1. Introduction

The increasing popularity of renewable energy over the last few decades has gained momentum owing to the continuing scarcity of fossil fuels. This has also pushed the significance of, and the need for, electrical energy. Against this backdrop, the photovoltaic (PV) industry has been continuously growing at a rapid rate. Photovoltaic (PV) systems can hold the world’s electricity production. One hundred gigawatts (GW) had been added during 2018; therefore, the total capacity of the installed PV systems reaches up to 505 GW worldwide [

1]. During 2018, China alone added around 45 GW, and its total capacity increased to 176 GW.

Silicon crystalline PV modules are widely used around the world. Nowadays, new PV technologies with cheaper manufacturing costs than traditional silicon crystalline-based modules are available, such as amorphous silicon, copper indium selenide (CIS), and cadmium telluride. In addition, new standards and testing schemes are being developed to be compatible with the new or improved technologies. With the steady increase in electricity prices, domestic PV systems could be implemented and used with a low system cost. The noticeable drop in the cost of PV systems means that they could compete with electricity prices both nationally and regionally in locations with high irradiation, such as the solar belt regions. However, PV installations are mainly ground mounted. By contrast, in Germany, building integrated photovoltaic (BIPV) and roof top installations have a big role in PV projects, and ordinary Germans incur a benefit from these projects through a reduction in their energy bills. Photovoltaic power output depends on many factors, such as sun position, the intensity of solar irradiance, temperature, and load demand. Accordingly, the dynamic response of PV systems must be evaluated thoroughly for utility grid (UG) performance, since interconnecting a PV system with a UG may lead to instability [

2]. The uncertainty of the PV performance models is still too high. The focus point of much of the existing current research on this subject has largely been on evaluating module performance rather than system performance.

The effect of dust accumulation on the performance of PV systems has been investigated in many studies. The results indicated that dust accumulating rate predominantly depends on the weather conditions of the site. For example, in Colorado, a dust deposition rate of 1–50 mg·m

−2·day

−1 was recorded by Boyle et al. [

3]. In a similar work, Hegazy [

4] reported a rate of 150–300 mg·m

−2·day

−1 in Egypt. The noticeable difference between these results was due to the varied weather conditions. Gholami et al. [

5], in 2018, conducted an experimental work to study the impact of dust after 70 days without rain. The main finding proved that during the period of the experiment, dust surface density increased up to 6.0986 g/m

2, which caused a 21.47% reduction in the power output. The impact of particle sizes and the tilt angle on the dust deposition characteristics of a PV system has been investigated by Lu and Zhao [

6]. The maximum deposition rate has been observed for the 150 μm dust particles. For a tilt angle of 155°, the deposition rate is 9.78%. In the same direction, in 2019, Ricardo et al. [

7] investigated the effect of soiling on the optimum tilt angle.

However, Kaldellis [

8] investigated the effect of dust upon PV system output energy. Different air pollutants had been considered, and the results of the investigation proved that the energy output of a PV system was reduced. Such reduction depends upon the composition and the source of pollutants. A theoretical analysis was also subsequently carried out for studying and simulating the impact of air pollution on PV system performance. Ghazi [

9] utilized a three-perspective technique/framework for investigating the impact of dust and different solid particle accumulations on PV system performance. This framework included simulation, experimental validation, and a statistical analysis of the effect of weather conditions on the system performance of two different PV plants. The first plant was located on the roofs of the Cockcroft Building. It included 132 PV modules tilted at 18° towards the southwest. Anodized water has been utilized for cleaning the PV modules twice yearly. The second system was located at One Brighton with a maximum capacity of 10 kWp. It included 40 PV modules, each having a 250 W rating with an orientation towards the south. The PV modules were regularly cleaned via pails of hot soapy water once annually. The results from both plants revealed that weather conditions (i.e., dust, relative humidity, rain, and snow) have a primarily negative effect on a PV panel’s performance. The effect of accumulated dust on the PV panels was lessened by the level of air pollution and the regional weather in Brighton, and was more affected by the bird droppings, which could cause hot spots on the panel resulting in a drop in efficiency. Sulaiman et al. [

10] investigated the impact of dust on the performance and peak power of a 50 W PV panel. Clear plastic and two types of artificial dusts were scrutinized with constant solar radiation from a simulator inside the laboratory. The results showed that maximum power and efficiency were reduced by 18% and 50%, respectively, with slight differences in results obtained from mud and talcum. Similarly, Darwish [

11] studied PV performance with different types of dust pollutants. A study of the existing literature identified 15 types of dust pollutants, with each having some form of impact on PV system performance. The main pollutant types, which have a significant influence on PV system performance are limestone, ash, and silica. Mehmet et al. [

12] discussed only the effect of panel quality and strength on production efficiency (i.e., dust accumulation and water drops were not considered). They focused on studying the negative impact of energy losses in a PV system. The main finding confirmed that the effects of the errors in the energy losses of the PV system resulted in a low and clear energy efficiency of 0.96%. Additionally, solar energy losses represent only 4.26% of all fault energy losses. Thus, energy losses from failures account for 22.34% and 27.58% of net energy efficiency.

Table 1 summarizes some previous investigations of the performance of photovoltaic power systems (PVPSs) worldwide.

By studying the related literature, one can note that there exist several environmental factors that have a detrimental impact on a PVPS’ performance, some of which possess positive effects, and others negative effects, on the system output. In addition, it can also be seen that numerous researchers have contributed to studying the environmental factors affecting PV systems, but have negated the combination of all those factors at once, as each study only selected a few of the factors that were mentioned. The environmental factors affecting PVPS performance, as shown in previous investigations, are collected in

Table 2. This research integrates most of the environmental factors that have a detrimental impact on PVPS performance at once. Therefore, to overcome these deficiencies in the current study, an experimental work has been carried out to examine the impact of various environmental factors on a PV system’s performance. These include the impact of four common factors, such as the accumulation of dust, water droplets, birds’ droppings, and partial shading conditions on the system. This study will show the direct and quantitative effect of each factor on PVPS performance. The results obtained in this work may encourage future research by integrating numerous causal factors into one singular study. This eases the burden and tedious task of having to examine numerous texts, separate studies, and causal factors pertaining to the environmental factors affecting PVPS performance, while offering a more rounded and comprehensive understanding of the numerous factors that impede the system’s overall performance.

The remainder of the paper is organized as follows: the effects on PV system performance are discussed in

Section 1.

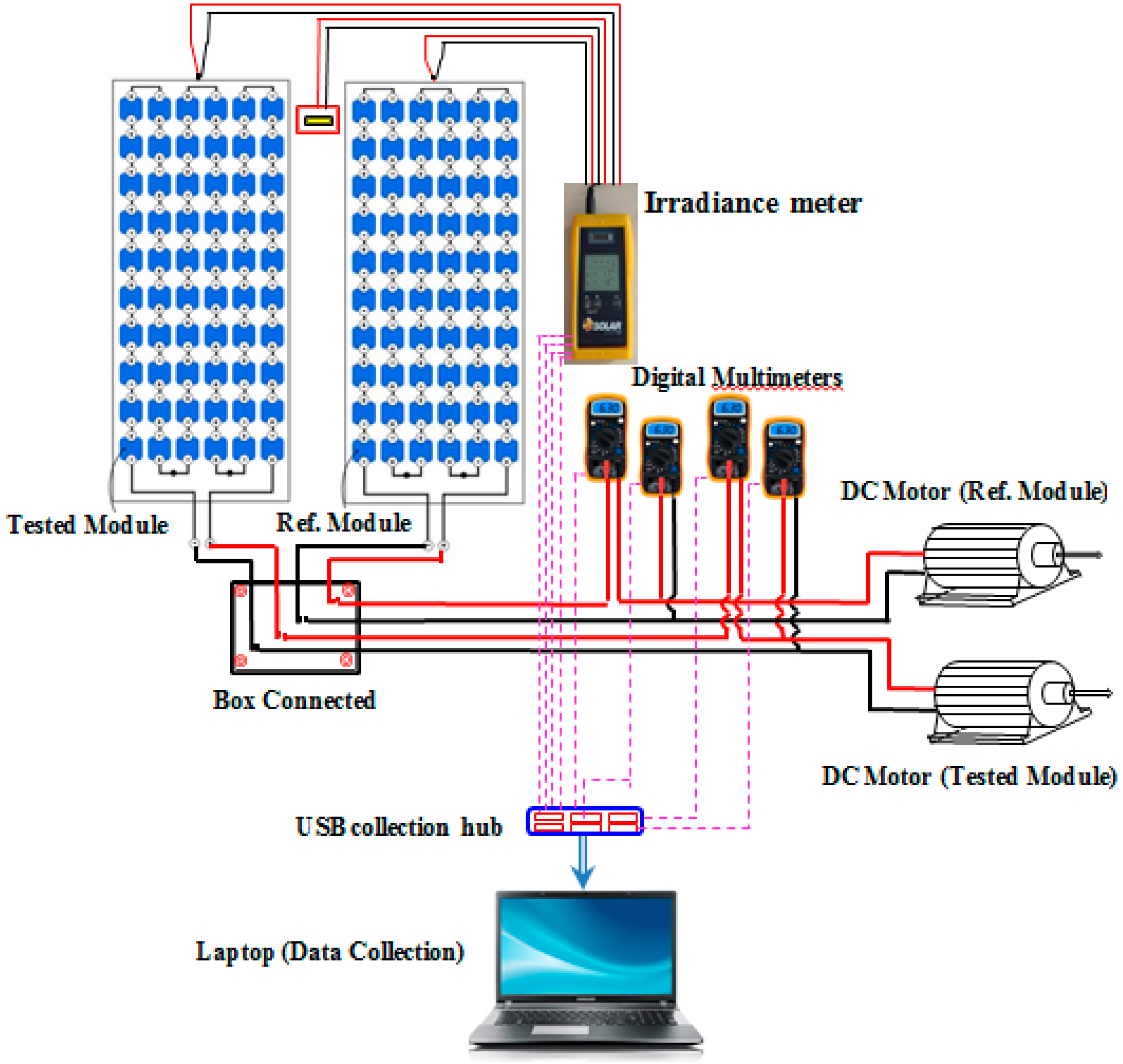

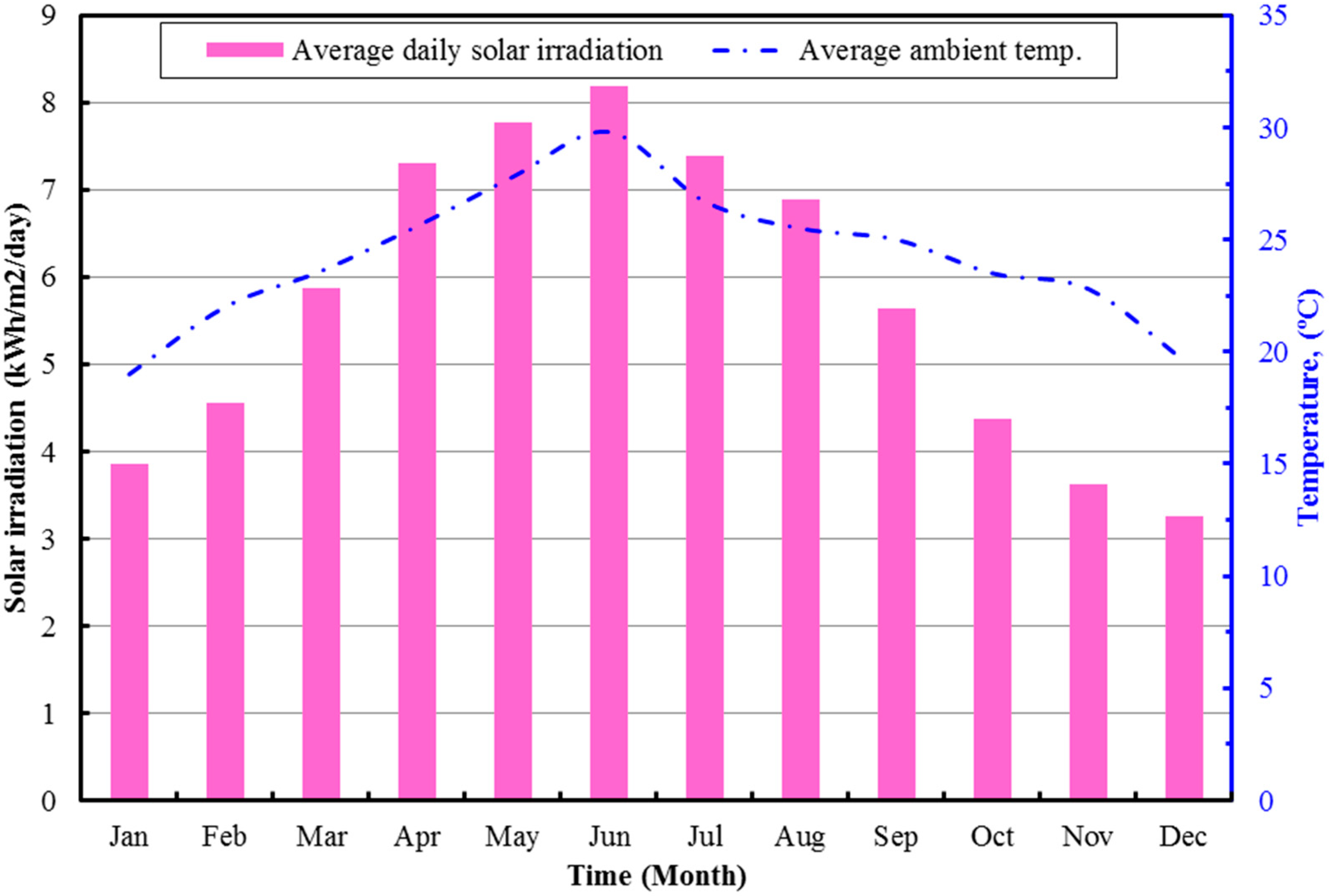

Section 2 describes the system components and the experimental procedure. The obtained results are shown and discussed in

Section 3. Finally,

Section 4 outlines the main findings.

4. Data Uncertainty

The uncertainties of the experimental results from measuring errors in the electric power output are calculated according to the method ascribed by Kline and McClintock [

44]. Such a technique is based on the careful specifications of the uncertainties in various primary experimental measurements and a consideration of the following equation:

where

j,

M,

, and

denote the specific parameter counter, the number of the independent variables, the uncertainties associated with the dependent (

R) variable, and the uncertainties associated with the independent (

Xj) variable, respectively.

The electric power is calculated as:

where

V and

I are measured as

V = 16.7 V ± 0.5% and

I = 7.04 A ± 2%. The nominal value of the power is equal to 117,568 W. The uncertainty in this value is calculated by applying Equation (4).

The uncertainty value for electric power output is found to be 2.423 W or 2.06%. This value is adequately acceptable as it lies within the standard limits.

5. Conclusions

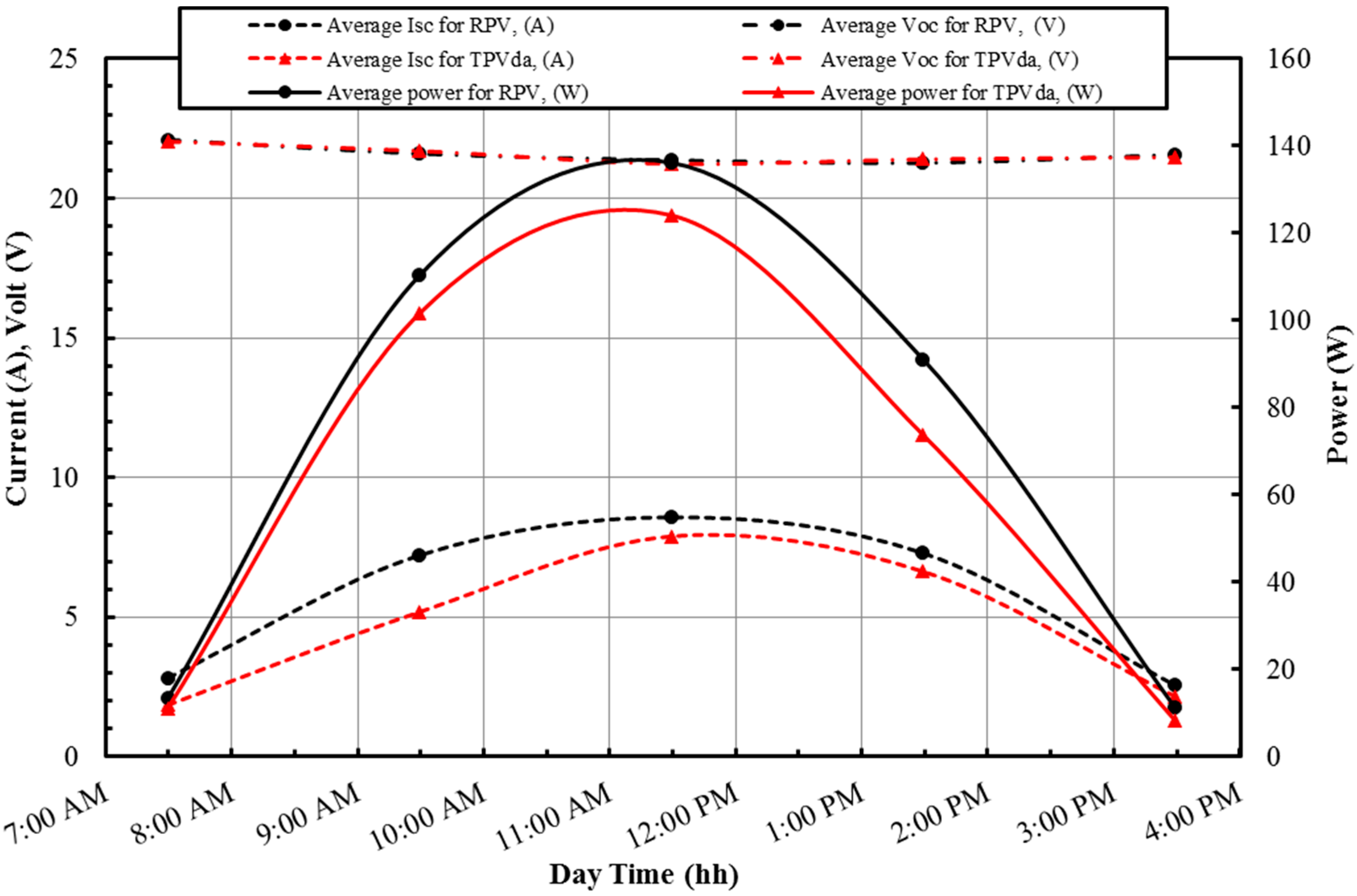

The environmental impacts on the performance of solar photovoltaic systems are experimentally investigated. For the first time, four specific experiments under each subsequent category were carried out in one singular study. These categories of investigation included: dust accumulation, water drops, shading effects, and bird droppings (fouling). Each was developed and tested. The results obtained for the two PV modules show that dust accumulation reduces the power output by 8.80% and the efficiency by 11.86%. As such, solar cells should be cleaned regularly (once a week at a minimum and particularly in seasonal equinox) in accordance with the severity of the weather conditions of its applied geographical locale.

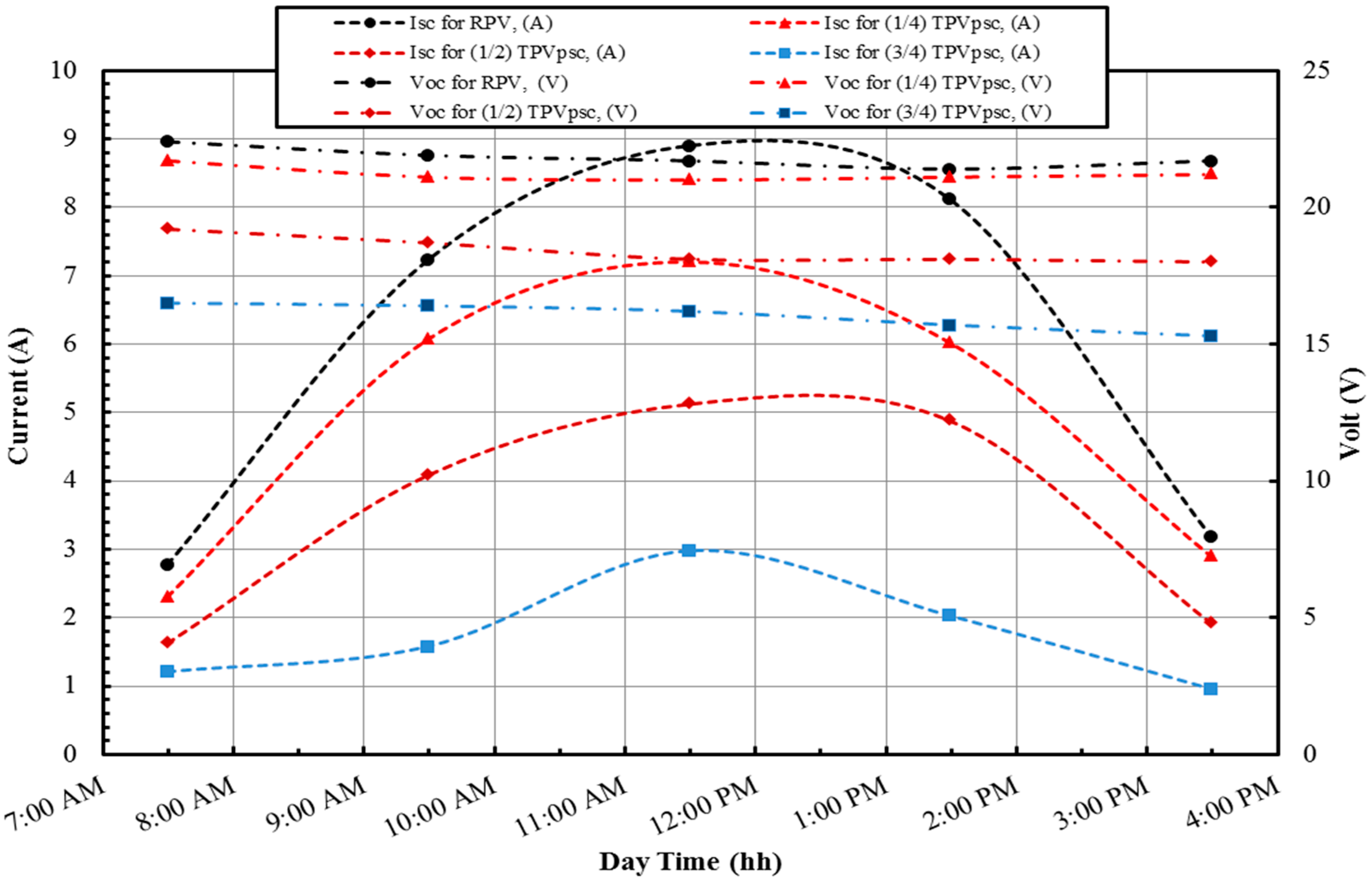

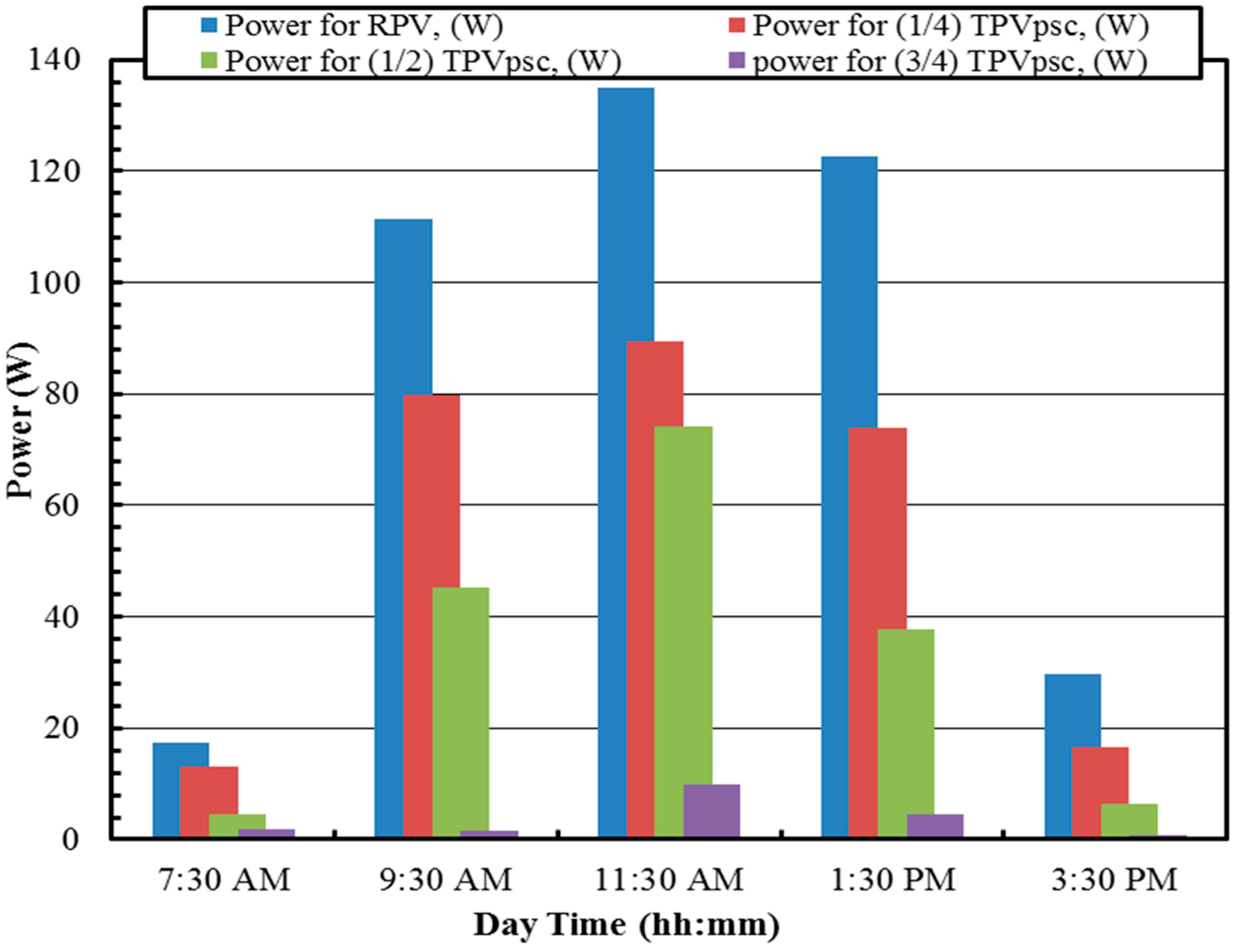

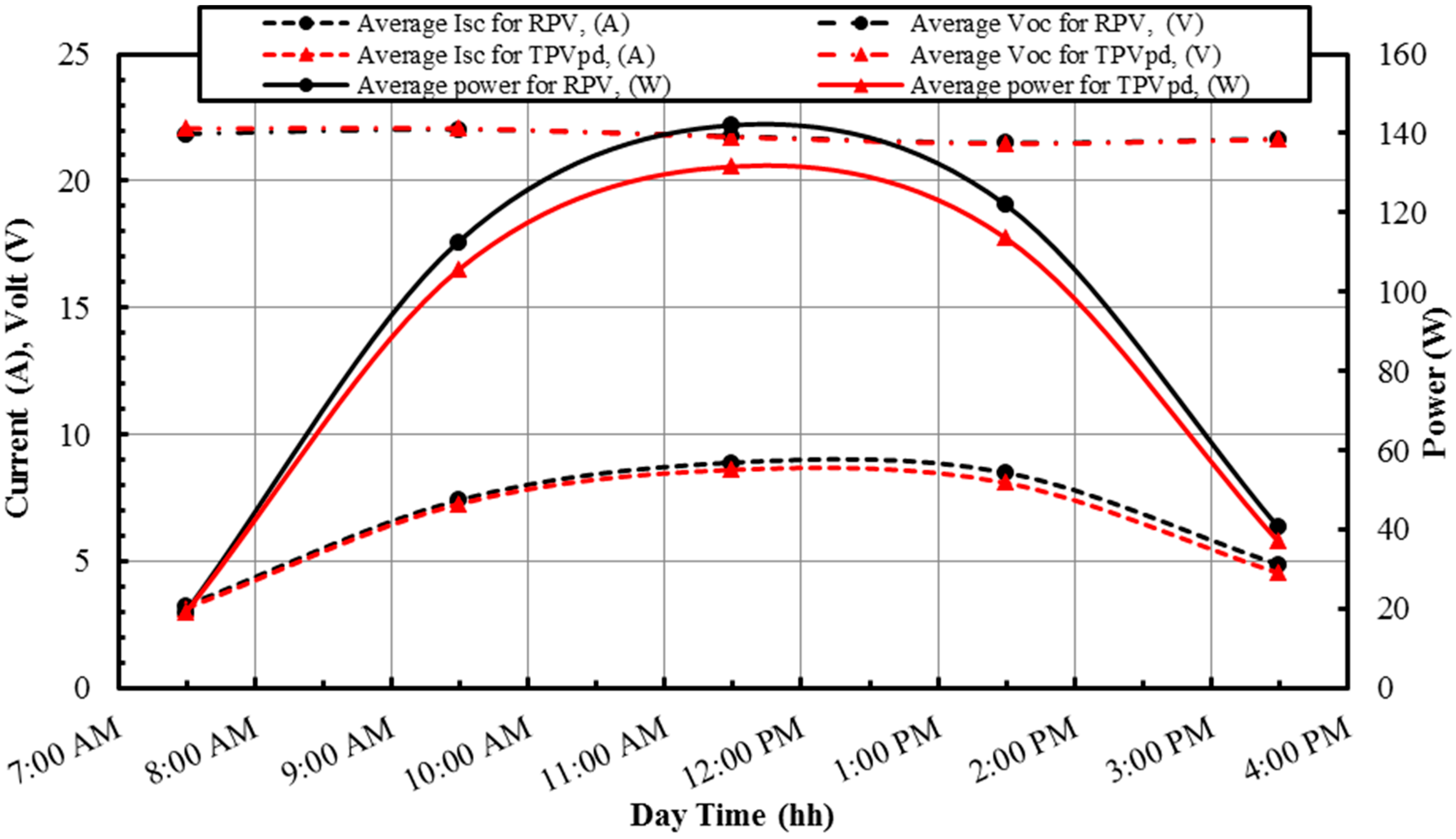

The harvested energy from the partially shaded PV system is much lower than that assumed from the mean solar irradiance, and the percentage of reduction increased by decreasing the area of PV modules that receive sunlight. The results show that the highest reductions occurred in the case of the three quarters shaded area, and the reductions in the short circuit current, open circuit voltage, and power output were 66.5%, 25.3%, and 92.6%, sequentially. The implication of this is that the PV system must be placed and installed in appropriate locations for maximum efficiency and avoiding shading conditions.

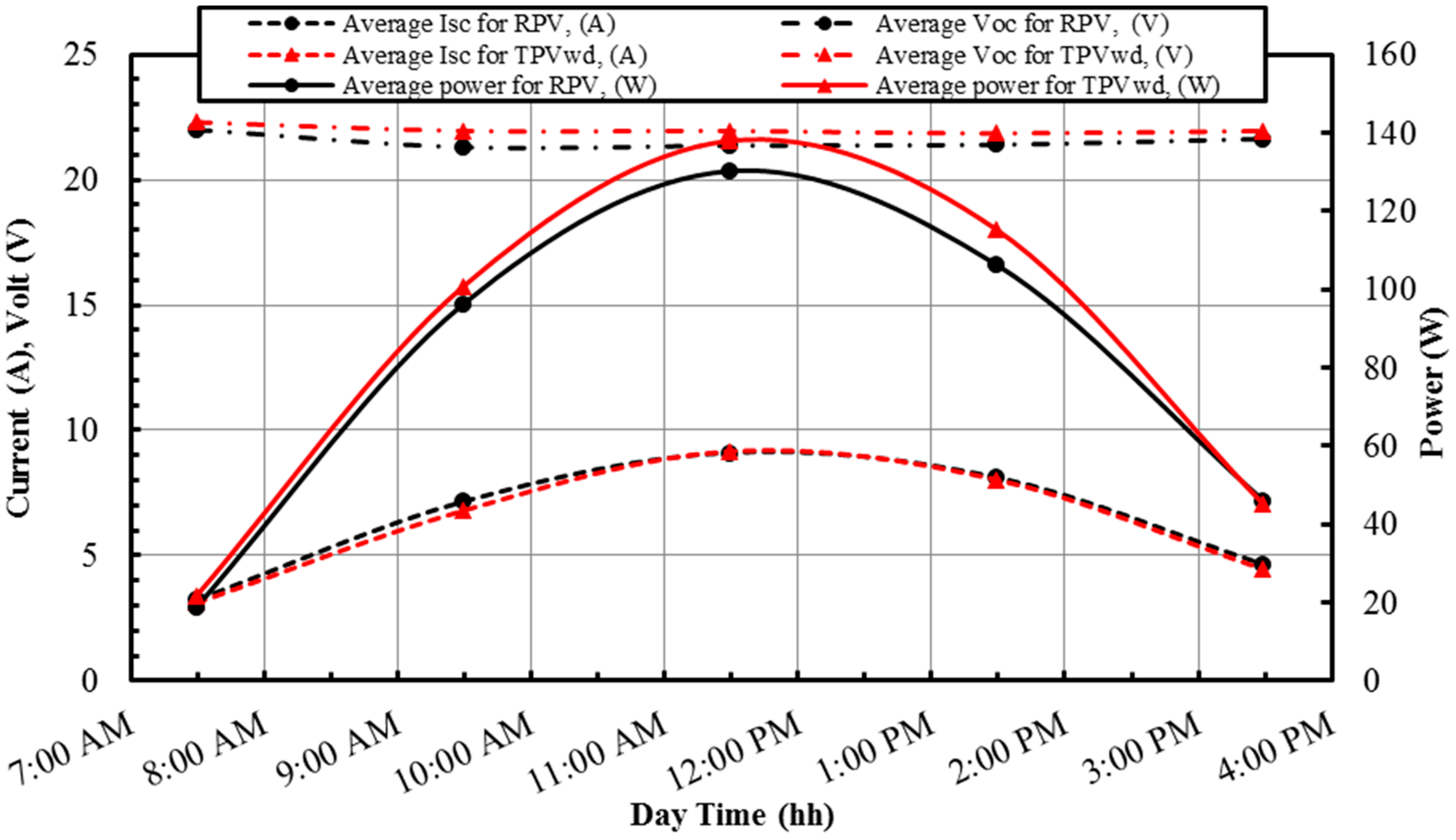

Results of tests on the impact of water droplets on a PV panel indicate an improvement in the power output of the PV module exposed to water droplets of at least 5.9%. Water droplets seem to decrease the temperature of the front and back surfaces of the PV panels (i.e., they seem to have a cooling effect) while increasing the PV voltage. It is also apparent that using water as a coolant on the PV panel surfaces can be an effective cooling process for such surfaces, and hence generate more energy, particularly on sunny days, when the sun is at more of a direct angle above the solar panels.

The PV module that was covered by bird droppings was found to reduce the output power of the PV system by about 7.4%. Therefore, the results suggest that the reduction in the power output of the PV modules depends on the quantity of bird droppings. Consequently, the importance of periodically cleaning the solar cells should not be overlooked when trying to attain a desired efficiency of a PV module system. The uncertainty value for the electric power output of the PV system is found to be 2.423 W or 2.06%, and this value is adequately acceptable as it lies within the standard limits.