Analysis and Characterization of Risk Methodologies Applied to Industrial Parks

Abstract

1. Introduction

- (1)

- A primary accidental scenario (i.e., loss of containment (LOC) due to shell breaking, wrong weld, overpressure, incorrect handling) with an initial event (i.e., fire, explosion) that initiates the domino sequence by means of physical phenomena such as heat radiation, blast wave, or fragment projection.

- (2)

- The propagation and escalation due to the physical effects of the primary event that results in the damage of at least one secondary equipment item. Characteristics are the overpressure, the fire, and heat generation in form of pool fire, jet fire, and vapor cloud explosions.

- (3)

- As a consequence, one or more secondary events appear from the newly damaged equipment (i.e., additional fire, explosion, and toxic dispersion).

2. Methodology and Proposal of Characterization

- (1)

- (2)

- (3)

- Specifically for the worst situation of possible domino effects in industrial parks, being: Does not perform the treatment (NT), it performs a general treatment (GT), and it performs a specific treatment (ST).

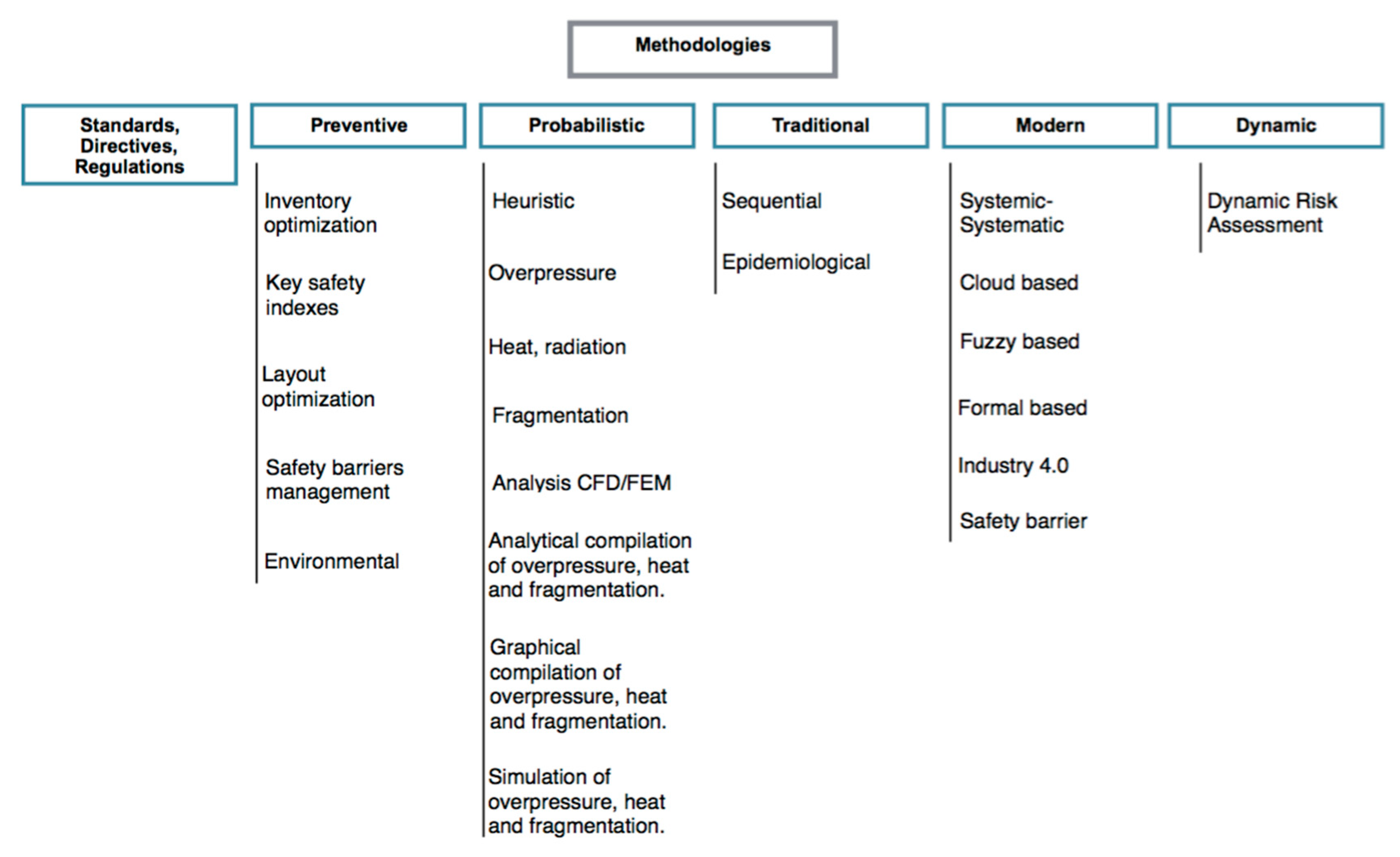

- (1)

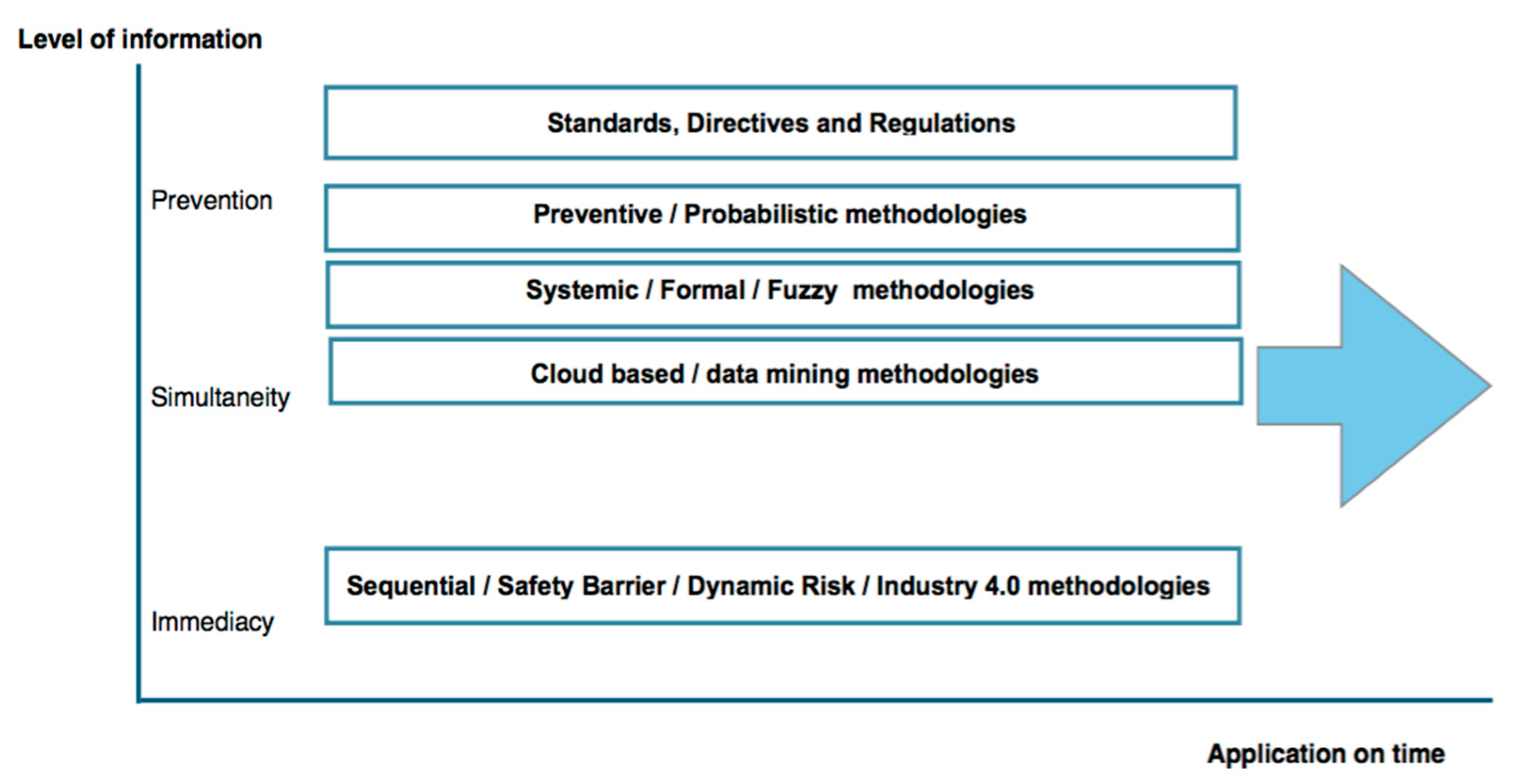

- The first group is the corresponding to the standards, directives, and regulations. This group collects the most important standards and regulations concerning risk management and highlighting the need, in situations of major hazard, to establish a preventive policy in the different work areas of an installation.

- (2)

- The second group covers the preventive methodologies, as a result of the application of the directives concerning major hazard situations and guidelines.

- (3)

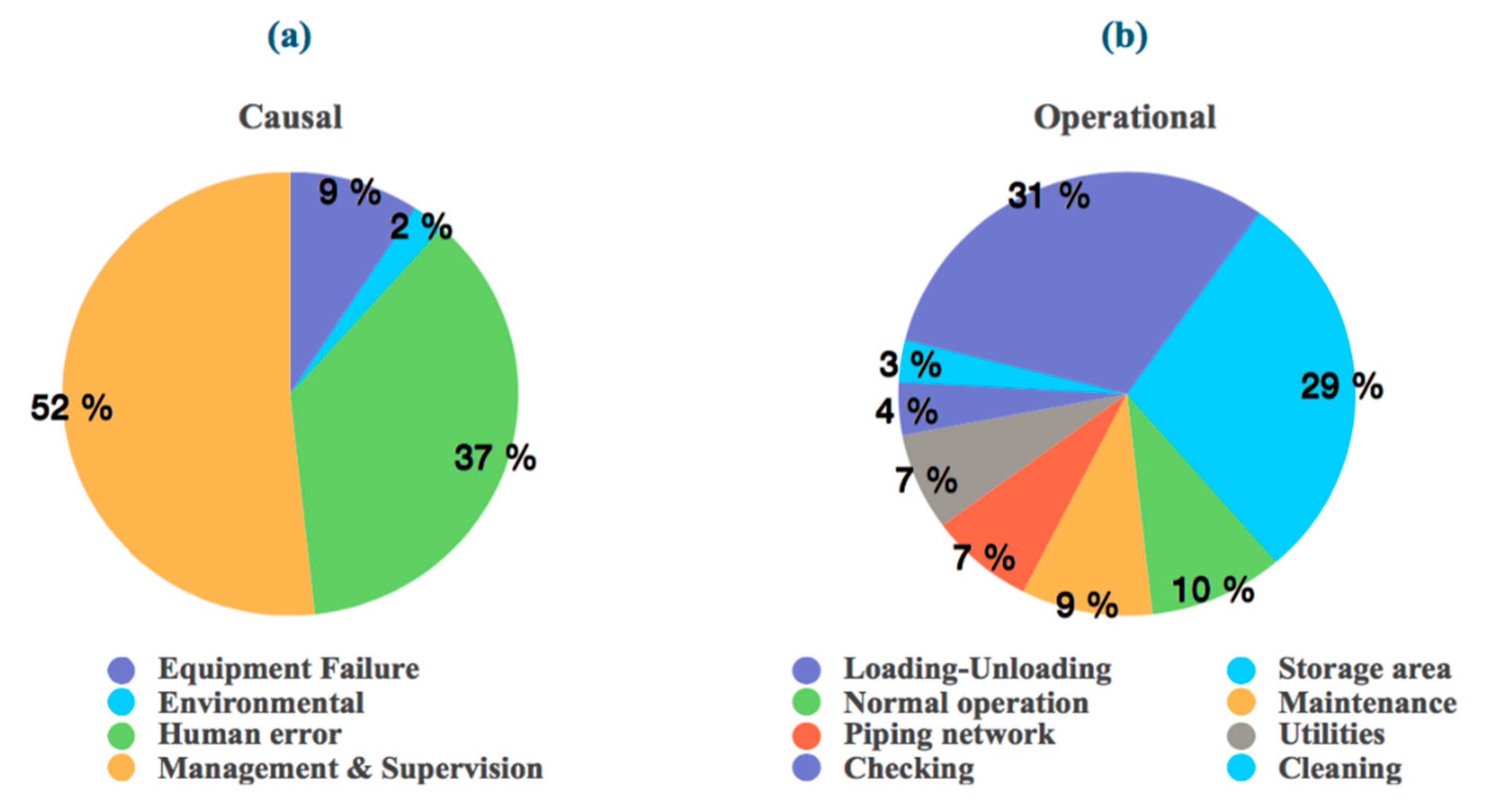

- The third group compiles the probabilistic methodologies, based on the three characteristics of a domino effect scenario: Overpressure, heat radiation due to fire, and fragment emission [27].

- (4)

- The fourth group covers the traditional methodologies, including the sequential and the epidemiological models [28].

- (5)

- The fifth group considers the modern methodologies, including five models: The systematic; cloud based; the fuzzy based; formal based; industry 4.0 and safety barrier based.

- (6)

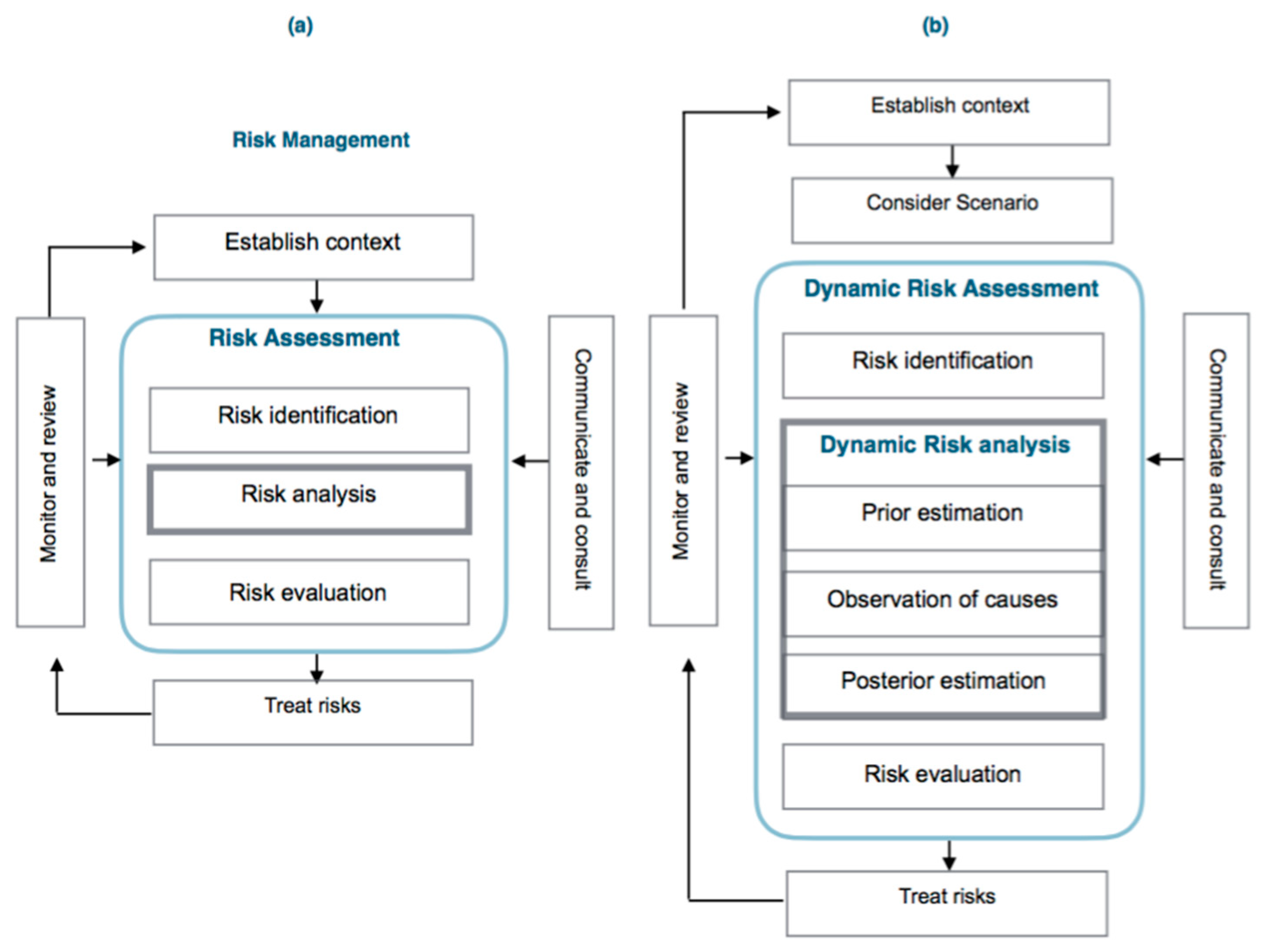

- The sixth group, which is encompassed in the modern methodologies, is specific for dynamic models.

3. Analysis and Characterization

3.1. Standards, Directives, and Regulations

| Method | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| ISO/IEC 31010:2019 [12,29] | Risk management process, based on a Deming iterative cycle. Risk assessment performing identification, analysis, and evaluation. | (P) | MDSP HDSP MK,SK | GT |

| ISO 14005:2019 [30,31] | Environmental management process. With the same principles and based on the same Deming iterative cycle. | (P) | MDSP HDSP MK,SK | GT |

| ISO 45001:2018 [30,31] | Implementation of a system of safety and health at work. | (P) | MDSP HDSP MK,SK | NT Work Safety |

| 89/391/EEC [32] | Occupational framework. Introduction of measures for improvement in safety and health at work. | (P) | MDSP HDSP MK,SK | NT Work Safety |

| 98/24/EC, 2004/37/EC [33,34] | Occupational framework. Chemical and carcinogen limitations. | (P) | MDSP HDSP MK,SK | NT Work Safety |

| PMBOK, PRINCE2 [35,36,37] | Project management guidelines. Tailored documentation for initiating, planning, executing, controlling, and closing. | (P) | MDSP HDSP MK,SK | NT |

| 2012/18/EU, COMAH [9,10] | European and British equivalent for major hazards control, Seveso III directive. Emergency plan with major accident prevention policy. Revised every 5 years. | (P) | MDSP HDSP MK,SK | GT |

| CCPS [23,38,39,40] | Center for chemical process safety. Based on Layer of Protection Analysis (LOPA). A danger occurs if not interrupted by an independent protection layer (IPL). | (P) | MDSP HDSP MK,SK | GT |

| NORSOK 2010 [41,42,43] | (Norsk Sokkels Konkuranseposisjon). Norwegian petroleum industry guidelines in projects and operations. | (P) | MDSP HDSP MK,SK | GT |

| CPR18E [44] | Netherlands Commissie vor de Preventie van Rampenhat (CPR). Applied in installations and logistics. Loss of containment (LOC) events modeling the extension and dispersion of flammable and toxic clouds. | (P) | MDSP HDSP MK,SK | GT |

| EN 16991:2018 [45,46] | European norm for power generation and chemical facilities. Providing guidance for risk evaluation in inspection and maintenance operations. | (P) | MDSP HDSP MK,SK | GT |

3.2. Preventive Methodologies

| Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| Inventory optimization. [47] | Optimization, using Bayesian networks, for the allocation of chemical inventories. | (P) QRA framework | HDSP SK,RK MDSP MK,SK | ST GT |

| Key safety indexes. [48,49,50,51] | Based on key indicators defined in the function of the damage distance or the area and the number of events affecting the industrial park. | (P) QRA framework | HDSP SK,RK | ST |

| Layout optimization. [52,53,54,55,56] | Nonlinear and multi-objective programming developments to optimize the allocation of explosive facilities, considering domino effects caused by fire, overpressure, and fragments; minimizing the total escalation probabilities, and the total costs. An analytical hierarchical process combined with Bayesian network can be included to determine the weighted critical failure factors. | (P) QRA framework | HDSP SK,RK | ST |

| Safety barriers management and assessment. [57,58,59,60,61,62,63] | Management of safety barriers with the aim of detecting and responding to their performance. Assessment using qualitative and quantitative tools such as the BORA (Barrier and operational risk analysis). Optimization is realized using heuristic methodologies by maximizing a quality objective function. | (P) QRA framework | HDSP SK,RK | ST |

| Environmental management and assessment. [64,65,66,67,68] | Environmental Risk Management (ERM) and Assessment (ERA). Applying qualitative and quantitative methods, including additional tools such as analytic hierarchy process, fuzzy logic, and GIS (Geographical Information Systems). | (P) QRA framework | HDSP SK,RK | ST |

3.3. Probabilistic Methodologies

| Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| Heuristic analysis. [69,70,71,72] | Threshold and probability values provide the minimum intensity of physical effects able to cause an escalation, applied for a preliminary risk assessment of possible escalation scenarios | (P) QRA framework | LDSP BK,MK | ST |

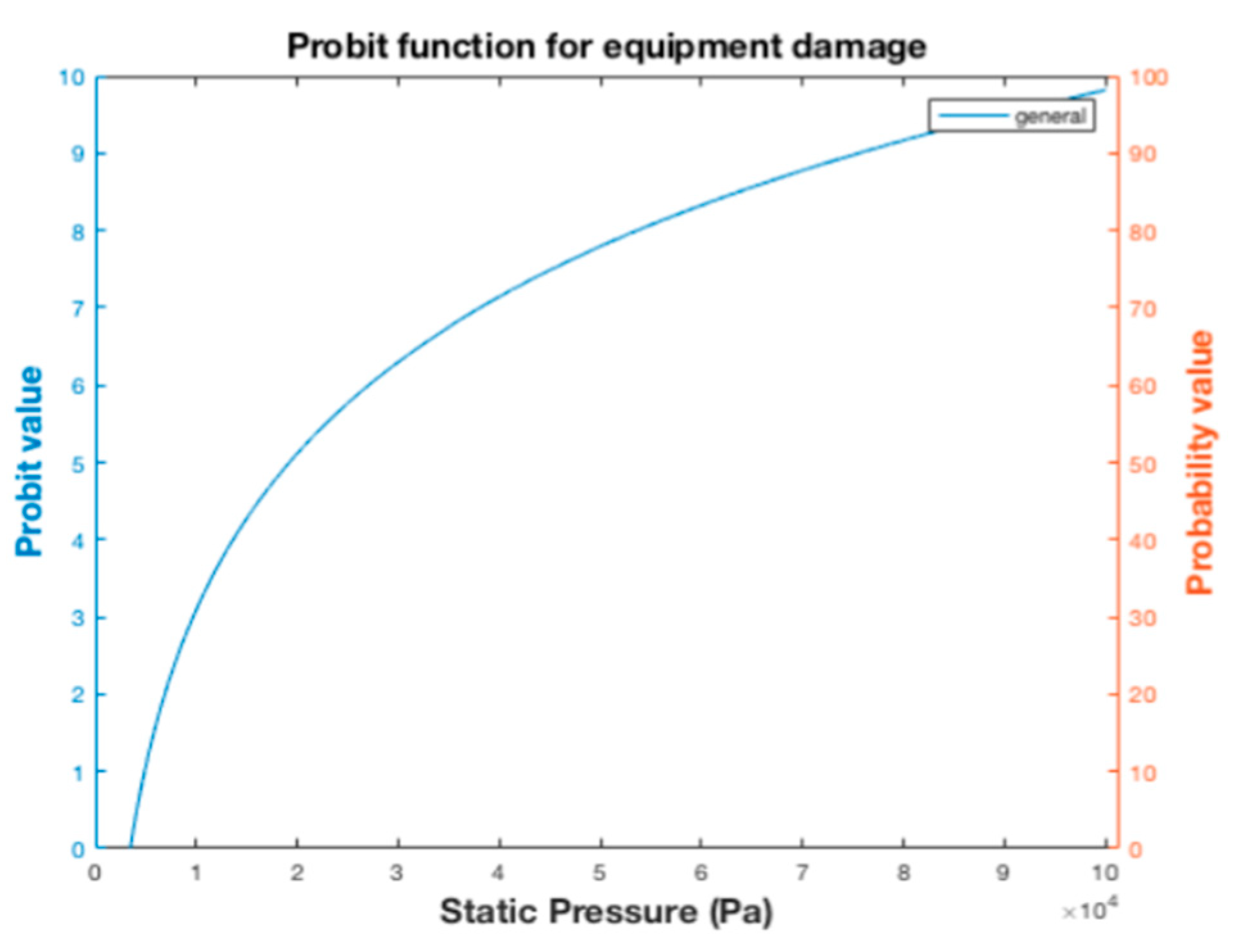

| Probability due to overpressure [73] | The probit damage function is applied considering distances from the center of primary scenario, the peak overpressure (static pressure), and the dynamic pressure. | (P) QRA framework | MDSP MK,SK | ST |

| Probability due to heat radiation. [74,75,76,77,78,79] | The damage mechanism of heat radiation is a gradual process. Probit models and graph methods are applied for estimating the damage probability of equipment exposed to heat. | (P) QRA framework | MDSP MK,SK | ST |

| Probability due to fragments. [80,81,82,83,84,85,86] | The total damage probability is the sum of the probabilities caused by fragment generation, impact, and target damage. Monte Carlo methods are applied to assess uncertainty in fragment generation. Mechanical rupture process and energy applied with consequent kinetic values are analyzed. | (P) QRA framework | HDSP SK,RK | ST |

| Probability due to analysis with CFD/FEM. [87,88,89,90,91,92] | Computational Fluid Dynamics (CFD) and the Finite Element Method (FEM). The CFD tool can simulate the evolution of jet and pool fires, and the FEM tool can simulate the thermal and mechanical parameters of vessel shells under heat radiation, such as heat radiation, wall temperature, and stress as the atmospheric dispersions. | (P) QRA framework | HDSP SK,RK | ST |

| Probability due to analytical compilation of overpressure, radiation, and fragments. [93,94,95,96,97,98,99] | Probit models with distance-based approach, considering escalation and damage directions. Fuzzy logic is applied to model uncertainties presented by complexity and randomness, and the experts’ scoring. The procedures can be matched to a GIS (Geographical Information System) to take into consideration actual plant lay-outs. | (P) (S) in GIS systems QRA framework | HDSP SK,RK | ST |

| Probability due to graphical compilation for overpressure, radiation, and fragments. [100,101,102] | A graphical network representing equipment as nodes N and arcs A connecting a pair of nodes proportional to the probability of propagation. Temporal evolution analyzed using Bayesian networks, Petri-net, and graphs. Fuzzy logic to manage uncertainty in parameters definition is included. | (P) QRA framework | HDSP SK,RK | ST |

| Probability due to simulation methods for overpressure, radiation, and fragments. [103,104] | Simulation tools for analyzing the evolution of a determined layout of equipment, assessing the probability of the domino effect and the failure frequency of the installation. Monte Carlo methods can be applied to assess frequency. | (P) QRA framework | HDSP SK,RK | ST |

- (1)

- Determination of the probability of occurrence of the primary explosion, where fragments’ number, mass, velocity, departure angles, the geometric shape, dimensions, and construction material properties are described with function distributions.

- (2)

- Determination of the target damage where the consequence of projectiles number, speed, angles, and energy at the impact, are related to target construction, dimensions, and depths of penetration that are described with probability distributions.

- (3)

- Risk assessment for the second scenario explosion (domino effect).

3.4. Traditional Methodologies

| Model Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| HAZOP/HAZID [116,117] | Technique for early identification of hazards usually applied in the design. The study is carried out by an experienced multi-discipline team using a checklist of potential hazards. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| EBM [118] | Energy Barrier Model defining a safety barrier management and considering that an accident occurs when hazards succeed in penetrating the safety barriers’ deficiencies. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| MORT [119] | Management Oversight and Risk Tree. Root cause determination. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| SCAT [120] | Systematic Cause Analysis. Causal analysis using a poster schematic, which enables the identification of relevant corrective and preventive actions. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| STEP [121] | Sequential Time Events Plotting. Identification of multiple causes in occupational accidents. | (P) (+/-S) QRA framework | HDSP MK,SK | NT-GT |

| MTO [122] | Man, Technology, and Organization. Root causes in occupational work affected by the organization; practice; management; procedures; and deficiencies in work environment. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| SOL [123] | Safety through Organizational Learning. Event analysis in two steps: (1) Description of the actual event situation, and (2) identification of contributing factors. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| 24 Model [124,125,126] | Analysis of the causes of accident through 6 levels; root causes, radical causes, indirect causes, event generation, and consequences. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| Epidemiological [127,128] | Propagation of events is analogous to a disease spreading considering their distribution and determinants. | (P) (+/-S) QRA framework | HDSP MK,SK | NT-GT |

3.5. Modern Methodologies

| Model Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| Systemic–Systematic [129] | General risk framework based on systemic model using control theory concepts and considering that social climate is affected systematically by government policy and budgeting, regulatory associations, organization, staff, and the work operation systems for which their limitations and their interactions can get preconditions for accidents. | |||

| AcciMap [130] | Fault Tree Analysis. Causes of risk. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| STAMP [131,132,133,134] | Event Tree Analysis. Consequence analysis. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT-ST |

| CREAM/DREAM [110,135,136] | (Cognitive-Driving Reliability and Error Analysis Method). Characterization of human performance and errors in accidents. | (P) (+/-S) QRA framework | HDSP MK,SK | GT-ST |

| FRAM [137,138] | Graphic including FTA and ETA models to represent causes and consequence events, and what the needed safety barriers are. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| AEB [139,140] | Step-by-step approach for identifying potential failures in safety barriers. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| Cloud based | Analysis is carried out in the cloud of scientific information and accident databases. | |||

| Data Mining [5,141] | Identifying behavioral patterns and dependence on causal factors. General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT-ST |

| Model Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| Fuzzy based | General application of fuzzy logical for define human behavior in risk situations. | |||

| HEART [142] | Human Error and Assessment Technique. The human behavior and reliability of any operator task performance may be modified by the influence of Error Promoting Conditions (EPCs). General application. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| CREAM-BN [143,144,145] | Upgrade of the systemic CREAM model. Human behavior has five components: Strategic, tactical, opportunistic, and scramble. Affected by common performance conditions (CPCs). Fuzzy logic is applied to every CPC and combined by applying a Bayesian network. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| Formal based | Accident causation is approached using probabilistic schemes and Bayesian networks. | |||

| WBA [86,146,147,148] | Why Because Analysis. Bayesian networks, fuzzy logic, Monte Carlo, and Delphi procedures can be applied. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| Industry 4.0 | Improve self-monitoring and diagnostics using communication and deep learning methods. | |||

| Machine learning [149,150,151] | Neural network and machine learning for risk identification in operations, construction, and maintenance. | (P) (+/-S) QRA framework | HDSP MK,SK | GT |

| Safety barrier | Safety barriers are assessed according to their performance. | |||

| PHPAM [152] | Process Hazard Prevention Accident Models. Accidents are initiated by hydrocarbon release. | (P) (+/-S) QRA framework | HDSP MK,SK | GT-ST |

| SHIPP [153] | System Hazard Identification Prediction and Prevention. Initial probability of risk updated according to data collected with application of Bayesian inference. General application. | (P) (S) QRA framework | HDSP MK,SK | GT |

3.6. Dynamic Methodologies

| Model Methodology | Description | Supplied Information (P); (S); (I) | Standard and User levels | Domino Effect Treatment |

|---|---|---|---|---|

| Dynamic | Bowtie graph approach and Bayesian inference analysis to update the failure probabilities from the information collected of incidences and potential causes of accident. | |||

| Dynamic Risk Assessment (DRA) [102,154,155,156,157] | A prior function for the statistical parameter that models the risk probability is defined. Precursors, events, or causes are observed, and through the application of Bayesian inference, the posterior function of the parameter is obtained. | (P) (S)(+/-I) DRA framework | HDSP MK,SK | GT |

| DyPasi [158] | Dynamic Procedure for Atypical Scenarios Identification. Identification and assessment of the potential hazards based on information from accidents or situations which are not captured by conventional HAZOP/HAZID techniques. | (P) (S)(+/-I) DRA framework | HDSP MK,SK | GT |

| Risk Barometer [14,59] | Risk influencing factors affecting the performance of the safety barriers that are defined based on BORA analysis. The presentation is a barometer graph. | (P) (S)(+/-I) DRA framework | HDSP MK,SK | GT |

| Dynamic Operational Risk Assessment [159] | Approach using Markov and Monte Carlo chain simulations applied to analyze the incidence of events and causes in each component of the process and its behavior. | (P) (+/-S) DRA framework | HDSP MK,SK | GT |

| Statistical Risk Control (SRC) [160,161] | Bowtie graph approach, performing Bayesian inference and hidden Markov analysis to update the failure probabilities of the process and safety barriers. This information is monitored through the use of charts and control tables. | (P) (S) (I) DRA framework | HDSP MK,SK | GT |

4. Discussion

4.1. Standards, Directives, and Regulations

4.2. Preventive Methodologies

4.3. Probabilistic Methodologies

4.4. Traditional Methodologies

4.5. Modern Methodologies

4.6. Dynamic Methodologies

4.7. Applicability and Implementation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations Industrial Development Organization (UNIDO). Advantages of industrial parks highlighted during Ukrainian Industrial Days. Available online: https://www.unido.org/news/advantages-industrial-parks-highlighted-during-ukrainian-industrial-days (accessed on 15 May 2020).

- United Nations Industrial Development Organization (UNIDO). UNIDO International Guidelines for Industrial Parks. 2019. Available online: https://www.unido.org/guidelines-industrial-parks (accessed on 28 May 2020).

- Official Journal of the European Union. The Role of Technology Parks in the Industrial Transformation of the New Member States. 2006. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52005IE1494&from=EN) (accessed on 2 June 2020).

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Ren, J.Z.; Chen, Q.H.; Liu, W.L.; Zhu, X.S. Co-benefits accounting for the implementation of eco-industrial development strategies in the scale of industrial park based on emergy analysis. Renew. Sust. Energ. Rev. 2018, 81, 1522–1529. [Google Scholar] [CrossRef]

- Hou, L.; Wu, X.G.; Wu, Z.; Wu, S.Z. Pattern identification and risk prediction of domino effect based on data mining methods for accidents occurred in the tank farm. Reliab. Eng. Syst. Saf. 2020, 193, 106646. [Google Scholar] [CrossRef]

- Zhou, J.F.; Reniers, G. A matrix-based modeling and analysis approach for fire induced domino effects. Proc. Saf. Environ. Prot. 2018, 116, 347–353. [Google Scholar] [CrossRef]

- Khakzad, N.; Landucci, G.; Cozzani, V.; Reniers, G.; Pasman, H. Cost-effective fire protection of chemical plants against domino effects. Reliab. Eng. Syst. Saf. 2018, 169, 412–421. [Google Scholar] [CrossRef]

- Khakzad, N.; Amyotte, P.; Cozzani, V.; Reniers, G.; Pasman, H. How to address model uncertainty in the escalation of domino effects? J. Loss Prev. Proc. Ind. 2018, 54, 49–56. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Directive 2012/18/EU of 4 July 2012 on the Control of Major Accident Hazards Involving Dangerous Substances. Council Directive 96/82/EC. Available online: http://data.europa.eu/eli/dir/2012/18/oj (accessed on 15 June 2019).

- COMAH. The Control of Major Accident Hazard Regulations, 3rd ed.; Health and Safety Executive (HSE) Books: Norwich, UK, 2015. Available online: https://www.legislation.gov.uk/uksi/2015/483/contents/made (accessed on 20 November 2019).

- ISO 31000:2018. Risk Management Guidelines. Available online: https://www.iso.org/iso-31000-risk-management.html (accessed on 20 September 2019).

- ISO/IEC 31010:2019. Risk Management—Risk Assessment Techniques. Available online: https://www.iso.org/standard/72140.html (accessed on 20 September 2019).

- Khan, F.; Rathnayaka, S.; Ahmed, S. Methods and models in process safety and risk management: Past, present and future. Proc. Saf. Environ. Protect. 2015, 98, 116–147. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Scarponi, G.E.; Khan, F.; Hauge, S. Addressing Dynamic Risk in the Petroleum Industry by Means of Innovative Analysis Solutions. Chem. Eng. Trans. 2014, 36, 451–456. [Google Scholar] [CrossRef]

- Bier, V.M.; Yi, W. A Bayesian method for analyzing dependencies in precursor data. Int. J. Fcst. 1995, 11, 25–41. [Google Scholar] [CrossRef]

- Meel, A. Dynamic Risk Assessment of Inherently Safer Chemical Processes: An Accident Precursor Approach. 2007. Available online: https://search.proquest.com/openview/b75c47f89e1984b2e6af5ea788cf26e2/1?pq-origsite=gscholar&cbl=18750&diss=y (accessed on 10 January 2018).

- Khan, F.; Hashemi, S.J.; Paltrinieri, N.; Amyotte, P.; Cozzani, V.; Reniers, G. Dynamic risk management: A contemporary approach to process safety management. Curr. Opn. Chem. Eng. 2016, 14, 9–17. [Google Scholar] [CrossRef]

- Khakzad, N.; Khan, F.; Amyotte, P. Safety analysis in process facilities: Comparison of fault tree and Bayesian network approaches. Reliab. Eng. Syst. Saf. 2011, 96, 925–932. [Google Scholar] [CrossRef]

- Kanes, R.; Ramirez-Marengo, C.; Abdel-Moati, H.; Cranefield, J.; Véchot, L. Developing a framework for dynamic risk assessment using Bayesian networks and reliability data. J. Loss Prev. Proc. Ind. 2017, 50, 142–153. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Reniers, G. Dynamic Risk Analysis for Seveso sites. J. Loss Prev. Proc. Ind. 2017, 49, 111–119. [Google Scholar] [CrossRef]

- Folch-Calvo, M.; Brocal, F.; Sebastián, M.A. New Risk Methodology Based on Control Charts to Assess Occupational Risks in Manufacturing Processes. Materials 2019, 12, 3722. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. ISO. Available online: https://www.iso.org/home.html (accessed on 28 May 2020).

- CCPS-AIChE. Center for Chemical Process Safety. Available online: https://www.aiche.org/ccps/resources/glossary/process-safety-glossary/standards (accessed on 29 May 2020).

- ASTM International. Form and Style for ASTM Standards. Available online: https://www.astm.org/FormStyle_for_ASTM_STDS.html (accessed on 29 May 2020).

- European Commission. Good Manufacturing Practices (GMP). Directive 2003/94/EC from 8 October 2003 for Laying down the principles and guidelines of good manufacturing practices. Available online: https://www.ema.europa.eu/en/human-regulatory/research-development/compliance/good-manufacturing-practice (accessed on 14 May 2020).

- FDA. Current Good Manufacturing Practice (CGMP). 21 CFR part 210 and 211. Available online: https://www.fda.gov/drugs/pharmaceutical-quality-resources/current-good-manufacturing-practice-cgmp-regulations (accessed on 14 May 2020).

- Kadri, F.; Chatelet, E. Domino Effect Analysis and Assessment of Industrial Sites: A Review of Methodologies and Software Tools. Int. J. Comp. Distr. Syst. 2013, 2, 1–10. Available online: https://hal.archives-ouvertes.fr/hal-01026495 (accessed on 20 October 2018).

- Al-shanini, A.; Ahmad, A.; Khan, F. Accident modeling and analysis in process industries. J. Loss Prev. Proc. Ind. 2014, 32, 319–334. [Google Scholar] [CrossRef]

- Deming, W.E. Out of the Crisis; MIT Press: Cambridge, MA, USA, 1986. [Google Scholar]

- ISO 14005:2019. Environmental Management Systems—Guidelines for a Flexible Approach to Phased Implementation. Available online: https://www.iso.org/standard/72333.html (accessed on 16 June 2020).

- ISO 45001:2018. Occupational Health and Safety Management Systems—Requirements with Guidance for Use. Available online: https://www.iso.org/obp/ui#iso:std:iso:45001:ed-1:v1:es (accessed on 19 May 2019).

- European Agency for Safety and Health at Work. Directive 89/391/EEC of 12 June 1989 on the Introduction of Measures to Encourage Improvements in the Safety and Health of Workers at Work—”Framework Directive”. Available online: https://osha.europa.eu/en/legislation/directives/the-osh-framework-directive/1 (accessed on 5 April 2019).

- European Agency for Safety and Health at Work. Directive 98/24/EC of 7 April 1998 on the Risks Related to Chemical Agents at Work. Available online: https://osha.europa.eu/en/legislation/directives/75 (accessed on 15 May 2019).

- European Agency for Safety and Health at Work. Directive 2004/37/EC of 29 April 2004 on the Carcinogens and Mutagens at Work. Available online: https://osha.europa.eu/en/legislation/directives/directive-2004-37-ec-carcinogens-or-mutagens-at-work (accessed on 15 May 2019).

- Matos, S.; Lopes, E. Prince2 or PMBOK—A question of choice. Procedia Technol. 2013, 9, 787–794. [Google Scholar] [CrossRef]

- PMBOK-Guide. A Guide to the Project Management Body of Knowledge, 6th ed.; Project Management Institute: Newtown Square, PA, USA, 2017; Available online: https://dinus.ac.id/repository/docs/ajar/PMBOKGuide_5th_Ed.pdf (accessed on 12 June 2020).

- ANSI American National Standards Institute. PMI FS-PMBOK-2017. Available online: https://webstore.ansi.org/sdo/pmi (accessed on 20 May 2019).

- Willey, R.J. Layer of Protection Analysis. Procedia Eng. 2014, 84, 12–22. [Google Scholar] [CrossRef]

- Jin, J.H.; Shuai, B.; Wang, X.D.; Zhu, Z.G. Theoretical basis of quantification for layer of protection analysis (LOPA). Ann. Nucl. Energy 2016, 87, 69–74. [Google Scholar] [CrossRef]

- Yan, F.; Xu, K. A set pair analysis based layer of protection analysis and its application in quantitative risk assessment. J. Loss Prev. Proc. Ind. 2018, 55, 313–319. [Google Scholar] [CrossRef]

- NORSOK. Z-013. Risk and emergency preparedness assessment Rev. 3. Oct. 2010. Available online: https://www.standard.no/en/sectors/energi-og-klima/petroleum/norsok-standard-categories/z-risk-analyses/z-0132/ (accessed on 14 January 2018).

- Yang, X.; Haugen, S. Classification of risk to support decision-making in hazardous processes. Saf. Sci. 2015, 80, 115–126. [Google Scholar] [CrossRef]

- Yang, X.; Haugen, S.; Paltrinieri, N. Clarifying the concept of operational risk assessment in the oil and gas industry. Saf. Sci. 2018, 108, 259–268. [Google Scholar] [CrossRef]

- CPR 18E. Guidelines for Quantitative Risk Assessment—Purple Book. Publication Series on Dangerous Substances. 1999. Available online: https://content.publicatiereeksgevaarlijkestoffen.nl/documents/PGS3/PGS3-1999-v0.1-quantitative-risk-assessment.pdf (accessed on 22 March 2019).

- European Committee for Standardization. New CEN Standard—EN 16991:2018. European Norm. Risk-Based Inspection Framework. Available online: https://www.cen.eu/news/brief-news/Pages/NEWS-2018-011.aspx (accessed on 12 January 2019).

- Khan, F.; Sadiq, R.; Haddara, M.M. Risk-based inspection and maintenance (RBIM). Multi-attribute Decision-making with Aggregative Risk Analysis. Proc. Saf. Environ. Protect. 2004, 82, 398–411. [Google Scholar] [CrossRef]

- Khakzad, N.; Khan, F.; Amyotte, P.; Cozzani, V. Risk Management of Domino Effects Considering Dynamic Consequence Analysis. Risk Anal. 2014, 34, 1128–1138. [Google Scholar] [CrossRef] [PubMed]

- van den Bosch, C.J.H.; Weterings, R.A.P.M. (Eds.) Methods for the Calculation of Physical Effects—Due to Releases of Hazardous Materials (Liquids and Gases); TNO: The Hague, The Netherlands, 2005; Available online: https://content.publicatiereeksgevaarlijkestoffen.nl/documents/PGS2/PGS2-1997-v0.1-physical-effects.pdf (accessed on 21 January 2020).

- Landucci, G.; Tugnoli, A.; Cozzani, V. Inherent safety key performance indicators for hydrogen storage systems. J. Hazard. Mater. 2008, 159, 554–566. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.G.; Chen, Y.T.; Qian, C.J. Study on safety capacity of chemical industrial park in operation stage. Procedia Eng. 2014, 84, 213–222. [Google Scholar] [CrossRef]

- Zhen, X.W.; Vinnem, J.E.; Næs, S. Building safety in the offshore petroleum industry: Development of risk-based major hazard risk indicators at a national level. Proc. Saf. Environ. Protect. 2019, 128, 295–306. [Google Scholar] [CrossRef]

- López-Molina, A.; Vázquez-Roman, R.; Mannan, M.S.; Félix-Flores, M.G. An approach for domino effect reduction based on optimal layouts. J. Loss. Prev. Proc. Ind. 2013, 26, 887–894. [Google Scholar] [CrossRef]

- Dan, S.; Shin, D.; Yoon, E.S. Layout Optimization of LNG-Liquefaction Process on LNG-FPSO Preventing Domino Effects. J. Chem. Eng. Jpn. 2015, 48, 646–655. [Google Scholar] [CrossRef]

- De Lira-Flores, J.; Vázquez-Román, R.; López-Molina, A.; Sam Mannan, M. A MINLP approach for layout designs based on the domino hazard index. J. Loss. Prev. Proc. Ind. 2014, 30, 219–227. [Google Scholar] [CrossRef]

- Bernechea, E.J.; Arnaldos, J. Optimizing the design of storage facilities through the application of ISD and QRA. Proc. Saf. Environ. Protect. 2014, 92, 598–615. [Google Scholar] [CrossRef]

- Khakzad, N.; Reniers, G. Risk-based design of process plants with regard to domino effects and land use planning. J. Hazard. Mater. 2015, 299, 289–297. [Google Scholar] [CrossRef] [PubMed]

- Hauge, S.; Øjen, K. Guidance for Barrier Management in the Petroleum Industry; SINTEF Technical Report No. A27623; SINTEF Technology and Society: Trondheim, Norway, 2016. [Google Scholar]

- Xue, L.N.; Fan, J.C.; Rausand, M.; Zhang, L.B. A safety barrier-based accident model for offshore drilling blowouts. J. Loss. Prev. Proc. Ind. 2013, 26, 164–171. [Google Scholar] [CrossRef]

- Aven, T.; Sklet, S.; Vinnem, J.E. Barrier and operational risk analysis of hydrocarbon releases (BORA-Release). Part I. Method description. J. Hazard. Mater. 2006, 137, 681–691. [Google Scholar] [CrossRef] [PubMed]

- Janssens, J.; Talarico, L.; Reniers, G.; Sörensen, K. A decision model to allocate protective safety barriers and mitigate domino effects. Reliab. Eng. Syst. Saf. 2015, 143, 44–52. [Google Scholar] [CrossRef]

- Du, Y.; Sun, J.H.; Duan, Q.L.; Qi, K.X.; Xiao, H.H.; Liew, K.M. Optimal Assignments of Allocating and Scheduling Emergency Resources to Accidents in Chemical Industrial Parks. J. Loss. Prev. Proc. Ind. 2020, 65, 104148. [Google Scholar] [CrossRef]

- Du, Y.G.; Xiao, H.H.; Sun, J.H.; Duan, Q.L.; Qi, K.X.; Chai, H.; Liew, K.M. Hierarchical pre-positioning of emergency resources for a chemical industrial parks concentrated area. J. Loss. Prev. Proc. Ind. 2020, 66, 104130. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Khakzad, N. Cost-benefit management of intentional domino effects in chemical industrial areas. Proc. Saf. Environ. Protect. 2020, 134, 392–405. [Google Scholar] [CrossRef]

- Ding, G.Y.; Xin, L.; Guo, Q.; Wei, Y.; Li, M.; Liu, X. Environmental risk assessment approaches for industry park and their applications. Resour. Conserv. Recy. 2020, 159, 104844. [Google Scholar] [CrossRef]

- Bellantuono, N.; Carbonara, N.; Pontrandolfo, P. The organization of eco-industrial parks and their sustainable practices. J. Clean. Prod. 2017, 161, 362–375. [Google Scholar] [CrossRef]

- Pilouk, S.; Koottatep, T. Environmental performance indicators as the key for eco-industrial parks in Thailand. J. Clean. Prod. 2017, 156, 614–623. [Google Scholar] [CrossRef]

- Valenzuela-Venegas, G.; Salgado, J.C.; Díaz-Alvarado, F.A. Sustainability indicators for the assessment of eco-industrial parks: Classification and criteria for selection. J. Clean. Prod. 2016, 133, 99–116. [Google Scholar] [CrossRef]

- Gao, C.K.; Gao, C.B.; Song, K.H.; Ye, Z.; Dong, J.H. Regional water ecosystem risk assessment based on GIS and pollutant diffusion model: A case study of Shenzhen eco-industrial park. Proc. Saf. Environ. Protect. 2019, 130, 182–189. [Google Scholar] [CrossRef]

- Alileche, N.; Cozzani, V.; Reniers, G.; Estel, L. Thresholds for domino effects and safety distances in the process industry: A review of approaches and regulations. Reliab. Eng. Syst. Saf. 2015, 143, 74–84. [Google Scholar] [CrossRef]

- Hemmatian, B.; Planas, E.; Casal, J. Fire as a primary event of accident domino sequences: The case of BLEVE. Reliab. Eng. Syst. Saf. 2015, 139, 141–148. [Google Scholar] [CrossRef]

- Khan, F.; Abbasi, S.A. An assessment of the likelihood of occurrence, and the damage potential of domino effect (chain of accidents) in a typical cluster of industries. J. Loss Prev. Proc. Ind. 2001, 14, 283–306. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Dust explosions–Cases, causes, consequences, and control. J. Hazard. Mater. 2007, 140, 7–44. [Google Scholar] [CrossRef]

- Mukhim, E.D.; Abbasi, T.; Tauseef, S.M.; Abbasi, S.A. Domino effect in chemical process industries triggered by overpressure-Formulation of equipment-specific probits. Proc. Saf. Environ. Protect. 2017, 106, 263–273. [Google Scholar] [CrossRef]

- Landucci, G.; Gubinelli, G.; Antonioni, G.; Cozzani, V. The assessment of the damage probability of storage tanks in domino events triggered by fire. Acc. Anal. Prev. 2009, 41, 1206–1215. [Google Scholar] [CrossRef]

- EPA. Hazard Modeling Program. Available online: https://www.epa.gov/cameo/aloha-software (accessed on 8 June 2020).

- Chen, C.; Reniers, G.; Zhang, L.B. An innovative methodology for quickly modeling the spatial-temporal evolution of domino accidents triggered by fire. J. Loss. Prev. Proc. Ind. 2018, 54, 312–324. [Google Scholar] [CrossRef]

- Khakzad, N.; Landucci, G.; Reniers, G. Application of dynamic Bayesian network to performance assessment of fire protection systems during domino effects. Reliab. Eng. Syst. Saf. 2017, 167, 232–247. [Google Scholar] [CrossRef]

- Ding, L.; Ji, J.; Khan, F. Combining uncertainty reasoning and deterministic modeling for risk analysis of fire-induced domino effects. Saf. Sci. 2020, 129, 104802. [Google Scholar] [CrossRef]

- Yang, R.C.; Khan, F.; Taleb-Berrouane, M.; Kong, D.P. A time-dependent probabilistic model for fire accident analysis. Fire Saf. J. 2020, 111, 102891. [Google Scholar] [CrossRef]

- Djelosevic, M.; Tepic, G. Identification of fragmentation mechanism and risk analysis due to explosion of cylindrical tank. J. Hazard. Mater. 2019, 362, 17–35. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.L.; Jiang, J.C.; Zhang, M.G.; Wang, Z.R.; Zhang, Y.N.; Cai, L.W. Investigation of multiple domino scenarios caused by fragments. J. Loss Prev. Proc. Ind. 2016, 40, 591–602. [Google Scholar] [CrossRef]

- Djelosevic, M.; Tepic, G. Probabilistic simulation model of fragmentation risk. J. Loss Prev. Proc. Ind. 2019, 60, 53–75. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Mebarki, A.; Ami Saada, R.; Mercier, F.; Reimeringer, M. Integrated probabilistic framework for domino effect and risk analysis. Adv. Eng. Softw. 2009, 40, 892–901. [Google Scholar] [CrossRef]

- Tugnoli, A.; Gubinelli, G.; Landucci, G.; Cozzani, V. Assessment of fragment projection hazard: Probability distributions for the initial direction of fragments. J. Hazard. Mater. 2014, 279, 418–427. [Google Scholar] [CrossRef]

- Sun, D.L.; Jiang, J.C.; Zhang, M.G.; Wang, Z.R.; Zhang, Y.N.; Yan, L.; Zhang, H.; Du, X.X.; Zou, Y.S. Investigation on the approach of intercepting fragments generated by vessel explosion using barrier net. J. Loss. Prev. Proc. Ind. 2017, 49, 989–996. [Google Scholar] [CrossRef]

- Mebarki, A.; Jerez, S.; Matasic, I.; Prodhomme, G.; Reimeringer, M. Explosions and structural fragments as industrial hazard: Domino effect and risks. Procedia Eng. 2012, 45, 159–166. [Google Scholar] [CrossRef]

- Ahmadi, O.; Mortazavi, S.B.; Pasdarshahri, H.; Mohabadi, H.A. Consequence analysis of large-scale pool fire in oil storage terminal based on computational fluid dynamic (CFD). Proc. Saf. Environ. Protect. 2019, 123, 379–389. [Google Scholar] [CrossRef]

- Baalisampang, T.; Abbasi, R.; Garaniya, V.; Khan, F.; Dadashzadeh, M. Fire impact assessment in FLNG processing facilities using Computational Fluid Dynamics (CFD). Fire Saf. J. 2017, 92, 42–52. [Google Scholar] [CrossRef]

- Scarponi, G.E.; Pastor, E.; Planas, E.; Cozzani, V. Analysis of the impact of wildland-urban-interface fires on LPG domestic tanks. Saf. Sci. 2020, 124, 104588. [Google Scholar] [CrossRef]

- PHAST Process Hazard Analysis Software. Available online: https://www.dnvgl.com/services/process-hazard-analysis-software-phast-1675 (accessed on 7 June 2020).

- Bahlali, M.L.; Dupont, E.; Carissimo, B. Atmospheric dispersion using a Lagrangian stochastic approach: Application to an idealized urban area under neutral and stable meteorological conditions. J. Wind Eng. Ind. Aerod. 2019, 193, 103976. [Google Scholar] [CrossRef]

- Tominaga, Y.; Stathopoulos, T. CFD simulation of near-field pollutant dispersion in the urban environment: A review of current modeling techniques. Atmos. Environ. 2013, 79, 716–730. [Google Scholar] [CrossRef]

- Pandya, N.; Gabas, N.; Marsden, E. Sensitivity analysis of Phast’s atmospheric dispersion model for three toxic materials (nitric oxide, ammonia, chlorine). J. Loss Prev. Proc. Ind. 2012, 25, 20–32. [Google Scholar] [CrossRef]

- Yang, R.C.; Khan, F.; Turco Neto, E.; Rusli, R.; Ji, J. Could pool fire alone cause a domino effect? Reliab. Eng. Syst. Saf. 2020, 202, 106976. [Google Scholar] [CrossRef]

- Cozzani, V.; Gubinelli, G.; Antonioni, G.; Spadoni, G.; Zanelli, S. The assessment of risk caused by domino effect in quantitative area risk analysis. J. Hazard. Mater. 2015, 127, 14–30. [Google Scholar] [CrossRef]

- Zhang, M.G.; Zheng, F.; Chen, F.Z.; Pan, W.J.; Mo, S.F. Propagation probability of domino effect based on analysis of accident chain in storage tank area. J. Loss Prev. Proc. Ind. 2019, 62, 103962. [Google Scholar] [CrossRef]

- Ji, J.; Tong, Q.; Khan, F.; Dadashzadeh, M.; Abbassi, R. Risk-Based Domino Effect Analysis for Fire and Explosion Accidents Considering Uncertainty in Processing Facilities. Ind. Eng. Chem. Res. 2018, 57, 3990–4006. [Google Scholar] [CrossRef]

- Misuri, A.; Antonioni, G.; Cozzani, V. Quantitative risk assessment of domino effect in Natech scenarios triggered by lightning. J. Loss. Prev. Proc. Ind. 2020, 64, 104095. [Google Scholar] [CrossRef]

- Cozzani, V.; Antonioni, G.; Spadoni, G. Quantitative assessment of domino scenarios by a GIS-based software tool. J. Loss. Prev. Proc. Ind. 2006, 19, 463–477. [Google Scholar] [CrossRef]

- Zheng, F.; Zhang, M.G.; Song, J.; Chen, F.Z. Analysis on Risk of Multi—Factor Disaster and Disaster Control in Oil and Gas Storage Tank. Procedia Eng. 2018, 211, 1058–1064. [Google Scholar] [CrossRef]

- Huang, K.X.; Chen, G.H.; Yang, Y.F.; Chen, P.Z. An innovative quantitative analysis methodology for Natech events triggered by earthquakes in chemical tank farms. Saf. Sci. 2020, 128, 104744. [Google Scholar] [CrossRef]

- Kamil, M.Z.; Taleb-Berrouane, M.; Khan, F.; Ahmed, S. Dynamic domino effect risk assessment using Petri-nets. Proc. Saf. Environ. Protect. 2019, 124, 308–316. [Google Scholar] [CrossRef]

- Zhang, L.B.; Landucci, G.; Reniers, G.; Ovidi, F.; Khakzad, N.; Zhou, J.F. Applying Agent Based Modelling and Simulation for Domino Effect Assessment in the Chemical Industries. Chem. Eng. Trans. 2018, 67, 127–132. [Google Scholar] [CrossRef]

- Rad, A.; Abdolhamidzadeh, B.; Abbasi, T.; Rashtchian, D. FREEDOM II: An improved methodology to assess domino effect frequency using simulation techniques. Proc. Saf. Environ. Protec. 2014, 92, 714–722. [Google Scholar] [CrossRef]

- Hosseini, N.; Givehchi, S.; Maknoon, R. Cost-based re risk assessment in natural gas industry by means of fuzzy FTA and ETA. J. Loss Prev. Proc. Ind. 2020, 63, 104025. [Google Scholar] [CrossRef]

- Landucci, G.; Bonvicini, S.; Cozzani, V. A methodology for the analysis of domino and cascading events in Oil & Gas facilities operating in harsh environments. Saf. Sci. 2017, 95, 182–197. [Google Scholar] [CrossRef]

- Alileche, N.; Olivier, D.; Estel, L.; Cozzani, V. Analysis of domino effect in the process industry using the event tree method. Saf. Sci. 2017, 97, 10–19. [Google Scholar] [CrossRef]

- Animah, I.; Shafiee, M. Application of risk analysis in the lique ed natural gas (LNG) sector: An overview. J. Loss Prev. Proc. Ind. 2020, 63, 103980. [Google Scholar] [CrossRef]

- Castiglia, F.; Giardina, M.; Tomarchio, E. THERP and HEART integrated methodology for human error assessment. Radiat. Phys. Chem. 2015, 116, 262–266. [Google Scholar] [CrossRef]

- Ribeiro, A.C.; Sousa, A.L.; Duarte, J.P.; Frutuoso e Melo, P.F. Human reliability analysis of the Tokai-Mura accident through a THERP–CREAM and expert opinion auditing approach. Saf. Sci. 2016, 87, 269–279. [Google Scholar] [CrossRef]

- Liu, X.Y.; Li, J.J.; Li, X.W. Study of dynamic risk management system for flammable and explosive dangerous chemicals storage area. J. Loss Prev. Proc. Ind. 2017, 49, 983–988. [Google Scholar] [CrossRef]

- Rausand, M. Reliability of Safety—Critical Systems. Theory and Applications, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Di Bona, G.; Silvestri, A.; Forcina, A.; Petrillo, A. Total efficient risk priority number (TERPN): A new method for risk assessment. J. Risk Res. 2018, 21, 1384–1408. [Google Scholar] [CrossRef]

- Rausand, M.; Hoyland, A. System Reliability Theory. Models Statistical Methods and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Zio, E. The Monte Carlo Simulation Method for System Reliability and Risk Analysis; Springer: London, UK, 2013. [Google Scholar]

- Koscielny, J.M.; Syfert, M.; Fajdek, B.; Kozak, A. The application of a graph of a process in HAZOP analysis in accident prevention system. J. Loss Prev. Proc. Ind. 2017, 50, 55–66. [Google Scholar] [CrossRef]

- Nakayama, J.; Sakamoto, J.; Kasai, N.; Shibutani, T.; Miyake, A. Preliminary hazard identification for qualitative risk assessment on a hybrid gasoline-hydrogen fueling station with an on-site hydrogen production system using organic chemical hydride. Int. J. Hydrogen Energy 2016, 41, 7518–7525. [Google Scholar] [CrossRef]

- Petroleum Safety Authority. Principles for Barrier Management in the Petroleum Industry. 2013. Available online: https://www.dphu.org/uploads/attachements/books/books_4529_0.pdf (accessed on 10 June 2020).

- Ferjencik, M.; Kuracina, R. MORT WorkSheet or how to make MORT analysis easy. J. Hazard. Mater. 2008, 151, 143–154. [Google Scholar] [CrossRef]

- Lees, F.P. Loss Prevention in the Process Industries, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2012; Available online: https://doi.org/10.1016/B978-0-12-397189-0.00042-2 (accessed on 18 January 2020).

- Nano, G.; Derudi, M. A Critical Analysis of Techniques for the Reconstruction of Workers Accidents. Chem. Eng. Trans. 2013, 31, 415–420. [Google Scholar] [CrossRef]

- Sklet, S. Comparison of some selected methods for accident investigation. J. Hazard. Mater. 2004, 111, 29–37. [Google Scholar] [CrossRef]

- Fahlbruch, B.; Schöbel, M. SOL—Safety through organizational learning: A method for event analysis. Saf. Sci. 2011, 49, 27–31. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.C.; Jia, Q.S.; Li, Z.H.; Chen, P.; Ge, Y. The development history of accident causation models in the past 100 years: 24Model, a more modern accident causation model. Proc. Saf. Environ. Protect. 2020, 134, 47–82. [Google Scholar] [CrossRef]

- Fu, G.; Zhao, Z.Q.; Hao, C.B.; Wu, Q. The Accident Path of Coal Mine Gas Explosion Based on 24Model: A Case Study of the Ruizhiyuan Gas Explosion Accident. Processes 2019, 7, 73. [Google Scholar] [CrossRef]

- Zhang, J.S.; Fu, J.; Hao, H.Y.; Fu, G.; Nie, F.C.; Zhang, W.Y. Root causes of coal mine accidents: Characteristics of safety culture deficiencies based on accident statistics. Proc. Saf. Environ. Protect. 2020, 136, 78–91. [Google Scholar] [CrossRef]

- Churchwell, J.S.; Zhang, K.S.; Saleh, J.H. Epidemiology of helicopter accidents: Trends, rates, and covariates. Reliab. Eng. Syst. Saf. 2018, 180, 373–384. [Google Scholar] [CrossRef]

- Ballester, O.C.; LLari, M.; Afquir, S.; Martin, J.L.; Bourdet, N.; Honoré, V.; Masson, C.; Arnoux, P.J. Analysis of trunk impact conditions in motorcycle road accidents based on epidemiological, accidentological data and multibody simulations. Acc. Anal. Prev. 2019, 127, 223–230. [Google Scholar] [CrossRef]

- Rasmussen, J. Risk management in a dynamic society: A modeling problem. Saf. Sci. 1997, 27, 183–213. [Google Scholar] [CrossRef]

- Salmon, P.M.; Cornelissen, M.; Trotter, M.J. Systems-based accident analysis methods: A comparison of Accimap, HFACS, and STAMP. Saf. Sci. 2012, 50, 1158–1170. [Google Scholar] [CrossRef]

- Yousefi, A.; Rodríguez Hernández, M. A novel methodology to measure safety level of a process plant using a system theory based method (STAMP). Proc. Saf. Environ. Protect. 2020, 136, 296–309. [Google Scholar] [CrossRef]

- Yousefi, A.; Rodríguez Hernández, M. Using a system theory based method (STAMP) for hazard analysis in process industry. J. Loss Prev. Proc. Ind. 2019, 61, 305–324. [Google Scholar] [CrossRef]

- Sultana, S.; Andersen, B.S.; Haugen, S. Identifying safety indicators for safety performance measurement using a system engineering approach. Proc. Saf. Environ. Protect. 2019, 128, 107–120. [Google Scholar] [CrossRef]

- Xing, J.D.; Meng, H.X.; Meng, X.K. An urban pipeline accident model based on system engineering and game theory. J. Loss. Prev. Proc. Ind. 2020, 64, 104062. [Google Scholar] [CrossRef]

- Hollnagel, E. Cognitive Reliability and Error Analysis Method (CREAM); Elsevier Science: Oxford, UK, 1998; Available online: https://doi.org/10.1016/B978-0-08-042848-2.X5000-3 (accessed on 25 January 2020).

- Habibovic, A.; Tivesten, E.; Uchida, N.; Bärgman, J.; Aust, M.L. Driver behavior in car-to-pedestrian incidents: An application of the Driving Reliability and Error Analysis Method (DREAM). Acc. Anal. Prev. 2013, 50, 554–565. [Google Scholar] [CrossRef]

- Bjerga, T.; Aven, T.; Zio, E. Uncertainty treatment in risk analysis of complex systems: The cases of STAMP and FRAM. Relib. Eng. Syst. Saf. 2016, 156, 203–209. [Google Scholar] [CrossRef]

- Yu, M.; Quddus, N.; Kravaris, C.; Sam Mannan, M. Development of a FRAM-based framework to identify hazards in a complex system. J. Loss Prev. Proc. Ind. 2020, 63, 103994. [Google Scholar] [CrossRef]

- Harms-Ringdahl, L. Analysis of safety functions and barriers in accidents. Safety Science. 2009, 47, 353–363. [Google Scholar] [CrossRef]

- Kang, J.; Zhang, J.X.; Gao, J.C. Analysis of the safety barrier function: Accidents caused by the failure of safety barriers and quantitative evaluation of their performance. J. Loss Prev. Proc. Ind. 2016, 43, 361–371. [Google Scholar] [CrossRef]

- Yan, F.; Xu, K.L. Methodology and case study of quantitative preliminary hazard analysis based on cloud model. J. Loss Prev. Proc. Ind. 2019, 60, 116–124. [Google Scholar] [CrossRef]

- Maniram Kumar, A.; Rajakarunakaran, S.; Arumuga Prabhu, V. Application of Fuzzy HEART and expert elicitation for quantifying human error probabilities in LPG refueling station. J. Loss Prev. Proc. Ind. 2017, 48, 186–198. [Google Scholar] [CrossRef]

- Zhou, Q.J.; Wong, Y.D.; Loh, H.S.; Yuen, K.F. A fuzzy and Bayesian network CREAM model for human reliability analysis—The case of tanker shipping. Saf. Sci. 2018, 105, 149–157. [Google Scholar] [CrossRef]

- Konstantdinidou, M.; Nivolianitou, Z.; Kiranoudis, C.; Markatos, N. A fuzzy modeling application of CREAM methodology for human reliability analysis. Reliab. Eng. Syst. Saf. 2006, 91, 706–716. [Google Scholar] [CrossRef]

- Ung, S.-T. Evaluation of human error contribution to oil tanker collision using fault tree analysis and modi ed fuzzy Bayesian Network based CREAM. Ocean Eng. 2019, 179, 159–172. [Google Scholar] [CrossRef]

- Nguyen, S.; Chen, P.S.-L.; Du, Y.Q.; Shi, W.M. A quantitative risk analysis model with integrated deliberative Delphi platform for container shipping operational risks. Transport. Res. E-log. 2019, 129, 203–227. [Google Scholar] [CrossRef]

- Syed, Z.; Lawryshyn, Y. Risk analysis of an underground gas storage facility using a physics-based T system performance model and Monte Carlo simulation. Reliab. Eng. Syst. Saf. 2020, 199, 106792. [Google Scholar] [CrossRef]

- Zhao, L.; Yan, Y.F.; Wang, P.; Yan, X.Z. A risk analysis model for underground gas storage well integrity failure. J. Loss Prev. Proc. Ind. 2019, 62, 103951. [Google Scholar] [CrossRef]

- Hegde, J.; Rokseth, B. Applications of machine learning methods for engineering risk assessment—A review. Saf. Sci. 2020, 122, 104492. [Google Scholar] [CrossRef]

- Rachman, A.; Chandima Ratnayake, M. Machine learning approach for risk-based inspection screening assessment. Reliab. Eng. Syst. Saf. 2019, 185, 518–532. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Comfort, L.; Reniers, G. Learning about risk: Machine learning for risk assessment. Saf. Sci. 2019, 118, 475–486. [Google Scholar] [CrossRef]

- Bucelli, M.; Landucci, G.; Haugen, S.; Paltrinieri, N.; Cozzani, V. Assessment of safety barriers for the prevention of cascading events in oil and gas offshore installations operating in harsh environment. Ocean Eng. 2018, 171–185. [Google Scholar] [CrossRef]

- Rostamabadi, A.; Jahangiri, M.; Zarei, E.; Kamalinia, M.; Alimohammadlou, M. A novel Fuzzy Bayesian Network approach for safety analysis of process systems; An application of HFACS and SHIPP methodology. J. Clean. Prod. 2020, 244, 118761. [Google Scholar] [CrossRef]

- Villa, V.; Paltrinieri, N.; Khan, F.; Cozzani, V. Towards dynamic risk analysis: A review of the risk assessment approach and its limitations in the chemical process industry. Saf. Sci. 2016, 89, 77–93. [Google Scholar] [CrossRef]

- Khakzad, N. Application of dynamic Bayesian network to risk analysis of domino effects in chemical infrastructures. Reliab. Eng. Syst. Saf. 2015, 138, 263–272. [Google Scholar] [CrossRef]

- Wu, S.M.; Zhang, L.B.; Fan, J.C.; Zhou, Y.F. Dynamic risk analysis of hydrogen sulfide leakage for offshore natural gas wells in MPD phases. Proc. Saf. Environ. Protect. 2019, 122, 339–351. [Google Scholar] [CrossRef]

- Meng, X.K.; Chen, G.M.; Zhu, G.G.; Zhu, Y. Dynamic quantitative risk assessment of accidents induced by leakage on offshore platforms using DEMATEL-BN. Int. J. Nav. Archit. Ocean Eng. 2018, 11, 22–32. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Tugnoli, A.; Cozzani, V. Hazard identification for innovative LNG regasification technologies. Reliab. Eng. Syst. Saf. 2015, 137, 18–28. [Google Scholar] [CrossRef]

- Wang, H.Z.; Khan, F.; Ahmed, S.; Imtiaz, S. Dynamic quantitative operational risk assessment of chemical processes. Chem. Eng. Sci. 2016, 142, 62–78. [Google Scholar] [CrossRef]

- Folch-Calvo, M.; Brocal, F.; Sebastián, M.A. Dynamic methodology for risk assessment in industrial processes by using quality control charts. Procedia Mfg. 2019, 41, 1111–1118. [Google Scholar] [CrossRef]

- Folch-Calvo, M. Development of a Dynamic Risk Assessment and Control Methodology for Industrial Accidents. Ph.D. Thesis, National University of Distance Education, Madrid, Spain, 2020. Available online: https://www.academia.edu/43333904/Development_of_a_dynamic_risk_assessment_and_control_methodology_for_industrial_accidents (accessed on 15 June 2020).

- Huang, B.J.; Yong, G.; Zhao, J.; Domenech, T.; Liu, Z.; Chiu, S.F.; McDowall, W.; Bleischwitz, R.; Liu, J.R.; Yao, Y. Review of the development of China’s Eco-industrial Park standard system. Resour. Conserv. Recy. 2019, 140, 137–144. [Google Scholar] [CrossRef]

- Swuste, P.; Van Nunen, K.; Reniers, G.; Khakzad, N. Domino effects in chemical factories and clusters: An historical perspective and discussion. Proc. Saf. Environ. Protect. 2019, 124, 18–30. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Khakzad, N. A thorough classification and discussion of approaches for modeling and managing domino effects in the process industries. Saf. Sci. 2020, 125, 104618. [Google Scholar] [CrossRef]

- Singh, K.; Maiti, J. A novel data mining approach for analysis of accident paths and performance assessment of risk control systems. Reliab. Eng. Syst. Saf. 2020, 202, 107041. [Google Scholar] [CrossRef]

| Characteristic | Description |

|---|---|

| Prevention (P) | The process of avoiding or mitigating the risks by reducing their probability of occurrence and their impacts on humans and society; geographical and landscape; economical and infrastructures; environmental and ecosystem preservation; accident and safety (human, assets, production); perception and expectations. |

| Simultaneity (S) | The capacity to update the risk evolution according to the real time situation of the operations. |

| Immediacy (I) | The capacity to inform or infer the existence of a risk with enough time for making the needed corrections before the accident occurs. |

| Characteristic 1 | Degree of Difficulty for Defining a Standard Procedure |

|---|---|

| LDSP | Low Difficulty. The procedure is defined and normalized without supervision. |

| MDSP | Medium Difficulty. The procedure has additional inputs and outputs of information not normalizable and needs some supervision. |

| HDSP | High Difficulty. The procedure has extensive inputs and outputs of information not normalizable with continuous supervision. |

| Characteristic | User Profile |

|---|---|

| EK | Early and no technical knowledge is needed about procedures, processes, and chemical installations. Level of plant operator. |

| BK | Basic knowledge of principles, procedures, processes, and chemical installations. Level of plant operator. |

| MK | Medium knowledge of principles, procedures, processes, and chemical installations. Level of supervisor. |

| SK | Strong knowledge of principles, procedures, processes, and chemical installations. Level of officer. |

| RK | Research knowledge. With high technical and scientific background for the implementation and interpretation of procedures, processes, and chemical installations. Level of officer, scientific researcher. |

| Equipment Category | a | b | Threshold |

|---|---|---|---|

| Atmospheric | −18.96 | 2.44 | 22 kPa |

| Pressurized | −42.44 | 4.33 | 16 kPa |

| Elongated | −28.07 | 3.16 | 31 kPa |

| Small | −17.79 | 2.18 | 37 kPa |

| Equipment Category | Treshold | Correlation |

|---|---|---|

| Atmospheric | 15 kW/m2 t ≥ 10 min | Y = 12.54 − 1.847 × ln(ttf) ln(ttf) = −1.128 × ln(l) − 2.667 × 10−5V + 9.887 |

| Pressurized | 50 kW t ≥ 10 min | Y = 12.54 − 1.847 × ln(ttf) ln(ttf) = −0.947 × ln(l) + 8.835V0.032 |

| Model Methodology | Description | Supplied Information (P); (S); (I) | Standard and User Levels | Domino Effect Treatment |

|---|---|---|---|---|

| Sequential | Are representative of the Quantitative Risk Assessment (QRA) methodology regarding accidents as outcomes of a chain of discrete events or factors that take place in a temporal order. Analyzing causes and consequences of risk. | |||

| FTA [23] | Fault Tree Analysis. Causes of risk. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| ETA [23,105,106,107,108] | Event Tree Analysis. Consequence analysis. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| THERP [109,110] | (Technique for Human Error Rate Prediction) a tool based on event-tree approach for evaluating human errors alone or in connection with equipment functioning, operational procedures, and practices. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| BOWTIE [23,111] | Graphic including Fault Tree Analysis (FTA) and Event Tree Analysis (ETA) models to represent causes and consequence events, and what are the needed safety barriers. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| FMEA [112] | Failure Mode Effect Analysis. Step-by-step approach for identifying potential failures. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| FMECA [112,113] | Failure Modes Effects and Criticality Analysis. Upgrade of the FMEA. The criticality is determined classifying the degree of potential failures. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| Check List-What if [114] | Systematic revision to find malfunctions and compliance with a list of requirements. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| Block-Diagrams [114] | Graphical procedure describing the function of the system and showing the logical connections of components needed to fulfill a specified system function. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

| RRA [115] | Reliability Assessment. Quantification of the probability of failure in a system. General application. | (P) (+/- S) QRA framework | HDSP MK,SK | GT |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Folch-Calvo, M.; Brocal-Fernández, F.; González-Gaya, C.; Sebastián, M.A. Analysis and Characterization of Risk Methodologies Applied to Industrial Parks. Sustainability 2020, 12, 7294. https://doi.org/10.3390/su12187294

Folch-Calvo M, Brocal-Fernández F, González-Gaya C, Sebastián MA. Analysis and Characterization of Risk Methodologies Applied to Industrial Parks. Sustainability. 2020; 12(18):7294. https://doi.org/10.3390/su12187294

Chicago/Turabian StyleFolch-Calvo, Martin, Francisco Brocal-Fernández, Cristina González-Gaya, and Miguel A. Sebastián. 2020. "Analysis and Characterization of Risk Methodologies Applied to Industrial Parks" Sustainability 12, no. 18: 7294. https://doi.org/10.3390/su12187294

APA StyleFolch-Calvo, M., Brocal-Fernández, F., González-Gaya, C., & Sebastián, M. A. (2020). Analysis and Characterization of Risk Methodologies Applied to Industrial Parks. Sustainability, 12(18), 7294. https://doi.org/10.3390/su12187294