2 Set all the possible solutions

- Phase 3.3 Calculate the degree of proximity to the ideal point (DPIP) of each possible solution

- Phase 3.4 Select the solution with the lowest DPIP

- Phase 4.1 Determine if the obtained solution is CE

- Phase 4.2 Adopt the most sustainable solution as a CE solution

- Phase 4.3 Discard alternative solutions other than CE

- Phase 4.4 Determine the economic, environmental, and social differences between both solutions

4. Example of Applying the Methodology to a SME that Recovers and Treats Used Tires

- Phase 1.1 Choose the feasible disposition alternatives according to product type

- Phase 1.2 Determine the sustainability parameters applicable to each alternative.

- Phase 1.3 Calculate the fixed values from both the company and context

- Phase 2.1 Collect the information transmitted by customers

- Phase 2.2 Discard non-viable alternatives in each specific case

- Phase 2.3 Calculate the variable values from each specific case

- Phase 3.1 Obtain the optimal value of each OF: economic, environmental and social

- Phase 3.2 Set all the possible solutions

- Phase 3.3 Calculate the degree of proximity to the ideal point (DPIP) of each possible solution

- Phase 4.1 Determine if the obtained solution is CE

- Phase 4.3 Discard alternative solutions other than CE

- Phase 4.4 Determine the economic, environmental and social differences between both solutions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Brundtland, G.H. Global change and our common future. Environment 1989, 31, 16–43. [Google Scholar]

- Elkington, I.H.; Rowlands, J. Cannibals with forks: The triple bottom line of 21st century business. Choice Rev. Online 1999, 36, 3976–3997. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Geisendorf, S.; Pietrulla, F. The circular economy and circular economic concepts—A literature analysis and redefinition. Thunderbird Int. Bus. Rev. 2018, 60, 771–782. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Gobierno de España. Estrategia Española De Economía Circular; Spanish Government: Madrid, Spain, 2018; Volume 1, p. 171. [Google Scholar]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- The Ellen MacArthur Foundation. Towards a Circular Economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Growth, W. A Circular Economy Vision for a Competitive Europe. Ellen MacArthur Found. 2015, 1–98. [Google Scholar]

- Guarnieri, P.; Silva, L.C.; de Vieira, B. How to Assess Reverse Logistics of E-Waste Considering a Multicriteria Perspective? A Model Proposition. Logistics 2020, 4, 25. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K. Analyzing disposition decisions for sustainable reverse logistics: Triple Bottom Line approach. Resour. Conserv. Recycl. 2019, 150, 104–448. [Google Scholar] [CrossRef]

- Farahani, S.; Otieno, W.; Barah, M. Environmentally friendly disposition decisions for end-of-life electrical and electronic products: The case of computer remanufacture. J. Clean. Prod. 2019, 224, 25–39. [Google Scholar] [CrossRef]

- Hazen, B.T.; Hall, D.J.; Hanna, J.B. Reverse logistics disposition decision-making: Developing a decision framework via content analysis. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 244–274. [Google Scholar] [CrossRef]

- Cortés, P.; Alarcón, F. Identification of reverse logistics decision types from mathematical models. J. Ind. Eng. Manag. 2018, 11, 239–249. [Google Scholar]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Kumar, S.; Malegeant, P. Strategic alliance in a closed-loop supply chain, a case of manufacturer and eco-non-profit organization. Technovation 2006, 26, 1127–1135. [Google Scholar] [CrossRef]

- Singh, R.K.; Agrawal, S. Analyzing disposition strategies in reverse supply chains: Fuzzy TOPSIS approach. Manag. Environ. Qual. Int. J. 2018, 29, 427–443. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. Disposition decisions in reverse logistics: Graph theory and matrix approach. J. Clean. Prod. 2016, 137, 93–104. [Google Scholar] [CrossRef]

- Skinner, L.R.; Bryant, P.T.; Richey, R.G. Examining the impact of reverse logistics disposition strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 518–539. [Google Scholar] [CrossRef]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. Omega 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Thierry, M.; Salomon, M.; Van Nunen, J.; Van Wassenhove, L. Strategic issues in product recovery management. Long Range Plann. 1995, 28, 120. [Google Scholar] [CrossRef]

- Krikke, H. Impact of closed-loop network configurations on carbon footprints: A case study in copiers. Resour. Conserv. Recycl. 2011, 55, 1196–1205. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Topi, C. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Rogers, D.S.; Tibben-Lembke, R.S. Going Backwards: Reverse Logistics Trends and Practices. Logist. Manag. 1999, 2, 58–71. [Google Scholar]

- Narayana, S.A.; Elias, A.A.; Pati, R.K. Reverse logistics in the pharmaceuticals industry: A systemic analysis. Int. J. Logist. Manag. 2014, 25, 379–398. [Google Scholar] [CrossRef]

- Sarkis, J.; Helms, M.M.; Hervani, A.A. Reverse logistics and social sustainability. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 337–354. [Google Scholar] [CrossRef]

- Fleischmann, M.; Krikke, H.R.; Dekker, R.; Flapper, S.D.P. A characterisation of logistics networks for product recovery. Omega 2000, 28, 653–666. [Google Scholar] [CrossRef]

- Sangwan, K.S. Key Activities, Decision Variables and Performance Indicators of Reverse Logistics. Procedia Cirp 2017, 61, 257–262. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kusi-Sarpong, S.; Luthra, S.; Bai, C.; Jakhar, S.K.; Khan, S.A. Operational excellence for improving sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 162, 105–125. [Google Scholar] [CrossRef]

- Hazen, B.T.; Wu, Y.; Cegielski, C.G.; Jones-Farmer, L.A.; Hall, D.J. Consumer reactions to the adoption of green reverse logistics. Int. Rev. Retail. Distrib. Consum. Res. 2012, 22, 417–434. [Google Scholar] [CrossRef]

- Krumwiede, D.W.; Sheu, C. A model for reverse logistics entry by third-party providers. Omega 2002, 30, 325–333. [Google Scholar] [CrossRef]

- Souza, G.C. Closed-Loop Supply Chains: A Critical Review, and Future Research. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Lacoba, S.R. El sistema de Logística Inversa en La Empresa: Análisis y Aplicaciones. Ph.D. Thesis, Universidad de Extremadura, Badajoz, Spain, 2003. [Google Scholar]

- Wadhwa, S.; Madaan, J.; Chan, F.T.S. Flexible decision modeling of reverse logistics system: A value adding MCDM approach for alternative selection. Robot. Comput. Integr. Manuf. 2009, 25, 460–469. [Google Scholar] [CrossRef]

- Ziout, A.; Azab, A.; Atwan, M. A holistic approach for decision on selection of end-of-life products recovery options. J. Clean. Prod. 2014, 65, 497–516. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Richey, R.G.; Genchev, S.E.; Chen, H. Reverse logistics: Superior performance through focused resource commitments to information technology. Transp. Res. Part E Logist. Transp. Rev. 2005, 41, 77–92. [Google Scholar] [CrossRef]

- Khor, J.K.S.; Udin, Z.M. Impact of reverse logistics product disposition towards business performance in Malaysian E&E companies: A conceptual study. J. Supply Chain Cust. Relatsh. Manag. 2012, 1, 1089–1098. [Google Scholar]

- Stock, J.R.; Mulki, J.P. Product returns processing: An examination of practices of manufacturers, wholesalers/distributors, and retailers. J. Bus. Logist. 2009, 30, 33–62. [Google Scholar] [CrossRef]

- Tibben-Lembke, R.S.; Rogers, D.S. Differences between forward and reverse logistics in a retail environment. Supply Chain Manag. Int. J. 2002, 7, 271–282. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; van der Laan, E.; van Nunen, J.A.E.E.E.E.; van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- Jeswiet, J.; Hauschild, M. EcoDesign and future environmental impacts. Mater. Des. 2005, 26, 629–634. [Google Scholar] [CrossRef]

- Goggin, K.; Browne, J. The resource recovery level decision for end-of-life products. Prod. Plan. Control 2000, 11, 628–640. [Google Scholar] [CrossRef]

- Mollenkopf, D.A.; Frankel, R.; Russo, I. Creating value through returns management: Exploring the marketing-operations interface. J. Oper. Manag. 2011, 29, 391–403. [Google Scholar] [CrossRef]

- Moyer, L.K.; Gupta, S.M. Environmental concerns and recycling/disassembly efforts in the electronics industry. J. Electron. Manuf. 1997, 7, 1–22. [Google Scholar] [CrossRef]

- Staikos, T.; Rahimifard, S. A decision-making model for waste management in the footwear industry. Int. J. Prod. Res. 2007, 45, 4403–4422. [Google Scholar] [CrossRef]

- de Brito, M.P.; Dekker, R. A Framework for Reverse Logistics. In Reverse Logistics; Springer: Berlin/Heidelberg, Germany, 2004; pp. 3–27. [Google Scholar]

- Mangun, D.; Thurston, D.L. Incorporating component reuse, remanufacture, and recycle into product portfolio design. IEEE Trans. Eng. Manag. 2002, 49, 479–490. [Google Scholar] [CrossRef]

- Mazhar, M.; Kara, S.; Kaebernick, H. Reusability assessment of components in consumer products—A statistical and condition monitoring data analysis strategy. In Proceedings of the 4th Australian LCA conference, Sydney, Australia, 23–25 February 2005; pp. 28–42. [Google Scholar]

- Nasr, N.; Thurston, M. Remanufacturing: A key enabler to sustainable product systems. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, LCE, Leuven, Belgium, 31 May–2 June 2006; pp. 15–18. [Google Scholar]

- Parlament, European. Parlamento Europeo y del Consejo de 20 de noviembre de 2013 relativa al Programa General de Acción de la Unión en materia de Medio Ambiente hasta 2020. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=CELEX%3A32013D1386 (accessed on 30 November 2020).

- Hazen, B.T.; Cegielski, C.; Hanna, J.B. Diffusion of green supply chain management: Examining perceived quality of green reverse logistics. Int. J. Logist. Manag. 2011, 22, 373–389. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development, Resolution 70/1, Resolution Adopted by the General Assembly on 25 September 2015. Available online: http://www.un.org/en/ga/search/view_doc.asp?symbol=A/RES/70/1 (accessed on 23 November 2020).

- Glavič, P.; Lukman, R. Review of sustainability terms and their definitions. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Johnston, P.; Everard, M.; Santillo, D.; Robèrt, K.H. Reclaiming the definition of sustainability. Environ. Sci. Pollut. Res. 2007, 14, 60–66. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Gusmerotti, N.M.; Testa, F.; Corsini, F.; Pretner, G.; Iraldo, F. Drivers and approaches to the circular economy in manufacturing firms. J. Clean. Prod. 2019, 230, 314–327. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Vermunt, D.A.; Negro, S.O.; Verweij, P.A.; Kuppens, D.V.; Hekkert, M.P. Exploring barriers to implementing different circular business models. J. Clean. Prod. 2019, 222, 891–902. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Bufardi, A.; Gheorghe, R.; Kiritsis, D.; Xirouchakis, P. Multicriteria decision-aid approach for product end-of-life alternative selection. Int. J. Prod. Res. 2004, 42, 3139–3157. [Google Scholar] [CrossRef]

- Iakovou, E.; Moussiopoulos, N.; Xanthopoulos, A.; Achillas, C.; Michailidis, N.; Chatzipanagioti, M.; Kikis, V. A methodological framework for end-of-life management of electronic products. Resour. Conserv. Recycl. 2009, 53, 329–339. [Google Scholar] [CrossRef]

- Lee, S.G.; Lye, S.W.; Khoo, M.K. A multi-objective methodology for evaluating product end-of-life options and disassembly. Int. J. Adv. Manuf. Technol. 2001, 18, 148–156. [Google Scholar] [CrossRef]

- Chan, J.W.K. Product end-of-life options selection: Grey relational analysis approach. Int. J. Prod. Res. 2008, 46, 2889–2912. [Google Scholar] [CrossRef]

- Vahabzadeh, A.H.; Asiaei, A.; Zailani, S. Green decision-making model in reverse logistics using FUZZY-VIKOR method. Resour. Conserv. Recycl. 2015, 103, 125–138. [Google Scholar] [CrossRef]

- Azapagic, A.; Millington, A.; Collett, A. A Methodology for Integrating Sustainability Considerations into Process Design. Chem. Eng. Res. Des. 2006, 84, 439–452. [Google Scholar] [CrossRef]

- Caudill, R.J.; Dickinson, D.A. Sustainability and end-of-life product management: A case study of electronics collection scenarios. IEEE Int. Symp. Electron. Environ. 2004, 15, 132–137. [Google Scholar]

- de Silva, N.; Jawahir, I.S., Jr.; Russell, M. A new comprehensive methodology for the evaluation of product sustainability at the design and development stage of consumer electronic products. Int. J. Sustain. Manuf. 2009, 1, 251–264. [Google Scholar] [CrossRef]

- Hula, A.; Jalali, K.; Hamza, K.; Skerlos, S.J.; Saitou, K. Multi-Criteria Decision-Making for Optimization of Product Disassembly under Multiple Situations. Environ. Sci. Technol. 2003, 37, 5303–5313. [Google Scholar] [CrossRef]

- Jaafar, I.H.; Venkatachalam, A.; Joshi, K.; Ungureanu, A.C.; De Silva, N.; Rouch, K.E.; Dillon, O.W.; Jawahir, I.S. Product Design for Sustainability: A New Assessment Methodology and Case Studies. Environ. Conscious Mech. Des. 2007, 5, 25–65. [Google Scholar]

- Mateus, R.; Bragança, L. Sustainability assessment and rating of buildings: Developing the methodology SBToolPT–H. Build. Environ. 2011, 46, 1962–1971. [Google Scholar] [CrossRef]

- Culaba, A.B.; Purvis, M.R.I. A methodology for the life cycle and sustainability analysis of manufacturing processes. J. Clean. Prod. 1999, 7, 435–445. [Google Scholar] [CrossRef]

- Andreoli, M.; Tellarini, V. Farm sustainability evaluation: Methodology and practice. Agric. Ecosyst. Environ. 2000, 77, 43–52. [Google Scholar] [CrossRef]

- Girardi, P.; Temporelli, A. Smartainability: A Methodology for Assessing the Sustainability of the Smart City. Energy Procedia 2017, 111, 810–816. [Google Scholar] [CrossRef]

- Presley, A.; Meade, L.; Sarkis, J. A strategic sustainability justification methodology for organizational decisions: A reverse logistics illustration. Int. J. Prod. Res. 2007, 45, 4595–4620. [Google Scholar] [CrossRef]

- Raúl, L.; María, J.M.; Ricardo, C. Methodology for sustainability strategic planning and management. Ind. Manag. Data Syst. 2010, 110, 249–268. [Google Scholar]

- Bakar, M.S.A.; Rahimifard, S. Computer-aided recycling process planning for end-of-life electrical and electronic equipment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1369–1374. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Sarkis, J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2019, 57, 1990–2008. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Janik, H.; Borzędowska-Labuda, K.; Kucińska-Lipka, J. Environmentally friendly polymer-rubber composites obtained from waste tyres: A review. J. Clean. Prod. 2017, 147, 560–571. [Google Scholar] [CrossRef]

- Signus. SIGNUS Memoria Web. 2020. Available online: https://www.signus.es/memoria2019/ (accessed on 25 November 2020).

- Horodytska, O.; Kiritsis, D.; Fullana, A. Upcycling of printed plastic films: LCA analysis and effects on the circular economy. J. Clean. Prod. 2020, 268, 122–138. [Google Scholar] [CrossRef]

| Tire Type | Disposition Alternatives |

|---|---|

| TUR | Reuse in the national market |

| Reuse in foreign markets | |

| Refurbishment | |

| TEUL | Recycling (steel, fiber, and rubber) |

| Incineration (fiber and rubber) |

| Economic Profitability Parameters: |

| Income generated to the company from the sale of the product or component after a specific disposal alternative. Costs associated with the operations necessary for the execution of a specific disposal alternative. |

| Environmental Impact Parameters: |

| Environmental impact of the operations necessary for the execution of a specific disposal alternative. |

| Social Impact Parameters: |

| Social impact of the operations necessary for the execution of a specific disposal alternative. |

| Economic Parameters with Fixed Values: |

| Income from recycling of components (steel, fiber, and rubber). Income from incineration of components (fiber and rubber). Cost of inspection and classification of the recovered product. Cost of packaging the product for reuse or resale. Cost of transporting the product from the collection and classification plant to the recovery plant. Cost of valuation of the product in components. Cost of recycling components. Cost of incineration of the components. |

| Environmental Parameters with Fixed Values: |

| Environmental impact of transporting the product from the collection and classification plant to the recovery plant. Environmental impact of the operations of valorization of the product in components. Environmental impact of the transport of the components to be recycled. Environmental impact of the transportation of the components to be incinerated. Environmental impact of recycling components. Environmental impact of the incineration of components. |

| Social Parameters with Fixed Values: |

| Social impact of transporting the product from the collection and classification plant to the recovery plant. Social impact of the operations of valorization of the product in components. Social impact of the transport of the components to be recycled. Social impact of the transportation of the components to be incinerated. Social impact of recycling components. Social impact of the incineration of components. |

| Economic Parameters with Variable Values: |

| Cost of transporting the product from the customer to the collection and classification plant. |

| Environmental Parameters with Variable Values: |

| Environmental impact of transporting the product from the customer to the collection and classification plant. |

| Social Parameters with Variable Values: |

| Social impact of the product collection, categorization, and storage operations from the customer to the collection and classification plant. |

| Recycling | Incineration | |||||

|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | |

| Economic profitability (€/unit) | 0.1400 | 0.7020 | 0.6090 | - | 1.1600 | 1.0150 |

| Environmental impact (points/unit) | 0.0003 | 0.0006 | 0.0012 | - | 0.0007 | 0.0013 |

| Social impact (points/unit) | 0.1073 | 0.1463 | 0.1524 | - | 0.1694 | 0.1371 |

| Objective Function | Recycling | Incineration | Optimal Value | ||||

|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | ||

| Economic | 1 | 0 | 0 | 0 | 1 | 1 | 2.3150 |

| Environmental | 1 | 1 | 1 | 0 | 0 | 0 | 0.0021 |

| Social | 1 | 0 | 1 | 0 | 1 | 0 | 0.4292 |

| Recycling | Incineration | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | Econom. | Environ. | Social | |

| Solution 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1.4510 | 0.0021 | 0.4061 |

| Solution 2 | 1 | 1 | 0 | 0 | 0 | 1 | 1.8571 | 0.0022 | 0.3907 |

| Solution 3 | 1 | 0 | 1 | 0 | 1 | 0 | 1.9092 | 0.0022 | 0.4292 |

| Solution 4 | 1 | 0 | 0 | 0 | 1 | 1 | 2.3151 | 0.0023 | 0.4138 |

| Recycling | Incineration | W1 Econom. | W2 Environ. | W3 Social | DPIP | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | 33.3% | 33.3% | 33.3% | ||

| Solution 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0.12 | - | 0.02 | 0.14 |

| Solution 2 | 1 | 1 | 0 | 0 | 0 | 1 | 0.07 | 0.02 | 0.03 | 0.12 |

| Solution 3 | 1 | 0 | 1 | 0 | 1 | 0 | 0.06 | 0.01 | - | 0.07 |

| Solution 4 | 1 | 0 | 0 | 0 | 1 | 1 | - | 0.04 | 0.01 | 0.05 |

| RECYCLING | INCINERATION | |||||

|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | |

| Solution 1 | 1 | 1 | 1 | 0 | 0 | 0 |

| 1 | 1 | 0 | 0 | 0 | ① | |

| 1 | 0 | 1 | 0 | ① | 0 | |

| 1 | 0 | 0 | 0 | ① | ① | |

| Objective Function | Recycling | Incineration | Optimal Value | ||||

|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | ||

| Economic | 1 | 1 | 1 | 0 | 0 | 0 | 1.4510 |

| Environmental | 1 | 1 | 1 | 0 | 0 | 0 | 0.0021 |

| Social | 1 | 1 | 1 | 0 | 0 | 0 | 0.4061 |

| Recycling | Incineration | Wj Econom. | Wj Environ. | Wj Social | DPIP | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | 33.3% | 33.3% | 33.3% | ||

| Solution 1 | 1 | 1 | 1 | 0 | 0 | 0 | - | - | - | 0 |

| REC | BUR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel | Fiber | Rubber | Steel | Fiber | Rubber | Econom. | Environ. | Social | ||

| Sustainable Solution | Solution 4 | 1 | 0 | 0 | 0 | 1 | 1 | 2.3150 | 0.0023 | 0.4138 |

| CE Solution | Solution 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1.4510 | 0.0021 | 0.4061 |

| Difference | −0.8640 | −0.0002 | −0.0077 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alarcón, F.; Cortés-Pellicer, P.; Pérez-Perales, D.; Sanchis, R. Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs. Sustainability 2020, 12, 10109. https://doi.org/10.3390/su122310109

Alarcón F, Cortés-Pellicer P, Pérez-Perales D, Sanchis R. Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs. Sustainability. 2020; 12(23):10109. https://doi.org/10.3390/su122310109

Chicago/Turabian StyleAlarcón, Faustino, Pascual Cortés-Pellicer, David Pérez-Perales, and Raquel Sanchis. 2020. "Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs" Sustainability 12, no. 23: 10109. https://doi.org/10.3390/su122310109

APA StyleAlarcón, F., Cortés-Pellicer, P., Pérez-Perales, D., & Sanchis, R. (2020). Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs. Sustainability, 12(23), 10109. https://doi.org/10.3390/su122310109