Glazed Photovoltaic-thermal (PVT) Collectors for Domestic Hot Water Preparation in Multifamily Building

Abstract

1. Introduction

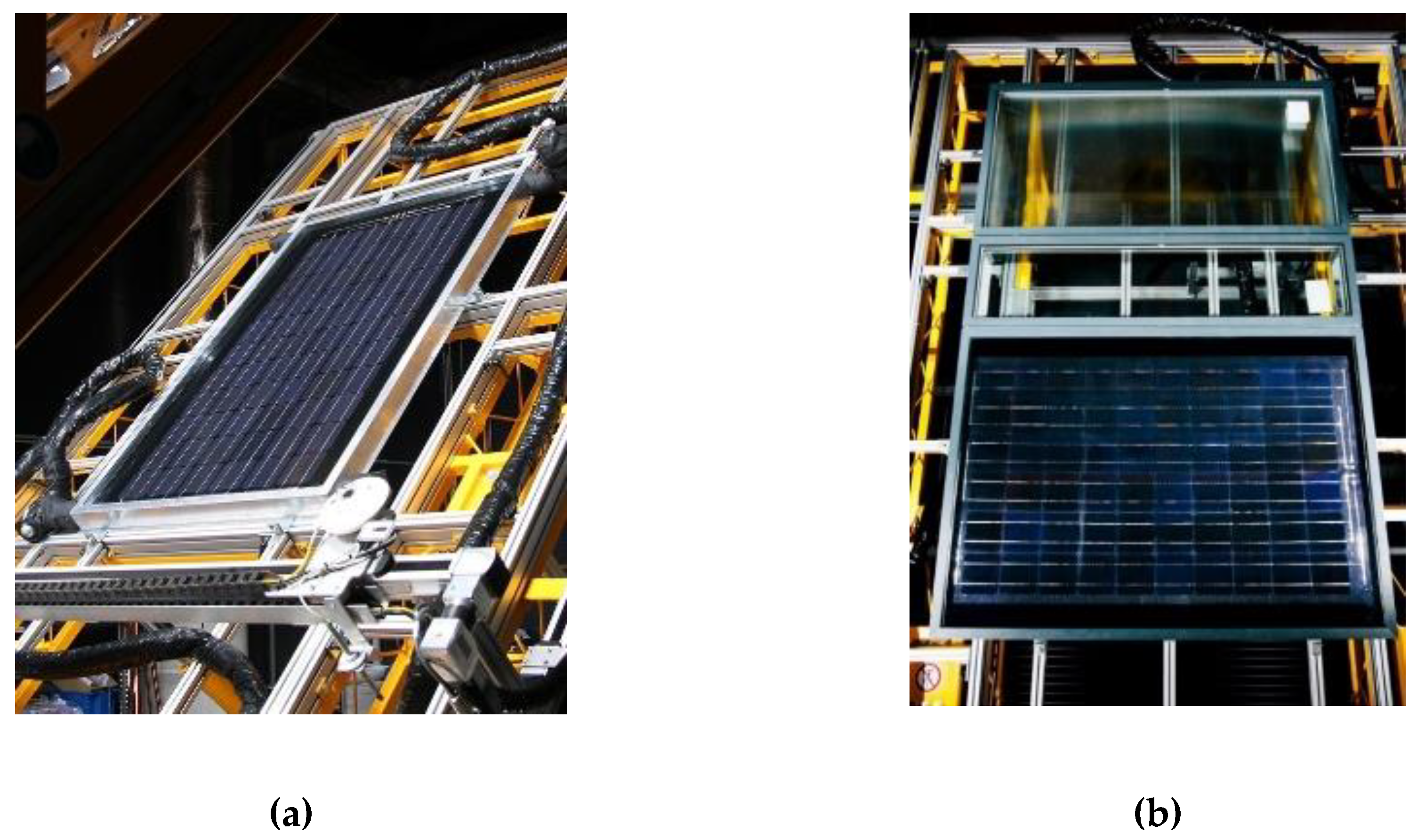

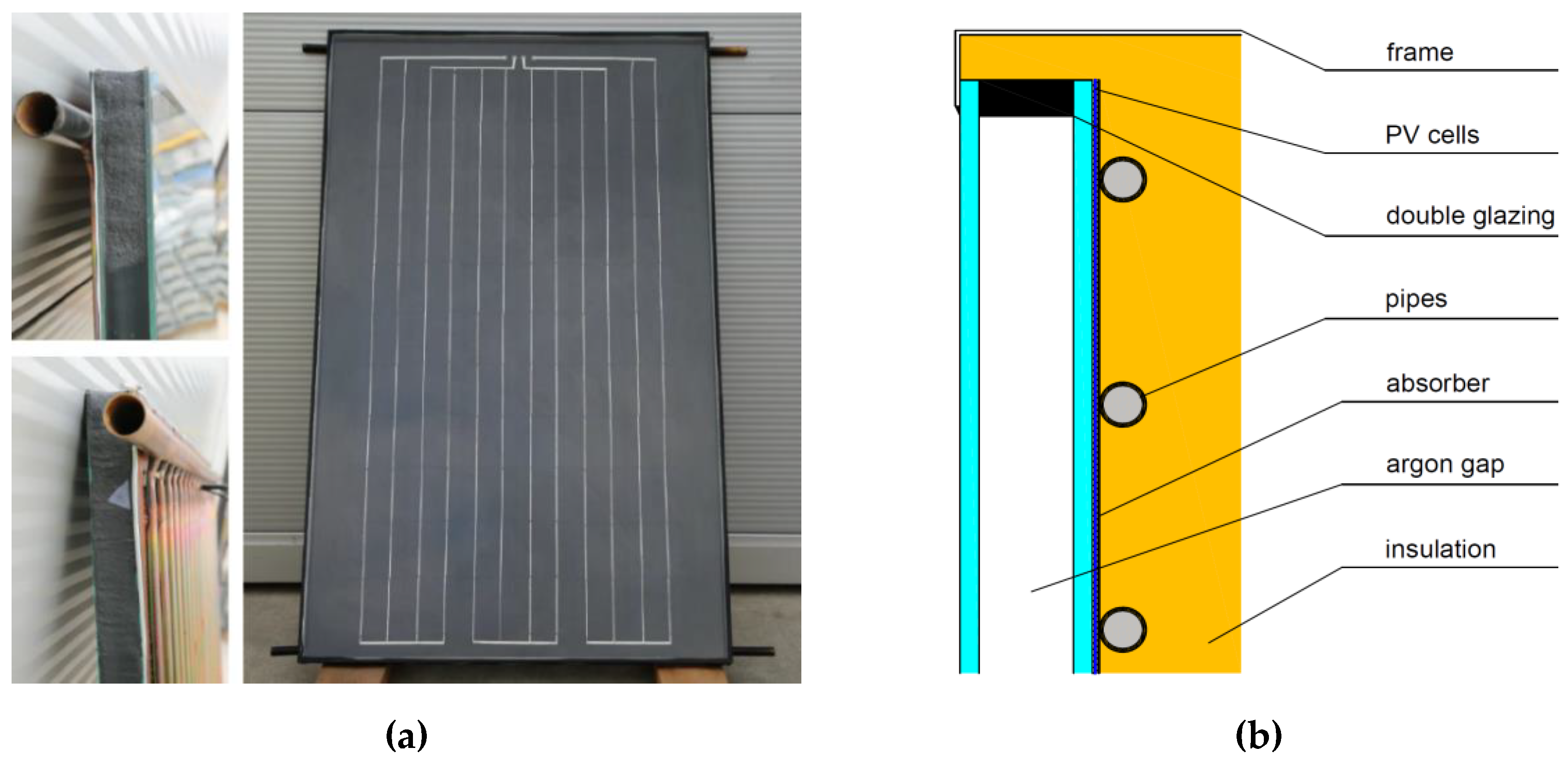

2. Concept of Glazed PVT Collector

3. Simulation Analysis of SDHW System for Multifamily Building

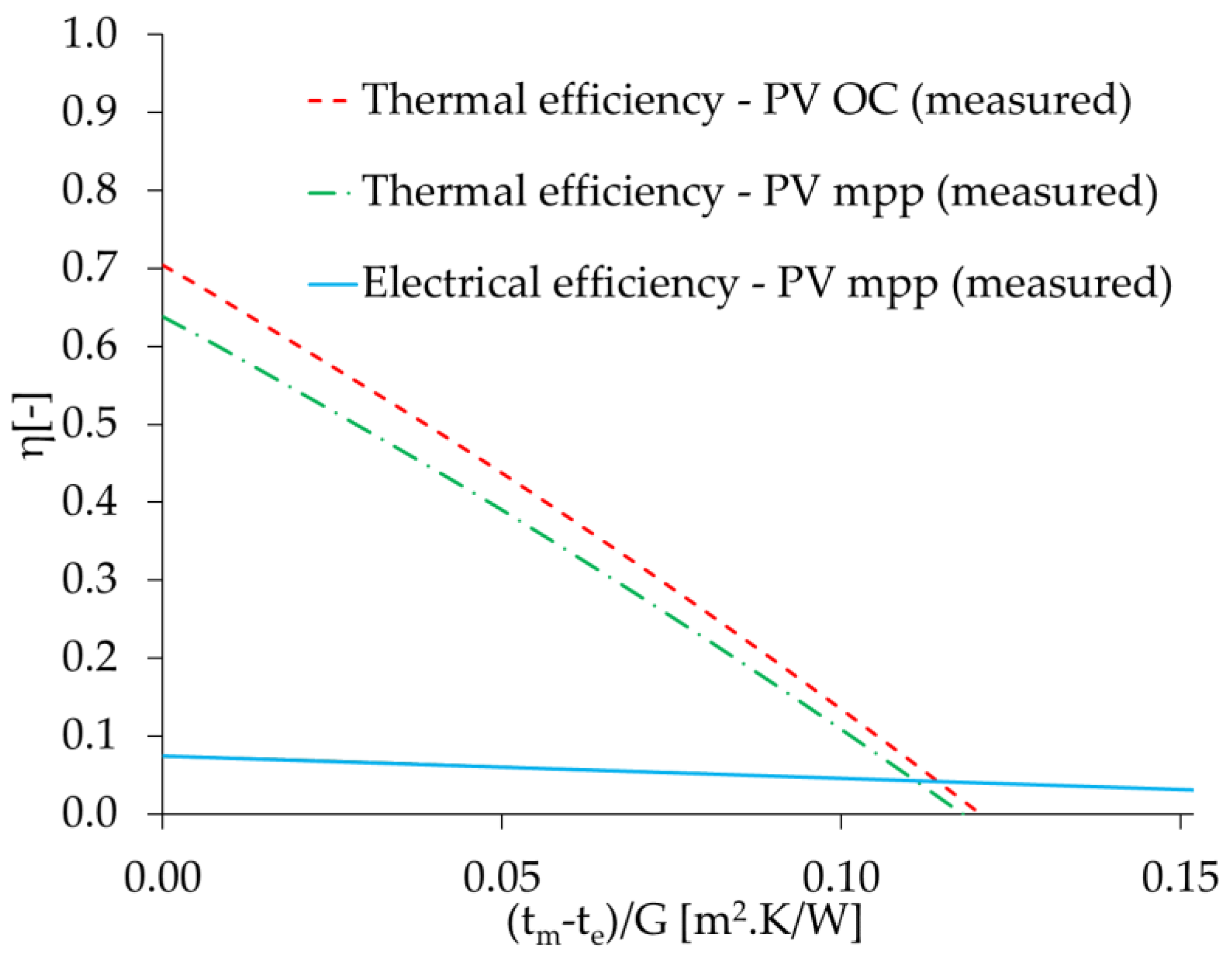

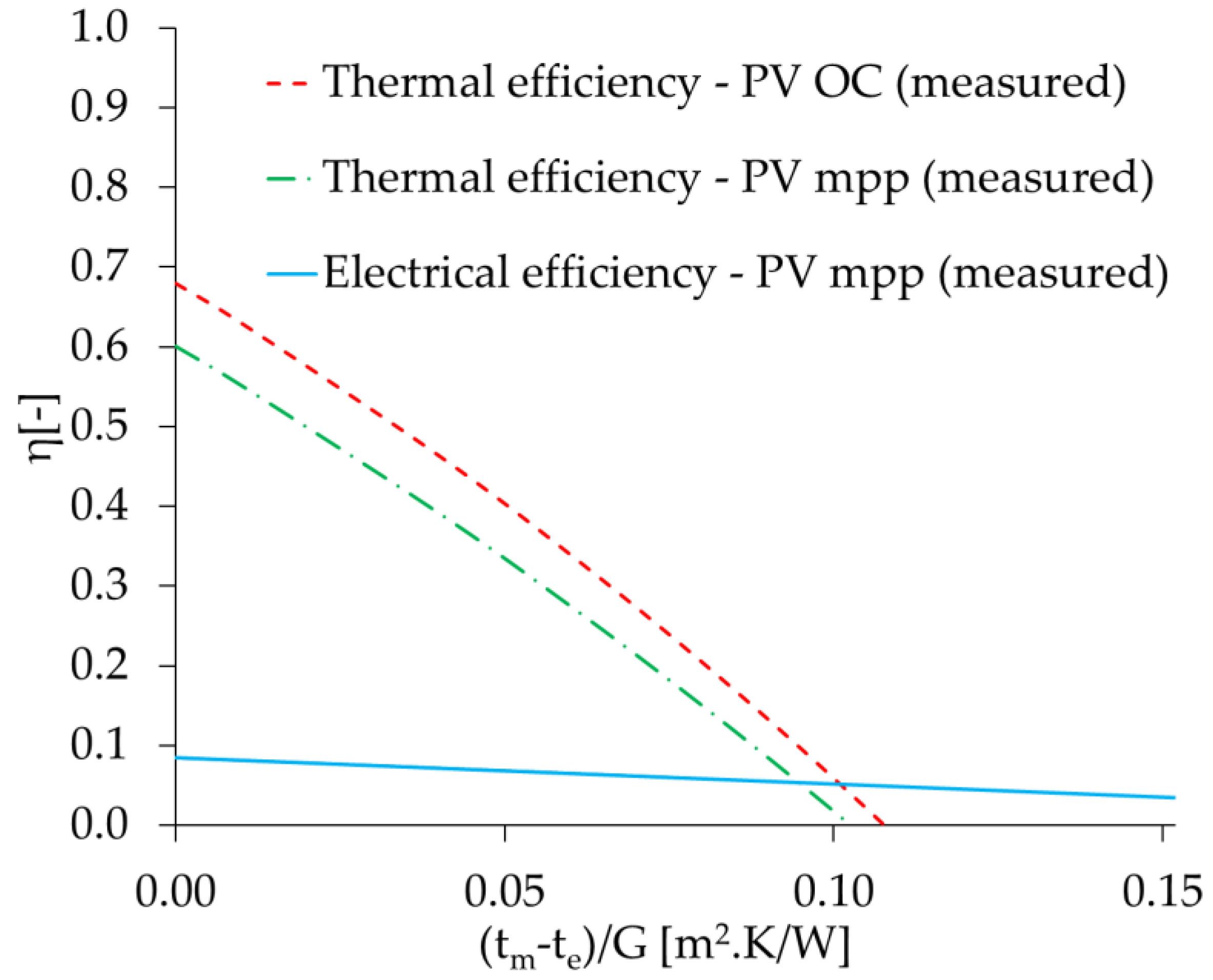

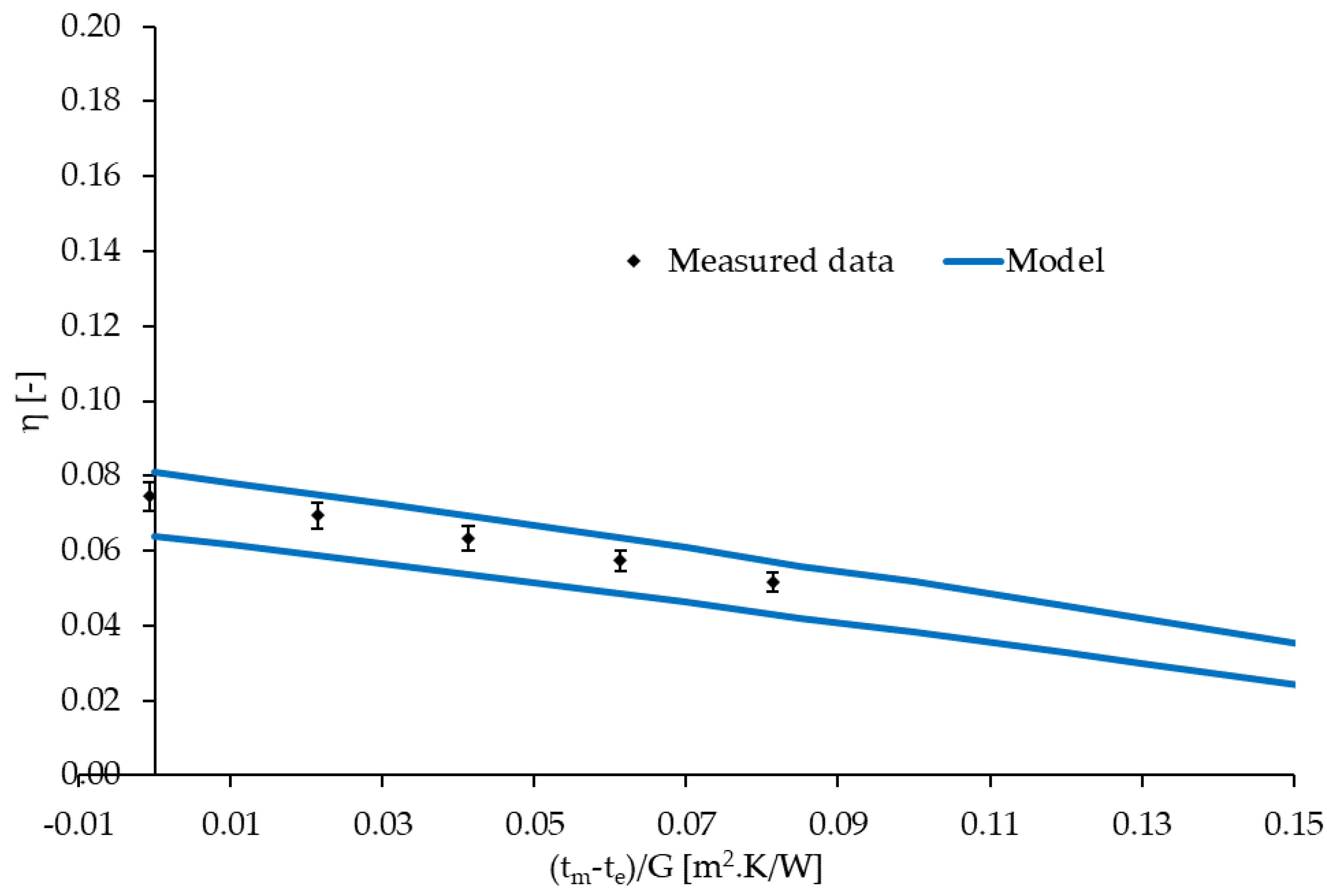

3.1. Mathematical Model of Glazed PVT Collector

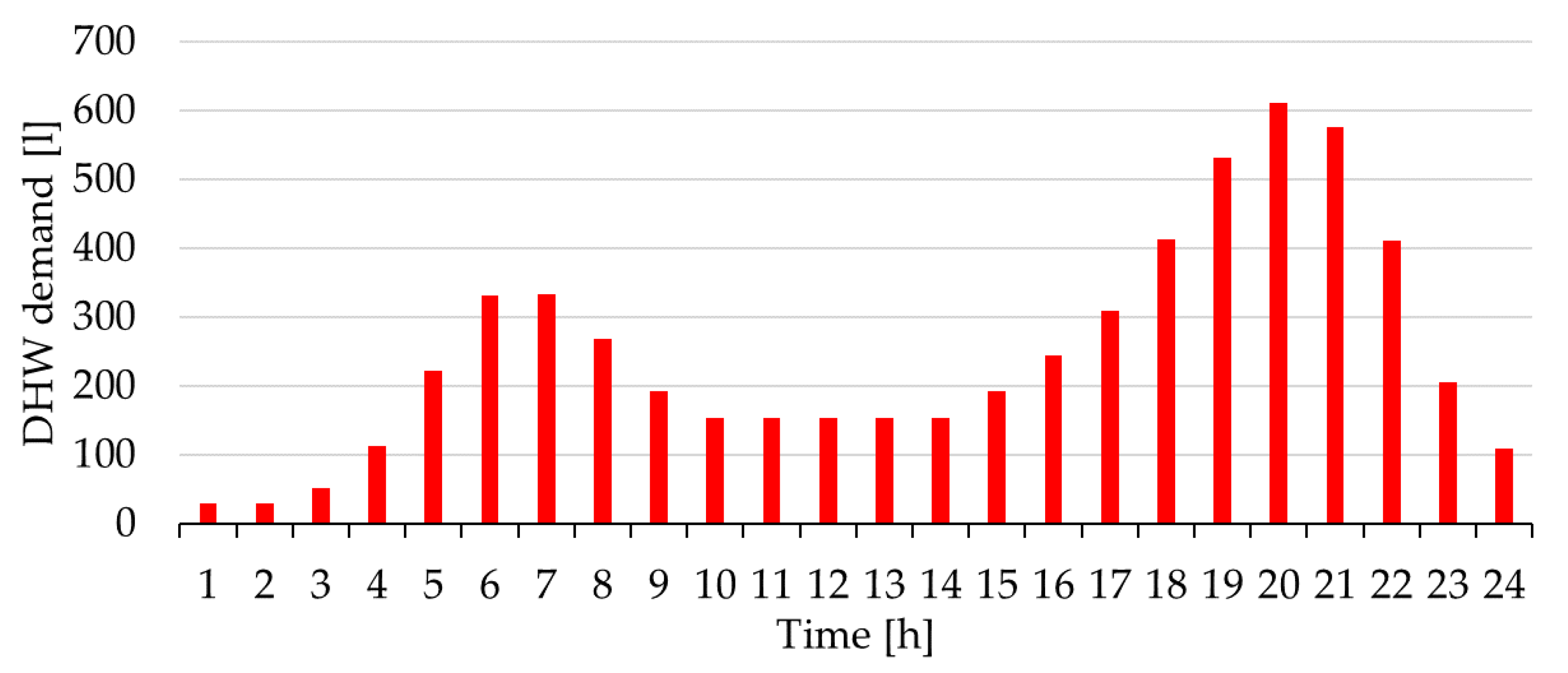

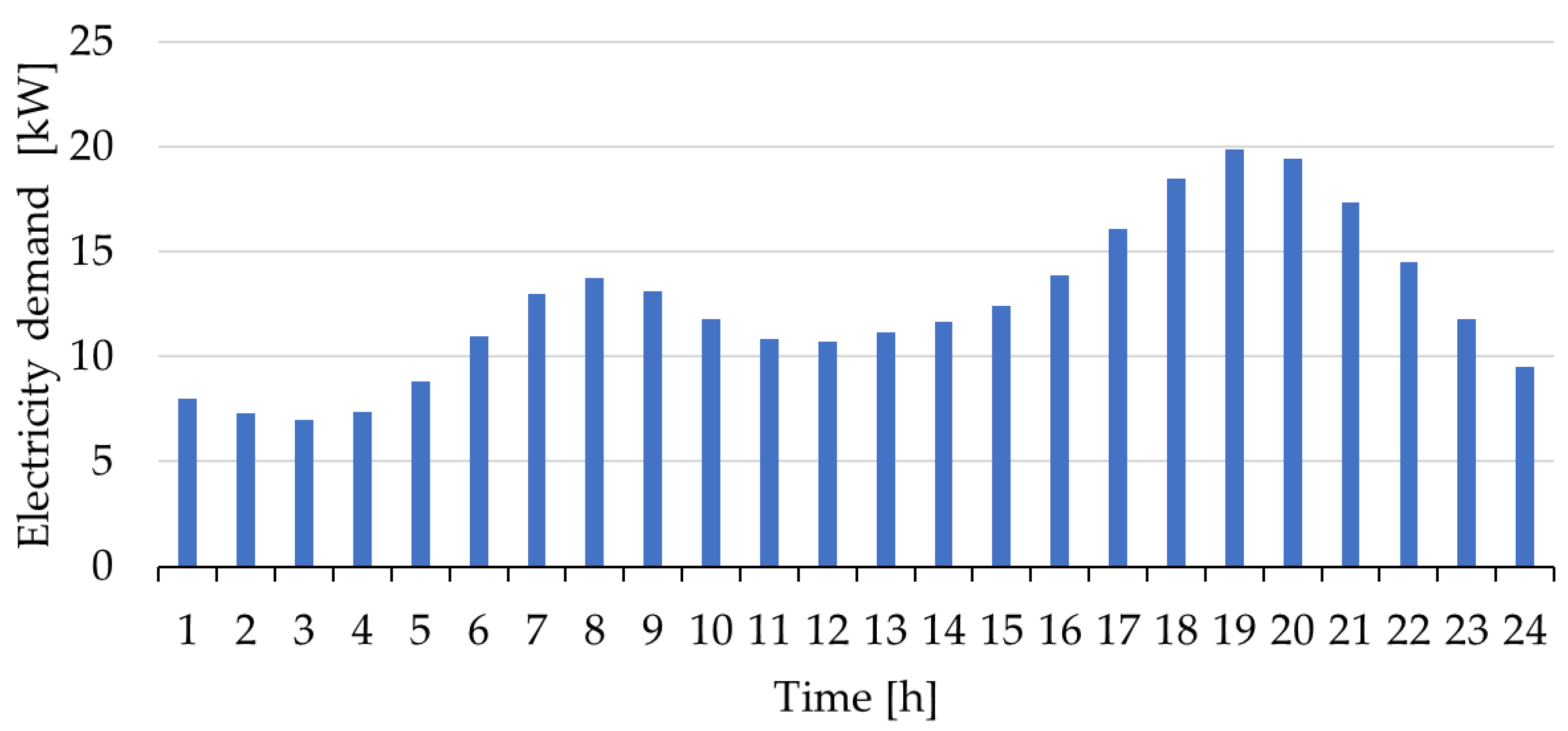

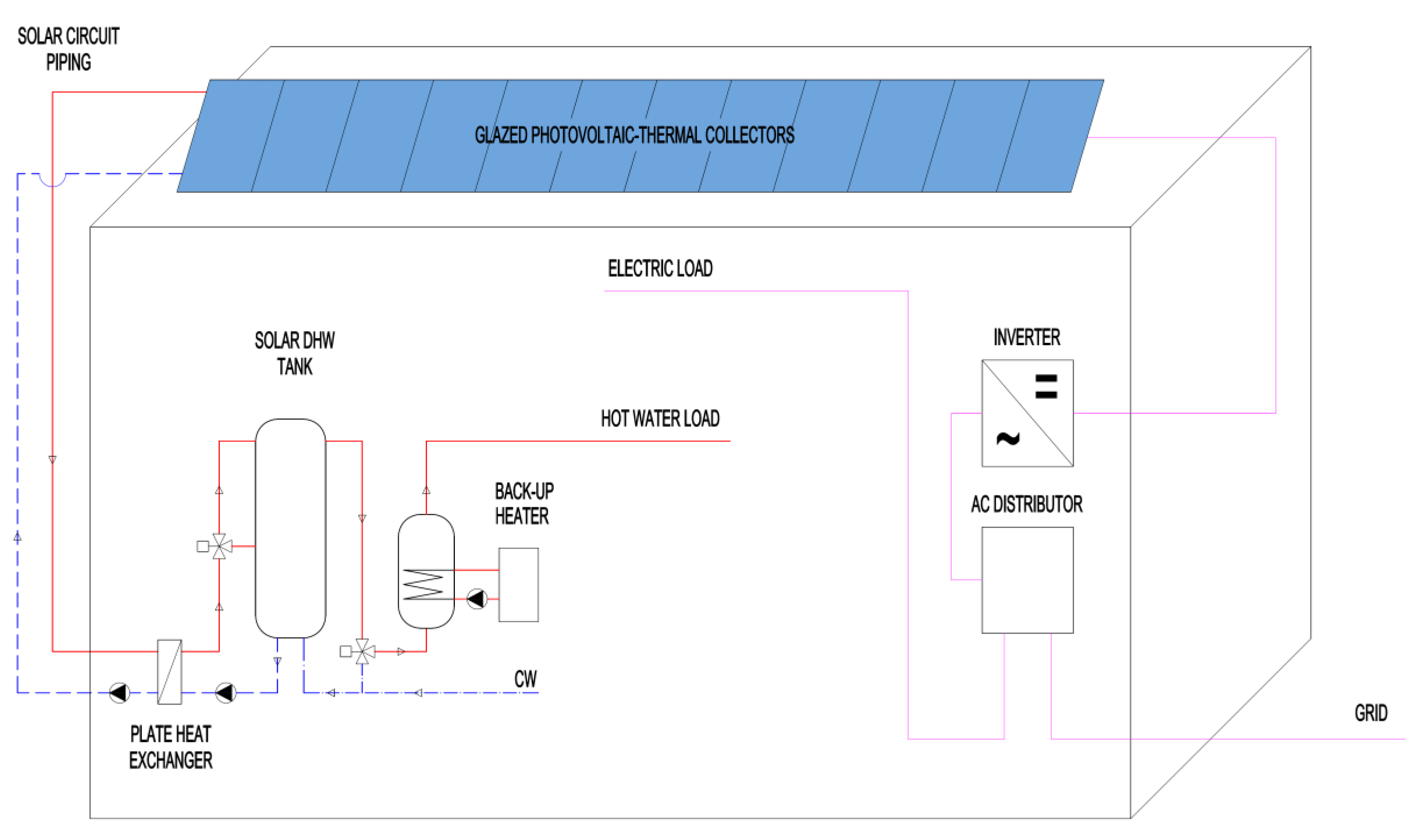

3.2. SDHW System in Multifamily Building

3.3. TRNSYS Simulation Deck

3.4. Installation of Solar Energy System on the Roof

3.5. Installation of Solar Energy System on the Façade

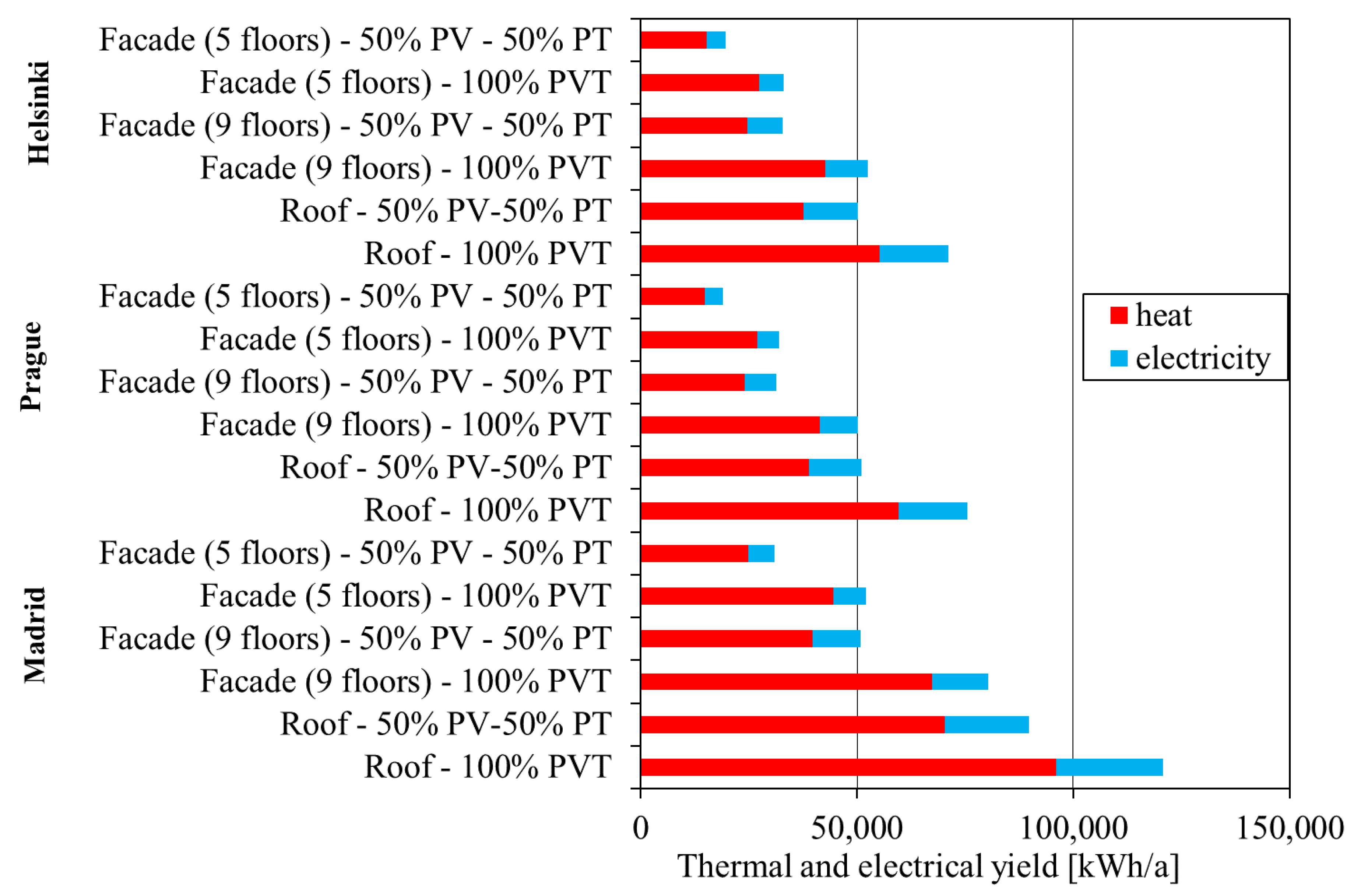

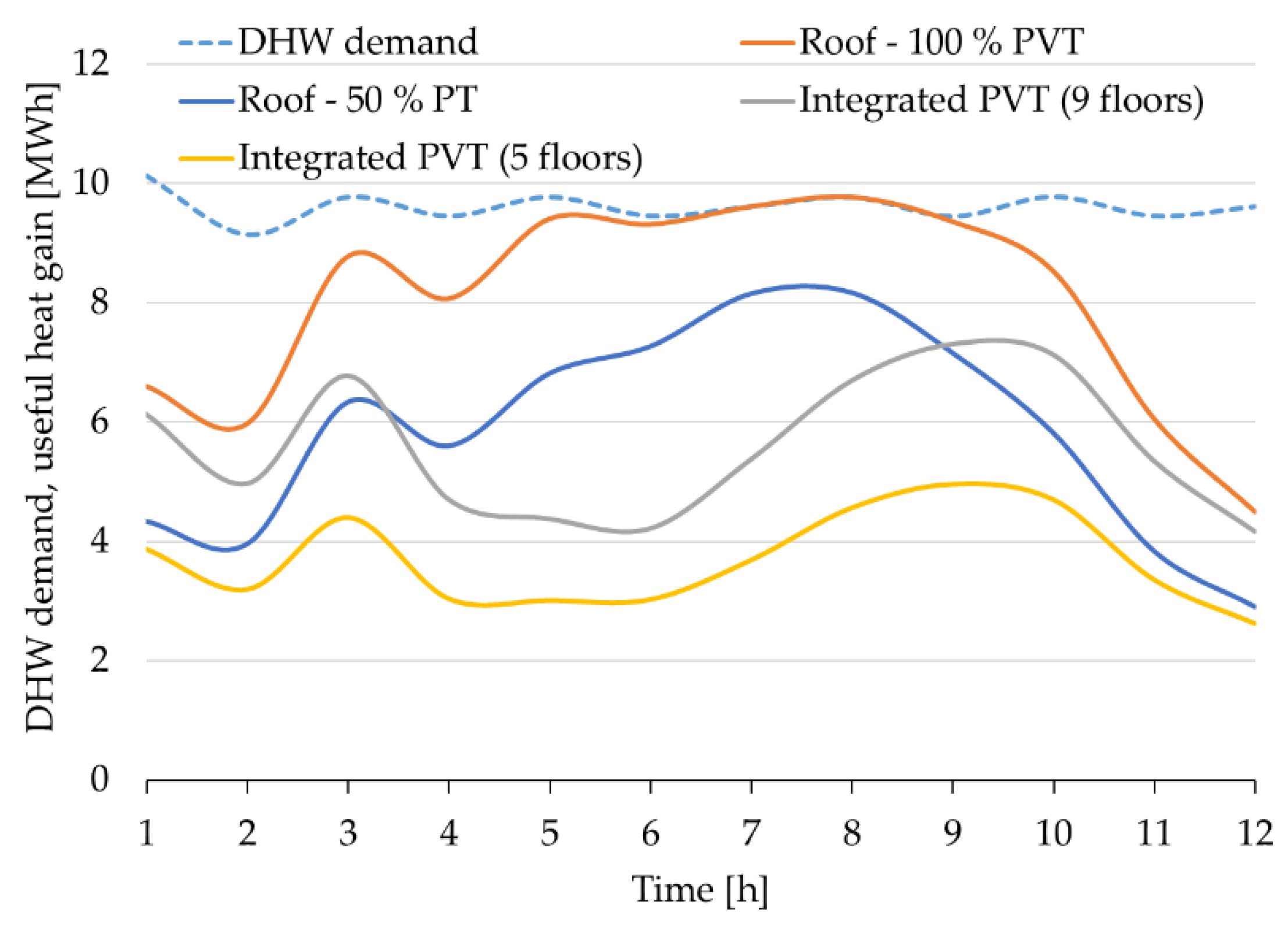

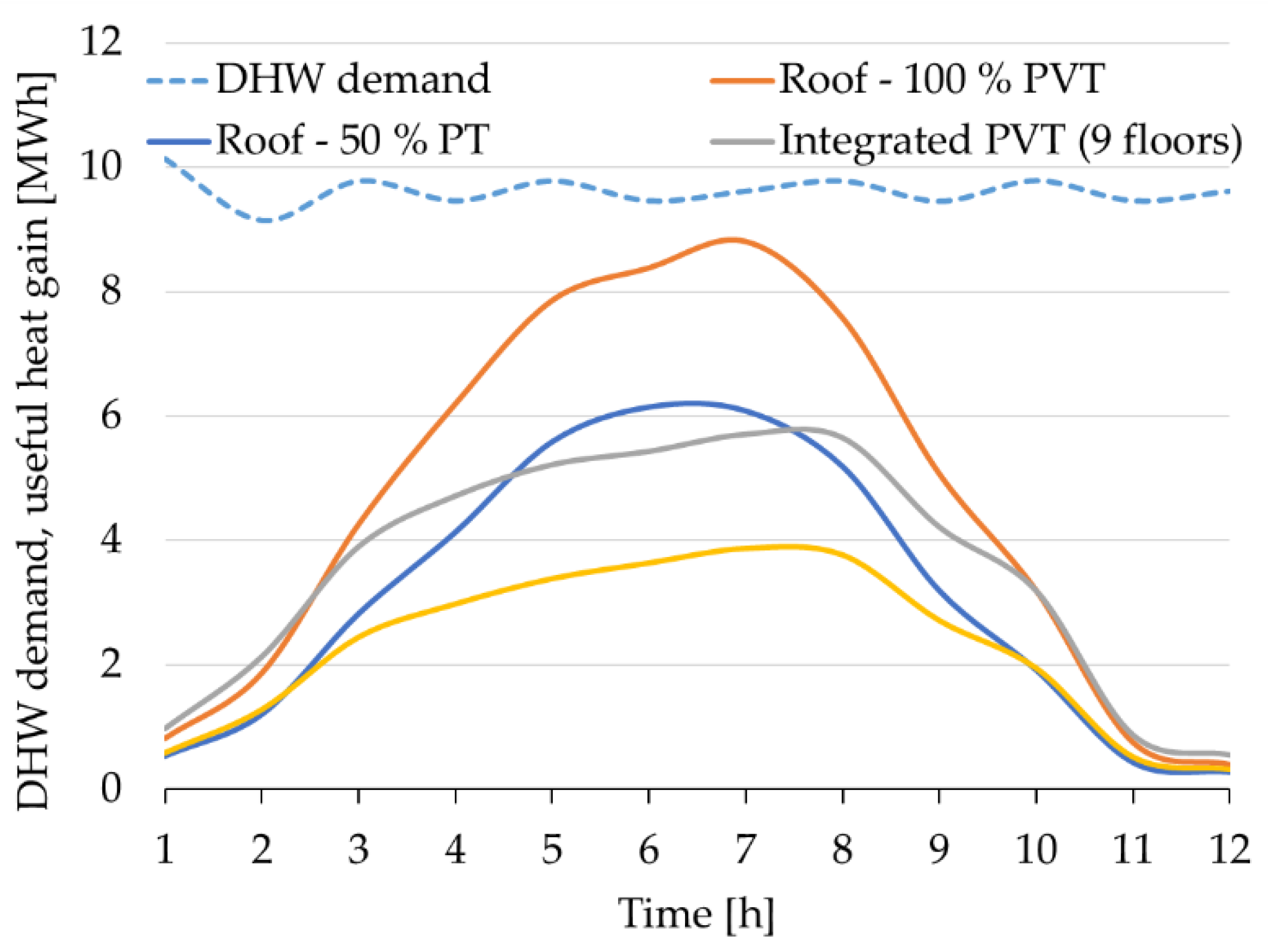

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Parameters | Separate PVT | Integrated PVT | Unit |

|---|---|---|---|

| Geometrical properties | |||

| Gross area | 1.65 | 1.56 | m2 |

| Aperture area | 1.55 | 1.37 | m2 |

| Gap between glazing and PVT absorber | 24 | 24 | mm |

| Gap between PVT absorber and frame | 5 | 5 | mm |

| Thickness of glass | 4 | 4 | mm |

| Thickness of insulation (back side) | 40 | 160 | mm |

| Thickness of insulation (lateral side) | 10 | 20 | mm |

| Properties of the sheet and tube absorber | |||

| Thermal conductivity of the absorber plate | 350 | 350 | W/m.K |

| Thickness of absorber plate | 0.2 | 0.2 | mm |

| Length of riser pipes | 1.515 | 1.415 | m |

| Number of riser pipes | 20 | 18 | - |

| Distance between riser pipes | 50 | 50 | mm |

| Internal diameter of riser pipes | 7.2 | 7.2 | mm |

| Thermal and optical properties | |||

| Normal solar transmittance of glass | 0.91 | 0.91 | - |

| Absorptance of PVT absorber | 0.90 | 0.90 | - |

| Front surface emissivity of PVT absorber | 0.30 | 0.85 | - |

| Back surface emissivity of PVT absorber | 0.85 | 0.85 | - |

| External surface emissivity of frame | 0.50 | 0.50 | - |

| Internal surface emissivity of frame | 0.50 | 0.50 | - |

| Thermal conductivity of glass | 0.80 | 0.80 | W/m.K |

| Outer surface emissivity of cover glass | 0.85 | 0.85 | - |

| Inner surface emissivity of cover glass | 0.85 | 0.85 | - |

| Thermal conductivity of insulation | 0.04 | 0.04 | W/m.K |

| Thermal conductivity of insulation (lateral side) | 0.04 | 0.04 | W/m.K |

| Thermal conductivity of lamination layer | 0.16 | 0.16 | W/m.K |

| Thickness of lamination layer | 2 | 2 | mm |

| Thickness of PV cells | 0.5 | 0.5 | mm |

| Thermal conductivity of PV cells | 149 | 149 | W/m.K |

| Properties of PV part | |||

| Reference electrical efficiency of PV part without cover glass pane (related to PV area) | 16.3 | 16.3 | % |

| Temperature coefficient of PV cell efficiency | 0.44 | 0.44 | %/K |

| Gas layer between glazing | Argon | Argon | - |

| Packing factor | 0.62 | 0.60 | - |

References

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide. Global Market Development and Trends in 2018. 2019. Available online: https://www.iea-shc.org/Data/Sites/1/publications/Solar-Heat-Worldwide-2019.pdf (accessed on 28 July 2020).

- Zondag, H.A.; van Helden, W.G.J. Stagnation temperature in PVT collectors. In Proceedings of the PV in Europe—From PV Technology to Energy Solutions Conference and Exhibition, Rome, Italy, 7–11 October 2002. [Google Scholar]

- Harrison, S.; Cruickshank, C.A. A review of strategies for the control of high temperature stagnation in solar collectors and systems. Energy Procedia 2012, 30, 793–804. [Google Scholar] [CrossRef]

- Lammle, M.; Thoma, C.; Hermann, M. A PVT Collector Concept with Variable Film Insulation and Low-emissivity Coating. Energy Procedia 2016, 91, 72–77. [Google Scholar] [CrossRef]

- Matuska, T.; Sourek, B.; Jirka, V.; Pokorny, N. Glazed PVT Collector with Polysiloxane Encapsulation of PV Cells: Performance and Economic Analysis. Int. J. Photoenergy 2015, 2015, 718316. [Google Scholar] [CrossRef]

- Poulek, V.; Strebkov, D.S.; Persic, I.S.; Libra, M. Towards 50 years lifetime of PV panels laminated with silicone gel technology. Sol. Energy 2012, 86, 3103–3108. [Google Scholar] [CrossRef]

- Dupeyrat, P.; Menezo, C.; Fortuin, S. Study of the thermal and electrical performances of PVT solar hot water system. Energy Build. 2014, 68, 751–755. [Google Scholar] [CrossRef]

- Zondag, H.A.; De Vries, D.W.; Van Helden, W.G.J.; Van Zolingen, R.J.C.; Van Steenhoven, A.A. The thermal and electrical yield of a PV-thermal collector. Sol. Energy 2002, 72, 113–128. [Google Scholar] [CrossRef]

- Gagliano, A.; Tina, G.M.; Aneli, S.; Nižetić, S. Comparative assessments of the performances of PV/T and conventional solar plants. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Rommel, M.; Zenhäusern, D.; Baggenstos, A.; Türk, O.; Brunold, S. Application of unglazed PVT collectors for domestic hot water pre-heating in a development and testing system. Energy Procedia 2014, 48, 638–644. [Google Scholar] [CrossRef]

- Bakker, M.; Zondag, H.A.; Elswijk, M.J.; Strootman, K.J.; Jong, M.J.M. Performance and costs of a roof-sized PV/thermal array combined with a ground coupled heat pump. Sol. Energy 2005. [Google Scholar] [CrossRef]

- Bertram, E.; Glembin, J.; Rockendorf, G. Unglazed PVT collectors as additional heat source in heat pump systems with borehole heat exchanger. Energy Procedia 2012, 30, 414–423. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A.; Vicidomini, M. Transient analysis, exergy and thermo-economic modelling of façade integrated photovoltaic/thermal solar collectors. Renew. Energy 2019. [Google Scholar] [CrossRef]

- Lammle, M.; Oliva, A.; Hermann, M.; Kramer, K.; Kramer, W. PVT collector technologies in solar thermal systems: A systematic assessment of electrical and thermal yields with the novel characteristic temperature approach. Sol. Energy 2017. [Google Scholar] [CrossRef]

- Giovannetti, F.; Föste, S.; Ehrmann, N.; Rockendorf, G. High transmittance, low emissivity glass covers for flat plate collectors: Applications and performance. Sol. Energy 2014, 104, 52–59. [Google Scholar] [CrossRef]

- Pokorny, N.; Matuska, T.; Sourek, B.; Jirka, V. Glazed PVT Collector Integrated Into Façade Module. In Proceedings of the 12th International Conference on Solar Energy and Buildings, Rapperswil, Switzerland, 10–13 September 2018. [Google Scholar]

- ISO 9806:2017(E). International Standard ISO Solar Energy—Solar Thermal Collectors—Test Methods; Comite Europeen de Normalisation: Brussels, Belgium, 2017. [Google Scholar]

- Dupeyrat, P.; Menezo, C.; Rommel, M.; Henning, H.M. Efficient single glazed flat plate photovoltaic-thermal hybrid collector for domestic hot water system. Sol. Energy 2011, 85, 1457–1468. [Google Scholar] [CrossRef]

- Lammle, M.; Kroyer, T.; Fortuin, S.; Wiese, M.; Hermann, M. Development and modelling of highly-efficient PVT collectors with low-emissivity coatings. Sol. Energy 2016, 130, 161–173. [Google Scholar] [CrossRef]

- Bergene, T.; Løvvik, O.M. Model calculations on a flat-plate solar heat collector with integrated solar cells. Sol. Energy 1995, 55, 453–462. [Google Scholar] [CrossRef]

- Chow, T.T. Performance analysis of photovoltaic-thermal collector by explicit dynamic model. Sol. Energy 2003, 75, 143–152. [Google Scholar] [CrossRef]

- Guarracino, I.; Mellor, A.; Ekins-Daukes, N.J.; Markides, C.N. Dynamic coupled thermal-and-electrical modelling of sheet-and-tube hybrid photovoltaic/thermal (PVT) collectors. Appl. Therm. Eng. 2016, 101, 778–795. [Google Scholar] [CrossRef]

- Haurant, P.; Menezo, C.H.; Gaillard, L.; Dupeyrat, P. Dynamic numerical model of a high efficiency PV-T collector integrated into a domestic hot water system. Sol. Energy 2015, 111, 68–81. [Google Scholar] [CrossRef]

- Solar Energy Laboratory. User Manual: TRNSYS 17 a TRaNsient SYstem Simulation Program—Volume 4—Mathematical Reference; Solar Energy Laboratory: Madison, WI, USA, 2009; Volume 4. [Google Scholar]

- Florschuetz, L.W. Extension of the Hottel-Whillier model to the analysis of combined photovoltaic/thermal flat plate collectors. Sol. Energy 1979, 22, 361–366. [Google Scholar] [CrossRef]

- Pokorny, N.; Matuska, T.; Sourek, B. Modeling of glazed liquid PV-T collector with use of detail model. In Proceedings of the 14th International Conference of IBPSA—Building Simulation 2015, BS 2015, Conference Proceedings, Hyderabad, India, 7–9 December 2015; pp. 2554–2560. [Google Scholar]

- Pokorny, N.; Matuska, T.; Sourek, B. Monitoring of Solar Domestic Hot Water System with Glazed Liquid PVT Collectors. In Proceedings of the EuroSun 2016: International Conference on Solar Energy and Buildings, Palma de Mallorca, Spain, 12–14 October 2016. [Google Scholar]

- Mathioulakis, E.; Voropoulos, K.; Belessiotis, V. Assessment of uncertainty in solar collector modeling and testing. Sol. Energy 1999, 66, 337–347. [Google Scholar] [CrossRef]

- Haller, M.; Paavilainen, J.; Dalibard, A.; Perers, B. TRNSYS Type 832 v3. 07, Dynamic Collector Model by Bengt Perers. Updated Input-Output Reference. 2009. [Google Scholar]

| Parameters | Separate PVT | Integrated PVT | Unit |

|---|---|---|---|

| Geometrical Properties | |||

| Gross area | 1.65 | 1.56 | m2 |

| Aperture area | 1.55 | 1.37 | m2 |

| Gap between glazing and front side of PVT absorber | 24 | 24 | mm |

| Gap between back side of PVT absorber and frame | 5 | 5 | mm |

| Thickness of glass | 4 | 4 | mm |

| Thickness of insulation (back side) | 40 | 160 | mm |

| Properties of the sheet and tube absorber | |||

| Thermal conductivity of the absorber plate | 350 | 350 | W/m.K |

| Thickness of absorber plate | 0.2 | 0.2 | mm |

| Number of riser pipes | 20 | 18 | - |

| Distance between the pipes | 50 | 50 | mm |

| Internal diameter of riser pipes | 7.2 | 7.2 | mm |

| Optical and thermal properties | |||

| Normal solar transmittance of glass cover | 0.92 | 0.91 | - |

| Absorptance of PVT absorber | 0.81 | 0.91 | - |

| Front surface emissivity of PVT absorber | 0.3 | 0.85 | - |

| Thermal conductivity of glass cover | 0.8 | 0.8 | W/m.K |

| Thermal conductivity of insulation (mineral wool) | 0.04 | 0.04 | W/m.K |

| Properties of PV part | |||

| Zero-loss electrical efficiency of PV part without cover glass pane (related to PV area) | 12.9 | 15.3 | % |

| Temperature coefficient of PV cell efficiency | 0.44 | 0.44 | %/K |

| Gas layer between glazing | Argon | Argon | - |

| Packing factor | 0.62 | 0.6 | - |

| Parameters | Separate PVT | Integrated PVT | Unit |

|---|---|---|---|

| Zero-loss thermal efficiency η0,G | 0.639 | 0.601 | - |

| Linear heat loss coefficient a1,G | 4.644 | 4.831 | W/m2.K |

| Quadratic heat loss coefficient a2,G | 0.007 | 0.009 | W/m2.K2 |

| Module zero-loss electrical efficiency ηe,G | 0.074 | 0.084 | - |

| Stagnation temperature | 171 | 156 | °C |

| Alternative | Solar Thermal Area [m2] | Solar Tank Volume [m3] | Collector Loop Dimension [mm] | Collector Loop Insulation [mm] |

|---|---|---|---|---|

| R—PVT | 165 | 8.3 | 35 × 1.5 | 25 |

| R—50PV50PT | 82.5 | 4.1 | 28 × 1.5 | 25 |

| F9—PVT | 140 | 7 | 35 × 1.5 | 25 |

| F9—50PV50PT | 70 | 3.5 | 28 × 1.5 | 25 |

| F5—PVT | 78 | 3.9 | 28 × 1.5 | 25 |

| F5—50PV50PT | 39 | 1.9 | 22 × 1.5 | 19 |

| Location | Alternative | Heat | Electricity |

|---|---|---|---|

| Madrid | Roof | 37% | 27% |

| Façade 9 floors | 70% | 19% | |

| Façade 5 floors | 79% | 22% | |

| Prague | Roof | 53% | 32% |

| Façade 9 floors | 72% | 21% | |

| Façade 5 floors | 81% | 23% | |

| Helsinki | Roof | 47% | 28% |

| Façade 9 floors | 72% | 23% | |

| Façade 5 floors | 81% | 25% |

| Alternative | Thermal Yield [kWh/m2] | Electricity Yield [kWh/m2] | Solar Thermal Fraction | Solar Electricity Fraction | |

|---|---|---|---|---|---|

| Madrid | Roof—100% PVT | 582 | 149 | 83% | 26% |

| Roof—50% PV—50% PT | 853 | 235 | 61% | 20% | |

| Façade (9 floors)—100% PVT | 481 | 94 | 58% | 14% | |

| Façade (9 floors)—50% PV—50% PT | 567 | 158 | 34% | 11% | |

| Façade (5 floors)—100% PVT | 571 | 96 | 39% | 8% | |

| Façade (5 floors)—50% PV—50% PT | 636 | 158 | 21% | 6% | |

| Prague | Roof—100% PVT | 361 | 96 | 52% | 17% |

| Roof—50% PV—50% PT | 473 | 147 | 34% | 13% | |

| Façade (9 floors)—100% PVT | 295 | 63 | 36% | 9% | |

| Façade (9 floors)—50% PV—50% PT | 343 | 104 | 21% | 8% | |

| Façade (5 floors)—100% PVT | 346 | 64 | 23% | 5% | |

| Façade (5 floors)—50% PV—50% PT | 382 | 104 | 13% | 4% | |

| Helsinki | Roof—100% PVT | 335 | 97 | 48% | 17% |

| Roof—50% PV—50% PT | 456 | 152 | 33% | 13% | |

| Façade (9 floors)—100% PVT | 304 | 71 | 37% | 10% | |

| Façade (9 floors)—50% PV—50% PT | 354 | 116 | 21% | 8% | |

| Façade (5 floors)—100% PVT | 352 | 73 | 24% | 6% | |

| Façade (5 floors)—50% PV—50% PT | 390 | 116 | 13% | 5% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokorny, N.; Matuška, T. Glazed Photovoltaic-thermal (PVT) Collectors for Domestic Hot Water Preparation in Multifamily Building. Sustainability 2020, 12, 6071. https://doi.org/10.3390/su12156071

Pokorny N, Matuška T. Glazed Photovoltaic-thermal (PVT) Collectors for Domestic Hot Water Preparation in Multifamily Building. Sustainability. 2020; 12(15):6071. https://doi.org/10.3390/su12156071

Chicago/Turabian StylePokorny, Nikola, and Tomáš Matuška. 2020. "Glazed Photovoltaic-thermal (PVT) Collectors for Domestic Hot Water Preparation in Multifamily Building" Sustainability 12, no. 15: 6071. https://doi.org/10.3390/su12156071

APA StylePokorny, N., & Matuška, T. (2020). Glazed Photovoltaic-thermal (PVT) Collectors for Domestic Hot Water Preparation in Multifamily Building. Sustainability, 12(15), 6071. https://doi.org/10.3390/su12156071