1. Introduction

The construction industry brings together a cooperation between many different sub industries and project partner members. As is well-documented in the construction management literature related to worker safety, the industry is thought to be open, receptive and unique. Additionally, it features layers of subcontracting, engineering participants and complex work types, coupled with the dynamic site characteristics and an operating environment equipped with a multitude of different operation types, which are mostly undertaken by temporary organizations, a high mobility labor pool, on-site management and construction management. This highly dynamic work environment and organizational arrangements leads to frequent accidents resulting in injuries to workers. The recognition of the importance of construction safety management often takes a minor role in the evaluation of construction project performance when compared to other factors, such as the cost of materials and overall management efficiency [

1]. However, realized profits and the prevention of accidents are not mutually exclusive, and both can complement each other. This novel perspective has spurred the construction industry to explore sustainable enhancements in construction safety management [

2]. Over the last decade, the burden of responsibility for construction accidents has been borne by the construction workers themselves. Recently, the community and business enterprises are now taking on more and more of these responsibilities [

3,

4]. There is a growing expectation of workers and construction enterprises that construction sites are safe and free from harm. This study investigates the factors that can assist the Taiwanese construction industry to improve construction safety performance. The study outcomes can help to inform construction enterprises on how to approach safety by a more systematic method.

Construction work experiences a relatively high accident frequency and fatality rate when compared to other related industries. For the period of 2011–2016, the average Rates of Occupational Fatal Injuries (ROFI) per 1000 workers in Taiwan’s construction industries was 0.122. This rate is over 3.6 times higher than all other industries (0.034) [

5]. Although Taiwan’s construction labor force accounts for only approximately 10% of the total labor force (approximately 400,000 persons), the annual rate of fatalities makes up about 45% to 55% of the total industrial sector in Taiwan [

6]. In comparison to other Asian countries with advanced economies, the ROFI of Taiwan’s construction industry performs better than countries such as South Korea and Hong Kong. However, incident rates are still high when compared with other advanced countries, including the United States (ROFI = 0.097) and United Kingdom (ROFI = 0.020), with rates 1.3 times and 4 times higher, respectively. This clearly highlights the opportunity to further improve the occupational safety management performance of Taiwan’s construction industry.

There are a multitude of drivers for improving construction site safety performance; social responsibility and regulatory expectations are prime drivers, as well as cost blowouts associated with delays to timelines. The safety research conducted to date has mostly addressed critical factors for safety success through pinpointing factors identified as critical for achieving safety related objectives. This gap drives the need for research into this area to be conducted in order to further identify various safety factors commonly associated with improved construction safety performance. With this consideration in mind, this study aims to identify a core group of factors considered essential to the knowledge base for effective construction safety performance. Such knowledge can guide the development and enhancement of industry-based strategies for enhancing construction safety performance outcomes. Although the characteristics of every construction site and trade are inherently different, identifying the critical factors affecting the success of site safety management (SSM) and exploring its relationship with the overall environment are helpful for guiding effective safety management measures on site. This article provides a table of terminology abbreviation in

Appendix A to facilitate readability.

2. Previous Study

D. Ronald Daniel first defined the term ‘success factors’ in 1961. According to the Oxford Dictionary, ‘success’ is defined as “the accomplishment of aiming at purpose; the definition of success is the completion of a goal or goal.” ‘Key success factor’ (KSF) is a management term for a unique element thought to be necessary for an organization or project to achieve its mission. A common definition of KSF is that of a “set of positive activities and results which signifies that a manager has realized their goals and objectives”. The range of factors associated with safety management during construction projects are well documented in the literature, including safety management measures, safety management system implementation, safety performance, strategy and safety risk management. This plethora of investigations into safety management on the construction site is typically conducted with a view to identify opportunities for reducing construction accidents.

2.1. Measuring and Implementing Safety Management

Over the past two to three decades, considerable effort has been made by researchers to measure safety management practices, focusing on behavioral and business management related factors. Hinze [

7] identified that management commitment to safety, project safety management personnel and a further nine measures of North American large-scale construction project site safety performance displayed a significant role in the measurement and implementation of safety management. Razuri et al. [

8] used utility indicators to better quantify and prioritize the effectiveness of the project safety and mortality rates for different safety management measures. The research found that focusing on professional management training, project planning and behavior-oriented safety programs was closely related to project safety management performance measures. Furthermore, Aksorn and Hadikusumo [

9] used factor analysis (FA) to identify four safety critical success factors—workers’ participation, safety prevention and control systems, safety agreements and management commitments—for large and medium construction projects in Thailand. Al Haadir [

10] embarked on a comprehensive literature review in combination with an analytical hierarchical process (AHP) to identify seven critical success factors (CSFs)—management support, clear and rational goals, personal attitudes, team work, effective implementation, safety training, safety training and appropriate supervision. These CSFs demonstrated the ability to affect the Saudi Arabian construction company’s implementation of safety programs.

The body of research on factors influencing construction site safety highlights the diversity and complexity of factors driving workplace safety. This diversity in research findings makes establishing a set of common factors particularly challenging. Furthermore, regional variations in institutional and professional cultures can have a notable influence on workplace practices and safety values [

11]. The findings of Ismail et al. [

12] identified that personal awareness is the most important factor affecting the success of the safety management system, followed by safety communication. The effective use of safety equipment and personal protection equipment (PPE) supports the improvement of safety outcomes. However, safety management processes, safety management information and a safety management committee were found to be the most important factors in Hong Kong’s construction industry, and are widely regarded as primary factors for safety in the construction industry [

13]. According to Hashem et al. [

14], the lack of training, funding and awareness are the main influential factors in the implementation of safety and health management system for construction projects in Libya.

Hinze et al. [

15] investigated the relationship between safety management measures and safety performance in 57 projects launched in the USA, including 22 basic safety management measures and 14 management measures. The application of the safety performance management measures for these construction projects significantly improved the overall measured safety performance. Based on the various considerations from the existing literature, Shen and Shi [

16] summarized 39 factors for construction safety management, and used a fuzzy factor analysis model to further extract seven key influencing factors, including consciousness and attitude, ability and experience, training and education, rules and coercion, resource input, project coordination, and project characteristics. Using factor analysis, Yu et al. [

17] extracted five key factors of the safety management of subway constructions, these being the safety attitude, the safety of the construction site, government regulation, market discipline and task prevention. Zhou et al. (2014) [

18] set up a data database following a network theory to provide practical cases and related solutions for subway construction safety management.

Most investigations regarding the influence factors related to the construction site safety management system have mainly applied AHP and conceptualization analysis methods to establish a safety management system performance model. The related findings consider nothing more than personal awareness and attitudes, communication, management attitudes, PPE, and effective regulation [

17,

18,

19,

20,

21]. This myopic view of construction site safety has the potential to overlook the complexity of the topic and exclude other important factors which could help with understanding safety performance, especially given the often diverse cultural settings of construction sites.

2.2. Managing Safety Performance and Safety Risk

Understanding the factors for managing safety performance is a long-standing issue in the construction industry. The viewpoint of Tam et al. [

22] is that deficiencies in safety awareness and training, together with the unwillingness to invest in appropriate resources for safety management, and reckless actions are the major factors influencing the construction safety performance in China. Teo et al. [

23] built the ‘3P + I model’ (policy, process, personnel and incentive mechanism management model) to better guide the project manager to manage safety on construction sites. In response to this, Abdul-Rashid et al. [

24] also identified that the safety awareness of the senior management and project management, along with the safety oversight, are the three influential factors that are thought to affect the corporate safety performance of large contractors in Egypt.

Dunwen et al. [

19] proposed an assessment structure based on the plan–do–check–action (P–D–C–A) management cycle outlined in OHSAS18001 combined with fuzzy AHP to build a safety performance check system. By using a case study method and targeting the construction site safety management personnel, Omran et al. [

25] extracted five CSFs which affect the safety performance of Malaysian construction projects. For the assessment of construction contractor’s safety performance, Mohamed [

26] adopted data envelopment analysis. The analysis safety indicators encompassed factors such as the organizational safety system, safety training, safety conference, safety equipment, safety supervision, safety incentives and punishment, workers’ safety attitude, and worker mobility, etc. In order to further clarify the understanding of safety performance, Koh and Rowlinson [

27] developed a conceptual model to understand the causal relationship between 376 Hong Kong construction industry practitioners. The safety management and safety culture required for improving safety performance requires teamwork rather than an individually-focused operation.

Assisted by contractors, owners and consultants, Memon et al. [

28] analyzed the key factors influencing the performance of Pakistan’s construction safety program. According to Hardison et al. [

29], the most important factor affecting safety performance is field based supervision. Simanaviciene et al. [

30] developed a multi-attribute decision-making model for occupational safety and health for construction projects. The three cases were analyzed to find out the best weights for the different scores. With 30 Chinese construction enterprises as the survey data source, Wu et al. [

31] conducted a survey of construction site safety performance. They attempted to characterize the causal relationship between safety performance factors and project objectives to further enhance safety performance in the construction industry.

Risk management is also held to be one of the key factors for enhancing construction site safety performance. Aminbakhsh et al. [

32] proposed a safety risk assessment framework. The framework not only quantifies the relative weight of risk factors but also responds with countermeasures to improve site safety management capacity. Fung et al. [

33] developed a risk assessment model to prevent construction accidents, enhance the safety knowledge and raise construction workers’ awareness of construction risk. This was to hopefully enhance the overall construction industry safety management performance. Rozenfeld et al. [

34] predicted volatility through construction job safety analysis in order to better support safety-conscious planning, safety risk levels and security management strength. Lopez del Puerto et al. [

35] found workers hold diverse views on and perceptions of safety culture regarding construction, commercial, and large public construction projects.

Based on the literature reviewed, the European and US safety concepts are considered more advanced and comprehensive than those found in the Taiwanese construction industry. What is more, there is now a growing trend in China and Hong Kong to conduct detailed research into the safety of the construction industry. However, due to culture differences and the research methods utilized, the CSFs which best represent safety management performance may vary depending of geographical and regional cultural differences. Identifying and summarizing the Key Safety Factors (KSFs) of SSM with consideration to regional differences can help to improve the overall performance of SSM.

3. Materials and Methods

By means of summarizing the characteristics of SSM and the influential factors for safety management, this study aims to develop an SSM factor scale. In this study, exploratory factor analysis (EFA) was used to extract the initial factors with an influence on site safety. To develop an understanding of how the factors are related, structural equation modeling (SEM) was utilized to further analyze the underlying relationships among the key factors. To capture the perceptions of construction workers, a targeted questionnaire was developed, which was distributed to construction safety professionals working in Taiwan. The purpose of the questionnaire was to capture and measure the perceptions of a diverse sample of professionals engaged in construction projects based on roles, to capture their views on various project attributes on site safety management. Building on the survey results this study also explored the ranking of individual success factors (SF) for achieving positive safety management outcomes on construction sites.

3.1. Questionnaire Development

Based on construction related safety theories, this study integrates safety management findings from previous related studies. As shown in

Table 1, eight dimensions were selected. Initially, 45 variables related to safety management in construction sites were extracted. The 45 initial variables were converted into 45 questions in the questionnaire. Dimensions of questionnaires adapted from earlier research [

36,

37] were also included in the questionnaire’s development. The intent was to evaluate the influential variables which were important to evaluating safety management, and SFs. The rating scale employed a multiple choice 5-point Likert type scale, ranging from 1, representing ‘strongly unimportant’, to 5, representing ‘strongly important’.

Before distributing the final questionnaire, five experienced construction safety experts with safety management licenses or certificates approved by the Occupational Safety and Health authority in Taiwan reviewed the questionnaire’s content. The five selected experts were invited to carefully examine the questionnaire for readability, comprehensiveness and accuracy. The content met the scrutiny of the selected experts, with the exception of 12 items which were subsequently removed. The final version of this questionnaire, otherwise known as the corrected instrument, contained 33 structural survey questions representing the 33 nominated SFs (NSFs). The final questionnaire was divided into four parts. The first two parts were used to capture the background characteristics and participation projects’ attributes of respondents. The third part was concerned with ‘project category accident perception’, and the fourth part dealt with ‘factors of site safety management.’

3.2. Questionnaire Distribution

The final questionnaire was electronically distributed via a weblink and E-mail, as well as mailed paper copies and personal delivery to construction safety practitioners across Taiwan. Altogether, 557 copies of the questionnaire were distributed, with 284 valid responses being received, giving a 55.25% return rate. The surveys were distributed across Taiwan, and were received between March and June 2015. A copy of the third part of questionnaire, focusing on ‘project category accident perception’, is provided in

Appendix B.

Most industry personnel who responded to this survey held undergraduate level college/university qualifications, were 31–40 years old, with 5–10 years’ industry work experience, and held safety management certification issued by a competent authority. Among these 284 respondents, 112 (22.1%) possessed safety engineer certificates. A total of 176 (62%) were the employees of contractors, 79 (27.8%) of 284 respondents were site engineers, and 70 (24.6%) were safety engineers. Around 60% (173) of the 284 respondents had participated in at least 10 projects. More than 68% (195) of the 284 respondents had a bachelor’s degree at least, with one third of them holding a master’s degree.

An analysis of the internal consistency was conducted to assess the validity and robustness of results for each of the selected characteristics and factors. Cronbach’s α value was utilized to verify the internal consistency and stability of the survey results. Where the Cronbach’s α coefficient exceeds 0.70, the reliability is considered high [

6]. The study’s Cronbach’s α coefficient (0.944) is greater than 0.70, indicating that the results are very credible.

The study assumes that the data collected followed a normal distribution, based on the sample size being above the central limit theorem threshold for normal distribution and the unbiased collection of survey data. Therefore, the use of parametric analysis and statistical tests can be reliably applied to the study.

4. Results

4.1. Extracting SFs of SSM

This study uses EFA to characterize the underlying relationships between safety management SFs. The 18 selected SFs were assessed using principal component analysis (PCA) with a follow up varimax rotation. PCA generates sets of linear combinations of variables to illuminate the variance observed in the data collected in the surveys [

52]. This type of analysis reduces the data being observed to a set of linear related factors. For this study, the resulting factor is posited as a ‘supervariable’ built by combining survey variables based on relationships. The benefit PCA has over other dimensional reduction methods is that the mathematical representation of the resulting linear combinations takes away the need to utilize potentially questionable causal models [

53].

Based on the Kaiser-Meyer-Olkin (KMO) measure of sampling value, Bartlett’s test of sphericity, commonality of factors, and factor loading selected adjustments were performed to obtain the best factor analysis results. The best results were obtained after 11 PCA runs. The result for the survey’s Bartlett test of sphericity was 2391.074, with a related p-value of less than 0.001, which demonstrates that the correlation matrix is significantly different from the identity matrix. The KMO is 0.915, exceeding the value of 0.5 required to be consider acceptable. The tests of the survey results indicate that the sample data collected is suitable for PCA.

To provide greater clarity between the extracted factors and SFs, the extracted factors were designated as a ‘cluster’. The cluster matrix shown in

Table 2 provides the post varimax rotation results. This new description avoids confusion among extracted SFs. Four clusters are selected, based on the Kaiser rule for the extraction of clusters with eigenvalues greater than 1. The four clusters were named according to the SFs which form them. The four clusters are Management Behaviors (MTH), Safe Work Environment and Resources (WER), Safety Behaviors of Workers (SBW), and Prevention and Remedial Actions (PRA), respectively. Each of the SFs were strongly associated with a single clusters, where factors with a loading over 0.5 (to round off) were retained. The absence of factor cross loading indicates that the questionnaires displayed robust convergent validity. The Cronbach’s α values for the four clusters exceeded 0.74. Finally, the PCA clusters extracted accounted for 63.45% of the total variance.

To explore the associations between the SFs, a correlation matrix analysis using a Pearson correlation coefficient was constructed. Pearson correlation coefficient values range from −1.00 for a negative relationship to +1.00 for positive relationship. Most of the SFs in the clusters showed a positive correlation, ranging between 0.36 and 0.59 (medium correlation). This result indicated that there is an underlying relationship between the SFs, which is worthy of further analysis.

4.2. SEM Framework for SFs of SSM

Structural equation modeling (SEM) is a widely accepted technique which simultaneously examines the relationships between multiple variables. Using conceptual models, a path diagram and a system of linear regression equations, SEM attempts to bring together complex dynamic relationships in the midst of a network of observed and unobserved variables. SEM may be easily mistaken for a regression model although they are fundamentally different; there is no clear distinction between dependent and independent variables, which is a hallmark of regression models. In the case of SEM, the variables are applied relative to each other. Given this, a dependent variable in a modelling equation can develop into an independent variable in other elements of the SEM system [

54,

55]. The inference of a causal relationship in the SEM model is due to the reciprocal nature of a variable.

4.2.1. SEM Framework Development

The use of the SEM framework is used to describe relationships between observed endogenous and latent variables founded on a series of logical assumptions. Observed variables are those that can be directly measured; latent variables represent concepts that cannot be observed directly. In this case, the data represented by latent variables must be expressed in a framework that describes them based on observed variables.

This study began to use SEM to develop and test the structural relationship between SFs for the construction site safety management. Based the theoretical expectations and empirical findings related to this field, the latent constructs and their corresponding measurements were incorporated into the initial SEM to develop the basic framework. Several iterations of the model were tested to achieve the final framework specification. The results of each iteration were evaluated using a combination of modified indices [

56] and a series of theoretical verifications until the final framework was determined.

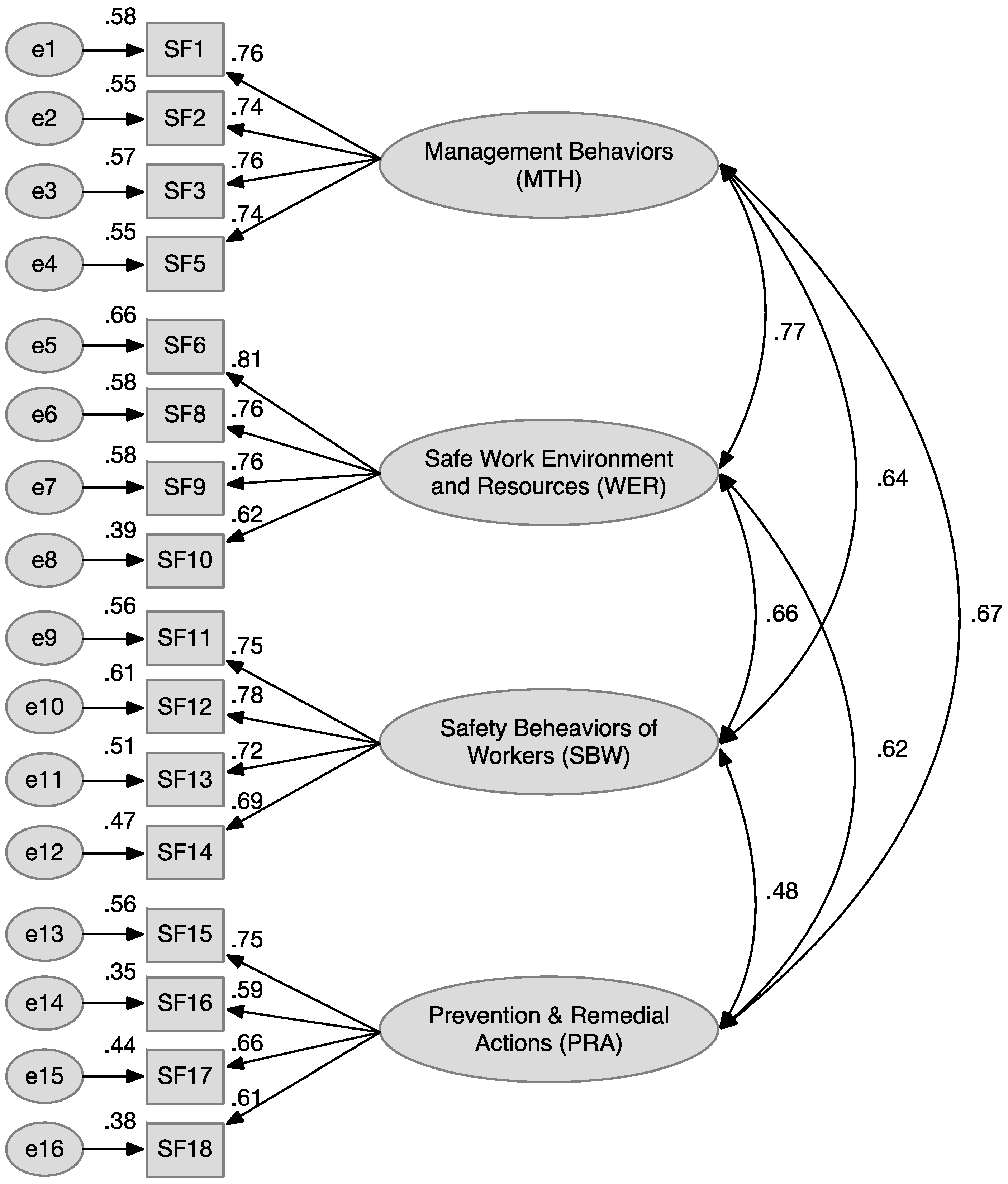

The SEM framework constructed for this study was composed of a measurement model and a structural model, using the AMOS 22 Software Package to construct the framework. The measurement model serves to examine the extent to which exogenous variables reflect the latent constructs. Contrastingly, the structural model simulates relationships among the latent variable constructs and the ability to model direct, indirect and relevant effects. The initial SEM frameworks with path coefficients are shown in

Figure 1, which indicates each variable’s impact on other variables, and the corresponding connections to SFs. The observed variables are represented by the rectangles shown in

Figure 1. The ellipses represent the unobserved latent variable constructs. The arrows in the figure signify the direction of the hypothesized effects. It is therefore clear that the degree of success for SSMs is determined by four major effects of SFs, and each SF has several impacts on the processes. Before performing the SEM analysis, a conceptual initial model was developed based on a comprehensive review of the related literature, and consideration given to the logic of the assumed relationships. If the initial model is compatible with the sample data, then the assumptions made can be accepted. Otherwise, the model must be respecified to achieve the required reliability.

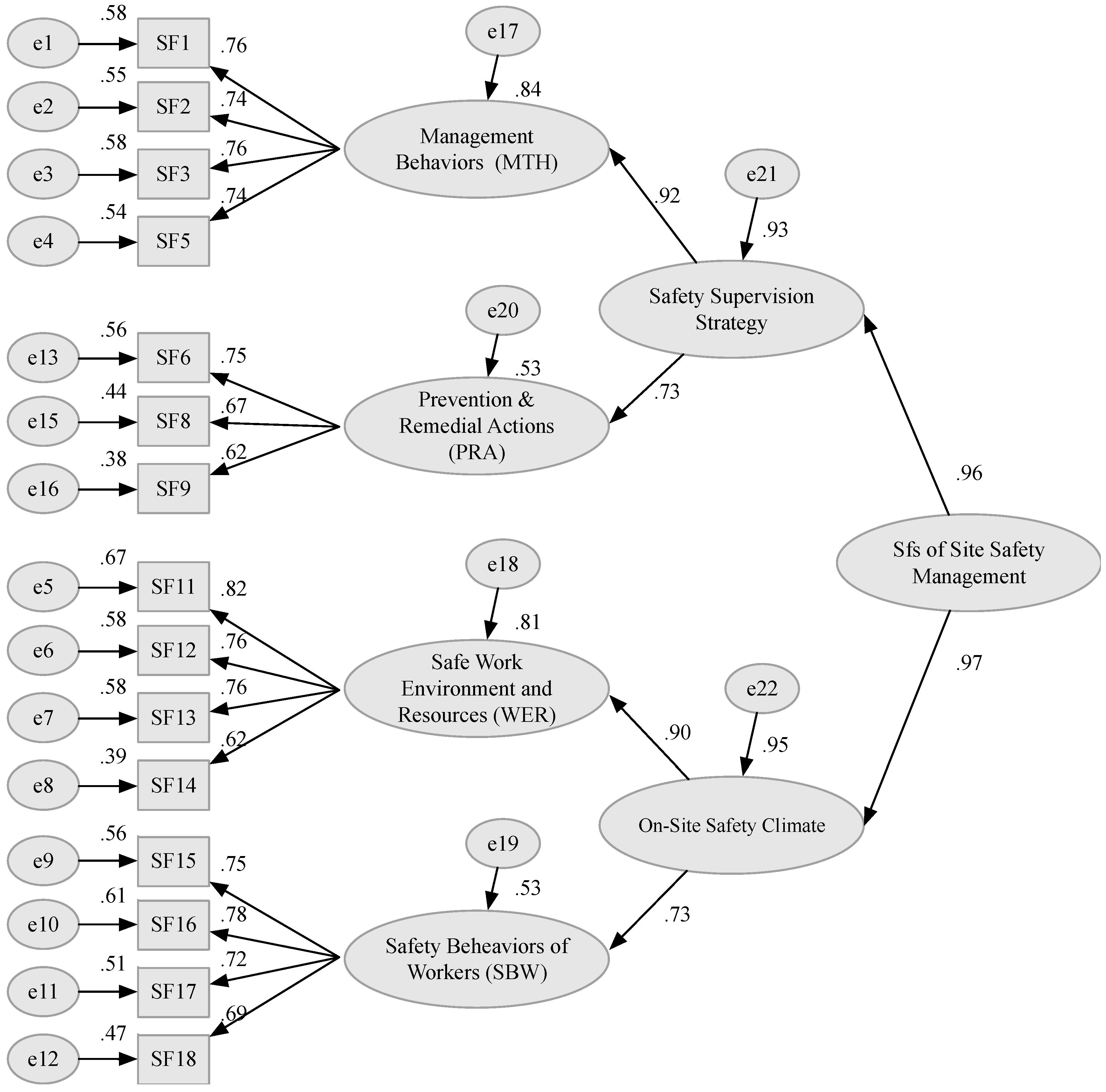

Figure 2 shows the safety management SFs’ final SEM, and the path correlation coefficients.

4.2.2. SEM Framework Assessment

The Goodness of Fit (GOF) indices are intended to confirm if the model’s fit is consistent with the actual sample data. If the model’s fitness index does not meet the suggested criteria, it will be modified by reference to Modification Indices (MI) in order to obtain an optimized model. This study utilized AMOS software to test the fitness of the first to third levels’ models by analyzing the SEM model with the previous factors. The results obtained from the model GOF tests are shown in

Table 3, which indicates that the GOF indicators were acceptable to the value suggested by Molenaar et al. [

57].

Table 3 summarizes the proposed GOF measures and the corresponding indexes for the initial model, and the following iterations of the SEM frameworks. The adjusted goodness of fit index (AGFI) (=0.899; remarkably close to 0.9) of the initial iteration of the SEM failed to meet the selected GOF measures, signaling the need to revise the initial framework. All of the GOF indices of the final SEM framework attained the chosen GOF levels following two revisions of the model. The final SEM framework is displayed in

Figure 2, with path coefficients. The final framework was comprised of four clusters (WER, SBW, MTB and PRA) providing a good representation of the success factors of construction safety management. In addition, because the correlation coefficients between the factors were found to be mostly greater than 0.4 (moderate correlation), and some values were up to 0.7 (highly correlated), there are presumed to be higher-order common factors.

In the measurement SEM, the path coefficients of the SEM framework were all nonzero, with a 95% confidence level. The final coefficients provide meaningful representations due to the significant relationships between the observed variables and the latent variables. Furthermore, the model demonstrated that the observed variables are sufficiently robust to represent the corresponding potential variables.

4.3. Measurement Model of the SEM Framework

Referring to

Figure 2, Cluster-MTH can be measured and interpreted by four observation factors, comprising of SF3, SF2, SF1 and SF5. Among the four SFs, SF1 had the greatest influence on Cluster-MTH (λ = 0.764); SF2 had the second highest influence on Cluster-MTH (λ = 0.739); SF5 showed the smallest influence on Cluster-MTH (λ = 0.738). Clearly, management structures appear to have a key influence on nurturing an organization’s safety culture, and the attitude of the management affects how employees view safety issues. With this in mind, if there is no safety commitment from the management level, safety management is doomed to failure [

58].

Cluster-PRA is comprised of SF18, SF15 and SF17. Of the three SFs, SF15 shows the greatest influence on Cluster-PRA (λ = 0.747), while, in contrast, SF18 has the smallest influence (λ = 0.619). Such results show that the key to achieving good site safety management performance mainly relies on the management level of the attitude and commitment in relation to site safety practices. Through active management approaches and a genuine presence at construction sites showing concerns about site safety, safety performance can be improved [

7,

59].

Cluster-WER is comprised of four SFs, where SF6 (λ = 0.816) showed the largest influence on Cluster-WER; conversely, SF10 had the smallest influence on the cluster (λ = 0.623). The causes of construction accidents can be divided broadly into ‘unsafe conditions’ and ‘unsafe behavior’. If people, objects and the environment are exposed to a dangerous situation during the construction process, then the successful completion of the project is problematic. Having the appropriate environmental and physical safety conditions are critical for operating personnel when it comes to the provision of a safe operating environment [

39,

60].

Cluster-SBW is comprised of four SFs. SF12 had the greatest influence on Cluster-SBW (λ = 0.782), and SF14 showed the smallest influence (λ = 0.687). The unsafe behaviors of the staff are an important reason why the safety accidents take place [

39]. The unsafe site behaviors tend to be intricately linked to their quality of output. The actions and values of the management organization and personnel are a key factor in successful safety management.

4.4. Structural Component of the SEM Framework

The acceptability of the final model heavily depends on whether all of the parameters can be reasonably explained. In other words, there must be a relevant theory to prove the rationale behind the model. Also, even if the sample data fit with the model, the model may not necessarily be reasonable. However, if the model is within the reasonable range, and the model is well-proportioned and reasonably interpreted, it is considered acceptable.

For the path analysis component of the SEM model, the effects can be decomposed to direct effect, indirect effect, and total effect. Firstly, direct effect indicates the direct influence of a potential independent variable on another potential dependent variable. Secondly, indirect effect indicates that a potential independent variable mediates the influence of other potential variables on another potential dependent variable. Next, total effect equals direct effect plus indirect effect. Finally, the direct effect is the path coefficient on the diagram, and the indirect effect is the product of the two related paths (Chen et al., 2013) [

61].

Based on

Figure 2, the first layer had two direct effect paths, i.e., Safety Supervision Strategies (0.963) and On-site Safety Climate (0.974). The second layer consisted of two direct effect paths, including Safety Supervision Strategies to MTH (0.915) and PRA (0.727), and On-site Safety Climate to WER (0.900) and SBW (0.730), respectively. The third layer contained four direct effect paths, i.e., four paths of MTH, three paths of PRA, four paths of WER, and four paths of SBW. The modified model has no effect path, as indicated in

Figure 2.

Among the weights of the two direct effects paths of the highest order layer, the path of ‘on-site safety climate’ (0.974) was slightly higher than that of ‘safety supervision strategy’ (0.963). This indicates that the influence effect of ‘on-site safety climate’ was more important than that of ‘safety supervision strategies’. Both appear equally important, since their path coefficients are both greater than 0.9. Of the two direct effect paths of ‘safety supervision strategies’, the path of MTH (0.915) shows more importance than PRA (0.727). Recently, the awareness of safety concepts within large-scale contractors in Taiwan has been gradually raised to some extent. Managerial contractors tend to display a very positive attitude towards safety management. According to the path analysis, the safety attitude of contractors’ management level demonstrates a strong relationship with the site safety management.

For the weights of the two direct effect paths for ‘on-site safety climate’, WER (0.900) had a much higher weight than that of SBW (0.730). The weightings indicate that creating a safe working environment is more influential than the safety actions of the workers themselves. This surprising phenomenon may be because enhancing the safety of the construction environment is easier than influencing worker behavior. Safety audits in Taiwan often focus on safety facilities and warning signals, with relatively little attention being paid to the assessment of worker safety behaviors. Consequently, contractors usually focus on addressing the safe operating environment as their primary goal.

There were 15 paths showing the direct effects of the observed variables. The Standardized Regression Weighted Coefficients (SRWC) ranged between 0.619 and 0.816 (less than 0.95), which demonstrated that the model’s GOF is acceptable. The SFs with the highest SRWC underneath each KSF consisted of SF1, SF15, SF6 and SF12, respectively. Among the factors under the four KSFs, the highest ones underneath each KSF include: (1) contractors are accountable for ensuring that safety practices and the site manager’s safety directions are met (SF1); (2) management proactively conduct safety inspections of the working area, and identified safety concerns are promptly responded to (SF15); (3) the site has adequate safety controls and equipment available (SF6); and (4) safe work behaviors are continuously displayed by workers (SF12). Most of the safety management items of the construction companies include these aforementioned four factors, which reflect the general situation of Taiwan’s construction projects by investigating the perception of the safety management personnel. WER was the most important aspect, followed by MTH and PRA. On this basis, the respondents tend to believe that improving the safety of the work site environment can effectively enhance the safety of the construction works.

4.5. Further Verification

The GOF of the SEM and related statistical analysis results showed that the original first-order fitness is poor. After the three-stage structural equation model analysis, all of the appropriate indicators satisfied the requirements. Therefore, the site safety management KSF model established in this study could be verified with other samples in the future.

4.5.1. Model Linear Relationship Analysis

The model’s linear relationship analysis displayed the correlation between each observed variable and non-observed variable. The same was the case for the regression weighting factor (factor loading). The linear relationship mainly shows the linear relationship between its influence direction, error term, estimated coefficient, and model. Furthermore, a single arrow represents a unidirectional influence, and each error term can be directly observed; meanwhile, a two-way arrow represents a mutual influence, and each error term cannot be directly observed. The value represents the error term in the measurement.

4.5.2. Variable Linear Relationship Analysis

The results of variable linear relationship analysis are presented in

Table 4. The factor loadings of the top factor (Safety Management Success Factors) to the Safety Supervision Strategy and On-Site Safety Climate are 0.963 and 0.974, respectively. After the model’s correction, the two factors of the second layer showed no mutual influence. The factor loadings of Safety Supervision Strategy to MTH and PRA were 0.915 and 0.727, respectively. The factor loadings of On-Site Safety Climate to WER and SBW were 0.900 and 0.730, respectively. The factor loadings of the four factors in the third layer with the observed variables ranged between 0.619 and 0.816. The factor loadings of the factors underneath MTH, WER, SBW, PRA were between 0.741 and 0.764, 0.623 and 0.816, 0.687 and 0.751, and 0.619 and 0.747, respectively. Additionally, the standardized regression weighting coefficient values estimated at each stage were significant at the level of

p < 0.001. Thus, the regression weighting coefficients of the model estimates are significant, indicating that the intrinsic quality of the model is quite good.

4.5.3. Squared Multiple Correlations Analysis

Squared Multiple Correlations (SMC) represent the percentage of the variability that can be explained by the observed variables; this method is employed to assess the internal structure of a factor. In the measurement model, the estimated SMC indicates the degree of correlation between each observed variable for every related variable, whereas the structural model demonstrates the capability of the independent variable to interpret the potential dependent variable. The closer the SMC is to 1, the stronger the relationship of the KSFs for site safety management. As shown in

Table 5, the SMC of PRA was lower than the others (between 0.384 and 0.558). This indicates that the internal observation variable of the PRA factor has lower explanatory power for PRA. Relatively speaking, the SMC of the other factors is relatively close and stable, indicating that the other factors have a certain degree of explanatory power.

5. Conclusions

Using contemporary literature on construction site safety management, this study leveraged the results of interviews of industry experts to identify 33 factors to measure construction site safety management. Using EFA, the final 18 construction site safety management factors were obtained and further reduced into four groups, these being MTH, relating to organizational safety management; WER, relating to the safety of the working environment; SBW, which captures safety related behaviors; and PRA, which relates to the actions taken to prevent construction site accidents.

Among the four clusters, WER was the most important one, encompassing 50% of the top 10 SFs. This result highlights the importance of the fact that the level of construction safety can be enhanced to a greater extent only when the operating environment is able to facilitate safe operations. The correlation analysis indicated moderate correlation between the factors related to a safe operating environment, where SF11 and SF13 have the strongest relationship (r = 0.601). This finding indicates that construction organizations need to focus greater attention on improvements to their safety oversight strategies and general safety climate. Furthermore, MTH, SBW, SBW and PRA must be jointly considered the top priority for improving the overall performance of construction site safety. For government regulators, these results highlight the need for a systematic approach to the safety of construction sites, as opposed to the strictly inspection- and compliance-type approaches applied in Taiwan. Through focusing on the supporting systems and management structures, a more holistic view of site safety performance can be obtained.

According to the 3-stage SEM process, there were two direct effect paths on the highest layer, including safety supervision strategy and on-site safety climate. The safety supervision strategy of the second layer showed two direct effect paths, these being ‘Management Behaviors’ and ‘Prevention and Remedial Actions’. Another second layer factor ‘On-site Safety Climate’ had direct influence on the paths of ‘Safe Work Environment and Resources’ and ‘Safety Behaviors of Workers’. Finally, the observed variables of the third layer of the final model had a direct effect on SF15, with the normalized regression weighting coefficients ranging between 0.619 and 0.816. The model GOF of the final SEM is in line with the defined standards. Such a result indicates that contractors should focus on their safety supervision strategy and on-site safety climate, and as such, should make MTB, WER, SBW and PRA the top priorities in terms of site safety management improvement items. To that end, the mastery of how the KSFs can be successfully applied for the safety management in this regard is required if the aim is to further reduce the occurrence of on-site accidents and enhance safety performance.

It is hoped that the proposed SEM model can provide on-site managers with key management factors so as to further improve site safety performance. The same approach can be applied to the provision of the information on the relevance and importance of KSFs for site safety management due to the limited knowledge of this aspect. However, the scope of the study focuses on the KSFs extracted, and not the barriers facing their successful implementation. Further research is required to understand how to optimize the implementation of safety improvement programs based on the findings of this study. Moreover, this study does not consider the analysis of the safety cognition and various project attributes of the respondents along with the possible differences in safety practices observed in urban and rural settings.

Furthermore, it is also worthy to explore the interdependence of personnel safety perception, professional practice and project attributes to better confirm the applicability of the proposed KSFs. A further limitation of this study is that the results reflect the view the practitioners selected, along with a small number of analytical samples with practical experience, and so the study results are limited to the context of the Taiwanese construction industry. Future study might be expanded to further examine the related industry as a whole.

Author Contributions

Conceptualization, W.T.C. and I.-C.T.; methodology, W.T.C. and I.-C.T.; software, J.-K.Y.; validation, S.T.L. and Y.-I.L.; formal analysis, W.T.C., I.-C.T. and H.C.M.; investigation, S.T.L. and Y.-I.L.; resources, Y.-I.L. and S.T.L.; data curation, I.-C.T., J.-K.Y. and L.M.; writing—original draft preparation, W.T.C. and I.-C.T.; writing—review and editing, W.T.C., H.C.M. and L.M.; visualization, J.-K.Y. and L.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Taiwan Ministry of Science and Technology, MOST103-2221-E-224-069 and MOST108-2625-M-424-001.

Acknowledgments

Special thanks go to the unnamed respondents, interviewees and reviewers; without their responses, this study would not have been possible. The authors would also like to thank the peer reviewers; their feedback and insights have helped to improve the paper greatly.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Terminology Abbreviation

| Terminology | Abbreviation |

| Adjusted Goodness of Fit Index | AGFI |

| Analytic Hierarchy Process | AHP |

| Chi-Squared | x2 |

| Comparative Fit Index | CFI |

| Critical Success Factor | CSF |

| Degree of Freedom | df |

| Exploratory Factor Analysis | EFA |

| Factor Analysis | FA |

| Fuzzy Factor Analysis Model | FFAM |

| Good of Fit | GFI |

| Good of Fit | GOF |

| Kaiser-Meyer-Olkin | KMO |

| Key Success Factor | KSF |

| Modification Indices | MI |

| Management Behaviors | MTH |

| Normed Fit Index | NFI |

| Nominated SF | NSF |

| Prevention and Remedial Actions | PRA |

| Principal Component Analysis | PCA |

| Personal Protective Equipment | PPE |

| Root Mean Residual | RMR |

| Root Mean Square Error of Approximation | RMSEA |

| Standard Error | S.E. |

| Structural Equation Modeling | SEM |

| Safety Beheaviors of Workers | SBW |

| Success Factor | SF |

| Squared Multiple Correlations | SMC |

| Standardized Regression Weighted Coefficients | SRWC |

| Site Safety Management | SSM |

| Safe Work Environment and Resources | WER |

| Chi-Squared/Degree of Freedom | x2/df |

| Akaike Information Criterion | AIC |

Appendix B. The Third Part of the Questionnaire, Focusing on ‘Project Category Accident Perception’

The following nominated SFs are selected for their potential to contribute to the success management of construction site safety. Please rate the importance of each item using the scale of 1–5 (1 representing strongly unimportant to 5 representing strongly important).

Rating: 5 = Very important, 4 = Important, 3 = neutral, 2 = Less important, 1 = Not important.

| No. | Nominated SF |

| 1 | Workers are prevented from working in dangerous environments |

| 2 | All materials are stored correctly and securely held in positions |

| 3 | Personnel are prevented from unauthorized access within the operating radius of construction equipment or unsafe places |

| 4 | Implementing appropriate hazard notification and warning systems for the worksite |

| 5 | Good flow of construction site personnel and machinery |

| 6 | Suitable safety equipment is provided and maintained within a suitable timeframe |

| 7 | Regular maintenance/adjustment of safety equipment to ensure that they are operating safely under site conditions |

| 8 | Safety facilities are designed with sufficient strength and operation safely |

| 9 | Site has adequate safety controls and equipment available |

| 10 | Workers have sufficient hazard identification ability |

| 11 | Workers wear and use personal protective equipment (PPE) which meets national standards |

| 12 | Safe work behaviors are continuously displayed by workers |

| 13 | Management’s safety instructions and advice are followed by workers |

| 14 | Workers receive safety training from safety managers |

| 15 | Workers display safe work behaviors and have skills fit for the tasks assigned |

| 16 | When executing high-risk tasks workers actively support and lookout for each other |

| 17 | Management proactively conduct safety inspections of working area, and identified safety concerns are promptly responded to |

| 18 | Workers are required to undertake regular health examinations and pre-employment medicals |

| 19 | Safety management personnel communicate with workers daily and address unsafe behaviors |

| 20 | Special operations, such as hanging and grouting operations, are completed with command and coordination personnel |

| 21 | Safety management personnel proactively inform workers of working environment, hazards and related safety information |

| 22 | There is a continued onsite presence of qualified safety personnel |

| 23 | Safety personnel are competent in the correct use of onsite safety equipment |

| 24 | Safety managers hold regular toolbox meetings |

| 25 | Project owner instigates safety incentives/disincentives during construction |

| 26 | The ability of contractors to complete construction safely is included in the selection of project delivery |

| 27 | There is active collaboration on safety issues within the contractor’s business structure |

| 28 | Generate targeted safety strategies via risk assessment process at the design stage |

| 29 | There is a continued demonstration of the importance of safety by onsite contractors |

| 30 | Frequent communication between management and workers and rectification of unsafe behavior |

| 31 | There is open safety dialogue between contractors and site management based on shared responsibility |

| 32 | Contractors are accountable for safety practices and site manager’s safety directions are met |

| 33 | On-site management actively monitor worker’s behavior and mentality |

References

- Ahn, S.; Kim, T.; Park, Y.-J.; Kim, J.-M. Improving Effectiveness of Safety Training at Construction Worksite Using 3D BIM Simulation. Adv. Civ. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Rajendran, S.; Gambatese, J.A. Development and Initial Validation of Sustainable Construction Safety and Health Rating System. J. Constr. Eng. Manag. 2009, 135, 1067–1075. [Google Scholar] [CrossRef]

- Hinze, J. The need for academia for academia to address construction site safety through design. In Proceedings of the Construction Congress VI, Orlando, FL, USA, 20–22 February 2000. [Google Scholar]

- Huang, X.; Hinze, J. Owner’s Role in Construction Safety. J. Constr. Eng. Manag. 2006, 132, 164–173. [Google Scholar] [CrossRef]

- ILOSH. Labor Inspection Statistics Annual Report; Institute of Labor Occupational Safety and Health: New Taipei City, Taiwan, 2018. [Google Scholar]

- Li, Y.; Ning, Y.; Chen, W.T. Critical Success Factors for Safety Management of High-Rise Building Construction Projects in China. Adv. Civ. Eng. 2018, 2018, 1–15. [Google Scholar] [CrossRef]

- Hinze, J. Improving Safety Performance on Large Construction Sites; CIB Working Commission W099: São Paulo, Brazil, 22–24 October 2003. [Google Scholar]

- Razuri, C.; Alarcón, L.F.; Diethelm, S. Evaluating the effectiveness of safety management practices and strategies in construction projects. In Proceedings of the 15th Annual Conf. of International Group for Lean Construction (IGLC-15), East Lansing, MI, USA, 18–20 July 2007. [Google Scholar]

- Aksorn, T.; Hadikusumo, B. Critical success factors influencing safety program performance in Thai construction projects. Saf. Sci. 2008, 46, 709–727. [Google Scholar] [CrossRef]

- Al Haadir, S.; Panuwatwanich, K. Critical Success Factors for Safety Program Implementation among Construction Companies in Saudi Arabia. Procedia Eng. 2011, 14, 148–155. [Google Scholar] [CrossRef]

- Noort, M.C.; Reader, T.W.; Shorrock, S.; Kirwan, B. The relationship between national culture and safety culture: Implications for international safety culture assessments. J. Occup. Organ. Psychol. 2015, 89, 515–538. [Google Scholar] [CrossRef]

- Ismail, Z.; Doostdar, S.; Harun, Z. Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 2012, 50, 418–423. [Google Scholar] [CrossRef]

- Cheng, E.W.; Ryan, N.; Kelly, S. Exploring the perceived influence of safety management practices on project performance in the construction industry. Saf. Sci. 2012, 50, 363–369. [Google Scholar] [CrossRef]

- Hashem, A.; Omar, R.; Yahya, M.Y. The factors affecting the implementation of safety and health practices in the Libyan Construction Sites. In Proceedings of the 1st FPTP Postgraduate Seminar 2013, Fakulti Pengurusan Teknologi dan Perniagaan, UTHM, Parit Raja, Malaysia, 23 December 2013; pp. 1–5. [Google Scholar]

- Hinze, J.; Hallowell, M.; Baud, K. Construction-Safety Best Practices and Relationships to Safety Performance. J. Constr. Eng. Manag. 2013, 139, 04013006. [Google Scholar] [CrossRef]

- Shen, L.J.; Shi, S. Analysis of Factors Affecting Safety Management of Construction Site Based on Fuzzy Factor Analysis Model. Adv. Mater. Res. 2013, 753, 1862–1867. [Google Scholar] [CrossRef]

- Yu, Q.; Ding, L.; Zhou, C.; Luo, H. Analysis of factors influencing safety management for metro construction in China. Accid. Anal. Prev. 2014, 68, 131–138. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Irizarry, J.; Li, Q. Using network theory to explore the complexity of subway construction accident network (SCAN) for promoting safety management. Saf. Sci. 2014, 64, 127–136. [Google Scholar] [CrossRef]

- Dunwen, L.; Lei, Y.; Bo, L. Fuzzy-Entropy Theory Comprehensive Evaluation Method and Its Application in Building Construction Safety. Procedia Eng. 2012, 43, 137–142. [Google Scholar] [CrossRef]

- Shin, I.J. Factors that affect safety of tower crane installation/dismantling in construction industry. Saf. Sci. 2015, 72, 379–390. [Google Scholar] [CrossRef]

- Sunindijo, R.Y.; Zou, P. Conceptualizing Safety Management in Construction Projects. J. Constr. Eng. Manag. 2013, 139, 1144–1153. [Google Scholar] [CrossRef]

- Tam, C.M.; Zeng, S.; Deng, Z. Identifying elements of poor construction safety management in China. Saf. Sci. 2004, 42, 569–586. [Google Scholar] [CrossRef]

- Teo, E.A.L.; Ling, F.Y.Y.; Chong, A.F.W. Framework for project managers to manage construction safety. Int. J. Proj. Manag. 2005, 23, 329–341. [Google Scholar] [CrossRef]

- Abdul-Rashid, I.; Bassioni, H.; Bawazeer, F. Factors affecting safety performance in large construction contractors in Egypt. In Proceedings of the 23rd Annual ARCOM Conference, Belfast, UK, 3–5 September 2007. [Google Scholar]

- Omran, A.; Omran, A.; Kadir, A.H.P. Critical Success Factors That Influencing Safety Program Performance in Malaysian Construction Projects: Case Studies. J. Acad. Res. Econ. 2010, 2, 125–134. [Google Scholar]

- Mohamed, S. Safety Climate in Construction Site Environments. J. Constr. Eng. Manag. 2002, 128, 375–384. [Google Scholar] [CrossRef]

- Koh, T.Y.; Rowlinson, S. Relational approach in managing construction project safety: A social capital perspective. Accid. Anal. Prev. 2012, 48, 134–144. [Google Scholar] [CrossRef] [PubMed]

- Memon, Z.A.; Khatri, K.L.; Memon, A.B. Identifying the Critical Factors Affecting Safety Program Performance for Construction Projects within Pakistan Construction Industry. Mehran Univ. Res. J. Eng. Technol. 2013, 32, 269–276. [Google Scholar]

- Hardison, D.; Behm, M.; Hallowell, M.; Fonooni, H. Identifying construction supervisor competencies for effective site safety. Saf. Sci. 2014, 65, 45–53. [Google Scholar] [CrossRef]

- Simanavičienė, R.; Liaudanskiene, R.; Ustinovichius, L. Assessing reliability of design, construction, and safety related decisions. Autom. Constr. 2014, 39, 47–58. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Q.; Zhang, L.; Skibniewski, M.J.; Wang, Y. Prospective safety performance evaluation on construction sites. Accid. Anal. Prev. 2015, 78, 58–72. [Google Scholar] [CrossRef]

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2013, 46, 99–105. [Google Scholar] [CrossRef]

- Fung, I.W.H.; Tam, V.W.; Lo, Y.T.; Lu, L.L. Developing a Risk Assessment Model for construction safety. Int. J. Proj. Manag. 2010, 28, 593–600. [Google Scholar] [CrossRef]

- Rozenfeld, O.; Sacks, R.; Rosenfeld, Y.; Baum, H. Construction Job Safety Analysis. Saf. Sci. 2010, 48, 491–498. [Google Scholar] [CrossRef]

- Del Puerto, C.L.; Clevenger, C.M.; Boremann, K.; Gilkey, D. Exploratory Study to Identify Perceptions of Safety and Risk among Residential Latino Construction Workers as Distinct from Commercial and Heavy Civil Construction Workers. J. Constr. Eng. Manag. 2014, 140, 04013048. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Chan, D.W.M.; Chiang, Y.H.; Tang, B.S.; Chan, E.H.; Ho, K.S.K. Exploring Critical Success Factors for Partnering in Construction Projects. J. Constr. Eng. Manag. 2004, 130, 188–198. [Google Scholar] [CrossRef]

- Black, C.; Akintoye, A.; Fitzgerald, E. An analysis of success factors and benefits of partnering in construction. Int. J. Proj. Manag. 2000, 18, 423–434. [Google Scholar] [CrossRef]

- Cheng, C.W.; Lin, C.C.; Chen, K.H. Using Safety Management Issues to Explore the Use of Behavior-Based Safety Model as a Management Model for the Construction Industry. J. Labor Occup. Saf. Health 2017, 25, 79–93. (In Chinese) [Google Scholar]

- Chi, S.; Han, S. Analyses of systems theory for construction accident prevention with specific reference to OSHA accident reports. Int. J. Proj. Manag. 2013, 31, 1027–1041. [Google Scholar] [CrossRef]

- Tsaur, C.C.; Xie, X. The Analysis of Unsafe Behavior Attribute to Occupational Accidents in Construction Industry; ILOSH Technic Report: Taipei, Taiwan, 2010. (In Chinese) [Google Scholar]

- Shin, M.; Lee, H.-S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef]

- Tsaur, C.C. Characteristics of Fatal Occupational Accidents in Small and Medium-Sized Enterprises; ILOSH Technic Report: Taipei, Taiwan, 2012. (In Chinese) [Google Scholar]

- Lin, C.C.; Jheng, C.W.; Yang, C.N. Major Accident Analysis in Small and Medium-Sized Construction Enterprises. J. Occup. Saf. Health 2013, 21, 288–310. [Google Scholar]

- Chi, C.F.; Yang, H.S.; Chen, W.S.; Liu, K.C.; Chang, T.C.; Ting, H.I. In-Depth Analysis and Prevention of Fatal Falls in Construction Industry. J. Occup. Saf. Health 2008, 16, 383–400. (In Chinese) [Google Scholar]

- Ali, A.; Amin, M.; Husin, A.E. Key Success Factors for Safety Programs Implementation in Indonesian Construction Projects. Int. J. Civ. Eng. Technol. 2019, 10, 1385–1394. [Google Scholar]

- Feng, Y. Effect of safety investments on safety performance of building projects. Saf. Sci. 2013, 59, 28–45. [Google Scholar] [CrossRef]

- Frazier, C.B.; Ludwig, T.D.; Whitaker, B.; Roberts, D.S. A hierarchical factor analysis of a safety culture survey. J. Saf. Res. 2013, 45, 15–28. [Google Scholar] [CrossRef]

- Feng, Y.; Teo, E.A.L.; Ling, F.Y.Y.; Low, S.P. Exploring the interactive effects of safety investments, safety culture and project hazard on safety performance: An empirical analysis. Int. J. Proj. Manag. 2014, 32, 932–943. [Google Scholar] [CrossRef]

- Biggs, H.C.; Biggs, S.E. Interlocked projects in safety competency and safety effectiveness indicators in the construction sector. Saf. Sci. 2013, 52, 37–42. [Google Scholar] [CrossRef]

- Liu, S.; Hu, J.; Li, Y.; Wang, Z.; Lin, X. Examining the cross-level relationship between shared leadership and learning in teams: Evidence from China. Leadersh. Q. 2014, 25, 282–295. [Google Scholar] [CrossRef]

- Fernandez-Muniz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Safety leadership, risk management and safety performance in Spanish firms. Saf. Sci. 2014, 70, 295–307. [Google Scholar] [CrossRef]

- Chen, W.T.; Merrett, H.C.; Huang, Y.-H.; Lu, S.-T.; Sun, W.C.; Li, Y.; Chen, L.; Sun, L. Exploring the Multilevel Perception of Safety Climate on Taiwanese Construction Sites. Sustainability 2019, 11, 4596. [Google Scholar] [CrossRef]

- Johnson, D.E. Applied Multivariate Methods for Data Analysts; Duxbury Resource Center: Duxbury, MA, USA, 1998. [Google Scholar]

- Bollen, K.A. Structural Equations with Latent Variables; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Kowalski, J.; Tu, X.M. Modern Applied U-Statistics; Wiley: New York, NY, USA, 2007. [Google Scholar]

- Hoyle, R. The Structural Equation Modeling Approach: Basic Concepts and Fundamental Issues. In Structural Equation Modeling: Concepts, Issues, and Applications; Hoyle, R.H., Ed.; Sage Publications, Inc.: New York, NY, USA, 1995; pp. 1–15. [Google Scholar]

- Molenaar, K.; Washington, S.; Diekmann, J. Structural Equation Model of Construction Contract Dispute Potential. J. Constr. Eng. Manag. 2000, 126, 268–277. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, B.-G.; Yu, G.S. Identifying the critical risks in underground rail international construction joint ventures: Case study of Singapore. Int. J. Proj. Manag. 2013, 31, 554–566. [Google Scholar] [CrossRef]

- Lee, C.K.; Yusmin, J. Prioritization of Factors Influencing Safety Performance on Construction Sites: A Study Based on Grade Seven (G7) Main Contractors’ Perspectives. In Proceedings of the 2012 International Conference on Business, Management and Governance (ICBMG2012), Hong Kong, 29–30 December 2012. [Google Scholar]

- Cui, J.; De-Fa, S. Risk prevention and control of safety management of construction enterprises. Constr. Technol. 2004, 30, TU714. (In Chinese) [Google Scholar]

- Chen, W.T.; Lu, C.S.; Liu, S.-S.; Wang, M.-S. Measuring the Perception of Safety among Taiwan Construction Managers. J. Civ. Eng. Manag. 2013, 19, 37–48. [Google Scholar] [CrossRef][Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).