Eco-innovation Capability and Sustainability Driven Innovation Practices in Romanian SMEs

Abstract

1. Introduction

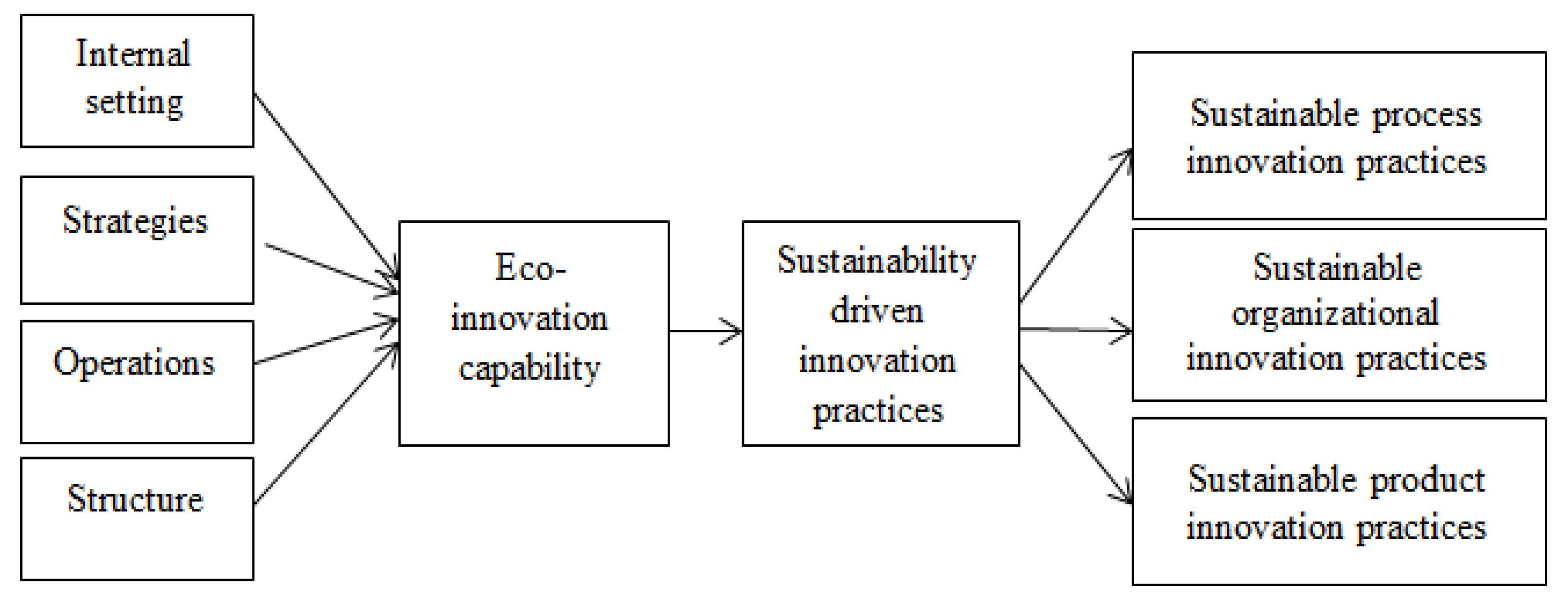

2. Literature Review and Hypothesis Development

2.1. Eco-innovation Capability

2.2. Sustainability Driven Innovation Practices and Eco-innovation

3. Materials and Methods

3.1. Questionnaire Development

3.2. Sampling

3.3. Common Method Bias

3.4. Method

4. Data Analysis and Results

4.1. Assessment of the Measurement Model

4.2. Assessment of the Structural Model

5. Discussion of the Empirical Findings

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cuerva, M.C.; Triguero-Cano, A.; Corcoles, D. Drivers of green and non-green innovation: Empirical evidence in Low-Tech SMEs. J. Clean. Prod. 2014, 68, 104–113. [Google Scholar] [CrossRef]

- Simboli, A.; Taddeo, R.; Morgante, A. Analysing the development of Industrial Symbiosis in a motorcycle local industrial network: The role of contextual factors. J. Clean. Prod. 2014, 66, 372–383. [Google Scholar] [CrossRef]

- Costantini, V.; Crespia, F.; Martini, C.; Pennacchio, L. Demand-pull and technology-push public support for eco-innovation: The case of the biofuels sector. Res. Policy 2015, 44, 577–595. [Google Scholar] [CrossRef]

- Przychodzen, J.W. Relationships between eco-innovation and financial performance—Evidence from publicly traded companies in Poland and Hungary. J. Clean. Prod. 2015, 90, 253–263. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. Drivers of different types of eco-innovation in European SMEs. Ecol. Econ. 2013, 92, 25–33. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. Eco-innovation by small and medium-sized firms in Europe: From end-of-pipe to cleaner technologies. Organ. Manag. 2015, 17, 24–40. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Farracho, M.; Bosworth, R.; Kemp, R. The front-end of eco-innovation for eco-innovative small and medium sized companies. J. Eng. Technol. Manag. 2014, 31, 43–57. [Google Scholar] [CrossRef]

- Brammer, S.; Hoejmose, S.; Marchant, K. Environmental management in SMEs in the UK: Practices, pressures and perceived benefits. Bus. Strategy Environ. 2012, 21, 423–434. [Google Scholar] [CrossRef]

- Keskin, D.; Diehl, J.C.; Molenaar, N. Innovation process of new ventures driven by sustainability. J. Clean. Prod. 2013, 45, 50–60. [Google Scholar] [CrossRef]

- de Jesus Pacheco, D.A.; tenCaten, C.S.; Jung, C.F.; Guitiss Navas, H.V.; Cruz-Machado, V.A. Eco-innovation determinants in manufacturing SMEs from emerging markets: Systematic literature review and challenges. J. Eng. Technol. Manag. 2018, 48, 44–63. [Google Scholar] [CrossRef]

- De Marchi, V. Environmental innovation and R&D cooperation: Empirical evidence from Spanish manufacturing firms. Res. Policy 2012, 41, 614–623. [Google Scholar]

- Hansen, E.G.; Klewitz, J. The role of an SME’s green strategy in public-private eco-innovation initiatives: The case of Ecoprofit. J. Small Bus. Entrep. 2012, 25, 451–477. [Google Scholar] [CrossRef]

- Klewitz, J.; Zeyen, A.; Hansen, E.G. Intermediaries driving eco-innovation in SMEs: A qualitative investigation. Eur. J. Innov. Manag. 2012, 15, 442–467. [Google Scholar] [CrossRef]

- Sáez-Martínez, F.J.; Díaz-García, C.; Gonzalez-Moreno, A. Firm technological trajectory as a driver of eco-innovation in young small and medium-sized enterprises. J. Clean. Prod. 2016, 138, 28–37. [Google Scholar] [CrossRef]

- Carrillo-Hermosilla, J.; Río, P.; Könnölä, T. Diversity of eco-innovations: Reflections from selected case studies. J. Clean. Prod. 2010, 18, 1073–1083. [Google Scholar] [CrossRef]

- Cai, W.; Zhou, X. On the drivers of eco-innovation: Empirical evidence from China. J. Clean. Prod. 2014, 79, 239–248. [Google Scholar] [CrossRef]

- Hottenrott, H.; Lopes-Bento, C. R&D collaboration and SMEs: The effectiveness of targeted public R&D support schemes. Res. Policy 2014, 43, 1055–1066. [Google Scholar]

- Lee, N.; Sameen, H.; Cowling, M. Access to finance for innovative SMEs since the financial crisis. Res. Policy 2015, 44, 370–380. [Google Scholar] [CrossRef]

- Aykol, B.; Leonidou, C.L. Researching the green practices of smaller service firms: A theoretical, methodological, and empirical assessment. J. Small Bus. Manag. 2014, 53, 1264–1288. [Google Scholar] [CrossRef]

- Wang, C.L.; Ahmed, P.K. The development and validation of the organizational innovativeness construct using confirmatory factor analysis. Eur. J. Innov. Manag. 2004, 7, 303–313. [Google Scholar] [CrossRef]

- Schaltegger, S. Sustainability as a driver for corporate economic success. Soc. Econ. 2011, 33, 15–28. [Google Scholar] [CrossRef]

- Caroli, E.; Van Reenen, J. Skill biased organizational change? Evidence from a panel of British and French establishments. Q. J. Econ. 2001, 116, 1149–1192. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management—An exploratory literature review. R D Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Halati, A.; He, Y. Intersection of economic and environmental goals of sustainable development initiatives. J. Clean. Prod. 2018, 189, 813–829. [Google Scholar] [CrossRef]

- Halila, F.; Rundquist, J. The development and market success of eco-innovations: A comparative study of eco-innovations and “other” innovations in Sweden. Eur. J. Innov. Manag. 2011, 14, 278–302. [Google Scholar] [CrossRef]

- Karakaya, E.; Hidalgo, A.; Nuur, C. Diffusion of eco-innovations: A review. Renew. Sustain. Energy Rev. 2014, 33, 392–399. [Google Scholar] [CrossRef]

- Rennings, K. Redefining innovation-eco-innovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Boons, F.; Montalvo, C.; Quist, J.; Wagner, M. Sustainable innovation, business models and economic performance: An overview. J. Clean. Prod. 2013, 45, 1–8. [Google Scholar] [CrossRef]

- Siqueira, R.P.; Pitassi, C. Sustainability-oriented innovations: Can mindfulness make a difference? J. Clean. Prod. 2016, 139, 1181–1190. [Google Scholar] [CrossRef]

- Gupta, M.C. Environmental management and its impact on the operations function. Int. J. Oper. Prod. Manag. 1995, 15, 34–51. [Google Scholar] [CrossRef]

- Sarkis, J.; Rasheed, A. Greening the manufacturing function. Bus. Horiz. 1995, 38, 17–27. [Google Scholar] [CrossRef]

- Kitazawa, S.; Sarkis, J. The relationship between ISO 14001 and continuous source reduction programs. Int. J. Oper. Prod. Manag. 2000, 20, 225–248. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. Environmental proactivity and business performance: An empirical analysis. Omega 2005, 33, 1–15. [Google Scholar] [CrossRef]

- Bansal, P.; Gao, J. Building the future by looking to the past: Examining research published on organizations and environment. Organ. Environ. 2006, 19, 458–478. [Google Scholar] [CrossRef]

- Darnall, N.; Henriques, I.; Sadorsky, P. Do environmental management systems improve business performance in an international setting? J. Int. Manag. 2008, 14, 364–376. [Google Scholar] [CrossRef]

- Ahmad, S.; Schroeder, R.G. The impact of human resource management practices on operational performance: Recognizing country and industry differences. J. Oper. Manag. 2003, 21, 19–43. [Google Scholar] [CrossRef]

- Yang, C.L.; Lin, S.P.; Chan, Y.H.; Sheu, C. Mediated effect of environmental management on manufacturing competitiveness: An empirical study. Int. J. Prod. Econ. 2010, 123, 210–220. [Google Scholar] [CrossRef]

- Jacobs, B.W.; Singhal, V.R.; Subramanian, R. An empirical investigation of environmental performance and the market value of the firm. J. Oper. Manag. 2010, 28, 430–441. [Google Scholar] [CrossRef]

- Zeng, S.X.; Xie, X.M.; Tam, C.M.; Wan, T.W. Competitive priorities of manufacturing firms for internationalization: An empirical research. Meas. Bus. Excell. 2008, 12, 44–55. [Google Scholar] [CrossRef]

- Wagner, M. Integration of environmental management with other managerial functions of the firm. Empirical effects on drivers of economic performance. Long Range Plan. 2007, 40, 611–628. [Google Scholar] [CrossRef]

- Horbach, J. Determinants of environmental innovation – new evidence from German panel data sources. Res. Policy 2008, 37, 163–173. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- Darnall, N. Why firms mandate ISO 14001 certification. Bus. Soc. 2006, 45, 354–381. [Google Scholar] [CrossRef]

- Bansal, P.; Hunter, T. Strategic explanations for the early adoption of ISO 14001. J. Bus. Ethics 2003, 46, 289–299. [Google Scholar] [CrossRef]

- Bos-Brouwers, H.E.J. Corporate sustainability and innovation in SMEs: Evidence of themes and activities in practice. Bus. Strategy Environ. 2010, 19, 417–435. [Google Scholar] [CrossRef]

- del Brío, J.A.; Junquera, B. A review of the literature on environmental innovation management in SMEs: Implications for public policies. Technovation 2003, 23, 939–948. [Google Scholar] [CrossRef]

- Mazzanti, M.; Zobloi, R. Environmental innovations, SME strategies and policy induced effects: Evidence for a district-based local system in northern Italy. ICFAI J. Environ. Econ. 2008, 6, 7–34. [Google Scholar]

- Sanches-Medina, P.S.; Corbett, J.; Toledo-Lopez, A. Environmental innovation and sustainability in small handicraft businesses in Mexico. Sustainability 2011, 3, 984–1002. [Google Scholar] [CrossRef]

- Fernández-Viné, M.; Gómez-Navarro, T.; Capuz-Rizo, S. Eco-efficiency in the SMEs of Venezuela. Current status and future perspectives. J. Clean. Prod. 2010, 18, 736–746. [Google Scholar] [CrossRef]

- Suh, S.; Lee, M.K.; Ha, S. Eco-efficiency for pollution prevention in small to medium-sized enterprises: A case from South Korea. J. Ind. Ecol. 2005, 9, 223–240. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Exploring drivers for energy efficiency within small-and medium-sized enterprises: First evidences from Italian manufacturing enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Demirel, P.; Kesidou, E. Sustainability-oriented capabilities for eco-innovation: Meeting the regulatory, technology, and market demands. Bus. Strategy Environ. 2019, 28, 847–857. [Google Scholar] [CrossRef]

- Russo, M.; Fouts, P. A resource-based perspective on corporate environmental performance and sustainability. Acad. Manag. J. 1997, 40, 534–559. [Google Scholar]

- Katkalo, V.; Pitelis, C.; Teece, D. Introduction: On the nature and scope of dynamic capabilities. Ind. Corp. Chang. 2010, 19, 1175–1186. [Google Scholar] [CrossRef]

- Teece, D.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Helfat, C.; Peteraf, C. Understanding dynamic capabilities: Progress along a developmental path. Strateg. Organ. 2009, 7, 91–102. [Google Scholar] [CrossRef]

- Ambrosini, V.; Bowman, C.; Collier, N. Dynamic capabilities: An exploration of how firms renew their resource base. Br. J. Manag. 2009, 20 (Suppl. s1), S9–S24. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Bloom, N.; Genakos, C.; Martin, R.; Sadun, R. Modern management: Good for the environment or just hot air? Econ. J. 2010, 120, 551–572. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green product innovation in manufacturing firms: A sustainability-oriented dynamic capability perspective. Bus. Strategy Environ. 2017, 2, 490–506. [Google Scholar] [CrossRef]

- Jiang, W.; Chai, H.; Shao, J.; Feng, T. Green entrepreneurial orientation for enhancing firm performance: A dynamic capability perspective. J. Clean. Prod. 2018, 198, 1311–1323. [Google Scholar] [CrossRef]

- Hofmann, K.H.; Theyel, G.; Wood, C.H. Identifying firm capabilities as drivers of environmental management and sustainability practices–evidence from small and medium-sized manufacturers. Bus. Strategy Environ. 2012, 21, 530–545. [Google Scholar] [CrossRef]

- Antonioli, D.; Mancinelli, S.; Mazzanti, M. Is environmental innovation embedded within high performance organizational changes? The role of human resource management and complementarity in green business strategies. Res. Policy 2013, 42, 975–988. [Google Scholar] [CrossRef]

- Kesidou, E.; Demirel, P. On the drivers of eco-innovations: Empirical evidence from the UK. Res. Policy 2012, 41, 862–870. [Google Scholar] [CrossRef]

- Melander, L. Customer and supplier collaboration in green product ınnovation: External and ınternal capabilities. Bus. Strategy Environ. 2018, 27, 677–693. [Google Scholar] [CrossRef]

- Kabongo, J.D.; Boiral, O. Doing more with less: Building dynamic capabilities for eco-efficiency. Bus. Strategy Environ. 2017, 26, 956–971. [Google Scholar] [CrossRef]

- Ko, W.W.; Liu, G. Environmental strategy and competitive advantage: The role of small-and medium-sized enterprises’ dynamic capabilities. Bus. Strategy Environ. 2017, 26, 584–596. [Google Scholar] [CrossRef]

- Pacheco, L.M.; Alves, M.F.R.; Liboni, L.B. Green absorptive capacity: A mediation-moderation model of knowledge for innovation. Bus. Strategy Environ. 2018, 27, 1502–1513. [Google Scholar] [CrossRef]

- Lee, S.; Klassen, R.D. Firms’ response to climate change: The interplay of business uncertainty and organizational capabilities. Bus. Strategy Environ. 2016, 25, 577–592. [Google Scholar] [CrossRef]

- Aragon-Correa, J.; Sharma, S. A contingent resource-based view of proactive corporate environmental strategy. Acad. Manag. Rev. 2003, 28, 71–88. [Google Scholar] [CrossRef]

- Henriques, I.; Sadorsky, P. The relationship between environmental commitment and managerial perceptions of stakeholder importance. Acad. Manag. Rev. 1999, 42, 87–99. [Google Scholar]

- Aragon-Correa, J.A.; Rubio-Lopez, E. Proactive corporate environmental strategies: Myths and misunderstandings. Long Range Plan. 2007, 40, 357–381. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. A review of determinant factors of environmental proactivity. Bus. Strategy Environ. 2006, 15, 87–102. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, S. Drivers of proactive environmental strategy in family firms. Bus. Ethics Q. 2011, 21, 309–334. [Google Scholar] [CrossRef]

- Demirel, P.; Iatridis, K.; Kesidou, E. The impact of regulatory complexity upon self-regulation: Evidence from the adoption and certification of environmental management systems. J. Environ. Manag. 2018, 207, 80–91. [Google Scholar] [CrossRef]

- Hawn, O.; Ioannou, I. Mind the gap: The interplay between external and internal actions in the case of corporate social responsibility. Strateg. Manag. J. 2016, 37, 2569–2588. [Google Scholar] [CrossRef]

- Potoski, M.; Prakash, A. Voluntary environmental programs: A comparative perspective. J. Policy Anal. Manag. 2012, 31, 123–138. [Google Scholar]

- Arimura, T.H.; Hibiki, A.; Katayama, H. Is a voluntary approach an effective environmental policy instrument? A case for environmental management systems. J. Environ. Econ. Manag. 2008, 55, 281–295. [Google Scholar] [CrossRef]

- Rennings, K.; Ziegler, A.; Ankele, K.; Hoffmann, E. The influence of different characteristics of the EU environmental management and auditing scheme on technical environmental innovations and economic performance. Ecol. Econ. 2006, 57, 45–59. [Google Scholar] [CrossRef]

- Heras-Saizarbitoria, I.; Arana, G.; Boiral, O. Outcomes of environmental management systems: The role of motivations and firms’ characteristics. Bus. Strategy Environ. 2016, 25, 545–559. [Google Scholar] [CrossRef]

- Mazzi, A.; Toniolo, S.; Mason, M.; Aguiari, F.; Scipioni, A. What are the benefits and difficulties in adopting an environmental management system? The opinion of Italian organizations. J. Clean. Prod. 2016, 139, 873–885. [Google Scholar] [CrossRef]

- De Luca, L.M.; Verona, G.; Vicari, S. Market orientation and R&D effectiveness in high-technology firms: An empirical ınvestigation in the biotechnology ındustry. J. Prod. Innov. Manag. 2010, 27, 299–320. [Google Scholar]

- Dangelico, R.M.; Vocalelli, D. “Green Marketing”: An analysis of definitions, strategy steps, and tools through a systematic review of the literature. J. Clean. Prod. 2017, 165, 1263–1279. [Google Scholar] [CrossRef]

- Ottman, J.A.; Stafford, E.R.; Hartman, C.L. Avoiding green marketing myopia: Ways to improve consumer appeal for environmentally preferable products. Environ. Sci. Policy Sustain. Dev. 2006, 48, 22–36. [Google Scholar] [CrossRef]

- Heusinkveld, S.; Benders, J.; van den Berg, R.-J. From market sensing to new concept development in consultancies: The role of information processing and organizational capabilities. Technovation 2009, 29, 509–516. [Google Scholar] [CrossRef]

- Tsai, M.-T.; Chuang, L.-M.; Chao, S.-T.; Chang, H.-P. The effects assessment of firm environmental strategy and customer environmental conscious on green product development. Environ. Monit. Assess. 2012, 184, 4435–4447. [Google Scholar] [CrossRef]

- Hansen, O.E.; Sondergard, B.; Meredith, S. Environmental innovations in small and medium sized enterprises. Technol. Anal. Strateg. Manag. 2002, 14, 37–56. [Google Scholar] [CrossRef]

- Scarpellini, S.; Aranda, A.; Aranda, J.; Llera, E.; Marco, M. R&D and eco-innovation: Opportunities for closer collaboration between universities and companies through technology centers. Clean Technol. Environ. Policy 2012, 14, 1047–1058. [Google Scholar]

- De Jesus Pacheco, D.A.; Caten, C.S.; Jung, C.F.; Ribeiro, J.L.D.; Navas, H.V.G.; Cruz-Machado, V.A. Eco-innovation determinants in manufacturing SMEs: Systematic review and research directions. J. Clean. Prod. 2017, 142, 2277–2287. [Google Scholar] [CrossRef]

- Maçaneiro, M.B.; Cunha, S.K.; Balbinot, Z. Drivers of the adoption of eco-innovations in the pulp, paper, and paper products industry in Brazil. Lat. Am. Bus. Rev. 2013, 14, 179–208. [Google Scholar] [CrossRef]

- Paramanathan, S.; Farrukh, C.; Phaal, R.; Probert, D. Implementing industrial sustainability: The research issues in technology management. R D Manag. 2004, 34, 527–537. [Google Scholar] [CrossRef]

- Noci, G.; Verganti, R. Managing ‘green’ product innovation in small firms. R D Manag. 1999, 29, 3–15. [Google Scholar] [CrossRef]

- Fernando, Y.; Jabbour, C.J.C.; Wah, W.X. Pursuing green growth in technology firms through the connections between environmental innovation and sustainable business performance: Does service capability matter? Resour. Conserv. Recycl. 2019, 141, 8–20. [Google Scholar] [CrossRef]

- Li, D.; Zheng, M.; Cao, C.; Chen, X.; Ren, S.; Huang, M. The impact of legitimacy pressure and corporate profitability on green innovation: Evidence from China top 10. J. Clean. Prod. 2017, 141, 41–49. [Google Scholar] [CrossRef]

- Rossiter, W.; Smith, D.J. Green innovation and the development of sustainable communities: The case of Blueprint Regeneration’s Trent Basin development. Int. J. Entrep. Innov. 2018, 19, 21–32. [Google Scholar] [CrossRef]

- Huber, J. Technological environmental innovations (TEIs) in a chain analytical and life-cycle-analytical perspective. J. Clean. Prod. 2008, 16, 1980–1986. [Google Scholar] [CrossRef]

- Altham, W. Benchmarking to trigger cleaner production in small businesses: Dry cleaning case study. J. Clean. Prod. 2007, 15, 798–813. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Leal-Millan, A.; Cepeda-Carrion, G. The antecedents of green innovation performance: A model of learning and capabilities. J. Bus. Res. 2016, 69, 4912–4917. [Google Scholar] [CrossRef]

- De Palma, R.; Dobes, V. An integrated approach towards sustainable entrepreneurship—Experience from the TEST project in transitional economies. J. Clean. Prod. 2010, 18, 1807–1821. [Google Scholar] [CrossRef]

- Côté, R.; Booth, A.; Louis, B. Eco-efficiency and SMEs in Nova Scotia, Canada. J. Clean. Prod. 2006, 14, 542–550. [Google Scholar] [CrossRef]

- Lee, S.; Klassen, R. Drivers and enablers that foster environmental management capabilities in small- and medium-sized suppliers in supply chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T.; Isaksson, R. The support of Quality Management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Vaccaro, I.G.; Jansen, J.J.P.; Van Den Bosch, F.A.J.; Volberda, H.W. Management innovation and leadership: The moderating role of organizational size. J. Manag. Stud. 2012, 49, 28–51. [Google Scholar] [CrossRef]

- Zbaracki, M. The rhetoric and reality of total quality management. Adm. Sci. Q. 1998, 43, 602–636. [Google Scholar] [CrossRef]

- Qi, G.; Zeng, S.; Li, X.; Tam, C. Role of internalization process in defining the relationship between ISO 14001 certification and corporate environmental performance. Corp. Soc. Responsib. Environ. Manag. 2012, 19, 129–140. [Google Scholar] [CrossRef]

- Maas, S.; Reniers, G. Development of a CSR model for practice: Connecting five inherent areas of sustainable business. J. Clean. Prod. 2013, 64, 104–114. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources. A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Zhang, D.; Rong, Z.; Ji, Q. Green innovation and firm performance: Evidence from listed companies in China. Resour. Conserv. Recycl. 2019, 144, 48–55. [Google Scholar] [CrossRef]

- Sethi, R.; Smith, D.C.; Park, C.W. Cross-functional Product Development Teams, Creativity, and the Innovativeness of New Consumer Products. J. Mark. Res. 2001, 38, 73–85. [Google Scholar] [CrossRef]

- Henard, D.H.; Szymanski, D.M. Why some new products are more successful than others. J. Mark. Res. 2001, 38, 362–375. [Google Scholar] [CrossRef]

- Danneels, E.; Kleinschmidt, E.J. Product innovativeness from the firm’s perspective: Its dimensions and their relation with product selection and performance. J. Prod. Innov. Manag. 2001, 18, 357–373. [Google Scholar] [CrossRef]

- Chen, Y. The driver of green innovation and green image—Green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A.; Hurtado-Torres, N.; Sharma, S.; García-Morales, V.J. Environmental strategy and performance in small firms: A resource-based perspective. J. Environ. Manag. 2008, 86, 88–103. [Google Scholar] [CrossRef]

- Jenkins, H. A ‘business opportunity’ model of corporate social responsibility for small- and medium-sized enterprises. Bus. Ethics 2009, 18, 21–36. [Google Scholar] [CrossRef]

- Alshanty, A.M.; Emeagwali, O.L. Market-sensing capability, knowledge creation and innovation: The moderating role of entrepreneurial-orientation. J. Innov. Knowl. 2019, 4, 171–178. [Google Scholar] [CrossRef]

- Li, D.; Zhao, Y.; Zhang, L.; Chen, X.; Cao, C. Impact of quality management on green innovation. J. Clean. Prod. 2018, 170, 462–470. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Howard, M.C.; Nitzl, C. Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. J. Bus. Res. 2020, 109, 101–110. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective, 7th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Malhotra, N.K.; Birks, D.; Wills, P. Marketing Research: Applied Approach, 4th ed.; Pearson: New York, NY, USA, 2012. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–45. [Google Scholar] [CrossRef]

- Sarstedt, M.; Mooi, E.A. A Concise Guide to Market Research: The Process, Data, and Methods Using IBM SPSS Statistics, 2nd ed.; Springer: Berlin, Germany, 2014. [Google Scholar]

- Johansson, G.; Sundin, E. Lean and green product development: Two sides of the same coin. J. Clean. Prod. 2014, 85, 104–121. [Google Scholar] [CrossRef]

- Larson, T.; Greenwood, R. Perfect complements: Synergies between lean production and eco-sustainability initiatives. Environ. Qual. Manag. 2004, 13, 27–36. [Google Scholar] [CrossRef]

- Kurdve, M.; Zackrisson, M.; Wiktorsson, M.; Harlin, U. Lean and Green integration into production system models? Experiences from Swedish industry. J. Clean. Prod. 2014, 85, 180–190. [Google Scholar] [CrossRef]

- Vinodh, S.; Arvind, K.R.; Somanaathan, M. Tools and techniques for enabling sustainability through lean initiatives. Clean Technol. Environ. Policy 2011, 13, 469–479. [Google Scholar] [CrossRef]

- Aguado, S.; Alvarez, R.; Domingo, R. Model of efficient and sustainable improvements in a lean production system through processes of environmental innovation. J. Clean. Prod. 2013, 47, 141–148. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Modelling lean and green: A review from business models. Int. J. Lean Six Sigma 2013, 4, 228–250. [Google Scholar] [CrossRef]

- Williander, M. Absorptive capacity and interpretation system’s impact when “going green”: An empirical study of Ford, Volvo cars and Toyota. Bus. Strategy Environ. 2007, 16, 202–213. [Google Scholar] [CrossRef]

- Pereira, D.; Leitão, J. Absorptive capacity, coopetition and generation of product innovation: Contrasting Italian and Portuguese manufacturing firms. Int. J. Technol. Manag. 2016, 71, 1–28. [Google Scholar] [CrossRef]

- Ceptureanu, S.I.; Ceptureanu, E.G. Knowledge Management in Romanian Companies. Qual.-Access Success 2015, 16, 61–66. [Google Scholar]

| Factor | Description | References |

|---|---|---|

| Internal setting | Availability of appropriate HR resources | [5,8,11,14,46,47,48,50,89,90,91] |

| Past performance of the firm as a source for eco-innovation capability development | ||

| Availability of technological expertise | ||

| Strategies | Strategic relevance of eco-innovation for top management | [5,11,14,46,47,48,49,50,90] |

| Long term strategies focused on eco-innovation | ||

| Commitment to eco-innovation implementation | ||

| Operations | Cooperation within supply networks | [5,11,14,46,47,48,50,90] |

| Process flexibility supporting eco-innovation | ||

| Recycling practices and reverse logistics processes | ||

| Structure | Eco-innovation oriented methods | [5,11,14,46,47,48,49,50,51,88,89,90] |

| Organizational structure support for eco-innovation | ||

| Risk management to avoid negative environmental impact |

| Factor | Items | References |

|---|---|---|

| Sustainable process innovation practices | Involvement in cleaner production practices | [6,46,50,96,97,98,99,100,101,102,114,115,116] |

| Involvement in waste handling and recycling on a regular basis | ||

| Integration of eco-efficiency in its activities | ||

| Development of new channels for sustainable products | ||

| Integration of customers’ suggestions or complaints | ||

| Sustainable product innovation practices | Implementation of environment management system | [6,46,50,80,103,104,105,106,107,108,114,115,116,117] |

| Implementation of ISO 14001 standards | ||

| Implementation of marketing innovations | ||

| Involvement in sustainable supply chain management practices | ||

| Implementation of managerial innovations | ||

| Sustainable organizational innovation practices | Implementation of eco-design and eco-label actions | [6,50,80,109,110,111,113,114,115,116] |

| Use of eco-friendly raw materials | ||

| Focus on new product development | ||

| Continuous adaptation of product design to meet customers’ needs | ||

| Continuous improvement of old products and raise quality of new products |

| Surveyed SMEs (N = 397) | Frequency | % | |

|---|---|---|---|

| Company size | Micro (<10) | 58 | 14.61% |

| Small (10–49) | 236 | 59.45% | |

| Medium (50–249) | 103 | 25.94% | |

| Company age | <5 years old | 73 | 18.39% |

| 5–10 years | 105 | 26.45% | |

| 10–15 years | 116 | 29.22% | |

| >15 years old | 103 | 25.94% | |

| Construct | Items | Convergent Validity | Internal Consistency/Reliability | ||||

|---|---|---|---|---|---|---|---|

| Loadings | AVE | Cronbach α | CR | ||||

| Eco-innovation capability | Internal setting | Availability of appropriate HR resources | IS1 | 0.738 | 0.598 | 0.862 | 0.902 |

| Past performance of the firm as a source for eco-innovation capability development | IS2 | 0.824 | |||||

| Availability of technological expertise | IS3 | 0.730 | |||||

| Strategies | Strategic relevance of eco-innovation for top management | S1 | 0.723 | 0.621 | 0.878 | 0.908 | |

| Long-term strategies focused on eco-innovation | S2 | 0.868 | |||||

| Commitment to eco-innovation implementation | S3 | 0.854 | |||||

| Operations | Cooperation within supply networks | O1 | 0.909 | 0.796 | 0.914 | 0.922 | |

| Process flexibility supporting eco-innovation | O2 | 0.928 | |||||

| Recycling practices and reverse logistics processes | O3 | 0.830 | |||||

| Structure | Eco-innovation oriented methods | ST1 | 0.852 | 0.747 | 0.888 | 0.912 | |

| Organizational structure support for eco-innovation | ST2 | 0.842 | |||||

| Risk management to avoid negative environmental impact | ST3 | 0.867 | |||||

| Sustainability driven innovation practices | Sustainable process innovation practices | Involvement in cleaner production practices | PRIP1 | 0.819 | 0.737 | 0.911 | 0.928 |

| Involvement in waste handling and recycling on a regular basis | PRIP2 | 0.888 | |||||

| Integration of eco-efficiency in its activities | PRIP3 | 0.879 | |||||

| Development of new channels for sustainable products | PRIP4 | 0.854 | |||||

| Integration of customers’ suggestions or complaints | PRIP5 | 0.887 | |||||

| Sustainable product innovation practices | Implementation of environment management system | PIP1 | 0.874 | 0.831 | 0.842 | 0.904 | |

| Implementation of ISO 14001 standards | PIP2 | 0.944 | |||||

| Implementation of marketing innovations | PIP3 | 0.931 | |||||

| Involvement in sustainable supply chain management practices | PIP4 | 0.885 | |||||

| Implementation of managerial innovations | PIP5 | 0.892 | |||||

| Sustainable organizational innovation practices | Implementation of eco-design and eco-label actions | OIP1 | 0.855 | 0.791 | 0.834 | 0.897 | |

| Use of eco-friendly raw materials | OIP2 | 0.857 | |||||

| Focus on new product development | OIP3 | 0.890 | |||||

| Continuous adaptation of product design to customers’ needs | OIP4 | 0.921 | |||||

| Continuous improvement of old products and raise quality of new products | OIP5 | 0.914 | |||||

| Constructs | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Internal setting | 0.773 | 0.530 | 0.126 | 0.250 | 0.774 | 0.522 | 0.485 |

| Strategies | 0.530 | 0.788 | 0.313 | 0.793 | 0.116 | 0.250 | 0.392 |

| Operations | 0.126 | 0.313 | 0.892 | 0.564 | 0.522 | 0.265 | 0.530 |

| Structure | 0.250 | 0.793 | 0.564 | 0.864 | 0.313 | 0.009 | 0.421 |

| Sustainable process innovation practices | 0.774 | 0.116 | 0.522 | 0.313 | 0.859 | 0.319 | 0.485 |

| Sustainable product innovation practices | 0.522 | 0.250 | 0.265 | 0.009 | 0.319 | 0.911 | 0.141 |

| Sustainable organizational innovation practices | 0.485 | 0.392 | 0.530 | 0.421 | 0.485 | 0.141 | 0.889 |

| VIF | Hypothesized Relationships | R2 | f2 | |

|---|---|---|---|---|

| Internal setting → eco-innovation capability | 1.453 | 0.115 | 884.876 | |

| Strategies → eco-innovation capability | 1.882 | 0.244 | 2950.008 | |

| Operations → eco-innovation capability | 2.665 | 0.303 | 3378.032 | |

| Structure → eco-innovation capability | 2.180 | 0.287 | 3508.424 | |

| Sustainable process innovation practices → sustainability driven innovation practices | 2.305 | 0.248 | 2564.975 | |

| Sustainable product innovation practices → sustainability driven innovation practices | 1.277 | 0.187 | 2657.396 | |

| Sustainable organizational innovation practices → sustainability driven innovation practices | 1.316 | 0.096 | 684.335 | |

| Eco-innovation capability → sustainability driven innovation practices | 1.014 | 0.603 | 0.382 | 0.588 |

| Path Coefficient | Standard Error | t-Value | p-Value | R2 | |

|---|---|---|---|---|---|

| Internal setting → eco-innovation capability | 0.115 | 0.115 | 5.010 | 0.000 | |

| Strategies → eco-innovation capability | 0.244 | 0.240 | 16.394 | 0.000 | |

| Operations → eco-innovation capability | 0.303 | 0.306 | 19.311 | 0.000 | |

| Structure → eco-innovation capability | 0.287 | 0.282 | 24.173 | 0.000 | |

| Sustainable process innovation practices → sustainability driven innovation practices | 0.248 | 0.248 | 19.931 | 0.000 | |

| Sustainable product innovation practices → sustainability driven innovation practices | 0.187 | 0.184 | 3.393 | 0.001 | |

| Sustainable organizational innovation practices → sustainability driven innovation practices | 0.096 | 0.096 | 3.443 | 0.001 | |

| Eco-innovation capability → sustainability driven innovation practices | 0.603 | 0.608 | 17.242 | 0.000 | 0.382 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceptureanu, S.I.; Ceptureanu, E.G.; Popescu, D.; Anca Orzan, O. Eco-innovation Capability and Sustainability Driven Innovation Practices in Romanian SMEs. Sustainability 2020, 12, 7106. https://doi.org/10.3390/su12177106

Ceptureanu SI, Ceptureanu EG, Popescu D, Anca Orzan O. Eco-innovation Capability and Sustainability Driven Innovation Practices in Romanian SMEs. Sustainability. 2020; 12(17):7106. https://doi.org/10.3390/su12177106

Chicago/Turabian StyleCeptureanu, Sebastian Ion, Eduard Gabriel Ceptureanu, Doina Popescu, and Olguta Anca Orzan. 2020. "Eco-innovation Capability and Sustainability Driven Innovation Practices in Romanian SMEs" Sustainability 12, no. 17: 7106. https://doi.org/10.3390/su12177106

APA StyleCeptureanu, S. I., Ceptureanu, E. G., Popescu, D., & Anca Orzan, O. (2020). Eco-innovation Capability and Sustainability Driven Innovation Practices in Romanian SMEs. Sustainability, 12(17), 7106. https://doi.org/10.3390/su12177106