Quick Wins Workshop and Companies Profiling to Analyze Industrial Symbiosis Potential. Valenciaport’s Cluster as Case Study

Abstract

1. Introduction

2. Materials and Methods

- Information gathering about resource exchange possibilities among Valenciaport companies.

- Resource analysis and classification into categories.

- Identification of IS possibilities of Valenciaport with other industrial ecosystems.

- Identification of IS possibilities within the Valenciaport community.

- Classification of companies into groups, according to their IS potential.

- Definition of IS projects to be nurtured and developed further.

2.1. Information Gathering about Resource Exchange Possibilities among Valenciaport Companies

2.2. Resources Analysis and Classification into Categories

2.3. Identification of IS Possibilities of Valenciaport with Other Industrial Ecosystems

2.4. Description of Identified Matchings between Valenciaport Companies

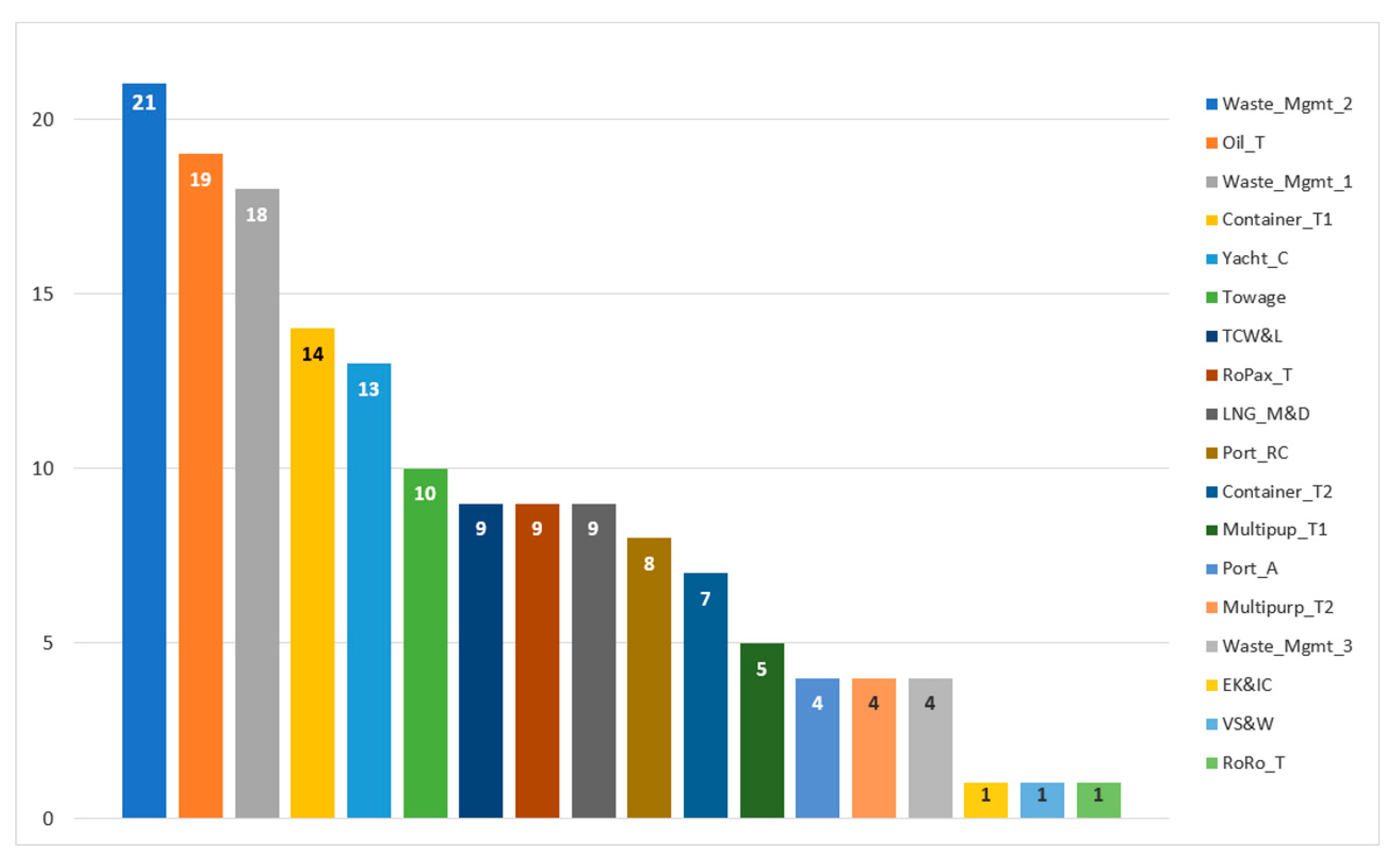

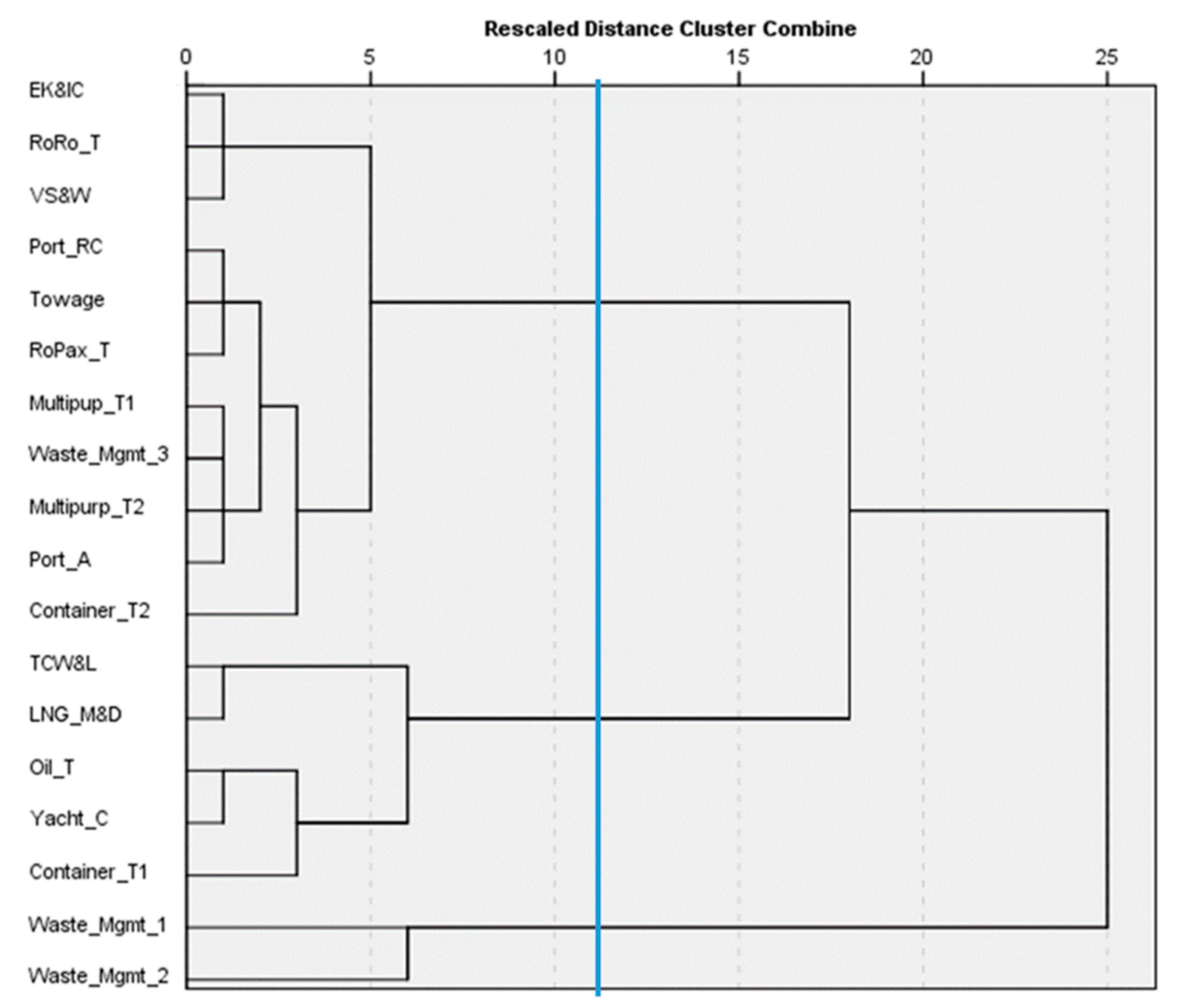

2.5. Classification of Valenciaport Companies into Groups According to their IS Potential

- Number of “haves”: sum of the total resources offered by each company.

- Number of “wants”: sum of the total resources requested by each company.

- Number of different categories of resources offered by each company.

- Number of different categories of resources requested by each company.

- Number of matchings as supplier: number of synergies in which the company acts as a supplier.

- Number of matchings as seeker: number of synergies in which the company acts as a seeker.

2.6. Definition of IS Projects to Be Nurtured and Developed Further

3. Results

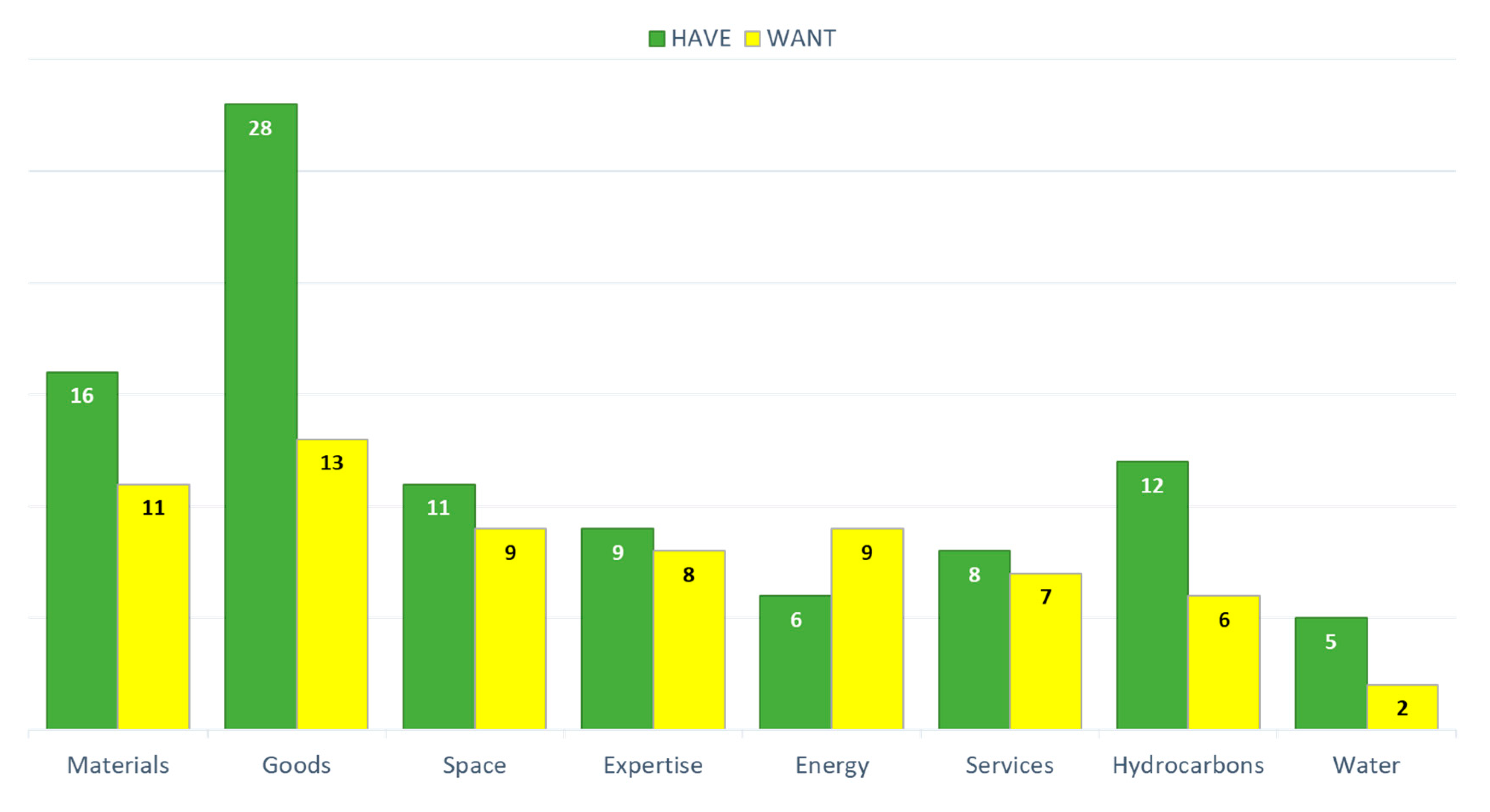

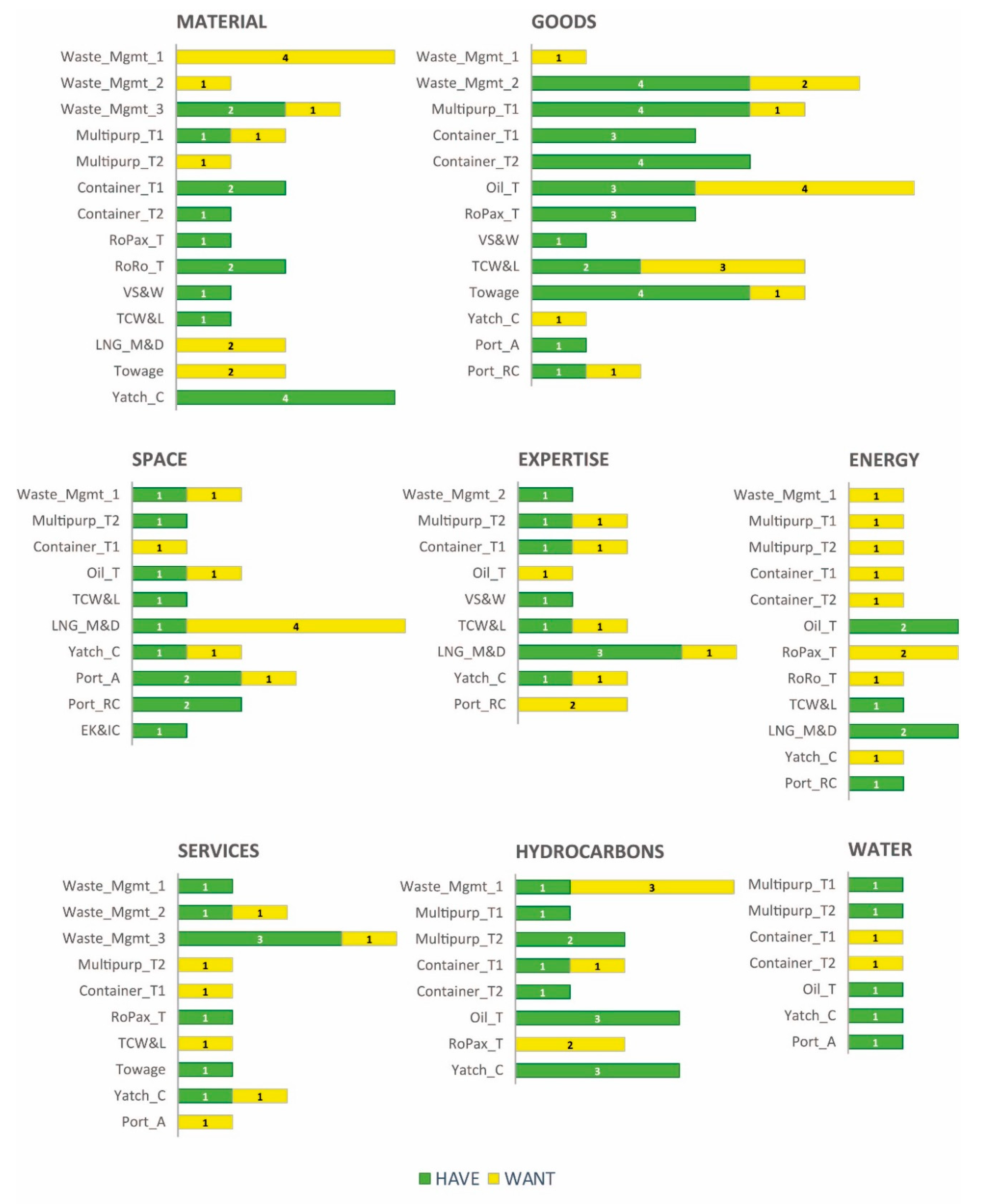

3.1. Resources Analysis and Classification into Categories

3.2. Identification of IS Possibilities of Valenciaport with Other Industrial Ecosystemns

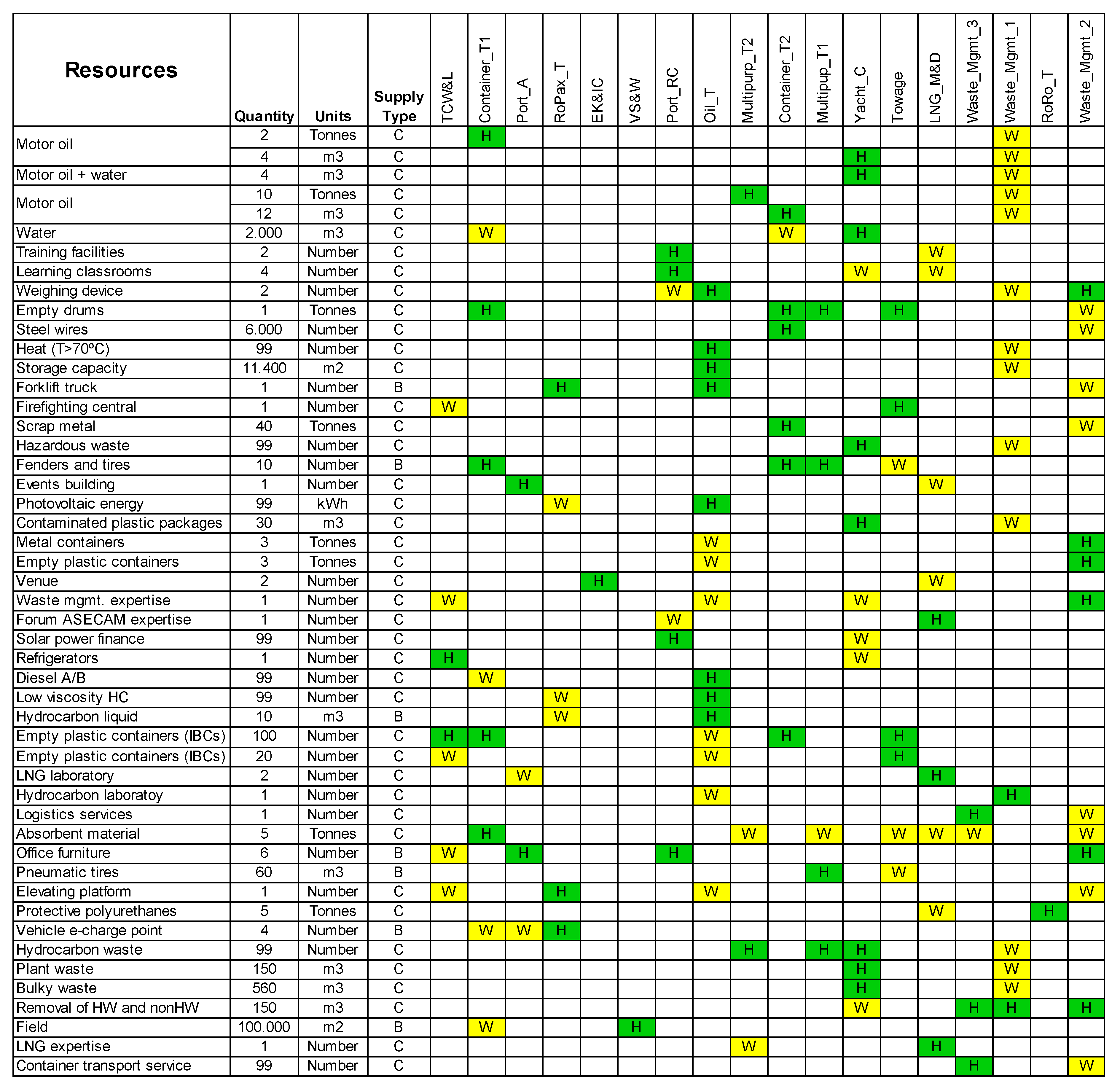

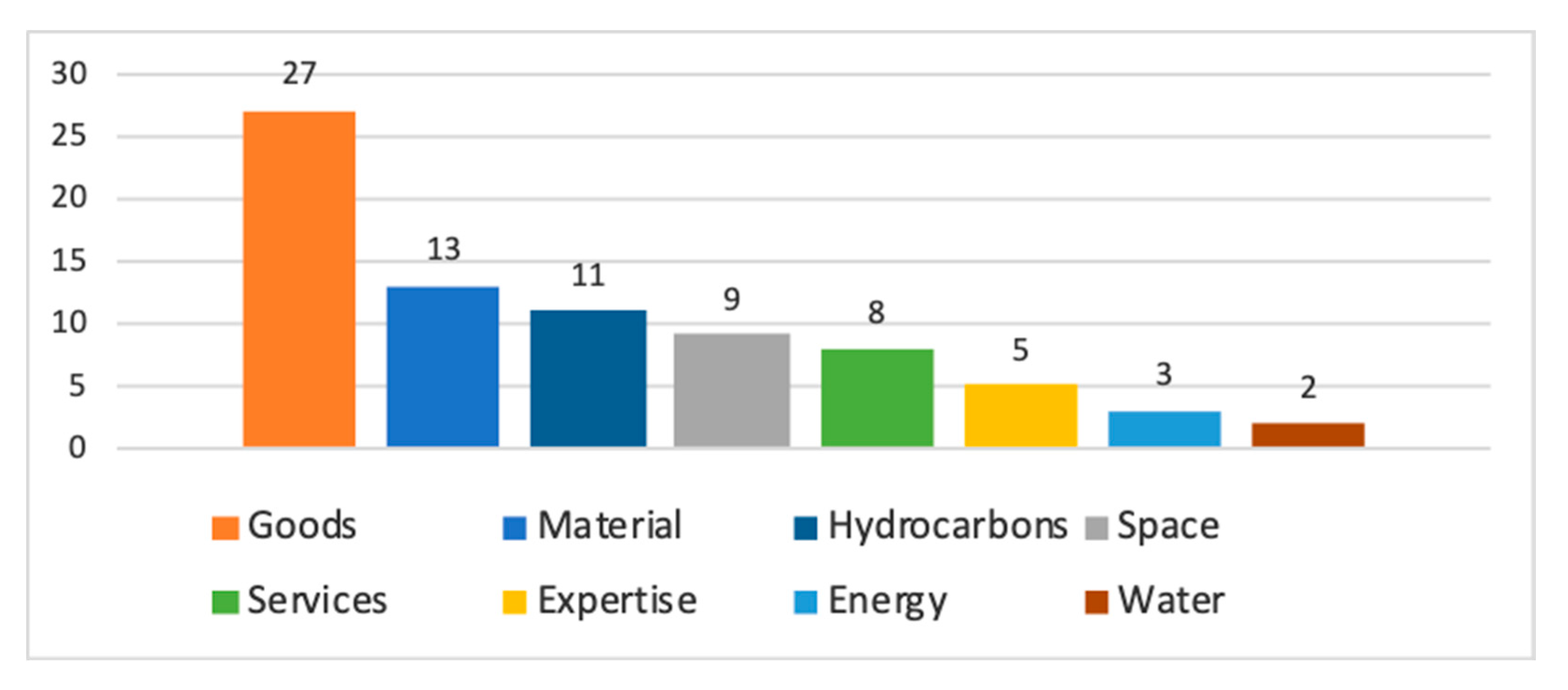

3.3. Description of Identified Matchings between Valenciaport Companies

3.4. Classification of Valenciaport Companies into Groups According to Their IS Potential

3.5. Definition of IS Projects to Be Nurtured and Developed Further

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Albino, V.; Fraccascia, L.; Savino, T. Industrial Symbiosis for a Sustainable City: Technical, Economical and Organizational Issue. Procedia Eng. 2015, 118, 950–957. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energ. Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Z.; Chen, T. Analysis on the theory and practice of industrial symbiosis based on bibliometrics and social network analysis. J. Clean. Prod. 2019, 213, 956–967. [Google Scholar] [CrossRef]

- Lee, D. Turning waste into by-product. Manuf. Serv. Oper. Manag. 2012, 14, 115–127. [Google Scholar] [CrossRef]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for promoting industrial symbiosis: A systematic review. J. Ind. Ecol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef]

- Yuan, Z.; Shi, L. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. J. Clean. Prod. 2009, 17, 1295. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Chertow, M.R. “Uncovering” industrial symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef]

- Chertow, M.R. The eco-industrial park model reconsidered. J. Ind. Ecol. 1999, 2, 8–10. [Google Scholar] [CrossRef]

- Baas, L.W.; Boons, F.A. An industrial ecology project in practice: Exploring the boundaries of decision-making levels in regional industrial systems. J. Clean. Prod. 2004, 12, 1073–1085. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Implementing industrial ecology? Planning for eco-industrial parks in the USA. Geoforum 2004, 36, 429–439. [Google Scholar] [CrossRef]

- Korhonen, J.; Snaikin, J.P. Analyzing the evolution of industrial ecosystems: Concepts and application. Ecol. Econ. 2005, 52, 169–186. [Google Scholar] [CrossRef]

- Tudor, T.; Adam, E.; Bates, M. Drivers and limitations for the successful development and functioning of EIPs (eco-industrial parks): A literature review. Ecol. Econ. 2007, 61, 199–207. [Google Scholar] [CrossRef]

- Velenturf, A.P.M. Promoting industrial symbiosis: Empirical observations of low-carbon innovations in the Humber region, UK. J. Clean. Prod. 2016, 128, 116–130. [Google Scholar] [CrossRef]

- Chertow, M.R.; Ehrenfeld, J. Organizing self-organizing systems: Toward a theory of industrial symbiosis. J. Ind. Ecol. 2012, 16, 13–27. [Google Scholar] [CrossRef]

- Symbiosis Institute. 2019. Available online: http://www.symbiosis.dk/.fgde (accessed on 5 February 2020).

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; Technical Report; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Cervo, H.; Ferrasse, J.H.; Descales, B.; van Eetvelde, G. Blueprint: A methodology facilitating data exchanges to enhance the detection of industrial symbiosis opportunities—Application to a refinery. Chem. Eng. Sci. 2020, 211, 115254. [Google Scholar] [CrossRef]

- European Union. Study and Portfolio Review of the Projects on Industrial Symbiosis in DG Research and Innovation: Findings and Recommendations; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Miteco Ministry. España Circular 2030. Estrategia Española de Economía Circular. 2020. Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/temas/economia-circular/espanacircular2030_def1_tcm30-509532.PDF (accessed on 4 June 2020).

- Kotowska, I. Policies applied by seaport authorities to create sustainable development in port cities. Transp. Res. Proc. 2016, 16, 236–243. [Google Scholar] [CrossRef]

- Cerceau, J.; Mat, N.; Junqua, G.; Lin, L.; Laforest, V.; Gonzalez, C. Implementing industrial ecology in port cities: International overview of case studies and cross-case analysis. J. Clean. Prod. 2014, 74, 1–16. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L. Management Innovation for Environmental Sustainability in Seaports: Managerial Accounting Instruments and Training for Competitive Green Ports beyond the Regulations. Sustainability 2018, 10, 783. [Google Scholar] [CrossRef]

- Gravagnuolo, A.; Angrisano, M.; Girard, L.F. Circular Economy Strategies in Eight Historic Port Cities: Criteria and Indicators towards a Circular City Assessment Framework. Sustainability 2019, 11, 3512. [Google Scholar] [CrossRef]

- Karimpour, R.; Ballini, F.; Ölcer, A.I. Circular economy approach to facilitate the transition of the port cities into self-sustainable energy ports—A case study in Copenhagen-Malmö Port (CMP). WMU J. Marit. Aff. 2019, 18, 225–247. [Google Scholar] [CrossRef]

- Williams, J. The Circular Regeneration of a Seaport. Sustainability 2019, 11, 3424. [Google Scholar] [CrossRef]

- Review of Maritime Transport 2019. United Nations Conference on Trade and Development Website. Available online: https://unctad.org/en/PublicationsLibrary/rmt2019_en.pdf (accessed on 11 March 2020).

- Zhang, Q.; Geerlings, H.; El Makhloufi, A.; Chen, S. Who governs and what is governed in port governance: A review study. Transp. Policy 2018, 64, 51–60. [Google Scholar] [CrossRef]

- Acciaro, M.; Ghiara, H.; Cusano, M.I. Energy management in seaports: A new role for port authorities. Energy Policy 2014, 71, 4–12. [Google Scholar] [CrossRef]

- Acciaro, M. Corporate responsibility and value creation in the port sector. Int. J. Logist. Res. Appl. 2015, 18, 291–311. [Google Scholar] [CrossRef]

- Acciaro, M.; Vanelslander, T.; Sys, C.; Ferrari, C.; Roumboutsos, A.; Giuliano, G.; Lam, J.S.L.; Kapros, S. Environmental sustainability in seaports: A framework for successful innovation. Marit. Policy Manag. 2014, 41, 480–500. [Google Scholar] [CrossRef]

- Grant, G.B.; Seager, T.P.; Massard, G.; Nies, L. Information and communication technology for industrial symbiosis. J. Ind. Ecol. 2010, 14, 740–753. [Google Scholar] [CrossRef]

- van Capelleveen, G.; Amrit, C.; Yazan, D.M. A literature survey of information systems facilitating industrial symbiosis. In From Science to Society; Otjacques, B., Hitzelberger, P., Naumann, F., Wohlgemuth, V., Eds.; Springer: Cham, Switzerland, 2018; pp. 155–169. [Google Scholar]

- The Materials Marketplace. Available online: http://materialsmarketplace.org/ (accessed on 24 August 2020).

- Online Waste Exchange for Businesses and Organizations in Singapore. Available online: http://www.zerowastesg.com/ (accessed on 23 August 2020).

- Zero Waste Scotland. Available online: http://cme.resourceefficientscotland.com/materials (accessed on 21 August 2020).

- Cecelja, F.; Raafat, T.; Trokanas, N.; Innes, S.; Smith, M.; Yang, A.; Zorgios, Y.; Korkofygas, A.; Kokossis, A. E-symbiosis: Technology-enabled support for industrial symbiosis targeting small and medium enterprises and innovation. J. Clean. Prod. 2015, 98, 336–352. [Google Scholar] [CrossRef]

- Low, J.S.C.; Tjandra, T.B.; Yunus, F.; Chung, S.Y.; Tan, D.Z.L.; Raabe, B.; Ting, N.Y.; Yeo, Z.; Bressan, S.; Ramakrishna, S.; et al. A collaboration platform for enabling industrial symbiosis: Application of the database engine for waste-to-resource matching. Procedia CIRP 2018, 69, 849–854. [Google Scholar] [CrossRef]

- Brown, J.; Gross, D.; Wiggs, L. The MatchMaker! system: Creating virtual eco-industrial parks. Yale F&ES Bull. 2002, 106, 103–136. [Google Scholar]

- Laybourn, P. Industrial symbiosis and circular economy: Best practices from the UK National Industrial Symbiosis Programme (NISP). In Proceedings of the ResourceFULL Use Workshop, Portland, OR, USA, 17 August 2017. [Google Scholar]

- Kastner, C.A.; Lau, R.R.; Kraft, M.M. Quantitative tools for cultivating symbiosis in industrial parks: A literature review. Appl. Energy 2015, 155, 599–612. [Google Scholar] [CrossRef]

- Evans, D.S.; Schmalensee, R. Failure to launch: Critical mass in platform businesses. Rev. Netw. Econ. 2010, 9, 1–26. [Google Scholar] [CrossRef]

- Ayres, R. Toward Zero Emissions: Is There a Feasible Path; INSEAD working paper, 1997, # 97/80/EPS; INSEAD: Fontainebleau, France, 1997. [Google Scholar]

- Baas, L. Developing an industrial ecosystem in Rotterdam: Learning by what? J. Ind. Ecol. 2000, 4, 4–6. [Google Scholar] [CrossRef]

- Park, H.S.; Won, J.Y. Ulsan Eco-industrial Park, challenges and opportunities. J. Ind. Ecol. 2007, 11, 11–13. [Google Scholar] [CrossRef]

- Boehme, S.E.; Panero, M.A.; Munoz, G.R.; Powers, C.W.; Valle, S.N. Collaborative problem solving using an industrial ecology approach. The New York/New Jersey Harbor economy-wide substance flow case studies. J. Ind. Ecol. 2009, 13, 811–829. [Google Scholar] [CrossRef]

- Girard, L.F.; Di Palma, M. La simbiosi come strumento di rigenerazione urbana nelle città portuali. BDC Bollettino Del Centro Calza Bini 2016, 16, 239–250. [Google Scholar] [CrossRef]

- De Vita, G.E.; Gravagnuolo, A.; Ragozino, S. Circular models for the city’s complexity. Urban. Inf. INU 2018, 278, 10–14. [Google Scholar]

- Mat, N.; Cerceau, J.; Shi, L.; Park, H.S.; Junqua, G.; Lopez-Ferber, M. Socio-ecological transitions toward low-carbon port cities: Trends, changes and adaptation processes in Asia and Europe. J. Clean. Prod. 2016, 114, 362–375. [Google Scholar] [CrossRef]

- Schlüter, L.; Mortensen, L.; Kørnøv, L. Industrial symbiosis emergence and network development through reproduction. J. Clean. Prod. 2020, 252, 119631. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical factors for industrial symbiosis emergence process. J. Clean. Prod. 2020, 212, 56–69. [Google Scholar] [CrossRef]

- Laybourn, P.; Morrissey, M. National Industrial Symbiosis Programme: The Pathway to a Low Carbon Sustainable Economy International Synergies; National Industrial Symbiosis Programme: Birmingham, UK, 2009. [Google Scholar]

- Van Eetvelde, G. Industrial symbiosis. In Resource Efficiency of Processing Plants: Monitoring and Improvement, 1st ed.; Krämer, S., Engell, S., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 441–469. [Google Scholar]

- Lombardi, D.R.; Laybourn, P. Redefining industrial symbiosis. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- Punj, G.; Stewart, D.G. Cluster Analysis in Marketing Research: Review and Suggestions for Application. J. Mark. Res. 1983, 20, 134–148. [Google Scholar] [CrossRef]

- Wilks, D.S. Statistical Methods in the Atmospheric Sciences, 3rd ed.; Academic press: San Diego, CA, USA, 2011. [Google Scholar]

- Kaufman, L.; Rousseeuw, P.J. Finding Groups in Data: An. Introduction to Cluster Analysis; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Albino, V.; Fraccascia, L.; Giannoccaro, I. Exploring the role of contracts to support the emergence of self-organized industrial symbiosis networks: An agent-based simulation study. J. Clean. Prod. 2016, 112, 4353–4366. [Google Scholar] [CrossRef]

- Chopra, S.S.; Khanna, V. Understanding resilience in industrial symbiosis networks: Insights from network analysis. J. Environ. Manag. 2014, 141, 86–94. [Google Scholar] [CrossRef]

- Paquin, R.L.; Howard-Grenville, J. The evolution of facilitated industrial symbiosis. J. Ind. Ecol. 2012, 16, 83–93. [Google Scholar] [CrossRef]

- Paquin, R.L.; Howard-Grenville, J. Blind dates and arranged marriages: Longitudinal processes of network orchestration. Organ. Stud. 2013, 34, 1623–1653. [Google Scholar] [CrossRef]

- Jensen, P.D. The role of geospatial industrial diversity in the facilitation of regional industrial symbiosis. Resour. Conserv. Recycl. 2016, 107, 92–103. [Google Scholar] [CrossRef]

- Domenech, T.; Davies, M. Structure and morphology of industrial symbiosis networks: The case of Kalundborg. Procedia Soc. Behav. Sci. 2011, 10, 79–89. [Google Scholar] [CrossRef]

- Ducruet, C. Typologie Mondiale des Relations Ville-Port. Cybergeo 417. 2008. Available online: http://cybergeo.revues.org/17332 (accessed on 14 March 2020).

- van Klink, H.A. The port network as a new stage in port development: The case of Rotterdam. Environ. Plan. A 1998, 30, 143–160. [Google Scholar] [CrossRef]

- De Langen, P.W. Chapter 20-stakeholders, conflicting interests and governance in port clusters. Res. Transp. Econ. 2006, 17, 457–477. [Google Scholar] [CrossRef]

- Boons, F.; Baas, L. Types of IE: The problem of coordination. J. Clean. Prod. 1997, 5, 79–86. [Google Scholar] [CrossRef]

- Brullot, S. Mise en Oeuvre de Projets Territoriaux D’écologie Industrielle en France: Vers un Outil Méthodologique D’aide à la Decisión. Ph.D. Thesis, Université de Technologie de Troyes, Troyes, France, 2009. [Google Scholar]

- Mileva-Boshkoska, B.; Rončević, B.; Uršič, E.D. Modeling and Evaluation of the Possibilities of Forming a Regional Industrial Symbiosis Networks. Soc. Sci. 2018, 7, 13. [Google Scholar] [CrossRef]

- Boletin Oficial del Estado. Available online: https://www.boe.es/eli/es/rdlg/2011/09/05/2 (accessed on 1 April 2020).

- Cloquell-Ballester, V.A.; Lo-Iacono-Ferreira, V.G.; Artacho-Ramírez, M.A.; Capuz-Rizo, S.F. RUE Index as a Tool to Improve the Energy Intensity of Container Terminals—Case Study at Port of Valencia. Energies 2020, 13, 2556. [Google Scholar] [CrossRef]

- Boons, F.; Howard-Grenville, J. The Social Embeddedness of Industrial Ecology; Edward Elgar Publishing: Northampton, MA, USA, 2009. [Google Scholar]

- Baas, L.W.; Huisingh, D. The synergistic role of embeddedness and capabilities in industrial symbiosis: Illustration based upon 12 years of experiences in the Rotterdam harbour and Industry complex. Prog. Ind. Ecol. Int. J. 2008, 5, 399–421. [Google Scholar] [CrossRef]

- European Spatial Planning Observation Network (ESPON). CIRCTER—Circular Economy and Territorial Consequences. Draft Synthesis Report; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 amending Directive 2008/98/EC on Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32018L0851 (accessed on 12 March 2020).

- Costa, I.; Massard, G.; Agarwal, A. Waste management policies for industrial symbiosis development: Case studies in European countries. J. Clean. Prod. 2010, 18, 815–822. [Google Scholar] [CrossRef]

- Jiao, W.; Boons, F. Toward a research agenda for policy intervention and facilitation to enhance industrial symbiosis based on a comprehensive literature review. J. Clean. Prod. 2014, 67, 14–25. [Google Scholar] [CrossRef]

- Deutz, P.; Ioppolo, G. From theory to practice: Enhancing the potential policy impact of industrial ecology. Sustainability 2015, 7, 2259–2273. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Efficacy of landfill tax and subsidy policies for the emergence of industrial symbiosis networks: An agent-based simulation study. Sustainability 2017, 9, 521. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Clean. Prod. 2011, 19, 1865–1875. [Google Scholar] [CrossRef]

| Stakeholder’s Activity | ID | Number of Stakeholders |

|---|---|---|

| Waste Management | Waste_Mgmt. | 3 |

| Multipurpose Port Terminal | Multipurp_T | 2 |

| Container Terminal | Container_T | 2 |

| Oil Terminal | Oil_T | 1 |

| RoPax Terminal | RoPax_T | 1 |

| RoRo Terminal | RoRo_T | 1 |

| Vessels Stowage & Warehousing | VS&W | 1 |

| Temperature-controlled Warehouse and Logistic | TCW&L | 1 |

| LNG Management & Distribution | LNG_M&D | 1 |

| Towage | Towage | 1 |

| Yacht Club | Yacht_C | 1 |

| Port Authority | Port_A | 1 |

| Port Research Centre | Port_RC | 1 |

| Environmental Knowledge and Innovation Community | EK&IC | 1 |

| Total number of Stakeholders: | 18 | |

| Materials | Goods | Space | Expertise | Energy | Services | Hydrocarbon | Water |

|---|---|---|---|---|---|---|---|

| Absorbent material | Forklift truck | Offices for rent | Installations | Residual heat | Vehicle e-charge point | Motor oil | Collected rainwater |

| Broken ceramic material | Tractor unit | Events building | Energy certification | Photovoltaic energy | Training | Hydrocarbon liquid | Water from air conditioners |

| Paper waste | Elevating Platform | Conference room | Stowage | Kinetic energy | Leisure facilities | Motor oil + water | Sanitary sewage |

| Stowage remaining wood | Weighing device | Venue | Mgmt. system | Electricity | Logistics | Fuel sludge | Water |

| Scrap metal | Refrigerators | Field | Forum ASECAM | Renewable energy | Firefighting central | Diesel A/B | |

| Plant waste | Used floating barrier | Training facilities | Energy mgmt. | Alternative energy source | Gas station | Low viscosity HC | |

| Bulky waste | Steel wires | Learning classrooms | LNG expertise | Solar power finance | Removal of HW and non-HW | Hydrocarbon waste | |

| Organic/solid waste | Towropes | Storage capacity | Waste mgmt. | Heat (T > 70 °C) | Container transport | ||

| Contaminated wraps | Office furniture | Recording space | Waste legislation | Cold energy | |||

| Protective polyurethanes | Fenders and tires | LNG laboratory | Water expertise | ||||

| Protective tablecloths | 208L containers | Hydrocarbon laboratory | Business mgmt. | ||||

| Contaminated plastic packaging | Empty plastic containers (IBC) | ||||||

| Plastic waste | Empty drums | ||||||

| Hazardous waste | |||||||

| Electronic waste | |||||||

| Used pneumatic tires |

| Requested Resources without Inner Offer | Offered Resources without Inner Demand | |

|---|---|---|

| Electricity | Installation expert | Recording space |

| Renewable energy | Offices for rent | Training services |

| Alternative energy sources | Plastic waste | Leisure facilities |

| Gas station | Energy certification experts | 208 L containers |

| Waste legislation experts | Broken ceramic material | Towropes |

| Water purification expert | Conference room | Kinetic energy |

| Business management expertise | Tractor unit | Residual heat |

| Paper waste | Energy management expertise | |

| Ship loading expertise | Cold energy | |

| Field | Organic/Solid waste | |

| Rainwater collection | Contaminated wraps | |

| Used floating barrier | Fuel sludge | |

| Sanitary sewage | Protective tablecloths | |

| Management systems experts | Electronic waste | |

| Variables | Cluster | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Num. of Haves | 5 | 7 | 3.7 |

| Num. of Wants | 8.5 | 4.7 | 1.7 |

| Matchings as Supplier | 5.5 | 5.7 | 2.8 |

| Matchings as Seeker | 14 | 5.4 | 1.1 |

| Haves Typologies | 3 | 3 | 2.7 |

| Wants Typologies | 3.5 | 3.1 | 1.8 |

| Cluster | Number of Cases | Cluster Membership |

|---|---|---|

| 1 | 2 | Waste_Mgmt_1 |

| Waste_Mgmt_2 | ||

| 2 | 7 | TCW & L |

| Container_T1 | ||

| RoPax_T | ||

| Oil_T | ||

| Yacht_C | ||

| Towage | ||

| LNG_M & D | ||

| 3 | 9 | Multipurp_1 |

| Multipurp_2 | ||

| RoRo_T | ||

| Container_T2 | ||

| Waste_Mgmt_3 | ||

| VS & W | ||

| Port_A | ||

| Port_RC | ||

| EK & IC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Artacho-Ramírez, M.A.; Pacheco-Blanco, B.; Cloquell-Ballester, V.A.; Vicent, M.; Celades, I. Quick Wins Workshop and Companies Profiling to Analyze Industrial Symbiosis Potential. Valenciaport’s Cluster as Case Study. Sustainability 2020, 12, 7495. https://doi.org/10.3390/su12187495

Artacho-Ramírez MA, Pacheco-Blanco B, Cloquell-Ballester VA, Vicent M, Celades I. Quick Wins Workshop and Companies Profiling to Analyze Industrial Symbiosis Potential. Valenciaport’s Cluster as Case Study. Sustainability. 2020; 12(18):7495. https://doi.org/10.3390/su12187495

Chicago/Turabian StyleArtacho-Ramírez, Miguel A., Bélgica Pacheco-Blanco, Víctor A. Cloquell-Ballester, Mónica Vicent, and Irina Celades. 2020. "Quick Wins Workshop and Companies Profiling to Analyze Industrial Symbiosis Potential. Valenciaport’s Cluster as Case Study" Sustainability 12, no. 18: 7495. https://doi.org/10.3390/su12187495

APA StyleArtacho-Ramírez, M. A., Pacheco-Blanco, B., Cloquell-Ballester, V. A., Vicent, M., & Celades, I. (2020). Quick Wins Workshop and Companies Profiling to Analyze Industrial Symbiosis Potential. Valenciaport’s Cluster as Case Study. Sustainability, 12(18), 7495. https://doi.org/10.3390/su12187495