Optimization of Remanufacturing Disassembly Line Balance Considering Multiple Failures and Material Hazards

Abstract

1. Introduction

2. Literature Review

2.1. Disassembly Line Balancing Problem

2.2. NSGA-II

2.3. Study Motivation

3. Multi-constraint Remanufacturing Disassembly Line Balancing Model

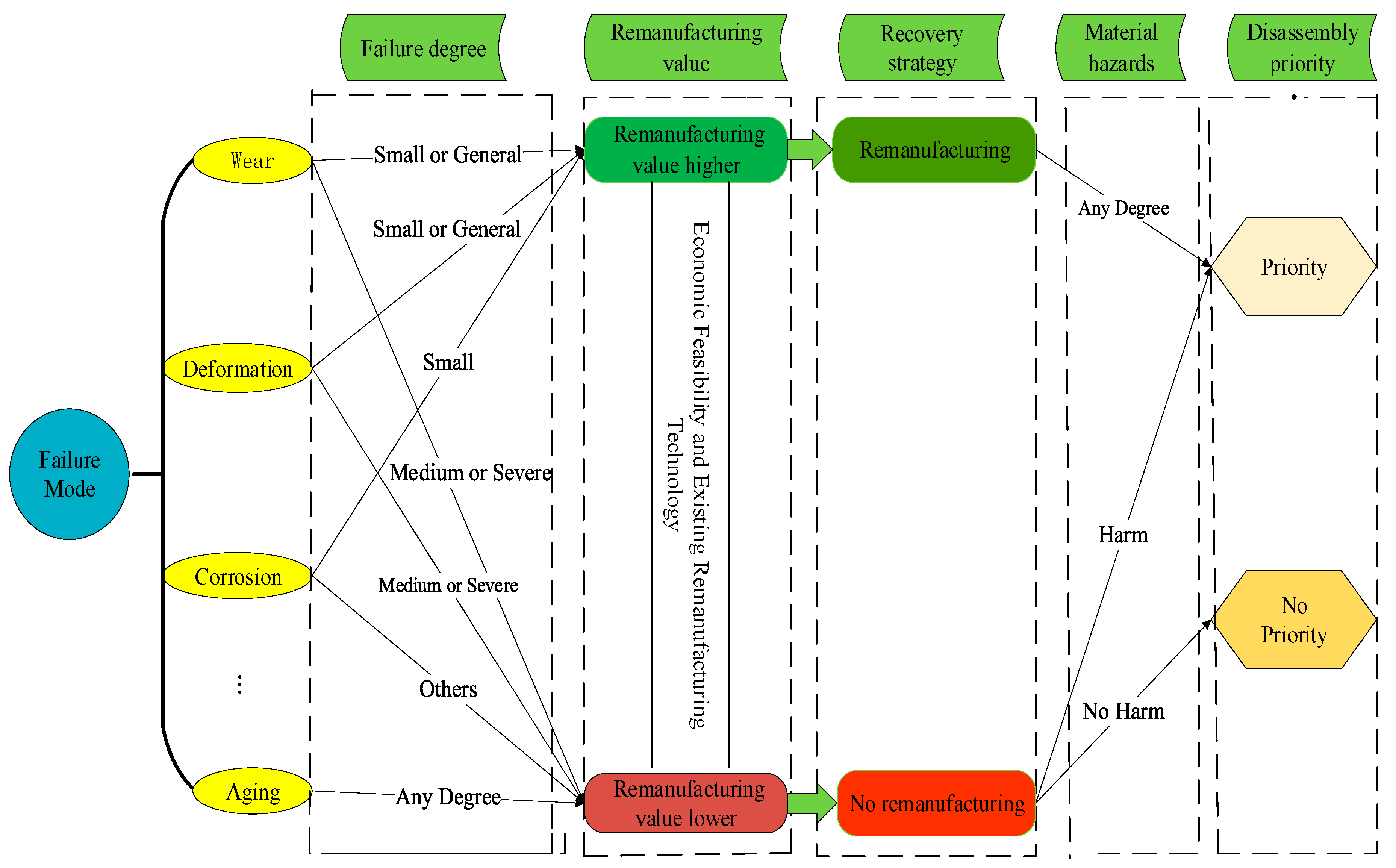

3.1. Remanufacturing Disassembly Priority Decision Based on Multiple Failures

3.2. Remanufacturing Disassembly Priority Decision Based on Material Hazards

3.3. Remanufacturing Disassembly Priority Decision

- (1)

- Failure Mode Matrix C1where .

- (2)

- Failure Degree Matrix C2where

- (3)

- Economic Feasibility Matrix C3where .

- (4)

- Hazard matrix C4where .

3.4. Construction of Multi-Constraint Remanufacturing Disassembly Line Balance Mathematical Model

- (1)

- Objective functions

- (2)

- Constraint conditions

4. Optimization of Multi-Constraint Remanufacturing Disassembly Line Balance (MC-RDLB) Based on ENSGA-II

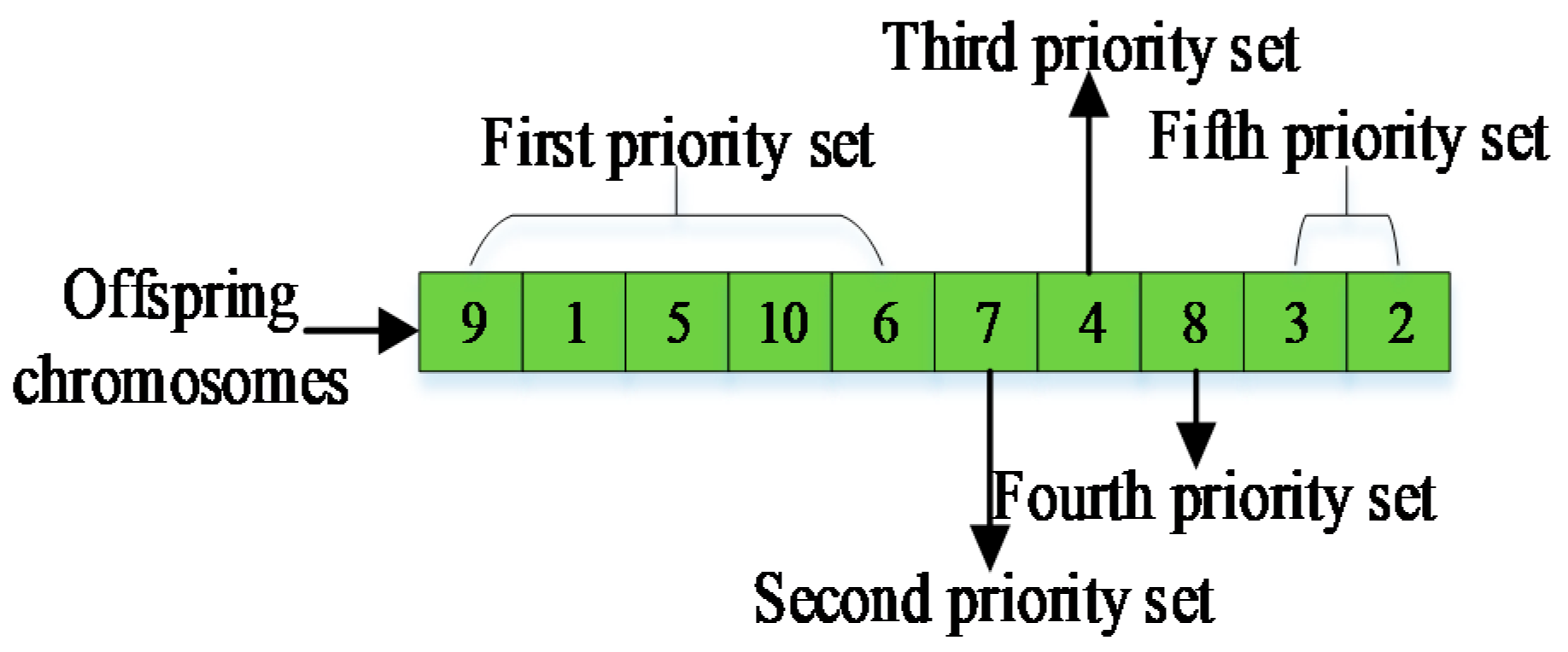

4.1. Chromosome Encoding and Decoding

- Step 1. Set the cycle time CT, number of disassembled parts m, disassembly time of the ith task , set I = 1 and N = 1.

- Step 2. Assign the ith disassembly task of feasible sequences to the Nth disassembly workstation and calculate the remaining disassembly time of workstation RT = CT − ti. Let i = i + 1.

- Step 3. If i ≤ m, go to Step 4; otherwise, go to Step 5.

- Step 4. If ti ≤ RT, go to Step 2; otherwise, N++.

- Step 5. Output workstation number N.

- Step 1. Assign a disassembly task to the workstation and record the remaining time of the workstation.

- Step 2. Compare the remaining times of all the workstations for each task sequence. If the remaining time of the previous task is less than that of the next task, record it as the remaining time of the current workstation.

- Step 3. Calculate the workstation equilibrium rate using Equation (9).

4.2. Acquisition of Initial Population Considering Failure and Hazard Constraints

- Step 1. According to the disassembly process plan of EOL products, construct the disassembly task priority matrix A and determine the novel multi-constraint matrix B using Equations (5)–(7). The comprehensive priority matrix S can then be derived. Define the initial population matrix as Q, which is the set of feasible disassembly sequences considering the failure and material hazards, and the disassembly task matrix Gm×m.

- Step 2. Let i = 1 and judge whether the matrix S is a zero matrix. If so, go to Step 3. If not, according to Equation (16), put the disassembling part into the disassembly task matrix Gm×m and update the matrix S.

- Step 3. Take out the ith row in G and randomly generate pop gene fragments, then store them in Q. Update the ith row in G at the same time and let i = i + 1.

- Step 4. Judge whether G is a zero matrix. If so, output Q; otherwise, go to Step 3.

4.3. Rules of Chromosome Evolution

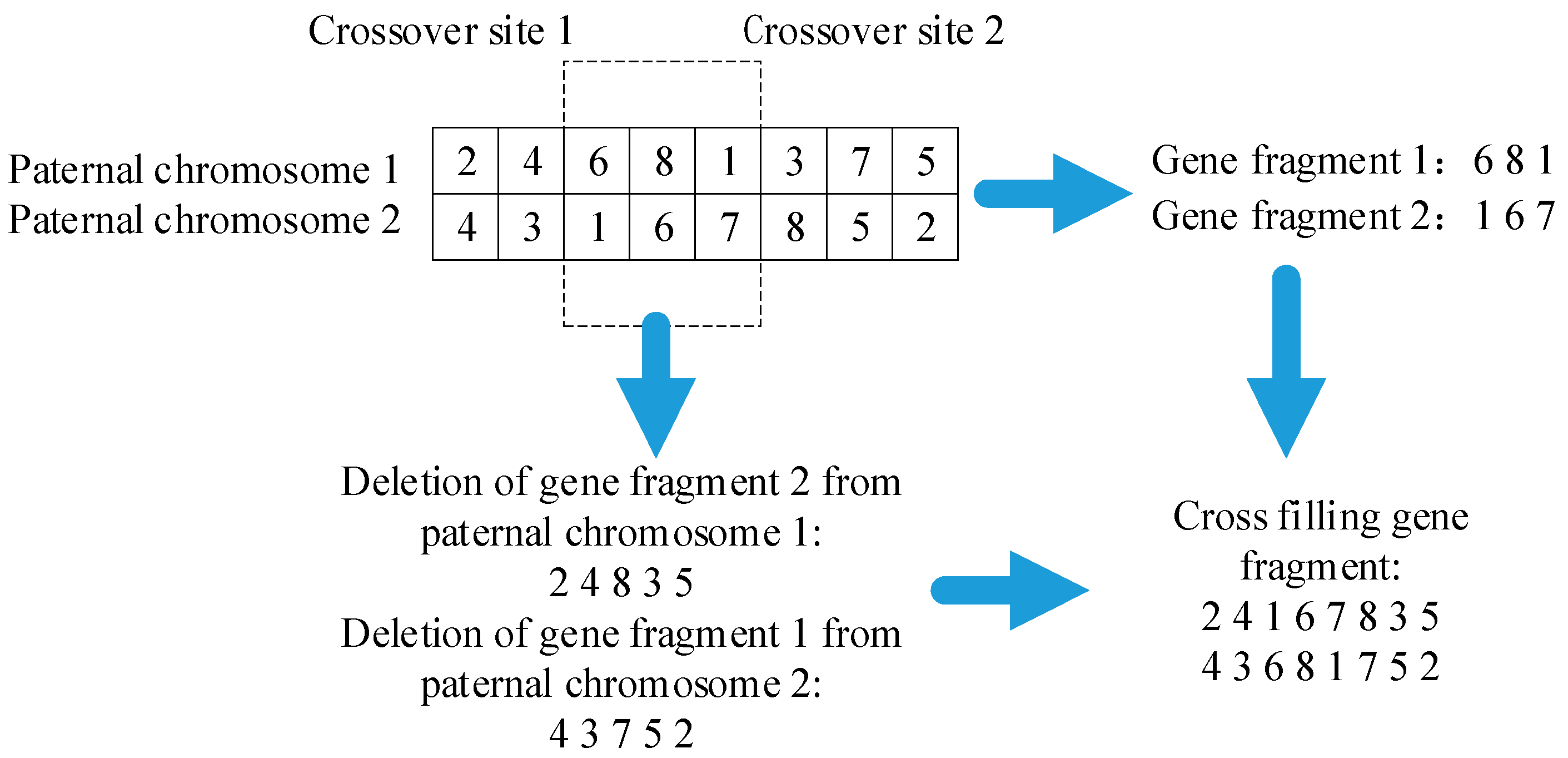

4.3.1. Crossover Operators

4.3.2. Chromosome Screening Mechanism

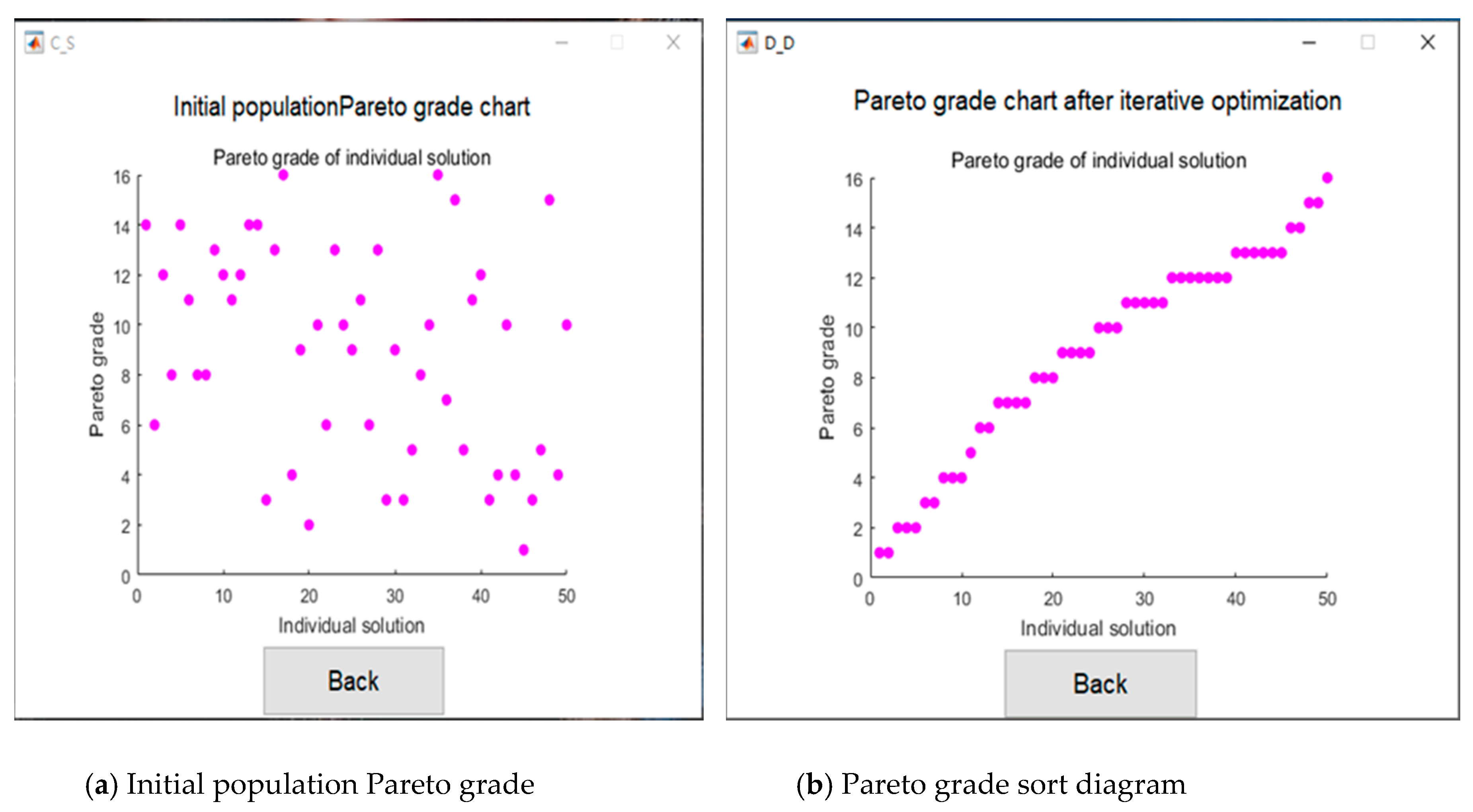

4.4. Evaluation of Non-Dominant Solution Based on Pareto Grade

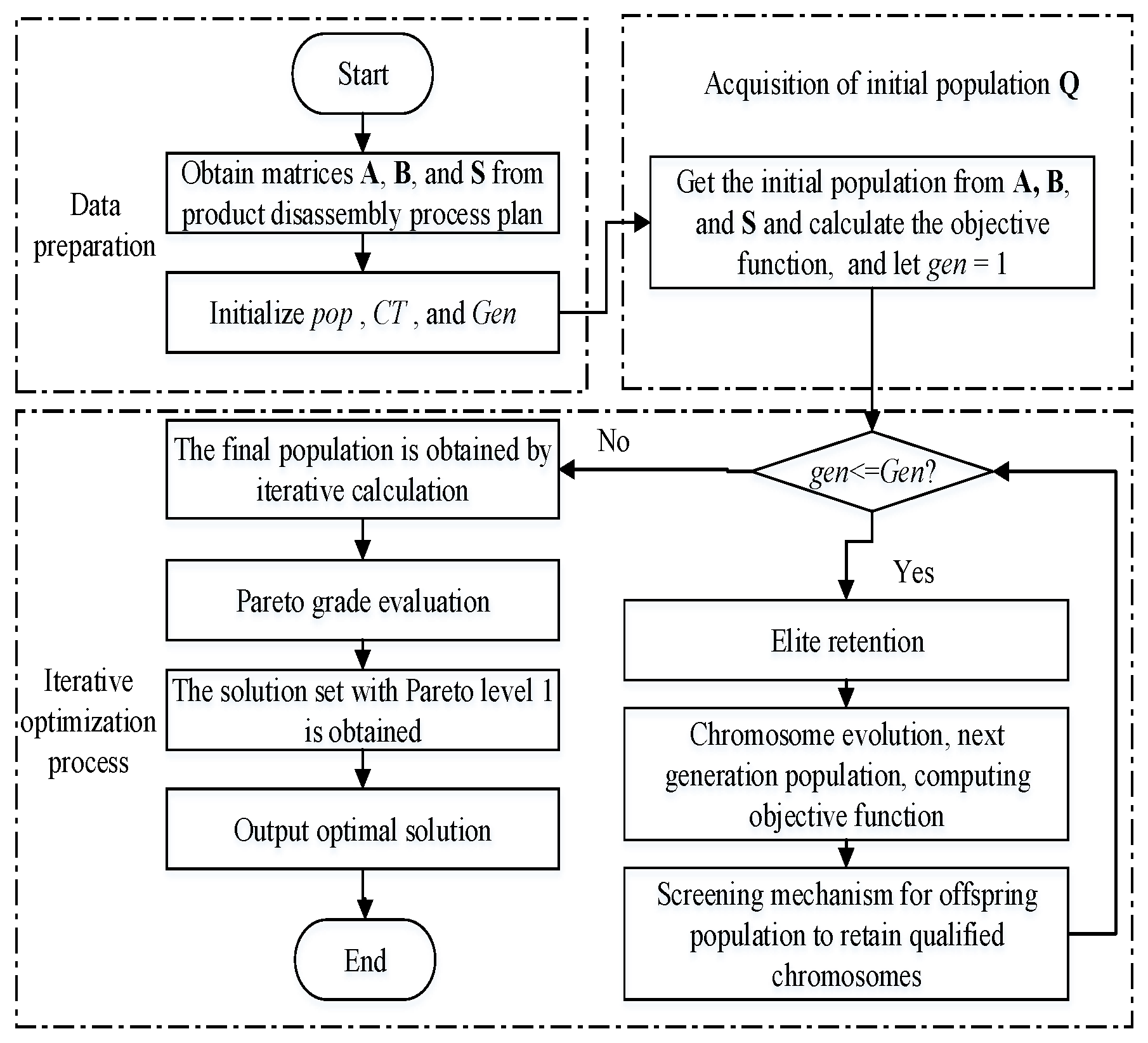

4.5. Solution Process of Remanufacturing Disassembly Line Balance Problem

- (1) Data preparation. The matrices A and B are constructed by analyzing the disassembly process scheme of the EOL product, and the comprehensive priority relation matrix S is derived. Initialize pop, CT, and Gen.

- (2) Acquisition of initial population Q.

- (3) Iterative optimization process. The initial population chromosomes are screened to obtain the non-dominant solutions using Equation (16). The optimal solution is obtained through evolution and iterative optimization.

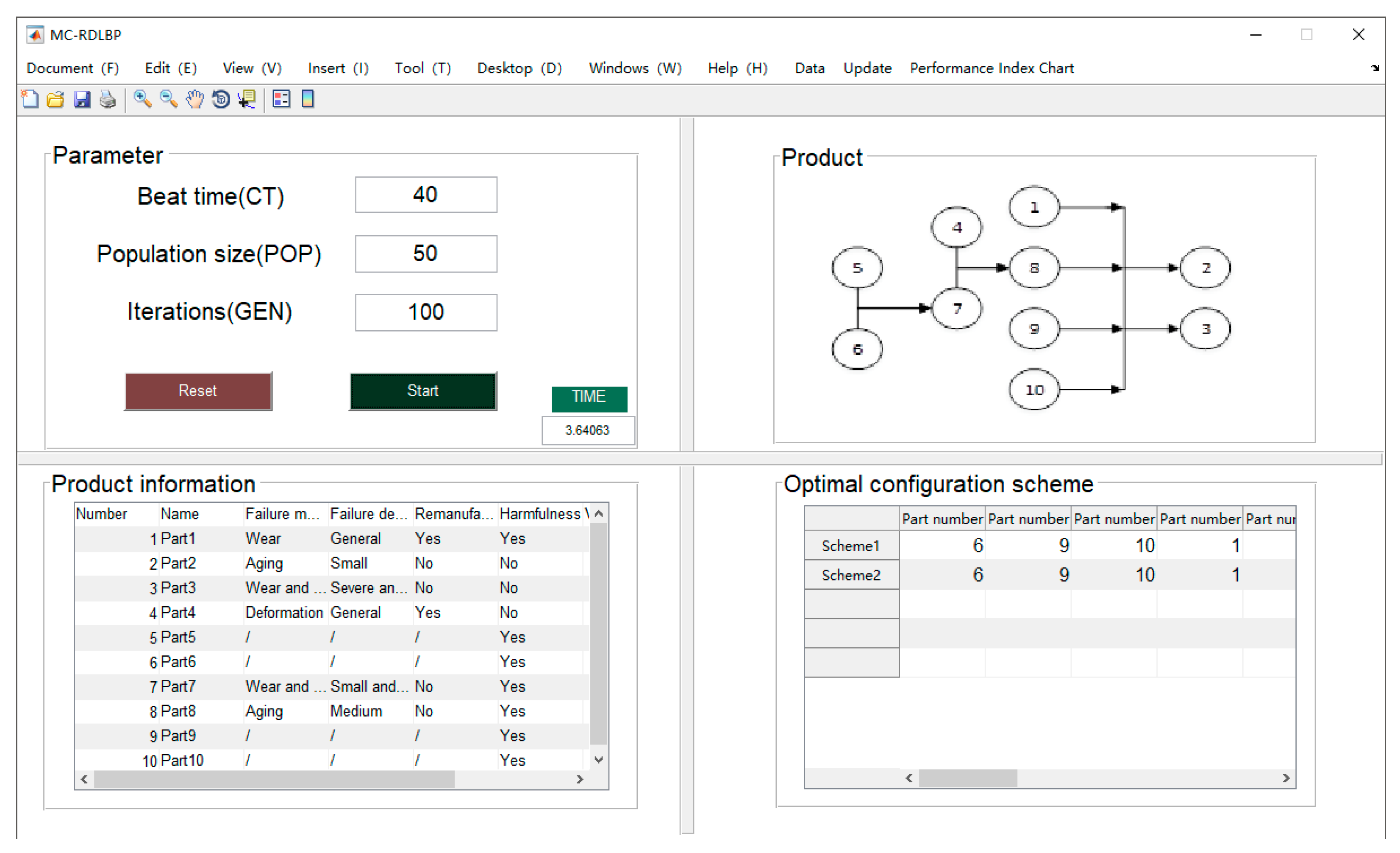

5. Case Study

5.1. Verification

5.2. Algorithm Performance Analysis

- (1)

- The complexity is for the construction of the initial population Q.

- (2)

- The Pareto grade evaluation strategy requires the classification of S Pareto grades for pop chromosomes based on the non-dominant relationship, and the complexity is

- (3)

- The complexity is to preserve the elitist solution, and we must screen Q chromosomes for pop/2 cross variants.

6. Conclusions

- (1)

- The multi-constraint remanufacturing disassembly line balance model (MC-RDLBM) takes into account constraints such as the assembly relationship of used mechanical and electrical products, multiple failure modes, failure degree, and material hazards, which is more in line with the engineering practice.

- (2)

- An initial population acquisition method considering multiple failure and material hazard constraints was proposed. The convergence speed of the algorithm was improved. The chromosome evolution rule was improved, which combined the Pareto dominance and crowding distance constraints to realize the autonomous evolution of chromosomes and expand the search scope simultaneously.

- (3)

- In this paper, 10 disassembly tasks from the literature [35] were selected to verify the proposed algorithm, and two optimal configuration schemes for the remanufacturing disassembly line were obtained. The results indicated that the ENSGA-II algorithm had significant advantages in terms of the solution speed, the remanufacturing value index, and the workstation balance rate.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deniz, N.; Ozcelik, F. An extended review on disassembly line balancing with bibliometric & social network and future study realization analysis. J. Clean. Prod. 2019, 225, 697–715. [Google Scholar]

- Kazancoglu, Y.; Ozturkoglu, Y. Integrated framework of disassembly line balancing with green and business objectives using a mixed MCDM. J. Clean. Prod. 2018, 191, 179–191. [Google Scholar] [CrossRef]

- Özceylan, E.; Kalayci, C.B.; Güngör, A.; Gupta, S.M. Disassembly line balancing problem: A review of the state of the art and future directions. Int. J. Prod. Res. 2018, 57, 4805–4827. [Google Scholar]

- Duta, L.; Caciula, I.; Patic, P.C. Column generation approach for disassembly line balancing. IFAC Pap. Online 2016, 49, 916–920. [Google Scholar] [CrossRef]

- Mete, S.; Çil, Z.A.; Celik, E.; Ozceylan, E. Supply-driven rebalancing of disassembly lines: A novel mathematical model approach. J. Clean. Prod. 2019, 213, 1157–1164. [Google Scholar] [CrossRef]

- Fang, Y.; Ming, H.; Li, M.; Liu, Q.; Pham, D.T. Multi-objective evolutionary simulated annealing optimisation for mixed-model multi-robotic disassembly line balancing with interval processing time. Int. J. Prod. Res. 2019, 1, 1–17. [Google Scholar] [CrossRef]

- Avikal, S.; Jain, R.; Mishra, P.K. A Kano model, AHP and M-TOPSIS method-based technique for disassembly line balancing under fuzzy environment. Appl. Soft Comput. 2014, 25, 519–529. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, C.; Zhao, F.; Tian, G.; Lin, W.; Meng, L.; Li, H. Disassembly line balancing problem using interdependent weights-based multi-criteria decision making and 2-Optimal algorithm. J. Clean. Prod. 2018, 174, 1475–1486. [Google Scholar] [CrossRef]

- Tuncel, E.; Zeid, A.; Kamarthl, S. Solving large scale disassembly line balancing problem with uncertainty using reinforcement learning. J. Intell. Manuf. 2014, 25, 647–659. [Google Scholar] [CrossRef]

- Xia, X.; Liu, W.; Zhang, Z.; Wang, L.; Cao, J.; Liu, X. A balancing method of nixed-model disassembly line in random working environment. Sustainability 2019, 11, 2304. [Google Scholar] [CrossRef]

- Mete, S.; Çil, Z.A.; Ağpak, K.; Özceylan, E.; Dolgui, A. A solution approach based on beam search algorithm for disassembly line balancing problem. J. Manuf. Syst. 2016, 41, 188–200. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Q.; Feng, Y.; Zheng, H.; Zheng, B.; Tan, J. An energy-saving optimization method of dynamic scheduling for disassembly line. Energies 2018, 11, 1261. [Google Scholar] [CrossRef]

- Li, Z.; Çil, Z.A.; Mete, S.; Kucukkoc, I. A fast branch, bound and remember algorithm for disassembly line balancing problem. Int. J. Prod. Res. 2019, 58, 3220–3234. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L. A multi-objective discrete flower pollination algorithm for stochastic two-sided partial disassembly line balancing problem. Comput. Ind. Eng. 2019, 130, 634–649. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Zhu, L.; Wang, Y. A Pareto improved artificial fish swarm algorithm for solving a multi-objective fuzzy disassembly line balancing problem. Expert Syst. Appl. 2017, 86, 165–176. [Google Scholar] [CrossRef]

- McGovern, S.M.; Gupta, S.M. A balancing method and genetic algorithm for disassembly line balancing. Eur. J. Oper. Res. 2007, 179, 692–708. [Google Scholar] [CrossRef]

- Seidi, M.; Saghari, S. The balancing of disassembly line of automobile engine using genetic algorithm (GA) in fuzzy environment. Ind. Eng. Manag. Syst. 2016, 15, 364–373. [Google Scholar] [CrossRef]

- Pistolesi, F.; Lazzerini, B.; Mura, M.D.; Dini, G. EMOGA: A hybrid genetic algorithm with extremal optimization core for multiobjective disassembly line balancing. IEEE Trans. Ind. Inform. 2018, 14, 1089–1098. [Google Scholar] [CrossRef]

- Wang, Z.; Ong, Y.-S.; Ishibashi, H. On scalable multi-objective test problems with hardly dominated boundaries. IEEE Trans. Ind. Inform. 2019, 23, 217–231. [Google Scholar]

- Zhang, Y.; Hu, X.; Wu, C. A modified multi-objective genetic algorithm for two-sided assembly line re-balancing problem of a shovel loader. Int. J. Prod. Res. 2017, 56, 3043–3063. [Google Scholar] [CrossRef]

- Wang, K.P.; Li, X.Y.; Gao, L. Modeling and optimization of multi-objective partial disassembly line balancing problem considering hazard and profit. J. Clean. Prod. 2019, 211, 115–133. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, D.; Zhang, C.; Tian, G.; Meng, L.; Zhou, X. An improved gravitational search algorithm for profit-oriented partial disassembly line balancing problem. Int. J. Prod. Res. 2017, 55, 7302–7316. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L.; Garg, A. Partial disassembly line balancing for energy consumption and profit under uncertainty. Robot. Comput. Integr. Manuf. 2019, 59, 235–251. [Google Scholar] [CrossRef]

- Altekin, F.T.; Kandiller, L.; Ozdemirel, N.E. Profit-oriented disassembly-line balancing. Int. J. Prod. Res. 2008, 46, 2675–2693. [Google Scholar] [CrossRef]

- Zhu, L.X.; Zhang, Z.Q.; Wang, Y. A Pareto firefly algorithm for multi-objective disassembly line balancing problems with hazard evaluation. Int. J. Prod. Res. 2018, 56, 7354–7374. [Google Scholar] [CrossRef]

- Özceylan, E.; Paksoy, T.; Betas, T. Modeling and optimizing the integrated problem of closed-loop supply chain network design and disassembly line balancing. Transp. Res. Part E Logist. Transp. Rev. 2014, 61, 142–164. [Google Scholar] [CrossRef]

- Li, Z.; Kucukkoc, I.; Zhang, Z. Iterated local search method and mathematical model for sequence-dependent U-shaped disassembly line balancing problem. Comput. Ind. Eng. 2019, 137, 106056. [Google Scholar] [CrossRef]

- Zheng, F.; He, J.; Chu, F.; Liu, M. A new distribution-free model for disassembly line balancing problem with stochastic task processing times. Int. J. Prod. Res. 2018, 56, 7341–7353. [Google Scholar] [CrossRef]

- Mcgovern, S.M.; Gupta, S.M. Ant colony optimization for disassembly sequencing with multiple objectives. Int. J. Adv. Manuf. Technol. 2006, 30, 481–496. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Pham, D.T.; Xu, W.; Yan, J.; Liu, A.; Liu, Q. An improved multi-objective discrete bees algorithm for robotic disassembly line balancing problem in remanufacturing. Int. J. Adv. Manuf. Technol. 2018, 97, 3937–3962. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Pham, D.T.; Xu, W.; Ji, C.; Liu, Q. Collaborative optimization of robotic disassembly sequence planning and robotic disassembly line balancing problem using improved discrete Bees algorithm in remanufacturing. Robot. Comput. Integr. Manuf. 2020, 61, 101829. [Google Scholar] [CrossRef]

- Edis, E.B.; Ilgin, M.A.; Edis, R.S. Disassembly line balancing with sequencing decisions: A mixed integer linear programming model and extensions. J. Clean. Prod. 2019, 238, 117826. [Google Scholar] [CrossRef]

- Kwak, M. Optimal line design of new and remanufactured products: A model for maximum profit and market share with environmental consideration. Sustainability 2018, 10, 4283. [Google Scholar] [CrossRef]

- Xia, X.H.; Zhou, M.; Wang, L.; Cao, J.H. Remanufacturing disassembly service line and balancing optimization method. Comput. Integr. Manuf. Syst. 2018, 24, 2492–2501. [Google Scholar]

- Zhang, X.F.; Yu, G.; Liu, X. Product failure mode information transfer polychromatic model for design for remanufacture. J. Mech. Eng. 2019, 30, 2091–2099. [Google Scholar] [CrossRef]

| Symbol | Instructions |

|---|---|

| m | Number of disassembled parts |

| Number of disassembly workstations | |

| CT | Cycle time |

| M | Number of disassembly tasks for a disassembly workstation |

| Time required for ith disassembly task | |

| ith disassembly task is assigned to workstation r | |

| Remanufacturing value of disassembled parts in ith disassembly task | |

| Disassembly task set in workstation r | |

| Li | Position of part i in the configuration plan of disassembly line |

| Disassembly task i takes precedence over disassembly task j | |

| B | Multi-constraint matrix of waste mechanical and electrical products |

| A | Disassembly task priority relation matrix |

| S | Disassembly task comprehensive priority relation matrix |

| Part Number | Failure Mode | Failure Degree | Remanufacturing | Material Hazards | Remanufacturing Value (CNY) | Disassembly Time (s) |

|---|---|---|---|---|---|---|

| 1 | Wear | General | Yes | Yes | 0 | 14 |

| 2 | Aging | Small | No | No | 500 | 10 |

| 3 | Wear | Severe | No | No | 0 | 12 |

| Corrosion | Small | |||||

| 4 | Deformation | General | Yes | No | 0 | 17 |

| 5 | Null | Null | Null | Yes | 0 | 23 |

| 6 | Null | Null | Null | Yes | 750 | 14 |

| 7 | Deformation | Small | No | Yes | 295 | 19 |

| Corrosion | General | |||||

| 8 | Aging | Medium | No | Yes | 0 | 36 |

| 9 | Null | Null | Null | Yes | 360 | 14 |

| 10 | Null | Null | Null | Yes | 0 | 10 |

| Running Times | Optimal Solution/ns | ||

|---|---|---|---|

| Pareto Grade Evaluation Strategy | Construct Initial Population Q | Screening Mechanisms | |

| 1 | 1.69 | 0.04 | 2.80 |

| 2 | 2.20 | 0.04 | 2.70 |

| 3 | 2.21 | 0.04 | 2.70 |

| 4 | 2.07 | 0.05 | 2.57 |

| 5 | 1.91 | 0.05 | 2.70 |

| 6 | 2.20 | 0.03 | 2.29 |

| 7 | 1.77 | 0.04 | 2.90 |

| 8 | 2.20 | 0.05 | 2.80 |

| 9 | 2.20 | 0.04 | 2.90 |

| 10 | 2.20 | 0.04 | 2.21 |

| Minimum value | 1.69 | 0.03 | 2.21 |

| Average value | 2.06 | 0.04 | 2.60 |

| Maximum value | 2.21 | 0.05 | 2.90 |

| Algorithm | Cycle Time/s | Minimum Values/ns | Average Values/ns | Maximum Values/ns |

|---|---|---|---|---|

| GA | 40 | 5 | 5.3 | 6 |

| ITLBO | 40 | 5 | 5 | 5 |

| ENSGA-II | 40 | 3.924 | 4.7 | 5.15 |

| Algorithm | Remanufacture Disassembly Line Configuration Scheme | Workstation Number f1 | Workstation Equilibrium Rate f2 | Remanufacturing Value Index f3 | Pareto Grade |

|---|---|---|---|---|---|

| GA | 10, 6, 9, 4, 5, 7, 1, 8, 3, 2 | 5 | 8.865 | 9740 | - |

| ITLBO | 6, 9, 10, 1, 5, 7, 4, 8, 2, 3 | 5 | 8.59 | 7740 | - |

| ENSGA-II | 9, 6, 10, 1, 5, 7, 4, 8, 2, 3 | 5 | 4.02 | 7740 | 1 |

| 10, 6, 9, 5, 1, 7, 4, 8, 3, 2 | 5 | 4.02 | 7740 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, W.; Zhang, X. Optimization of Remanufacturing Disassembly Line Balance Considering Multiple Failures and Material Hazards. Sustainability 2020, 12, 7318. https://doi.org/10.3390/su12187318

Meng W, Zhang X. Optimization of Remanufacturing Disassembly Line Balance Considering Multiple Failures and Material Hazards. Sustainability. 2020; 12(18):7318. https://doi.org/10.3390/su12187318

Chicago/Turabian StyleMeng, Wei, and Xiufen Zhang. 2020. "Optimization of Remanufacturing Disassembly Line Balance Considering Multiple Failures and Material Hazards" Sustainability 12, no. 18: 7318. https://doi.org/10.3390/su12187318

APA StyleMeng, W., & Zhang, X. (2020). Optimization of Remanufacturing Disassembly Line Balance Considering Multiple Failures and Material Hazards. Sustainability, 12(18), 7318. https://doi.org/10.3390/su12187318