Recurring Patterns and Blueprints of Industrial Symbioses as Structural Units for an IT Tool

Abstract

1. Introduction

2. Methods

- IS main structures and compositions:

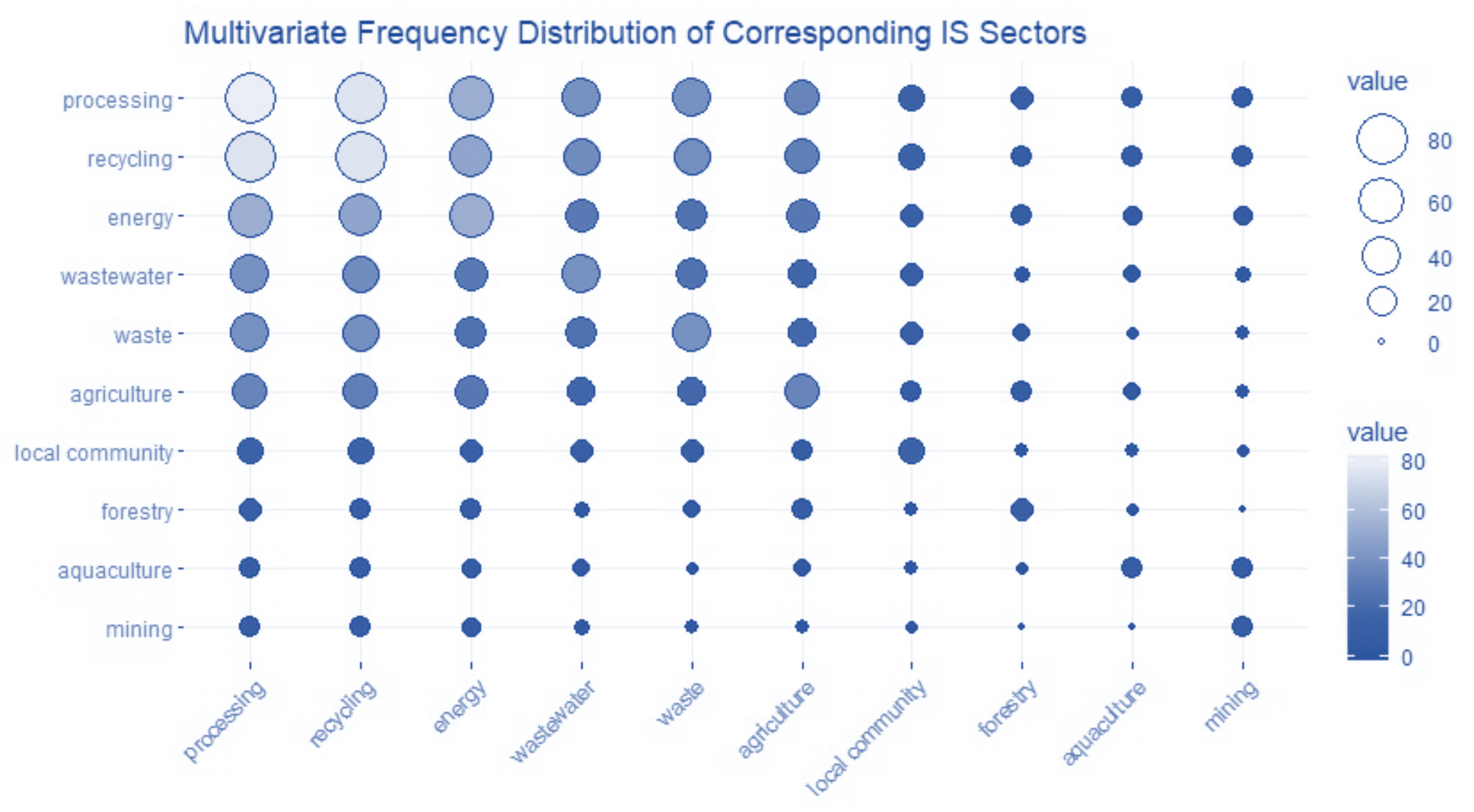

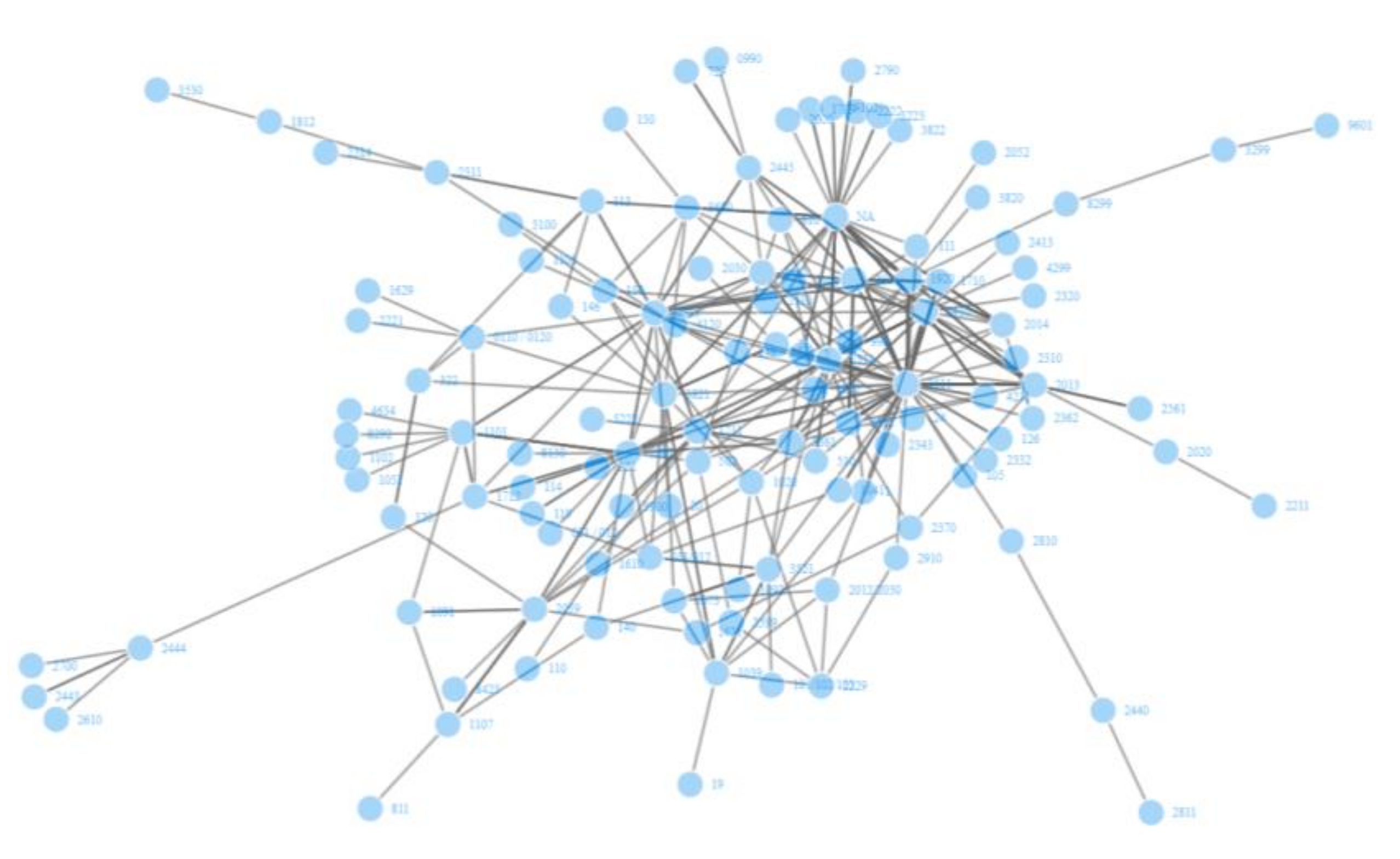

- Participating sector-specific entities: were documented for the investigation of recurring composition patterns in IS systems in order to identify repetitious cooperating IS industries (specific IS sector clusters) for the facilitated recommendation of potential IS partners and blueprint-IS network constellations.

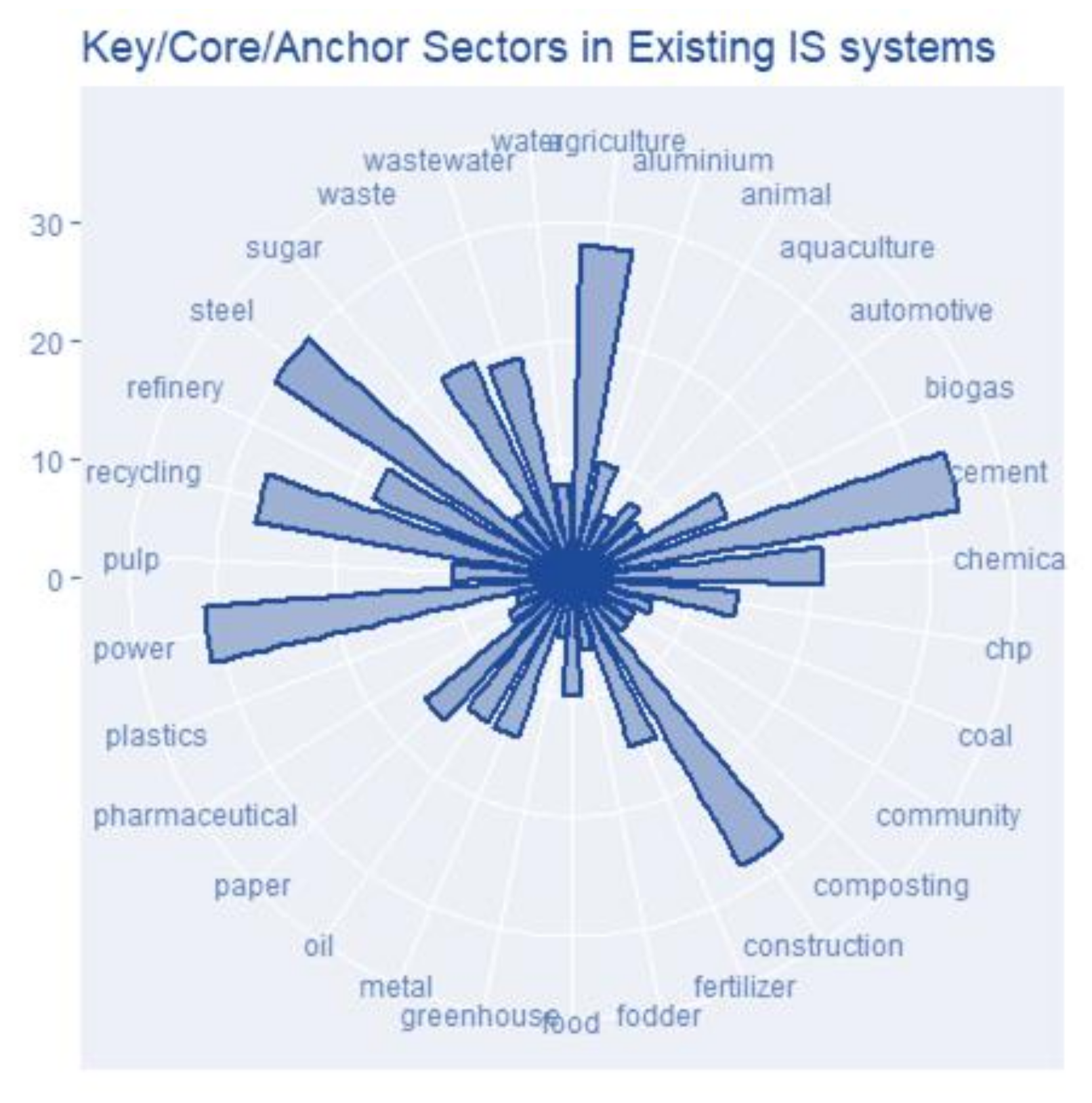

- IS key/core/anchor entities: were detected based on the identified IS sector clusters.

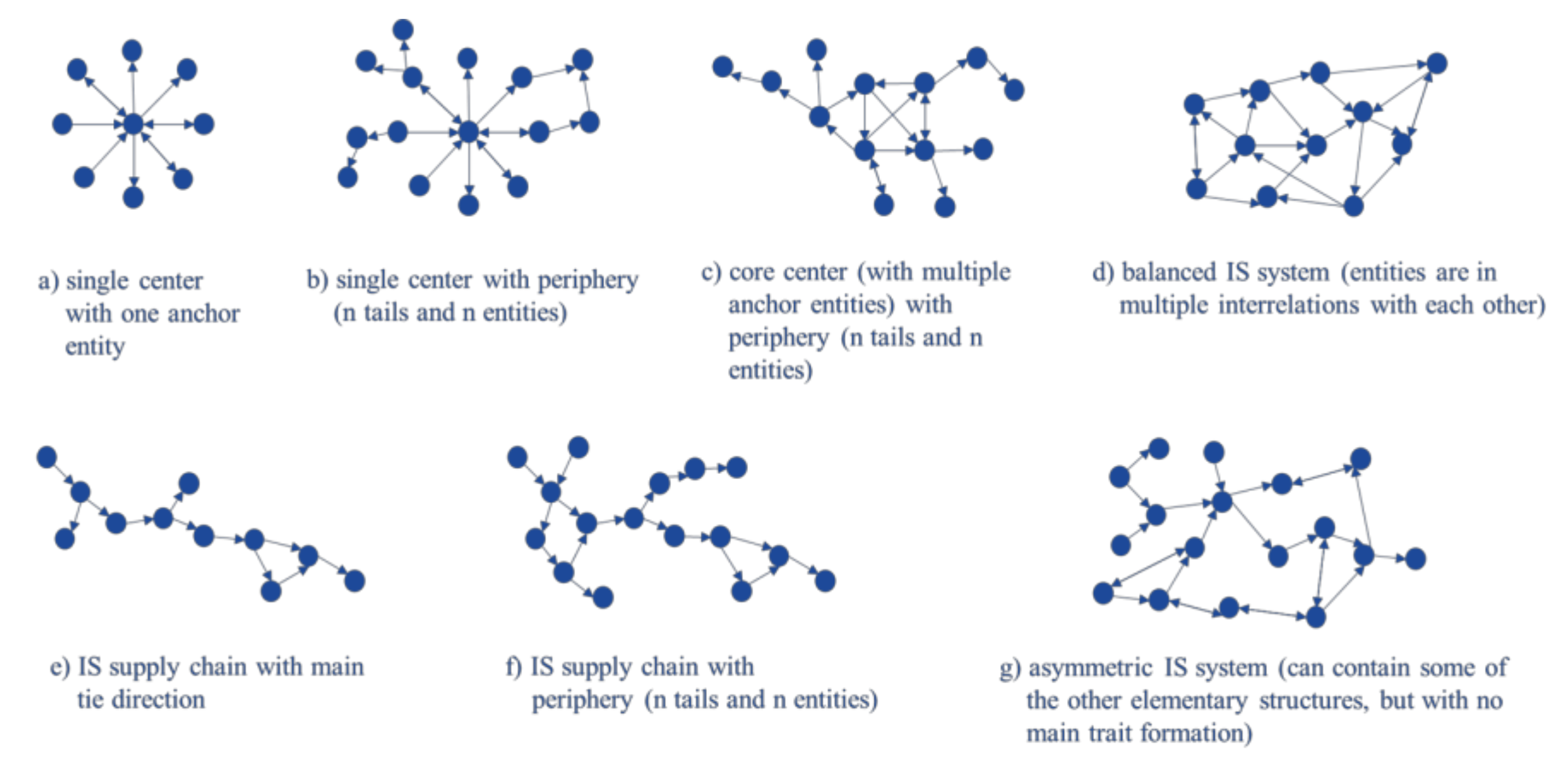

- IS structures: and characteristics, attributes and causations were abstracted in order to break down elementary IS archetype formations, which can be used to build structural IS systems.

- IS activities and measures:

- Material, energy, (waste) water, knowledge and utility exchanges: The different exchange types and their relative occurrence are identified. Material exchanges were defined as material, solid waste, by-product and residual flows which were exchanged between at least two entities. Energy exchanges were defined as all energy flows between at least two entities covering thermal, steam, (process/waste) water for heating or cooling reasons, power/electricity, (bio-)gas, (bio-)fuel flows. (Waste) water exchanges were defined as all (process/waste) water flows which were used as secondary raw material or process water in another entity. Knowledge exchanges were defined as all coordinated information, data and knowledge/expertise sharing between at least two entities through for example an organizational (network) unit, third party consultancy or an (IT-supported) information system. Utility sharing was defined as shared infrastructure and services which are operated/organized jointly, e.g., joint management of procurement and disposal/recycling processes, kindergarten, cafeteria.

| Nr. | References | IS/EIP Name | Region of IS System |

|---|---|---|---|

| 1 | [25] | Heavy Industrial District Gladstone | Australia |

| 2 | [26] | Kwinana Industrial Park | Australia |

| 3 | [27] | Ecopark Hartberg | Austria |

| 4 | [28] | Waste disposal network Styria | Austria |

| 5 | [29] | Industrial Symbiosis Cluster Koekhoven | Belgium |

| 6 | [30] | Norte Fluminense industrial area | Brazil |

| 7 | [31] | Steelmaking, Cement Manufacturing, Zinc Smelting Cluster | Brazil |

| 8 | [32] | Burnside Industrial Park | Canada |

| 9 | [33] | Beijiang Power Plant Complex | China |

| 10 | [34] | Circuit board industry in Suzhou New District | China |

| 11 | [35] | Guitang Group | China |

| 12 | [19] | Gujiao Eco-Industrial Park | China |

| 13 | [36] | Hai Hua Industrial Symbiosis | China |

| 14 | [37] | Harbin Yingbin Eco-Industrial Park | China |

| 15 | [38] | Hazardous waste symbiosis network | China |

| 16 | [39] | Iron and steel industrial Park in Gansu | China |

| 17 | [40] | Jinan City | China |

| 18 | [41] | Liuzhou City | China |

| 19 | [42] | Lubei National Eco-industrial Demonstration Park | China |

| 20 | [43] | Midong | China |

| 21 | [44] | Nanning Sugar Co. Ltd. | China |

| 22 | [45] | Qijiang Industrial Park | China |

| 23 | [46] | Rizhao Economic and Technology Development Area | China |

| 24 | [47] | Shenyang Economic and Technological Development Zone | China |

| 25 | [48] | Smeltery | China |

| 26 | [42] | Suzhou Industrial Park | China |

| 27 | [49] | Tianjin Economic & Technical Development Area (TEDA) | China |

| 28 | [50] | Yongcheng | China |

| 29 | [51] | Sustainable Industrial Network Program (SINP) | Colombia |

| 30 | [52] | Industrial Area of Aalborg | Denmark |

| 31 | [53] | Kalundborg | Denmark |

| 32 | [54] | Monfort Boys Town Integrated Biosystem | Fiji |

| 33 | [5] | Kymi Mill in Kouvola | Finland |

| 34 | [55] | Pulp and paper mill on the river Kymijoki in Kuusankoski | Finland |

| 35 | [56] | Rantasalmi Eco-industrial Park | Finland |

| 36 | [57] | Uimaharju | Finland |

| 37 | [58] | Harjavalta industrial eco park | Finland |

| 38 | [59] | Dunkirk | France |

| 39 | [60] | Industrial Symbiosis in an Industrial zone | France |

| 40 | [28] | Recycling Network Ruhr Area | Germany |

| 41 | [28] | Waste disposal network Emden-Dollart Port | Germany |

| 42 | [61] | Nea Karvali | Greece |

| 43 | [6] | Mysuru | India |

| 44 | [62] | Business cluster in Mysore in the State of Karnataka | India |

| 45 | [63] | Cement Industry | Indonesia |

| 46 | [64] | Halmahera Eco-Industrial Estate | Indonesia |

| 47 | [65] | Abruzzo Region - Bussi Chemical Site (BCS) | Italy |

| 48 | [66] | Agro-Food context of IS in L‘Aquila | Italy |

| 49 | [66] | Automotive context of IS in Chieti | Italy |

| 50 | [67] | Tanneries in S. Croce sull´Arno | Italy |

| 51 | [68] | Taranto industrial district | Italy |

| 52 | [69] | Waste Electrical and Electronic Equipment (WEEE) cluster | Italy |

| 53 | [70] | Eco-Town Kawasaki | Japan |

| 54 | [71] | Tanegashima | Japan |

| 55 | [72] | Three major polluting industries | Mauritius |

| 56 | [59] | Altamira-Tampico industrial corridor | Mexico |

| 57 | [73] | Eco-Industrial Park in Mongstad | Norway |

| 58 | [74] | Hayatabad Industrial Estate | Pakistan |

| 59 | [75] | Reguengos de Monsaraz Industrial Symbiosis Network | Portugal |

| 60 | [76] | Relvão Eco Industrial Park | Portugal |

| 61 | [77] | Barceloneta | Puerto Rico |

| 62 | [77] | Guayama Industrial Symbiosis | Puerto Rico |

| 63 | [78] | Ten IS systems | several |

| 64 | [79] | Food Waste Industrial Symbiosis Network | Singapore |

| 65 | [80] | Ulsan Eco-Industrial Park | South Korea |

| 66 | [81] | Forssjö | Sweden |

| 67 | [82] | Händelö | Sweden |

| 68 | [56] | Jämtland | Sweden |

| 69 | [83] | Landskrona Industrial Symbiosis | Sweden |

| 70 | [81] | Mönsterås | Sweden |

| 71 | [84] | Norrköping | Sweden |

| 72 | [85] | Sotenäs IS network | Sweden |

| 73 | [81] | Värö | Sweden |

| 74 | [86] | Ecosite Geneva | Switzerland |

| 75 | [87] | Iskenderun Bay | Turkey |

| 76 | [88] | Humber Region Industrial Symbiosis Programme (HISP) | United Kingdom |

| 77 | [88] | West Midlands Industrial Symbiosis Programme (WISP) | United Kingdom |

| 78 | [89] | By-Product Synergy Central Gulf Coast Project | USA |

| 79 | [90] | Food Cycling in New Haven | USA |

| 80 | [91] | General Motors | USA |

3. Results

3.1. Patterns in Industrial Symbiosis Structures and Compositions

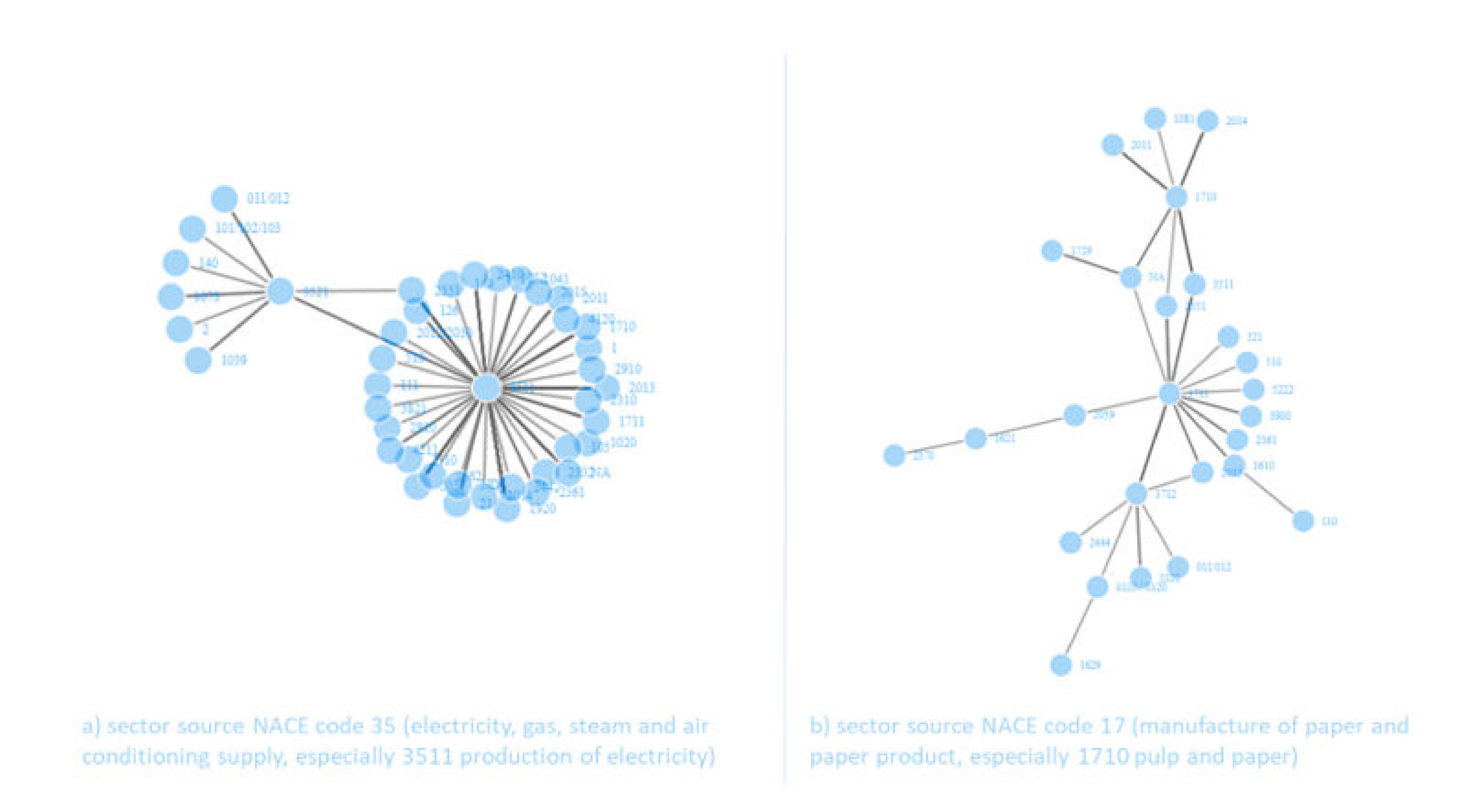

3.1.1. Industrial Symbiosis Compositions, Clusters and Key Entities

- NACE code 0110: Growing of non-perennial crops,

- NACE code 1020: Processing and preserving of fish, crustaceans and mollusks,

- NACE code 1081: Manufacture of sugar,

- NACE code 1101: Distilling, rectifying and blending of spirits,

- NACE code 1710: Manufacture of pulp, paper and paperboard,

- NACE code 1920: Manufacture of refined petroleum products,

- NACE code 2015: Manufacture of fertilizers and nitrogen compounds,

- NACE code 2059: Manufacture of other chemical products,

- NACE code 2351: Manufacture of cement,

- NACE code 2410: Manufacture of basic iron and steel and of ferro-alloys,

- NACE code 3511: Production of electricity,

- NACE code 3521: Manufacture of gas,

- NACE code 3821: Treatment and disposal of non-hazardous waste,

- NACE code 4120: Construction of residential and non-residential buildings,

- NACE code 4211: Construction of roads and motorways,

- NACE code NA: urban entities.

3.1.2. Classification of Structural Industrial Symbiosis Archetype Formations

3.2. Industrial Symbiosis Activities and Measures

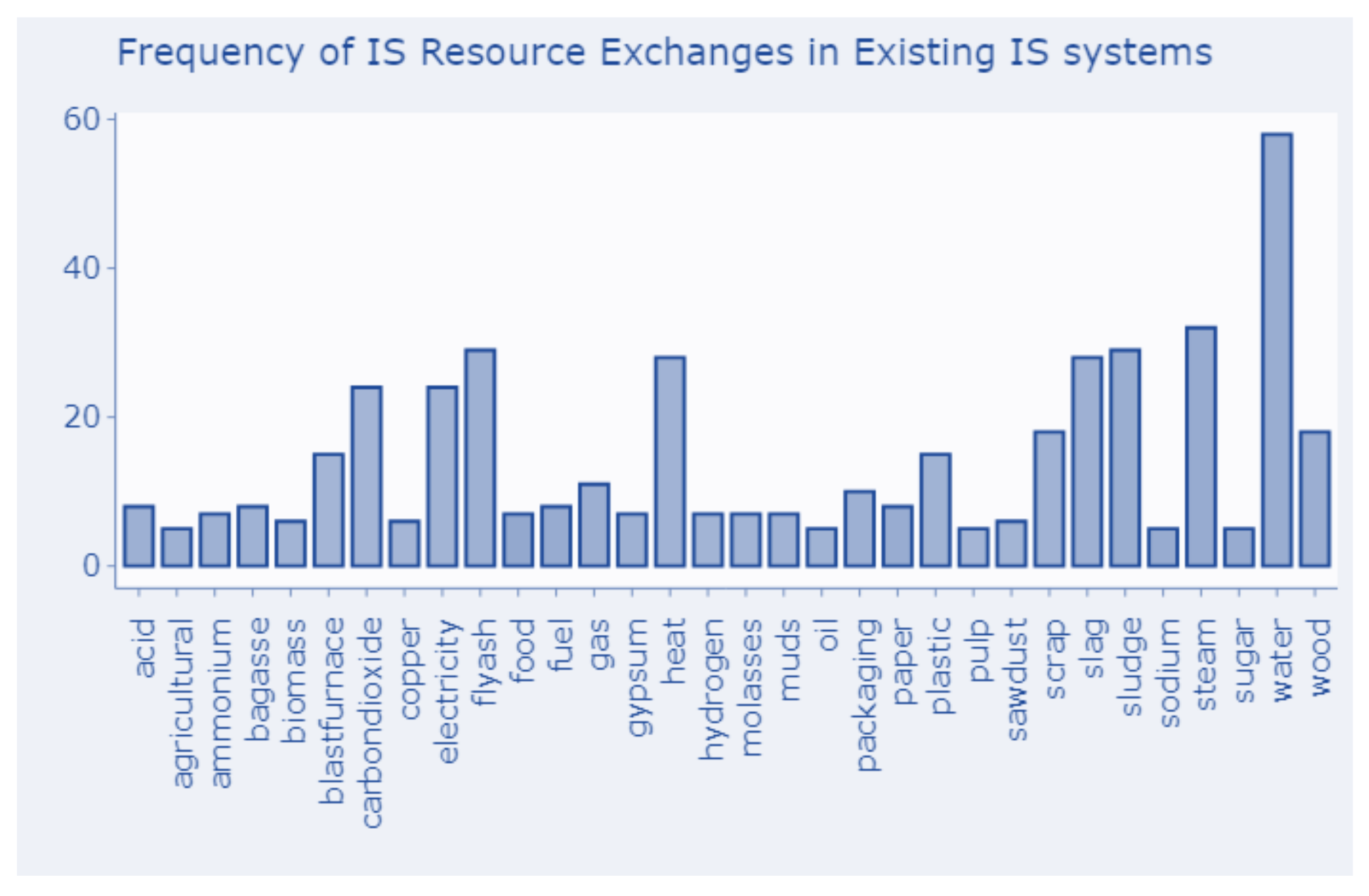

3.2.1. Industrial Symbiosis Resource Exchanges

- Materials:

- Secondary raw/substitute material exchanges: companies use waste flows of other entities as secondary raw/substitute, auxiliary and operating materials. Ref. [27] investigated an Austrian IS system, in which the manufacturer of cellulose insulation collected wastepaper from onsite companies to re-process it for material (re-)utilization. Ref. [57] presented a Finnish case study, in which a pulp mill fed its bark residues to a combined heat and power plant (CHP) for energetic utilization.

- gaseous waste/aerosols: can be directly (or various substances are extracted out/treated beforehand) transferred to other companies as secondary raw, auxiliary and operating materials. Ref. [62] examined an Indian business cluster in Mysore, in which inter alia the CO2 emissions from a distillery are forwarded to a CO2 bottling facility. Aerosol waste flows such as (coal) fly ash can be inserted as cement [25,36] or soil additive [57,68].

- sludge/slag: can be directly (or various substances are extracted out/treated beforehand) forwarded to other companies as secondary raw materials. Ref. [41] presented a Chinese IS case study of an iron and steel industry which transferred its blast furnace and steel slag to a cement company.

- Energy:

- electricity: energy producing companies (as their core or side business, for example with an onsite CHP plant) transfer power to other entities. Ref. [58] showed a Finnish IS network, mainly covering copper and nickel flash smelters, nickel chemical producer, energy producer, hydrogen plant, sulphuric acid plant and the town of Harjavalta, which has implemented energy cascading and material exchanges.

- Water:

- (waste/process) water: companies forward their (process) water to other entities for direct (or in the meantime treated water) utilization. Ref. [44] presented a Chinese case study, in which industrial process and white water of paper production was recovered to re-utilize it in pulp production. Wastewater from a food processing company (e.g., olives, cereals, fruits and vegetables) can be further used for the fertilized irrigation of agricultural land [68,77] or further processed into a fertilizer product.

3.2.2. Industrial Symbiosis Resource Exchange Catalog

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Crutzen, P.J. Geology of mankind. Nature 2002, 415, 23. [Google Scholar] [CrossRef] [PubMed]

- Rockström, J.; Steffen, W.; Foley, J.A. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- EEA (European Environment Agency). More from less—Material resource efficiency in Europe. EEA report No 10/2016; European Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Geng, Y. Industrial and urban symbiosis in Japan: Analysis of the Eco-Town program 1997-2006. J. Environ. Manag. 2009, 90, 1544–1556. [Google Scholar] [CrossRef] [PubMed]

- Sokka, L.; Lehtoranta, S.; Nissinen, A.; Melanen, M. Analyzing the Environmental Benefits of Industrial Symbiosis: Life Cycle Assessment Applied to a Finnish Forest Industry Complex. J. Ind. Ecolol. 2011, 15, 137–155. [Google Scholar] [CrossRef]

- Chertow, M.; Gordon, M.; Hirsch, P.; Ramaswami, A. Industrial symbiosis potential and urban infrastructure capacity in Mysuru, India. Environ. Res. Lett. 2019, 14. [Google Scholar] [CrossRef]

- Bacudio, L.R.; Benjamin, M.F.D.; Eusebio, R.C.P.; Holaysan, S.A.K.; Promentilla, M.A.B.; Yu, K.D.S.; Aviso, K.B. Analyzing barriers to implementing industrial symbiosisnetworks using DEMATEL. Sustain. Prod. Consum. 2016, 7, 57–65. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, Z.; Wu, J.; He, Y.; Xu, H. Which factors promote or inhibit enterprises’ participation in industrial symbiosis? An analytical approach and a case study in China. J. Clean. Prod. 2020, 244, 118600. [Google Scholar] [CrossRef]

- Sakr, D.; Baas, L.; El-Haggar, S.; Huisingh, D. Critical success and limiting factors for eco-industrial parks: Global trends and Egyptian context. J. Clean. Prod. 2011, 19, 1158–1169. [Google Scholar] [CrossRef]

- Ismail, Y. Industrial Symbiosis at Supply Chain. Int. J. Bus. Econ. Law 2014, 4. ISSN 2289-1552. [Google Scholar]

- Grant, G.B.; Saeger, T.P.; Massard, G.; Nies, L. Information and communication technology for industrial symbiosis. J. Ind. Ecol. 2010, 5, 5–753. [Google Scholar] [CrossRef]

- Maqbool, A.S.; Mendez Alva, F.; Van Eetvelde, G. An Assessment of European Information Technology Tools to Support Industrial Symbiosis. Sustainability 2019, 11. [Google Scholar] [CrossRef]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for promoting industrial symbiosis: A systematic review. J. Ind. Ecolol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Ruiz-Puente, C. Fostering Circular Economy Through the Analysis of Existing Open Access Industrial Symbiosis Databases. Sustainability 2020, 12, 952. [Google Scholar] [CrossRef]

- Kosmol, L. Sharing is caring—Information and knowledge in industrial symbiosis: A systematic review. In Proceedings of the 21st Conference on Business Informatics (CBI), Moscow, Russia, 15–17 July 2019; pp. 21–30. [Google Scholar]

- Lütje, A.; Wohlgemuth, V. Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting. Adm. Sci. 2020, 10, 10. [Google Scholar] [CrossRef]

- Heeres, R.R.; Vermeulen, W.J.V.; de Walle, F.B. Eco-industrial park initiatives in the USA and the Netherlands: First lessons. J. Clean. Prod. 2004, 12, 985–995. [Google Scholar] [CrossRef]

- Isenmann, R. Beitrag betrieblicher Umweltinformatik für die Industrial Ecology—Analyse von BUISSoftware-Werkzeugen zur Unterstützung von Industriesymbiosen. In IT-gestütztes Ressourcen- und Energiemanagement; Gómez, J.M., Lang, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Lütje, A.; Willenbacher, M.; Engelmann, M.; Kunisch, C.; Wohlgemuth, V. Exploring the system dynamics of industrial symbiosis (IS) with machine learning (ML) techniques—A framework for a hybrid-approach. In Advances and New Trends in Environmental Informatics—ICT for Sustainable Solutions; Schaldach, R., Simon, K.-H., Weismüller, J., Wohlgemuth, V., Eds.; Springer Nature Switzerland AG: Basel, Switzerland, 2019; pp. 117–130. [Google Scholar]

- Cecelja, F.; Raafat, T.; Trokanas, N.; Innes, S.; Smith, M.; Yang, A.; Zorgios, Y.; Korkofygas, A.; Kokossis, A. e-Symbiosis: Technology-enabled support for industrial symbiosis targeting SMEs and innovation. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Livet, P.; Phan, D.; Sanders, L. Why do we need Ontology for Agent-Based Models. In Complexity and Artificial Markets; Springer-Verlag: Berlin/Heidelberg, Germany, 2008; pp. 133–145. [Google Scholar]

- Sharma, G. Pros and cons of different sampling techniques. Int. J. Appl. Res. 2017, 3, 749–752. [Google Scholar]

- Evans, S.; Benedetti, M.; Holgado Granados, M. Library of Industrial Symbiosis case studies and linked exchanges. 2017. Available online: https://www.repository.cam.ac.uk/handle/1810/267849 (accessed on 12 February 2020).

- Golev, A.; Corder, G.; Giurcob, D.P. Industrial symbiosis in Gladstone: A decade of progress and future development. J. Clean. Prod. 2014, 84, 421–429. [Google Scholar] [CrossRef]

- Van Beers, D.; Bossilkov, A.; Corder, G.; Van Berkel, R. Industrial Symbiosis in the Australian Minerals Industry—The Cases of Kwinana and Gladstone. J. Ind. Ecolol. 2007, 11, 55–72. [Google Scholar] [CrossRef]

- Liwarska-Bizukojc, E.; Bizukojc, M.; Marcinkowski, A.; Doniec, A. The conceptual model of an eco-industrial park based upon ecological relationships. J. Clean. Prod 2009, 17, 732–741. [Google Scholar] [CrossRef]

- Kaluza, B.; Blecker, T. Interindustrielle Unternehmensnetzwerke in der betrieblichen Entsorgungslogistik; University of Duisburg: Duisburg, Germany, 1996; Discussion Papers of the department of Economics. [Google Scholar]

- Verguts, V.; Dessein, J.; Dewulf, A.; Lauwers, L.; Werkman, R.; Termeer, C.J.A.M. Industrial symbiosis as sustainable development strategy: Adding a change perspective. Int. J. Sustain. Dev. 2016, 19, 15–35. [Google Scholar] [CrossRef]

- Santos, V.E.N.; Magrini, A. Biorefining and industrial symbiosis: A proposal for regional development in Brazil. J. Clean. Prod. 2018, 177, 19–33. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Murakami, F.K. Industrial Symbiosis: A Case Study Involving a Steelmaking, a Cement Manufacturing, and a Zinc Smelting Plant. Chem. Eng. Trans. 2018, 70. [Google Scholar] [CrossRef]

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Li, Y. Comparative study on the pathways of industrial parks towards sustainable development between China and Canada. Resour. Conserv. Recycl. 2018, 128, 417–425. [Google Scholar] [CrossRef]

- Li, P.-m. A case study of Industrial Symbiosis: The Beijiang power plant complex in Tianjing, China. In Proceedings of the International Conference on E-Business and E-Government (ICEE), Shanghai, China, 6–8 May 2011. [Google Scholar]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Zhu, Q.; Côté, R.P. Integrating green supply chain management into an embryonic eco-industrial development: A case study of the Guitang Group. J. Clean. Prod. 2004, 12, 1025–1035. [Google Scholar] [CrossRef]

- Cui, H.; Liu, C.; Côté, R.; Liu, W. Understanding the evolution of industrial symbiosis with a system dynamics model. A case study of Hai Hua Industrial Symbiosis China. Sustainability 2018. [Google Scholar] [CrossRef]

- Fangliang, L.; Xiujuan, Y. An ALB model of Eco-Industrial Parks. Appl. Mech. Mater. 2013, 274, 485–489. [Google Scholar] [CrossRef]

- Wu, J.; Guo, Y.; Li, C.; Qi, H. The redundancy of an industrial symbiosis network: A case study of a hazardous waste symbiosis network. J. Clean. Prod. 1016, 149, 49–59. [Google Scholar] [CrossRef]

- Wu, J.; Pu, G.; Ma, Q.; Qi, H.; Wang, R. Quantitative environmental risk assessment for the iron and steel industrial symbiosis network. J.Clean. Prod. 2017, 157, 106–117. [Google Scholar] [CrossRef]

- Fraccascia, L.; Albino, V.; Di Bari, P.; Giannoccaro, I. Circular economy at the urban level View project SHAREBOX-Implementation of an IT platform for secure management of resource sharing View project. 2017. Available online: http://openarchive.enea.it/bitstream/handle/10840/9067/V2017_SUN-Proceedings.pdf?sequence=1 (accessed on 12 February 2020).

- Sun, L.; Spekkink, W.; Cuppen, E.; Korevaar, G. Coordination of industrial symbiosis through anchoring. Sustainability 2017, 9. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress toward a circular economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of promoting industrial symbiosis in a chemical industrial park: A case of Midong. J. Clean. Prod. 2016, 135, 995–1008. [Google Scholar] [CrossRef]

- Yang, S.; Feng, N. A case study of industrial symbiosis: Nanning Sugar Co., Ltd. in China. Resour. Conserv. Recycl. 2008, 52, 813–820. [Google Scholar] [CrossRef]

- Li, B.; Xiang, P.; Hu, M.; Zhang, C.; Dong, L. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. J. Clean. Prod. 2017, 157, 267–277. [Google Scholar] [CrossRef]

- Yu, F.; Han, F.; Cui, Z. Evolution of industrial symbiosis in an eco-industrial park in China. J. Clean. Prod. 2015, 87, 339–347. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, Z.; Xue, B.; Dong, H.; Fujita, T.; Chiu, A. Emergy-based assessment on industrial symbiosis: A case of Shenyang Economic and Technological Development Zone. Environ. Sci. Pollut. Res. 2014, 21, 13572–13587. [Google Scholar] [CrossRef]

- Yuan, Z.; Shi, L. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. J. Clean. Prod. 2009, 17, 1295–1302. [Google Scholar] [CrossRef]

- Shi, H.; Chertow, M.; Song, Y. Developing country experience with eco-industrial parks: A case study of the Tianjin Economic-Technological Development Area in China. J. Clean. Prod. 2010, 18, 191–199. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S.; Wang, K.; Gao, Y.; Zhang, R. Uncovering the benefits of integrating industrial symbiosis and urban symbiosis targeting a resource-dependent city: A case study of Yongcheng, China. J. Clean. Prod. 2020, 255, 120210. [Google Scholar] [CrossRef]

- Park, J.; Duque-Hernández, J.; Díaz-Posada, N. Facilitating business collaborations for industrial symbiosis: The pilot experience of the sustainable industrial network program in Colombia. Sustainability 2018, 10, 3637. [Google Scholar] [CrossRef]

- Sacchi, R.; Ramsheva, Y.K.; Konstantinova Ramsheva, Y. The effect of price regulation on the performances of industrial symbiosis: A case study on district heating. Int. J. Sustain. Energy Plan. Manag. 2017, 14, 39–56. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Applications and Implementation Industrial Symbiosis in Kalundborg, Denmark A Quantitative Assessment of Economic and Environmental Aspects. 2006. Available online: http://mitpress.mit.edu/jie (accessed on 12 February 2020).

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Pakarinen, S.; Mattila, T.; Melanen, M.; Nissinen, A.; Sokka, L. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resour. Conserv. Recycl. 2010, 54, 1393–1404. [Google Scholar] [CrossRef]

- Saikku, L. Eco-industrial parks: A Background Report for the Ecoindustrial Park Project at Rantasalmi; Regional Council of Etelä-Savo: Mikkeli, Finland, 2006. [Google Scholar]

- Korhonen, J.; Snäkin, J.-P. Analysing the evolution of industrial ecosystems: Concepts and application. Ecol. Econ. 2005, 52, 169–186. [Google Scholar] [CrossRef]

- Jyrki, H. Harjavalta Industrial Eco Park—A Success Story of the Industrial Ecology in the Area of Metallurgical Industry to Increase Regional Sustainability; University of Oulu: Oulu, Finland, 2009. [Google Scholar]

- Morales, E.M.; Diemer, A.; Cervantes, G.; Carrillo-González, G. “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 Years of industrial ecology in Mexico. Resour. Conserv. Recycl. 2019, 140, 235–245. [Google Scholar] [CrossRef]

- Hein, A.; Jankovic, M.; Feng, W.; Farel, R.; Yune, J.; Yannou, B. Stakeholder Power in Industrial Symbioses: A Stakeholder Value Network Approach. J. Clean. Prod. 2017, 148, 923–933. [Google Scholar] [CrossRef]

- Gaidajis, G.; Kakanis, I. Examination of Industrial Symbiosis Potential Interactions in an Industrial Area Of NE Greece. J. Eng. Sci. Technol. Rev. 2015, 8, 130–135. [Google Scholar] [CrossRef]

- Bain, A.; Shenoy, M.; Ashton, W.; Chertow, M. Industrial symbiosis and waste recovery in an Indian industrial area. Resour. Conserv. Recycl. 2010, 54, 1278–1287. [Google Scholar] [CrossRef]

- Ulhasanah, N.; Goto, N. Preliminary Design of Eco-City by Using Industrial Symbiosis and Waste Co-Processing Based on MFA, LCA, and MFCA of Cement Industry in Indonesia. Int. J.Environ. Sci. Dev. 2013, 553–561. [Google Scholar] [CrossRef]

- Aswie, V.; Ariastita, P.; Setyasa, P.; Andriani, N.; Malaysia, P. Development Halmahera as a New Sustainable Future City with Industrial Symbiosis Infiltration Concept. In Proceedings of the ASEAN Youth Conference, Kuala Lumpur, Malysia, 16–17 December 2017; Volume 1. [Google Scholar]

- Taddeo, R.; Simboli, A.; Morgante, A. Implementing eco-industrial parks in existing clusters. Findings from a historical Italian chemical site. J. Clean. Prod. 2012, 33, 22–29. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A. The Development of Industrial Symbiosis in Existing Contexts. Experiences From Three Italian Clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Daddi, T.; Nucci, B.; Iraldo, F. Using Life Cycle Assessment (LCA) to measure the environmental benefits of industrial symbiosis in an industrial cluster of SMEs. J. Clean. Prod. 2017, 147, 157–164. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Marconi, M.; Gregori, F.; Germani, M.; Papetti, A.; Favi, C. An approach to favor industrial symbiosis: The case of waste electrical and electronic equipment. Procedia Manuf. 2018, 21, 502–509. [Google Scholar] [CrossRef]

- Hashimoto, S.; Fujita, T.; Geng, Y.; Nagasawa, E.; Hashimoto, A.S.; Nagasawa, D.E. Realizing CO2 emission reduction through industrial symbiosis: A cement production case study for Kawasaki. Resour. Conserv. Recycl. 2010, 54, 10–704. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Kanematsu, Y.; Ugo, M.; Hamada, Y.; Okubo, T. Industrial Symbiosis Centered on a Regional Cogeneration Power Plant Utilizing Available Local Resources: A Case Study of Tanegashima. J. Ind. Ecol. 2016, 20, 276–288. [Google Scholar] [CrossRef]

- Mauthoor, S. Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. J. Clean. Prod. 2017, 147, 506–513. [Google Scholar] [CrossRef]

- Zhang, X.; Strømman, A.H.; Solli, C.; Hertwich, E.G. Model-centered approach to early planning and design of an eco-industrial park around an oil refinery. Environ. Sci. Tech. 2008, 42, 4958–4963. [Google Scholar] [CrossRef]

- Khan, N.H.; Nafees, M.; Saeed, T.; Khan, A.; Bashir, A. Industrial Symbiosis and Industrial Waste Management in Wood-Based Industries. J. Ind. Pollut. Control 2018, 34, 2152–2158. [Google Scholar]

- Barroso, J.L. Potential for Implementing an Industrial Symbiosis Network in Rural Portugal. Master’s Thesis, The International Institute for Industrial Environmental Economics, Lund, Sweden, 2007. ISSN 1401-9191. [Google Scholar]

- Costa, I.; Ferrão, P. A case study of industrial symbiosis development using a middle-out approach. J. Clean. Prod. 2010, 18, 984–992. [Google Scholar] [CrossRef]

- Chertow, M.R.; Ashton, W.S.; Espinosa, J.C. Industrial symbiosis in Puerto Rico: Environmentally related agglomeration economies. Reg. Stud. 2008, 42, 1299–1312. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Chen, B.; Yang, N. Social network analysis and network connectedness analysis for industrial symbiotic systems: Model development and case study. Fron. Earth Sci. 2013, 7, 169–181. [Google Scholar] [CrossRef]

- Kerdlap, P.; Choong Low, J.S.; Steidle, R.; Loong Tan, D.Z.; Herrmann, C.; Ramakrishna, S. Collaboration Platform for Enabling Industrial Symbiosis: Application of the Industrial-Symbiosis Life Cycle Analysis Engine. Procedia CIRP 2019, 80, 655–660. [Google Scholar] [CrossRef]

- Behera, S.K.; Kim, J.H.; Lee, S.Y.; Suh, S.; Park, H.S. Evolution of “designed” industrial symbiosis networks in the Ulsan Eco-industrial Park: “Research and development into business” as the enabling framework. J. Clean. Prod. 2012, 29–30, 103–112. [Google Scholar] [CrossRef]

- Wolf, A.; Petersson, K. Industrial symbiosis in the Swedish forest industry. Prog. Ind. Ecol. Int. J. 2007, 4, 348. [Google Scholar] [CrossRef]

- Martin, M.; Eklund, M.; Sokka, L. Industrial Symbiosis in the Biofuel Industry Quantification of the Environmental Performance and Identification of Synergies; Linköpings universitet Institutionen för ekonomisk och industriell utveckling & Linköpings universitet Tekniska högskolan (n.d.): Linkoping, Sweden, 2013. [Google Scholar]

- Mirata, M.; Emtairah, T. Industrial symbiosis networks and the contribution to environmental innovation: The case of the Landskrona industrial symbiosis programme. J. Clean. Prod. 2005, 13, 993–1002. [Google Scholar] [CrossRef]

- Hatefipour, S.; Baas, L.; Eklund, M. The Händelö area in Norrköping, Sweden Does it fit for Industrial Symbiosis Development? In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar]

- Martin, M.; Harris, S. Prospecting the sustainability implications of an emerging industrial symbiosis network. Resour. Conserv. Recycl. 2018, 138, 246–256. [Google Scholar] [CrossRef]

- Massard, G. Industrial symbioses: A New Strategy for Improving How Economic Activities Use Material and Energy Resources. Ph.D. Thesis, University of Lausanne, Lausanne, Switzerland, 2011. [Google Scholar]

- Alkaya, E.; Böğürcü, M.; Ulutaş, F. Industrial Symbiosis in Iskenderun Bay:A Journey from Pilot Applications to a National Program in Turkey. In Proceedings of the SYMBIOSIS, Athens, Greece, 19–21 June 2014. [Google Scholar]

- Mirata, M. Experiences from early stages of a national industrial symbiosis programme in the UK: Determinants and coordination challenges. J. Clean. Prod. 2004, 12, 967–983. [Google Scholar] [CrossRef]

- Francis, C.G. The chemical industry from an industrial ecology perspective. In Perspectives on Industrial Ecology; Bourg, D., Erkman, S., Eds.; Greenleaf Publishing Limited: Sheffield, UK, 2003. [Google Scholar]

- Alexander, D.; Benoit, C.; Malloch, I.; Noah, E. Food Cycling Within New Haven, Connecticut: Creating Opportunities for Economic, Civic, and Environmental Progress Through Industrial Symbiosis. Yale Sch. Env. Stud. Bull. 2001, 106, 379–412. [Google Scholar]

- Ali, K.A.; Wang, Y.; Alvarado, L.J. Facilitating industrial symbiosis to achieve circular economy using value-added by design: A case study in transforming the automobile industry sheet metal waste-flow into Voronoi facade systems. J. Clean. Prod. 2019, 234, 1033–1044. [Google Scholar] [CrossRef]

- Earley, K. Industrial symbiosis: Harnessing waste energy and materials for mutual benefit. Renew. Energy Focus 2015, 16, 75–77. [Google Scholar] [CrossRef]

- Lütje, A.; Willenbacher, M.; Möller, A.; Wohlgemuth, V. Enabling the identification of industrial symbiosis (IS) through information communication technology (ICT). In Proceedings of the the 52nd Hawaii International Conference on System Sciences (HICSS), Maui, HI, USA, 8–11 January 2019; pp. 709–719. [Google Scholar] [CrossRef]

- Lütje, A.; Wohlgemuth, V. Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks. Admin. Sci. 2020, 10, 1. [Google Scholar] [CrossRef]

- Cervo, H.; Ferrasse, J.-H.; Descales, B.; van Eetvelde, G. Blueprint: A methodology facilitating data exchanges to enhance the detection of industrial symbiosis opportunities—Application to a refinery. Chem. Eng. Sci. 2019, 211, 115254. [Google Scholar] [CrossRef]

- Gibbs, D. Trust and networking in inter-firm relations: The case of eco-industrial development. Local Econ. 2003, 18, 222–236. [Google Scholar] [CrossRef]

- Van Capelleveen, G.; Amrit, C.; Yazan, D.M.; Amrit, C.; Yazan, D.M. A Literature Survey of Information Systems Facilitating the Identification of Industrial Symbiosis. In Science to Society; Otjacques, B., Hitzelberger, P., Naumann, S., Wohlgemuth, V., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Chopra, S.; Khanna, V. Understanding resilience in industrial symbiosis networks: Insights from network analysis. J. Environ. Manag. 2014, 141, 86–94. [Google Scholar] [CrossRef]

- Fleig, A.-K. Eco-industrial parks, a strategy towards industrial ecology in developing and newly industrialized countries. 2000. Available online: http://www.meso-nrw.de/toolkit/Downloads/etc-11.pdf (accessed on 12 February 2020).

- Zhu, J.; Ruth, M. Exploring the resilience of industrial ecosystems. J. Environ. Manag. 2013, 122, 65–75. [Google Scholar] [CrossRef]

| Providing Sector | Receiving Sector | Exchanged Waste Flow | Processed into/Used as |

|---|---|---|---|

| automotive industry | aluminum smelter | aluminum scrap | aluminum |

| animal processing | biodiesel production | animal residues | biodiesel |

| CHP power plant | fertilizing industry | ash | fertilizer: ash pellets |

| sugar refinery | pulp plant | bagasse | pulp |

| pulp and paper plant | power plant | bark | biofuel |

| pulp mill | CHP power plant | bark | energy |

| pulp mill | pellet production | bark | pellets |

| iron and steel industry | cement industry | BF and steel slag | cement additive |

| sugar refinery | cement industry | bio sludge | cement additive |

| pulp plant | alkali recovery | black liquid | alkali |

| pulp production | boiler plant | bleaching water | heated water |

| CHP plant | landscaping | bottom ash | soil additive |

| power plant | bricks manufacturer | bottom ash | bricks additive |

| biogas plant | greenhouse | CO2 emissions | CO2 plant growth gas |

| burning facility | greenhouse | CO2 emissions | CO2 plant growth gas |

| distillery | CO2 bottling facility | CO2 emissions | CO2 raw material |

| ethanol production | algae production | CO2 emissions | algae |

| pulp and paper plant | calcium carbonate plant | CO2 emissions | calcium carbonate additive |

| power plant | cement & construction | coal fly ash | cement additive |

| aquaculture | power plant | cooling water | cooling water |

| cement industry | hospital | cooling water | cooling water |

| refinery | power plant | cooling water | process cooling water |

| algae production | fertilizing industry | dead algae/microbes | fertilizer |

| power plant | chemical industry | deminerlized water | process water |

| wastewater treatment plant | cement industry | dried sewage sludge | cement additive |

| hydropower plant | pulp and paper plant | electricity | process energy |

| biogas plant | agriculture | fermentation residuals | compost |

| aquaponic | compost facility | fish solids | compost |

| CHP power plant | cement industry | fly ash | cement additive |

| power plant | agriculture | fly ash | soil quality improvement and fertilizer |

| power plant | glass and glass-ceramic production | fly ash | ceramic additiv |

| power plant | production of bricks | fly ash | bricks additive |

| power plant | road construction | fly ash | concrete additive |

| chemical industry | plaster board manufacturer | gypsum | gypsum board |

| CHP power plant | cement industry | gypsum | cement additive |

| CHP plant | desalination plant | low pressure steam | process steam |

| animal farm | biogas plant | manure | biogas |

| animal farm | fertilizing industry | manure | manure pellets |

| sugar cane refinery | alcohol distillery | molasses | alcohol |

| algae ponds | fish farming | nutrient rich water | fish feeding |

| algae production | fish farm | nutrient rich water | fish |

| biogas plant | algae production | nutrient rich water | algae |

| fish farm | vegetable farm | nutrient rich water | vegetables |

| agroethanol plant | animal farming | organic residuals | fodder |

| agro-food industry | agriculture | organic residuals | fertilizer |

| biogas plant | agriculture | organic residuals | fertilizer |

| pulp and paper plant | fertilizing industry | organic residuals | fertilizer |

| fish farming | local farms | organic residues | animal feeding |

| local farms | biogas plant | organic waste | biogas |

| CHP power plant | chemical industry | steam | process steam |

| power plant | various industries | steam | process heat |

| automotive industry | metal casting | steel/iron scraps | steel/iron |

| various industries | steel industry | steel/iron scraps | steel/iron |

| power plant | industrial landfills | waste ash | stabilizer |

| power plant | road construction | waste ash | aggregate material |

| power plant | electricity production | waste heat | process heat |

| power plant | fish farm | waste heat | heat |

| power plant | olive mill | waste heat | process heat |

| power plant | urban entities | waste heat | district heating |

| CHP power plant | greenhouse | waste heat/steam | organic food |

| local communities | iron and steel industry | waste plastics | fuel material |

| local communities | waste-to-energy plant | waste plastics | power |

| agro-food industry | agriculture | waste water | fertilized irrigation |

| chlorine dioxide plant | calcium carbonate plant | waste water | process water |

| pig farming | biogas plant | waste water | biogas |

| power plant | various industries | waste water | process water |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rohde-Lütje, A.; Wohlgemuth, V. Recurring Patterns and Blueprints of Industrial Symbioses as Structural Units for an IT Tool. Sustainability 2020, 12, 8280. https://doi.org/10.3390/su12198280

Rohde-Lütje A, Wohlgemuth V. Recurring Patterns and Blueprints of Industrial Symbioses as Structural Units for an IT Tool. Sustainability. 2020; 12(19):8280. https://doi.org/10.3390/su12198280

Chicago/Turabian StyleRohde-Lütje, Anna, and Volker Wohlgemuth. 2020. "Recurring Patterns and Blueprints of Industrial Symbioses as Structural Units for an IT Tool" Sustainability 12, no. 19: 8280. https://doi.org/10.3390/su12198280

APA StyleRohde-Lütje, A., & Wohlgemuth, V. (2020). Recurring Patterns and Blueprints of Industrial Symbioses as Structural Units for an IT Tool. Sustainability, 12(19), 8280. https://doi.org/10.3390/su12198280