Abstract

The emergence of Industry 4.0, also referred to as the fourth industrial revolution, has entirely transformed how the industry or business functions and evolves. It can be attributed to its broadening focus on automation, decentralization, system integration, cyber-physical systems, etc. Its implementation promises numerous benefits in terms of higher productivity, greater volatility, better control and streamlining of processes, accelerated enterprise growth, sustainable development, etc. Despite the worldwide recognition and realization of Industry 4.0, its holistic adoption is constrained by the requirements of specific skills among the workforce. The personnel are expected to acquire adaptive thinking, cognitive and computational skills, predominantly in the area of information technology, data analytics, etc. Thus, the universities that laid the foundation for future talents or trends in society have to adapt and modernize the existing programs, facilities, and infrastructure. This reshaping of higher education in consonance with the vision of Industry 4.0 possesses its opportunities and challenges. There are, of course, a multitude of factors involved and they need a reasonable assessment to strategically plan this metamorphosis. Therefore, this work aims to explore and analyze the different factors that influence the progression and enactment of Industry 4.0 in universities for sustainable education. For this purpose, a systematic approach based on a questionnaire as well as a SWOT (strengths (S), weaknesses (W), opportunities (O), and threats (T)) integrated with the analytic hierarchy process (AHP) is adopted. The questionnaires are administered to university employees and students (or stakeholders) to assess their viewpoint, as well as to estimate the priority values for individual factors to be included in SWOT. The AHP is implemented to quantify the different factors in terms of weights using a pairwise comparison matrix. Finally, the SWOT matrix is established depending on the questionnaire assessment and the AHP weights to figure out stakeholders’ perspectives, in addition to the needed strategic scheme. The SWOT implementation of this research proposes an aggressive approach for universities, where they must make full use of their strengths to take advantage of the emerging opportunities in Industry 4.0. The results also indicate that there are fundamental requirements for universities in Industry 4.0, including effective financial planning, skilled staff, increased industrial partnerships, advanced infrastructure, revised curricula, and insightful workshops. This investigation undoubtedly underlines the importance of practical expertise and the implementation of digital technologies at the university level to empower novices with the requisite skills and a competitive advantage for Industry 4.0.

1. Introduction

One of the primary indices to determine the economic progress of a country is its gross domestic product (GDP). The higher the percentage of GDP, the better will be the country’s performance in terms of economic production and growth. Among the several sectors, the industry and manufacturing domains accounted for 25% and 16%, respectively, of the world’s GDP in 2018 [1]. Thus, it emphasizes the significance of these factions in setting up the path for any nation’s development and advancement. Certainly, these sectors can contribute more than 50% of the overall GDP of the country in any fiscal year [2]. Moreover, past pieces of evidence have shown that the countries that judiciously evolved their industries exhibited steady economic growth, as well as maintained global manufacturing competitiveness.

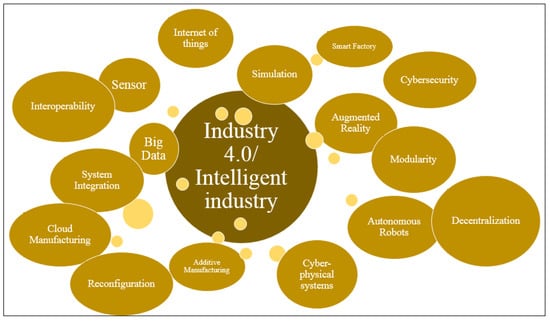

Since the 1800s, the world has been subjected to gradual technological transformation, known as the industrial revolution [3]. The first industrial revolution marked the initiation of machine manufacturing. The products that were once drafted by hands were now mechanized, owing to the introduction of steam power as well as the development of new machines and techniques in textiles, iron industries, etc. Subsequently, the second industrial revolution that noticed expeditious progress in the steel, automobile, and electric industries, hydroelectric power, etc., took place from the late 19th century until the beginning of the 20th century. It was a period when goods were produced in large volumes, assembly lines were realized, and standardization happened. The third industrial revolution, which occurred in the early 1970s, experienced a metamorphosis into a digital world and renewable energies. This new industrial era into digitization was initiated with the emergence of electronics (such as transistors, microprocessors, etc.), telecommunications, information technology (IT), computers, green electricity, etc. Indeed, it resulted in a higher level of manufacturing automation through programmable logic controllers and industrial robots. Now a fourth industrial revolution, known as Industry 4.0, is underway. Industry 4.0 can be represented through a range of cutting-edge technologies, comprising the internet of things (IoT), cloud computing, virtual (and augmented) reality, simulation, three-dimensional (3D) printing, artificial intelligence (AI), data analytics, cybersecurity, smart factories (or cities), advanced robotics, etc. (Figure 1). This current industrial transition is aimed to attain digitalization by creating a virtual world through integration of the physical, digital, and biological systems.

Figure 1.

Pictorial representation of Industry 4.0 [4,5].

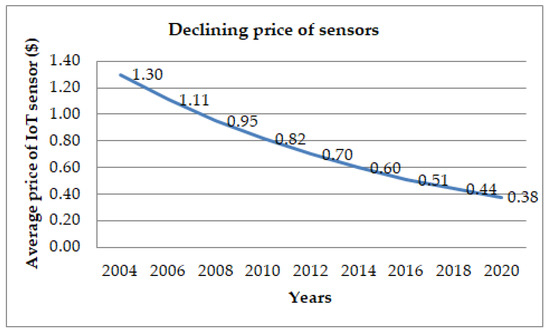

The philosophy of Industry 4.0 (can also be known as smart industry, intelligent industry or smart manufacturing) was initially generalized in 2011 as “Industrie 4.0” with a strong desire to strengthen German competitiveness in the manufacturing sector [6]. As a matter of fact, its conception and reasoning was unusually consequential and appealing that it was subsequently adopted by many countries around the world. The developed nations, including Japan, France, United States of America (USA), Britain, etc., already put forth momentous efforts in this direction by establishing and promoting extensive programs. As depicted in Figure 1, the changeover to Industry 4.0 can be perceived as an information-exhaustive transformation of industries in a unified environment so that the tangible industrial resources and digital technologies can be linked in cyber-physical systems [7]. It comprises of IoT-enabled settings, where people, processes, services, etc., are interconnected to transfer data over a network and utilize valuable information for the realization of a smart system with innovation and cooperation. Indeed, it can be described as the digitalization of the industries, manufacturing methods, and systems, service sectors, etc., by deploying embedded sensors, pervasive cyber-physical systems, and the provision of analyzing relevant data [8]. The trend towards Industry 4.0 made the usage of robot, simulation, and automation systems, ubiquitous in order to enhance effectiveness, performance, and productivity. While the journey for Industry 4.0 progresses ahead, sensors would be the basis for information gathering to encourage sustainable transition of production systems, towns (smart cities), educational centers, health care, etc., into integrated, affordable, and dependable services [9]. Industry 4.0 is very much about combining smart sensors to the network and making informed strategic decisions using the data. The greater influence of sensors on corporate value is mainly through their cost reduction, both currently and in the years to come. For instance, an IoT sensor’s average cost has dropped from 1.30 USD in 2004 to 0.44 USD in 2018, as per Microsoft’s study on “2019 Manufacturing Trends” (Figure 2) [10]. With the decline in sensor prices, it is now possible to acquire more data to make intelligent choices at a reduced price [11,12]. Now, since sensor costs are lowering, the result of Industry 4.0 can be attained more effectively and with a higher profit on invested capital.

Figure 2.

Cost effectiveness due to lower prices of sensors in Industry 4.0 [10].

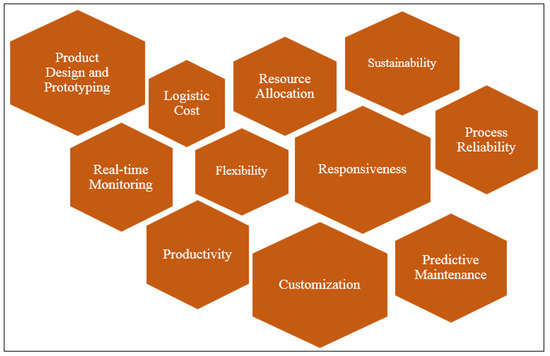

The applications of Industry 4.0 are ample, ranging among product design, prototyping, production, predictive maintenance, environment, and health monitoring, etc., [13]. Currently, Industry 4.0 has taken up a pioneering role in industries, owing to its innumerable advantages (Figure 3), and many countries are adapting their infrastructure to meet its requirements. The following is a summary of some of the benefits associated with the fourth industrial revolution. The prevailing industrial transition can significantly contribute to efficient resource allocation, higher responsiveness to market demands, real-time monitoring and maintenance, reduced labor and logistics cost, sustainability, customization according to customer needs, improved productivity and quality, greater flexibility, process reliability, etc. [14,15,16].

Figure 3.

Characteristics of Industry 4.0 [17].

Industry 4.0 represents a complex system that is not straightforward to accomplish. It apparently would take at least five or more years to realize and streamline its implementation [18]. A multitude of facets can be associated with a smart industry; therefore, at present its employment experiences many hindrances involving scientific and technological challenges, economic and social problems, political issues, etc. The sincere work for these challenges in a holistic manner would simplify and systemize its execution. Certainly, one of the major challenges encountered by most of the countries in their path to Industry 4.0 is connected with the requisite skills of the workforce [4]. It is because the employees are expected to acquire advanced skills in the domain of AI, IT, data analytics, robotics, etc. There are also many other skills and abilities, including cognitive abilities, analytical thinking, decision-making ability, organizational skills, social intelligence, system and technical expertise, logical reasoning, troubleshooting, etc., that can be associated with Industry 4.0 [19]. Certainly, a wider gap between the existing skills and required skills (that is cognitive and system intelligence) have been observed and this disparity would further intensify if mandatory actions are not adopted on time. In the journey to develop essential skills, intelligence, and expertise, and to prepare the workforce for Industry 4.0, the higher education system or the universities must adapt [20]. The countries or industries might be lagging in the process of Industry 4.0 if they train the personnel at the job level. The learning or the realization of the different concepts of Industry 4.0 both theoretically and practically at the university would enormously help its application at the industrial level. It suggests that the universities and educational institutes should deliver courses and trainings to cope with the varied requirements of the new trends of Industry 4.0 [21]. The young talents should be nurtured and exposed to the various aspects of smart technology at the earliest so that they are well-equipped and prepared for the existent industrial revolution [22,23]. The transformation of higher education following the requisite concepts and aspects of Industry 4.0 exhibit its advantages and limitations. Henceforth, this work investigates the different factors that can affect the evolution and execution of Industry 4.0 in universities for sustainable education. To accomplish the goal, this research utilizes a systematize method depending on a questionnaire and a SWOT (strengths (S), weaknesses (W), opportunities (O), and threats (T)) unified with the analytic hierarchy process (AHP). As a result, a set of recommendations detailing the modifications required in the curriculum design, student and staff activities, etc., at the university will be established.

This article has been organized as follows. Section 2 presents the literature survey on the significance of universities or higher education in Industry 4.0, as well as different SWOT–AHP studies. Section 3 explains a methodology that has been used to determine the decision variables and the steps for the consequent application of SWOT–AHP. In Section 4, the results and findings of the research are presented and discussed. Section 5 provides the recommendations. Finally, Section 6 concludes this study with future directions.

2. Literature Survey

A collection of work, asserting the revamping of the higher education system in keeping with Industry 4.0, can be listed out from the literature. These works have indeed emphasized the significance of building up the imminent talent pool at the university level. It is because the employees and the labor pool needed in the companies are expected to acquire elemental technical competence in Industry 4.0, comprising IT knowledge, skills to interact with contemporary interfaces, etc. [24]. Although the fourth industrial revolution brings numerous benefits, the enterprises encounter challenges in their implementation because the hired, as well as the existing staff, are not highly skilled in applications and technologies encompassing Industry 4.0. The universities (higher education schools and vocational courses) can thus play a pivotal role in promoting the social and cultural transitions required for Industry 4.0 [5]. However, today’s universities were established from the perspective of the three preceding industrial revolutions, which do not offer the needed competencies to strengthen the Industry 4.0 revolution [25]. It underlines the fact that the universities or higher education system have to adapt for the sake of training and preparing the students for future industries. For instance, the Malaysian government, in order to embrace Industry 4.0, has been remodeling its higher education system [24]. They have created a Malaysia Education Blueprint 2015–2025 that includes a ten shifts program for preparing their students. The Malaysian government intends to encourage self-learning methods, in addition to acclimatizing their students, according to the requirements of Industry 4.0. Certainly, the administrations in any country should work out an applied curriculum and a hands-on learning environment for promoting effective knowledge transfer as a prerequisite to Industry 4.0 [26]. This move would enhance the industrial management skills as well as the qualifications of graduates and the industrial workforce. The qualifications in terms of problem-solving skills, failure analysis, coping with fickle demands, decoding new problems and unscheduled tasks, dealing with a large amount of data, etc., have to be developed among the personnel [27]. A generic roadmap to revise engineering education in agreement with the necessities of Industry 4.0 was designed by Coskun et al. [20] and implemented at the Turkish German University, Istanbul. Their plan was based on three main pillars, including the transformations in curriculum design, laboratory setup, and student club functioning. They recommended the introduction of new courses, composed of programming languages such as Python and R, statistical methods of analysis, database systems, machine learning, security systems and management, embedded systems, industrial robotics, etc. They suggested the upgradation of conventional laboratories with visualization software tools, simulators, 3D printing systems, etc., to realize real-world Industry 4.0 applications. They also maintained the relevance of student club activities in spreading the importance of Industry 4.0 and imparting knowledge about its various aspects. In the same manner, Barakabitze et al. [28] also analyzed the African education system and insisted on the widespread adoption of computers, software, IT, etc., in science, technology, engineering, and mathematics courses. They developed various education models that endorsed exhaustive information communication technology (ICT) related skill training to teachers, increased ICT equipment, and applications in the universities, as well as the evolution of living laboratories and innovation centers, etc. Certainly, the integration of Industry 4.0 in the current education system is not instantly feasible or free of obstructions. Its smooth implementation is only plausible if the current impediments can be addressed. Accordingly, Buasuwan [29] based his work on Thailand’s higher education system to recognize the limitations and barriers that the system may encounter if it proceeds with Industry 4.0. The research involved three principal methods of data collection, including in-depth interviews, document assessment, and questionnaires. The statistical tools based on a priority need index (PNI) and one-way ANOVA were exploited to make inferences and figure out the implications. The researchers reported that the establishment of knowledge bases, public–private–community interactions, change in attitude and modern skill set in lecturers and students, as well as the adoption of new technologies, is needed for the effective execution of Industry 4.0. As reported by Umachandran et al. [21] the higher education system needs to be aligned with the idea of Industry 4.0 for accomplishing smart factories, intelligent manufacturing, etc. The educational setup has to be reformed so that they can provide the current generation with appropriate education and training opportunities. With this in view, Mourtzis et al. [30] and Mourtzis [4] advocated the changes in practices being employed in manufacturing education. They underlined the necessity of integration or knowledge transfer between industries and educational institutes for attaining the advanced manufacturing education (i.e., Education 4.0). Education 4.0 is a new concept that was lately coined owing to the widespread recognition of Industry 4.0 in the education sectors. It encourages and facilitates the techniques, seminars, and workshops that can enlighten inspiring engineers with the newly developed technologies of Industry 4.0 [31]. The aspiring engineers in Education 4.0 are prepared in such a manner so that they can perform any task independently to meet the requirements of Industry 4.0. For example, EAFIT University pursued a transformational change in their education structure to establish desired competence in their students for Industry 4.0 [32]. They aimed to achieve their objectives of modernization by executing innovative teaching–learning structures with active and experimental learning, in addition to incorporating the latest concepts in their curriculum. Besides, it is also important to assess the performance of students in terms of their level of creativity, and their practical expertise in Industry 4.0-related aspects using appropriate approaches [33,34]. Ellahi et al. [35] also emphasized the change in didactic approaches and methods of education. They carried out qualitative research intended to revise the curriculum and teaching methods in accordance with Industry 4.0 principles. They suggested a curriculum matrix, including data science, machine learning, virtual reality, and cloud computing, IoT, and other emerging technologies, for students to acclimatize with Industry 4.0. Likewise, Silva et al. [36] also pointed at the overhauling of curricula and the introduction of new subjects in teaching organizations. They conducted an exploratory study and advocated revamping curricula, enhancing university programs, and facilitating Industry 4.0 training programs to advance human competencies. They also asserted on technology transfer involving successful convergence of university–industry–government with high-tech companies. The risks posed by Industry 4.0 in teaching institutes must be met as effectively and correctly by all stakeholders in order to improve sustainability education [37]. According to Tilak and Singh [38], the job opportunities will be proportional to the skill variable in the era of the fourth industrial revolution. It suggests that the job market will pick up automatically if the students are well-versed and acquainted with various concepts of Industry 4.0. The same notion was originated in the final report of the Industrie 4.0 Working Group [39], where they also pointed at training and sustaining professional development as one of the primary blocks within Industry 4.0 application. Thus, a cogent transformation is needed in the existing conventional education systems to meet the requirements of the future smart industries. Although Industry 4.0 exhibits numerous benefits, it poses many challenges when it comes with its implementation. One principal threat is the mindset of a large population as well as their resistance to change from familiar and traditional to automated practices. Similarly, the preparation and modification of universities in meeting the requirements of emerging technologies, cybernetic governance, and accountability, digital flexibility, etc., is mandatory in the realization of Industry 4.0 [40]. Facing the paradigm of Industry 4.0, the revamping of educational strategies will play a dominant role, enabling the workforce to be educated on the rapid evolution of manufacturing tools and to compete effectively in the job market [41]. While Industry 4.0 keeps evolving the working atmosphere, fresh difficulties are emerging. For instance, absence of e-skills, missing foresight or encouragement from the management, higher investment prerequisite, uncertain financial gains, mandatory acquisition or formation of new teams, and the general unwillingness to mutation by stakeholders are some of the fundamental issues at the global level [42,43]. Herceg et al. [44] also provided an in-depth analysis of the opportunities and challenges faced by the businesses in Serbia, while implementing Industry 4.0. Their study concluded technical expertise, incompetency, and finances as the biggest hurdles to the adoption of Industry 4.0. The study by Hamada [45] explored the actual situation of companies transitioning to Industry 4.0 and the dimensions that could hinder this change. The questionnaire survey technique and statistical analysis were exploited to collect and analyze data, as well as to uncover the variables associated with decision-makers. This research showed that the decision-makers’ optimistic mindset, relevant knowledge, and ability to adjust as the key determinants to Industry 4.0. Industry 4.0 anticipated substantial improvements in the management of people and the skills of the manpower. Therefore, Stachová et al. [46] highlighted the significance of collaboration and knowledge sharing between the educational institutes and business organizations. According to them, partnership between companies and universities provide greater competitiveness, versatility, and interoperability during the Industry 4.0 era. It asserts that university education should be more dynamic and that higher education should be closely associated with business, government institutions, and technical communities for collaboration and partnerships [29]. There are many questions that need to be answered before the holistic acceptance of Industry 4.0, especially in the domain of universities and higher education systems. One of the primary questions is the strategic position or the current state of universities in the context of Industry 4.0.

SWOT (Strength, Weakness, Opportunity, Threat) is a useful technique for strategic planning [47]. For example, using SWOT, professionals can reap the benefits of the strengths/opportunities presented by a new venture while making strategic decisions to mitigate the possibility of the threats/weaknesses that emerged with the prospect. SWOT analysis is regarded as a strategic planning tool in which strengths, weaknesses, opportunities, and threats are explored and assessed [48,49]. The approach typically entails the participation of a wider community, so that perspectives and viewpoints can be accrued across the organization [50]. Many previous studies have used the SWOT analysis as a screening tool in their research to carry out strategic planning. It seems that SWOT analysis is expanding over time into a widening field of applications, such as implementation of Industry 4.0 [47,51], renewable energy schemes [48,52], water management [53], strategies for economic sustainability [54], oil and gas industry [55], waste management [56], and solar power development [57]. One of the major drawbacks of this technique, however, is that the influence of each criterion in decision-making cannot be gauged quantitatively. Fundamentally, it is hard to determine which variable most influences the strategic decision [58]. However, if utilized in tandem with the analytic hierarchy process (AHP), the SWOT approach can offer a quantitative measure of priority for each element in decision-making [59]. There are numerous applications that have successfully used SWOT–AHP in strategic planning. For example, Shrestha et al. [60] analyzed the potential benefits and challenges for the deployment of silvopasture; Kim and Park [61] focused on the sustainable action plan for the textile industry in Uzbekistan; Brunnhofer et al. [62] studied the prospect and issues of introducing biorefinery in European paper and pulp industry; Gorener et al. [63] utilized the concept of SWOT–AHP in manufacturing industry; Du and Liu [64] employed this method for ecofriendly evaluation; Ashutosh et al. [65] generated strategic alternatives for a fiber cement sheet company; Laroche et al. [66] explored the effect of different factors while introducing agroforestry intercropping systems; Mor et al. [67] used SWOT–AHP to estimate the essential variables of the dairy supply chain; D’Adamo et al. [68] analyzed the replacement of natural gas by biomethane in European transport; and so on. The efficacious utilization of SWOT–AHP in numerous domains or sectors provided a reasonable basis for its use in this work. It has been employed in examining the various factors and consequences of Industry 4.0 in universities, which is indeed lacking in the previous research. The purpose is to discover the difficulties and simplify the implementation of Industry 4.0 in universities in order to facilitate sustainable education.

It is well known from past studies that Industry 4.0 has important sustainable strategic implications on global business development. Because of the significance of this subject, its influence on industries has in recent years been under intensive research. Consequently, extensive work is underway to provide insight into the possibilities, challenges, and solutions relevant to Industry 4.0 design, implementation, and evaluation. While there are an enormous number of research papers on industrial and manufacturing businesses, much remains to be explored in the field of education. Research findings on problems and opportunities valuable for the implementation of Industry 4.0 in universities are indeed inadequate and inconclusive. The reports point to the sluggish and the hesitant introduction of Industry 4.0 in universities as a result of the uncertain benefits and barriers. The university’s main stakeholders are professors, researchers, students, etc. They can have a huge impact on the design of strategic plans for sustainability education. However, earlier studies rarely considered their stance or collaborated with them for policy formulation and execution of Industry 4.0. Indeed, the research on the influence of Industry 4.0 in universities from the perspectives of its stakeholders is currently untapped. Another question that has been noticed is the apprehension by the university on how to tackle Industry 4.0. They do not know their existing situation or strategy to be adopted in the era of Industry 4.0. They do not know how to leverage their strengths to take advantage of Industry 4.0’s possibilities and overcome their vulnerabilities and risks. To the authors’ knowledge, few studies have addressed the real scenario of universities and their willingness to adapt to Industry 4.0 and the factors inhibiting them from pursuing it. Furthermore, SWOT application, which is one of the widely used strategic planning methods, is less discussed when it comes to policy-making in universities. As is evident in the literature, the SWOT–AHP, which can overcome SWOT’s inability to quantitatively prioritize decision factors, has gained prominence in all fields excluding universities within the scope of Industry 4.0. To minimize these research gaps, this study focuses on the exploratory study in universities for detailed analyses of their strengths, weaknesses, opportunities, and challenges. SWOT–AHP may be used for the first time in this work to evaluate universities’ standing in the Industry 4.0 era and to develop strategic plans/approaches accordingly. The current research aims at closing the gap in the existing literature and thereby broadening the knowledge base by systematically planning the analysis to gather data and eventually report the detailed outcomes.

It is evident from the previous section that a thorough study of universities from the viewpoint of their stakeholders is crucial in the Industry 4.0 era. It is imperative to increase the understanding by methodically designing the research to acquire data and subsequently reveal meaningful results. The gaps in the available literature certainly contribute to the following important questions that will guide this research work:

- What are the important decision variables that can influence the implementation of Industry 4.0 in universities?

- What would be the relevant classification (in terms of the university’s strengths, weaknesses, opportunities, and challenges) of these variables from the stakeholder’s perspective?

- What should be the approach or the strategic agenda of universities at this juncture for their smooth transition in Industry 4.0 and to achieve sustainable education?

- How to effectively utilize, contrive, or systematize the employment of SWOT-AHP for analyzing the prospect of Industry 4.0 in universities?

- What are the appropriate steps to adapt universities with prospective Industry 4.0 principles?

3. Research Method

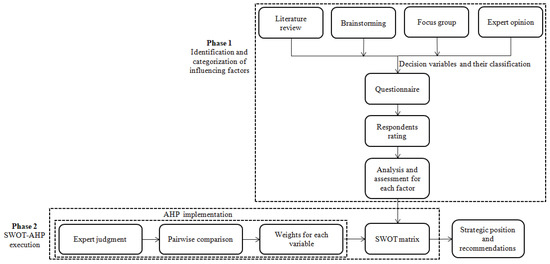

The objective of this study is to develop a conceptual framework that provides the current strategic position of universities and recommendations for effective pursuit of Industry 4.0. A unified approach focused on SWOT–AHP was employed to achieve the goal. There are, actually, a myriad of factors involved and they necessitate thorough analysis to tactically prepare universities for the fourth industrial revolution. This research, thereby embarked on the discovery and study of the various factors affecting the planning and application of Industry 4.0 in universities for sustainable education. This methodology, shown in Figure 4, proceeded in two primary phases. Phase 1 included the identification and analysis of key factors involved in the decision problem, as well as their categorization into strengths (S), weaknesses (W), opportunities (O), and threats (T) for the questionnaire survey. Phase 2 consisted of implementing AHP and subsequent formation of the SWOT matrix.

Figure 4.

Methodology adopted in the research (SWOT: strengths, weaknesses, opportunities, and threats; AHP: analytic hierarchy process).

3.1. Phase 1: Identification and Categorization of Influencing Factors

The adoption of Industry 4.0 in universities depends on several factors, including the employee willingness, students understanding, infrastructure, experts’ availability, training programs, internet accessibility, industrial collaborations, planning commission, etc. It infers that information on the decision variables that can influence the deployment of Industry 4.0 in universities is indispensable. Considering the exploratory aspect of the study, questionnaire surveys were embraced to seek feedback from stakeholders and to assess the significance of various determinants. The design of the questionnaire (attached in Supplementary File S1) was one of the most essential elements of this research in order to acquire appropriate and adequate data. The factors (or the questions) in the questionnaire were identified and classified based on literature review, brainstorming, focus groups, and expert opinions. The preliminary list of decision factors were prepared through literature survey and brainstorming. Since prior studies discussed the impact of Industry 4.0 in the manufacturing, education, healthcare, etc., in various contexts, the literature was presumed to provide us with the prime source for identifying important factors. Besides systematic literature review, verbal brainstorming sessions were conducted. In brainstorming, the authors participated in active dialogue and interaction by verbally sharing their ideas one at a time [69,70]. After preparing the list of decision factors, they were categorized using the inputs from the focus group. The focus group, also known as discussion group, is a widely used qualitative means of acquiring knowledge into the notions, attitudes, and opinions of stakeholders [71,72]. A focus group with a size of ten participants was used in this study. It consisted of students, instructors, and researchers, who were well-versed with the idea of Industry 4.0, as well as the authors. Consequently, the expert opinion approach was employed to assess the questionnaire by the experts (specialists in the field) in order to formalize it. The experts who have been active in the field of Industry 4.0 (with a good number of publications) were contacted online and in-person for their feedback on the questionnaire. The questions (indicative of different variables) in the questionnaire were scaled by a Likert scale of five points [73]. This questionnaire was designed to be relevant to any university in its transformation to University 4.0 for the sustainability education. The key factors in the implementation of Industry 4.0 and their categorization is shown in Figure 5.

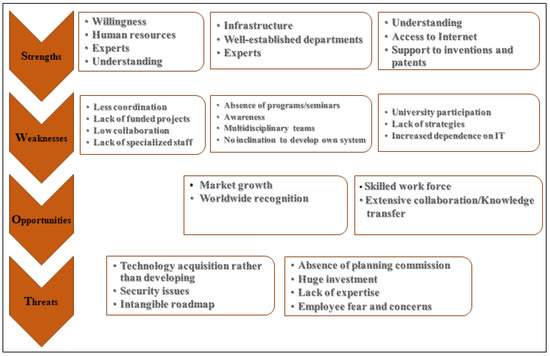

Figure 5.

Recognition of strengths, weaknesses, opportunities, and threats.

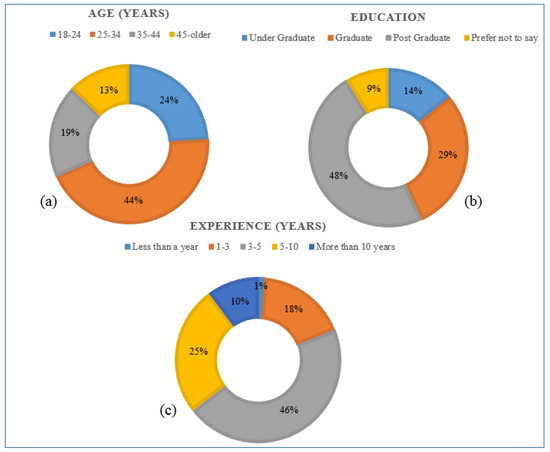

A sample of 200 respondents, chosen using a nonrandom sampling methodology was given questionnaire surveys. The nonrandom approach was used in this research in order to improve the robustness of the collected data [44,74,75]. Thus, the students, teaching faculty, and researchers who had interest, experience, and some knowledge in Industry 4.0 were chosen as the respondents. All these participants belonged to different departments at the university, including informatics, engineering, and healthcare. The survey was conducted between June and December 2019 and the responses were gathered online and on paper. Of the 200 questionnaires, responses were received only from 124 participants, resulting in a response rate of 62%. The data filtering was subsequently performed, as some of the questionnaires were either not filled out or lacked sufficient information. About 15% of the questionnaires were excluded from the survey, resulting in a final sample of 106 questionnaires. The survey outcome indicated representation from across all the departments, including engineering, computer science, and science. Most of the people who completed the survey were over 25 years old, and the majority were highly educated (Figure 6a,b). The data obtained also showed that the large proportion of participants had some experience (Figure 6c). In all, the selected sample represented a balanced mix of mature, well-educated, and knowledgeable set of respondents.

Figure 6.

Information about participants (in percentage): (a) age, (b) education, and (c) experience.

The descriptive statistic referred to as frequency [34,73] was used to interpret the data. For each decision variable (or question), the percentage frequency was estimated according to the ratings given by the respondents. It was calculated by measuring the frequency of rating (obtained from the respondents) divided by the total number of participants and concurrently multiplied by 100. This analysis enabled assessment of the strengths and weaknesses of universities, as well as the opportunities and challenges associated with implementation of Industry 4.0. These data generated useful knowledge of the universities’ current situation and offered valuable insights for identifying leading variables, as well as for anticipating possible measures.

3.2. Phase 2: SWOT–AHP Analysis and Establishing a Strategy

This phase was carried out to ascertain the strategic approach to rationalize the deployment of Industry 4.0 in universities. The SWOT methodology involved in this phase employed a methodical assessment and a comprehensive interpretation of factors affecting a new technology, concept, strategy, etc. [60,76]. It is widely seen in strategic planning to enable researchers in analyzing variables as well as correlate opportunities and threats with strengths and weaknesses [76,77,78,79]. However, one of the principal disadvantages of this method is that the significance (or weights) of each decision factor cannot be measured quantitatively. The SWOT approach can provide a quantitative measure of the decision-making factors if it can be coupled with the AHP [59]. AHP assists decision-makers in estimating the relative significance of each factor by pairwise comparison. AHP can be described as a multicriteria decision making (MCDM) tool to evaluate and compute weights for various factors or alternatives [80,81,82]. This method was developed by Professor Thomas L. Saaty [80] in the 1970s to aid decision-making depending on experience, intuition, and heuristics. This approach utilized paired comparisons of each factor with each other to give a matrix for eigenvector and hence weight calculations. Thus, the steps involved in the SWOT–AHP methodology can be elaborated as follows. The first step involved the identification of the weights or the importance of decision variables identified in phase 1 (see Figure 4). For this purpose, it was crucial to acquire the judgments of different experts in the field of Industry 4.0. Thereby, four experts who had experience and understanding regarding the usefulness of decision factors in Industry 4.0 implementation were finalized by the authors. Consequently, the SWOT factors described in Figure 5 were used to develop a score sheet (attached in Supplementary File S2). This score sheet consisted of a qualitative rating scale known as Saaty’s scale (see Table 1) to weigh each factor relative to the other. For instance, the experts were asked to evaluate if both factors were equally important or one was more important than the other. During the rating, the respondents first had to decide which of the two factors was more important, and then assigned a value ranging from 1 to 9 indicating the relative magnitude of its importance. In the second step, the acquired scores were transformed into quantitative numbers (or a priority value for each factor in the SWOT matrix) through pairwise comparison.

Table 1.

Scale for pairwise quantitative comparison of alternatives [81].

The AHP procedure applied to obtain the priority weights is discussed as follows. The pairwise comparison of different factors was carried out by first arranging them to form a square matrix. The diagonal elements of the matrix were represented as 1. The elements in the lower triangle were reciprocal to elements in the upper triangle. Suppose f factors (F1, F2, F3, ......., Ff) were rated by e experts (E1, E2, E3, ....., Ee). As a result, e matrices with ratings from various experts were formed. The square matrix E1 represented the ratings by expert E1 for f factors:

where aij represents rating of ith factor relative to jth variable, and = , ........., = .

The principal eigenvalue and the corresponding normalized eigenvector value of the square matrix resulted in the relative importance of the different factors being compared. The elements of the normalized eigenvector were termed as weights for the given factor. To get the eigenvector values, the following steps were adopted. The comparison matrix (e.g., E1) was multiplied by itself to provide a resultant matrix R1 (= E1 × E1). Subsequently, the sum across the rows in R1 was estimated. The normalized principal eigenvector column representing the relative ranking of the factor was obtained by dividing each row sum with the sum of its column. The resultant matrix R2 was computed by multiplying the matrix R1 with itself, such that R2 = R1 × R1. The normalized principal eigenvector values were computed for R2. This process of computation of the resultant matrix and its normalized eigenvector continued until the eigenvector values were the same. Furthermore, the third step consisted of the analysis to ensure that the consistency ratios (CR) were less than 0.1, as suggested in Saaty [83,84]. It was mandatory to validate if the judgments made by the experts were appropriate or not. Professor Saaty proposed a random consistency index (RI), shown in Table 2, and defined the consistency ratio, CR (= ) as the comparison between the consistency index (CI) and RI. It represents the amount of inconsistency allowed in the judgment. The CI can be defined as a degree of consistency among pairwise comparisons and is defined as CI = .

Table 2.

Random consistency index.

The λmax represents the maximum eigenvalue of the decision matrix and m is the number of factors. The computation of λmax was performed in the following manner:

- The mth root of the product of row elements across each row in the square matrix was computed.

- The values obtained for each row in the preceding step were divided by the column (mth root column) sum.

- A column matrix was estimated by multiplying the square decision matrix with the column matrix obtained in the previous step.

- Each of the elements in the previously calculated column matrix was divided by the corresponding elements in the column matrix obtained in the second step.

- The average of the column matrix computed in the fourth step provided λmax.

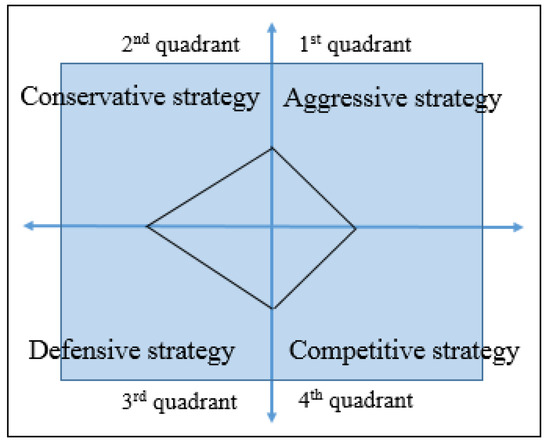

If CR was less than or equal to 10%, the inconsistency was acceptable, otherwise the subjective judgment had to be revised. The criteria weights for each decision-maker were aggregated using the geometric mean (GM = , where e is the number of experts) approach [85]. Finally, the group decision weights were calculated by normalizing the scores. Thus, these weights reflected the priority scores for decision variables of each SWOT group. The fourth step involved the construction of a SWOT plot to discover standpoint or the perspective of the universities about Industry 4.0. SWOT is regarded as one of the significant and applicable tools for defining the strategic position of an organization [86]. The ratings compiled from the respondents for every factor in the questionnaire were averaged to compute the descriptive statistic called the mean. The mean ratings were then multiplied by weights (obtained using AHP) to estimate the overall value (= mean rating × weights) for that particular factor. The overall values for each factor within each SWOT group were summed up to quantitatively score the university’s strength, and weakness, as well as an opportunity, and threat associated with the implementation of Industry 4.0. Consequently, the difference between strength and weakness (S–W) was estimated in addition to the difference between the opportunity and threat (O–T). These scores were then plotted on a SWOT diagram, as shown in Figure 7. Depending on the plotted score in the SWOT matrix, the following strategies can be adopted [87]. For example, if the estimated score falls into the first quadrant, an aggressive strategy is preferred, while the conservative approach is most relevant if the score lies in the second quadrant. Similarly, if the estimated score resides in the third quadrant, a defensive strategy should be chosen, and the competitive approach is suggested if the score lies in the fourth quadrant. Finally, depending on the suggested strategy, appropriate recommendations can be made.

Figure 7.

SWOT matrix.

4. Results Analysis

The adoption of the fourth Industrial Revolution suggests developing an Industry 4.0 compliant workforce. A workforce that is proficient in the Industry 4.0 associated fields can accomplish a smooth and uninterrupted transformation to Industry 4.0. The efforts have to be made at the very beginning in the universities to equip students with appropriate information skills concerning Industry 4.0. In this context, several questions were prepared in this work to determine the familiarity of the Industry 4.0 concept among the students and the university staff. The objective was to understand the level of awareness about the different basic ideas utilized in Industry 4.0.

4.1. Findings and Discussion

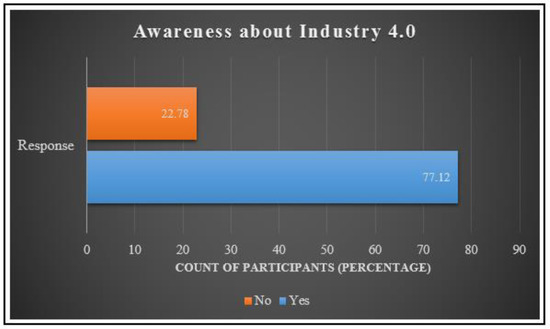

The findings (Figure 8) revealed that there was a good level of awareness (approximately 77%) about Industry 4.0 among the participants. These respondents believed that they had some understanding of the Industry 4.0 concepts and were aware of its benefits. Only 22.78% reported they were not aware of the subject.

Figure 8.

Number of participants acquainted with the term Industry 4.0.

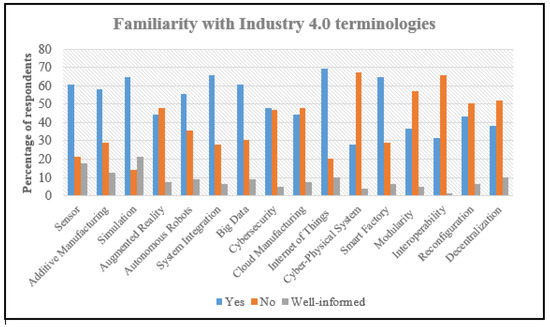

The survey designed for this study also consisted of terminologies that are the core of Industry 4.0 to realize the extent of the respondent’s understanding. The outcomes observed in Figure 9 show that the majority of the respondents were acquainted with the basic terms, including sensor, additive manufacturing, simulation, autonomous robots, system integration, big data, cybersecurity, IoT, and smart factory. The concepts, such as augmented reality, cloud manufacturing, cyber-physical systems, modularity, interoperability, reconfiguration, and decentralization were still unknown to a large group of respondents.

Figure 9.

Familiarity with different aspects of Industry 4.0.

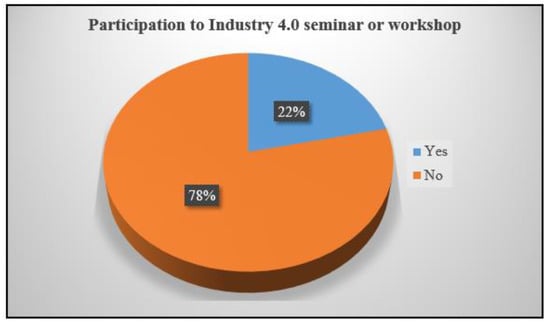

Interestingly, none of the interviewees agreed to possess detailed knowledge about these nomenclatures. This implies the need for the development and organization of programs, such as symposiums, workshops, or seminars that can impart extensive knowledge about the different facets of Industry 4.0, as well as communicate simple yet informational topics to those who are naïve to this idea. The survey reported in Figure 10 also revealed a striking contrast between the respondents who have attended the seminar and those who have not. It depicts that 78% of the participants had never participated in seminars associated with Industry 4.0. Only 22% of the respondents answered positively when asked if they attended within university premises the events focusing on Industry 4.0.

Figure 10.

Statistics about respondents in Industry 4.0 events.

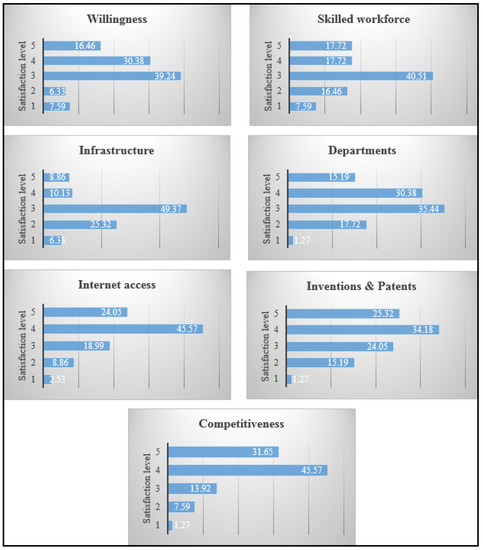

The knowledge acquisition about available resources is indispensable to analyze the organization’s strengths and ease out the digital transformation to Industry 4.0 (or University 4.0). In this context, the factors, including readiness and eagerness, available skilled workforce, infrastructure, department capabilities, internet accessibility, provision of inventions and patents, competitiveness, etc., are of particular importance (see Figure 11). When surveyed about the extent to which the university is willing for digital transformation, 30% of respondents strongly agreed, while 40% agreed to a certain extent or displayed a neutral viewpoint, as they were not sure of the university’s inclination. Besides, the availability of a skilled workforce required to implement Industry 4.0 remained ambiguous as approximately 40% of the participants moderately agreed. They were not clear if they require special talents or skills, and if they are required, what are the fields where they are required and what should be their appropriate number. Only 18% of those surveyed very strongly agreed that their university has already acquired the skilled workers, while 18% strongly conveyed that it possesses the desired skills. Moreover, 8% said that their university entirely lacks the special skills required for Industry 4.0, while 16% were slightly agreed that their university exhibit the skills but only in certain areas. A greater segment of university staff was perplexed and unsure of the available skilled force. It can be attributed to the lack of knowledge about the core concepts of Industry 4.0 and hence the desired talent mandatory for its execution. Therefore, there is a need for universities to pay greater attention in developing the knowledge, understanding, and expertise of their staff and students, as well as hire a digitally experienced employee.

Figure 11.

Outcomes (in percentage) assumed to be university’s strength.

When interviewed about the existing infrastructure, only 9% of the respondents staunchly agreed and 10% strongly acknowledged the presence of necessary infrastructure. Among those who interviewed, approximately 50% just agreed that their university possesses a suitable infrastructure to promote the transition to Industry 4.0. Furthermore, 25% of those surveyed emphasized that their university acquire some elements of the needed infrastructure, while the remaining 6% agreed on the complete lack of any such infrastructure in place. The feedback from the participants represented diverse figures to a question that asked the degree to which computer science and engineering departments have matured and established to support Industry 4.0. Among them, 30% and 15% of the respondents had a strong or a very strong viewpoint, respectively, that the departments mentioned are advanced and developed to handle Industry 4.0. The majority of the respondents (approximately 40%) had an undecided perspective or a fair agreement on the potential of engineering and computer science departments. A majority of survey respondents rated internet accessibility as high (46%) and very high (24%) within their university premises. Only 2% said internet accessibility and speed is very poor. Inventions and patent generation should also be encouraged in organizations because they can help attract investment as well as motivate the young researchers, and speed up the digital transformation. When asked whether the university supports inventions and patent generations, approximately two-thirds of the respondents said the university does (34% strongly and 26% very strongly). The instinct and realization of the importance of a change is also a critical aspect and can be identified as one of the strengths of the organization. If the majority of the employees feel that the transformation is necessary, then it becomes easy for the administrators to achieve that transition smoothly. When questioned if the digital transformation to Industry 4.0 could improve the university’s competitiveness at the international stage, more than 75% of participants had a positive response with either a strong or very strong instinct. Only less than 10% said they disagree and exhibited negative feedback. The survey and interviews about the strengths show that the universities exhibit competence, especially in the following areas: employee’s and student’s intuition about competitiveness (80%), internet accessibility (70%), and support for internet and patent generation (60%). Nevertheless, the areas, such as the university administration’s desire and willingness (46%), department’s sophistication (45%), available expertise (36%), and infrastructure (19%), have a wider scope for improvement. The values in the brackets represent the percentage of participants with a strong agreement for that particular question. The universities, although having ample strengths to sustain Industry 4.0, as discussed, also have limitations and weak areas that need refinement and improvement.

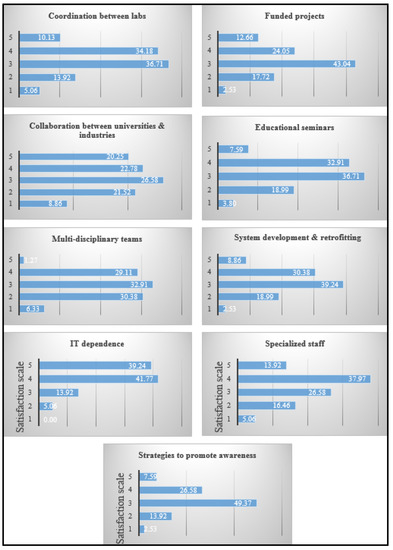

Most staff and students surveyed understand the significance of coordination between various laboratories as the prerequisite for digital transformation in universities. A majority of respondents (as shown in Figure 12), approximately 37%, reported that there is somewhat lesser communication between various laboratories. The appropriate communication channel can be valuable in the exchange of information, ideas, and resources between various laboratories. If integrated through a common software platform, then the services that are now inaccessible among the different laboratories can be availed efficiently and effectively. Moreover, the integration that is an important aspect of Industry 4.0 can be achieved to some extent within the university through these small-scale collaborations. The inadequate funds or insufficient funded projects, especially in areas associated with Industry 4.0, can delay its implementation. It was apparent in the survey results that almost 43% of the respondents had agreed that the projects related to Industry 4.0 are insufficient and the universities should encourage and support more projects within this domain. In addition to the lack of projects, lesser collaboration between universities and industries will postpone as well as complicate the accomplishment of University 4.0. In this study, more than 40% of the participants had strongly agreed to fewer associations of the university with industries.

Figure 12.

Factors analyzed to survey the university’s weaknesses.

The university should also invest greater efforts to expose students and employees with the benefits, business impact, and primary enablers for Industry 4.0. Almost 80% of those surveyed recognized the absence of sufficient educational forums, symposiums, etc., enlightening on Industry 4.0. The university must encourage and organize educational seminars and workshops, specialized in Industry 4.0, digitalization, and automation. Moreover, the responses from the survey demonstrated a positive picture concerning the projects, involving multidisciplinary teams. More than 60% of those questioned had agreed to the existence of projects combining several branches of science and engineering. The primary impact of Industry 4.0 can be noticed in modernization, value-creating processes, etc. With the IoT tools, cloud manufacturing, cyber-physical systems, etc., the existing processes can be enhanced and innovations can be perceived. It emphasizes that the technical staff or students should develop their system or retrofit the existing ones, rather than purchase the entire system. It would be useful to understand and gain practical experience on the various technical facets of Industry 4.0. However, over 75% of the respondents agreed with the lack of interest of the current staff to evolve their systems. When asked about IT dependence, the majority of the participants (more than 80%) were worried (or strongly agreed) that there will be more reliance on the IT systems. They might find it difficult or impossible to switch from the traditional systems to the highly automated systems. Moreover, the industrial experience can be crucial among the staff for the transformation of the existing university’s working style, in line with Industry 4.0. However, in this survey, unsatisfactory figures in relation to the distinguished and distinctive staff were noticed. Among those who were examined, nearly 52% of the attendants had strongly acknowledged the fact that there is an absence of specialized staff with substantial experience in the universities. Industry 4.0 is considered as the sophisticated platform that will modernize the existing system and will enhance human efficiency. To avail the very benefits of Industry 4.0, the strategies have to be designed that can promote and generate the desired level of awareness and interest among the people. This incentive is especially needed in the universities because almost 50% of interviewees had approved to the scarcity of informative programs dedicated to Industry 4.0. The survey and questions about the weaknesses depict that the universities exhibit limitations in certain areas, such as inadequate collaboration between laboratories, dearth of funded projects in Industry 4.0, lesser collaboration between laboratories and industries, infrequent educational seminars or promoting strategies, people-fear due to increased IT dependence, insufficient specialized staff, etc. If the university can overcome the weaknesses and work on its strength, Industry 4.0 can also provide many opportunities (see Figure 13) to grow and become superior among its peers. The staff or students who participated in this survey, see greater scope for domestic market growth under Industry 4.0. The knowledge and expertise gained at the university level will eventually help the customer-oriented market to expand and prosper. The young talent can be prepared in advance in University 4.0 to handle the complexities of Industry 4.0 and understand customer needs and preferences. For instance, the already skilled and acquainted fresh employees will be able to analyze a large amount of data from machines, production, and customer information systems. The resources can be utilized efficiently and the predictive maintenance can be performed. The talent pool at the higher education level will help to streamline the transformation of existing manufacturing and service sectors to incorporate Industry 4.0 concepts. According to more than 40% respondents, there is a great opportunity for domestic growth if the universities can prepare their students for Industry 4.0.

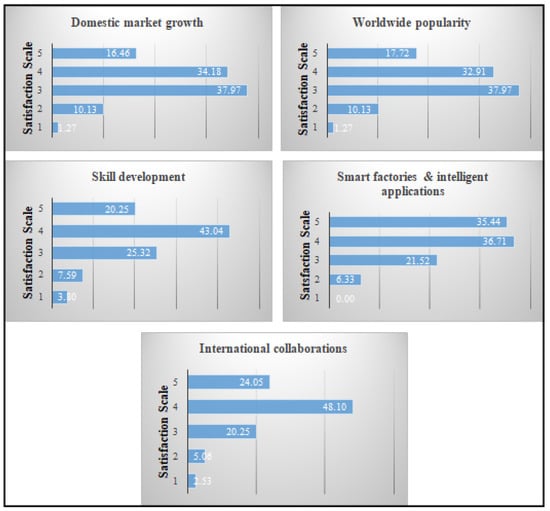

Figure 13.

Opportunities provided by University 4.0.

Industry 4.0 is a contemporary philosophy and many countries are naïve to this idea of the fourth industrial revolution. These countries are gearing up and taking measures to spread awareness among its people and train them for various advanced technologies. Therefore, it is a great opportunity, especially for developing countries, to step up and maintain their progress along with the developed nations. So, when people were asked that Industry 4.0 provide opportunities to the universities for creating its name on the world stage, over 80% agreed with this statement. Certainly, the execution of Industry 4.0 will develop new skills and generate a pool of talented young people who can make their country proud on the international stage. Only 10% of respondents disagreed, while more than 80% agreed that bringing of Industry 4.0 at the higher education level will produce new skills necessary in Industry 4.0-dominated markets. The smart factories and intelligent applications can be easily established according to more than 90% of respondents, if the higher education system can be modeled as per the requirements of Industry 4.0. The implementation of University 4.0 would open doors for international collaborations according to more than 90% of the participants who were surveyed. The universities can send their students to other countries for training on new systems and technologies, as well as established themselves to train international students. Along with its many opportunities, Industry 4.0 also brings with it many threats and risks.

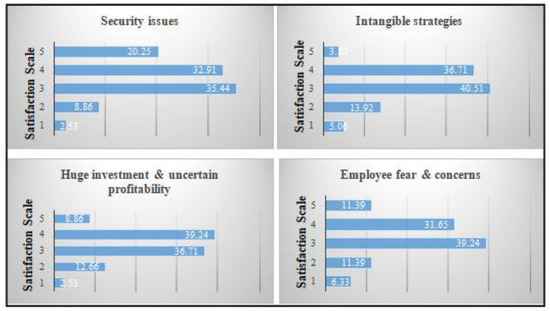

The IoT, services, data, and people, along with other numerous benefits, also open doors for data theft, cybersecurity issues, and attack by hackers. A majority of the respondents believe that cyber-risk could increase strongly (33%) or very strongly (20%) as a result of Industry 4.0 (see Figure 14). Almost 35% agreed that the cyber-risks will increase, while only 12% did not agree that Industry 4.0 would result in any security issues. Cyber attacks and viruses can have a disrupting influence on Industry 4.0, bringing smart factories, intelligent systems, and big networks to a halt, causing a huge loss in money and time. Customized risk management systems, suitable security approaches, limited access permission, decentralized frameworks, etc., can be useful to overcome these risks. When asked if intangible roadmaps, strategies, and framework are a hindrance in the implementation of Industry 4.0, almost 40% of respondents agreed and 37% strongly agreed to this. It emphasizes the requirement of appropriate guidelines, directive plans, and a proper roadmap to realize the full potential of Industry 4.0. The administrators most often are doubtful about the execution of Industry 4.0 due to the involvement of huge investments and uncertain profits. Almost 80% of participants had conveyed that it is very important to convince the higher authorities or decision-makers about the opportunities that Industry 4.0 can bring. Furthermore, the benefits or opportunities from Industry 4.0 will always weigh more than the risks if strategic schemes and financial planning can be designed appropriately. The digital transformation to Industry 4.0 will also bring new challenges owing to employee fears and concerns. The employee may oppose the implementation of a new ideology because of being replaced by the more advanced and skillful staff. Therefore, the senior management should counsel their existing and old staff, as well as train them in operating new applications. They should also give sufficient time to adjust to this change and modernization. Greater attention should be given in developing the necessary competencies and train them in digitally sophisticated systems.

Figure 14.

Threats or risks associated with Industry 4.0.

4.2. SWOT–AHP Outcome

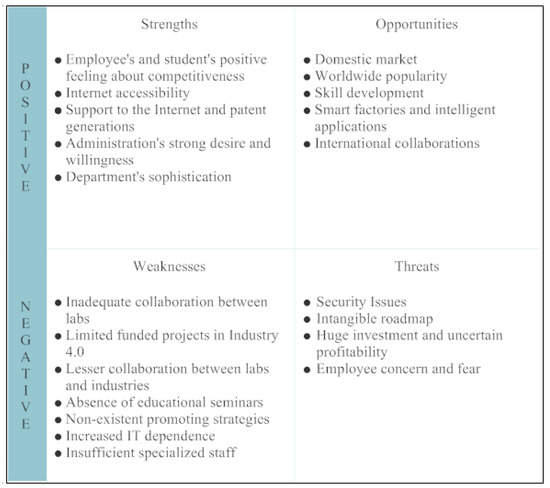

Depending on the survey results and its analysis, the internal strengths and weaknesses were assessed, and the opportunities and threats were determined. This concluded the first phase of the adopted methodology.

Phase 1 as anticipated, identified a list of decision factors and classified them into four groups, as presented in Figure 15. In phase 2 of the approach, the SWOT–AHP technique was applied. The primary objective in phase 2 was to discover the strategic standpoints or the perspective of the universities about Industry 4.0. The AHP computed the weights for each factor by generating the pairwise comparison matrices. A total of sixteen pairwise comparison matrices of four experts were obtained (refer to Supplementary File S3). The objective behind multiple experts was that the opinions of more than one expert could be brought together to eliminate any bias. The CR was estimated for each expert to validate if the judgment made by them was acceptable or not. The steps for computing CR can be observed in Supplementary File S4. As shown in Table 3, the inconsistency was acceptable since CR in each case was less than 10%.

Figure 15.

SWOT analysis.

Table 3.

Measurement of inconsistency in expert judgment.

Subsequently, the normalized weights (as shown in Table 4) for each factor were calculated using the AHP methodology as discussed in Section 3. The steps to estimate the desired weight of the factors are provided in Supplementary File S5.

Table 4.

Weights obtained for each factor.

The score values estimated for each factor in the questionnaire and AHP weights were multiplied in the SWOT table (Table 5). These scores were then aggregated to obtain the overall score for the particular SWOT group. The procedure discussed in phase 2 of Section 3 was utilized and the sample calculations are discussed in Supplementary File S6.

Table 5.

SWOT table.

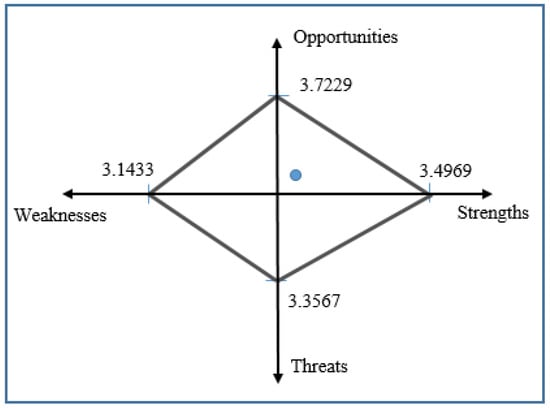

Depending on computed data, the score computed for the group Strength was 3.4969 and the score for Weakness was 3.1433, and the difference between them (S–W) was 0.3536. Similarly, the score for Opportunity was 3.7229 and for Threat was 3.3567, and the difference between them (O-T) was 0.3662. These data were plotted on a SWOT diagram (Figure 16) to locate the strategic standing of universities in the context of Industry 4.0.

Figure 16.

Output SWOT matrix diagram.

According to Figure 16, the estimated coordinates fall in the first quadrant, emphasizing the execution of an aggressive approach. The coordinates of the blue dot represents the current standing or the strategic position of the universities in the era of the fourth industrial revolution. It suggests that the universities should use the strength–opportunity strategy or the aggressive approach to accomplish success in the highly competitive market of Industry 4.0. It refers to the maximum utilization of the strengths in order to avail the existing opportunities in the market. It demands to resort to the university’s strengths to take advantage of the external opportunities. However, the current position of universities is not sustainable as it is in immediate proximity to conservative, competitive, and defensive regions. Therefore, the universities should also consider overcoming weaknesses as well as avoiding risks. The universities can take advantage of the University 4.0 opportunities and inhibit its risks by focusing on their strengths and overcoming weaknesses. The principal reasons that can be attributed to universities aggressive posture are the authority’s or university administration’s willingness and strong desire to support programs pertaining to Industry 4.0, students and staffs excitement and strong feeling about Industry 4.0, high internet accessibility and speed within the universities, universities encouragement for inventions and patent generation, and well-established computer science and engineering departments.

5. Recommendations

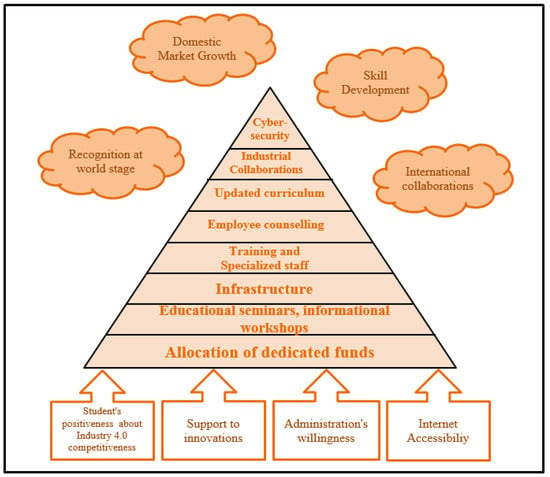

As universities are a key driver of development, therefore, they should be at the forefront to overcome the issues of industries within the country. They should become the supplier of the required talent pool and established themselves as the knowledge center for firms, industries, manufacturing units, government organizations, etc. Based on the findings and outcomes, several measures can be recommended to prepare universities for Industry 4.0. As shown in Figure 17, the foremost requirement in the transformation pyramid is the allotment of sufficient funds needed for the latest industrial revolution. The universities should prioritize investments in research projects or ventures that are aligned with the philosophy or objectives of Industry 4.0. The creation of adequate awareness among the students, employees, etc., is critical in the realization of Industry 4.0. It can be accomplished through the organization of educational seminars, workshops, etc., routinely within the universities. The experts from around the world should be invited to discuss Industry 4.0, its aspects, implementations, significance, and challenges. They must discuss their pilot studies or practical examples to expose students to the various terms of Industry 4.0 and the real issues associated with transforming the traditional systems into smart systems. Adding to that, the universities can organize regular sessions, where students, employees, etc., can congregate, discuss, and share subject matters, uncertainties, and information on the different components and aspects associated with Industry 4.0. Sessions like that will be useful to incite the interest and impart in the staff significant knowledge and information related to Industry 4.0. Moreover, the Industry 4.0 journey needs the most advanced infrastructure to store, manage, and analyze information. The infrastructure in the universities is not entirely ready to support the digital transformation to Industry 4.0. Therefore, the universities should innovate their functioning, laboratories, and curriculum by adopting technologies, such as additive manufacturing, simulation software, robotic systems, AI programming, automation, IoT and analytics platforms, cloud storage, high-performance computing, cognitive technologies, advanced materials, augmented reality, digitized administrative operations, etc. It can also be emphasized that Industry 4.0 is about utilizing the appropriate tool, which does not necessarily imply spending excessively in new systems. Existing systems can be upgraded to include Industry 4.0-related technologies that expedite its embracement. In addition to advanced infrastructure, the universities need specialized staff in University 4.0 for adapting the students to the concepts of Industry 4.0. For instance, to program AI or for visualizing big data, unquestionably qualified lecturers or professors are needed. These initiatives can be supported to establish new institutes or vocational training centers for educating the teaching staff and qualifying them for the challenges of the digital age. The universities can also boost up the interest of their staff through the induction of certification and internship programs relevant to Industry 4.0. The universities can collaborate with private firms to provide self-sufficient internship programs, to their staff as well as students. The e-learning platform can be introduced so that the students and employees can have access to diverse data and information contributed by world-renowned professionals. These platforms that are conducive to learning can also be opened to external people who are interested in Industry 4.0 content. Specialization and computer skills are necessary for Industry 4.0, but they also bring a new challenge in terms of employee fears and concerns. The staff is anxious or nervous due to the insecurity of being replaced by robots, a specialized workforce, etc., as well as the difficulties of adapting to new technologies. Therefore, they should be guided and advised accordingly. They must realize that they will still be needed in Industry 4.0; however, new skills will be required that can be acquired through specialized training. This dealing with people will need an effective, motivated, and adaptive management plan in the organizations. The educational institutions must also advertise the latest ideology by funding students or employees who wish to attend training or conferences on Industry 4.0 aspects. The universities should also upgrade the existing curriculum or introduce new courses, such as data analytics, AI design, IoT, robotics, application development, sensors and sensor circuit design, etc., to assure that future talent meets the requirements of future industries. The universities should make these courses (related to Industry 4.0) as a core subject for everyone to develop soft skills and, in turn, groom them for the future. The curriculum can be revamped by incorporating e-learning techniques, such as game-based learning, digital labs, cognitive computing, machine learning, and intelligent systems, in addition to innovation and entrepreneurship organizational skills. The active learning framework that focuses on real-world Industry 4.0 ventures where students participate in collaborative teams and practice creative problem-solving skills must be embraced. Project-based learning should be promoted, as it enables students to learn skills related to leadership, decision-making, communication, teamwork, and time management. The data and a lot of data are an asset or trend of Industry 4.0; therefore, every student, staff, etc., should be equipped with tools and expertise to manage and analyze the avalanche of information. The courses and projects can be designed to inculcate critical and adaptive thinking, sound technical competence, multidisciplinary knowledge, computational intelligence, etc., among the students. Certainly, it is not possible to manage or regulate the technology revolution on a mass scale at this moment. However, the governments can take small, yet influential steps by supporting and endorsing their educational institutes to nurture upskill as well as prepare the workforce for the future. Furthermore, it is suggested that the universities must collaborate with industries to enhance the quality of human resources, upgrading their skills, and inject new ideas. The industry association is cardinal to adjust to the needs of the digital world. University education alone cannot advance the new generation—it needs the support and partnership of tech-businesses for embracing the work-based learning system. It is also essential that universities and research institutions market their research and thus generate funding from outside investors for more research projects in Industry 4.0. The educators must work with businesses to create collaborative assignments for promoting project-based learning and cutting-edge scientific research. Moreover, the cybersecurity risk introduces a greater concern in the Industry 4.0 than in the traditional systems and should be addressed as part of the overall Industry 4.0 architecture. It can be achieved through the establishment of strong regulatory policies, periodic employee education, customized risk management systems, decentralized structures, limited access protocols, etc. Indeed, the passage to Industry 4.0 has to be defined, planned, and executed at a pace suitable to the particular organization or university. It can be more effective to encourage a pilot study or students’ undergraduate projects to explore the concepts of Industry 4.0 in a manageable environment.

Figure 17.

University transformation pyramid with Industry 4.0.

6. Conclusions

This work investigated the pathway of remodeling current universities to University 4.0, and identified the challenges associated with this digital transformation. Certainly, the modernization of higher education in agreement with the idea of Industry 4.0 exhibits its opportunities and risks. Henceforth, in this research, SWOT–AHP methodology was employed to analyze this transformation and study the likely impacts. This study underlines the significance of functional knowledge and the experience of digital technologies at the university level.

This work depicts the insights attained through a literature review and survey acknowledged by one hundred six respondents. The findings revealed that there are inherent and accepted requirements of adequate financial planning, specialized staff, increased industrial collaborations, upgraded infrastructure, updated curriculum, robust security systems, as well as awareness and informative programs or promotional strategies in order for universities to prepare for Industry 4.0. Therefore, it is recommended that universities must train the existing staff, acquire new talent, overcome employee fear and concerns through proper counseling and job security, prepare a roadmap or a set of guidelines with the aid of experts in the field, allocate sufficient funds, and set down procedures to minimize security threats. Certainly, these prerequisites and the university’s strengths should be taken into account, while planning Industry 4.0 transformation to make use of the available opportunities and reap its benefits.

The execution of Industry 4.0 brings about many advantages, such as higher productivity, greater flexibility, better control and streamlining of processes, sustainability development, accelerated enterprise growth, etc. Therefore, the universities that will be unsuccessful to educate and train their students on the latest technologies may be late for the opportunities that are guaranteed with Industry 4.0. The fourth industrial revolution, like the earlier revolutions, has the potential to boost a nation’s income level and enhance the quality of life for the common man. Digital technology has resulted in newer products and services that improve the efficiency and comfort of people’s lives.

Although this article is making an important contribution to the current state of research, it also has its limitations. The data acquired through questionnaire surveys are based on subjectivity or human understanding. This lack of objectivity can add some prejudice or bias in the outcome. The authors, however, tried to address the prejudice by interviewing the participants who had a good perspective and the inclination toward Industry 4.0. Also, the experts who participated in this study possessed the desirable and profound expertise with Industry 4.0, which ensured the credibility of the results. Additionally, it cannot be assured that the set of potential factors or decision variables used in the research was exhaustive. Although the identification of decision factors was premised on the extensive literature review of Industry 4.0 and the use of expert information, still the possibility of other significant factors cannot be ignored. Therefore, a deeper study of the decision variables in the future can provide a more consistent analysis of the current scenario in the age of Industry 4.0. In terms of improving the ability to generalize and robustness of the results, a quantitative empirical study incorporating a larger sample can be the direction for future research. It would also be interesting to combine SWOT analysis with the fuzzy AHP to adequately address and manage the interrelationships between decision matrix and the ambiguous, unpredictable, and incomplete data available in actual scenarios.

Supplementary Materials

The following are available online at https://www.mdpi.com/2071-1050/12/15/6100/s1.

Author Contributions

Conceptualization, B.S. and S.H.M.; methodology, S.H.M. and B.S.; data acquisition, W.A., B.S. and K.M.; data curation, W.A. and B.S.; validation and analysis, S.H.M. and H.A.; writing—original draft preparation, S.H.M.; writing—review and editing, S.H.M., and K.M.; supervision, B.S.; project administration, H.A.; funding acquisition, H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Deanship of Scientific Research at King Saud University through Research Group number RG-1441-349.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding this work through research group number RG-1441-349.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The World Bank. World Development Indicators 2018; World Bank Publications: Washington, DC, USA, 2018; Available online: http://wdi.worldbank.org/table/4.2 (accessed on 25 August 2019).

- The World Bank. World Bank National Accounts Data, and OECD National Accounts Data Files (License: CC BY-4.0), Manufacturing, Value Added (% of GDP). Available online: https://data.worldbank.org/indicator/NV.IND.MANF.ZS?end=2018&locations=SA&start=1968&view=chart (accessed on 25 August 2019).

- Pikas, B.; Zhang, X.; Peek, W.A.; Lee, T. The Transformation and Upgrading of the Chinese Manufacturing Industry: Based on “German Industry 4.0”. J. Appl. Bus. Econ. 2016, 18, 97–105. [Google Scholar]

- Mourtzis, D. Development of Skills and Competences in Manufacturing Towards Education 4.0: A Teaching Factory Approach. In Lecture Notes in Mechanical Engineering, Proceedings of 3rd International Conference on the Industry 4.0 Model for Advanced Manufacturing, AMP 2018, Belgrade, Serbia, 5–7 June 2018; Ni, J., Majstorovic, V., Djurdjanovic, D., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Bongomin, O.; Gilibrays Ocen, G.; Oyondi Nganyi, E.; Musinguzi, A.; Omara, T. Exponential Disruptive Technologies and the Required Skills of Industry 4.0. J. Eng. 2020, 2020, 4280156. [Google Scholar] [CrossRef]