Valorization of Orange Peel Waste Using Precomposting and Vermicomposting Processes

Abstract

1. Introduction

2. Materials and Methods

2.1. Precomposting Process

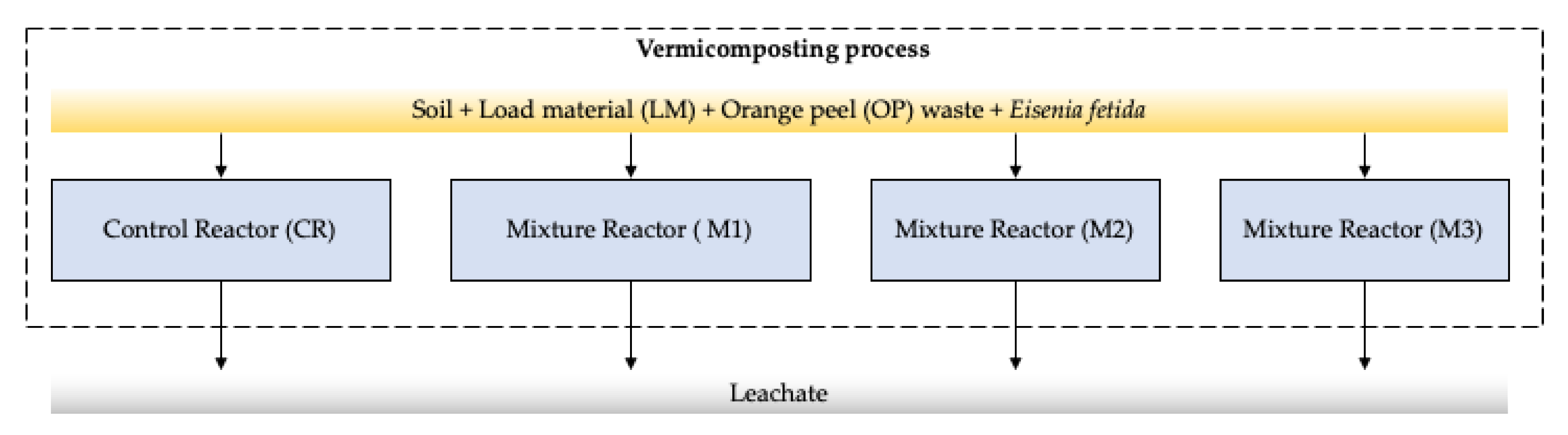

2.2. Vermicomposting Process

2.3. Physicochemical Parameters and Sensory Specifications

2.4. Statistical Analysis

3. Results and Discussion

3.1. Precomposting Process

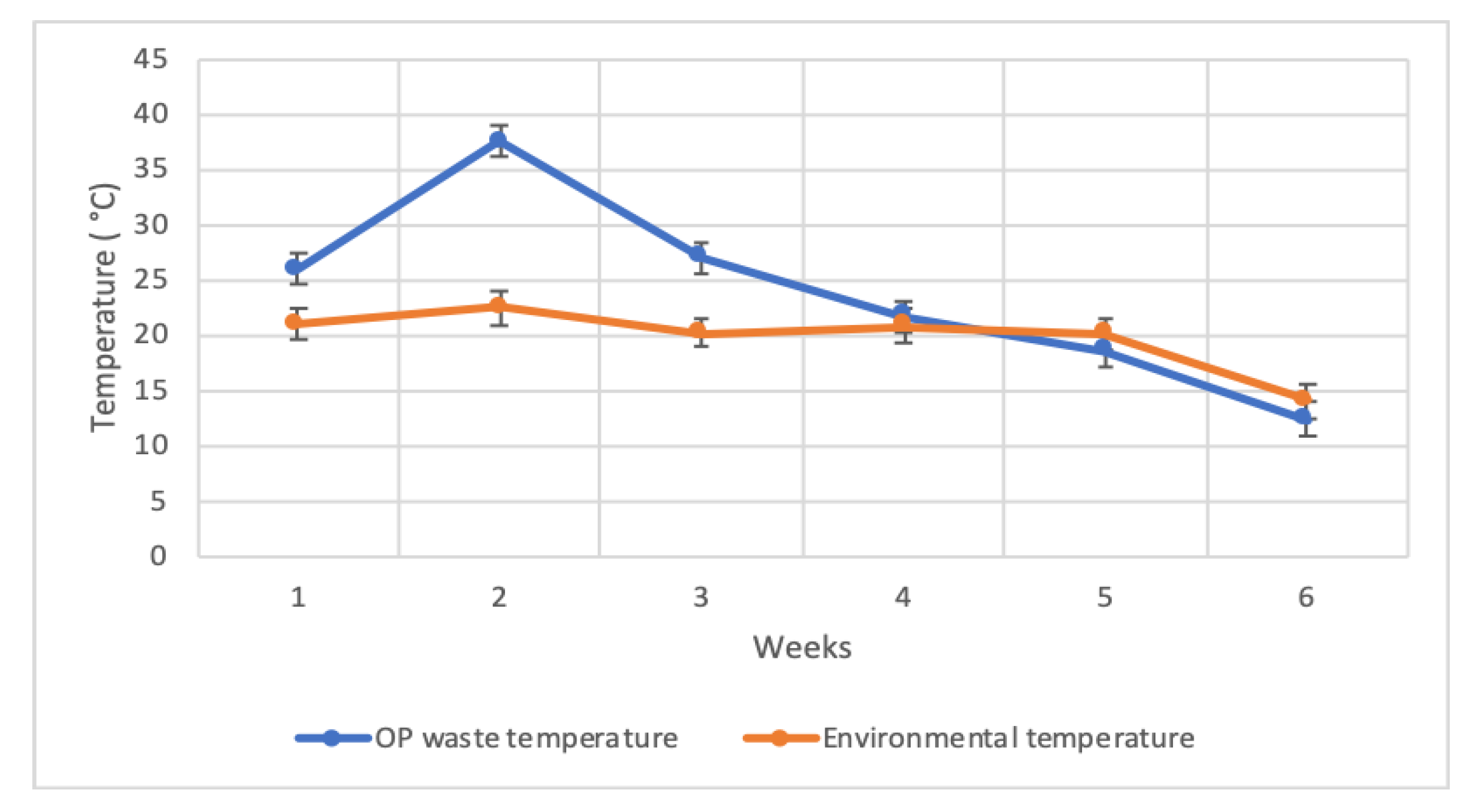

3.1.1. Temperature

3.1.2. pH

3.1.3. Humidity

3.1.4. Organic Matter (OM), Total Organic Carbon (TOC), Total Nitrogen (TN) and Carbon/Nitrogen (C/N) Ratio

3.1.5. Sensory Characteristics of Precomposting

3.2. Vermicomposting Process

3.2.1. Temperature

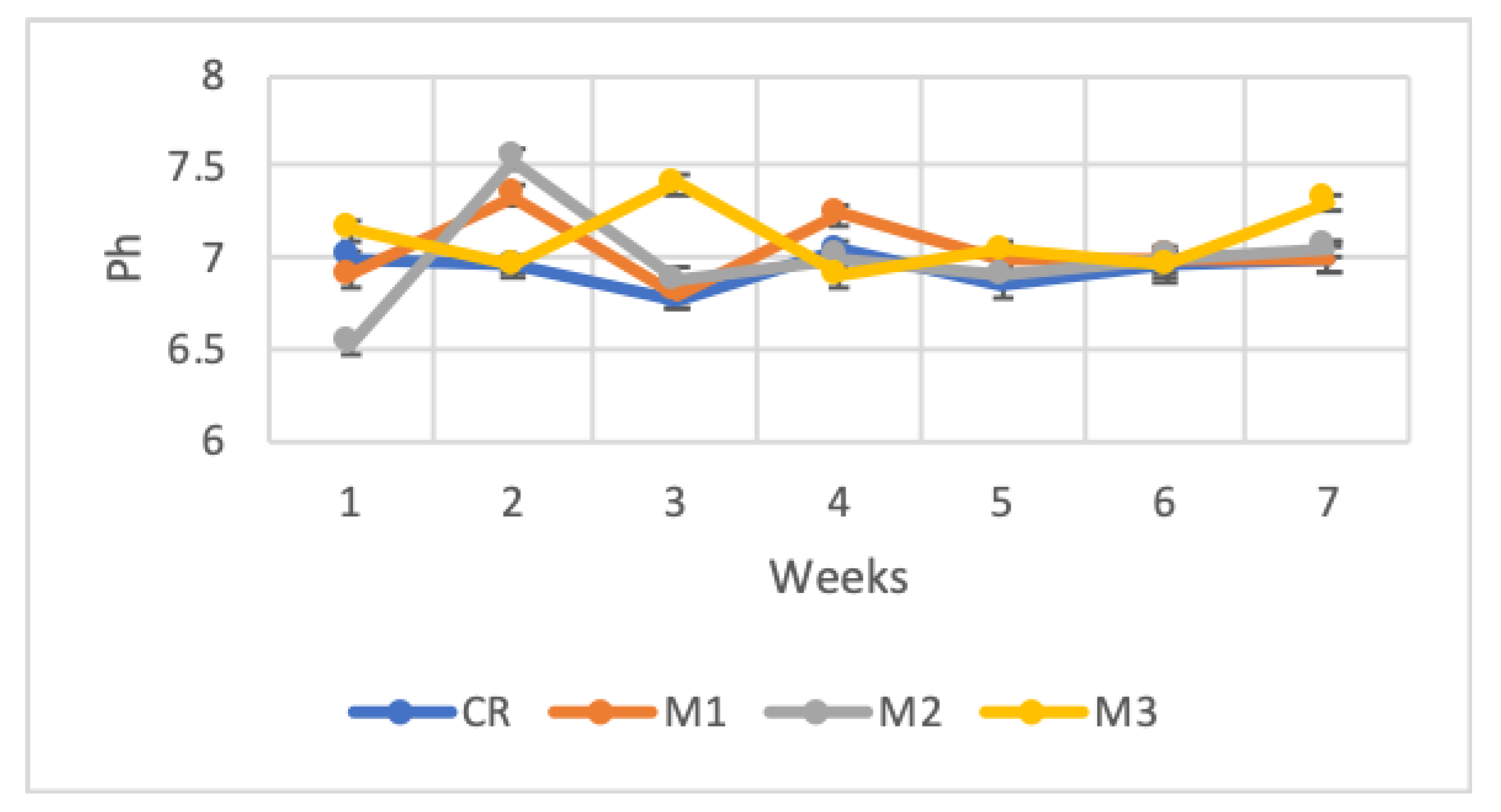

3.2.2. pH

3.2.3. Humidity

3.2.4. Organic Matter (OM), Total Organic Carbon (TOC), Total Nitrogen (TN) and Carbon/Nitrogen (C/N) Ratio

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rezzadori, K.; Benedetti, S.; Amante, E.R. Proposals for the residues recovery: Orange waste as raw material for new products. Food Bioprod. Process. 2012, 90, 606–614. [Google Scholar] [CrossRef]

- Shahbandeh, M. Orange juice production volume worldwide from 2014/2015 to 2018/2019 (in million metric tons). Food Nutr. 2019. Available online: https://www.statista.com/statistics/1044906/world-orange-juice-production/ (accessed on 15 June 2020).

- Caserta, R.; Teixeira, S.N.S.; Granato, L.M.; Dorta, S.O.; Rodrigues, C.M.; Mitre, L.K.; Yochikawa, J.T.H.; Fischer, E.R.; Nascimento, C.A.; Souza, N.R.R.; et al. Citrus biotechnology: What has been done to improve disease resistance in such an important crop? Biotechnol. Res. Innov. 2020, 54, 95–109. [Google Scholar] [CrossRef]

- USDA/FAS Foreign Agricultural Services. Citrus: World Markets and Trade 2019. Available online: https://apps.fas.usda.gov/psdonline/circulars/citrus.pdf (accessed on 18 June 2020).

- Negro, V.; Ruggeri, B.; Fino, D.; Tonini, D. Life cycle assessment of orange peel waste management. Resour. Conserv. Recycl. 2017, 127, 148–158. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Paone, E.; Komilis, D. Strategies for the sustainable management of orange peel waste through anaerobic digestion. J. Environ. Manag. 2018, 212, 462–468. [Google Scholar] [CrossRef] [PubMed]

- Lazcano, C.; Gómez-Brandón, M.; Domínguez, J. Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure. Chemosphere 2008, 72, 1013–1019. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, P.; Safique, S.; Jahan, A.; Bhagat, R.M. Effect of vermicomposting on treated hard stem leftover wastes from pruning of tea plantation: A novel approach. Ecol. Eng. 2016, 97, 410–417. [Google Scholar] [CrossRef]

- Castillo, B.E.; López, G.R.C. Planta de Lombricomposteo “Beneficio de Mejora de Suelo en Zona de Trabajo Ejidal”; Universidad Autónoma Metropolitana: Ciudad de México, Mexico, 2010; Available online: http://www.pa.gob.mx/publica/rev_46/an%C3%A1lisis/Erika_Castillo_Brise%C3%B1o.pdf (accessed on 27 August 2020).

- SCFI. Norma Mexicana NMX-FF-109-SCFI-2007.Vermicompost (Worm Casting)—Specifications and Test Methods; Secretaría de Comercio y Fomento Industrial, Diario Oficial de la Federación: Mexico City, Mexico, 2007; Available online: http://www.economia-nmx.gob.mx/normas/nmx/2007/nmx-ff-109-scfi-2008.pdf (accessed on 15 June 2020).

- US Composting Council. Compost. The Sustainable Solutions Soil Water Plants. 2013. Available online: https://www.compostfoundation.org/Portals/2/Images/Increasing%20the%20OM%20in%20Soil%207%2002%2014%20CURRENT.pdf (accessed on 27 August 2020).

- Jack, A.L.H.; Thies, J.E. Compost and Vermicompost as Amendments Promoting Soil Health. Biological Approaches to Sustainable Soil Systems; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- SEMARNAT. Residuos. Secretaría de Medio Ambiente y Recursos Naturales. Mexico, 2008. Available online: https://apps1.semarnat.gob.mx:8443/dgeia/informe_2008_ing/pdf/cap_7_residuos.pdf (accessed on 27 August 2020).

- Racines, C.A.V.D.R. Análisis de Reducción de Emisiones de Gases de Efecto Invernadero Mediante. Descomposición Aeróbica de Residuos Industriales en Mezcla con Residuos Pecuarios. Master’s Thesis, Universidad Andina Simón Bolívar, Bolivia, Ecuador, 2018. Available online: http://repositorio.uasb.edu.ec/handle/10644/6058 (accessed on 27 August 2020).

- Martínez-Blanco, J.; Muñoz, P.; Antón, A.; Rieradevall, J. Life cycle assessment of the use of compost from municipal organic waste for fertilization of tomato crops. Resour. Conserv. Recycl. 2009, 53, 340–351. [Google Scholar] [CrossRef]

- Favoretto, P.L.B.; Ademola, I.A.; Abosede, O.O.; Vinicius, B.A.; Olimpia, O.R.M. Chemical study of vermicomposted agroindustrial wastes. Int. J. Recycl. Org. Waste Agric. 2016, 5, 55–63. [Google Scholar]

- Lee, L.H.; Wu, T.Y.; Low, Z.X. Reuse of Powdered Eggshells in Vermicomposting of Acidic Waste; Monash University: Bandar Sunway, Malaysia, 2015; Available online: https://www.semanticscholar.org/paper/Reuse-of-powdered-eggshells-in-vermicomposting-of-Lee-Wu/5254fdc716e9032c87544028e33dfd8bc7a30146 (accessed on 27 August 2020).

- Hanc, A.; Vasak, F. Processing separated digestate by vermicomposting technology using earthworms of the genus Eisenia. Int. J. Environ. Sci. Technol. 2015, 12, 1183–1190. [Google Scholar] [CrossRef]

- Rogayan, D.V., Jr.; Tomboc, E.H.F.; Paje, A.V.; Lim, K.L.P.; Ararro, J.A.R.; Ocampo, J.G.; Gregorio, H.S. Vermiculture and Vermicomposting; Ramon Magsaysay Technological University: San Marcelino, Zambales, 2010; Available online: https://www.researchgate.net/publication/333892881_Vermiculture_and_Vermicomposting (accessed on 5 June 2020).

- Mikolic, C.; Ruffinelli, S.; Dardano, B.; Escudero, G.J.; Andreoni, I.; Gómez, A.; Basile, D. Manual de Vermicompostaje: Cómo Reciclar Nuestros Residuos Orgánicos; Departamento de Desarrollo Ambiental: Montevideo, Uruguay, 2018; Available online: https://montevideo.gub.uy/sites/default/files/biblioteca/imvermicompostajeinterior.pdf (accessed on 18 June 2020).

- Pattnaik, S.; Reddy, V. Nutrient Status of Vermicompost of Urban Green Waste Processed by Three Earthworm Species—Eisenia fetida, Eudrilus eugeniae, and Perionyx excavates. Appl. Environ. Soil Sci. 2010, 2010, 967526. [Google Scholar] [CrossRef]

- Castro, A.R.; Cova, L.J.; García, D.E.; Medina, M.G. Efecto de la cáscara de huevo en la producción de cápsulas de la lombriz roja (Eisenia andrei). Zootec. Trop. 2007, 25, 135–142. [Google Scholar]

- FAO. Manual de Compostaje del Agricultor: Experiencias en América Latina; Food and Agriculture Organization: Santiago, Chile, 2013; Available online: http://www.fao.org/3/a-i3388s.pdf (accessed on 18 June 2020).

- Nagavallemma, K.P.; Lacroix, S.; Vineela, C.; Sahrawat, K.L.; Padmaja, V.V.; Rao, B.M.; Wani, S.P. Vermicomposting: Recycling Wastes into Valuable Organic Fertilizer. Global Themeon Agrecosystems Report no. 8. Patancheru 502 324; International Crops Research Institute for the Semi-Arid Tropics: Andhra Pradesh, India, 2006; Volume 2, pp. 1–16. [Google Scholar]

- Hincke, M.T.; Nys, Y.; Gautron, J. The role of matrix proteins in eggshell formation. Jpn. Poult. Sci. Assoc. 2010, 47, 208–219. [Google Scholar] [CrossRef]

- Huang, K.; Li, F.; Wei, Y.; Fu, X.; Chen, X. Effects of inoculation with Phanerochaete chrysosporium at various time points on enzyme activities during agricultural waste composting. Bioresour. Technol. 2014, 101, 222–227. [Google Scholar]

- SEMARNAT. Norma Oficial Mexicana NOM-02-RECNAT-2000. Especificaciones de Fertilidad, Salinidad y Clasificación de Suelos. Estudios, Muestreo y Análisis; Secretaría de Medio Ambiente y Recursos Naturales, Diario Oficial de la Federación: Mexico City, Mexico, 2002. [Google Scholar]

- SCFI. Norma Mexicana NMX-F-066-S-1978. Determinación de Cenizas; Secretaría de Comercio y Fomento Industrial, Diario Oficial de la Federación: Mexico City, Mexico, 1978. [Google Scholar]

- SEDUE. Norma Mexicana NMX-AA-24-1984. Protección al Ambiente-Contaminación del Suelo-Residuos Sólidos Municipales-Determinación de Nitrógeno Total; Secretaría de Desarrollo Urbano y Ecología, Diario Oficial de la Federación: Mexico City, Mexico, 1992. [Google Scholar]

- Mahaly, M.; Senthilkumar, A.K.; Arumugam, S.; Kaliyaperumal, C.; Karupannan, N. Vermicomposting of distillery sludge waste with tea leaf residues. Sustain. Environ. Res. 2018, 1, 223–227. [Google Scholar] [CrossRef]

- Ros, M.; García, C.; Hernández, T. A full-scale study of treatment of pig slurry by composting: Kinetic changes in chemical and microbial properties. Waste Manag. 2006, 26, 1108–1118. [Google Scholar] [CrossRef]

- Sepúlveda, V.L.A.; Alvarado, T.J.A. Manual de Aprovechamiento de Residuos Orgánicos a Través de Sistemas de Compostaje y Lombricultura en el Valle de Aburrá, Medellín, Colombia 2013. Available online: http://www.earthgreen.com.co/descargas/manual-compostaje.pdf (accessed on 20 April 2020).

- Castillo-González, E.; Giraldi-Díaz, M.R.; De Medina-Salas, L.; Sánchez-Castillo, M.P. Pre-Composting and Vermicomposting of Pineapple (Ananas comosus) and Vegetable Waste. Appl. Sci. 2019, 9, 3564. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Thami, A.I. Composting parameters and compost quality: A literature review. Org. Agric. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- Yang, F.; Li, Y.; Han, Y.; Qian, W.; Li, G.; Luo, W. Performance of manure to control gaseous emissions in kitchen waste composting. Sci. Total Environ. 2019, 657, 262–269. [Google Scholar] [CrossRef]

- Swarnam, T.P.; Velmurugan, A.; Kumar, P.S.; Dam, R.S. Enhancing nutrient recovery and compost maturity of coconut husk by vermicomposting technology. Bioresour. Technol. 2016, 207, 76–84. [Google Scholar] [CrossRef]

- Hanc, A.; Chadimova, Z. Nutrient recovery from Apple pomace waste by vermicomposting technology. Bioresour. Technol. 2014, 168, 240–244. [Google Scholar] [CrossRef] [PubMed]

- Rékási, M.; Mazsu, M.; Draskovits, E.; Bernhardt, B.; Szabó, A.; Rivier, P.A.; Farkas, C.; Borsányi, B.; Pirkó, B.; Molnár, S.; et al. Comparing the agrochemical properties of compost and vermicomposts produced from municipal sewage sludge digestate. Bioresour. Technol. 2019, 291, 121861. [Google Scholar] [CrossRef] [PubMed]

- Hanc, A.; Pliva, P. Vermicomposting technology as a tool for nutrient recovery from kitchen bio-waste. J. Mater. Cycles Waste Manag. 2013, 15, 431–439. [Google Scholar] [CrossRef]

- Bhat, S.A.; Singh, J.; Vig, A.P. Potential utilization of bagasse as feed material for earthworm Eisenia fetida and production of vermicompost. SpringerPlus 2015, 4, 2–9. [Google Scholar] [CrossRef]

- Acosta, D.C.M.; Solís, P.O.; Villegas, T.O.G.; Cardoso, V.L. Precomposteo de residuos orgánicos y su efecto en la dinámica poblacional de Eisenia foetida. Agron. Costarric. 2013, 37, 127–139. [Google Scholar]

- Li, W.; Ahmad, S.B.; Li, J.; Cui, G.; Wei, Y.; Yamada, T.; Li, F. Effect of excess activated sludge on vermicomposting of fruit and vegetable waste by using novel vermireactor. Bioresour. Technol. 2020, 302, 122816. [Google Scholar] [CrossRef]

- Nair, J.; Sekiozoic, V.; Anda, M. Effect of pre-composting on vermicomposting of kitchen waste. Bioresour. Technol. 2006, 97, 2091–2095. [Google Scholar] [CrossRef]

- Taeporamaysamai, O.; Ratanatamskul, C. Co-composting of various organic substrates from municipal solid waste using an on-site prototype vermicomposting reactor. Int. Biodeterior. Biodegrad. 2016, 113, 357–366. [Google Scholar] [CrossRef]

- Li, G.; Zhu, Q.; Jiang, Z.; Li, M.; Ma, C.; Li, X.; Liu, H.; Liu, Y.; Li, Q. Roles of non-ionic surfactant sucrose ester on the conversion of organic matters and bacterial community structure during composting. Bioresour. Technol. 2020, 308, 123279. [Google Scholar] [CrossRef]

- Ameen, A.; Ahmad, J.; Raza, S. Determination of total organic matter of mature compost prepared by using municipal solid waste. Int. J. Sci. Res. Publ. 2016, 6, 293–295. [Google Scholar]

- Gelsomino, A.; Abenavoli, M.R.; Princi, G.; Anttina, E.; Cacco, G.; Sorgoná, A. Compost from Fresh Orange Waste: A Suitable Substrate for Nursery and Field Crops? Compos. Sci. Util. 2010, 18, 201–210. [Google Scholar] [CrossRef]

- Oviedo, O.E.R.; Domínguez, I.; Komilis, D.; Sánchez, A. Co-composting of Green Waste Mixed with Unprocessed and Processed Food Waste: Influence on the Composting Process and Product Quality. Waste Biomass Valor 2019, 10, 63–74. [Google Scholar] [CrossRef]

- Kucbel, M.; Raclavská, H.; Růžičková, J.; Švédová, B.; Sassmanová, V.; Drozdová, J.; Raclavský, K.; Juchelková, D. Properties of composts from household food waste produced inautomatic composters. J. Environ. Manag. 2019, 236, 657–666. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S.M.; Richard, T.L.; Honeyman, M.S. Carbon, nutrient, and mass loss during composting. Nutr. Cycl. Agroecosystems 2002, 62, 15–24. [Google Scholar] [CrossRef]

- Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Fruit peel waste: Characterization and its potential uses. Curr. Sci. 2017, 113, 1–11. [Google Scholar] [CrossRef]

- Ren, L.; Cai, C.; Zhang, J.; Yang, Y.; Wu, G.; Luo, L.; Huang, H.; Zhou, Y.; Qin, P.; Yuc, M. Key environmental factors to variation of ammonia-oxidizing archaea community and potential ammonia oxidation rate during agricultural waste composting. Bioresour. Technol. 2018, 270, 278–285. [Google Scholar] [CrossRef]

- Kumar, M.; Liang, O.Y.; Gaw, L.J. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.Y.; Tin, L.C.; Phun, C.B.C.; Shiun, L.J.; Roji, S.M.; Jaromír, K.J. A review on the impacts of compost on soil nitrogen dynamics. Chem. Eng. Trans. 2018, 63, 349–354. [Google Scholar]

- Lima, J.Z.; Raimondia, I.S.; Schalchb, V.; Rodriguesa, V.G.S. Assessment of the use of organic composts derived from municipal solid waste for the adsorption of Pb, Zn; Cd. J. Environ. Manag. 2018, 226, 386–399. [Google Scholar] [CrossRef]

- Neugebauera, M.; Sołowieja, P.; Piechockia, P.; Czekałab, W.; Janczak, D. The influence of the C: N ratio on the composting rate. Int. J. Smart Grid Clean Energy 2017, 2, 54–60. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Zhang, Y.; Huang, K. Quality of vermicompost and Microbial Community Diversity Affected by the Contrasting Temperature during Vermicomposting of Dewateres Sludge. Int. J. Environ. Res. Public Health 2020, 17, 1748. [Google Scholar] [CrossRef]

- Indrani, R.Y.; Adil, A.A.; Ori, L. Vermicomposting of different organic materials using the epigeic earthworm Eisenia foetida. Int. J. Recycl. Org. Waste Agric. 2018, 1, 23–36. [Google Scholar]

- Stewart, W.S.S. Efficacy of organic amendments used in containerized plant production: Part 1—Compost-based amendments. Sci. Hortic. 2020, 266, 108856. [Google Scholar] [CrossRef]

- Lleó, T.; Albacete, E.; Barrena, R.; Font, X.; Artola, A.; Sánchez, A. Home and vermicomposting as sustainable options for biowaste management. J. Clean. Prod. 2013, 47, 70–76. [Google Scholar] [CrossRef]

- Alparslan, A.Y.; Karacali, U.C.A.; Kilinc, N. Composting as a Waste Management Method. Int. Environ. Appl. Sci. 2017, 12, 244–255. [Google Scholar]

- Luo, W.; Ji, Y.; Qu, L.; Dang, Z.; Xie, Y.; Yang, C.; Tao, X.; Zhou, J.; Lu, G. Effects of eggshell addition on calcium-deficient acid soils contaminated with heavy metals. Front. Environ. Sci. Eng. 2018, 12, 4. [Google Scholar] [CrossRef]

- Sudharsan, V.V.; Kalamdhad, A.S. Efficiency of Rotary Drum Composting for Stabilizing Vegetable Waste during Pre-Composting and Vermicomposting. Environ. Process. 2016, 3, 829–841. [Google Scholar]

- Domínguez, J.; Martínez, C.H.; Álvarez, C.M.; Lores, M. Vermicomposting grape marc yields high quality organic biofertiliser and bioactive polyphenols. Waste Manag. Res. 2014, 32, 1235–1240. [Google Scholar] [CrossRef]

- Yadav, A.; Gard, V.K. Industrial wastes and sludges management by vermicomposting. Rev. Environ. Sci. Bio/Technol. 2011, 10, 243–276. [Google Scholar] [CrossRef]

- Devi, C.; Khwairakpam, M. Bioconversion of Lantana camara by vermicomposting with two different earthworm species in monoculture. Bioresour. Technol. 2020, 296, 122308. [Google Scholar] [CrossRef]

- Ansari, A.; Hanief, A. Microbial degradation of organic waste through vermicomposting. Int. J. Sustain. Agric. Res. 2015, 2, 45–54. [Google Scholar] [CrossRef]

- Che., J.; Lin, W.; Liao, H.; Yu, Z.; Lin, H.; Zhou, S. Insights into compositional changes of dissolved organic matter during a full-scale vermicomposting of cow dung by combined spectroscopic and electrochemical techniques. Bioresour. Technol. 2020, 301, 122757. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Gupta, R.K.; Kumar, S. Variation in organic carbon content and carbon nitrogen ratio in vermicompost as affected by substrate Straw. Forage Res. 2017, 43, 46–49. [Google Scholar]

- Nahrul, H.Z.; Abdul, K.H.P.S.; Jawaid, M.; Hakimi, I.M.; Astimar, A.A. Exploring chemical analysis of vermicompost of various oil palm fibre waste. Enviromentalist 2010, 30, 273–278. [Google Scholar] [CrossRef]

- Lakshmi, P.M.; Nagalakshmi, N.; Shanmuga, P.M. Analysis of nutrient contents in vermicompost. Eur. J. Mol. Biol. Biochem. 2015, 2, 42–48. [Google Scholar]

- Othman, N.; Irwan, J.M.; Roslan, M.A. Vermicomposting of food waste. Int. J. Integr. Eng. 2012, 4, 39–48. [Google Scholar]

- Akbar, B.A.; Goudarzi, G.; Neisi, A.; Ebrahimi, Z.; Alavi, N. Vermicomposting of cow dung, kitchen waste and sewage sludge with bagasse using Eisenia fetida. J. Adv. Environ. Health Res. 2016, 4, 88–94. [Google Scholar]

- Ravindran, B.; Mnkeni, P.N.S. Bio-optimization of the carbon-to-nitrogen ratio for efficient vermicomposting of chicken manure and wastepaper using Eisenia fetida. Environ. Sci. Pollut. Res. 2016, 23, 16965–16976. [Google Scholar] [CrossRef] [PubMed]

- USDA. Carbon to Nitrogen Ratios in Cropping Systems. United States Department of Agriculture. Natural Resources Conservation Service. 2011. Available online: https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcseprd331820.pdf (accessed on 27 August 2020).

| Physicochemical Parameters | Test |

|---|---|

| pH | Potentiometer |

| Temperature | Environmental thermometer |

| Humidity | Gravimetric method |

| Organic matter | By calcination |

| Total organic carbon | From the percentage of organic matter, using the Van Bemmelen factor |

| Total nitrogen | Kjendahl method |

| Parameters | CR | M1 | M2 | M3 |

|---|---|---|---|---|

| OM (%) | 76.97 ± 1.20 a | 76.97 ± 1.20 a | 73.93 ± 1.22 b | 72.88 ± 1.16 b |

| TOC (%) | 44.65 ± 0.71 a | 44.65 ± 0.71 a | 42.89 ± 0.91 b | 42.28 ± 0.67 b |

| TN (%) | 2.12 ± 0.04 a | 2.12 ± 0.04 a | 1.20 ± 0.02 b | 1.60 ± 0.03 c |

| C/N Ratio | 24.93 | 24.93 | 38.20 | 26.16 |

| Parameters | CR | M1 | M2 | M3 |

|---|---|---|---|---|

| OM (%) | 63.79 ± 0.78 a | 64 ± 1.14 a | 65.80 ± 0.69 a | 64.88 ± 0.86 a |

| TOC (%) | 37 ± 0.64 a | 37.13 ± 0.71 a | 38.17 ± 0.53 a | 37.64 ± 0.79 a |

| TN (%) | 3.50 ± 0.08 a | 4.50 ± 0.10 b | 6.30 ± 0.13 c | 3.78 ± 0.09 d |

| C/N Ratio | 11.74 | 8.80 | 6.05 | 9.95 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Medina-Salas, L.; Giraldi-Díaz, M.R.; Castillo-González, E.; Morales-Mendoza, L.E. Valorization of Orange Peel Waste Using Precomposting and Vermicomposting Processes. Sustainability 2020, 12, 7626. https://doi.org/10.3390/su12187626

De Medina-Salas L, Giraldi-Díaz MR, Castillo-González E, Morales-Mendoza LE. Valorization of Orange Peel Waste Using Precomposting and Vermicomposting Processes. Sustainability. 2020; 12(18):7626. https://doi.org/10.3390/su12187626

Chicago/Turabian StyleDe Medina-Salas, Lorena, Mario Rafael Giraldi-Díaz, Eduardo Castillo-González, and Laura Elena Morales-Mendoza. 2020. "Valorization of Orange Peel Waste Using Precomposting and Vermicomposting Processes" Sustainability 12, no. 18: 7626. https://doi.org/10.3390/su12187626

APA StyleDe Medina-Salas, L., Giraldi-Díaz, M. R., Castillo-González, E., & Morales-Mendoza, L. E. (2020). Valorization of Orange Peel Waste Using Precomposting and Vermicomposting Processes. Sustainability, 12(18), 7626. https://doi.org/10.3390/su12187626