Home-Delivery-Oriented Agri-Food Supply Chain Alliance: Framework, Management Strategies, and Cooperation Stability Control

Abstract

1. Introduction

2. Literature Review

2.1. AE Market: Opportunities and Challenges

2.2. Strategic Supply Chain Alliance and Cooperation Instability

2.3. Summary

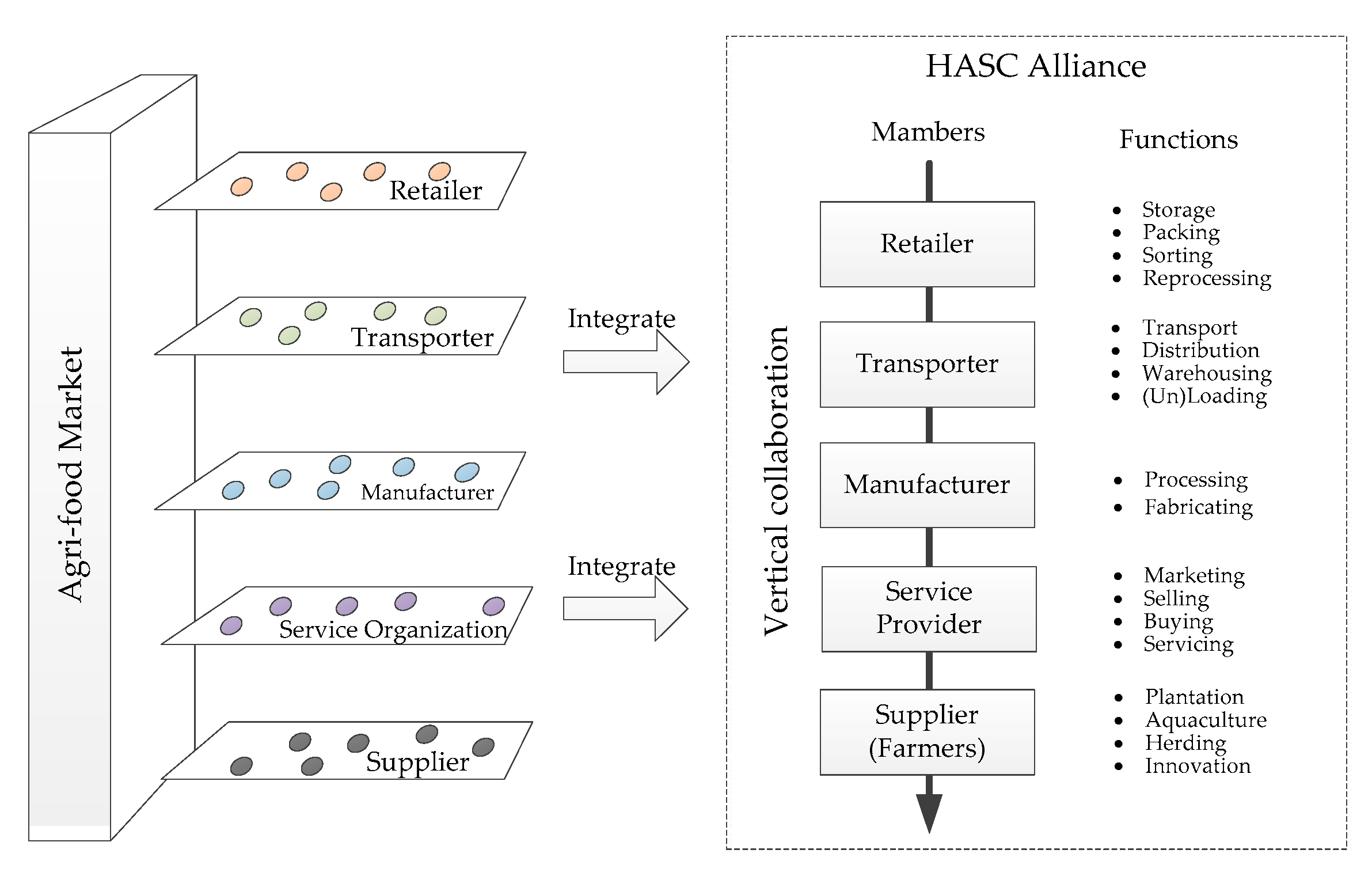

3. Conceptual Development of the HASC Alliance: Organizational Structure and Implementation Strategies

- Which organizational structure can maximize the competence of each entity of the HASC alliance?

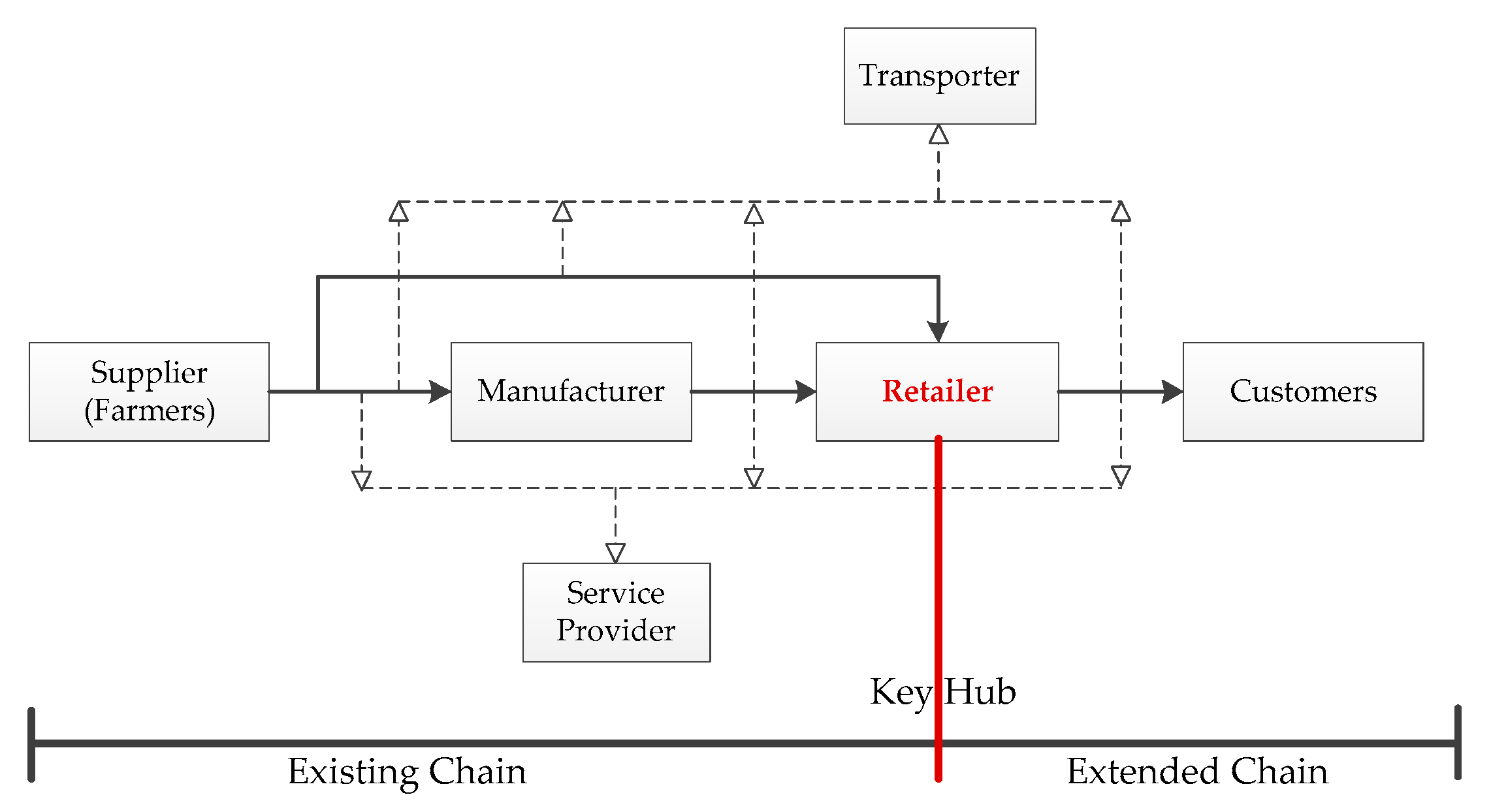

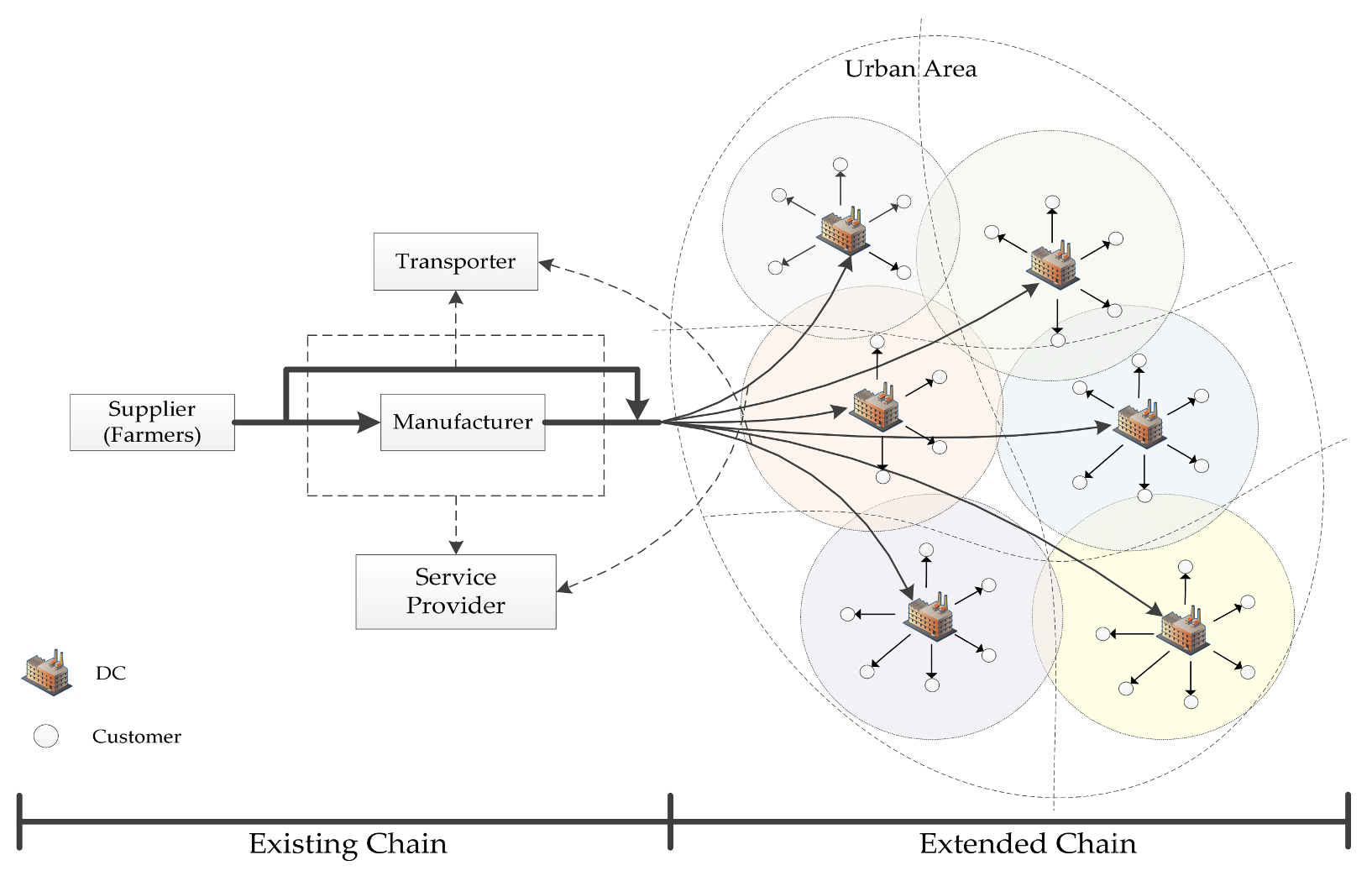

- How can the existing supply chain to the end customer be physically extended in the real-world?

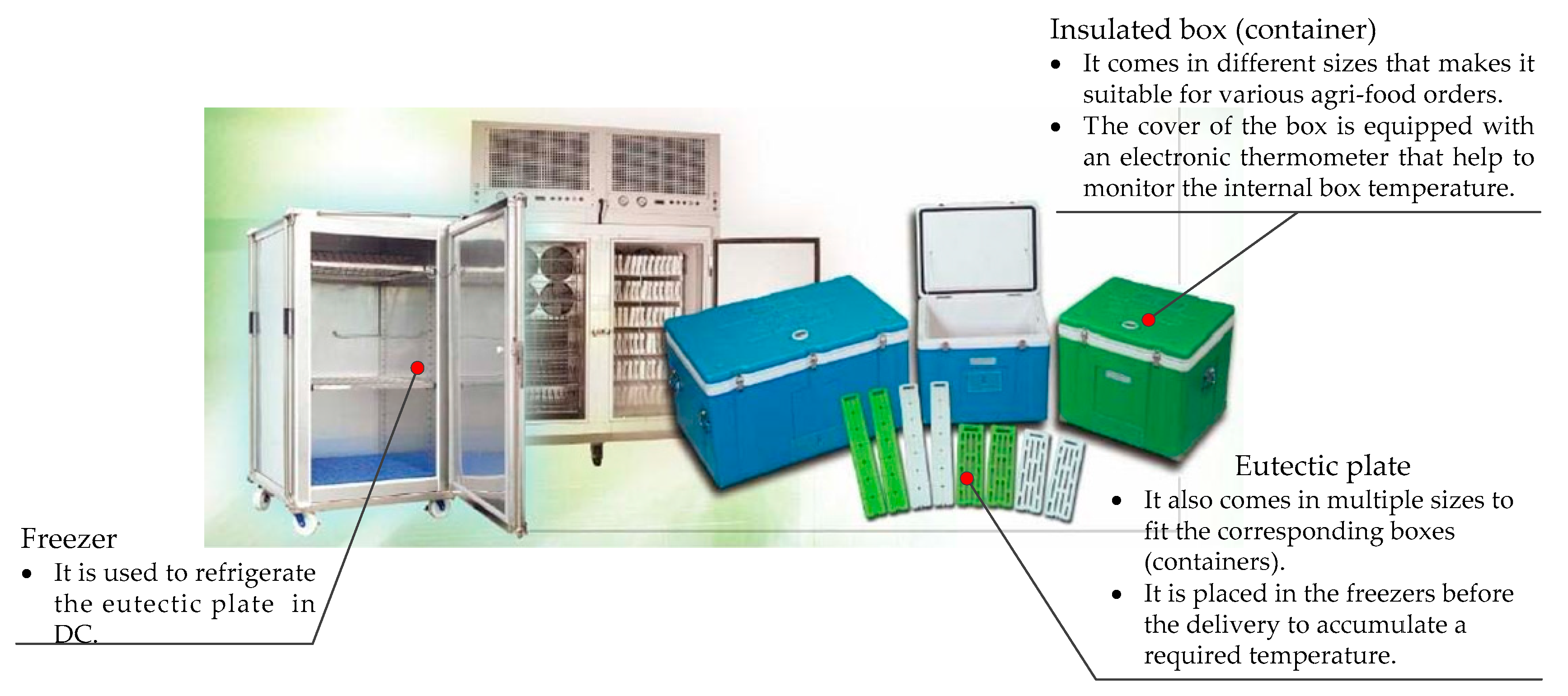

- How can a physical distribution system ensure that food quality and safety be established?

- How can the existing supply chain be effectively connected with the extended portion at the management level?

- How can the cooperation stability of the HASC alliance be controlled?

3.1. Organization Structure: Closer Vertical Co-Ordination

3.2. Last-Mile Chain Extension Strategy: Semi-Centralized Extension

3.3. Food Transport Strategy: MTJD Transport System

3.4. Production/Distribution Control Strategy: Hybrid Push-Pull Control

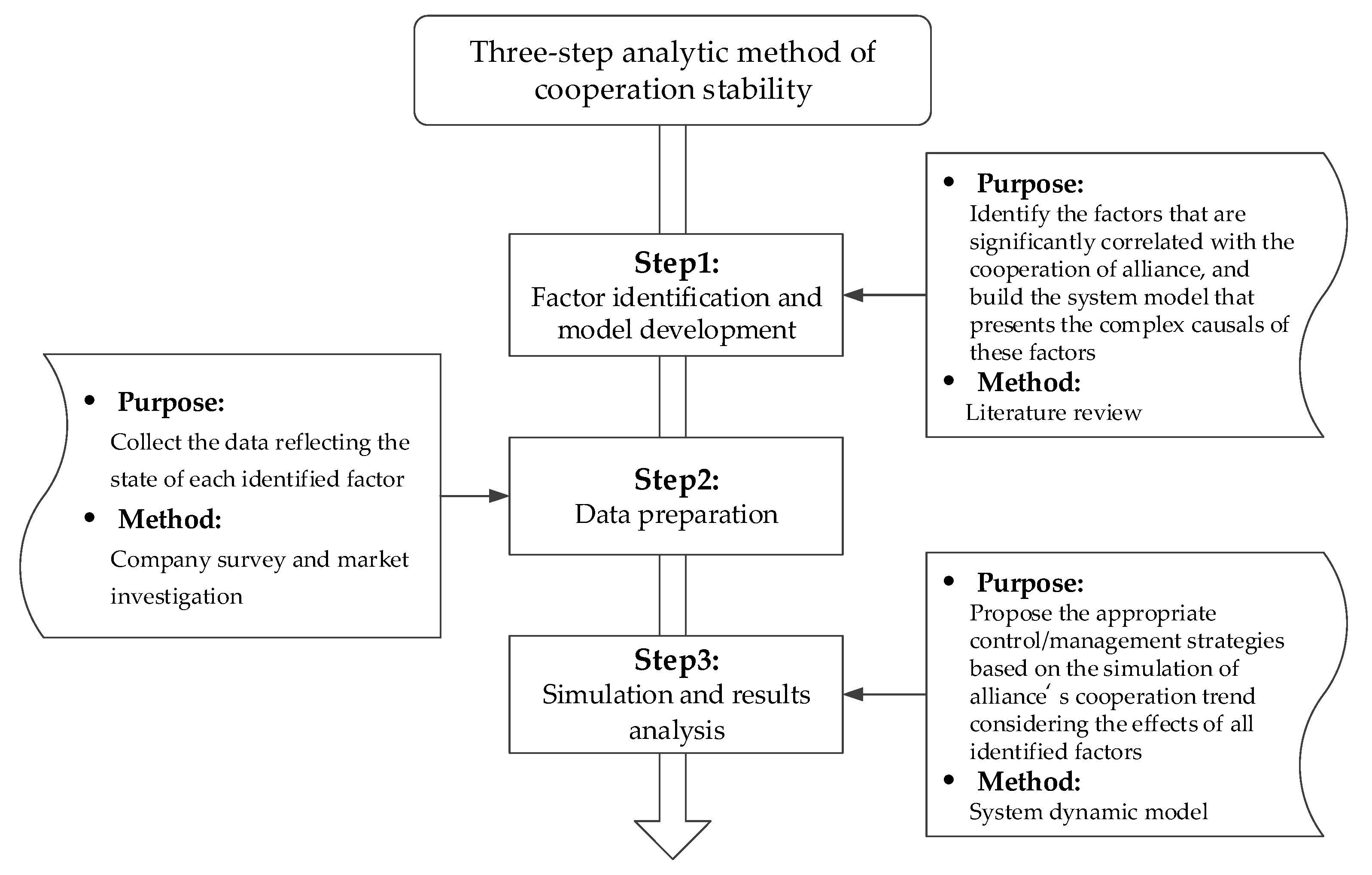

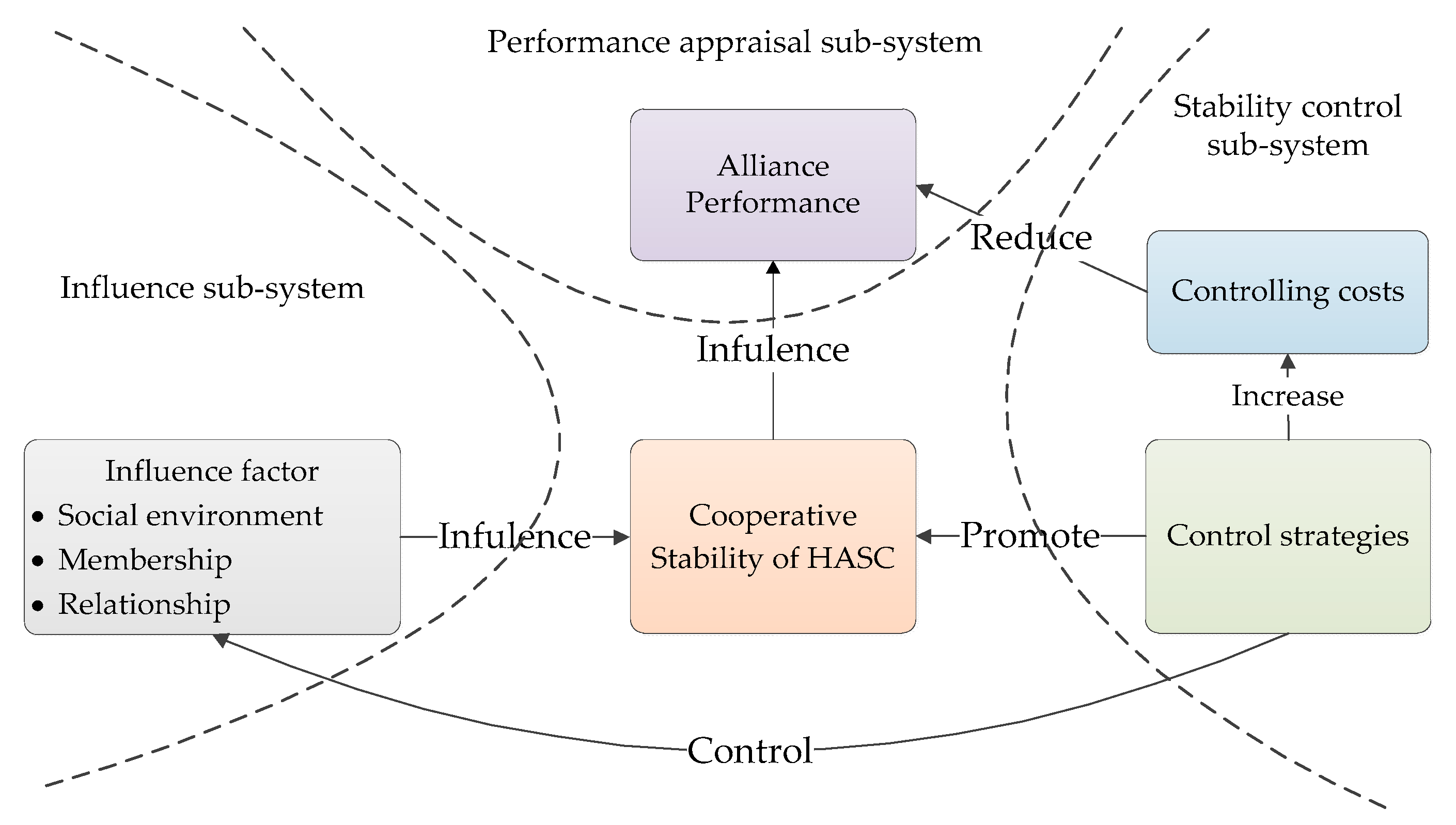

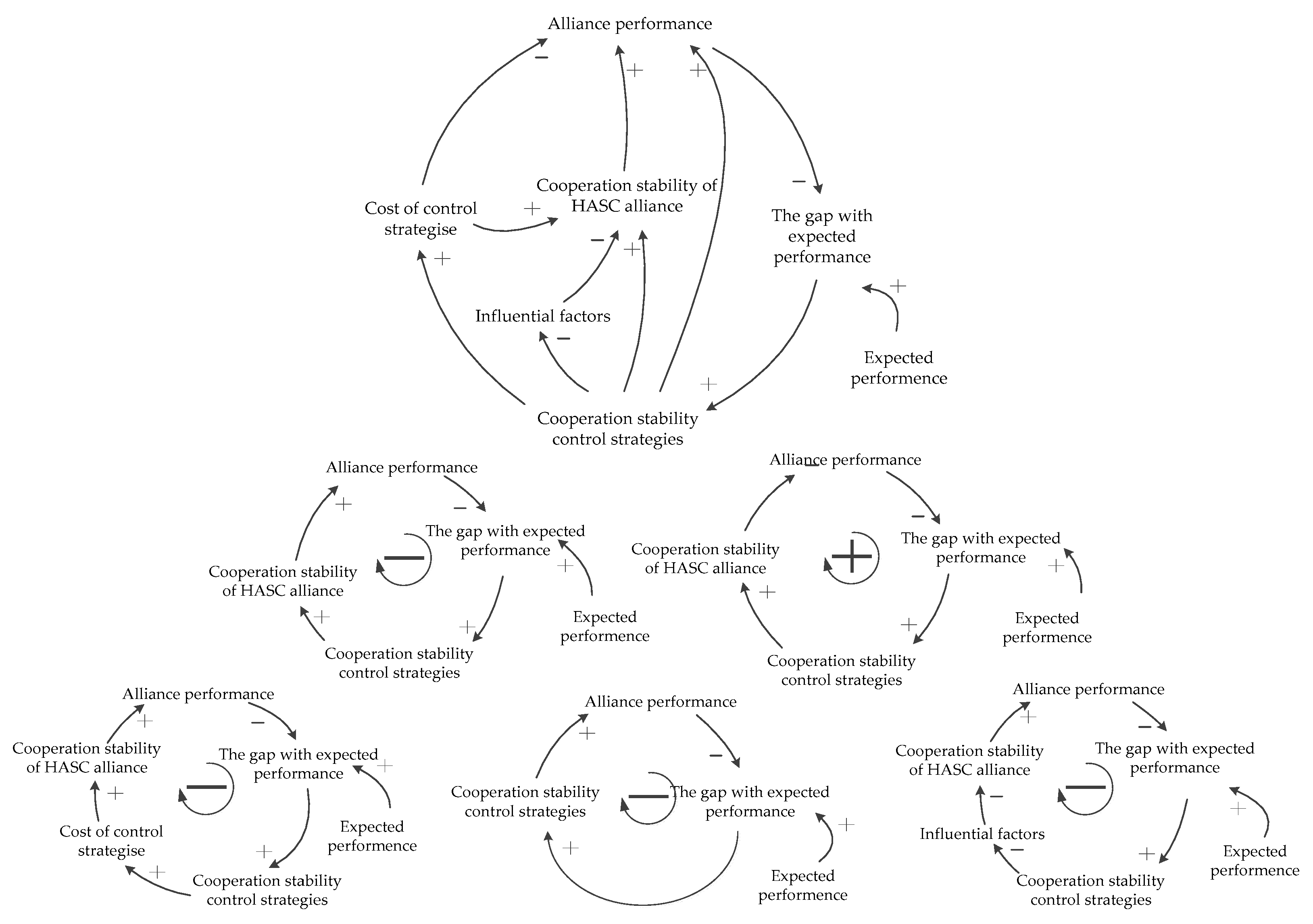

4. Cooperation Stability: Model of the HASC Alliance

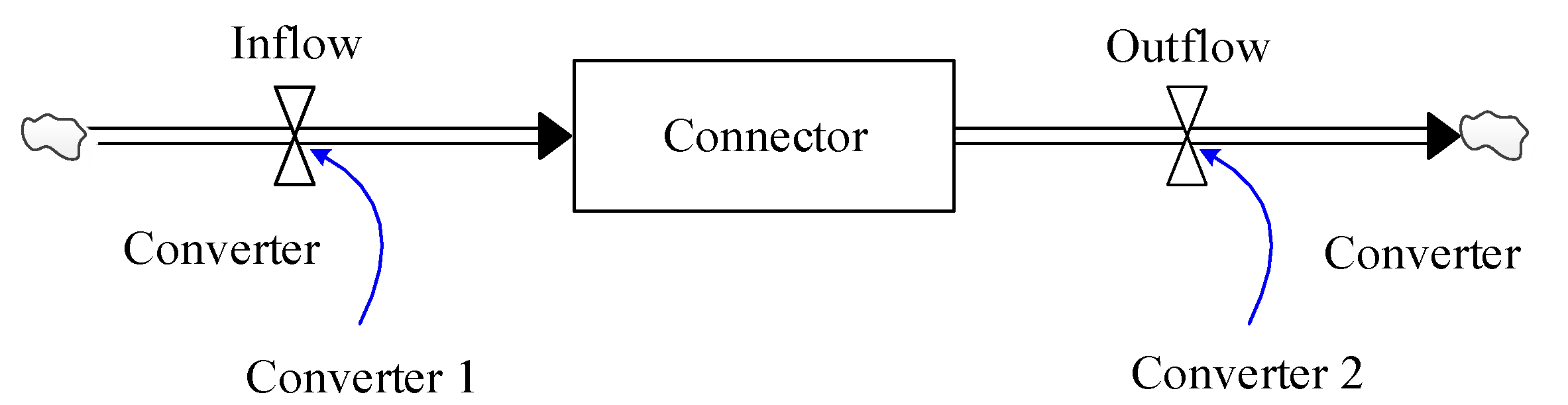

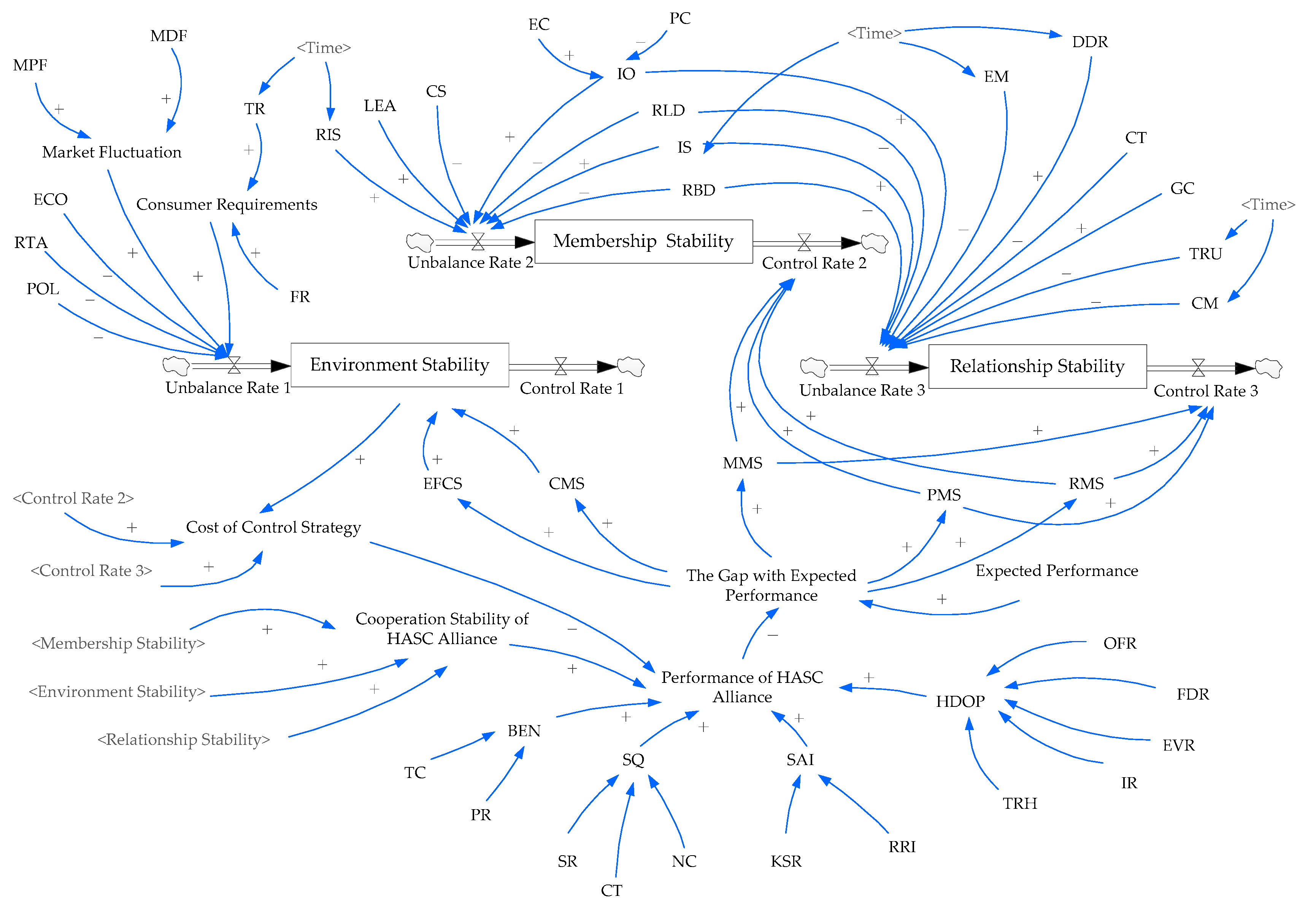

4.1. System Dynamics Model

4.1.1. Model Development

4.1.2. Influence Subsystem

- Environment. Any change in the natural and social environment affects the cooperation stability of the alliance. The natural factors are those that are not intentionally created by humans but can directly or indirectly influence human life, such as natural disasters. Due to the difficulty in data collection, we did not consider natural factors in this paper. We considered the environmental factors that are related to human economic activity and society because these factors are closely related to the development of the HASC alliance and are thus deemed internal factors of the HASC cooperation system. Based on previous studies [114,115,116,117,118,119,120,121,122,123], we selected the following factors: public policy (POL), economic situation (ECO), market fluctuations, including market demand fluctuation (MDF) and market price fluctuation (MPF), regional traffic accessibility (RTA), and consumer requirement, including timeliness requirement (TR) and freshness requirement (FR).

- Membership. Zineldin and Dodourova [124] found that cooperation motivation can significantly influence the stability of membership at the early stage of cooperation. Such motivation is associated with the resistance of internal staff (RIS), leadership (LEA), and capacity structure of the company (CS) [125,126]. Moreover, the design of the cooperation contract would also affect the stability of membership among the entities of the HASC alliance. The partners may be especially concerned about rationality and equity [75,127]. Therefore, the following factors were selected: rationality of labor distribution (RLD), rationality of benefit distribution (RBD), information symmetry (IS), and individual opportunism (IO). The study also considered the previous connection (PC) and expected cost for cooperation (EC), as they significantly influence individual opportunism.

- Relationship. In an alliance, many relationships exist among different participant companies, divisions, and members with respect to information, finance, and other exchange levels [128]. The interface management approach has been put forward to analyze such complex relationships. Three principle interfaces, i.e., material interface, information interface, and management interface, were investigated [14]. According to the literature, delivery delay rate (DDR) is the most important factor that affects the stability of the material interface [129]; trust (TRU), coordinating mechanism (CM), and exchange mechanism (EM) are the main influencing factors of information interface stability [73,130]; cultural tolerance (CT) and goal congruence (GC) are the key factors of management interface stability [131,132,133]. Additionally, information symmetry (IS), rationality of labor distribution (RLD), rationality of benefit distribution (RBD), and individual opportunism (IO) all have a significant impact on the relationship stability.

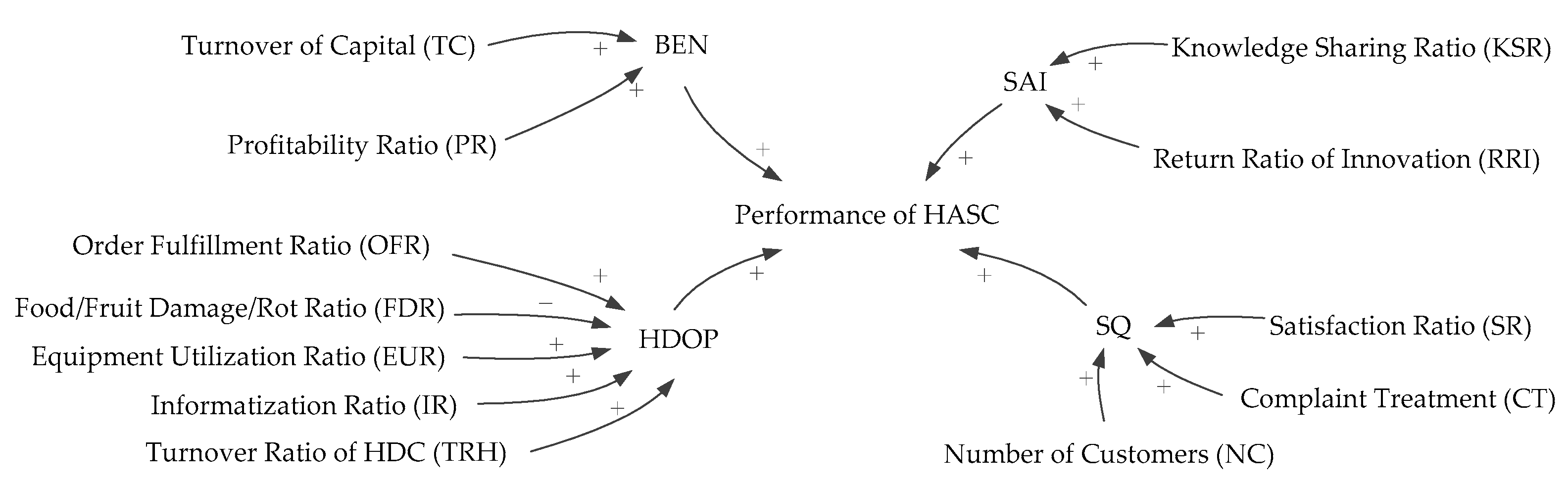

4.1.3. Performance Appraisal Subsystem

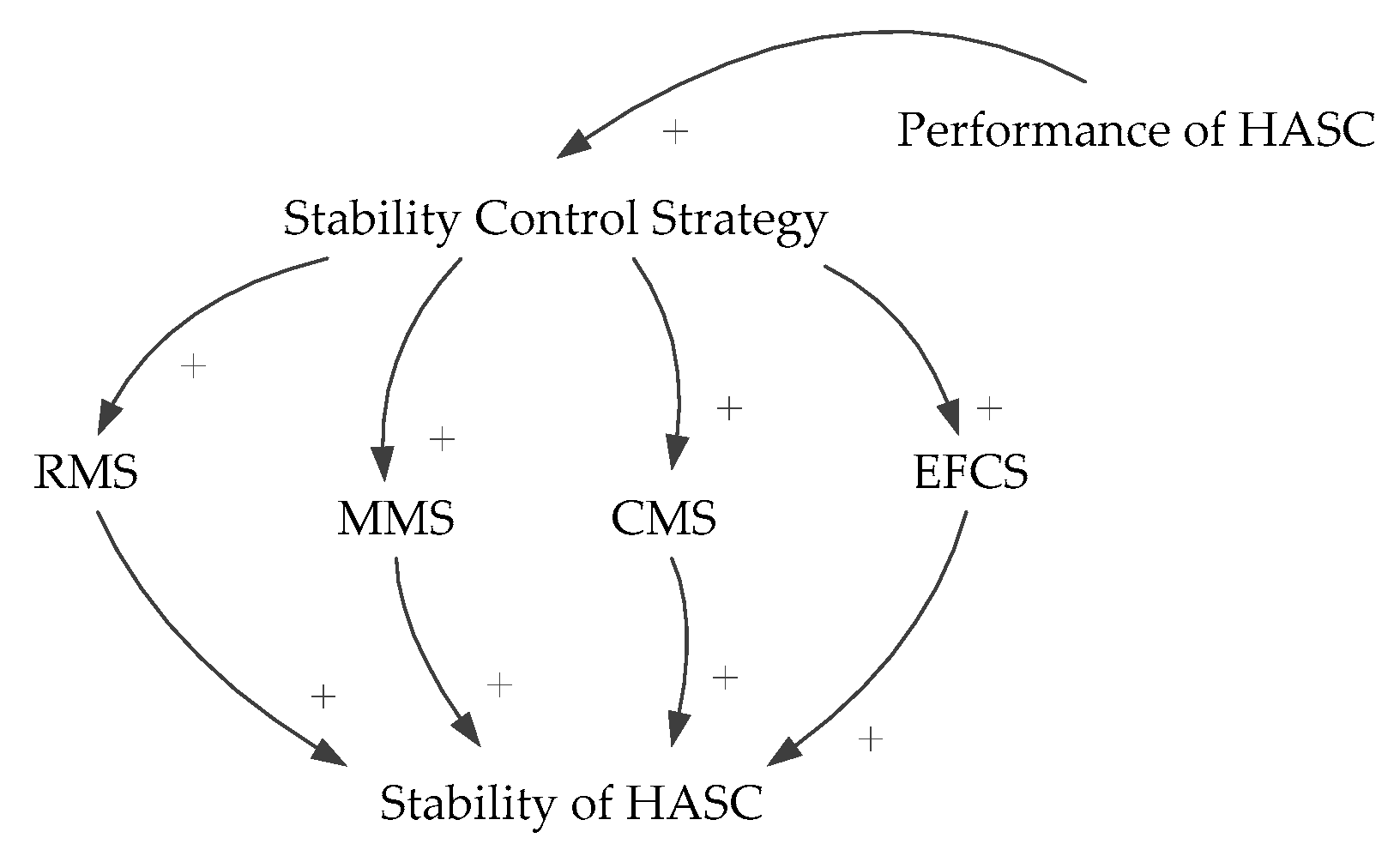

4.1.4. Stability Control Subsystem (Strategies)

4.1.5. Total System Model

4.2. Data Preparation

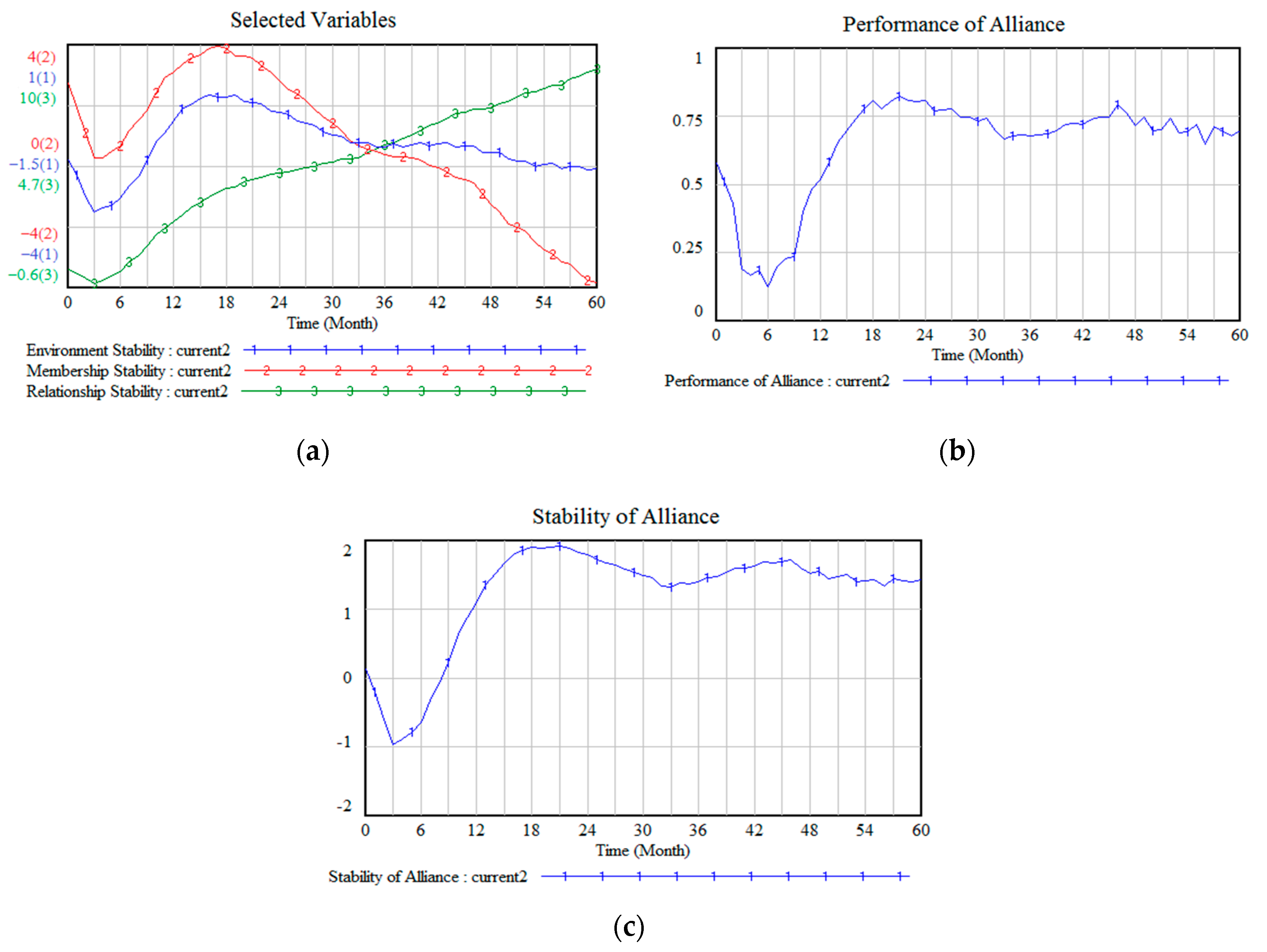

4.3. Simulation Results

4.3.1. Stability Tendency of Cooperation System

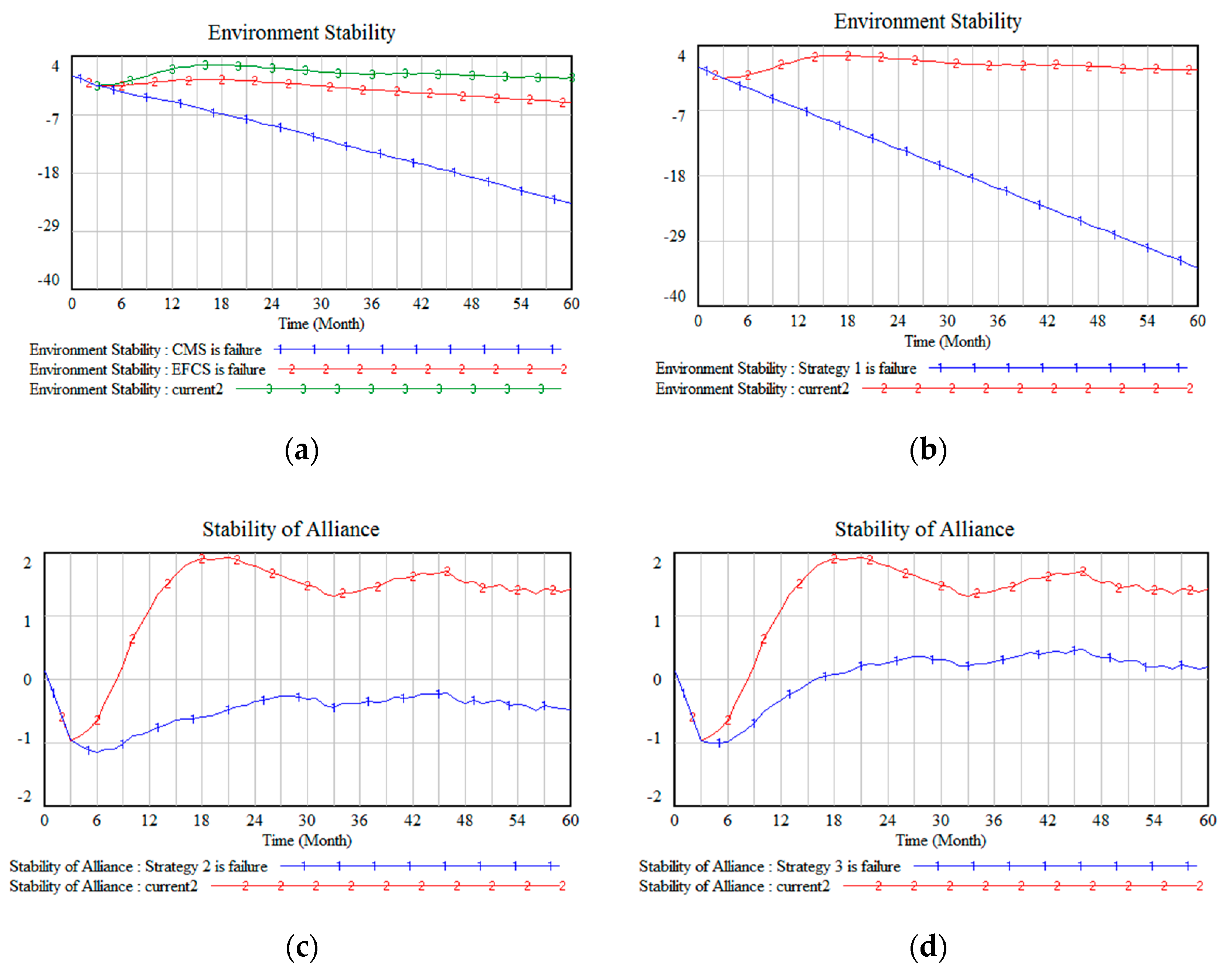

4.3.2. Effectiveness Analysis of Control Strategies

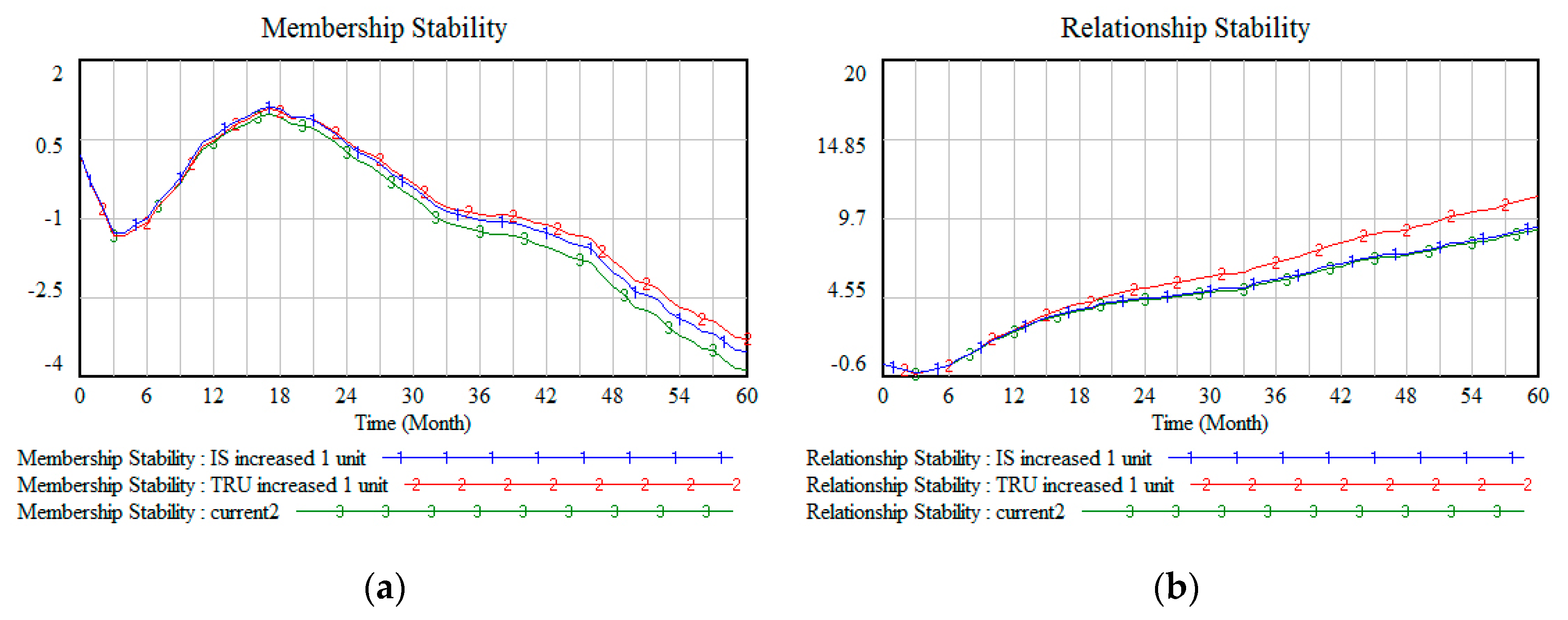

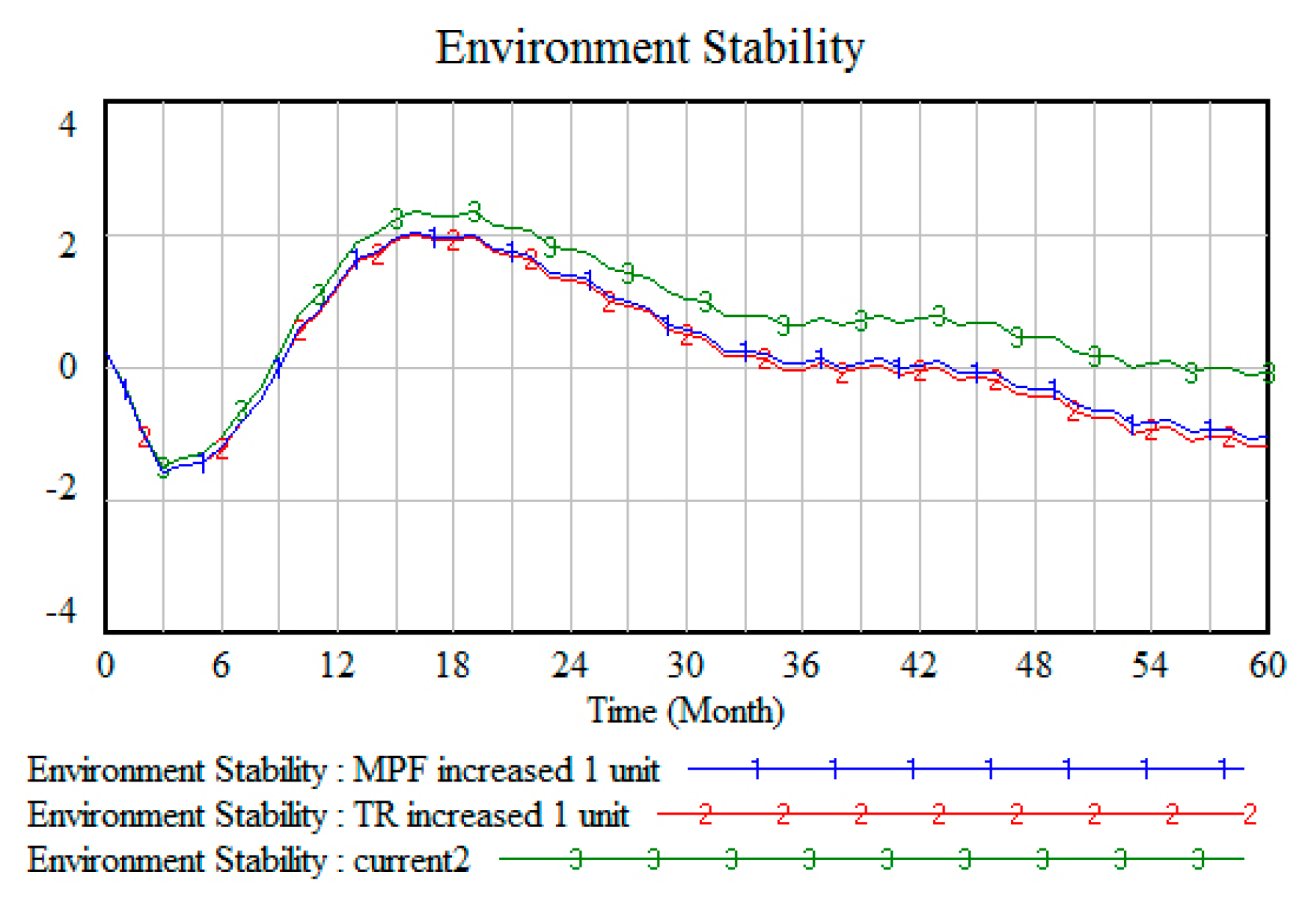

4.3.3. Impact of Change in Factors on Cooperation Stability

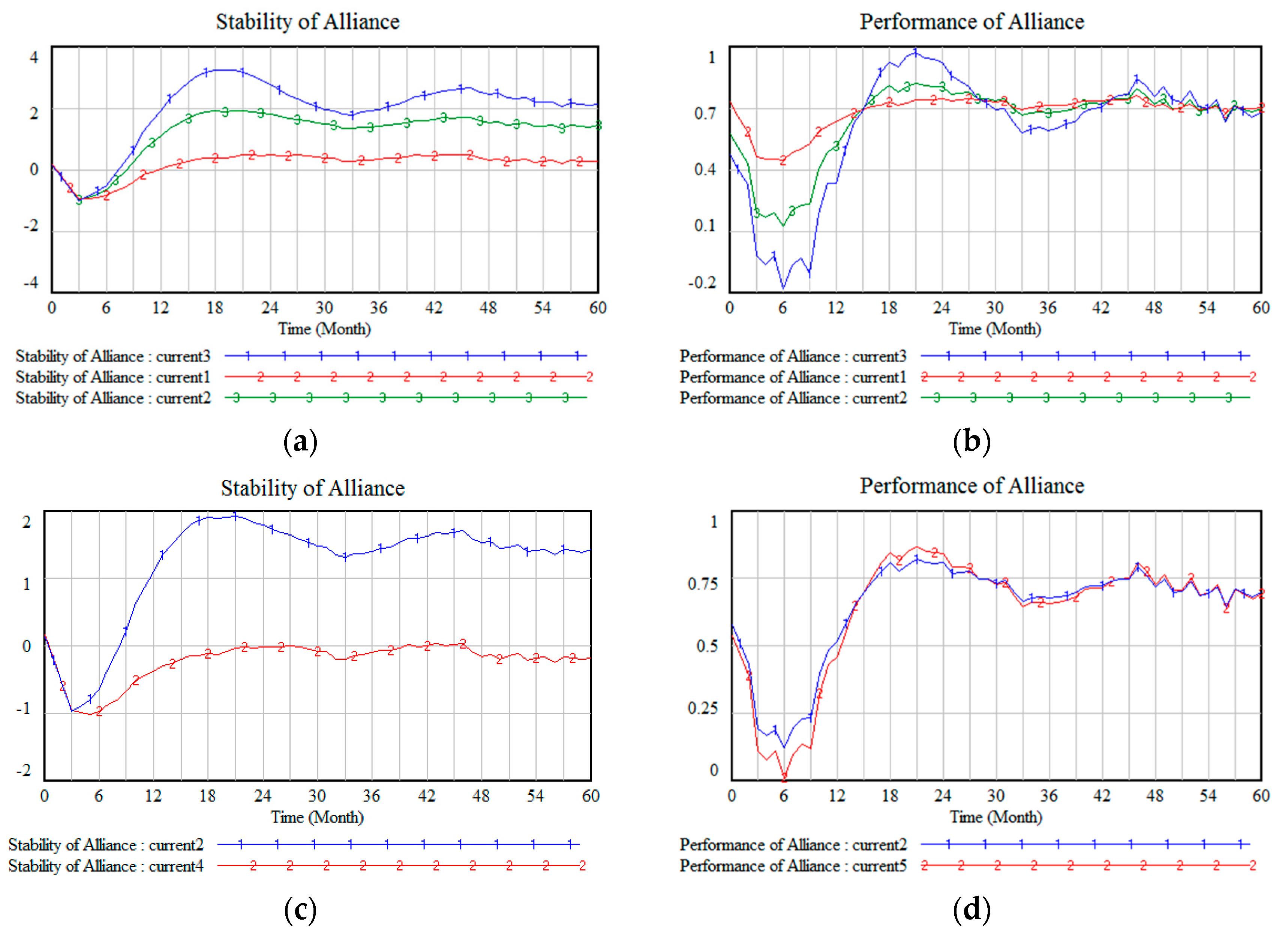

4.3.4. Sensitivity Analysis of Control Strategies Cost

5. Implications and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| No. | Equations |

|---|---|

| 1 | Environmental stability = INTEG (Control Rate1-Unblance Rate1, 0) |

| 2 | Unbalance Rate1 = RTA × 0.1424 + Costumer Requirement × 0.2848 + Market Fluctuation × 0.2992 + ECO × 0.1344 + POL × 0.1392 |

| 3 | Control Rate1 = DELAY3I (CMS × 0.6 + EFCS × 0.4, 3, 0) |

| 4 | Market Fluctuation = MPF × 0.4 + MDF × 0.6 |

| 5 | Costumer Requirement = (TR + FR)/2 |

| 6 | MDF = PULSE TRAIN (0, 0.3, 1.5, 60) |

| 7 | TR = WITH LOOKUP (Time, [(0, 0) − (60, 1)], (0, 0.8), (3, 0.79), (6, 0.78), (12, 0.76), (18, 0.73), (30, 0.7), (60, 0.7)) |

| 8 | Membership Stability = INTEG (Control Rate2-Unblance Rate2, 0) |

| 9 | Unbalance Rate2 = RIS × 0.1064 + IO × 0.2482 + CS × 0.1182 + LEA × 0.1359 + RBD × 0.1477 + IS × 0.1211 + RLD × 0.1226 |

| 10 | Control Rate2 = DELAY3I (MMS × 0.5 + PMS × 0.3333 + RMS × 0.1667, 3, 0) |

| 11 | IO = 0.3333 × PC × (0.5 − RAMP (0.008, 0, 60)) + EC × 0.6667 × (RAMP (0.008, 0, 60)) |

| 12 | RIS = WITH LOOKUP (Time, ([(0, 0) − (60, 1)], (0, 0.5), (3, 0.495), (6, 0.48), (9, 0.45), (12, 0.41), (15, 0.4), (18, 0.39), (21, 0.385), (24, 0.38), (60, 0.35)) |

| 13 | IS = WITH LOOKUP (Time, ([(0, 0) − (60, 1)], (0, 0.15), (7, 0.17), (15, 0.2), (23, 0.25), (30, 0.34), (37, 0.46), (45, 0.55), (52, 0.6), (60, 0.63)) |

| 14 | Relationship Stability = INTEG (Control Rate3-Unblance Rate3, 0) |

| 15 | Unbalance Rate3 = TRU × 0.0902 + CT × 0.0708 + CM × 0.1247 + GC × 0.0892 + RLD × 0.0789 + DDR × 0.0844 + IO × 0.1629 + IS × 0.0795 + RBD × 0.096 + EM × 0.1236 |

| 16 | Control Rate3 = DELAY3I (MMS × 0.1667 + PMS × 0.3333 + RMS × 0.5, 3, 0) |

| 17 | EM = WITH LOOKUP(Time, ([(0, 0.4) − (60, 1)], (0, 0.5), (3, 0.45), (6, 0.43), (9, 0.46), (12, 0.482), (15, 0.5), (18, 0.482), (21, 0.478), (24, 0.48), (27, 0.53), (30, 0.561), (33, 0.583), (36, 0.574), (39, 0.587), (42, 0.579), (45, 0.592), (48, 0.618), (51, 0.61), (54, 0.632), (57, 0.661), (60, 0.682)) |

| 18 | DDR = WITH LOOKUP (Time, ([(0, 0) − (60, 1)], (0, 0.5), (1, 0.49), (2, 0.485), (3, 0.47), (6, 0.45), (9, 0.42), (13, 0.4), (18, 0.39), (24, 0.38), (31, 0.37), (60, 0.35)) |

| 19 | TRU = WITH LOOKUP (Time, ([(0, 0) − (60, 1)], (0, 0.2), (6, 0.21), (12, 0.23), (18, 0.26), (24, 0.29), (30, 0.33), (36, 0.36), (42, 0.38), (60, 0.45)) |

| 20 | CM = WITH LOOKUP (Time, ([(0, 0.4) − (60, 1)], (0, 0.5), (3, 0.45), (6, 0.43), (9, 0.461), (12, 0.482), (15, 0.5), (18, 0.482), (21, 0.478), (24, 0.48), (27, 0.531), (30, 0.561), (33, 0.583), (36, 0.575), (39, 0.587), (42, 0.579), (45, 0.592), (48, 0.618), (51, 0.611), (54, 0.632), (57, 0.661), (60, 0.682)) |

| 21 | EFCS = RANDOM NORMAL (0.3, 1, 1, 1, 1) × The Gap with Expected Performance |

| 22 | CMS = RANDOM NORMAL (0.9, 1, 1) × (The Gap with Expected Performance ^ (0.8) + 0.4) |

| 23 | MMS = RANDOM NORMAL (0.8, 1.2, 4) × (The Gap with Expected Performance ^ (0.7) + 0.3) |

| 24 | PMS = RANDOM NORMAL (0, 0.8, 0.4, 1, 0) × The Gap with Expected Performance |

| 25 | RMS = RANDOM NORMAL (0.2, 0.8, 1) × (The Gap with Expected Performance ^ (0.7) + 0.3) |

| 26 | The Gap with Expected Performance = Expected Performance–Performance of HASC Alliance |

| 27 | Performance of HASC Alliance = ((BEN + SQ + SAI + HDOP)/4) + Cooperation Stability of HASC Alliance × 0.2 − Cost of Control Strategies |

| 28 | Cost of Control Strategies = (EXP ((Control Rate1 + Control Rate2 + Control Rate3)/3)) × 0.36 |

| 29 | Cooperation Stability of HASC Alliance = (Environmental stability × 0.25 + Membership Stability × 0.3 + Relationship Stability × 0.3) − Cost of Control Strategies × 0.15 |

| 30 | BEN = (TC + PR)/2 |

| 31 | SQ = (SR + CT + NC)/3 |

| 32 | SAI = (KSR + PPI)/2 |

| 33 | HDOP = (TRH + IR + EVR + FDR + OFR)/5 |

| Subsystem | Factor | Description | Weight | Initial Value |

|---|---|---|---|---|

| Cooperative environment | POL | Public Policy | 0.139 | 0.6 |

| ECO | Economic Situation | 0.134 | 0.3 | |

| MF | Market Fluctuation | 0.299 | - | |

| MDF | Market Demand Fluctuation | 0.6 | 0.79 | |

| MPF | Market Price Fluctuation | 0.4 | 0.3 | |

| RTA | Regional Traffic Accessibility | 0.142 | 0.9 | |

| CR | Consumer Requirements | 0.285 | - | |

| TR | Timeliness Requirement | 0.5 | - | |

| FR | Freshness Requirement | 0.5 | 0.9 | |

| Membership factor | IO | Individual Opportunism | 0.248 | - |

| EC | Expected Cost | 0.667 | 0.85 | |

| PC | Previous Contraction | 0.333 | 0.85 | |

| RLD | Rationality of Labor Distribution | 0.123 | 0.78 | |

| IS | Information Symmetry | 0.121 | - | |

| RBD | Rationality of Benefit Distribution | 0.148 | 0.84 | |

| CS | Capacity Structure | 0.118 | 0.67 | |

| LEA | Leadership | 0.136 | 0.75 | |

| Relationship factor | RIS | Resistance of Internal Staff | 0.106 | - |

| IO | Individual Opportunism | 0.163 | - | |

| EC | Expected Cost | 0.667 | 0.85 | |

| PC | Previous Contraction | 0.333 | 0.85 | |

| RLD | Rationality of Labor Distribution | 0.079 | 0.78 | |

| IS | Information Symmetry | 0.08 | - | |

| RBD | Rationality of Benefit Distribution | 0.096 | 0.84 | |

| DDR | Delivery Delay Rate | 0.084 | - | |

| CT | Cultural Tolerance | 0.071 | 0.79 | |

| GC | Goal Congruence | 0.089 | 0.85 | |

| TRU | Trust | 0.09 | - | |

| CM | Coordinating Mechanism | 0.125 | - | |

| EM | Exchange Mechanism | 0.124 | - |

Appendix B

| Score | 1 | 2 | 3 | 4 | 5 | ||||

| Magnitude | Very slight | Slight | Average | Heavy | Very important | ||||

| Factors | Meaning | Category | Level | ||||||

| 1 | 2 | 3 | 4 | 5 | |||||

| Policy | The policies promulgated by the government for promoting the development of agri-food e-commerce and supporting the business of related enterprises. | Environment | |||||||

| Economy | Local macroeconomic conditions and average household economic state. | ||||||||

| Accessibility | The accessibility of local traffic network (including spatial and temporal accessibility). | ||||||||

| Market | The conditions of the whole agri-food market, including price, demand, competition, and so on. | ||||||||

| Customer | The customer’s demand and acceptance of the services that are provided by e-business. | ||||||||

| Price fluctuation | The fluctuation of agri-food price. | Environment (Market) | |||||||

| Demand fluctuation | The fluctuation of agri-food demand. | ||||||||

| Timeliness requirement | Customer’s requirement for timeliness. | Environment (Customer) | |||||||

| Freshness requirement | Customer’s requirement for food freshness. | ||||||||

| Resistance from internal staff | Whether the internal staff of a company has opposite opinions on the decision to join the alliance. | Membership | |||||||

| Capacity structure (structure of ability) | The elements that constitute the capability of the company and how they are related to each other. | ||||||||

| Leadership | The abilities or qualities the leaders of each member company have, especially in the aspect of making decisions related to alliance business. | ||||||||

| Individual (company’s) opportunism | The behaviors of a company that takes advantage of any situation, often with no regard for principles or consequences | Membership/Relationship | |||||||

| Rationality of benefit distribution | Whether the alliance fairly distributes benefits to each member company in accordance with its contribution. | ||||||||

| Rationality of labor distribution | Whether the alliance reasonably assigns the work to each member company according to its competence. | ||||||||

| Information symmetry | Whether the companies are able to obtain the same information about any activities of the alliance and market. | ||||||||

| Delivery delay rate | The rate at which the downstream companies in the chain unsuccessfully deliver the goods in time (schedule) to their upstream partners. | Relationship | |||||||

| Cultural tolerance | How much the participant companies are willing to accept or tolerate each other, especially when encountering opinions or behaviors that may not be shared by the others. | ||||||||

| Goal congruence | Whether the goals of companies in the alliance are similar or fit together well. | ||||||||

| Coordinating mechanism | Given the complex relationship between members of an alliance, a series of regulations, rules, and provisions are made to coordinate the relations of member companies. | ||||||||

| Exchange mechanism | To ensure the unhindered communication within the alliance, a series of regulations, rules, and provisions are made. | ||||||||

| Trust | How much do the member companies trust each other? | ||||||||

| Expected cost | The cost that the company expected for joining the alliance. | Membership/Relationship (Individual opportunism) | |||||||

| Previous connection | The degree to which partners know each other before forming a cooperative alliance. | ||||||||

References

- Agatz, N.; Campbell, A.; Savelsbergh, M.; Savelsbergh, M. Time slot management in attended home delivery. Transp. Sci. 2008, 45, 435–449. [Google Scholar] [CrossRef]

- Duin, J.H.; Goffau, W.D.; Wiegmans, B.; Tavasszy, L.A.; Saes, M. Improving home delivery efficiency by using principles of address intelligence for b2c deliveries. Transp. Res. Procedia 2016, 12, 14–25. [Google Scholar] [CrossRef]

- Riccardo, M.; Gino, M.; Sara, P.; Angela, T. A review of the environmental implications of B2C e-commerce: A logistics perspective. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 565–591. [Google Scholar]

- Patricia, J.D.; Cornelia, D. Organizational structure in divisional manufacturers: The potential for outsourcing logistical services. Int. J. Phys. Distrib. Logist. Manag. 1997, 21, 22–29. [Google Scholar]

- Rotem-Mindali, O.; Weltevreden, J.W. Transport effects of e-commerce: What can be learned after years of research? Transportation 2013, 40, 867–885. [Google Scholar] [CrossRef]

- Lu, Q.; Meng, F.W.; Goh, M. Choice of supply chain governance: Self-managing or outsourcing? Int. J. Prod. Econ. 2014, 154, 32–38. [Google Scholar] [CrossRef]

- Dean, E.; Yunus, K. The effects of global outsourcing strategies on participants’ attitudes and organizational effectiveness. Int. J. Manpow. 2000, 21, 112–128. [Google Scholar]

- Kremic, T.; Oya, I.T.l.; Walter, O. Outsourcing decision support: A survey of benefits, risks, and decision factors. Supply Chain Manag. Int. J. 2006, 11, 467–482. [Google Scholar] [CrossRef]

- Gandhi, S.J.; Gorod, A.; Sauser, B. Prioritization of outsourcing risks from a systemic perspective. Strateg. Outsourc. 2012, 5, 39–71. [Google Scholar] [CrossRef]

- Shahani, R. Good outsourcing requires good governance. Supply Chain Manag. Rev. 2007, 11, 15–16. [Google Scholar]

- Das, T.K.; Teng, B.S. Trust, control, and risk in strategic alliances: An integrated framework. Organ. Stud. 2001, 22, 251–283. [Google Scholar] [CrossRef]

- Christoffersen, J.; Plenborg, T.; Robson, M.J. Measures of strategic alliance performance classified and assessed. Int. Bus. Rev. 2014, 23, 479–489. [Google Scholar] [CrossRef]

- Gomes, E.; Barnes, B.R.; Mahmood, T. A 22-year review of strategic alliance research in the leading management journals. Int. Bus. Rev. 2014, 25, 15–27. [Google Scholar] [CrossRef]

- Albers, S.; Wohlgezogen, F.; Zajac, E.J. Strategic alliance structures: An organization design perspective. J. Manag. 2016, 42, 582–614. [Google Scholar] [CrossRef]

- Angelo, C.; Evi, H.; Matthias, S.F. Intra-industry strategic alliances for managing sustainability-related supplier risks: Motivation and outcome. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 387–409. [Google Scholar]

- Kim, D.; John, S.; Eric, D. An organization-level framework for the NZ food industry—Its development and application. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 728–743. [Google Scholar]

- Zhang, J.; Frazier, G.V. Strategic alliance via co-opetition: Supply chain partnership with a competitor. Decis. Support Syst. 2011, 51, 853–863. [Google Scholar] [CrossRef]

- Lo, V.H.Y.; Yeung, A.H.W. Practical framework for strategic alliance in pearl river delta manufacturing supply chain: A total quality approach. Int. J. Prod. Econ. 2004, 87, 231–240. [Google Scholar] [CrossRef]

- Mellat-Parast, M.; Digman, L.A. A framework for quality management practices in strategic alliances. Manag. Decis. 2007, 45, 802–818. [Google Scholar] [CrossRef]

- Sambasivan, M.; Siew, L.; Mohamed, Z.A.; Leong, Y.C. Factors influencing strategic alliance outcomes in a manufacturing supply chain: Role of alliance motives, interdependence, asset specificity and relational capital. Int. J. Phys. Distrib. Logist. Manag. 2013, 141, 339–351. [Google Scholar] [CrossRef]

- Sambasivan, M.; Siew, L.; Mohamed, Z.A.; Leong, Y.C. Impact of interdependence between supply chain partners on strategic alliance outcomes. Manag. Decis. 2011, 54, 548–569. [Google Scholar] [CrossRef]

- Fynes, B.; Búrca, S.; Mangan, J. The effect of relationship characteristics on relationship quality and performance. Int. J. Prod. Econ. 2008, 111, 56–69. [Google Scholar] [CrossRef]

- Patel, T. The role of dynamic cultural theories in explaining the viability of international strategic alliances: A focus on Indo-French alliances. Manag. Rev. 2007, 45, 1532–1559. [Google Scholar] [CrossRef]

- Sambasivan, M.; Nget, Y.C. Strategic alliances in a manufacturing supply chain: Influence of organizational culture from the manufacturer’s perspective. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 456–474. [Google Scholar] [CrossRef]

- China e-Business Research Center. China Fresh E-Commerce Report; China e-Business Research Center: Hangzhou, China, 2015; Available online: http://www.100ec.cn/detail--6292936.html. (accessed on 12 August 2020).

- Chaffey, D. E-Business and E-Commerce Management: Strategy, Implementation and Practice; FT Prentice Hall: Harlow, UK, 2009. [Google Scholar]

- Zhuang, Y.; Lederer, A.L. An instrument for measuring the business benefits of e-commerce retailing. Int. J. Electron. Commun. 2003, 7, 65–99. [Google Scholar]

- Karagozoglu, N.; Lindell, M. Electronic commerce strategy, operations, and performance in small and medium-sized enterprises. J. Small Bus. Enterp. Dev. 2004, 11, 290–301. [Google Scholar] [CrossRef]

- Lim, S.; Jin, X.; Srai, J. Consumer-driven e-commerce: A literature review, design framework, and research agenda on last-mile logistics models. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 308–332. [Google Scholar] [CrossRef]

- Dabhilkar, M.; Bengtsson, L.; Haartman, R.V.; Ahlstrom, P. Supplier selection or collaboration? Determining factors of performance improvement when outsourcing manufacturing. J. Purch. Supply Manag. 2009, 15, 143–153. [Google Scholar] [CrossRef]

- Monica, B. Outsourcing the benefits and the risks. Hum. Resour. Manag. Rev. 2009, 16, 269–279. [Google Scholar]

- Mao, S.Y.; Shi, Q.; He, Q.Y.; Gao, Z.H.; Bi, Y. Research on the mode optimization of home delivery of fresh products. Logist. Eng. Manag. 2015, 37, 50–52. [Google Scholar]

- Cox, J.; Dale, B.G. Service quality and, e-commerce: An exploratory analysis. Manag. Serv. Qual. Int. J. 2001, 11, 121–131. [Google Scholar] [CrossRef]

- Julia, B.E.; Alan, C.M.; Sharon, L.C. Comparative analysis of the carbon footprints of conventional and online retailing: A “last mile” perspective. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 103–123. [Google Scholar]

- Park, H.; Park, D.; Jeong, I.J. An effects analysis of logistics collaboration in last-mile networks for CEP delivery services. Transp. Policy 2016, 50, 115–125. [Google Scholar] [CrossRef]

- David, H.T. Problems of Food Supply Logistics in Russia and the CIS. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 15–22. [Google Scholar]

- Bodini, A.; Zanoli, R. Competitive factors of the agri-food e-commerce. J. Food Prod. Mark. 2011, 17, 241–260. [Google Scholar] [CrossRef]

- Rikka, K.; Iskra, D.; Lauri, L. Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 262–276. [Google Scholar]

- Van der Vorst, G.; Van Dongen, S.; Nouguier, S.; Hilhorst, R. E-business initiatives in food supply chains; definition and typology of electronic business models. Int. J. Logist. Res. Appl. 2002, 5, 119–138. [Google Scholar] [CrossRef]

- Kuo, J.C.; Chen, M.C. Developing an advanced multi-temperature joint distribution system for the food cold chain. Food Control 2010, 21, 559–566. [Google Scholar] [CrossRef]

- Has, C.I.; Liu, K.P. A model for facilities planning for multi-temperature joint distribution system. Food Control 2011, 22, 1873–1882. [Google Scholar]

- Has, C.I.; Chen, W.T.; Wu, W.J. Optimal delivery cycles for joint distribution of multi-temperature food. Food Control 2013, 34, 106–114. [Google Scholar]

- Sun, N. Research Report on the Current Situation and Development Trend of Fresh Food E-Commerce Market in China (2016–2022); Zhiyan Consulting Group: Beijing, China, 2015; pp. 206–208. [Google Scholar]

- Bjørgen, A.; Bjerkan, K.Y.; Hjelkrem, O.A. E-groceries: Sustainable last mile distribution in city planning. Res. Transp. Econ. 2019, 100805. [Google Scholar] [CrossRef]

- Gevaers, R.; Van de Voorde, E.; Vanelslander, T. Cost modelling and simulation of last-mile characteristics in an innovative B2C supply chain environment with implications on urban areas and cities. Procedia Soc. Behav. Sci. 2014, 125, 398–411. [Google Scholar] [CrossRef]

- Ehrler, V.C.; Schöder, D.; Seidel, S. Challenges and perspectives for the use of electric vehicles for last mile logistics of grocery e-commerce—Findings from case studies in Germany. Res. Transp. Econ. 2019, 100757. [Google Scholar] [CrossRef]

- Beverland, M. Can cooperatives brand? Exploring the interplay between cooperative structure and sustained brand marketing success. Food Policy 2007, 32, 480–495. [Google Scholar] [CrossRef]

- Wachsmuth, D. Infrastructure alliances: Supply-chain expansion and multi-city growth coalitions. Econ. Geogr. 2017, 93, 44–65. [Google Scholar] [CrossRef]

- Gulati, R.; Nohria, N.; Zaheer, A. Strategic networks. Strateg. Manag. J. 2000, 21, 203–215. [Google Scholar] [CrossRef]

- Koka, B.R.; Prescott, J.E. Designing alliance networks: The influence of network position, environmental change, and strategy on firm performance. Strateg. Manag. J. 2008, 29, 639–661. [Google Scholar] [CrossRef]

- Street, C.T.; Cameron, A.F. External relationships and the small business: A review of small business alliance and network research. J. Small Bus. Manag. 2007, 45, 239–266. [Google Scholar] [CrossRef]

- Dubois, A.; Fredriksson, P. Cooperating and competing in supply networks: Making sense of a triadic sourcing strategy. J. Purch. Supply Manag. 2008, 14, 170–179. [Google Scholar] [CrossRef]

- Siew-Phaik, L.G.; Downe, A.; Sambasivan, M. Strategic alliances with suppliers and customers in a manufacturing supply chain. Asia Pac. J. Bus. Adm. 2013, 5, 192–214. [Google Scholar] [CrossRef]

- Choi, J.; Yeniyurt, S. Contingency distance factors and international research and development (r&d), marketing, and manufacturing alliance formations. Int. Bus. Rev. 2015, 24, 1061–1071. [Google Scholar]

- Ukko, J.; Saunila, M. Understanding the practice of performance measurement in industrial collaboration: From design to implementation. J. Purch. Supply Manag. 2020, 26, 100529. [Google Scholar] [CrossRef]

- David, M.; Muange, R.; Maru, L.C. Strategic alliances on performance of retail firms in nairobi county, Kenya. TQM 2015, 27, 732–740. [Google Scholar]

- Arend, R.J. SME—Supplier alliance activity in manufacturing: Contingent benefits and perceptions. Strateg. Manag. J. 2006, 27, 741–763. [Google Scholar] [CrossRef]

- Min, J.; Mitsuhashi, H. Dynamics of unclosed triangles in alliance networks: Disappearance of brokerage positions and performance consequences. J. Manag. Stud. 2012, 49, 1078–1108. [Google Scholar] [CrossRef]

- Lee, J.W.; Abosag, I.; Kwak, J. The role of networking and commitment in foreign market entry process: Multinational corporations in the Chinese automobile industry. Int. Bus. Rev. 2012, 21, 27–39. [Google Scholar] [CrossRef]

- Blind, K.; Mangelsdorf, A. Alliance formation of SMEs: Empirical evidence from standardization committees. IEEE Trans. Eng. Manag. 2013, 60, 148–156. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Y.; Gao, S. The stability of strategic alliances: Characteristics, factors and stages. J. Int. Manag. 2008, 14, 173–189. [Google Scholar] [CrossRef]

- Tang, M.; Lan, H. An empirical research on factors influencing the stability of the storage alliance based on contract. In LISS; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Nielsen, B.B.; Gudergan, S. Exploration and exploitation fit and performance in international strategic alliances. Int. Bus. Rev. 2012, 21, 558–574. [Google Scholar] [CrossRef]

- Parkhe, A. Strategic alliance structuring: A game theoretic and transaction cost examination of inter-firm cooperation. Acad. Manag. J. 1993, 36, 794–829. [Google Scholar]

- Lloyd, H.L.E.; Varey, R.J. Factors affecting internal communication in a strategic alliance project. Corp. Commun. Int. J. 2003, 8, 197–207. [Google Scholar] [CrossRef]

- Agarwal, R.; Croson, R.; Mahoney, J.T. The role of incentives and communication in strategic alliances: An experimental investigation. Strateg. Manag. J. 2010, 31, 413–437. [Google Scholar] [CrossRef]

- Swoboda, B.; Meierer, M.; Foscht, T.; Morschett, D. International SME alliances: The impact of alliance building and configurational fit on success. Long Range Plan. 2011, 44, 271–288. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, Y.; Pei, Y.L.; Wang, G. Entrepreneurial orientation, strategic alliances, and firm performance: Inside the black box. Long Range Plan. 2014, 49, 103–116. [Google Scholar] [CrossRef]

- Liu, C. An investigation of relationship learning in cross-border buyer—Supplier relationships: The role of trust. Int. Bus. Rev. 2012, 21, 311–327. [Google Scholar] [CrossRef]

- Silva, S.C.; Bradley, F.; Sousa, C. Empirical test of the trust—Performance link in an international alliances’ context. Int. Bus. Rev. 2012, 21, 293–306. [Google Scholar] [CrossRef]

- Grudinschi, D.; Sintonen, S.; Hallikas, J. Relationship risk perception and determinants of the collaboration fluency of buyer—Supplier relationships in public service procurement. J. Purch. Supply Manag. 2014, 20, 82–91. [Google Scholar] [CrossRef]

- Sartorious, K.; Kirsten, J. A framework to facilitate institutional arrangements for smallholder supply in developing countries: An agribusiness perspective. Food Policy 2007, 32, 640–655. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wong, C.; Lai, K.H. Relational stability and alliance performance in supply chain. Omega 2008, 36, 600–608. [Google Scholar] [CrossRef]

- Lee, S.M.; Parast, M.M. The formation of initial trust in the strategic supply chain partnership. Int. J. Manag. Enterp. Dev. 2009, 7, 28–43. [Google Scholar] [CrossRef]

- Zybell, U. Partner management managing service partnerships in the supply chain a systemic perspective. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 231–261. [Google Scholar] [CrossRef]

- Liu, R.; Gao, Z.; Nayga, R.M.; Snell, H.A.; Ma, H. Consumers’ valuation for food traceability in china: Does trust matter? Food Policy 2019, 88, 101768. [Google Scholar] [CrossRef]

- Cullen, J.B.; Johnson, J.L.; Sakano, T. Success through commitment and trust: The soft side of strategic alliance management. J. World Bus. 2000, 35, 223–240. [Google Scholar] [CrossRef]

- Grant, S.B. The impact of market group culture on the appearance of post contractual opportunism in supply chain ‘partnerships’. Int. J. Serv. Oper. Manag. 2009, 5, 94–119. [Google Scholar] [CrossRef]

- Slater, S. Social capital in Japanese-Western Alliances: Understanding cultural effects. Int. Mark. Rev. 2012, 29, 6–23. [Google Scholar] [CrossRef]

- Kemper, N.P.; Popp, J.S.; Nayga, R.M.; Kerr, J.B. Cultural worldview and genetically modified food policy preferences. Food Policy 2018, 80, 68–83. [Google Scholar] [CrossRef]

- Bidault, F.; Salgado, M. Stability and complexity of inter-firm co-operation: The case of multi-point alliances. Eur. Manag. J. 2001, 19, 619–628. [Google Scholar] [CrossRef]

- Bidault, F. Managing Joint Innovation; Palgrave Macmillan: London, UK, 2012. [Google Scholar]

- Wittmann, C.M.; Hunt, S.D.; Arnett, D.B. Explaining alliance success: Competences, resources, relational factors, and resource-advantage theory. Ind. Mark. Manag. 2009, 38, 743–756. [Google Scholar] [CrossRef]

- Waheed, Z. Supply chain performance: Collaboration, alignment and coordination. Facilities 2018, 30, 177–178. [Google Scholar] [CrossRef]

- Graham, G.; Moon, S.; Kim, D. Systems thinking ability for supply chain management. Supply Chain Manag. Int. J. 2005, 10, 394–401. [Google Scholar]

- Hassan, M.M.D. Engineering supply chains as systems. Syst. Eng. 2006, 9, 73–89. [Google Scholar] [CrossRef]

- Ghadge, A.; Dani, S.; Chester, M.; Kalawsky, R. A systems approach for modelling supply chain risks. Supply Chain Manag. Int. J. 2013, 18, 523–538. [Google Scholar] [CrossRef]

- Gandolfo, D. Systems thinking and sustainability in organisations. J. Organ. Transform. Soc. Chang. 2015, 12, 1–3. [Google Scholar]

- Shongwe, M.I. A systems thinking approach to investigating complex sugarcane supply and processing systems: Integrating rich pictures and Bayesian networks. Syst. Pract. Action Res. 2018, 31, 75–85. [Google Scholar] [CrossRef]

- Holmberg, S. A systems perspective on supply chain measurements. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 847–868. [Google Scholar] [CrossRef]

- Nagarajan, V.; Savitskie, K.; Ranganathan, S.; Sen, S.; Alexandrov, A. The effect of environmental uncertainty, information quality, and collaborative logistics on supply chain flexibility of small manufacturing firms in India. Asia Pac. J. Mark. Logist. 2013, 25, 784–802. [Google Scholar] [CrossRef]

- Prajogo, D.; Tang, A.K.Y.; Kee-Hung, L. The diffusion of environmental management system and its effect on environmental management practices. Int. J. Oper. Prod. Manag. 2014, 34, 565–585. [Google Scholar] [CrossRef]

- Jangga, R.; Ali, N.M.; Ismail, M.; Sahari, N. Effect of environmental uncertainty and supply chain flexibility towards supply chain innovation: An exploratory study. Procedia Econ. Financ. 2015, 31, 262–268. [Google Scholar] [CrossRef]

- Choy, K.L.; Chow, H.K.H.; Tan, K.H.; Chan, C.K.; Mok, E.C.M.; Wang, Q. Leveraging the supply chain flexibility of third-party logistics—Hybrid knowledge-based system approach. Expert Syst. Appl. 2008, 35, 1998–2016. [Google Scholar] [CrossRef]

- Bashiri, M.; Tabrizi, M.M. Supply chain design: A holistic approach. Expert Syst. Appl. 2010, 37, 688–693. [Google Scholar] [CrossRef]

- Galli, F.; Prosperi, P.; Favilli, E.; Amico, S.; Bartolini, F.; Brunori, G. How can policy processes remove barriers to sustainable food systems in Europe? Contributing to a policy framework for agri-food transitions. Food Policy 2020, 101871. [Google Scholar] [CrossRef]

- Hobbs, J.E.; Young, L.M. Closer vertical coordination in agri-food supply chains: A conceptual framework and some preliminary evidence. Supply Chain Manag. 2000, 5, 131–143. [Google Scholar] [CrossRef]

- Lin, H.; Darnall, N.J. Strategic alliance formation and structural configuration. J. Bus. Ethics 2015, 127, 549–564. [Google Scholar] [CrossRef]

- Cozzarin, B.P.; Barry, P.J. Organizational structure in agricultural production alliances. Int. Food Agribus. Manag. Rev. 1998, 1, 149–165. [Google Scholar] [CrossRef]

- Saban, K.; Mawhinney, J.; Drake, M. An integrated approach to managing extended supply chain networks. Bus. Horiz. 2017, 60, 689–697. [Google Scholar] [CrossRef]

- Kuo, J.C.; Chung, J.C.; Lin, C.C. Feasible Study for Healthy Logistics Service System; Technical Report; Industrial Technology and Research Institute: Hsinchu, Taiwan, 2003. [Google Scholar]

- Tajima, M. Strategic value of RFID in supply chain management. J. Purch. Supply Manag. 2007, 13, 261–273. [Google Scholar] [CrossRef]

- Takahashi, K.; Nakamura, N. Push, pull, or hybrid control in supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2004, 17, 126–140. [Google Scholar] [CrossRef]

- Riccardo, M.; Guang, S.; Alessandro, P. Distribution network design: A literature review and a research agenda. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 506–531. [Google Scholar]

- Benita, M.B.; Jose, M.B. A hybrid push/pull control algorithm for multi-stage, multi-line production systems. Prod. Plan. Control 2000, 11, 349–356. [Google Scholar]

- Fu, H.; Ma, Y.; Ni, D.; Cai, X. Coordinating a decentralized hybrid push–pull assembly system with unreliable supply and uncertain demand. Ann. Opera Res. 2017, 257, 537–557. [Google Scholar] [CrossRef]

- Naylor, J.B.; Naim, M.M.; Berry, D. Legality: Integrating the lean and agile manufacturing paradigms in the total supply chain. Int. J. Prod. Econ. 1999, 62, 107–118. [Google Scholar] [CrossRef]

- Rudberg, M.; Wikner, J. Mass customization in terms of the customer order decoupling point. production systems. Prod. Plan. Control 2004, 15, 445–458. [Google Scholar] [CrossRef]

- Nasirzadeh, F.; Khanzadi, M.; Mir, M. A hybrid simulation framework for modelling construction projects using agent-based modelling and system dynamics: An application to model construction workers’ safety behavior. Int. J. Constr. Manag. 2018, 18, 132–143. [Google Scholar] [CrossRef]

- Forrester, J.W. System dynamics, systems thinking, and soft operation research. Syst. Dyn. Rev. 1994, 245–256. [Google Scholar] [CrossRef]

- Ahmad, S.; Tahar, R.M.; Muhammad-Sukki, F.; Munir, A.B.; Rahim, R.A. Application of system dynamics approach in electricity sector modelling: A review. Renew. Sustain. Energy Rev. 2016, 56, 29–37. [Google Scholar] [CrossRef]

- Ye, G.; Yuan, H.; Wang, H. Estimating the generation of construction and demolition waste by using system dynamics a proposed model. In Proceedings of the International Conference on Bioinformatics and Biomedicine Engineering, Chengdu, China, 18–20 June 2010; pp. 1–4. [Google Scholar]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Ciobanu, C.; Bejou, D. Forging new global alliances: Emerging markets and advanced economies. J. Relatsh. Mark. 2009, 8, 280–298. [Google Scholar] [CrossRef]

- Kumar, A.; Shinoj, P.; Joshi, P.K. Global economic crisis and Indian agriculture: Impacts and perspectives. Ind. J. Agric. Econ. 2010, 65, 508–519. [Google Scholar]

- Ellinger, P.N.; Tirupattur, V. An overview of the linkages of the global financial crisis to production agriculture. Am. J. Agric. Econ. 2009, 91, 1399–1405. [Google Scholar] [CrossRef]

- Lynch, M.D.F. Public policy and global supply chain capabilities and performance: A resource-based view. J. Int. Mark. 2002, 10, 25–51. [Google Scholar]

- Mintcheva, V. Indicators for environmental policy integration in the food supply chain (the case of the tomato ketchup supply chain and the integrated product policy. J. Clean. Prod. 2005, 13, 717–731. [Google Scholar] [CrossRef]

- Greys, S. Impact of demand uncertainty on stability of supplier alliances in assembly models. Prod. Oper. Manag. 2011, 20, 905–920. [Google Scholar]

- Peter, K.; Andy, C.; Edwin, T.C. Supplier alliances and environmental uncertainty: An empirical study. Int. J. Prod. Econ. 2009, 120, 190–204. [Google Scholar]

- Chen, C.; Chiu, H.; Chi, Y.; Wu, S. Does uncertain demand affect service quality? Int. J. Hosp. Manag. 2015, 46, 76–78. [Google Scholar] [CrossRef]

- Giri, B.; Bardhan, S. Coordinating a supply chain under uncertain demand and random yield in presence of supply disruption. Int. J. Prod. Res. 2015, 53, 5070–5084. [Google Scholar] [CrossRef]

- Dias, J.; Vítor, M. The impact of resource conditions and environmental uncertainty on inter-firm alliance strategies. Appl. Econ. 2009, 43, 757–765. [Google Scholar] [CrossRef]

- Zineldin, M.; Dodourova, M. Motivation, achievements and failure of strategic alliances. Eur. Bus. Rev. 2013, 17, 460–470. [Google Scholar] [CrossRef]

- Wendel, D.L. Modeling alliance membership in a three-dimensional space. Int. Interact. 2001, 27, 29–60. [Google Scholar] [CrossRef]

- Chang, W.; Chiu, C. Coopetition under alliance? applying awareness-motivation-capability competitive dynamics perspective. J. Bus. Econ. Manag. 2016, 17, 701–716. [Google Scholar] [CrossRef][Green Version]

- Ma, X. Stability analysis of supply chain cooperation contract under asymmetric information. Appl. Mech. Mater. 2011, 44, 794–798. [Google Scholar] [CrossRef]

- Tage, S.; Christian, T.; Claus, A. Supply chain collaboration: Theoretical perspectives and empirical evidence. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 531–549. [Google Scholar]

- Paul, S.; Asian, S.; Goh, M.; Torabi, S. Managing sudden transportation disruptions in supply chains under delivery delay and quantity loss. Ann. Oper. Res. 2017, 3, 1–32. [Google Scholar] [CrossRef]

- Hueth, B.; Lawrence, J. Information transmission in cattle markets: A case study of the Chariton valley beef alliance. J. Agribus. 2006, 24, 93–107. [Google Scholar]

- Steensma, H.; Marino, L.; Weaver, K.M. Attitudes toward cooperative strategies: A cross-cultural analysis of entrepreneurs. J. Int. Bus. Stud. 2000, 31, 591–609. [Google Scholar] [CrossRef]

- Gill, J.; Butler, R.J. Managing instability in cross-cultural alliances. Long Range Plan. 2003, 36, 543–563. [Google Scholar] [CrossRef]

- Feng, H.; Cui, Y. Cross-cultural adaptation management among partnerships in supply chain alliance. In Proceedings of the 2008 IEEE International Conference on Service Operations and Logistics, and Informatics, Beijing, China, 12–15 October 2008. [Google Scholar]

- Faisal, M. Sustainability metrics for a supply chain: The case of small and medium enterprises. Int. Ser. Oper. Res. Manag. Sci. 2012, 13, 392–414. [Google Scholar] [CrossRef]

- Agatz, N.; Campbell, A.; Fleischmann, M.; Savels, M. Challenges and opportunities in attended home delivery. In The Vehicle Routing Problem: Latest Advances and New Challenges: Operations Research/Computer Science Interfaces; Springer: Boston, MA, USA, 2008; Volume 43, pp. 379–396. [Google Scholar]

- Lee, H.Y.; Yoo, D. The determinants of perceived SQ and its relationship with satisfaction. J. Serv. Mark. 2000, 14, 217–231. [Google Scholar] [CrossRef]

- Sureshchander, G.S.; Rajendran, C.; Anatharaman, R.N. The relationship between service quality and customer satisfaction—A factor specific approach. J. Serv. Mark. 2002, 16, 363–379. [Google Scholar] [CrossRef]

- Nitin, S.; Deshmukh, S.G.; Vrat, P. A conceptual model for quality of service in the supply chain. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 547–575. [Google Scholar]

- Prajogo, D.I.; Sohal, A.S. The relationship between organizational strategy, total quality, management and organizational performance, Mediating role of TQM. Eur. J. Oper. Res. 2006, 16, 35–50. [Google Scholar] [CrossRef]

- Kaliappen, N.; Hillman, H. Validity and reliability of the strategic factors and organizational performance scales. Middle East J. Sci. Res. 2013, 16, 1719–1724. [Google Scholar]

- Kamakoty, J.; Sohani, N. Measurement of service quality of upstream and downstream supply chain. Int. J. Serv. Oper. Manag. 2016, 25, 99–119. [Google Scholar] [CrossRef]

- Boulkedid, R.; Abdoul, H.; Loustau, M.; Sibony, O.; Alberti, C. Using and reporting the Delphi method for selecting healthcare quality indicators: A systematic review. PLoS ONE 2011, 6, e20476. [Google Scholar] [CrossRef] [PubMed]

- Sourani, A.; Sohail, M. The Delphi method: Review and use in construction management research. Int. J. Constr. Educ. Res. 2015, 11, 54–76. [Google Scholar] [CrossRef]

- Peters, H. Game Theory: A Multi—Leveled Approach; Springer: Berlin, Germany, 2008. [Google Scholar]

- Mesterton-Gibbons, M. An Introduction to Game—Theoretic Modelling, 2nd ed.; American Mathematical Society: Providence, RI, USA, 2004. [Google Scholar]

- Beimborn, D. The stability of cooperative sourcing coalitions—Game theoretical analysis and experiment. Electr. Mark. 2014, 24, 19–36. [Google Scholar] [CrossRef]

- Cachon, G.P.; Netessine, S. Game theory in supply chain analysis. In Handbook of Quantitative Supply Chain Analysis; International Series in Operations Research & Management Science; Springer: Boston, MA, USA, 2004; Volume 74. [Google Scholar]

- Arthanari, T.; Carfì, D.; Musolino, F. Game theoretic modeling of horizontal supply chain coopetition among growers. Int. Game Theory Rev. 2015, 17, 1540013. [Google Scholar] [CrossRef]

| Variable | Description | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 155 | 52.01% |

| Female | 143 | 47.99% | |

| Age | 18–30 | 161 | 54.03% |

| 30–39 | 42 | 14.09% | |

| 40–49 | 42 | 14.09% | |

| 50–59 | 38 | 12.75% | |

| ≥60 | 15 | 5.03% | |

| Education | Below high school degree | 54 | 18.12% |

| High school degree | 39 | 13.09% | |

| Bachelor’s degree | 113 | 37.92% | |

| Graduate degree | 38 | 12.75% | |

| Post-graduate degree | 54 | 18.12% | |

| Employment | Workers | 108 | 36.24% |

| Students | 91 | 30.54% | |

| Part-time | 20 | 6.71% | |

| Self-employed | 34 | 11.41% | |

| Retired | 33 | 11.07% | |

| Other | 12 | 4.03% | |

| Family status | Live alone | 110 | 36.91% |

| Couple without children | 73 | 24.50% | |

| Couple with children | 81 | 27.18% | |

| Other | 34 | 11.41% | |

| Income (RMB per month) | Low (<3000) | 139 | 46.64% |

| Low to mid (3000–6000) | 107 | 35.91% | |

| Mid (6000–9000) | 32 | 10.74% | |

| Mid to high (9000–12,000) | 15 | 5.03% | |

| High (>12,000) | 5 | 1.68% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Pervez, A.; Wu, J.; Shen, X.; Zhang, D. Home-Delivery-Oriented Agri-Food Supply Chain Alliance: Framework, Management Strategies, and Cooperation Stability Control. Sustainability 2020, 12, 6547. https://doi.org/10.3390/su12166547

Han C, Pervez A, Wu J, Shen X, Zhang D. Home-Delivery-Oriented Agri-Food Supply Chain Alliance: Framework, Management Strategies, and Cooperation Stability Control. Sustainability. 2020; 12(16):6547. https://doi.org/10.3390/su12166547

Chicago/Turabian StyleHan, Chunyang, Amjad Pervez, Jingqiong Wu, Xiaojing Shen, and Dezhi Zhang. 2020. "Home-Delivery-Oriented Agri-Food Supply Chain Alliance: Framework, Management Strategies, and Cooperation Stability Control" Sustainability 12, no. 16: 6547. https://doi.org/10.3390/su12166547

APA StyleHan, C., Pervez, A., Wu, J., Shen, X., & Zhang, D. (2020). Home-Delivery-Oriented Agri-Food Supply Chain Alliance: Framework, Management Strategies, and Cooperation Stability Control. Sustainability, 12(16), 6547. https://doi.org/10.3390/su12166547