2.1. Overview of Safety Distance Standard

The “safety distance” refers to the minimum separation distance required to protect people and surrounding properties from the risk factors (i.e., explosion pressure, fragments, thermal radiation, etc.) that accompany the accidental explosion of a chamber. The general concept of a safety distance is the same for each country; different safety distance standards are applied considering the characteristics by country. Most North Atlantic Treaty Organization (NATO) members comply with Allied Ammunition Storage and Transport Publication (AASTP) [

32,

33,

34]. The United Nations (U.N.) follows the International Ammunition Technical Guideline, while the United States (U.S.) complies with the Department of Defense Explosives Safety Board (DDESB) 6055.9-STD [

13,

35]. The Republic of Korea prepared the “Instruction of Safety Control Standard for Ammunition and Explosion” based on the DDESB 6055.9-STD, and it has performed various explosion tests centered on the Agency for Defense Development to establish a reference equation for the safety distance in cooperation with the U.S. Department of Defense [

14]. In this study, safety distance standards were analyzed by employing DDESB 6055.9-STD and Korea’s “Instruction of Safety Control Standard for Ammunition and Explosion”. However, details on equations, charts, and tables on the safety distance are not provided in this paper due to the security and nondisclosure contents.

The method for estimating the safety distance differs, depending on the risk factors of an accidental explosion. The military protection area must observe the maximum value among the estimated values of safety distance. The dominant risk factors vary, depending on the ammunition type, but in general the explosion pressure and fragments are dominant. Meanwhile, as the allowable risk level varies according to the objects of risk exposure, the safety distance also differs. The risk exposure objects considered in the current standards include inhabited buildings, public traffic routes, internal maintenance facilities, and nearby ammunition magazines.

Figure 1 shows different types of safety distances, according to the risk factors and risk exposure objects.

In summary, the safety distances are classified into an inhabited building distance (IBD), public traffic route distance (PTRD), intraline distance (ILD), and inter-magazine distance (IMD), according to the risk exposure objects. The equation for calculating each safety distance also differs according to the risk factors. In general, a long safe distance is calculated for the risk exposure object with a small acceptable degree of damage. The IBD has the longest length among the safety distances, since an inhabited building has the highest vulnerable protection object (i.e., persons). Therefore, it is the main cause of civil complaints, owing to the extensive use of land. The order of the length in the safety distance standards is IBD, PTRD, ILD, and IMD.

The safety distance is calculated by multiplying the net explosion weight by a coefficient determined according to the risk exposure objects and risk factors, as seen in Equation (1). The coefficient was determined through a number of experiments and numerical analyses.

Here, D and K are the safety distance (m) and the coefficient, respectively, corresponding to the risk factors and risk exposure objects, and W refers to the net explosion weight (kg).

The dominant threat between explosion pressure and fragment can vary, depending on the composition and type of explosives. Therefore, the coefficient K in Equation (1) also depends on the composition and type of explosives. The coefficient for the explosion pressure is determined based on the minimum pressure to prevent damage to the risk exposure objects. On the other hand, the factors that affect the coefficient for the fragment are the impact energy and density in a certain area. However, fragments can be prevented through barriers. In addition, the underground-type ammunition magazines considered in this study have the effect of locking fragments by rock and tunnel passages. Thus, this study exclusively considered the threat of explosion pressure.

2.2. Effect of Reduction in Safety Distance of Underground-Type Ammunition Magazines

Unlike a ground-type ammunition magazine, an underground-type ammunition magazine has a feature in that the underground rock traps explosion pressure and fragments. Thus, underground-type magazines can significantly reduce the effects of explosion pressure and fragments, which are the two most dominant risk factors in ammunition. However, if the critical thickness of the chamber in the upward direction (i.e., the distance from the chamber to the ground surface) is unsatisfied, the ground over the top of the chamber may be ruptured, allowing explosion pressure and fragments to propagate to the surroundings. Thus, the critical thickness of the chamber in the upward direction is the minimum thickness to the degree that the ground surface will not be ruptured by an accidental explosion. Ammunition magazines can be classified as underground-type only if the critical thickness of the chamber in the upward direction is satisfied. The critical thickness of chamber in the upward direction is also calculated using Equation (1) by using different coefficients with other safety distances.

If the critical thickness of chamber in the upward direction is satisfied, there is no need to consider the safety distance for the explosion pressure and fragments, as they are trapped in the rock. However, the effects of explosion pressures and fragments that can burst out from the exit should be considered. Nevertheless, the safety distances necessary for explosion pressure and fragments that burst from exits are generally less than the safety distances of ground-type ammunition magazines if the entrance barricade is constructed. The safety distance for explosion pressure at the exit can be calculated by Equation (2). The safety distance for fragments at the exit is not necessary to consider after installing the entrance barricade.

Here, DE and K are the safety distance at the exit (m) and the coefficient, respectively, corresponding to the risk factors and risk exposure objects. A and P are the minimum cross-sectional area (m2), and the perimeter (m), respectively, at a distance of not more than five times the diameter of the exit from the exit. VE is the volume of blast pressure through the inside of a tunnel (m3), and PSO is the acceptable incident pressure to risk exposure objects (Pa).

In addition, ground shocks occur in the underground-type ammunition magazine, owing to the explosion of the chamber besides the explosion pressure and fragments. Ground shock vibrates the surrounding structures, which can lead to structural damage or usability degradation owing to the relative movements of the ground and structures. Therefore, the maximum allowable velocity of ground particles should be specified according to the importance of the facilities and the safety distance should be calculated accordingly [

36,

37]. In other words, the coefficient K in Equation (1) for ground shock is determined based on the maximum allowable speed of the ground particles to ensure that risk exposure objects are not damaged. However, as this effect is less dangerous than the effects of explosion pressures and fragments, the safety distance can be much reduced. Furthermore, there is no need to consider the safety distance related to the ground shock for internal maintenance facilities and nearby ammunition magazines.

Finally, the chambers of the underground-type ammunition magazine should be sufficiently separated to prevent chain explosions in adjacent chambers. There are three cases in which a chain explosion can occur in an underground-type ammunition magazine:

- 1

A piece of rock from the wall surface in an adjacent chamber is crushed during explosion (i.e., scabbing), resulting in ammunition damage.

- 2

The explosion pressure that propagates through cracks in the rock damages ammunition.

- 3

The explosion pressure and fragments that propagate through the vehicle passage (i.e., tunnel) damage ammunition.

The explosion pressure and fragments propagating through the tunnel can be prevented by installing a blast door. In addition, if damage by scabbing is prevented, the explosion pressure does not propagate through cracks in the rock. In other words, the safety distance for preventing scabbing is the most dominant among the three cases explained above.

In summary, types of safety distances that should be considered in regards to the underground-type ammunition magazine are illustrated in

Figure 2 according to risk factors and risk exposure objects. In addition, the considerations for calculating safety distances for underground-type ammunition magazines are summarized in

Table 1 in comparison with ground-type magazines. The most dominant factors for determining the safety distance are summarized in

Table 2, depending on the types of ammunition magazines. The total weight of ammunition that is generally stored in ammunition magazines and the compatibility group standards were considered, even though the details could vary depending on the ammunition type and risk rating. For the ground-type ammunition magazine, the risk by explosion pressure is the highest; thus, the IBD for the explosion pressure requires the longest safety distance. On the other hand, the explosion pressure that bursts out at the exit is the most dominant risk effect for the underground-type ammunition magazine. However, this effect usually affects the unit facilities of the ammunition corps, and it can be significantly reduced by changing the movement path of explosion pressure and the size of the chambers and exit cross-section or by installing various protective structures. Therefore, the riskiest factor for the underground-type ammunition magazine is the ground shock, and the IBD for this is the longest.

The amount of land that can be saved using an underground-type ammunition magazine relative to a conventional ground-type was evaluated by comparatively calculating the safety distance for the same net explosive weight.

Figure 3 shows a graph comparing the IBD for the explosion pressure of the ground-type ammunition magazine and the IBD for the ground shock of the underground-type magazine.

Figure 4 compares the other dominant safety distance of the underground-type magazine (i.e., IBD for explosion pressure at exit) with that of the ground-type ammunition magazine (i.e., IBD for the explosion pressure). Here, it was assumed that the exit of the underground ammunition magazine had 15 m of width and 7.5 m of height with an arch configuration, according to the construction cases. The tunnel from the chamber where the explosion might occur to the exit was set to be 300 m [

38].

Figure 3 shows that the underground-type ammunition magazine can reduce the IBD by up to 88.4% as compared to the ground-type. The degree of reduction in safety distance increased with an increase in the net explosive weight stored in the chamber, then maintained at 88.4% after 130 tons. This is because the damage from explosion pressure increases exponentially as the net explosive weight increases. Thus, the equation of the IBD for explosion pressure for ground-type ammunition magazine adopts a high safety factor for more than a certain net explosive weight. In contrast, the ground shock effect of the underground-type ammunition magazine does not take into account differential safety factors that depend on net explosive weight. In

Figure 4, the differential safety factors are considered depending on net explosive weight in all equations, since both ground-type ammunition magazines and underground-type ammunition magazines represent safety distances for explosion pressure. However, the effects of explosion pressure can be reduced in the case of underground-type ammunition magazines by locking them in the ground formation. Therefore, the IBD reduction effect can be achieved by up to 25.7% without the installation of entrance barricades in the underground-type ammunition magazine. Only the entrance barricades must be constructed when designing underground-type ammunition magazines because the IBD reduction effect can increase to 62.8% by installing entrance barricades. As discussed before, however, the IBD for explosion pressure at the exit of underground-type ammunition magazines is not a significant cause of conflicts between the civil and military communities since it mostly affects the facilities of the relevant ammunition unit.

In this chapter, the safety distance standards of ground-type ammunition magazines and underground-type ammunition magazines were compared to each other. The reduction effects of the IBD, the most dominant safety distance, were directly compared. However, military protection zones of ammunition storage facilities are determined through the combination of several dominant safety distances. Therefore, the actual effect of the reduction in the military protection zones was assessed through an example in the next chapter.

2.3. Analysis of Economic and Environmental Effects of Underground-Type Ammunition Magazines

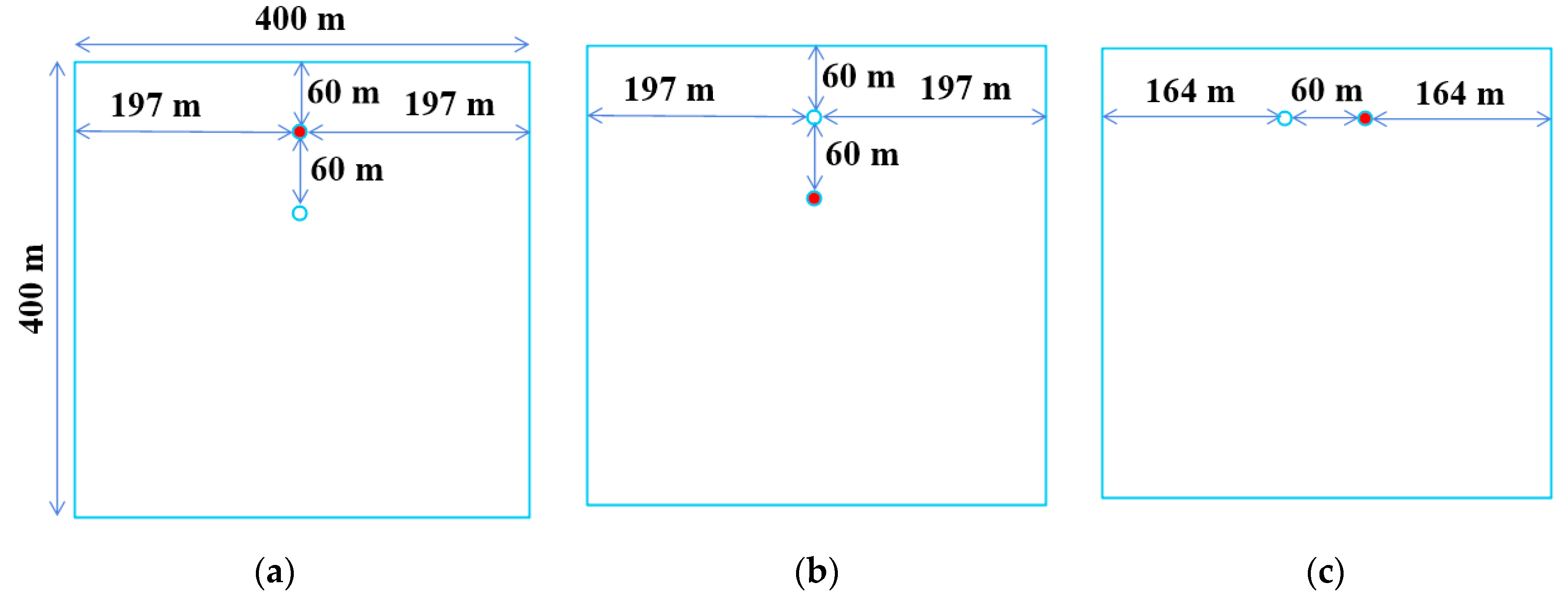

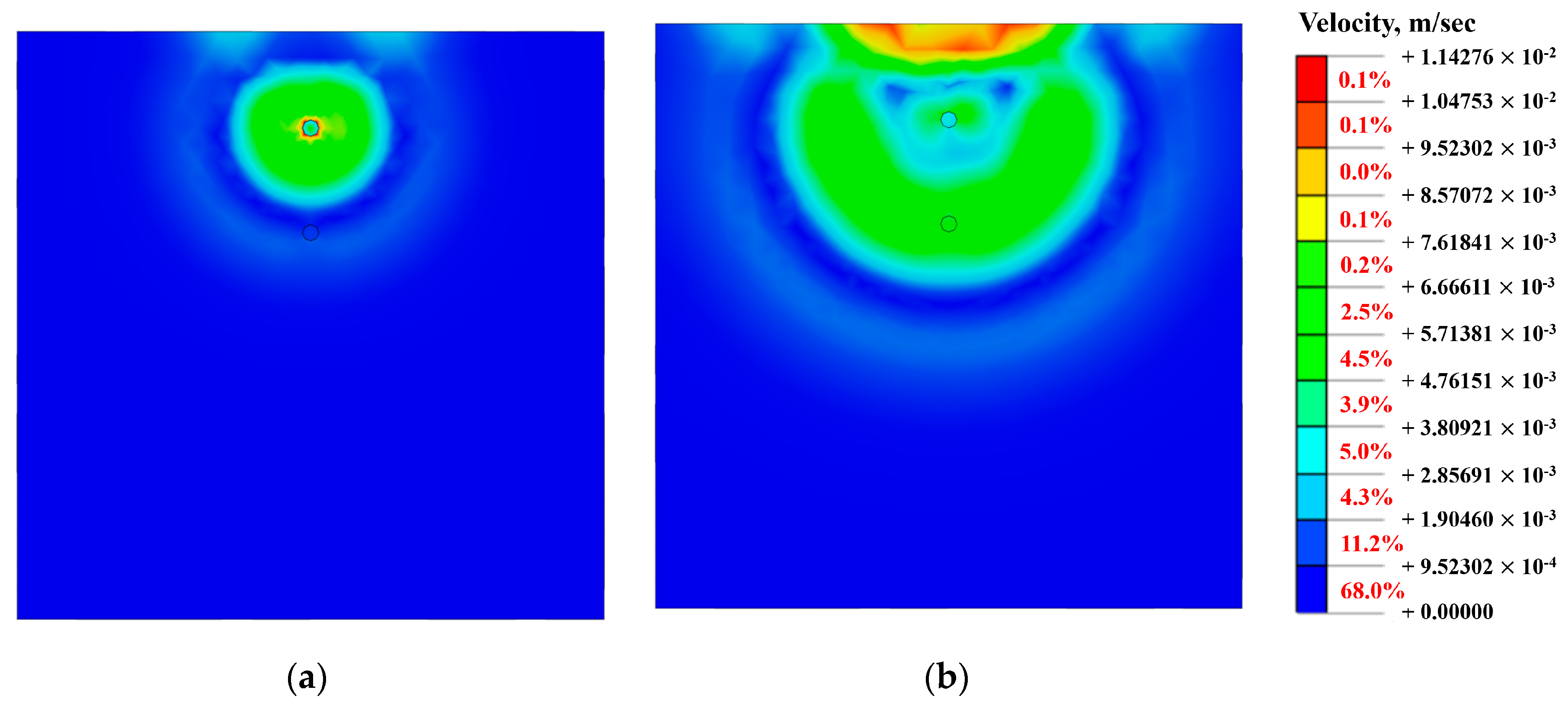

The effect of reducing the military protection zone of an underground-type ammunition facility compared to a ground-type ammunition facility was additionally analyzed by combining the various dominant safety distances indicated in

Table 2. Based on the construction cases for an underground ammunition magazine, a total of 10 chambers were assumed to be installed in 15 m of width, 7.5 m of height, and 60 m length for arch configuration [

38]. In this case, the total area for storing ammunition was 9000 m

2. It meant that a total of 20 ground-type ammunition magazines with an area of 450 m

2 were needed. The ground-type ammunition magazine with an area of 450 m

2 was assumed according to the standard specifications of the Republic of Korea. The specifications of the underground-type ammunition magazine and ground-type ammunition magazine considered in the example are shown in

Table 3.

Assuming that first-class ammunition with a total net explosive weight of 5,000,000 lb was stored, the underground-type ammunition magazines should store 500,000 lb per chamber. In the same way, the ground-type ammunition magazines should store 250,000 lb per magazine. Then, the IBD and the distance between each magazine (i.e., IMD for ground-type and ICD for underground-type ammunition magazines) were calculated, as shown in

Table 4, according to the type of ammunition magazines. The IBD for explosion pressure at the exit in the underground-type ammunition magazines was calculated assuming that the tunnel from the chamber where the explosion might occur to the exit was 300 m. Entrance barricades were also assumed to be constructed. Consequently, the maximum military protection zone to be secured in ground-type and underground-type ammunition facilities are shown in

Figure 5, based on the calculated safety distances.

In

Figure 5, ground-type ammunition magazines are arranged in 4 × 5 configurations, while underground-type chambers are placed in 2 × 5 configurations, assuming that a U-type tunnel is constructed. The military protection zones were conservatively calculated as about 85.16 km

2 for the ground-type ammunition facility and about 12.37 km

2 for the underground-type ammunition facility, respectively. The reduction effect of the military protection zone was about 85.47% when adopting underground-type ammunition magazines as a substitute for ground-type ammunition magazines. With a decrease in the safety distance, the secured land can be used for local development.

In addition to the site savings, the underground-type ammunition magazine can save on the amount of concrete used in construction, thereby reducing CO

2 emissions. In the above example, the amount of concrete was calculated to be 8166 m

3 and 6462 m

3 for ground-type and underground-type ammunition magazines, respectively, when assuming that both types had the same concrete thickness (i.e., 0.3 m for this example). If the weight of concrete per cubic meter is about 2.7 tons, about 4600 tons of concrete can be saved by constructing the underground-type ammunition magazines. The saving effect of concrete usage is 20.87%. A total of 14,500 tons of CO

2 emissions can be decreased by constructing underground-type ammunition magazines in the example, when considering that the CO

2 emissions per unit weight of ready-mixed concrete are 3.152 tons CO

2/ton (refer to

Table 5) [

39].

The reduction effect may be even greater considering the production of steel bars, curing, management, and demolition. The construction of underground-type ammunition magazines is an effective alternative technology that can greatly contribute not only to economic effects but also to environmental effects.