Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective

Abstract

1. Introduction

How can a ‘product’, ‘service’, and ‘system’ perspective support realizing CE for the concrete industry?

2. Background

2.1. The Notions of CE and the Existing Link to PSS

2.2. From PSS to ‘Product’, ‘Service’ and ‘System’

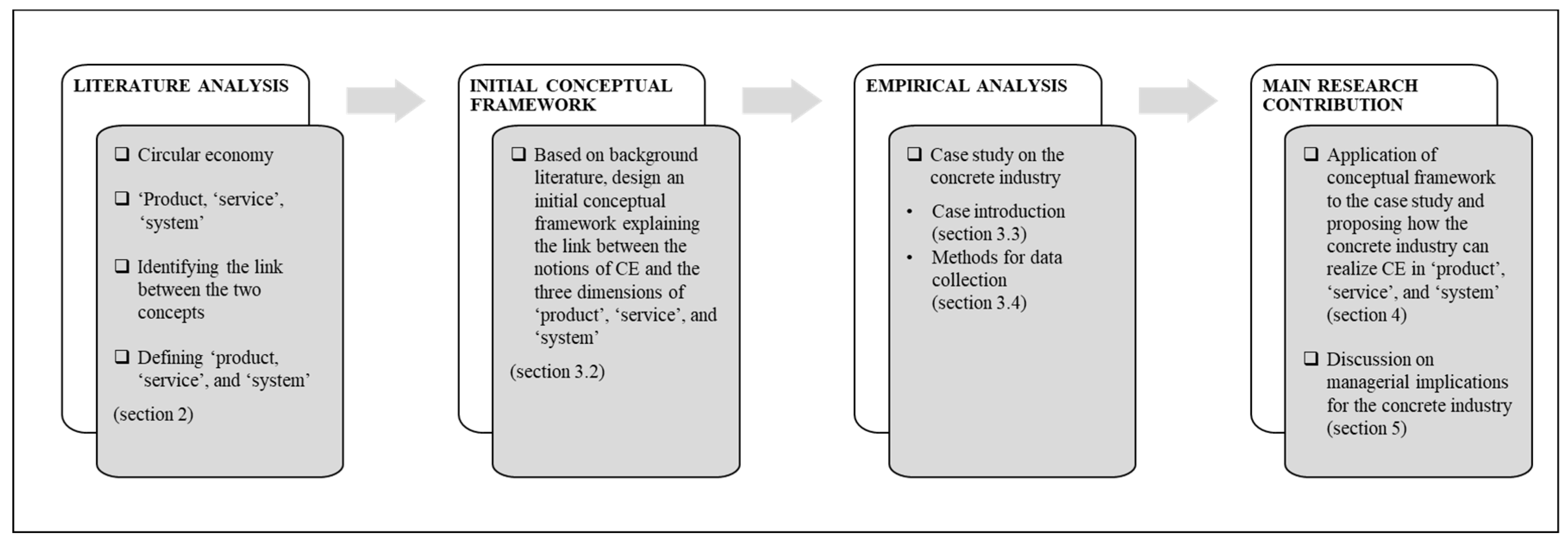

3. Methodology

3.1. Research Design

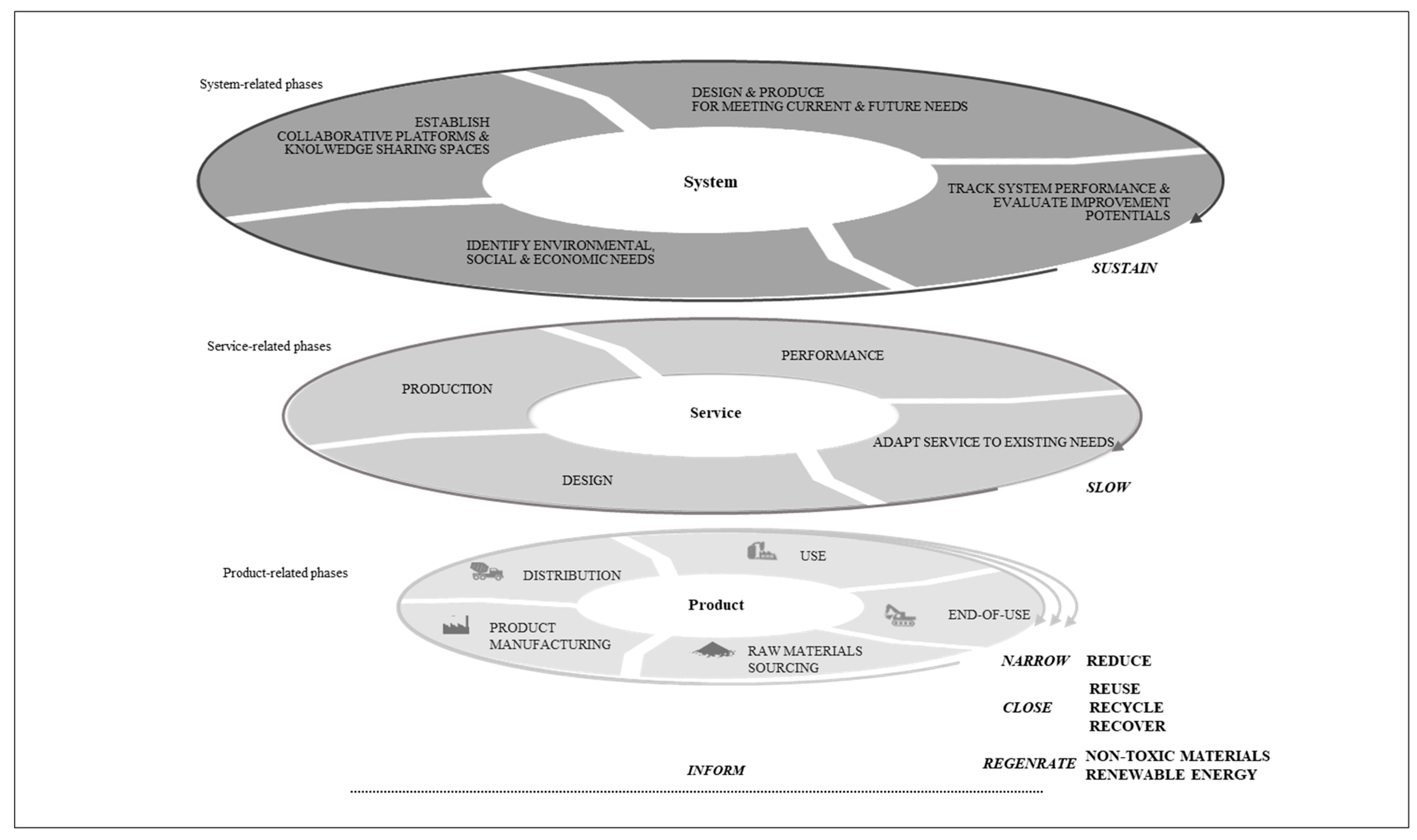

3.2. Initial Conceptual Framework for Realising CE in ‘Product’, ‘Service and ‘System’

3.3. Case Introduction

3.4. Data Collection Methods and Data Analysis

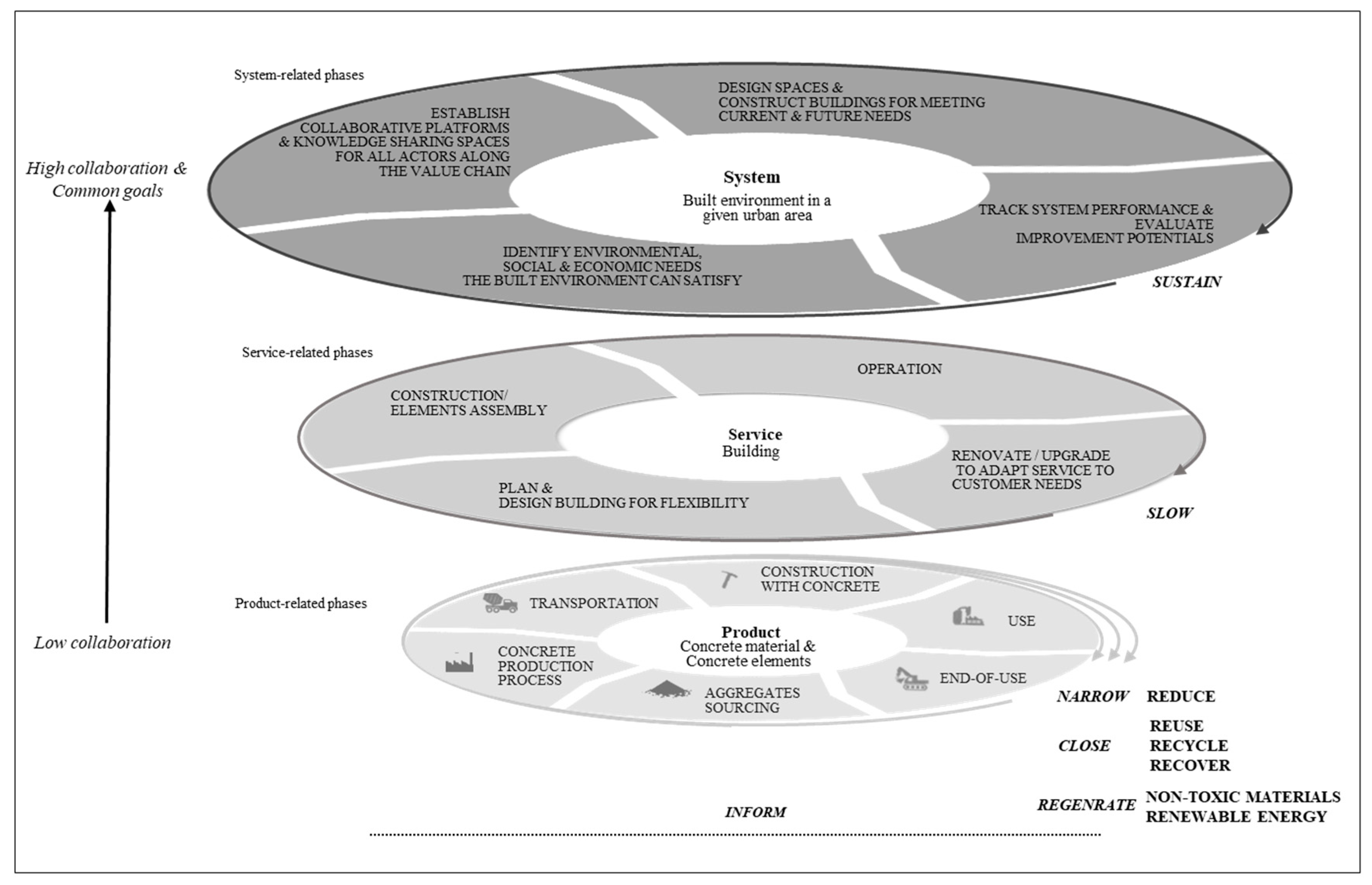

4. Applying the Conceptual Framework on the Case of the Concrete Industry in Denmark

4.1. Realizing CE in ‘Product’ Dimension

“for our normal day-to-day business, it is all customer-driven and if the customer asks for it, we can deliver…it might come at a price”,

“…not able to pay for “greener” product….at the moment there is not anything in the tenders (requirements) … describing greener concrete or circular economy”

4.2. Realizing CE in ‘Service’ Dimension

“it has to be a good business model…the structure of the building is the last thing that we are going to reuse….with more flexible office for example it will be easier to adapt to fit a new customer”

“Unfortunately, screening reports (prior to demolition) are requested to include information about reuse or recycling, but I am afraid in most cases they (demolition companies) don’t really distinguish between reuse and recycling. A priority should be on the reuse if possible, if not possible—it should be on recycling, and if that is not possible, other solutions should be considered.”

4.3. Realizing CE in ‘System’ Dimension

“one of the big challenges for us as producers…we only enter the projects at a very late stage …and connections are already decided and fixed, and to push a little and influence the choice of connections and geometries was a very good things for us…and to have our concerns and opinions heard.”

“…the environment in Circle House …we were around the same table and looking at the same thing, at the same time (…) we are all connected to each other and we all need to understand each other’s businesses and somehow cooperate to make it happen…”

“in the beginning there were a lot of crossed arms, because they (concrete elements producer) wanted to be circular, but didn’t want to change anything (in the production process), but then after being put in the same room with the same challenge…having the same agenda and the same issues we wanted to solve …we ended up having a system that was designed for disassembly and circular. And in the workshop, we also had the (company proving the concrete material and concrete joints) and the contractor, so we had all people around the table…we were quickly able to have your idea approved or shot down by other disciplines that have something to say…it was really helpful and what was able to push the building industry further.”

“...every element has a cast-in chip and is all hooked up to a database. You only need to scan it with a phone and you can get all the needed information as a test to see what we can do and what we can use it for…. There are a lot of issues and different concerns we need to address. It is also a big discussion who should own this data. It could be service we provide and give access to the data database. If we should provide it as a service, it could be a business opportunity for us and one of the drivers (of CE) actually.”

“If the data is owned by a provide company, there is always a risk that that company won’t exist in 30 years or so, and what should then be done with ensuring the data availability…”

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2018. [Google Scholar]

- Oberle, B.; Bringezu, S.; Hatfield-Dodds, S.; Hellweg, S.; Schandl, H.; Clement, J.; Cabernard, L.; Che, N.; Chen, D.; Droz-Georget, H.; et al. Global Resources Outlook 2019: Natural Resources for the Future We Want; A Report of the International Resource Panel. United Nations Environment Programme. Nairobi, Kenya; IRP: Paris, France, 2019. [Google Scholar]

- WBCSD. The Cement Sustainability Initiative (CSI) Recycling Concrete Excutive Summary; World Business Council for Sustainable Development: Geneva, Switzerland, 2009. [Google Scholar]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2017, 114, 2–26. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China. Part II. Structural behaviour of recycled aggregate concrete and engineering applications. Resour. Conserv. Recycl. 2009, 53, 107–112. [Google Scholar] [CrossRef]

- Zhao, Z.; Courarda, L.; Groslambertb, S.; Jehinc, T.; Léonardb, A.; Xiao, J. Use of recycled concrete aggregates from precast block for the production of new building blocks: An industrial scale study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Huuhka, S.; Kaasalainen, T.; Hakanen, J.H.; Lahdensivu, J. Reusing concrete panels from buildings for building: Potential in Finnish 1970s mass housing. Resour. Conserv. Recycl. 2015, 101, 105–121. [Google Scholar] [CrossRef]

- Maerckx, A.-L.; D’otreppe, Y.; Scherrier, N. Building circular in Brussels: An overview through 14 inspiring projects. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 12059. [Google Scholar] [CrossRef]

- McAloone, T.C.; Pigosso, D.C.A. Designing product service systems for a circular economy. In Designing for the Circular Economy; Charter, M., Ed.; Routledge: Abingdon, UK, 2018; pp. 102–112. [Google Scholar]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. From theory to practice: Systematising and testing business model archetypes for circular economy. Resour. Conserv. Recycl. 2020, 162, 105029. [Google Scholar] [CrossRef]

- Huang, G.Q.; Qu, T.; Zhong, R.Y.; Li, Z.; Yang, H.D.; Zhang, Y.F.; Chen, Q.X.; Jiang, P.Y.; Chen, X. Establishing production service system and information collaboration platform for mold and die products. Int. J. Adv. Manuf. Technol. 2011, 52, 1149–1160. [Google Scholar] [CrossRef]

- Green Building Council Denmark. Cirkulaer Økonomi og DGNB-Guide til Cirkulaere Principper i DGNB Baeredygtighedscertificering; Green Building Council Denmark: Copenhagen, Denmark, 2018. [Google Scholar]

- Tebbatt, K.; Bsc, A.; Ba, M.O.; Thorpe, T.; Dean, M.; Bsc, J.T. Circular economy in construction: Current awareness, challenges and enablers. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar]

- Ramsheva, Y.; Prosman, E.J.; Wæhrens, B.V. Dare to make investments in industrial symbiosis? A conceptual framework and research agenda for developing trust. J. Clean. Prod. 2019, 223, 989–997. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Tate, W.L.; Bals, L.; Bals, C.; Foerstl, K. Seeing the forest and not the trees: Learning from nature’s circular economy. Resour. Conserv. Recycl. 2019, 149, 115–129. [Google Scholar] [CrossRef]

- Høibye, L.; Sand, H. Circular Economy in the Nordic Construction Sector: Identification and Assesment of Potential Policy Instruments That Can Accelerate a Transition toward a Circular Economy; Nordic Council of Ministers: Copenhagen, Denmark, 2018. [Google Scholar]

- Leising, E.; Quist, J.; Bocken, N. Circular economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular ecosystem innovation: An initial set of principles. J. Clean. Prod. 2020, 253, 119942. [Google Scholar] [CrossRef]

- Bocken, N.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. A tool to analyze, ideate and develop circular innovation ecosystems. Sustainability 2020, 12, 417. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Levin, S.A. Self-organization and the emergence of complexity in ecological systems. BioScience 2005, 55, 1075–1079. [Google Scholar] [CrossRef]

- Schöggl, J.P.; Stumpf, L.; Baumgartner, R.J. The narrative of sustainability and circular economy—A longitudinal review of two decades of research. Resour. Conserv. Recycl. 2020, 163, 105073. [Google Scholar] [CrossRef]

- Baldassarre, B.; Keskin, D.; Diehl, J.C.; Bocken, N.; Calabretta, G. Implementing sustainable design theory in business practice: A call to action. J. Clean. Prod. 2020, 273, 123113. [Google Scholar] [CrossRef]

- Corvellec, H.; Stål, H.I. Evidencing the waste effect of Product-Service Systems (PSSs). J. Clean. Prod. 2017, 145, 14–24. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, L. Application review of LCA (Life Cycle Assessment) in circular economy: From the perspective of PSS (Product Service System). Procedia CIRP 2019, 83, 210–217. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From linear to circular economy: PSS conducting the transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Halstenberg, F.A.; Stark, R. Introducing product service system architectures for realizing circular economy. Procedia Manuf. 2019, 33, 663–670. [Google Scholar] [CrossRef]

- Kühl, C.; Tjahjono, B.; Bourlakis, M.; Aktas, E. Implementation of circular economy principles in PSS operations. Procedia CIRP 2018, 73, 124–129. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Han, J.; Heshmati, A.; Rashidghalam, M. Circular economy business models with a focus on servitization. Sustainability 2020, 12, 8799. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; Halen, C.J.G.V.; Riele, H.R.M.T.; Rommens, P.J.M. Product Service Systems—Ecological and Economic Basics; PricewaterhouseCoopers, Storrm, Pré Consultants for Ministry of Economic Affairs: The Hague, The Netherlands, 1999. [Google Scholar]

- Kristensen, H.S.; Remmen, A. A framework for sustainable value propositions in product-service systems. J. Clean. Prod. 2019, 223, 25–35. [Google Scholar] [CrossRef]

- Van Ostaeyen, J.; van Horenbeek, A.; Pintelon, L.; Duflou, J.R. A refined typology of product service systems based on functional hierarchy modeling. J. Clean. Prod. 2013, 51, 261–276. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Parliament: Brussels, Belgium, 2008. [Google Scholar]

- Yin, R.K. Case Study Research: Designs and Methods; Sage Publications: London, UK, 2013. [Google Scholar]

- Yin, R.K. Case Study Research and Applications, 6th ed.; Sage Publications, Inc.: Los Angeles, CA, USA, 2018. [Google Scholar]

- Mack-Vergara, Y.L.; John, V.M. Life cycle water inventory in concrete production—A review. Resour. Conserv. Recycl. 2017, 122, 227–250. [Google Scholar] [CrossRef]

- Dansk Beton. Beton Styrker Bæredygtighed—Om Bæredygtige Fordele ved Beton; Dansk Beton: Copenhagen, Denmark, 2017. [Google Scholar]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-specific Life Cycle Assessment of ready mix concrete: Comparison between a recycled and an ordinary concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

- The Danish Environmental Protection Agency. Genanvendelse af Knust Beton i nye Betonkonstruktioner; The Danish Environmental Protection Agency (EPA): Copenhagen, Denmark, 2018.

- Ministry of Environment in Denmark. Udredning af Teknologiske Muligheder for at Genbruge og Genanvende Beton; Ministry of Environment in Denmark: Copenhagen, Denmark, 2015.

- Jensen, K.G.; Sommer, J. Building a Circular Future, 3rd ed.; GNX: Copenhagen, Denmark, 2018. [Google Scholar]

- Maxwell, J.A. Qualitative Research Design an Interactive Approach, 2nd ed.; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2005. [Google Scholar]

- Cembreau. Cement, Concrete & the Circular Economy: The Role of Cement in Concrete; Cembreau: Brussels, Belgium, 2016. [Google Scholar]

- UN Environment (Ed.) Global Environment Outlook—GEO-6: Healthy Planet, Healthy People; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- López Ruiz, L.A.; Ramón, X.R.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Hopkinson, P.; Chen, H.M.; Zhou, K.; Wang, Y.; Lam, D. Recovery and reuse of structural products from end-of-life buildings. Proc. Inst. Civ. Eng. Eng. Sustain. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- Planing, P. Business model innovation in a circular economy reasons for non-acceptance of circular business models. Open J. Bus. Model Innov. 2015, 1, 1–11. [Google Scholar]

- Guldmann, E.; Huulgaard, R.D. Barriers to circular business model innovation: A multiple-case study. J. Clean. Prod. 2020, 243, 118160. [Google Scholar] [CrossRef]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Environment Agency European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denamrk, 2020. [Google Scholar]

- European Commission. EU Construction and Demolition Waste Protocol and Guidelines; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Resource Efficient Use of Mixed Wastes Improving Management of Construction and Demolition Waste Final Report; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Delgado, M.D.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Copenhagen Resource Institute. Resource Efficiency in the Building Sector Final Report; Ecorys: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Da Costa Fernandes, S.; Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Towards product-service system oriented to circular economy: A systematic review of value proposition design approaches. J. Clean. Prod. 2020, 257, 120507. [Google Scholar]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/service-systems for a circular economy: The route to decoupling economic growth from resource consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Configuring new business models for circular economy through product–service systems. Sustainability 2019, 11, 3727. [Google Scholar] [CrossRef]

- Zhang, N.; Mei, L. Sustainable development in the service industry: Managerial learning and management improvement of Chinese retailers. Sustainability 2020, 12, 1430. [Google Scholar] [CrossRef]

- Milios, L. Policy Framework for Material Resource Efficiency Pathway Towards a Circular Economy; The International Institute for Industrial Environmental Economics (IIIEE): Lund, Sweden, 2020. [Google Scholar]

| No. | Employee Function | Activity of the Organization | Main CE Activities |

|---|---|---|---|

| 1 | Senior concrete technologist | cement production and distribution | Establishing industrial symbiosis (contributed to reduction of virgin resource use, energy use, greenhouse gas emissions)

|

| 2 | Production director | ready-mix concrete production and distribution to building sites, concrete casting | Recover and recycle concrete Emission-free construction sites Reuse of surface water |

| 3 | Business developer | household and industrial waste handling | Recycle, repair and upcycle materials and other recovered products, including concrete after demolition process |

| 4 | Municipal team leader | municipal household and industrial waste handling | Recover, recycle and utilise diverse waste materials, including concrete from concrete producers or demolition processes Sorting and crushing concrete waste to be used as paving stone, road-base or asphalt as a substitute of virgin aggregates (ex. gravel) |

| 5 | Project leader | partnership organization for sustainable renovations | Involve all value chain stakeholders from the construction industry for improving the renovation process of buildings in terms of:

|

| 6 | Technical manager | concrete elements production, design, delivery, assembly, service | Design for disassembly Reuse of concrete elements |

| 7 | Director | concrete connections and composite beams production | Design for disassembly/design flexible infrastructures Reduction of quantity input material per module output |

| 8 | Architect | innovation unit focused on circular design, digital design | “Circle House” project responsible Design of “circular buildings” by involving all value chain stakeholders (incl. interviewed organizations no. 2 & 3) Design for disassembly/flexibility/circularity Optimization of construction time Optimization of infrastructure maintenance through the support of digital technologies |

| 9 | Director | Danish concrete industry association focused on promoting the interests of the concrete industry | Dissemination of knowledge of concrete (properties, production process, use) Ensure member interests in front of authorities, contractors, other institutions, general public Promote cooperation between members of the association |

| Topic | Questions | |

|---|---|---|

| 1 | CE activities already initiated |

|

| 2 | CE opportunities |

|

| 3 | Existing barriers and challenges |

|

| 4 | The role of collaboration |

|

| PRODUCT (Concrete Material and Concrete Elements) | SERVICE (Building) | SYSTEM (Built Environment in a Given Urban Area) | |||

|---|---|---|---|---|---|

| NARROW (Reduce) | CLOSE (Reuse, Recycle, Recover) | REGENERATE (Use of Non-Toxic Materials, Renewable Energy) | SLOW (Design for Disassembly and Adaptability, Monitoring and Renovation) | SUSTAIN (Establish Collaborative Networks for Sustainable Solutions) | |

| CE opportunities | Reduced environmental impact (avoided emissions) and social impact assoc. with virgin aggregates sourcing or landfill Reduced resource use (virgin aggregates, water, energy) | New market opportunities Improved indoor space use Higher revenue margin - Lower production costs of mass-produced/low-variability of standardize components (for pre-casted elements) - Improved resource efficiency (material, energy, water) and life-time of building materials (incl. concrete) through service and renovation | Collaborative learning platform for development of sustainable solutions and competitive strategy Effective utilization of resources Addressed societal needs leading to improved health and well-being | ||

| Savings on input material costs | Additional value capture (reused concrete or recovered and recycled concrete aggregates) Improved efficiency of resource use and reduced waste quantities Building a CE narrative for concrete | ||||

| Existing challenges | Environmental and social costs of concrete currently not reflected in the market price Construction companies unwilling to pay an extra cost for “greener“ concrete (with reduced impact properties) | Low cost of virgin aggregates and high local availability in Denmark A well-established process for recovering concrete for the purpose of road fill and paving Current low landfill rate for concrete waste in Denmark | “Low-hanging fruit” already achieved High investment costs for research and realization of new projects (e.g., renewable energy plant, recirculation and reuse water from concrete production process, etc.) | At present public tenders for construction projects generally do not include requirements for design for disassembly | Platforms for collaboration and development of sustainable solutions and competitive strategy not considered “business as usual” Existing legislation does not include specific regulations and expectations for implementing CE in the construction sector Local government planning doesn’t fully support a ‘system’ focus when initiating area plan for construction |

| Technology for monitoring performance of concrete, as well as of buildings not fully developed Control over data storage and data ownership rights for monitoring materials and product performance not in place | |||||

| Cross-organizational stakeholder collaboration | Establishing dialogue and written agreements periphery to core activities | Collaboration for evaluating whether a new/existing building provides the needed ‘service’ to its users and find ways to adapt space to users’ needs | Dynamic collaborative (physical and virtual) environment for establishing common goals and shared values | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramsheva, Y.K.; Moalem, R.M.; Milios, L. Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective. Sustainability 2020, 12, 9423. https://doi.org/10.3390/su12229423

Ramsheva YK, Moalem RM, Milios L. Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective. Sustainability. 2020; 12(22):9423. https://doi.org/10.3390/su12229423

Chicago/Turabian StyleRamsheva, Yana K., Rikke M. Moalem, and Leonidas Milios. 2020. "Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective" Sustainability 12, no. 22: 9423. https://doi.org/10.3390/su12229423

APA StyleRamsheva, Y. K., Moalem, R. M., & Milios, L. (2020). Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective. Sustainability, 12(22), 9423. https://doi.org/10.3390/su12229423