Integrated and Consolidated Review of Plastic Waste Management and Bio-Based Biodegradable Plastics: Challenges and Opportunities

Abstract

1. Introduction

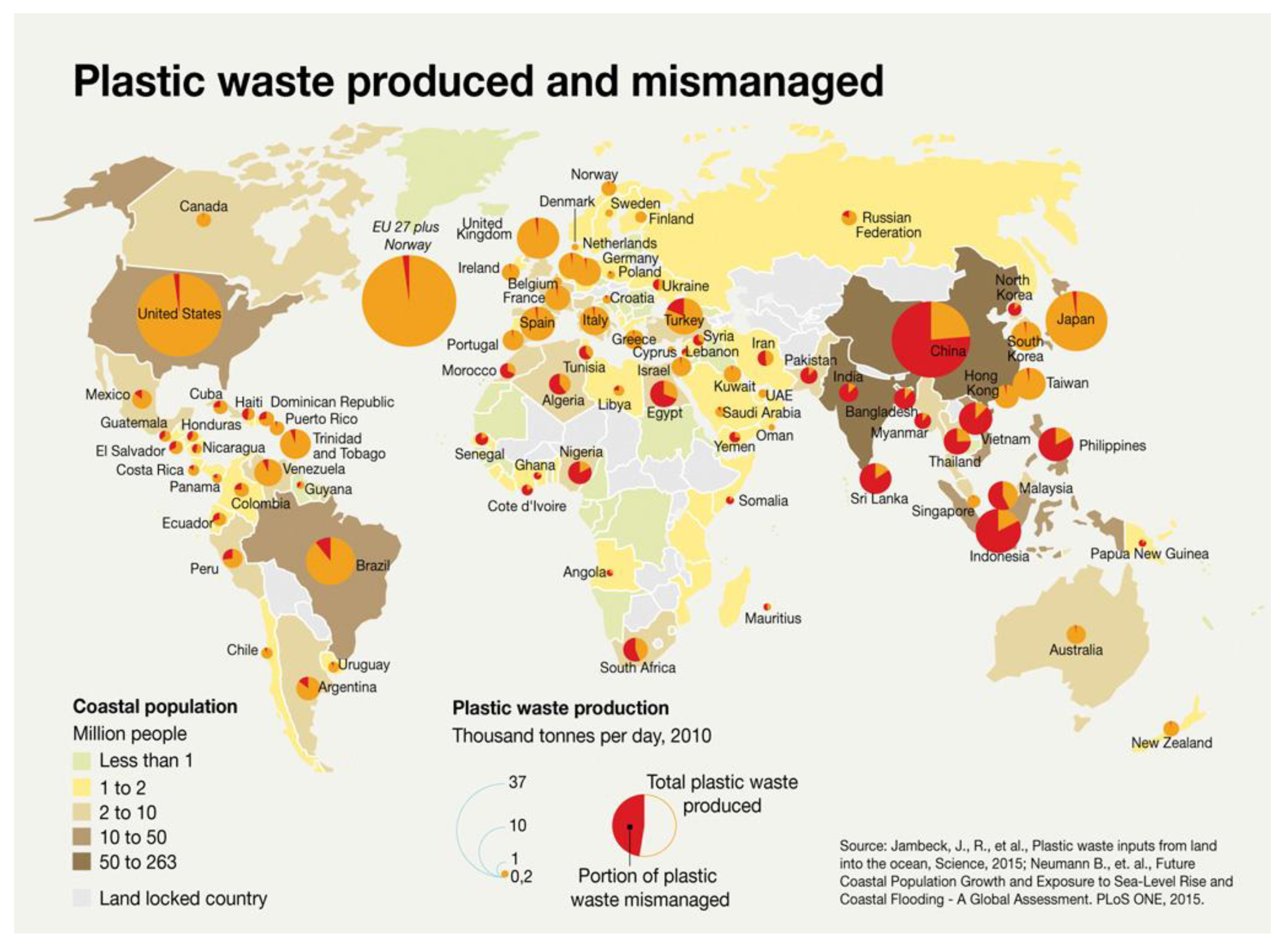

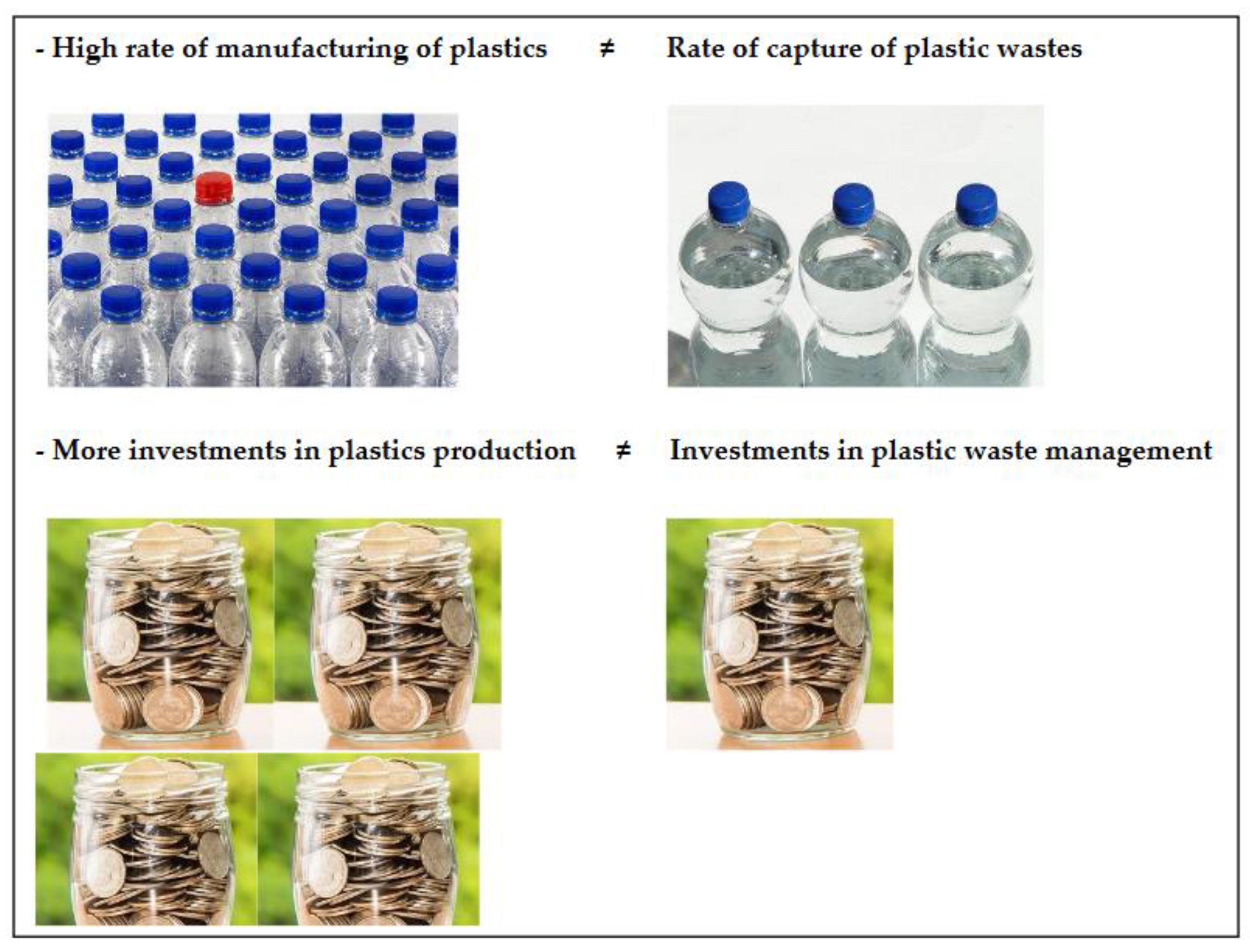

1.1. The Plastic Waste Management Challenge or Problem

1.2. Inventory of Plastic Management Systems

- To conduct an integrative review on plastic and its management and post-consumer use that provides the current status quo globally as well as establishes where more resources should be channeled in order to mitigate the impacts of mismanaged plastic waste on humans, animals, and the environment.

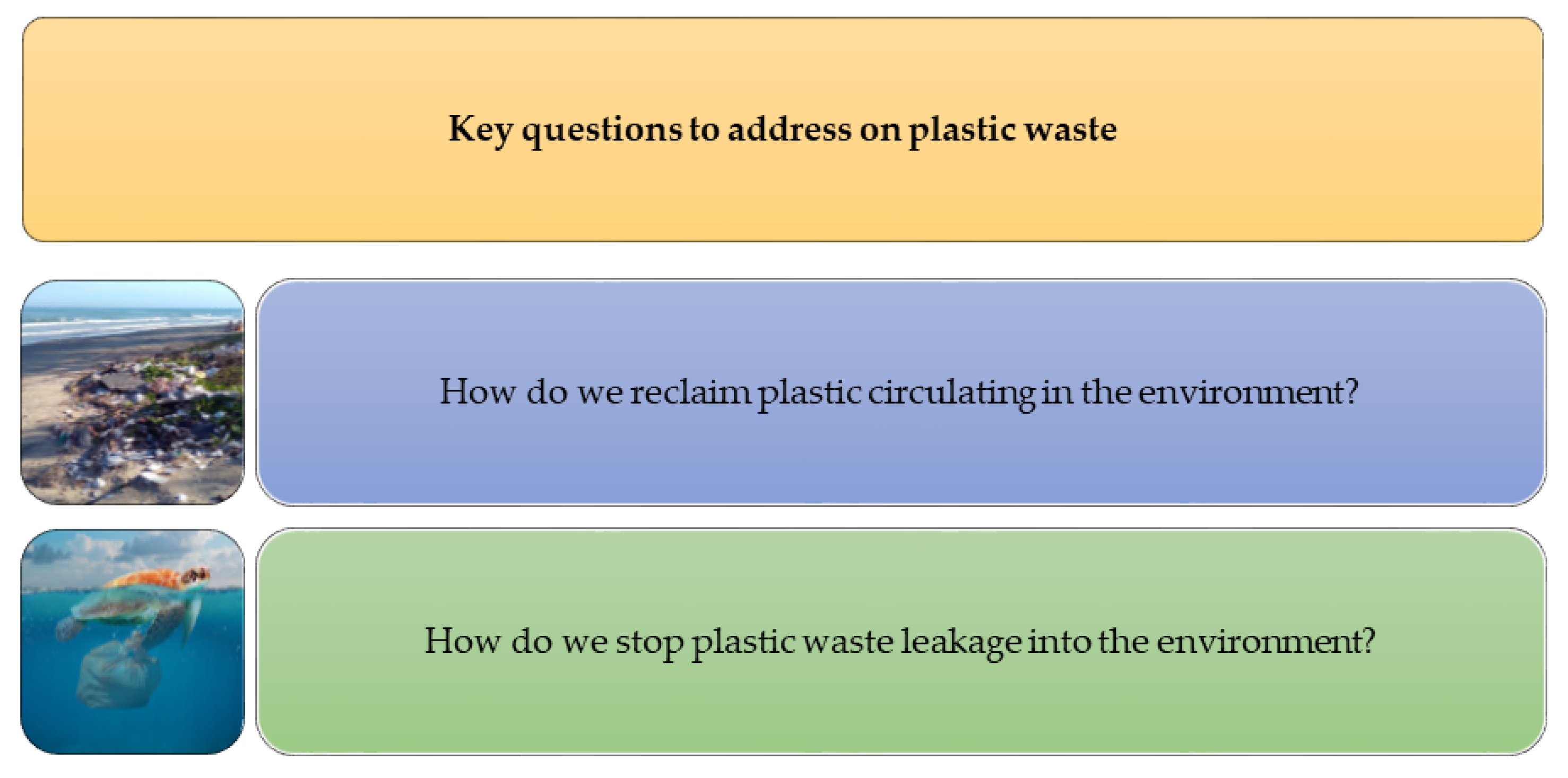

- To assess the possibility of reclaiming plastic waste that is currently circulating in the environment, both on land and in the marine environment.

- To comparatively evaluate if alternative materials to traditional plastics are more environmentally sustainable and provide the potential associated consequences of replacing plastics.

- To determine the strengths and shortcomings of some bio-based biodegradable plastics on the market as well as assess the areas of application where they are best suited.

- To determine whether EPR and DRS are beneficial tools in plastic waste management.

2. Data Sources

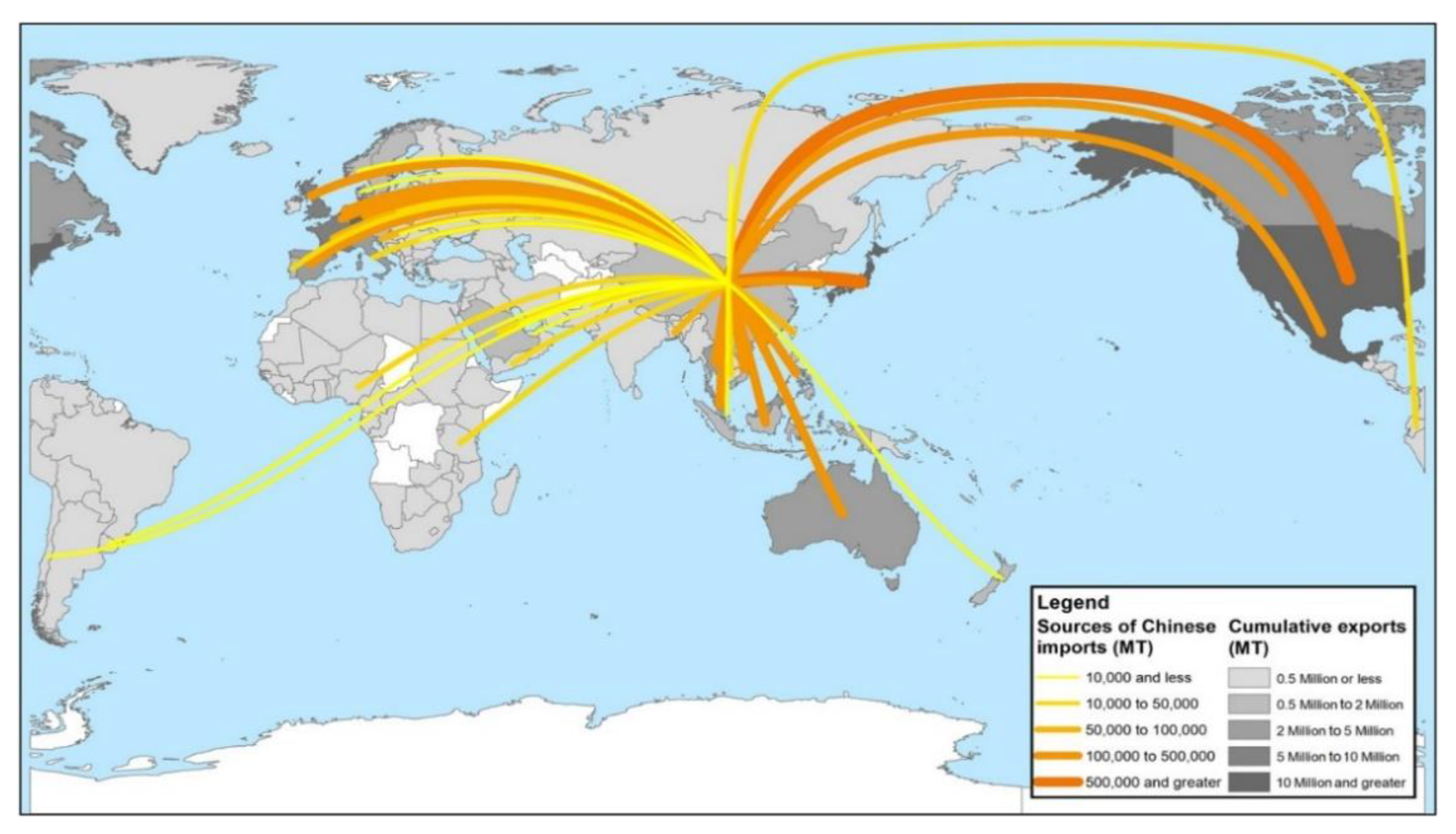

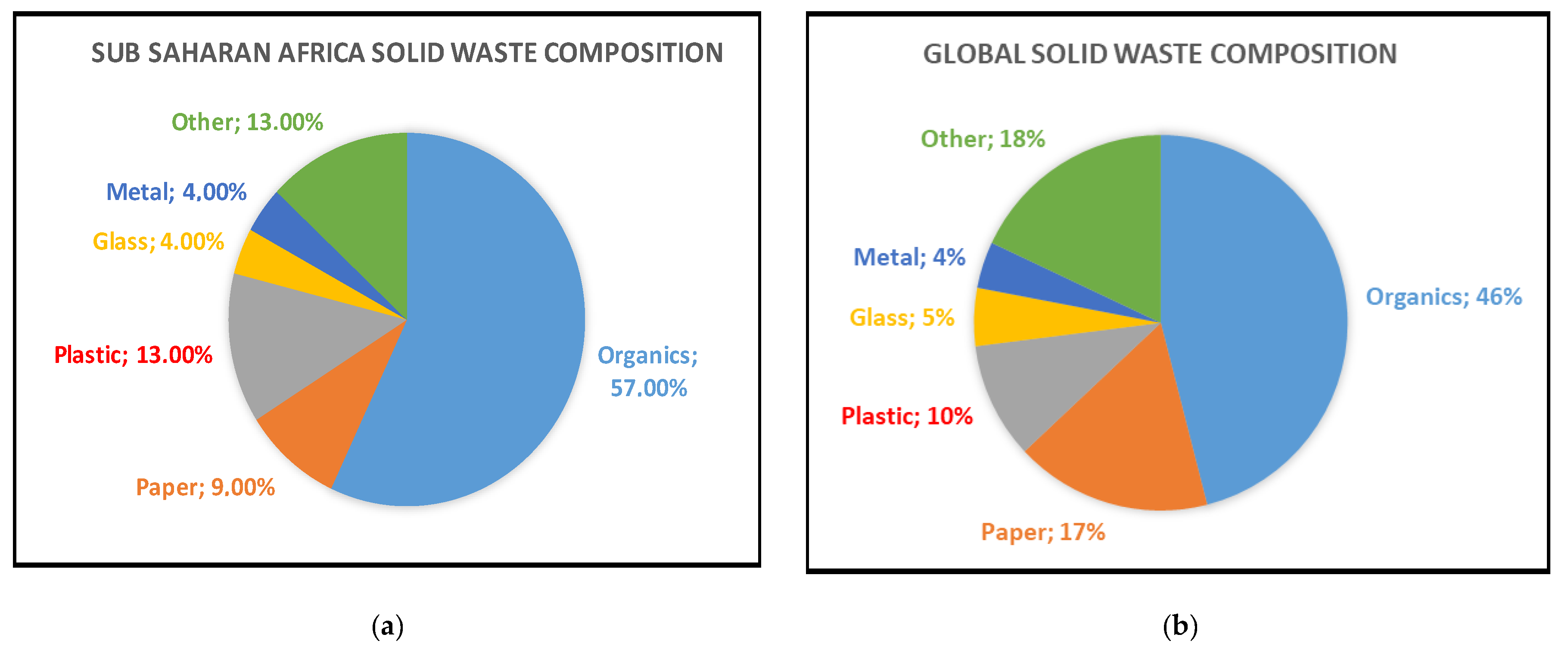

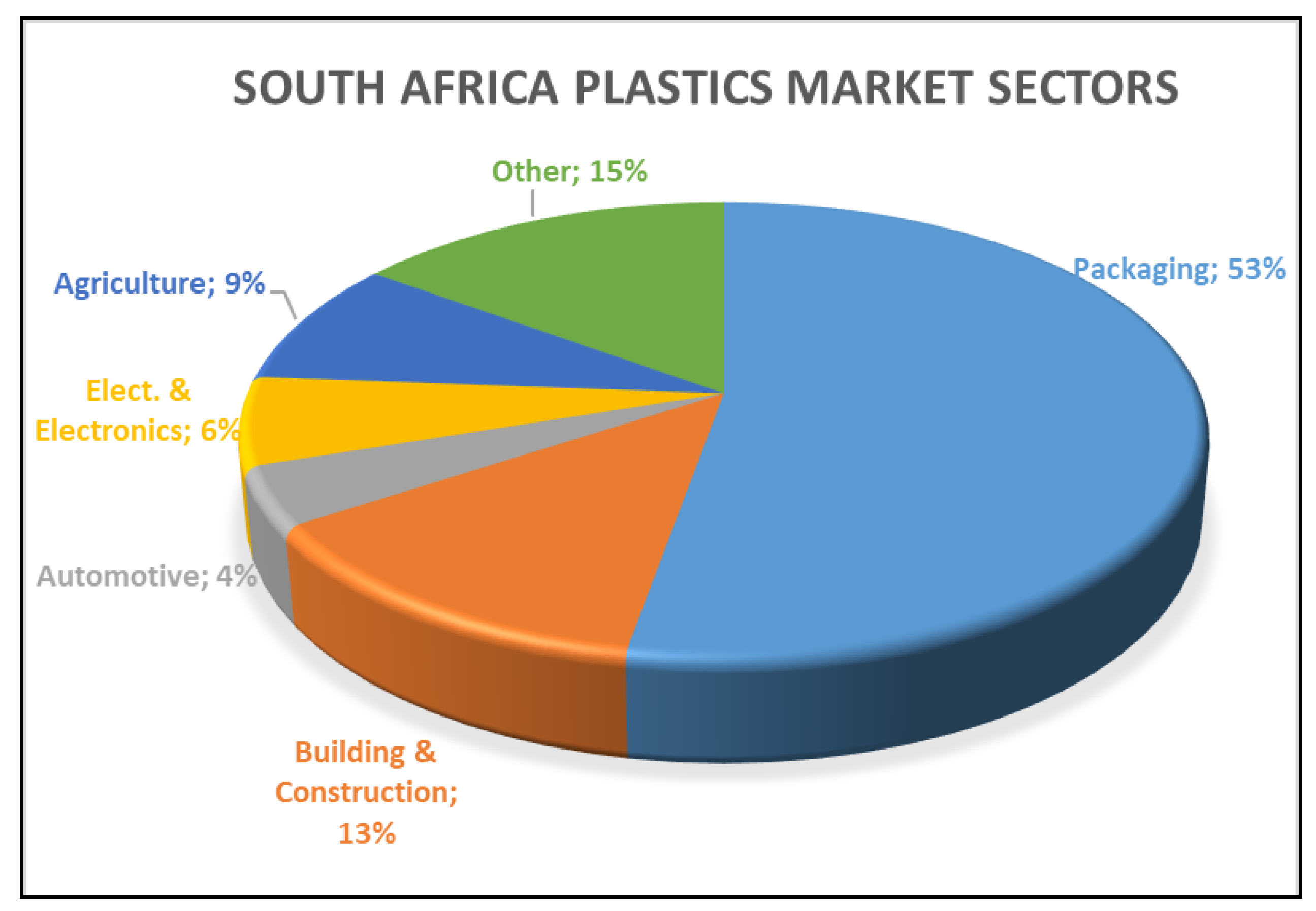

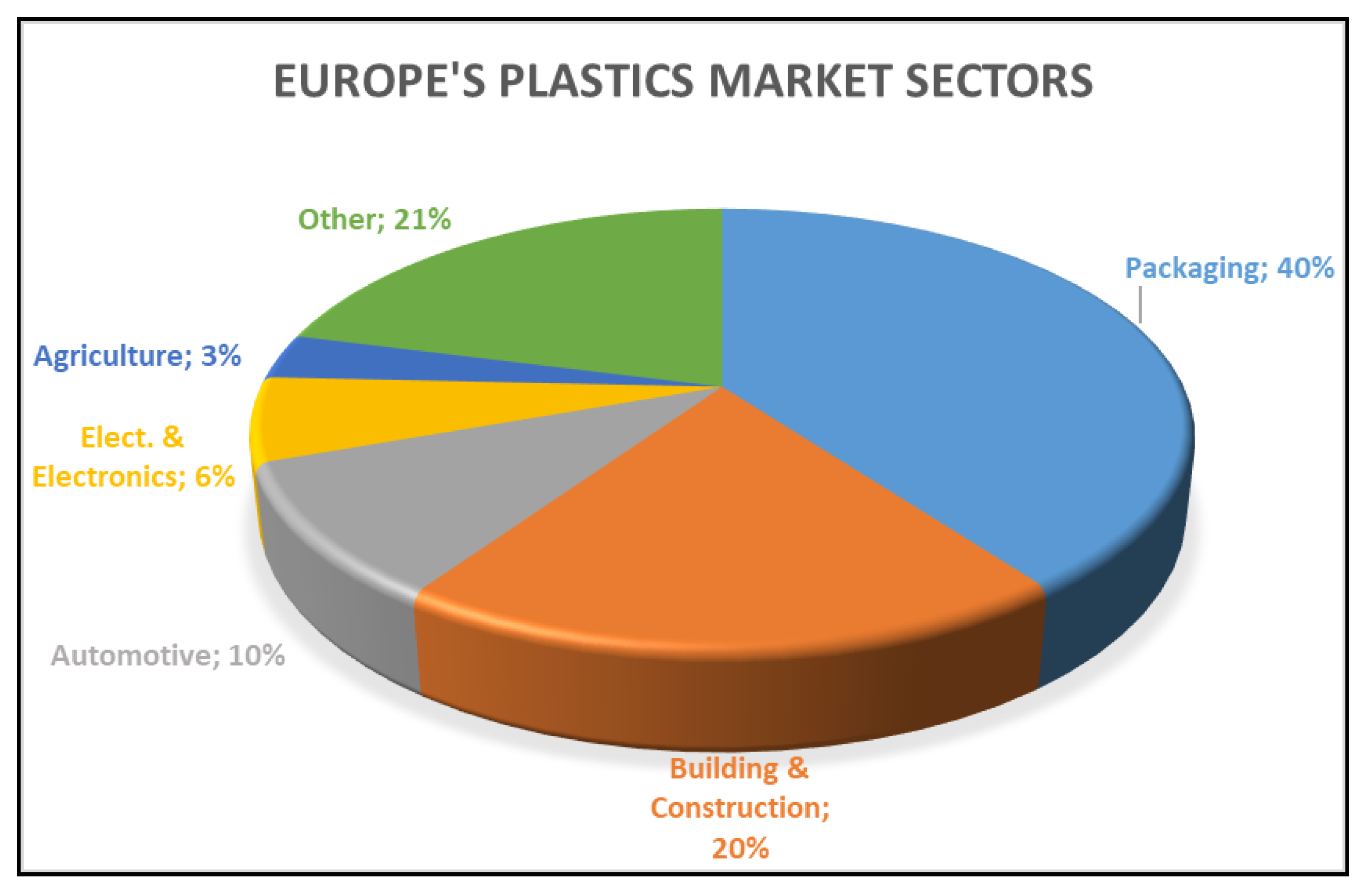

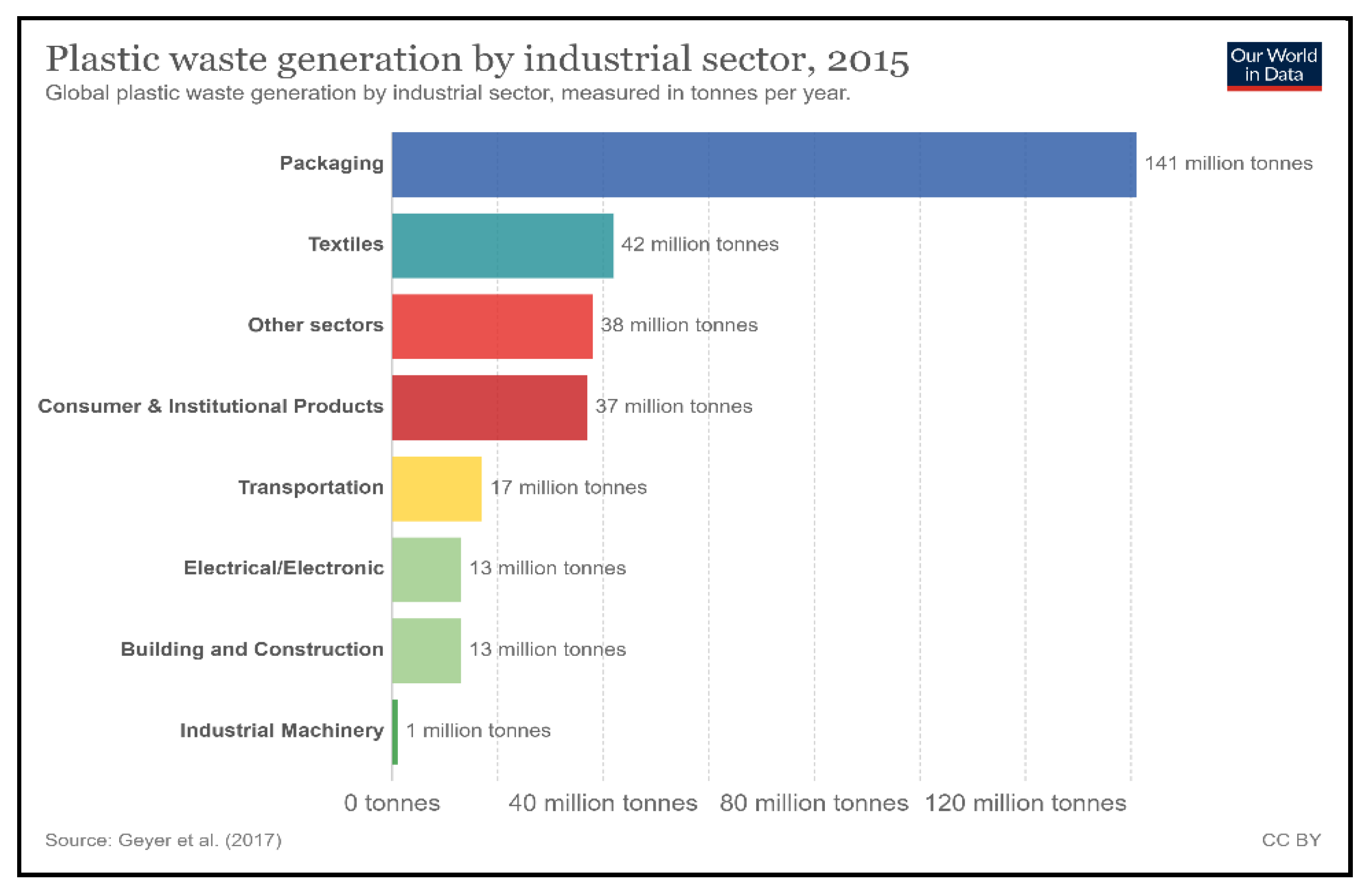

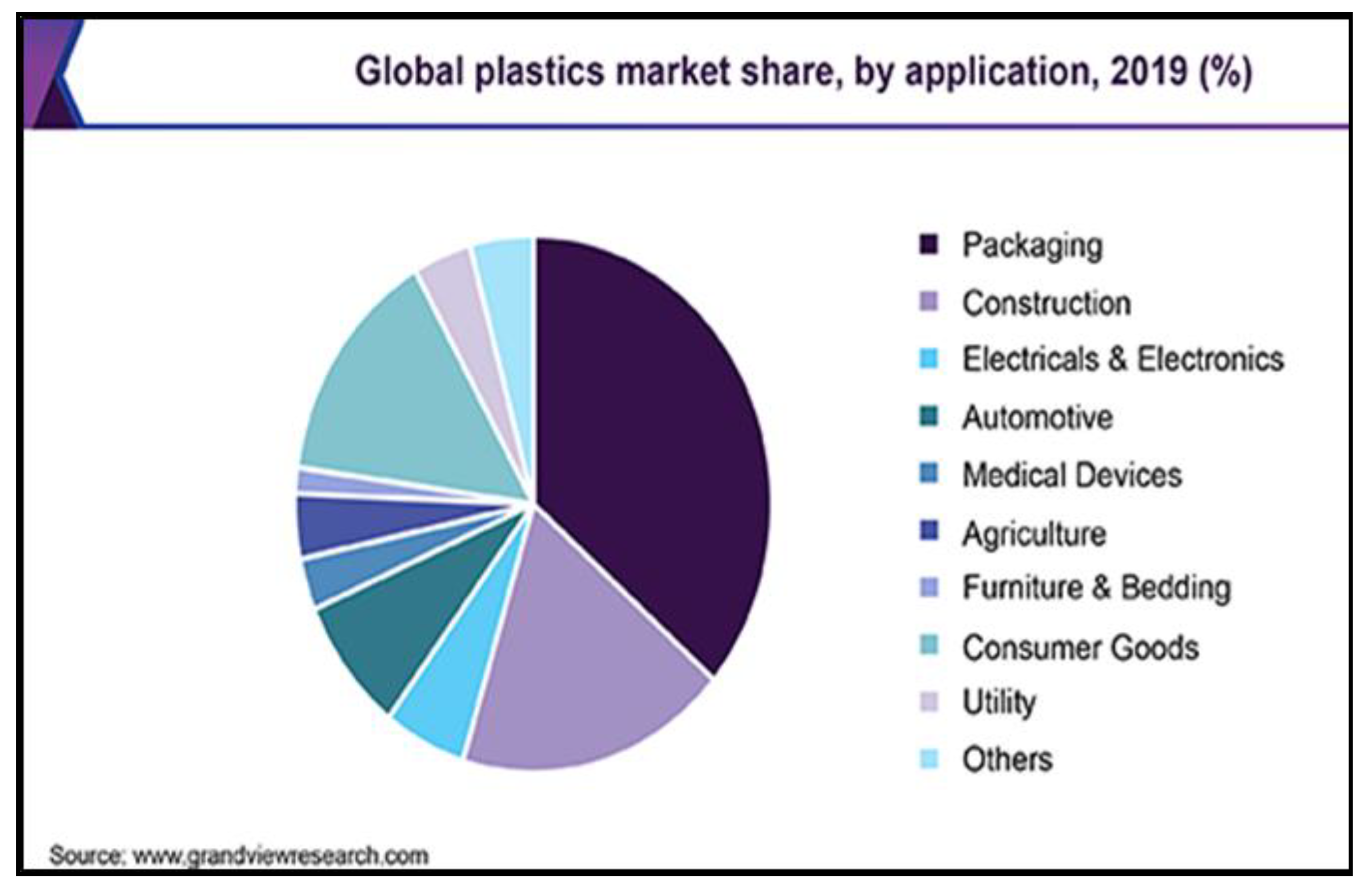

3. Inventory of Plastic Production and Its Waste Management

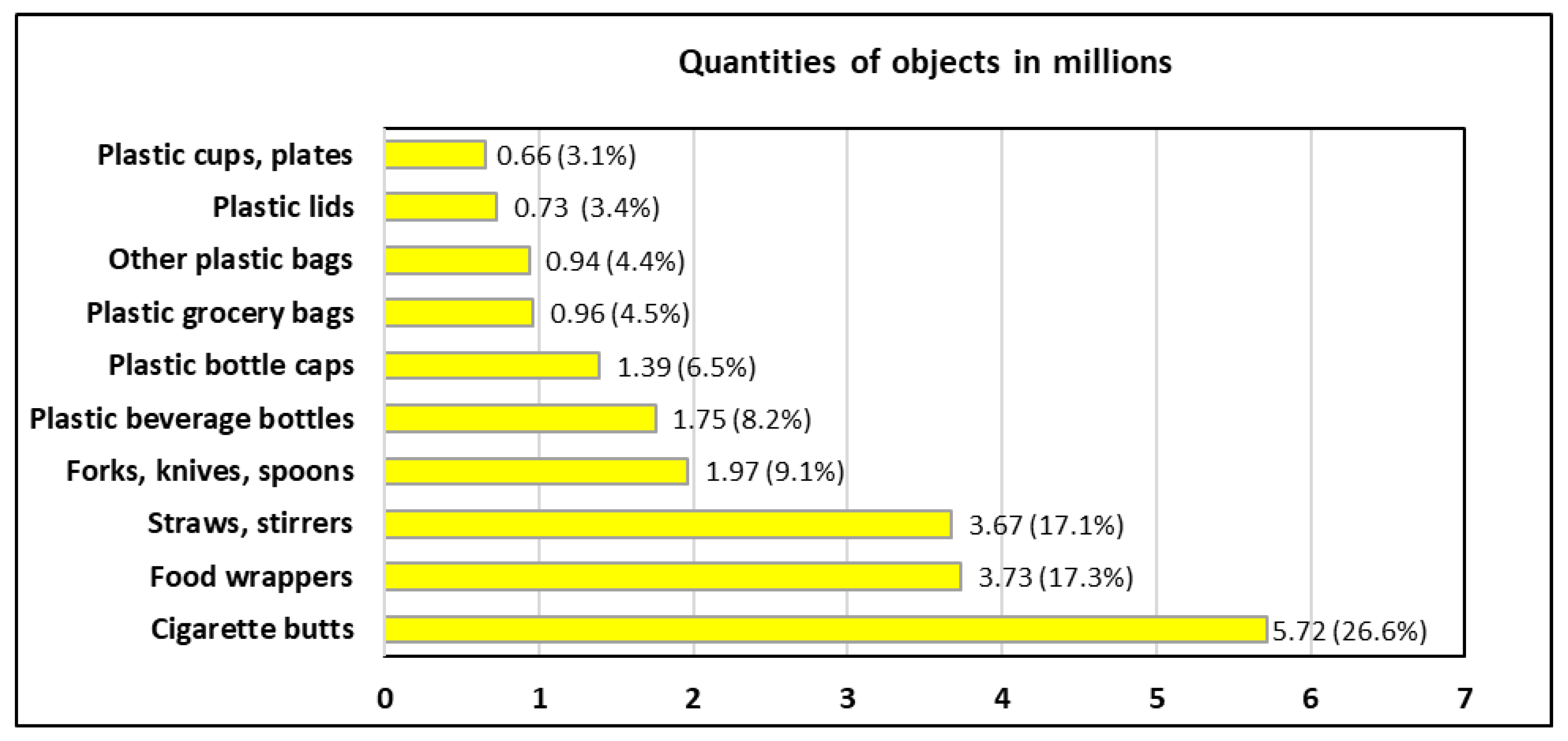

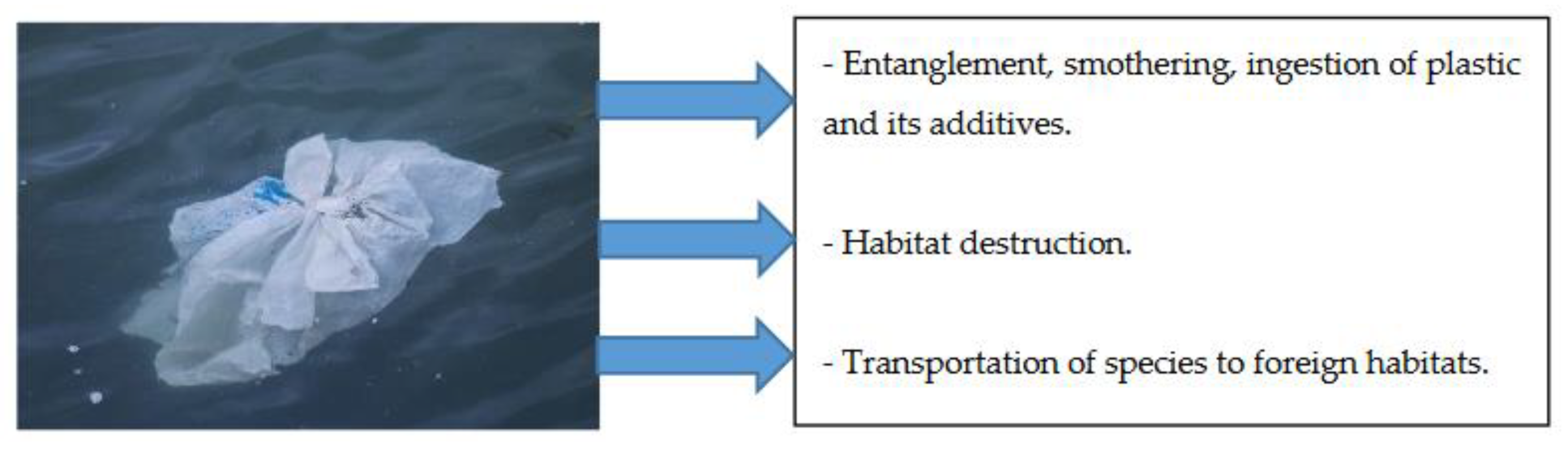

4. Marine Environment

Alternatives to Conventional or Single Use Plastics

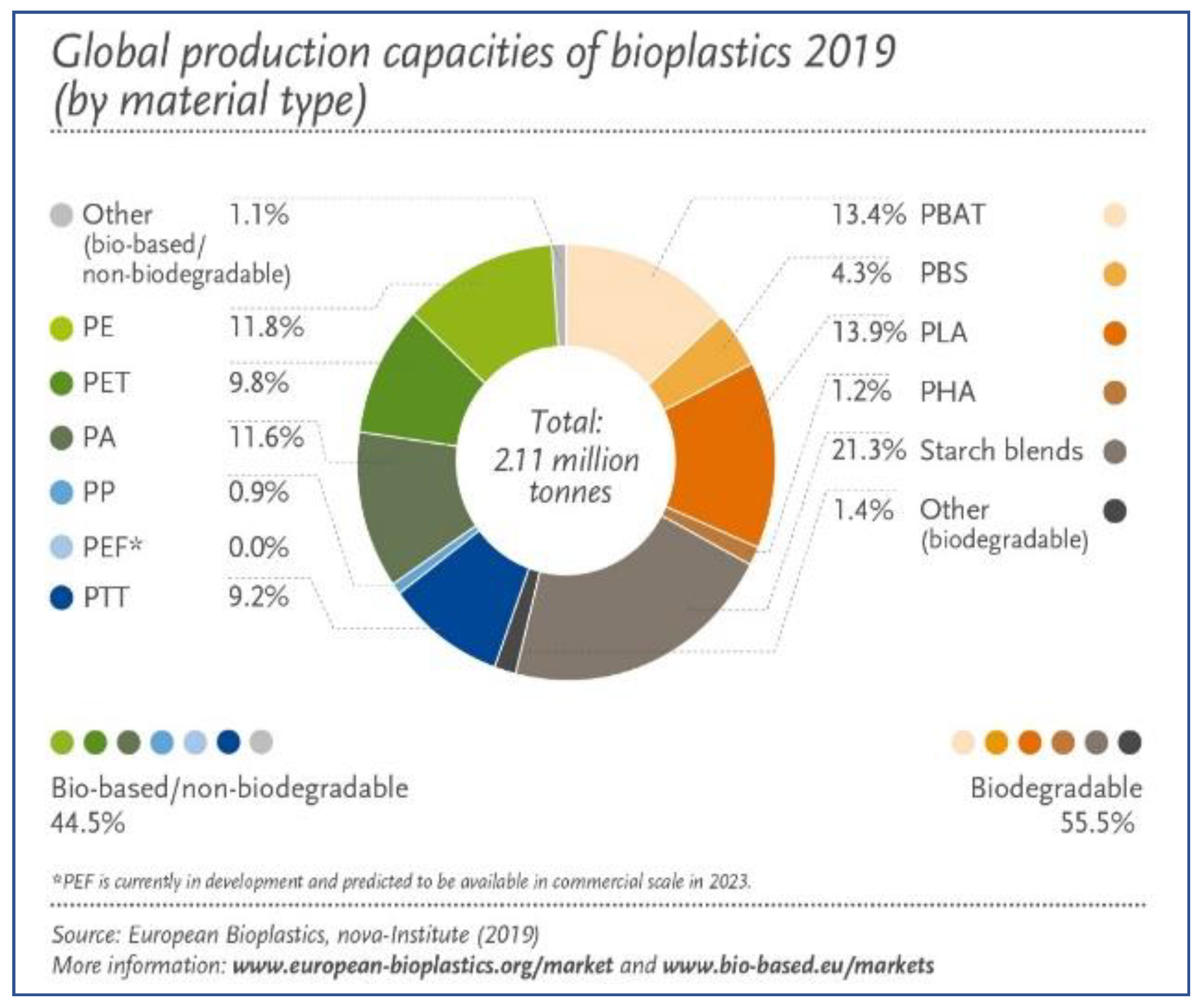

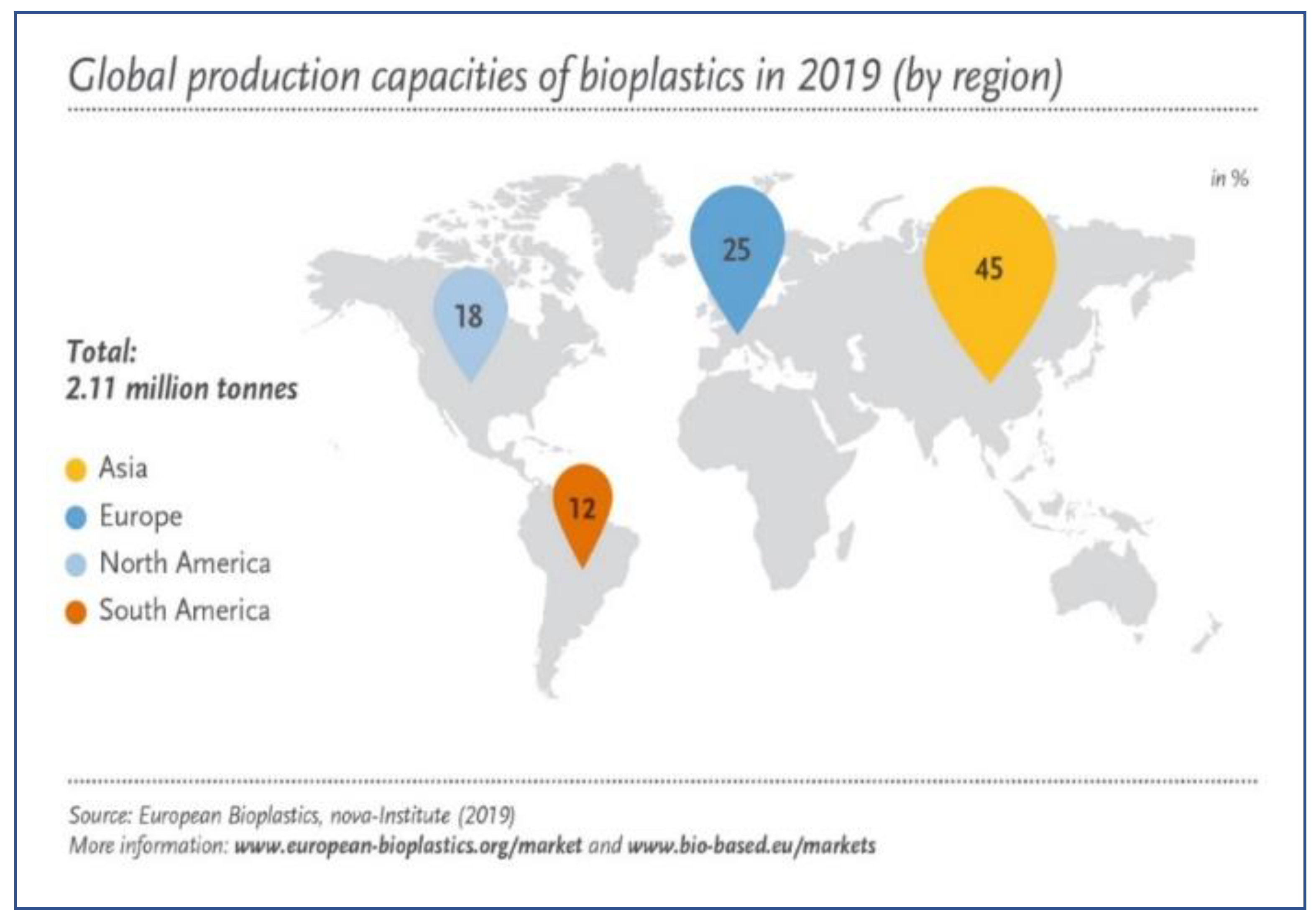

5. Bioplastics

5.1. Need for Review of Bio-Based Biodegradable Plastics

- The presence of microorganisms such as bacteria, fungi, and actinomycetes

- Oxygen (aerobic environment), moisture, and mineral nutrients

- Temperature range 20 °C to 60 °C (55–60 °C for industrial composting)

- Frequent mixing

- A pH between 5 and 8

5.1.1. Polyhydroxyalkanoates (PHAs)

Shortcomings of PHAs

5.1.2. Polybutylene Succinate (PBS)

Shortcomings of PBS

5.1.3. Polylactide/Polylactic Acid (PLA)

- Environmental impact is minimal

- Production costs are reduced

- Reduced dependency on petroleum

- Reduced carbon dioxide emissions

- The process uses a biocatalyst

Shortcomings of PLA

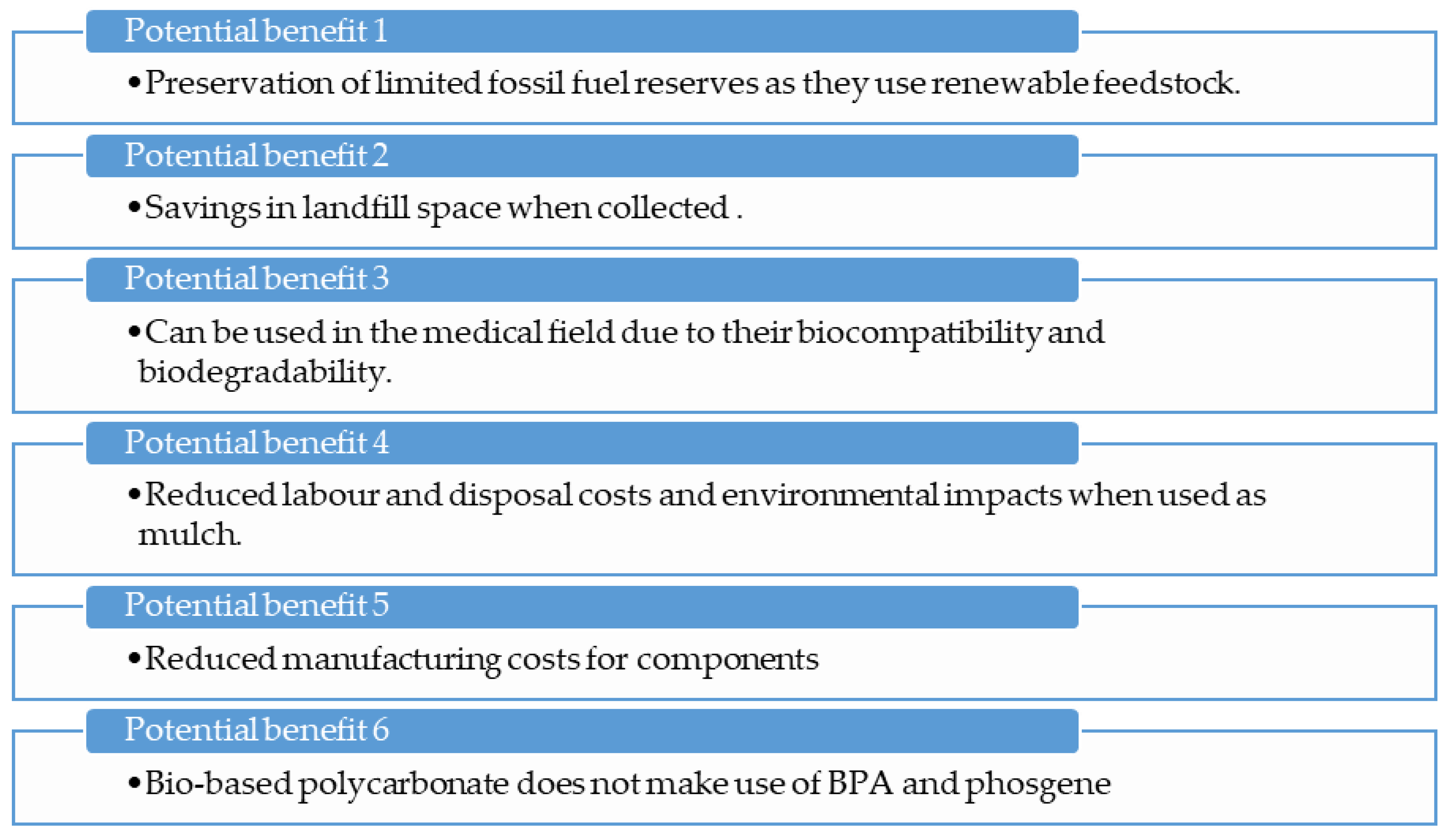

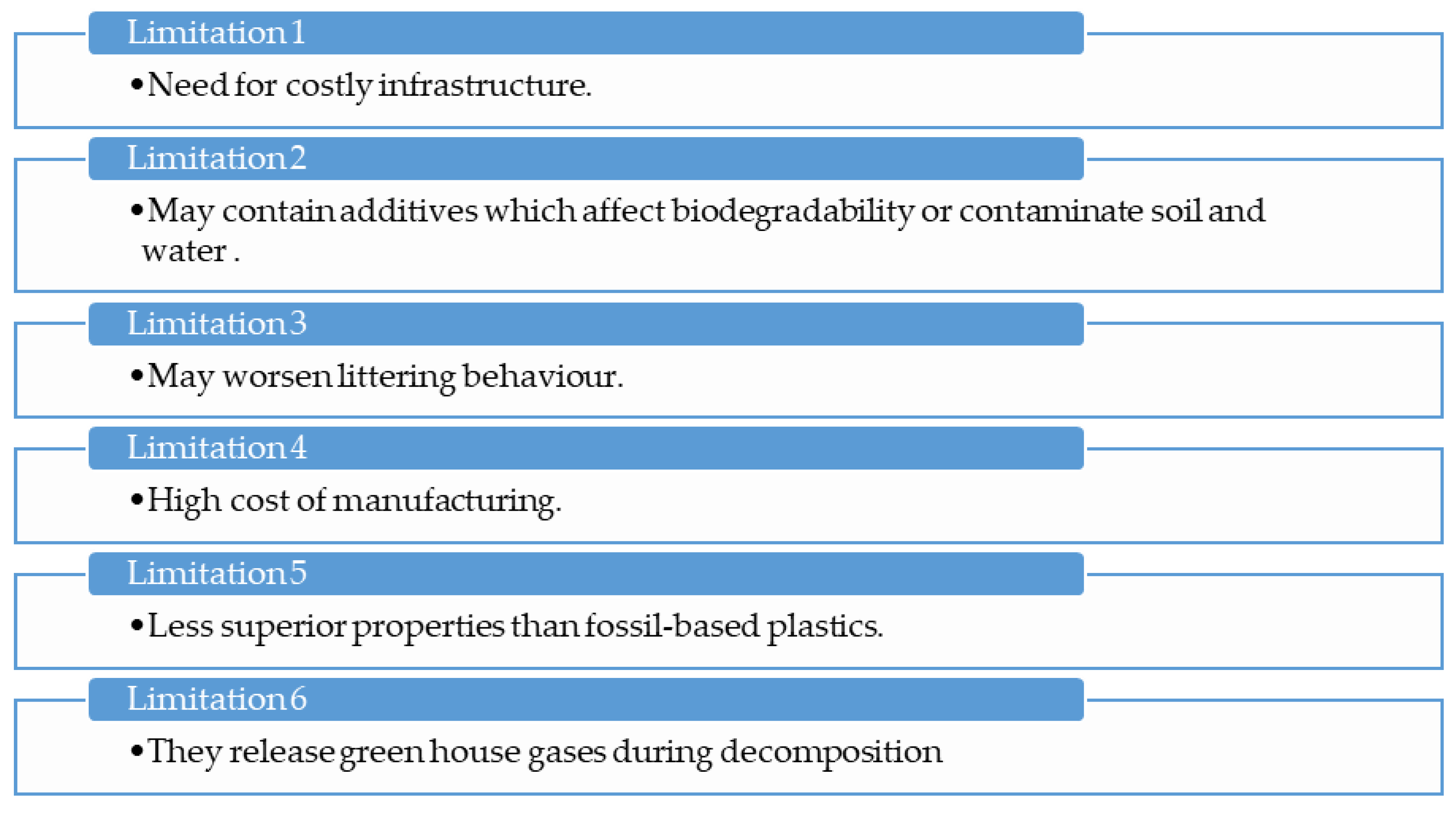

5.1.4. Polycarbonates (PCs)

Shortcomings of Bio-Polycarbonates

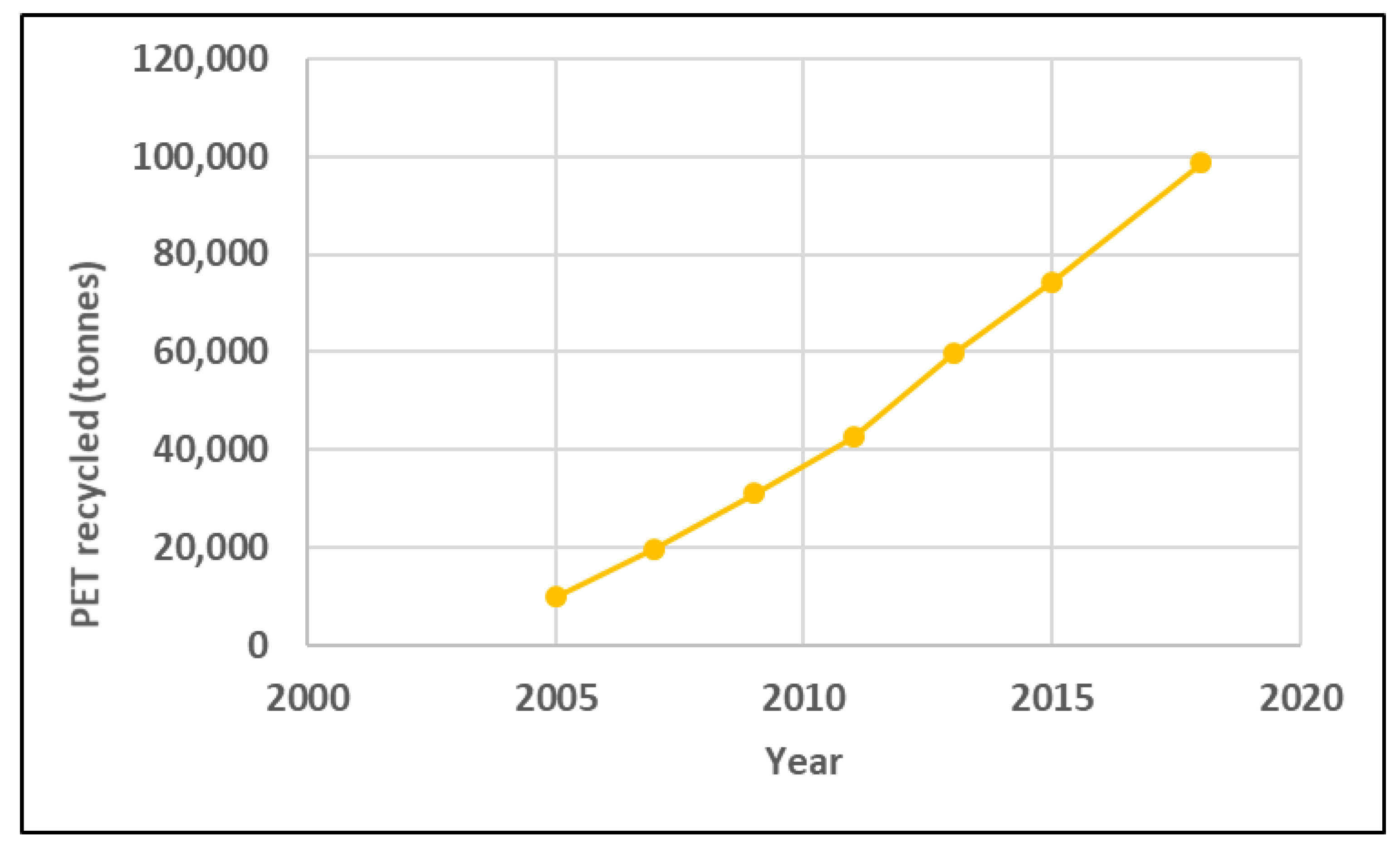

6. Extended Producer Responsibility (EPR)

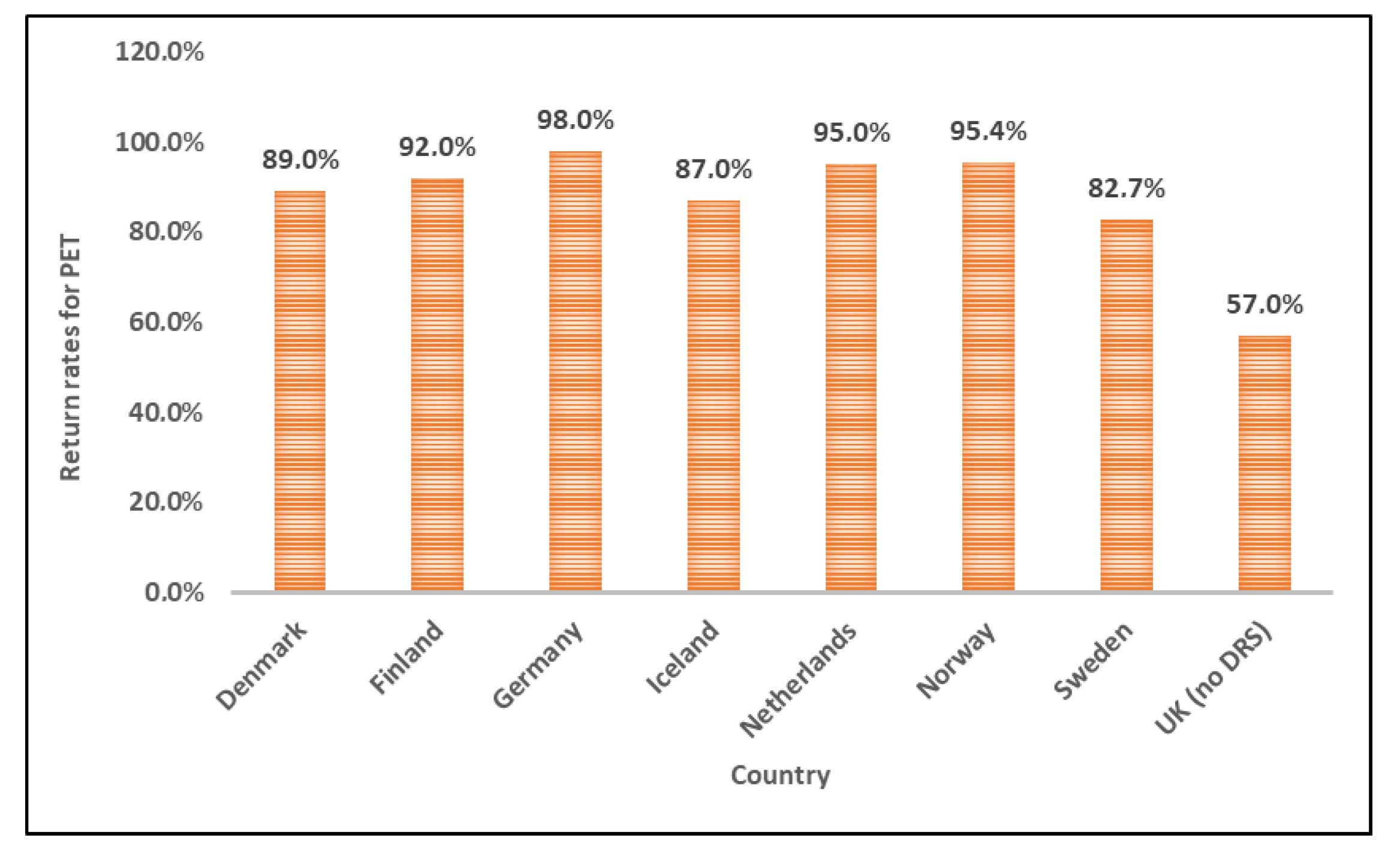

Deposit Refund Scheme

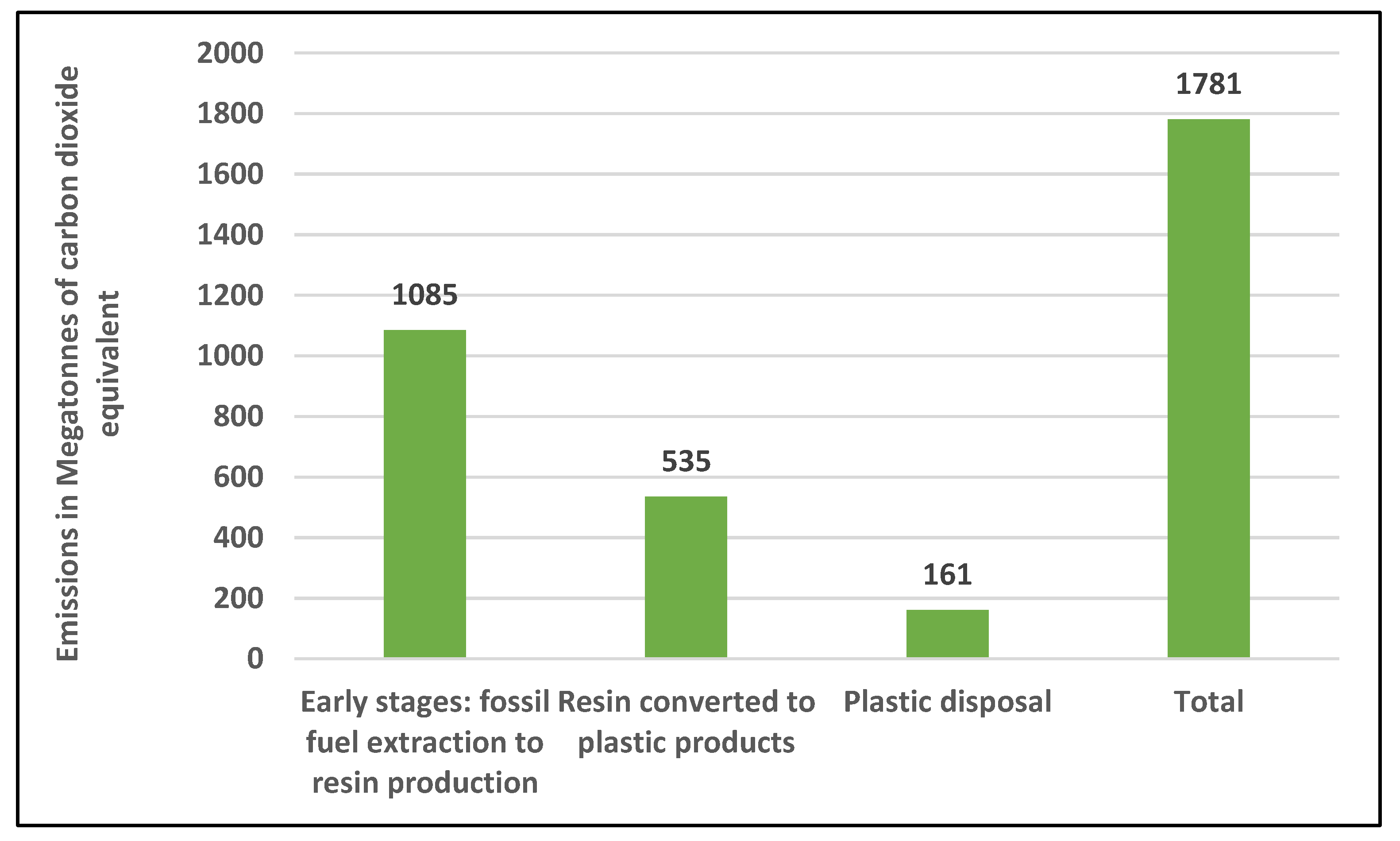

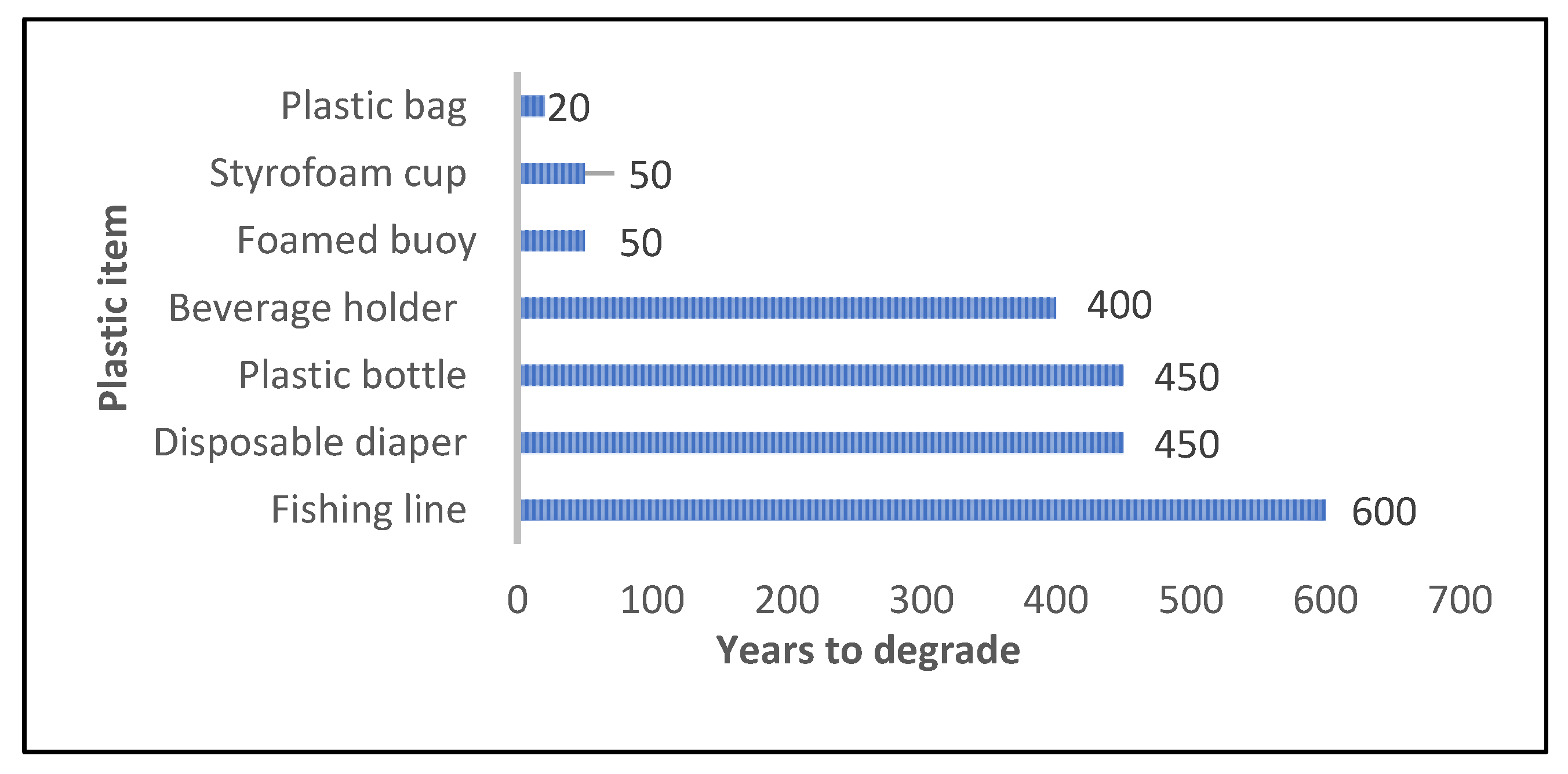

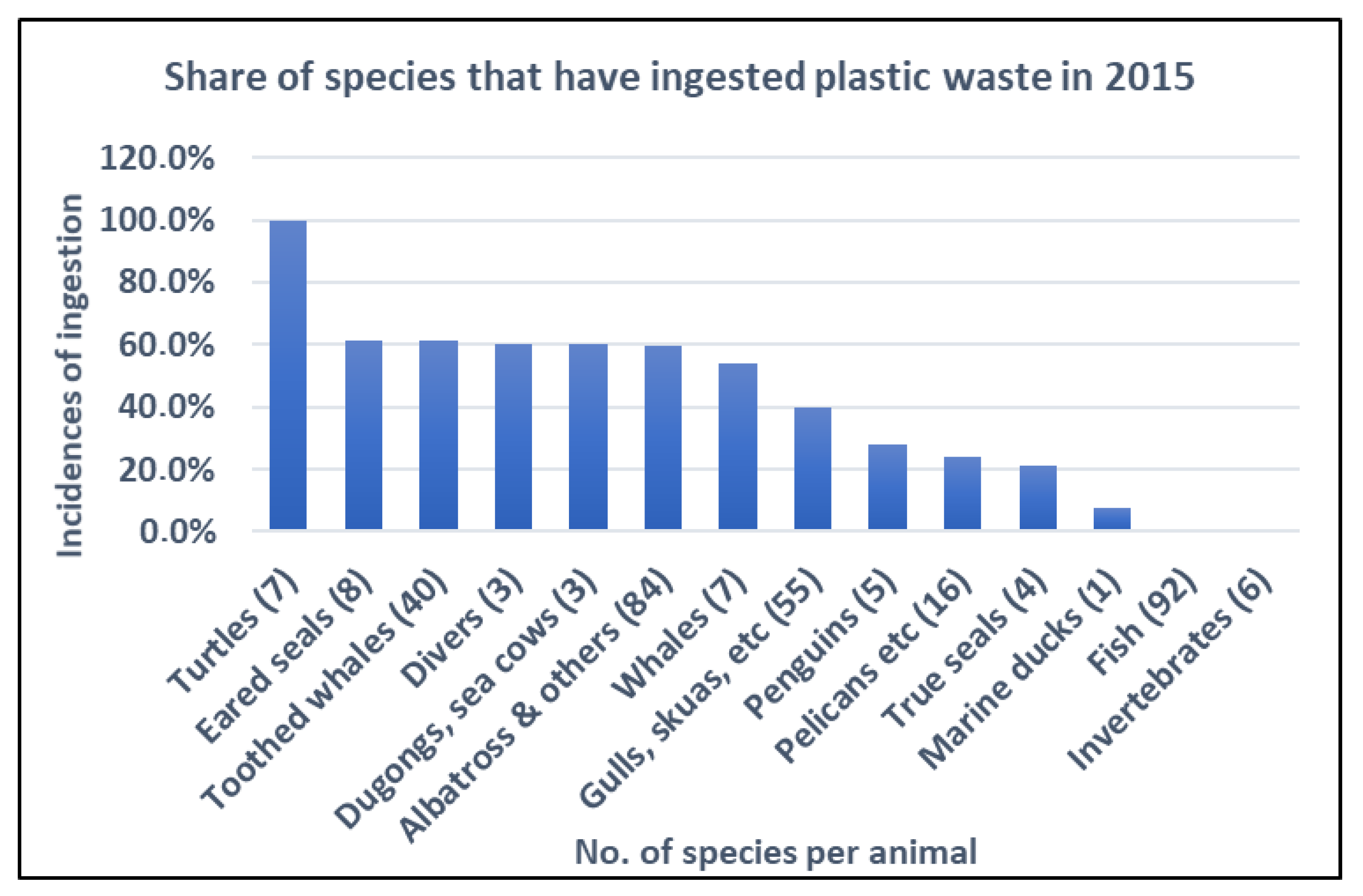

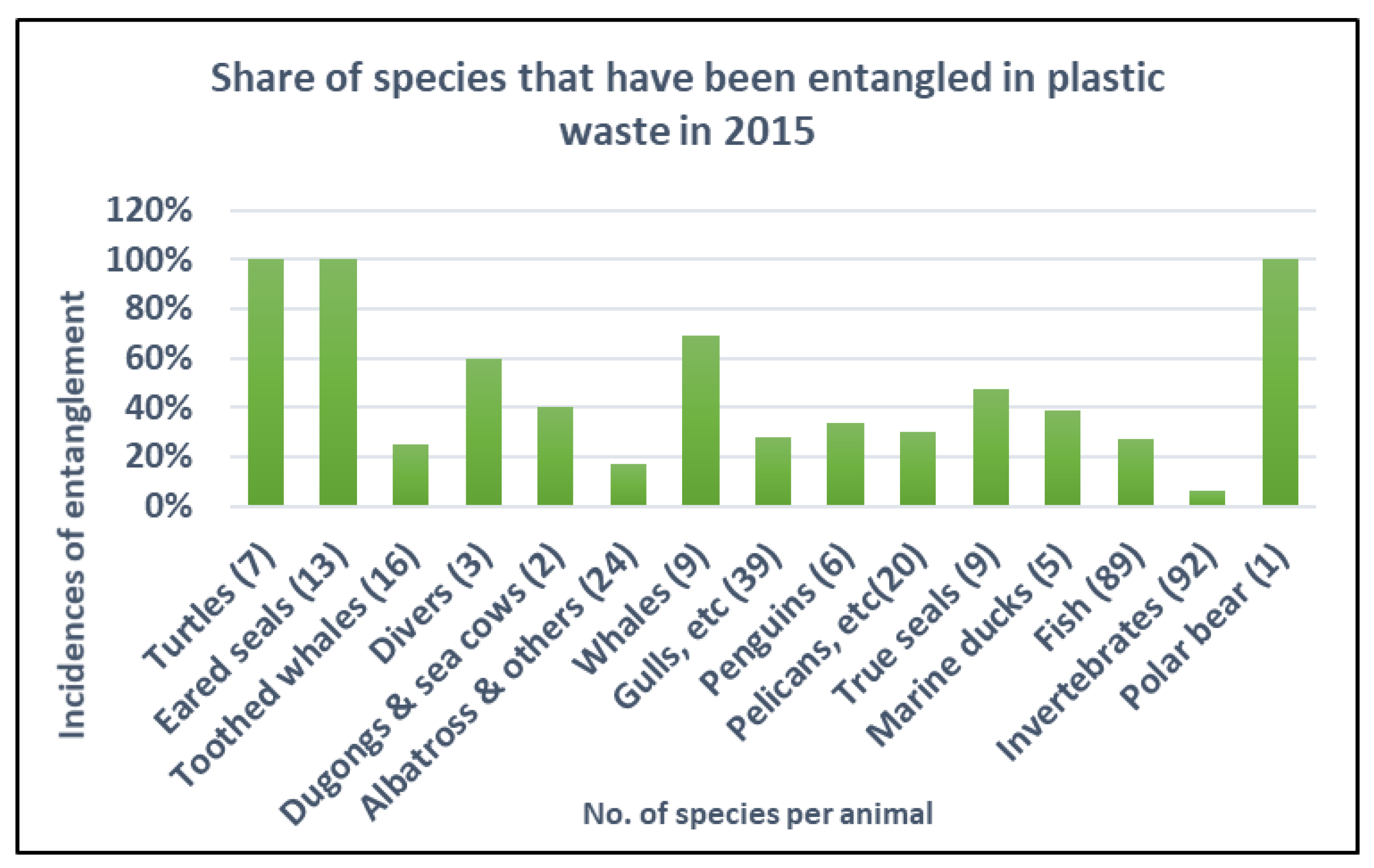

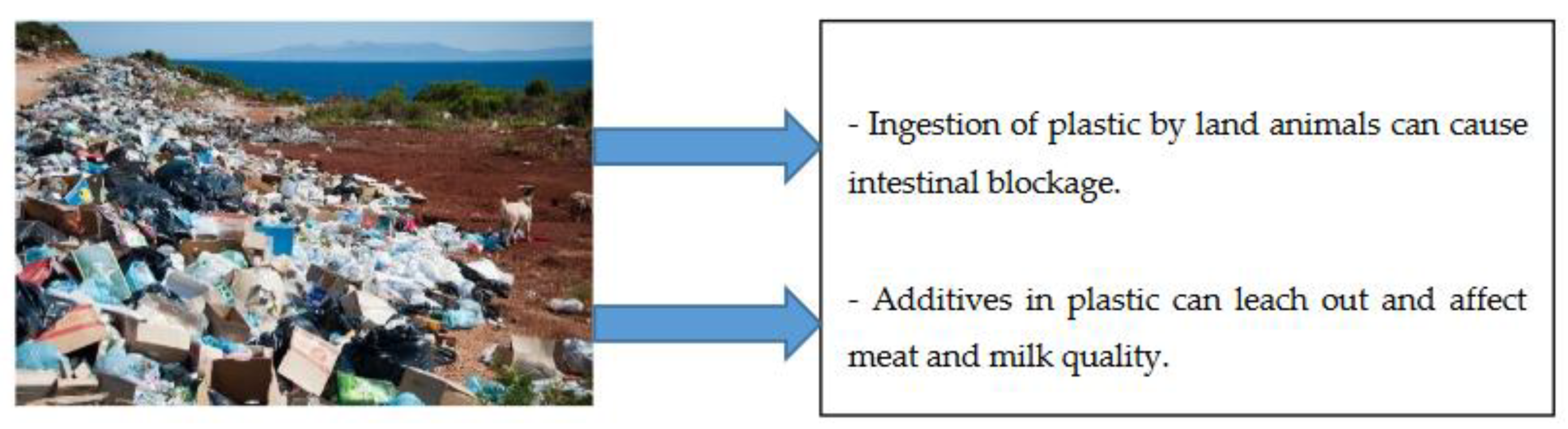

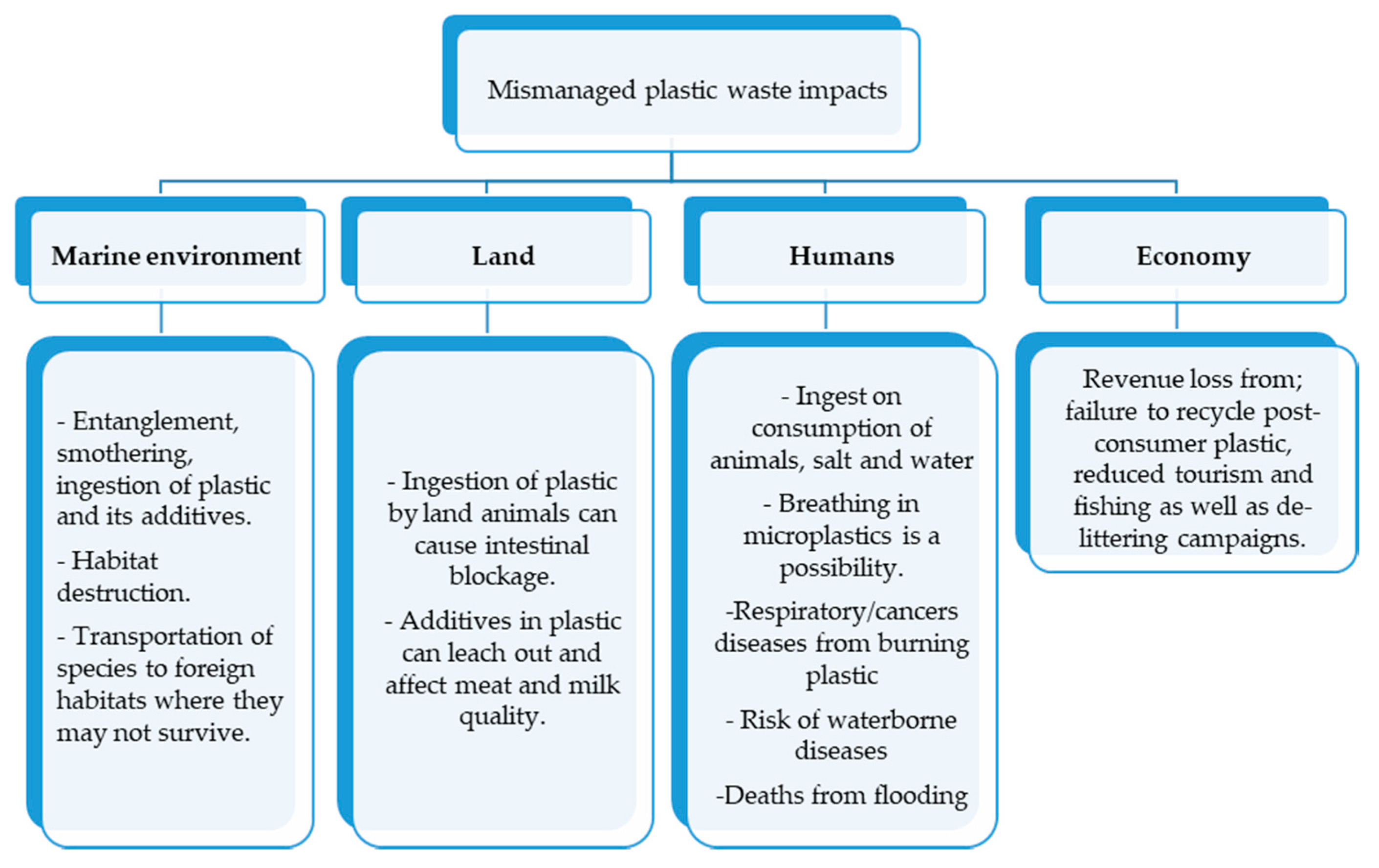

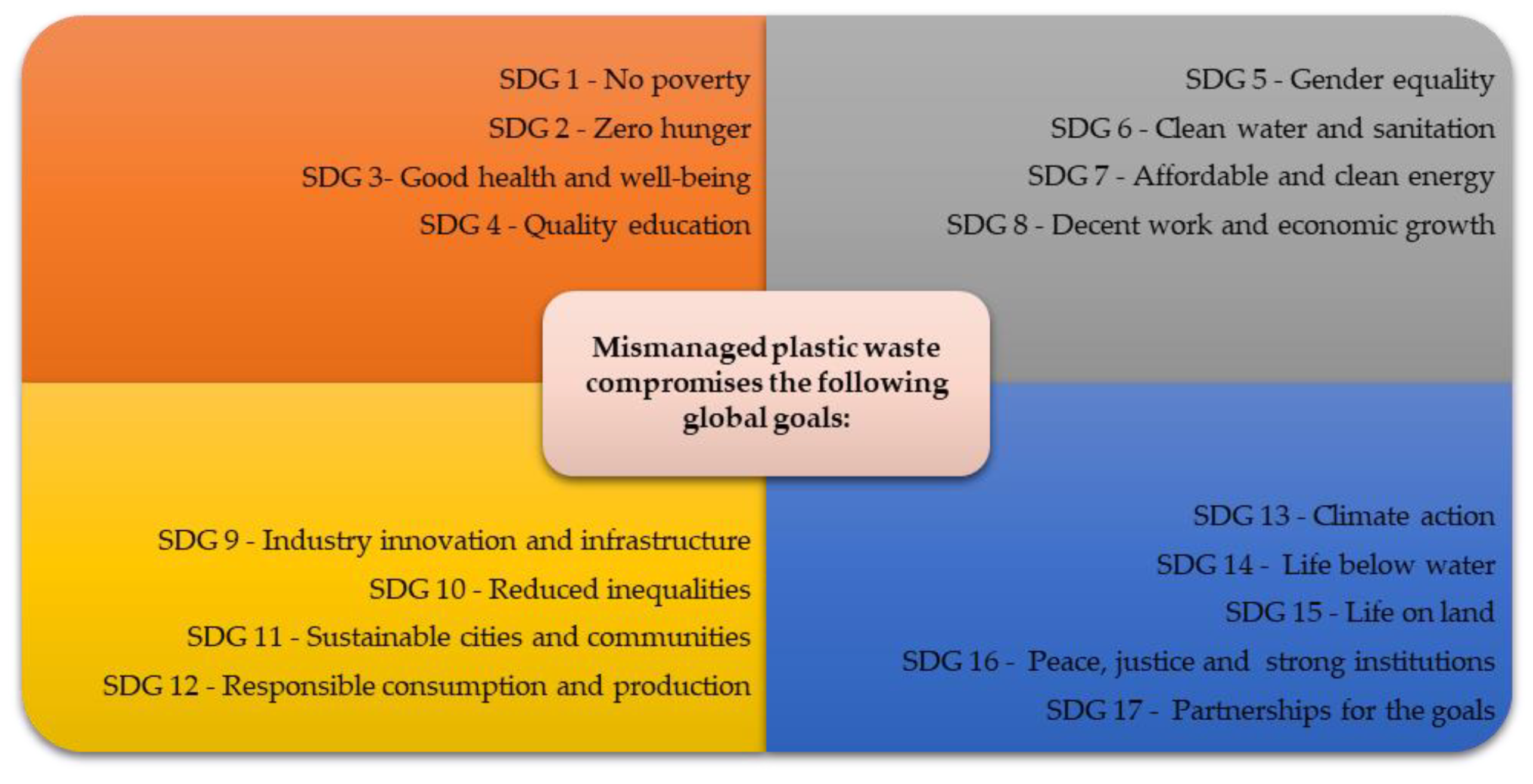

7. Summary of Mismanaged Plastic Waste Impacts

8. Discussion and Conclusions

8.1. Key Questions to Address in Plastic Waste Management

8.2. Potential Mitigation Measures and Challenges Expected

8.2.1. Mechanical Recycling

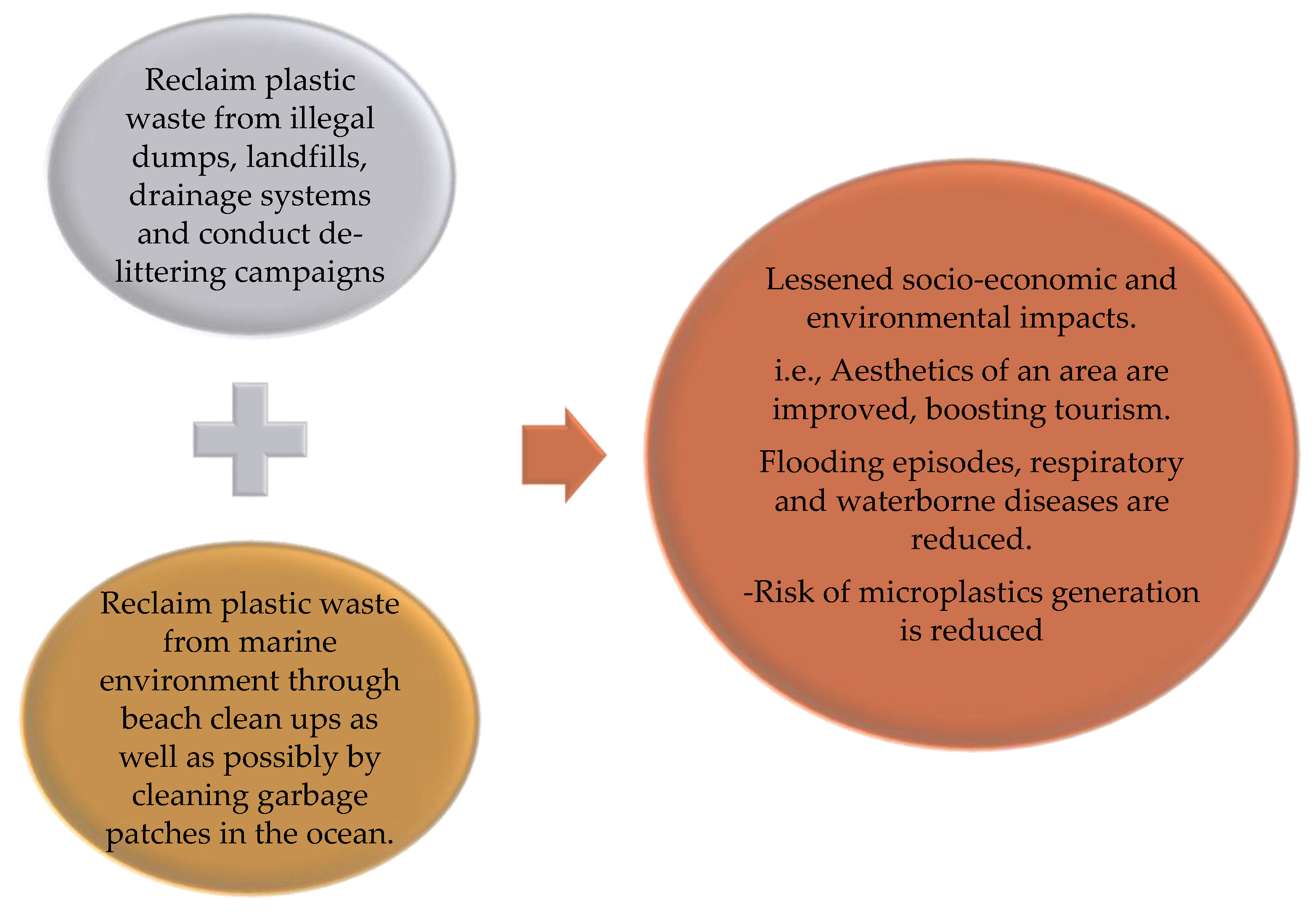

8.2.2. Reclamation of Plastic Waste from Land and Marine Environments

8.2.3. Banning of Problematic Plastics

8.2.4. Feasibility of Replacing Fossil-Based Plastics with Alternatives

8.3. Bio-Based Biodegradable Plastics Analysis

What Will Drive Growth in the Industry?

8.4. Socio-Economic and Environmental Benefits of Fossil-Based Plastics and Effects of Their Ban

8.5. Key Lessons for South Africa’s Bioplastics Manufacturing Project

- Setting up of adequate infrastructure for these plastics to avoid leakages is critical.

- Labels or pictograms indicating home or industrial composting suitability should be put on products in order to avoid consumer confusion [76].

- Provision for compost bins or gardens to facilitate home composting as well as areas of application for the generated compost [291].

- Both the consumers and composters should be educated about these materials and how to prevent contamination of the compost by non-biodegradable material.

- Trials should also be done on all products before introduction onto the market to ensure that they do not only partially decompose under the stated conditions [76].

- Biodegradable plastic blends should also be evaluated.

9. Directions for Future Research

- No data on bioplastics production and consumption patterns in Africa could be found during the review. Without properly documented African statistical data, a clear picture cannot be ascertained for the continent.

- Research on bio-based polycarbonates including end of life options and their properties when compared to their traditional counterparts is still limited.

- More research on the negative impacts of reclaiming plastic waste from the marine environment is also required.

- Research pertaining to presence of additives in biodegradable plastics is also lacking.

- More peer-reviewed research is required on the socio-economic and environmental impacts of replacing fossil-based plastics as well as the effectiveness of plastic bans.

- Africa-based LCA studies on plastic waste incineration for energy are lacking.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thompson, R.C.; Swan, S.H.; Moore, C.J.; Vom Saal, F.S. Our plastic age. Phil. Trans. R. Soc. B 2009, 364, 1973–1976. [Google Scholar] [CrossRef] [PubMed]

- American Chemical Society. Leo Hendrick Baekeland and the Invention of Bakelite. Available online: https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/bakelite.html (accessed on 21 September 2020).

- Gowariker, V.R.; Viswanathan, N.V.; Sreedhar, J. Polymer Science, 1st ed.; New Age International: New Delhi, India, 2005; pp. 9–14. [Google Scholar]

- Britannica. Available online: https://www.britannica.com/science/polymerization (accessed on 5 April 2020).

- Mazhandu, Z.S.; Muzenda, E. Global Plastic Waste Pollution Challenges and Management. In Proceedings of the 7th International Renewable and Sustainable Energy Conference, Agadir, Morocco, 27–30 November 2019. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, H.; Roser, M. Plastic Pollution. Available online: https://ourworldindata.org/plastic-pollution (accessed on 1 April 2020).

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Phil. Trans. R. Soc. B 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- Tuladhar, R.; Yin, S. Sustainability of using recycled plastic fiber in concrete. In Use of Recycled Plastics in Eco-efficient Concrete; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 441–460. [Google Scholar]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics and Catalysing Action. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/PEC-Hybrid_English_22-11-17_Digital.pdf (accessed on 1 July 2020).

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- United Nations Environment Programme. UNEP. Single-Use Plastics: A Roadmap for Sustainability. Available online: https://www.unenvironment.org/resources/report/single-use-plastics-roadmap-sustainability (accessed on 5 June 2018).

- Williams, M.; Gower, R.; Green, J.; Whitebread, E.; Lenkiewicz, Z.; Schröder, P.; Fauna and Flora International (FFI); Waste Aid and The Institute of Development Studies (IDS). No Time to Waste. Tackling the Plastic Pollution Crisis before It’s Too Late. Available online: https://www.ids.ac.uk/publications/no-time-to-waste-tackling-the-plastic-pollution-crisis-before-its-too-late/ (accessed on 14 May 2019).

- Lusher, A.L.; Hernandez-Milian, G.; O’Brien, J.; Berrow, S.; O’Connor, I.; Officer, R. Microplastic and macroplastic ingestion by a deep diving, oceanic cetacean: The True’s beaked whale Mesoplodon mirus. Environ. Pollut. 2015, 199, 185–191. [Google Scholar] [CrossRef]

- United Nations Environment Programme. The Missing Science: Could Our Addiction to Plastic Be Poisoning Us? Available online: https://www.unenvironment.org/news-and-stories/story/missing-science-could-our-addiction-plastic-be-poisoning-us (accessed on 4 June 2018).

- Armstrong, M.; Statista. Where Do the Oceans’ Microplastics Come From? Available online: https://0-www-statista-com.ujlink.uj.ac.za/chart/17957/where-the-oceans-microplastics-come-from/ (accessed on 10 May 2019).

- Statista. Global Species with Records of Marine Debris Ingestion. 2015. Available online: https://www.statista.com/statistics/596991/share-of-species-with-with-records-of-marine-debris-ingestion/ (accessed on 16 August 2016).

- De Stephanis, R.; Giménez, J.; Carpinelli, E.; Gutierrez-Exposito, C.; Cañadas, A. As main meal for sperm whales: Plastics debris. Mar. Pollut. Bull. 2013, 69, 206–214. [Google Scholar] [CrossRef]

- Statista. Global Animal Species with Records of Marine Debris Entanglement 2015. Available online: https://www.statista.com/statistics/596960/share-of-species-with-with-records-of-entanglement-in-marine-debris/ (accessed on 16 August 2016).

- Facts and Figures on Marine Pollution. Available online: http://www.unesco.org/new/en/natural-sciences/ioc-oceans/focus-areas/rio-20-ocean/blueprint-for-the-future-we-want/marine-pollution/facts-and-figures-on-marine-pollution/ (accessed on 1 April 2020).

- Mato, Y.; Isobe, T.; Takada, H.; Kanehiro, H.; Ohtake, C.; Kaminuma, T. Plastic resin pellets as a transport medium for toxic chemicals in the marine environment. Environ. Sci. Technol. 2001, 35, 318–324. [Google Scholar] [CrossRef]

- Tanaka, K.; Takada, H.; Yamashita, R.; Mizukawa, K.; Fukuwaka, M.A.; Watanuki, Y. Accumulation of plastic-derived chemicals in tissues of seabirds ingesting marine plastics. Mar. Pollut. Bull. 2013, 69, 219–222. [Google Scholar] [CrossRef]

- Gallo, F.; Fossi, C.; Weber, R.; Santillo, D.; Sousa, J.; Ingram, I.; Nadal, A.; Romano, D. Marine litter plastics and microplastics and their toxic chemicals components: The need for urgent preventive measures. Environ. Sci. Eur. 2018, 30, 13. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.; Love, D.C.; Rochman, C.M.; Neff, R.A. Microplastics in seafood and the implications for human health. Curr. Environ. Health Rep. 2018, 5, 375–386. [Google Scholar] [CrossRef]

- Priyanka, M.; Dey, S. Ruminal impaction due to plastic materials—An increasing threat to ruminants and its impact on human health in developing countries. Vet. World 2018, 11, 1307–1315. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Valuing Plastic: The Business Case for Measuring, Managing and Disclosing Plastic Use in the Consumer Goods Industry. 2014. Available online: http://wedocs.unep.org/handle/20.500.11822/9238 (accessed on 3 April 2020).

- Mazhandu, Z.; Muzenda, E.; Belaid, M.; Mamvura, T. Potential Impact of the Covid-19 Pandemic on Plastic Medical Waste Management in South Africa. S. Afr. J. Sci. 2020. [Google Scholar]

- Alabi, O.A.; Ologbonjaye, K.I.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A Review. J. Toxicol. Risk Assess. 2019, 5, 021. [Google Scholar]

- Narancic, T.; O’Connor, K.E. Plastic waste as a global challenge: Are biodegradable plastics the answer to the plastic waste problem? Microbiology 2019, 165, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Deng, S.; Chen, P.; Ruan, R. Polylactic acid (PLA) synthesis and modifications: A review. Front. Chem. 2009, 4, 259–264. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261. [Google Scholar] [CrossRef]

- Branded. Break Free from Plastic. Available online: https://www.breakfreefromplastic.org/wp-content/uploads/2018/10/BRANDED-Report-2018-FINAL.pdf (accessed on 23 March 2020).

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Facts and Figures about Materials, Waste and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data (accessed on 10 April 2020).

- Morin, N.; Arp, H.P.H.; Hale, S.E. Bisphenol A in solid waste materials, leachate water, and air particles from Norwegian waste-handling facilities: Presence and partitioning behavior. Environ. Sci. Technol. 2015, 49, 7675–7683. [Google Scholar] [CrossRef]

- Carlini, G. Centre for International Environmental Law. One Small Edit for a Legal Text, One Giant Leap for Addressing Plastic Pollution: A New Plastic Waste Proposal for the Basel Convention. 2018. Available online: https://www.ciel.org/plastic-waste-proposal-basel-convention/ (accessed on 8 April 2020).

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 2018, 4, eaat0131. [Google Scholar] [CrossRef]

- Parker, L. National Geographic. China’s Ban on Trash Imports Shifts Waste Crisis to Southeast Asia. Available online: https://www.nationalgeographic.com/environment/2018/11/china-ban-plastic-trash-imports-shifts-waste-crisis-southeast-asia-malaysia/ (accessed on 8 April 2020).

- 5 Gyres. Frequently Asked Questions. Available online: https://www.5gyres.org/faq (accessed on 1 July 2020).

- Crawford, A.; BBC News. Why Is UK Recycling Being Dumped by Turkish Roadsides? Available online: https://www.bbc.com/news/av/uk-53181948 (accessed on 1 July 2020).

- Reeves, S.; Phys Org. China plastic Waste Ban Throws Global Recycling into Chaos. 2019. Available online: https://phys.org/news/2019-04-china-plastic-global-recycling-chaos.html (accessed on 8 April 2020).

- Basel Convention. Available online: http://www.basel.int/TheConvention/Overview/tabid/1271/Default.aspx (accessed on 1 April 2020).

- Daniel Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management. Available online: https://openknowledge.worldbank.org/handle/10986/17388 (accessed on 7 April 2020).

- Plastics SA. Overview of the Plastics Industry in South Africa. Available online: https://www.thedti.gov.za/parliament/2014/Plastics_part1.pdf (accessed on 7 April 2020).

- Grand View Research. Market Research Report. 2020. Available online: https://www.grandviewresearch.com/industry-analysis/global-plastics-market (accessed on 7 April 2020).

- Denkstatt. How Packaging Contributes to Food Waste Prevention. Specific Examples from Austrian Stakeholder Projects, Including Carbon Footprint Assessments. Available online: https://www.save-food.org/cgi-bin/md_interpack/lib/all/lob/return_download.cgi/3_Interpack_2017_denkstatt_Packaging_Food_Waste_Prevention_V1.0.pdf?ticket=g_u_e_s_t&bid=5684&no_mime_type=0 (accessed on 2 August 2020).

- United Nations—Treaty Series. Multilateral Convention for the Prevention of Marine Pollution by Dumping from Ships and Aircraft. Signed at Oslo on 15 February 1972. Available online: https://treaties.un.org/doc/Publication/UNTS/Volume%20932/volume-932-I-13269-English.pdf (accessed on 18 March 2020).

- United States Environmental Protection Agency. Ocean Dumping: International Treaties. Available online: https://www.epa.gov/ocean-dumping/ocean-dumping-international-treaties (accessed on 18 March 2020).

- International Maritime Organization. International Convention for the Prevention of Pollution from Ships (MARPOL). Available online: http://www.imo.org/en/About/Conventions/ListOfConventions/Pages/nternational-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx (accessed on 26 March 2020).

- United Nations—Treaty Series. Multilateral. Convention for the Prevention of Marine Pollution from Land-Based Sources (with Annexes). Concluded at Paris on 4 June 1974. Available online: https://treaties.un.org/doc/Publication/UNTS/Volume%201546/volume-1546-I-26842-English.pdf (accessed on 26 March 2020).

- European Commission. The Barcelona Convention for the Protection of the Marine Environment and the Coastal Region of the Mediterranean Adopted in 1995. Available online: https://ec.europa.eu/environment/marine/international-cooperation/regional-sea-conventions/barcelona-convention/index_en.htm (accessed on 23 March 2020).

- Chitaka, T.Y.; von Blottnitz, H. Accumulation and characteristics of plastic debris along five beaches in Cape Town. Mar. Pollut. Bull. 2019, 138, 451–457. [Google Scholar] [CrossRef]

- The Beach and Beyond. International Coastal Cleanup. 2018. Available online: https://oceanconservancy.org/wp-content/uploads/2019/09/Final-2019-ICC-Report.pdf (accessed on 9 April 2020).

- Gómez, F.; Rima, S. World Economic Forum. Setting the Facts Straight on Plastics. 4 October 2019. Available online: https://www.weforum.org/agenda/2019/10/plastics-what-are-they-explainer/ (accessed on 30 July 2020).

- Lebreton, L.; Slat, B.; Ferrari, F.; Sainte-Rose, B.; Aitken, J.; Marthouse, R.; Hajbane, S.; Cunsolo, S.; Schwarz, A.; Levivier, A.; et al. Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 2018, 8, 1–15. [Google Scholar] [CrossRef] [PubMed]

- United Nations. Sustainable Development Goals. Goal 14: Conserve and Sustainably Use the Oceans, Seas and Marine Resources. Available online: https://www.un.org/sustainabledevelopment/oceans/ (accessed on 23 March 2020).

- Cole, M.; Lindeque, P.; Fileman, E.; Halsband, C.; Galloway, T.S. The impact of polystyrene microplastics on feeding, function and fecundity in the marine copepod Calanus helgolandicus. Environ. Sci. Technol. 2015, 49, 1130–1137. [Google Scholar] [CrossRef] [PubMed]

- Civancik-Uslu, D.; Puig, R.; Hauschild, M.; Fullana-i-Palmer, P. Life cycle assessment of carrier bags and development of a littering indicator. Sci. Total Environ. 2019, 685, 621–630. [Google Scholar] [CrossRef] [PubMed]

- Chitaka, T.Y.; Russo, V.; von Blottnitz, H. In pursuit of environmentally friendly straws: A comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 2020, 25, 1818–1832. [Google Scholar] [CrossRef]

- Russo, V.; Stafford, W.; Nahman, A. Comparing Grocery Carrier Bags in South Africa from an Environmental and Socio-Economic Perspective. In Waste Research Development and Innovation Roadmap Research Report; Department of Science and Innovation: Pretoria, South Africa, 2020. [Google Scholar]

- Harding, K.G.; Dennis, J.S.; Von Blottnitz, H.; Harrison, S.T.L. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Bisinella, V.; Albizzati, P.F.; Astrup, T.F.; Damgaard, A.; Government of Denmark LCA. Life Cycle Assessment of Grocery Carrier Bags. 2018. Available online: https://www2.mst.dk/Udgiv/publications/2018/02/978-87-93614-73-4.pdf (accessed on 14 July 2020).

- Edwards, C.; Fry, J.M. Life Cycle Assessment of Supermarket Carrier Bags 2011. Environment Agency, Horizon House, Deanery Road, Bristol, BS1 5AH. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/291023/scho0711buan-e-e.pdf (accessed on 14 July 2020).

- Government of Quebec LCA. Available online: https://monsacintelligent.ca/wp-content/uploads/2018/03/ENGLISH_FINAL-Quebec-LCA-Full- (accessed on 14 July 2020).

- Bentley West Management Consultants. Socio—Economic Impact of the Proposed Plastic Bag Regulations. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEiZvZ2iiZXsAhVVH7cAHRL5BT4QFjAAegQIAxAC&url=http%3A%2F%2Fnew.nedlac.org.za%2Fwp-content%2Fuploads%2F2014%2F10%2FSocioEconomicImpactPlasticExecSummary.pdf&usg=AOvVaw16A4P31dqb3mQIgmO_4vt9 (accessed on 14 July 2020).

- European Bioplastics. Biobased Plastics. Available online: https://www.european-bioplastics.org/bioplastics/materials/biobased/#:~:text=Biobased%20or%20partially%20biobased%20durable,reduce%20a%20product%27s%20carbon%20footprint (accessed on 14 July 2020).

- European Bioplastics. Bioplastics Facts and Figures. Available online: https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf (accessed on 14 July 2020).

- Bioplastics Guide. What Are Bioplastics? Available online: http://www.bioplastics.guide/ref/bioplastics/what-are-bioplastics/ (accessed on 11 July 2020).

- European Bioplastics. Bioplastics Market Data. 2019. Available online: https://www.european-bioplastics.org/market/ (accessed on 10 April 2020).

- Rudin, A.; Choi, P. The Elements of Polymer Science and Engineering, 3rd ed.; Elsevier: Waltham, MA, USA, 2013; pp. 521–535. [Google Scholar]

- Höfer, R.; Selig, M. Green chemistry and green polymer chemistry. In Polymer Science: A Comprehensive Reference; Polymers for a Sustainable Environment and Green Energy; Matyjaszewski, K., Möller, M., McGrath, J.E., Hickner, M.A., Höfer, R., Eds.; Elsevier BV: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Polymer Properties Database. Biodegradable Bioplastics. Available online: https://polymerdatabase.com/polymer%20classes/Bioplastics.html (accessed on 11 July 2020).

- Bioplastics Magazine. Biodegradable Polymers Market Forecast to Rise Sharply by 2023. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/2018-July-27-Biodegrable-plastics-market-forcast-to-rise-sharply-by-2023.php (accessed on 11 July 2020).

- Institute for Bioplastics and Biocomposites. Available online: https://www.ifbb-hannover.de/en/facts-and-statistics.html (accessed on 11 July 2020).

- Allied Market Research. Available online: https://www.alliedmarketresearch.com/biodegradable-plastic-market#:~:text=Biodegradable%20plastic%2C%20by%20Application,to%20the%20growing%20environmental%20awareness (accessed on 5 June 2020).

- Van den Oever, M.; Molenveld, K.; van der Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics: Facts and Figures: Focus on Food Packaging in the Netherlands; Wageningen Food and Biobased Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- Barrett, A.; Bioplastics News. Japan Funds Bioplastics Industry in South Africa. Available online: https://bioplasticsnews.com/2019/08/01/japan-funds-bioplastics-industry-in-south-africa/ (accessed on 12 July 2020).

- United Nations Industrial Development Organization. Japan Funds UNIDO Project in South Africa to Find Alternatives to Single-Use Plastic. Available online: https://www.unido.org/news/japan-funds-unido-project-south-africa-find-alternatives-single-use-plastic (accessed on 10 May 2020).

- The SA Plastics Pact. Available online: https://www.saplasticspact.org.za/why/ (accessed on 10 May 2020).

- Regional Plastics Pact for Australia, New Zealand, and the Pacific Island Nations. Available online: https://www.ellenmacarthurfoundation.org/news/regional-plastics-pact-for-australia-new-zealand-and-the-pacific-island-nations (accessed on 14 May 2020).

- Statista. Market Value of Biodegradable Plastics Worldwide from 2018 to 2027. Available online: https://www.statista.com/statistics/979050/global-market-value-of-biodegradable-plastics/ (accessed on 10 April 2020).

- Globe Newswire. Global Biodegradable Plastics Market Is Expected to Reach USD 8.57 Billion by 2025: Fior Markets. Available online: https://www.globenewswire.com/news-release/2019/07/29/1892673/0/en/Global-Biodegradable-Plastics-Market-is-Expected-to-Reach-USD-8-57-Billion-by-2025-Fior-Markets.html (accessed on 24 July 2020).

- Wikipedia. Mulch. Available online: https://en.wikipedia.org/wiki/Mulch#:~:text=A%20mulch%20is20a%20layer,visual%20appeal%20of%20the%20area (accessed on 3 August 2020).

- Harrison, J.P.; Boardman, C.; O’Callaghan, K.; Delort, A.M.; Song, J. Biodegradability standards for carrier bags and plastic films in aquatic environments: A critical review. R. Soc. Open Sci. 2018, 5. [Google Scholar] [CrossRef]

- Joshi, S.; Sharma, U.; Goswami, G. Bio-Plastic from Waste Newspaper. In Proceedings of the International Conference on Emerging Trends of Research in Applied Sciences and Computational Techniques, Rajasthan, India, 21–22 February 2014. [Google Scholar]

- Hackett, M.; IHS Markit. Biodegradable Polymers Market Value. Available online: https://ihsmarkit.com/research-analysis/biodegradable-polymers-market-value.html (accessed on 12 July 2020).

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef]

- Artham, T.; Doble, M. Biodegradation of aliphatic and aromatic polycarbonates. Macromol. Biosci. 2008, 8, 14–24. [Google Scholar] [CrossRef]

- Ivanov, V.; Stabnikov, V.; Ahmed, Z.; Dobrenko, S.; Saliuk, A. Production and applications of crude polyhydroxyalkanoate-containing bioplastic from the organic fraction of municipal solid waste. Int. J. Environ. Sci. Technol. 2014, 12, 725–738. [Google Scholar] [CrossRef]

- Van Hille, R.; Zietsman, G.; van Hille, N. Biodegradable and Compostable Packaging: A Review of the South African Landscape. Available online: https://www.researchgate.net/publication/340310328_Biodegradable_and_Compostable_Packaging_A_review_of_the_South_African_landscape (accessed on 24 July 2020).

- Bioplastics News. Polyhydroxyalkanoates or PHA. Available online: https://news.com/polyhydroxyalkanoates-or-pha/ (accessed on 24 July 2020).

- Coats, E.R.; Loge, F.J.; Wolcott, M.P.; Englund, K.; McDonald, A.G. Synthesis of polyhydroxyalkanoates in municipal wastewater treatment. Water Environ. Res. 2007, 79, 2396–2403. [Google Scholar] [CrossRef] [PubMed]

- Israni, N.; Shivakumar, S. Polyhydroxyalkanoate (PHA) biosynthesis from directly valorized ragi husk and sesame oil cake by Bacillus megaterium strain Ti3: Statistical optimization and characterization. Int. J. Biol. Macromol. 2020, 148, 20–30. [Google Scholar] [CrossRef]

- Surendran, A.; Lakshmanan, M.; Chee, J.Y.; Sulaiman, A.M.; Van Thuoc, D.; Sudesh, K. Can Polyhydroxyalkanoates Be Produced Efficiently from Waste Plant and Animal Oils? Front. Bioeng. Biotechnol. 2020, 8, 169. [Google Scholar] [CrossRef]

- Meraldo, A. Introduction to bio-based polymers. In Multilayer Flexible Packaging, 2nd ed.; Wagner, J.R., Ed.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 47–52. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly (butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Kachrimanidou, V.; Kopsahelis, N.; Webb, C.; Koutinas, A.A. Bioenergy technology and food industry waste valorization for integrated production of polyhydroxyalkanoates. In Bioenergy Research: Advances and Applications; Elsevier BV: Amsterdam, The Netherlands, 2014; pp. 419–433. [Google Scholar]

- Voinova, O.; Gladyshev, M.; Volova, T.G. Comparative study of PHA degradation in natural reservoirs having various types of ecosystems. In Macromolecular Symposia; WILEY-VCH: Weinheim, Germany, 2008; Volume 269, pp. 34–37. [Google Scholar] [CrossRef]

- Rudnik, E. Compostable Polymer Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; p. 213. [Google Scholar]

- Ghanem, N.B.; Mabrouk, M.E.; Sabry, S.A.; El-Badan, D.E. Degradation of polyesters by a novel marine Nocardiopsis aegyptia sp. nov: Application of Plackett-Burman experimental design for the improvement of PHB depolymerase activity. J. Gen. Appl. Microbiol. 2005, 51, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Dudek, S.; Coskun, M.C. Biopolymer Compounds for Applications Requiring Marine Degradation. Available online: https://www.semanticscholar.org/paper/Biopolymer-Compounds-for-Applications-Requiring-Dudek-Coskun/866c08c107749cd8fdc58f1f7a04aab69da5bea9#citing-papers (accessed on 23 July 2020).

- Fibre to Fashion. Polypropylene Market Report and Price Trend. Available online: https://www.fibre2fashion.com/market-intelligence/textile-market-watch/polypropylene-price-trends-industry-reports/20/ (accessed on 23 July 2020).

- Rojas-Rosas, O.; Villafana-Rojas, J.; Lopez-Dellamary, F.A.; Nungaray-Arellano, J.; Gonzalez-Reynoso, O. Production and characterization of polyhydroxyalkanoates in Pseudomonas aeruginosa ATCC 9027 from glucose, an unrelated carbon source. Can. J. Microbiol. 2007, 53, 840–851. [Google Scholar] [CrossRef] [PubMed]

- Bengtsson, S.; Werker, A.; Christensson, M.; Welander, T. Production of polyhydroxyalkanoates by activated sludge treating a paper mill wastewater. Bioresour. Technol. 2008, 99, 509–516. [Google Scholar] [CrossRef] [PubMed]

- Beccari, M.; Bertin, L.; Dionisi, D.; Fava, F.; Lampis, S.; Majone, M.; Valentino, F.; Vallini, G.; Villano, M. Exploiting olive oil mill effluents as a renewable resource for production of biodegradable polymers through a combined anaerobic–aerobic process. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2009, 84, 901–908. [Google Scholar] [CrossRef]

- Mannina, G.; Presti, D.; Montiel-Jarillo, G.; Suárez-Ojeda, M.E. Bioplastic recovery from wastewater: A new protocol for polyhydroxyalkanoates (PHA) extraction from mixed microbial cultures. Bioresour. Technol. 2019, 282, 361–369. [Google Scholar] [CrossRef]

- Albuquerque, M.G.E.; Torres, C.A.V.; Reis, M.A.M. Polyhydroxyalkanoate (PHA) production by a mixed microbial culture using sugar molasses: Effect of the influent substrate concentration on culture selection. Water Res. 2010, 44, 3419–3433. [Google Scholar] [CrossRef]

- Bengtsson, S.; Pisco, A.R.; Reis, M.A.; Lemos, P.C. Production of polyhydroxyalkanoates from fermented sugar cane molasses by a mixed culture enriched in glycogen accumulating organisms. J. Biotechnol. 2010, 145, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.M.; Brigham, C.J.; Rha, C.; Sinskey, A.J.; Sudesh, K. Biosynthesis and characterization of polyhydroxyalkanoate containing high 3-hydroxyhexanoate monomer fraction from crude palm kernel oil by recombinant Cupriavidus necator. Bioresour. Technol. 2012, 121, 320–327. [Google Scholar] [CrossRef] [PubMed]

- Muhr, A.; Rechberger, E.M.; Salerno, A.; Reiterer, A.; Schiller, M.; Kwiecień, M.; Adamus, G.; Kowalczuk, M.; Strohmeier, K.; Schober, S.; et al. Biodegradable latexes from animal-derived waste: Biosynthesis and characterization of mcl-PHA accumulated by P. citronellolis. React. Funct. Polym. 2013, 73, 1391–1398. [Google Scholar] [CrossRef]

- Poomipuk, N.; Reungsang, A.; Plangklang, P. Poly-β-hydroxyalkanoates production from cassava starch hydrolysate by Cupriavidus sp. KKU38. Int. J. Biol. Macromol. 2014, 65, 51–64. [Google Scholar] [CrossRef] [PubMed]

- Korkakaki, E.; Mulders, M.; Veeken, A.; Rozendal, R.; van Loosdrecht, M.C.; Kleerebezem, R. PHA production from the organic fraction of municipal solid waste (OFMSW): Overcoming the inhibitory matrix. Water Res. 2016, 96, 74–83. [Google Scholar] [CrossRef]

- Duque, A.F.; Oliveira, C.S.; Carmo, I.T.; Gouveia, A.R.; Pardelha, F.; Ramos, A.M.; Reis, M.A. Response of a three-stage process for PHA production by mixed microbial cultures to feedstock shift: Impact on polymer composition. New Biotechnol. 2014, 31, 276–288. [Google Scholar] [CrossRef]

- Oliveira, C.S.; Silva, C.E.; Carvalho, G.; Reis, M.A. Strategies for efficiently selecting PHA producing mixed microbial cultures using complex feedstocks: Feast and famine regime and uncoupled carbon and nitrogen availabilities. New Biotechnol. 2017, 37, 69–79. [Google Scholar] [CrossRef]

- Carvalho, G.; Pedras, I.; Karst, S.M.; Oliveira, C.S.; Duque, A.F.; Nielsen, P.H.; Reis, M.A. Functional redundancy ensures performance robustness in 3-stage PHA-producing mixed cultures under variable feed operation. New Biotechnol. 2018, 40, 207–217. [Google Scholar] [CrossRef]

- Colombo, B.; Calvo, M.V.; Sciarria, T.P.; Scaglia, B.; Kizito, S.S.; D’Imporzano, G.; Adani, F. Biohydrogen and polyhydroxyalkanoates (PHA) as products of a two-steps bioprocess from deproteinized dairy wastes. Waste Manag. 2019, 95, 22–31. [Google Scholar] [CrossRef]

- Salamanca-Cardona, L.; Scheel, R.A.; Bergey, N.S.; Stipanovic, A.J.; Matsumoto, K.I.; Taguchi, S.; Nomura, C.T. Consolidated bioprocessing of poly (lactate-co-3-hydroxybutyrate) from xylan as a sole feedstock by genetically-engineered Escherichia coli. J. Biosci. Bioeng. 2016, 122, 406–414. [Google Scholar] [CrossRef]

- Elain, A.; Le Grand, A.; Corre, Y.M.; Le Fellic, M.; Hachet, N.; Le Tilly, V.; Loulergue, P.; Audic, J.L.; Bruzaud, S. Valorisation of local agro-industrial processing waters as growth media for polyhydroxyalkanoates (PHA) production. Ind. Crops Prod. 2016, 80, 1–5. [Google Scholar] [CrossRef]

- Ray, S.; Prajapati, V.; Patel, K.; Trivedi, U. Optimization and characterization of PHA from isolate Pannonibacter phragmitetus ERC8 using glycerol waste. Int. J. Biol. Macromol. 2016, 86, 741–749. [Google Scholar] [CrossRef] [PubMed]

- Padovani, G.; Emiliani, G.; Giovanelli, A.; Traversi, M.L.; Carlozzi, P. Assessment of glycerol usage by five different purple non-sulfur bacterial strains for bioplastic production. J. Environ. Chem. Eng. 2018, 6, 616–622. [Google Scholar] [CrossRef]

- Azizi, N.; Najafpour, G.; Younesi, H. Acid pretreatment and enzymatic saccharification of brown seaweed for polyhydroxybutyrate (PHB) production using Cupriavidus necator. Int. J. Biol. Macromol. 2017, 101, 1029–1040. [Google Scholar] [CrossRef] [PubMed]

- Sawant, S.S.; Salunke, B.K.; Kim, B.S. Consolidated bioprocessing for production of polyhydroxyalkanotes from red algae Gelidium amansii. Int. J. Biol. Macromol. 2018, 109, 1012–1018. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Gnaim, R.; Greiserman, S.; Fadeev, L.; Gozin, M.; Golberg, A. Macroalgal biomass subcritical hydrolysates for the production of polyhydroxyalkanoate (PHA) by Haloferax mediterranei. Bioresour. Technol. 2019, 271, 166–173. [Google Scholar] [CrossRef] [PubMed]

- Tůma, S.; Izaguirre, J.K.; Bondar, M.; Marques, M.M.; Fernandes, P.; da Fonseca, M.M.R.; Cesário, M.T. Upgrading end-of-line residues of the red seaweed Gelidium sesquipedale to polyhydroxyalkanoates using Halomonas boliviensis. Biotechnol. Rep. 2020, 27, e00491. [Google Scholar] [CrossRef] [PubMed]

- Wijeyekoon, S.; Carere, C.R.; West, M.; Nath, S.; Gapes, D. Mixed culture polyhydroxyalkanoate (PHA) synthesis from nutrient rich wet oxidation liquors. Water Res. 2018, 140, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Arumugam, A.; Senthamizhan, S.G.; Ponnusami, V.; Sudalai, S. Production and optimization of polyhydroxyalkanoates from non-edible Calophyllum inophyllum oil using Cupriavidus necator. Int. J. Biol. Macromol. 2018, 112, 598–607. [Google Scholar] [CrossRef]

- Kovalcik, A.; Kucera, D.; Matouskova, P.; Pernicova, I.; Obruca, S.; Kalina, M.; Enev, V.; Marova, I. Influence of removal of microbial inhibitors on PHA production from spent coffee grounds employing Halomonas halophila. J. Environ. Chem. Eng. 2018, 6, 3495–3501. [Google Scholar] [CrossRef]

- Al-Battashi, H.; Annamalai, N.; Al-Kindi, S.; Nair, A.S.; Al-Bahry, S.; Verma, J.P.; Sivakumar, N. Production of bioplastic (poly-3-hydroxybutyrate) using waste paper as a feedstock: Optimization of enzymatic hydrolysis and fermentation employing Burkholderia sacchari. J. Clean. Prod. 2019, 214, 236–247. [Google Scholar] [CrossRef]

- Porras, M.A.; Ramos, F.D.; Diaz, M.S.; Cubitto, M.A.; Villar, M.A. Modeling the bioconversion of starch to P (HB-co-HV) optimized by experimental design using Bacillus megaterium BBST4 strain. Environ. Technol. 2019, 40, 1185–1202. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Saratale, G.D.; Cho, S.K.; Kim, D.S.; Ghodake, G.S.; Kadam, A.; Kumar, G.; Bharagava, R.N.; Banu, R.; Shin, H.S. Pretreatment of kenaf (Hibiscus cannabinus L.) biomass feedstock for polyhydroxybutyrate (PHB) production and characterization. Bioresour. Technol. 2019, 282, 75–80. [Google Scholar] [CrossRef] [PubMed]

- Sohn, Y.J.; Kim, H.T.; Baritugo, K.A.; Song, H.M.; Ryu, M.H.; Kang, K.H.; Jo, S.Y.; Kim, H.; Kim, Y.J.; Choi, J.I.; et al. Biosynthesis of polyhydroxyalkanoates from sucrose by metabolically engineered Escherichia coli strains. Int. J. Biol. Macromol. 2020, 149, 593–599. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Guo, B.H. Microbial Succinic Acid, Its Polymer Poly (butylene succinate), and Applications. In Plastics from Bacteria; Springer: Berlin/Heidelberg, Germany, 2010; Volume 14. [Google Scholar]

- Suchao-in, K.; Koombhongse, P.; Chirachanchai, S. Starch grafted poly (butylene succinate) via conjugating reaction and its role on enhancing the compatibility. Carbohydr. Polym. 2014, 102, 95–102. [Google Scholar] [CrossRef]

- Okamoto, K.; Sinha Ray, S.; Okamoto, M. New poly (butylene succinate)/layered silicate nanocomposites. II. Effect of organically modified layered silicates on structure, properties, melt rheology, and biodegradability. J. Polym. Sci. B Polym. Phys. 2003, 41, 3160–3172. [Google Scholar] [CrossRef]

- Fujimaki, T. Processability and properties of aliphatic polyesters, ‘BIONOLLE’, synthesized by polycondensation reaction. Polym. Degrad. Stab. 1998, 59, 209–214. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical properties of poly (butylene succinate) (PBS) biocomposites reinforced with surface modified jute fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Hagewood, J. Technologies for the manufacture of synthetic polymer fibers. In Advances in Filament Yarn Spinning of Textiles and Polymers; Woodhead Publishing, Elsevier: Oxford, UK, 2014; pp. 48–71. [Google Scholar]

- Zhang, K.; Mohanty, A.K.; Misra, M. Fully biodegradable and biorenewable ternary blends from polylactide, poly (3-hydroxybutyrate-co-hydroxyvalerate) and poly (butylene succinate) with balanced properties. ACS Appl. Mater. Interfaces 2012, 4, 3091–3101. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Hua, K.; Zhang, W.; Ji, J.; Yang, X. Enhanced mechanical properties and degradability of poly (butylene succinate) and poly (lactic acid) blends. Iran. Polym. J. 2013, 22, 267–275. [Google Scholar] [CrossRef]

- Polyestertime. LDPE polyethylene prices Europe. Available online: https://www.polyestertime.com/ldpe-polyethylene-prices-europe/ (accessed on 26 July 2020).

- Sangroniz, A.; Zhu, J.B.; Tang, X.; Etxeberria, A.; Chen, E.Y.X.; Sardon, H. Packaging materials with desired mechanical and barrier properties and full chemical recyclability. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Li, Y.; Shahbazi, A.; Xiu, S. Succinic acid production from cheese whey using Actinobacillus succinogenes 130 Z. In Biotechnology for Fuels and Chemicals; Finkelstein, M., McMillan, J.D., Davison, B.H., Eds.; Humana Press: Totowa, NJ, USA, 2007; pp. 111–119. [Google Scholar] [CrossRef]

- Liu, Y.P.; Zheng, P.; Sun, Z.H.; Ni, Y.; Dong, J.J.; Zhu, L.L. Economical succinic acid production from cane molasses by actinobacillus succinogenes. Bioresour. Technol. 2008, 99, 1736–1742. [Google Scholar] [CrossRef] [PubMed]

- Zheng, P.; Dong, J.J.; Sun, Z.H.; Ni, Y.; Fang, L. Fermentative production of succinic acid from straw hydrolysate by Actinobacillus succinogenes. Bioresour. Technol. 2009, 100, 2425–2429. [Google Scholar] [CrossRef] [PubMed]

- Dorado, M.P.; Lin, S.K.C.; Koutinas, A.; Du, C.; Wang, R.; Webb, C. Cereal-based biorefinery development: Utilisation of wheat milling by-products for the production of succinic acid. J. Biotechnol. 2009, 143, 51–59. [Google Scholar] [CrossRef]

- Chen, K.Q.; Li, J.; Ma, J.F.; Jiang, M.; Wei, P.; Liu, Z.M.; Ying, H.J. Succinic acid production by Actinobacillus succinogenes using hydrolysates of spent yeast cells and corn fiber. Bioresour. Technol. 2011, 102, 1704–1708. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, H.; Miao, Y.; Wei, P.; Chen, J. Simultaneous saccharification and fermentation of acid-pretreated rapeseed meal for succinic acid production using Actinobacillus succinogenes. Enzym. Microb. Technol. 2011, 48, 339–344. [Google Scholar] [CrossRef]

- Wang, C.; Yan, D.; Li, Q.; Sun, W.; Xing, J. Ionic liquid pretreatment to increase succinic acid production from lignocellulosic biomass. Bioresour. Technol. 2014, 172, 283–289. [Google Scholar] [CrossRef]

- Carvalho, M.; Roca, C.; Reis, M.A. Improving succinic acid production by Actinobacillus succinogenes from raw industrial carob pods. Bioresour. Technol. 2016, 218, 491–497. [Google Scholar] [CrossRef]

- Shen, N.; Wang, Q.; Zhu, J.; Qin, Y.; Liao, S.; Li, Y.; Zhu, Q.; Jin, Y.; Du, L.; Huang, R. Succinic acid production from duckweed (Landoltia punctata) hydrolysate by batch fermentation of Actinobacillus succinogenes GXAS137. Bioresour. Technol. 2016, 211, 307–312. [Google Scholar] [CrossRef]

- Patsalou, M.; Menikea, K.K.; Makri, E.; Vasquez, M.I.; Drouza, C.; Koutinas, M. Development of a citrus peel-based biorefinery strategy for the production of succinic acid. J. Clean. Prod. 2017, 166, 706–716. [Google Scholar] [CrossRef]

- González-García, S.; Argiz, L.; Míguez, P.; Gullón, B. Exploring the production of bio-succinic acid from apple pomace using an environmental approach. Chem. Eng. J. 2018, 350, 982–991. [Google Scholar] [CrossRef]

- Gowman, A.; Wang, T.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. Bio-poly (butylene succinate) and its composites with grape pomace: Mechanical performance and thermal properties. ACS Omega 2018, 3, 15205–15216. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Cheng, J.; Chen, P.; Zheng, G.; Wang, D.; Hu, Y. Efficient production of succinic acid in engineered Escherichia coli strains controlled by anaerobically-induced nirB promoter using sweet potato waste hydrolysate. J. Environ. Manag. 2019, 237, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Olajuyin, A.M.; Yang, M.; Thygesen, A.; Tian, J.; Mu, T.; Xing, J. Effective production of succinic acid from coconut water (Cocos nucifera) by metabolically engineered Escherichia coli with overexpression of Bacillus subtilis pyruvate carboxylase. Biotechnol. Rep. 2019, 24, e00378. [Google Scholar] [CrossRef] [PubMed]

- Bioplastics News. Polylactic Acid or Polylactide (PLA). Available online: https://bioplasticsnews.com/polylacticacid-or-polylactide-pla/ (accessed on 24 July 2020).

- Lunelli, B.H.; Andrade, R.R.; Atala, D.I.P.; Wolf Maciel, M.R.; Maugeri Filho, F.; Maciel Filho, R. Production of lactic acid from sucrose: Strain selection, fermentation, and kinetic modeling. Appl. Biochem. Biotechnol. 2010, 161, 227–237. [Google Scholar] [CrossRef] [PubMed]

- Ibarra, V.G.; Sendón, R.; de Quirós, A.R.B. Antimicrobial food packaging based on biodegradable materials. In Antimicrobial Food Packaging; Academic Press, Elsevier: Amsterdam, The Netherlands, 2016; pp. 363–384. [Google Scholar]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Djukić-Vuković, A.; Mladenović, D.; Ivanović, J.; Pejin, J.; Mojović, L. Towards sustainability of lactic acid and poly-lactic acid polymers production. Renew. Sustain. Energy Rev. 2019, 108, 238–252. [Google Scholar] [CrossRef]

- Morão, A.; de Bie, F. Life cycle impact assessment of polylactic acid (PLA) produced from sugarcane in Thailand. J. Polym. Environ. 2019, 27, 2523–2539. [Google Scholar] [CrossRef]

- Hagen, R. Polylactic Acid. In Polymer Science: A Comprehensive Reference, 1st ed.; Moeller, M., Matyjaszewski, K., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2012; Volume 10, pp. 231–236. [Google Scholar] [CrossRef]

- Wilfred, O.; Tai, H.; Marriott, R.; Liu, Q.; Tverezovskiy, V.; Curling, S.; Tai, H.; Fan, Z.; Wang, W. Biodegradation of polylactic acid and starch composites in compost and soil. Int. J. Nano Rech 2018, 1, 1–11. [Google Scholar]

- Coltelli, M.B.; Mallegni, N.; Rizzo, S.; Cinelli, P.; Lazzeri, A. Improved impact properties in poly (lactic acid) (PLA) blends containing cellulose acetate (CA) prepared by reactive extrusion. Materials 2019, 12, 270. [Google Scholar] [CrossRef]

- Polyestertime. US Polyethylene Terephthalate PET Contract Prices. Available online: https://www.polyestertime.com/us-polyethylene-terephthalate-pet/ (accessed on 24 July 2020).

- Polymer Database. Poly (Ethylene Terephthalate) (PET). Thermo-Physical Properties. Available online: https://polymerdatabase.com/Commercial%20Polymers/PET.html (accessed on 24 July 2020).

- Wang, L.; Zhao, B.; Liu, B.; Yu, B.; Ma, C.; Su, F.; Hua, D.; Li, Q.; Ma, Y.; Xu, P. Efficient production of l-lactic acid from corncob molasses, a waste by-product in xylitol production, by a newly isolated xylose utilizing Bacillus sp. strain. Bioresour. Technol. 2010, 101, 7908–7915. [Google Scholar] [CrossRef] [PubMed]

- Coelho, L.F.; De Lima, C.J.B.; Bernardo, M.P.; Contiero, J. D(−)-lactic acid production by Leuconostoc mesenteroides B512 using different carbon and nitrogen sources. Appl. Biochem. Biotechnol. 2011, 164, 1160–1171. [Google Scholar] [CrossRef] [PubMed]

- Taskin, M.; Esim, N.; Ortucu, S. Efficient production of l-lactic acid from chicken feather protein hydrolysate and sugar beet molasses by the newly isolated Rhizopus oryzae TS-61. Food Bioprod. Process. 2012, 90, 773–779. [Google Scholar] [CrossRef]

- Flores-Albino, B.; Arias, L.; Gómez, J.; Castillo, A.; Gimeno, M.; Shirai, K. Chitin and L (+)-lactic acid production from crab (Callinectes bellicosus) wastes by fermentation of Lactobacillus sp. B2 using sugar cane molasses as carbon source. Bioproc. Biosyst. Eng. 2012, 35, 1193–1200. [Google Scholar] [CrossRef]

- Djukić-Vuković, A.P.; Mojović, L.V.; Vukašinović-Sekulić, M.S.; Nikolić, S.B.; Pejin, J.D. Integrated production of lactic acid and biomass on distillery stillage. Bioproc. Biosyst. Eng. 2013, 36, 1157–1164. [Google Scholar] [CrossRef]

- Nguyen, C.M.; Kim, J.S.; Nguyen, T.N.; Kim, S.K.; Choi, G.J.; Choi, Y.H.; Jang, K.S.; Kim, J.C. Production of land d-lactic acid from waste Curcuma longa biomass through simultaneous saccharification and cofermentation. Bioresour. Technol. 2013, 146, 35–43. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Ju, J.; Yu, B.; Ma, Y. Efficient production of polymer-grade d-lactate by Sporolactobacillus laevolacticus DSM442 with agricultural waste cottonseed as the sole nitrogen source. Bioresour. Technol. 2013, 142, 186–191. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Huang, F.; Wang, J.; Zhao, J.; Zhao, X.; Garza, E.; Manow, R.; Grayburn, S.; Zhou, S. Engineering and adaptive evolution of Escherichia coli W for l-lactic acid fermentation from molasses and corn steep liquor without additional nutrients. Bioresour. Technol. 2013, 148, 394–400. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Yong, Q.; Yang, S.T.; Ouyang, J.; Yu, S. Simultaneous saccharification and fermentation of xylo-oligosaccharides manufacturing waste residue for l-lactic acid production by Rhizopus oryzae. Biochem. Eng. J. 2015, 94, 92–99. [Google Scholar] [CrossRef]

- Bai, Z.; Gao, Z.; He, B.; Wu, B. Effect of lignocellulose-derived inhibitors on the growth and D-lactic acid production of Sporolactobacillus inulinus YBS1-5. Bioproc. Biosyst. Eng. 2015, 38, 1993–2001. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, C.; Cai, D.; Wang, Z.; Qin, P.; Tan, T. The optimization of L-lactic acid production from sweet sorghum juice by mixed fermentation of Bacillus coagulans and Lactobacillus rhamnosus under unsterile conditions. Bioresour. Technol. 2016, 218, 1098–1105. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Wang, Y.; Zhang, J.; Pan, J. Using tobacco waste extract in pre-culture medium to improve xylose utilization for l-lactic acid production from cellulosic waste by Rhizopus oryzae. Bioresour. Technol. 2016, 218, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Pleissner, D.; Neu, A.K.; Mehlmann, K.; Schneider, R.; Puerta-Quintero, G.I.; Venus, J. Fermentative lactic acid production from coffee pulp hydrolysate using Bacillus coagulans at laboratory and pilot scales. Bioresour. Technol. 2016, 218, 167–173. [Google Scholar] [CrossRef]

- de Oliveira Moraes, A.; Ramirez, N.I.B.; Pereira, N. Evaluation of the fermentation potential of pulp mill residue to produce D(−)-Lactic acid by separate hydrolysis and fermentation using Lactobacillus coryniformis subsp. torquens. Appl. Biochem. Biotechnol. 2016, 180, 1574–1585. [Google Scholar] [CrossRef] [PubMed]

- Oonkhanond, B.; Jonglertjunya, W.; Srimarut, N.; Bunpachart, P.; Tantinukul, S.; Nasongkla, N.; Sakdaronnarong, C. Lactic acid production from sugarcane bagasse by an integrated system of lignocellulose fractionation, saccharification, fermentation, and ex-situ nanofiltration. J. Environ. Chem. Eng. 2017, 5, 2533–2541. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, W.; Luo, J.; Wan, Y. Exploring the potential of lactic acid production from lignocellulosic hydrolysates with various ratios of hexose versus pentose by Bacillus coagulans IPE22. Bioresour. Technol. 2018, 261, 342–349. [Google Scholar] [CrossRef]

- Liu, P.; Zheng, Z.; Xu, Q.; Qian, Z.; Liu, J.; Ouyang, J. Valorization of dairy waste for enhanced D-lactic acid production at low cost. Process. Biochem. 2018, 71, 18–22. [Google Scholar] [CrossRef]

- Mladenović, D.; Pejin, J.; Kocić-Tanackov, S.; Djukić-Vuković, A.; Mojović, L. Enhanced lactic acid production by adaptive evolution of Lactobacillus paracasei on agroindustrial substrate. Appl. Biochem. Biotechnol. 2018, 187, 753–769. [Google Scholar] [CrossRef]

- Balakrishnan, R.; Tadi, S.R.R.; Sivaprakasam, S.; Rajaram, S. Optimization of acid and enzymatic hydrolysis of kodo millet (Paspalum scrobiculatum) bran residue to obtain fermentable sugars for the production of optically pure D (−) lactic acid. Ind. Crops. Prod. 2018, 111, 731–742. [Google Scholar] [CrossRef]

- Qiu, Z.; Gao, Q.; Bao, J. Engineering Pediococcus acidilactici with xylose assimilation pathway for high titer cellulosic L-lactic acid fermentation. Bioresour. Technol. 2018, 249, 9–15. [Google Scholar] [CrossRef]

- Pejin, J.; Radosavljević, M.; Pribić, M.; Kocić-Tanackov, S.; Mladenović, D.; Djukić-Vuković, A.; Mojović, L. Possibility of L-(+)-lactic acid fermentation using malting, brewing, and oil production by-products. Waste Manag. 2018, 79, 153–163. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, K. Polycondensation. In Polymer Science: A Comprehensive Reference, 1st ed.; Moeller, M., Matyjaszewski, K., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Gregory, G.L.; Kociok-Köhn, G.; Buchard, A. Polymers from sugars and CO2: Ring-opening polymerisation and copolymerisation of cyclic carbonates derived from 2-deoxy-d-ribose. Polym. Chem. 2017, 8, 2093–2104. [Google Scholar] [CrossRef]

- Ribeiro, E.; Ladeira, C.; Viegas, S. Occupational exposure to bisphenol A (BPA): A reality that still needs to be unveiled. Toxics 2017, 5, 22. [Google Scholar] [CrossRef] [PubMed]

- Centres for Disease Control and Prevention. CDC. National Biomonitoring Program. Available online: https://www.cdc.gov/biomonitoring/BisphenolA_FactSheet.html (accessed on 19 July 2020).

- Park, S.A.; Eom, Y.; Jeon, H.; Koo, J.M.; Lee, E.S.; Jegal, J.; Hwang, S.Y.; Oh, D.X.; Park, J. Preparation of synergistically reinforced transparent bio-polycarbonate nanocomposites with highly dispersed cellulose nanocrystals. Green Chem. 2019, 21, 5212–5221. [Google Scholar] [CrossRef]

- Centres for Disease Control and Prevention. Emergency Preparedness and Response Facts about Phosgene. Available online: https://emergency.cdc.gov/agent/phosgene/basics/facts.asp (accessed on 19 July 2020).

- Cui, S.; Borgemenke, J.; Liu, Z.; Li, Y. Recent advances of “soft” bio-polycarbonate plastics from carbon dioxide and renewable bio-feedstocks via straightforward and innovative routes. J. CO2 Util. 2019, 34, 40–52. [Google Scholar] [CrossRef]

- British Plastics Federation. Polycarbonate PC. Available online: https://www.bpf.co.uk/plastipedia/polymers/polycarbonate.aspx (accessed on 19 July 2020).

- Polymer Properties Database. Polycarbonates. Available online: https://polymerdatabase.com/polymer%20classes/Polycarbonate%20type.html (accessed on 18 July 2020).

- Ebrary.net. Polycarbonate Polyols. Available online: https://ebrary.net/14328/environment/polyols#:~:text=Relative%20to%20other%20polyols%2C%20the,coatings%2C%20elastomers%2C%20and%20adhesives (accessed on 19 July 2020).

- Begum, S.A.; Rane, A.V.; Kanny, K. Applications of compatibilized polymer blends in automobile industry. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 563–593. [Google Scholar]

- Building with Chemistry. Polycarbonate in Building and Construction. Available online: https://buildingwithchemistry.org/chemistry-in-bc/polycarbonate-in-building-and-construction/#:~:text=Polycarbonate%20is%20a%20high%2Dperforming,exterior%20elements%20for%20LED%20lighting (accessed on 19 July 2020).

- Shen, Z.; Chen, X.; Zhang, Y. New catalytic systems for the fixation of carbon dioxide, 2. Synthesis of high molecular weight epichlorohydrin/carbon dioxide copolymer with rare earth phosphonates/triisobuty-aluminium systems. Macromol. Chem. Phys. 1994, 195, 2003–2011. [Google Scholar] [CrossRef]

- Bell, B.M.; Briggs, J.R.; Campbell, R.M.; Chambers, S.M.; Gaarenstroom, P.D.; Hippler, J.G.; Hook, B.D.; Kearns, K.; Kenney, J.M.; Kruper, W.J.; et al. Glycerin as a renewable feedstock for epichlorohydrin production. The GTE process. Clean Soil Air Water 2008, 36, 657–661. [Google Scholar] [CrossRef]

- Nozaki, K.; Nakano, K.; Hiyama, T. Optically active polycarbonates: Asymmetric alternating copolymerization of cyclohexene oxide and carbon dioxide. J. Am. Chem. Soc. 1999, 121, 11008–11009. [Google Scholar] [CrossRef]

- Mmongoyo, J.A.; Mgani, Q.A.; Mdachi, S.J.M.; Pogorzelec, P.J.; Cole-Hamilton, D.J. Synthesis of a kairomone and other chemicals from cardanol, a renewable resource. Eur. J. Lipid Sci. Technol. 2012, 114, 1183–1192. [Google Scholar] [CrossRef]

- Winkler, M.; Romain, C.; Meier, M.A.R.; Williams, C.K. Renewable polycarbonates and polyesters from 1,4-cyclohexadiene. Green Chem. 2015, 17, 300–306. [Google Scholar] [CrossRef]

- Nakano, K.; Kamada, T.; Nozaki, K. Selective formation of polycarbonate over cyclic carbonate: Copolymerization of epoxides with carbon dioxide catalyzed by a Cobalt (III) Complex with a piperidinium end-capping arm. Angew. Chem. Int. Ed. 2006, 45, 7274–7277. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Yu, Y. Dehydration of ethanol to ethylene. Ind. Eng. Chem. Res. 2013, 52, 9505–9514. [Google Scholar] [CrossRef]

- Zhang, X.H.; Wei, R.J.; Zhang, Y.Y.; Du, B.Y.; Fan, Z.Q. Carbon dioxide/epoxide copolymerization via a nanosized zinc–cobalt (III) double metal cyanide complex: Substituent effects of epoxides on polycarbonate selectivity, regioselectivity and glass transition temperatures. Macromolecules 2015, 48, 536–544. [Google Scholar] [CrossRef]

- Mohsenzadeh, A.; Zamani, A.; Taherzadeh, M.J. Bioethylene production from ethanol: A review and technoeconomical evaluation. Chem. Biol. Eng. 2017, 4, 75–91. [Google Scholar] [CrossRef]

- Hu, Y.; Qiao, L.; Qin, Y.; Zhao, X.; Chen, X.; Wang, X.; Wang, F. Synthesis and Stabilization of Novel Aliphatic Polycarbonate from Renewable Resource. Macromolecules 2009, 42, 9251–9254. [Google Scholar] [CrossRef]

- Hilf, J.; Scharfenberg, M.; Poon, J.; Moers, C.; Frey, H. Aliphatic polycarbonates based on carbon dioxide, furfuryl glycidyl ether, and glycidyl methyl ether: Reversible functionalization and cross-linking. Macromol. Rapid Commun. 2015, 36, 174–179. [Google Scholar] [CrossRef]

- Mutlu, H.; Meier, M.A.R. Castor oil as a renewable resource for the chemical industry. Eur. J. Lipid Sci. Technol. 2010, 112, 10–30. [Google Scholar] [CrossRef]

- Li, C.; Sablong, R.J.; Koning, C.E. Synthesis and characterization of fully-biobased α,ω-dihydroxyl poly(limonene carbonate)s and their initial evaluation in coating applications. Eur. Polym. J. 2015, 67, 449–458. [Google Scholar] [CrossRef]

- Hauenstein, O.; Agarwal, S.; Greiner, A. Bio-based polycarbonate as synthetic toolbox. Nat. Commun. 2016, 7, 11862–11869. [Google Scholar] [CrossRef]

- Hauenstein, O.; Rahman, M.M.; Elsayed, M.; Krause-Rehberg, R.; Agarwal, S.; Abetz, V.; Greiner, A. Biobased polycarbonate as a gas separation membrane and “breathing glass” for energy saving applications. Int. J. Adv. Mater. Technol. 2017, 2. [Google Scholar] [CrossRef]

- Shaarani, F.W.; Bou, J.J. Synthesis of vegetable-oil based polymer by terpolymerization of epoxidized soybean oil, propylene oxide and carbon dioxide. Sci. Total Environ. 2017, 598, 931–936. [Google Scholar] [CrossRef] [PubMed]

- The Organisation for Economic Co-operation and Development (OECD) OECD Policy Highlights—Extended Producer Responsibility. Guidance for Efficient Waste Management. Available online: https://www.oecd.org/environment/waste/Extended-producer-responsibility-Policy-Highlights-2016-web.pdf (accessed on 4 August 2020).

- Pouikli, K. Concretising the role of extended producer responsibility in European Union waste law and policy through the lens of the circular economy. In ERA Forum; Springer: Berlin/Heideberg, Germany, 2020; Volume 20, pp. 491–508. [Google Scholar]

- Arvanitoyannis, I.S.; Tserkezou, P. Presentation and Comments on USA and Canada Legislation Related to Food Industries-Environment Interactions. Available online: http://hdl.handle.net/11615/25923 (accessed on 4 August 2020).

- The Pew Charitable Trusts and SYSTEMIQ. Breaking the Plastic Wave Thought Partners. A Comprehensive Assessment of Pathways towards Stopping Ocean Plastic Pollution. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwiGzIisqpXsAhXJ7HMBHag3Aq8QFjAAegQIBRAC&url=https%3A%2F%2Fwww.pewtrusts.org%2F-%2Fmedia%2Fassets%2F2020%2F07%2Fbreakingtheplasticwave_report.pdf&usg=AOvVaw3zhkyDhDNRl86-PTsNjw0o (accessed on 4 August 2020).

- The Organisation for Economic Co-operation and Development (OECD). Available online: http://www.oecd.org/environment/waste/Australia%20NTCRS%20OECD%20case%20study.pdf (accessed on 4 August 2020).

- Yamakawa, H. The Packaging Recycling Act: The Application of EPR to Packaging Policies in Japan. Available online: http://www.oecd.org/environment/waste/EPR_Japan_packagingFinal%20orrected0502.pdf (accessed on 4 August 2020).

- 20 years of EPR in France: Achievements, Lessons Learned and Challenges Ahead. French Ministry of Environment. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=cad=rja&uact=8&ved=2ahUKEwjF5IzYqpXsAhXh6XMBHRGoAp8QFjAAegQIBhAC&url=https%3A%2F%2Fwww.oecd.org%2Fenvironment%2Fwaste%2FFrance%2520(final).pdf&usg=AOvVaw1ykU8ZACvWWZowcBuccrV- (accessed on 29 July 2020).

- PETCO. An Industry-Driven and Industry-Financed Environment Solution for PET. Available online: https://petco.co.za/who-we-are/ (accessed on 1 May 2020).

- Nahman, A. Extended producer responsibility for packaging waste in South Africa: Current approaches and lessons learned. Resour. Conserv. Recycl. 2010, 54, 155–162. [Google Scholar] [CrossRef]

- SUEZ Recycling and Recovery. How a Deposit Return Scheme for “on the Go’ Could Be Designed for the UK. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=ja&uact=8&ved=2ahUKEwi78aH7qpXsAhXh8HMBHaVEBywQFjAAegQIBhAC&url=https%3A%2F%2Fwww.suez.co.uk%2F-%2Fmedia%2Fsuez-uk%2Ffiles%2Fpublication%2Fdrs-onthego-report-uk-1803.pdf&usg=AOvVaw0y8tpVMWjKiFItBGGjoo5y (accessed on 24 June 2020).

- Seas at Risk. Single-Use Plastics and the Marine Environment. Available online: https://seas-at-risk.org/24-publications/800-single-use-plastic-and-the-marine-environment.html (accessed on 24 June 2020).

- The Organisation for Economic Co-operation and Development (OECD). Deposit Refund Schemes. Available online: https://www.oecd.org/stories/ocean/deposit-refund-schemes-58baff8c (accessed on 4 August 2020).

- House of Commons. Environmental Audit Committee. Plastic bottles: Turning Back the Plastic Tide. First Report of Session. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwj37J3Jq5XsAhWV7HMBHZ4sDcEQFjAAegQIBRAC&url=https%3A%2F%2Fpublications.parliament.uk%2Fpa%2Fcm201719%2Fcmselect%2Fcmenvaud%2F339%2F339.pdf&usg=AOvVaw2AHvvC4FgkmPs9ln6dJtll (accessed on 31 July 2020).

- Coca Cola South Africa. Coca-Cola Beverages South Africa Reduces Plastic by Launching New 2l Returnable Pet Plastic Bottles. Available online: https://www.coca-cola.co.za/stories-and-press/launch-of-refpet-in-eastern-cape (accessed on 30 July 2020).

- Bhengu, C. You’ll Be Able to Return a 2-litre Coca-Cola Bottle & Get R9 Back. Available online: https://www.timeslive.co.za/sunday-times/lifestyle/food/2020-07-16-youll-be-able-to-return-a-2-litre-coca-cola-bottle-get-r9-back-herere-the-deets/ (accessed on 30 July 2020).

- Deposit-Refund System (DRS). Facts and Myths. Available online: https://www2.deloitte.com/content/dam/Deloitte/pl/Documents/Brochures/pl_DRS_Brochure_Deloitte.pdf (accessed on 4 August 2020).

- Gasperi, J.; Wright, S.L.; Dris, R.; Collard, F.; Mandin, C.; Guerrouache, M.; Langlois, V.; Kelly, F.J.; Tassin, B. Microplastics in air: Are we breathing it in? Curr. Opin. Environ. Sci. Health 2018, 1, 1–5. [Google Scholar] [CrossRef]

- The World Bank. What a Waste: An Updated Look into the Future of Solid Waste Management. Available online: https://www.worldbank.org/en/news/immersive-story/2018/09/20/what-a-waste-an-updated-look-into-the-future-of-solid-waste-management (accessed on 20 August 2020).

- Ritchie, H. FAQs on Plastics. Available online: https://ourworldindata.org/faq-on-plastics#how-long-does-it-take-plastics-to-break-down (accessed on 10 August 2020).

- Pikitup. Available online: http://www.pikitup.co.za/mandatory-separation-at-source-frequently-asked-questions/ (accessed on 10 August 2020).

- Green Cape. Available online: https://www.greencape.co.za/assets/Uploads/GreenCape-Market-Intelligence-Report-2015-Waste.pdf (accessed on 10 August 2020).

- Plastics—The Facts 2018. Plastic Europe. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjz97zNrJXsAhVHILcAHTxUCSQQFjAAegQIAxAC&url=https%3A%2F%2Fwww.plasticseurope.org%2Fapplication%2Ffiles%2F6315%2F4510%2F9658%2FPlastics_the_facts_2018_AF_web.pdf&usg=AOvVaw1t7xHOizx9qFw5yMuNs_en (accessed on 11 August 2020).

- South African Plastics Recycling Organisation. PETCO Position Papers. Available online: https://www.plasticrecyclingsa.co.za/position-papers/ (accessed on 11 August 2020).

- Department of Environmental Affairs. Available online: https://www.gov.za/sites/default/files/gcis_document/201912/42879gon1561.pdf (accessed on 11 August 2020).

- South Africa Plastics Recycling Organisation. Available online: https://www.plasticrecyclingsa.co.za/ (accessed on 6 August 2020).

- Fox News. Heavy Rain Leads to Garbage-Filled Neighborhood in Nigeria, Lagos Officials Vow Crackdown. Available online: https://www.foxnews.com/world/nigeria-rain-heavy-garbage-flood-neighborhood-lagos-crackdown (accessed on 6 August 2020).

- The Ocean Clean up. Available online: https://theoceancleanup.com/ (accessed on 3 April 2020).

- Martini, K.; Goldstein, M. The Ocean Cleanup, Part 2: Technical Review of the Feasibility Study. Available online: http://www.deepseanews.com/2014/07/the-ocean-cleanup-part-2-technical-review-of-the-feasibility-study/ (accessed on 6 August 2020).

- Dilkes-Hoffman, L.S.; Pratt, S.; Lant, P.A.; Laycock, B. The role of biodegradable plastic in solving plastic solid waste accumulation. In Plastics to Energy; Al-Salem, S.M., Ed.; Elsevier: Oxford, UK, 2019; pp. 469–505. [Google Scholar] [CrossRef]

- Australian Government. Available online: https://www.environment.gov.au/system/files/resources/b86c9f8-074e-4d66-ab11-08bbc69da240/files/national-waste-policy-action-plan-2019.pdf (accessed on 11 August 2020).

- Parker, L. Canada Aims to Ban Single-Use Plastics by 2021. Available online: https://www.nationalgeographic.com/environment/2019/06/canada-single-use-plastics-ban-2021/ (accessed on 11 August 2020).

- Gibbens, S. See the Complicated Landscape of Plastic Bans in the U.S. Available online: https://www.nationalgeographic.com/environment/2019/08/map-shows-the-complicated-landscape-of-plastic-bans/ (accessed on 11 August 2020).

- Calderwood, I.; Global Citizen. 16 Times Countries and Cities Have Banned Single-Use Plastics. Available online: https://www.globalcitizen.org/en/content/plastic-bans-around-the-world/ (accessed on 20 April 2020).

- Nicholls, F.; Greenpeace. 6 Amazing Plastic Bans from around the World. Available online: https://www.greenpeace.org/international/story/7390/6-amazing-plastic-bans-from-around-the-world/ (accessed on 20 April 2020).

- World Population Review. Available online: https://worldpopulationreview.com/continents/africa-population (accessed on 13 August 2020).

- European Commission. Available online: https://ec.europa.eu/commission/presscorner/detail/en/P_19_2631 (accessed on 13 August 2020).

- Herberz, T.; Barlow, C.Y.; Finkbeiner, M. Sustainability Assessment of a Single-Use Plastics Ban. Sustainability 2020, 12, 3746. [Google Scholar] [CrossRef]

- McLellan, H. Banning the Plastic Shopping Bag in South Africa—An Idea Whose Time has Come, Two Oceans Aquarium. In Proceedings of the 20th Waste Conference, Somerset West, Cape Town, South Africa, 6–10 October 2014. [Google Scholar]

- Ye, S.; Wang, S.; Lin, L.; Xiao, M.; Meng, Y. CO2 derived biodegradable polycarbonates: Synthesis, modification and applications. Adv. Ind. Eng. Polym. Res. 2019, 2, 143–160. [Google Scholar] [CrossRef]

- McGrath, J.E.; Hickner, M.A.; Höfer, R. Introduction: Polymers for a Sustainable Environment and Green Energy. In Polymers for a Sustainable Environment and Green Energy; Elsevier BV: Amsterdam, The Netherlands, 2012; pp. 1–3. [Google Scholar]

- Roma, A. Biosourced materials; a future for the car industry. In Proceedings of the 11th Bioplastics Conference, Berlin, Germany, 29–30 November 2016. [Google Scholar]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing biobased recyclable polymers for plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef]

- De Bie, F. Update on Corbion-Total JV Bringing Innovation to the PLA Market. Available online: https://bioplasticsnews.com/2017/05/30/corbion-total-jv-bringing-innovation-to-the-pla-market-francois-de-bie/ (accessed on 20 August 2020).

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Siracusa, V.; Genovese, L.; Ingrao, C.; Munari, A.; Lotti, N. Barrier properties of poly (propylene cyclohexanedicarboxylate) random eco-friendly copolyesters. Polymers 2018, 10, 502. [Google Scholar] [CrossRef]

- Ißbrücker, C. Available online: https://www.european-bioplastics.org/how-much-land-do-we-really-need-to-produce-bio-based-plastics/#:~:text=According%20to%20the%20estimation%20published,to%20grow%20food%20and%20feed (accessed on 20 August 2020).

- McGrath, M.; BBC. BP: Plastic Ban Could Have Unintended Consequences. Available online: https://www.bbc.com/news/science-environment-47255249#:~:text=Last%20November%2C%20researchers%20at%20Heriot,Buckland%2C%20who%20led%20the%20study (accessed on 20 August 2020).

- Economics. How Plastic Bag Bans Impact the Economy. Available online: https://www.thisisplastics.com/economics/how-plastic-bag-bans-impact-the-economy/ (accessed on 20 August 2020).

- Caliendo, H.; Plastics Today. The Economic Effect of Plastic Bag Bans. 6 February 2013. Available online: https://www.plasticstoday.com/business/economic-effect-plastic-bag-bans (accessed on 6 August 2020).

- Williams, D.L.; Gerba, C.P.; Maxwell, S.; Sinclair, R.G. Assessment of the potential for cross-contamination of food products by reusable shopping bags. Food Prot. Trends 2011, 31, 508–513. [Google Scholar]

- Askew, K.; Food Navigator. Food Waste and Plastic Pollution. Available online: https://www.foodnavigator.com/Article/2020/07/31/Food-waste-and-plastic-pollution-The-two-key-sustainability-drivers-are-carbon-and-circularity (accessed on 20 August 2020).

- UN Environment. Worldwide Food Waste. Available online: https://www.unenvironment.org/thinkeatsave/get-informed/worldwide-food-waste (accessed on 20 August 2020).

- G20 Information Centre. G20 Action Plan on Marine Litter. Available online: http://www.g20.utoronto.ca/2017/2017-g20-marine-litter.html (accessed on 26 March 2020).

- Convention on the Conservation of Migratory Species of Wild Animals. Available online: https://www.cms.int/ (accessed on 18 March 2020).

- The Abidjan Convention. Available online: https://abidjanconvention.org/ (accessed on 1 April 2020).

- United Nations Convention on the Law of the Sea. Available online: https://www.un.org/Depts/los/convention_agreements/texts/unclos/unclos_e.pdf (accessed on 18 March 2020).

- Cartagena Convention. Available online: http://cep.unep.org/cartagena-convention (accessed on 18 March 2020).

- The Nairobi Convention. Available online: https://www.nairobiconvention.org/ (accessed on 23 March 2020).

- Secretariat of the Pacific Regional Environment Programme. Available online: https://www.sprep.org/convention-secretariat/noumea-convention (accessed on 23 March 2020).

- The Commission on the Protection of the Black Sea against Pollution. Available online: http://www.blacksea-commission.org/_convention.asp (accessed on 10 March 2020).

- OSPAR Commission. OSPAR Convention. Available online: https://www.ospar.org/convention (accessed on 10 March 2020).

- HELCOM. The Helsinki Convention. Available online: https://helcom.fi/about-us/convention/ (accessed on 23 March 2020).

- Biodiversity. Convention on the Protection of the Marine Environment of the Baltic Sea Area (Helsinki Convention). Available online: https://www.biodiversitya-z.org/content/convention-on-the-protection-of-the-marine-environment-of-the-baltic-sea-area-helsinki-convention (accessed on 23 March 2020).

- Regional Action Plan on Marine Litter Management (Rapmali) for the Wider Caribbean Region. Available online: https://www.cbd.int/doc/meetings/mar/mcbem-2014-03/other/mcbem-2014-03-115-en.pdf (accessed on 18 March 2020).

- The Global Partnership on Marine Litter. The Honolulu Strategy: A Global Framework for Prevention and Management of Marine Debris. Available online: Marinelitternetwork.engr.uga.edu/global-projects/strategy/ (accessed on 26 March 2020).

- United Nations Environment Programme. The Honolulu Strategy. Available online: https://www.unenvironment.org/resources/report/honolulu-strategy (accessed on 26 March 2020).

- United Nations Environment Programme. Manilla Declaration. Available online: http://wedocs.unep.org/bitstream/handle/20.500.11822/12347/ManillaDeclarationREV.pdf?sequence=1&isAllowed=y (accessed on 26 March 2020).

- Rio Ocean Declaration. Available online: http://www.unesco.org/new/fileadmin/MULTIMEDIA/HQ/SC/pdf/pdf_Rio_Ocean_Declaration_2012.pdf (accessed on 26 March 2020).

- United Nations Environment Programme. Available online: Wedocs.unep.org (accessed on 26 March 2020).

- Talmon, S. German Practice in International Law. Towards an Agreement to Combat MARINE Litter. 2017. Available online: https://gpil.jura.uni-bonn.de/2017/09/towards-agreement-combat-marine-litter/ (accessed on 10 March 2020).

- Convention on Biological Diversity. Available online: https://www.cbd.int/doc/decisions/cop-13/cop-13-dec-10-en.pdf (accessed on 10 March 2020).

- Osaka Blue Ocean Vision G20 Implementation Framework for Actions on Marine Plastic Litter. Available online: https://papersmart.unon.org/resolution/uploads/for_projection_g20_osaka_blue_ocean_vision_and_g20_implementation_framework_moej.pdf (accessed on 10 March 2020).

- De Villiers, J. Business Insider SA. The New Pick n Pay ‘Plastic’ Bag Can be Used as Compost in Your Garden—This Is What It Looks Like. Available online: https://www.businessinsider.co.za/pick-n-pay-introduce-new-plastic-bags-which-are-compostable-degradable-international-plastic-bag-free-day-2018-7 (accessed on 15 August 2020).

- Consumer Goods Council of South Africa. Biodegradable and Compostable Packaging Key Considerations. Available online: https://www.plasticsinfo.co.za/wp-content/uploads/2019/11/Alliance-Biodegradable-position-paper.pdf (accessed on 20 August 2020).

- Bioplastics News. What Is the Difference between Biodegradable, Compostable and OXO Biodegradable? Available online: https://bioplasticsnews.com/2019/04/13/what-is-the-difference-between-biodegradable-compostable-and-oxo-degradable/ (accessed on 27 July 2020).

| Total plastic production in 1950 (million tonnes) | 2 |

| Total plastic production in 2015 (million tonnes) | 380 |

| Cumulative plastic production up to 2015 (billion tonnes) | 8.3 |

| Cumulative plastics that outlived usefulness and became waste (billion tonnes) between 1950 to 2015 | 6.3 |

| Percent of plastics sitting in landfills/natural environment | 79 |

| Percent of plastics incinerated | 12 |

| Percent of plastics recycled | 9 |

| Search Engines and Database | Key Words and Phrases |

|---|---|

Search Engines

|

|

| Polyhydroxyalkanoates (PHAs) | ||

|---|---|---|

| Feedstock | Year | Authors |

| Glucose | 2007 | [104] |

| Paper mill wastewater | 2008 | [105] |

| Fermented olive oil mill wastewater | 2009 2019 | [106] [107] |

| Fermented sugar cane molasses | 2010 2010 | [108] [109] |

| Crude palm kernel oil | 2012 | [110] |

| Tallow | 2013 | [111] |

| Cassava starch | 2014 | [112] |

| Municipal solid waste | 2016 | [113] |

| Fermented cheese whey | 2014 2017 2018 2019 | [114] [115] [116] [117] |

| Xylan | 2016 | [118] |

| Leguminous and fruit processing water | 2016 | [119] |

| Crude glycerol from bio-diesel production | 2016 2018 | [120] [121] |

| Macroalga (seaweed) | 2017 2018 2019 2020 | [122] [123] [124] [125] |

| Primary & secondary municipal wastewater sludge and Food waste | 2018 | [126] |

| Calophyllum inophyllum (native to Asia & Wallacea)-a large ever-green plant. | 2018 | [127] |

| Spent coffee grounds | 2018 | [128] |

| Wastepaper from municipal solid waste | 2019 | [129] |

| Corn starch | 2019 | [130] |

| Kenaf (Hibiscus cannabinus) Grows in the wild in Africa. India, Thailand and China are leading producers. | 2019 | [131] |

| Ragi husks (finger millet), sesame oil cake | 2020 | [94] |

| Sucrose | 2020 | [132] |

| Polybutylene Succinate (PBS) | ||

|---|---|---|

| Feedstock | Year | Authors |

| Cheese whey | 2007 | [143] |

| Sugar cane molasses | 2008 | [144] |

| Straw | 2009 | [145] |

| Wheat | 2009 | [146] |

| Corn fiber | 2011 | [147] |

| Rapeseed meal | 2011 | [148] |

| Pinewood | 2014 | [149] |

| Carob pods | 2016 | [150] |

| Duckweed | 2016 | [151] |

| Citrus peels | 2017 | [152] |

| Apple pomace (solid waste from cider & apple juice making) | 2018 | [153] |

| Grape pomace (main by-product of the wine & grape juice industries) | 2018 | [154] |

| Sweet potato waste | 2019 | [155] |

| Coconut water | 2019 | [156] |

| Polylactide (PLA) | ||

|---|---|---|

| Feedstock | Year | Authors |

| Corn cob molasses | 2010 | [168] |

| Sugar cane juice | 2011 | [169] |

| Sugar cane beet | 2012 | [170] |

| Crustacean waste | 2012 | [171] |

| Bread Stillage | 2013 | [172] |

| Waste Curcuma longa biomass | 2013 | [173] |

| Cotton seed | 2013 | [174] |

| Sugar cane molasses | 2013 | [175] |

| Xylo-oligosaccharides | 2015 | [176] |

| Corn stover | 2015 | [177] |

| Sweet sorghum juice | 2016 | [178] |

| Tobacco waste | 2016 | [179] |

| Coffee pulp | 2016 | [180] |

| Pulp mill residue | 2016 | [181] |

| Sugar cane bagasse | 2017 | [182] |

| Corn cob | 2018 | [183] |

| Dairy waste | 2018 | [184] |

| Potato stillage | 2018 | [185] |

| Kodo millet bran residue | 2018 | [186] |

| Wheat straw | 2018 | [187] |

| Brewer’s spent grain | 2018 | [188] |

| Polycarbonates (PCs) | ||

|---|---|---|

| Feedstock | Year | Authors |

| Glycerol | 1994 2008 | [201] [202] |

| Plant oils | 1999 2012 2015 | [203] [204] [205] |

| Lignocellulosic biomass, corn, sugar cane | 2006 2013 2015 2017 | [206] [207] [208] [209] |

| Oats, sugar cane, bagasse | 2009 2015 | [210] [211] |

| Castor oil plant | 2010 | [212] |

| Citrus oils, oak and pine tree | 2015 2016 2017 | [213] [214] [215] |

| Crude glycerol, plant oils, food wastes | 2017 | [216] |

| Framework/Declaration/Commitment | Date Signed/Launched | No. of Signatories/Parties | Targets/Goal | Additional Comments |

|---|---|---|---|---|

| London Convention on the Prevention of Marine Pollution by Dumping of Wastes and Other Matter [48] | 1972 | As of March 2018, there are 87 Contracting Parties to the London Convention | To control sea pollution through marine dumping | The United States of America is a contracting party |

| OSLO Dumping Convention [47] | 1972 | 13 signatories | Convention for the Prevention of Marine Pollution by Dumping from Ships and Aircraft | control dumping of harmful substances from ships and aircraft into the sea, including plastic |

| International Convention for the Prevention of Marine Pollution from Ships, 1973 (MARPOL 73/78) and its revised Annex V [49,269] | 1973 | 174 Member States and 3 Associate Members. | prevention of pollution of the marine environment by ships from operational or accidental causes. | complete ban imposed on the disposal into the sea of all forms of plastics. |