Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis

Abstract

1. Introduction

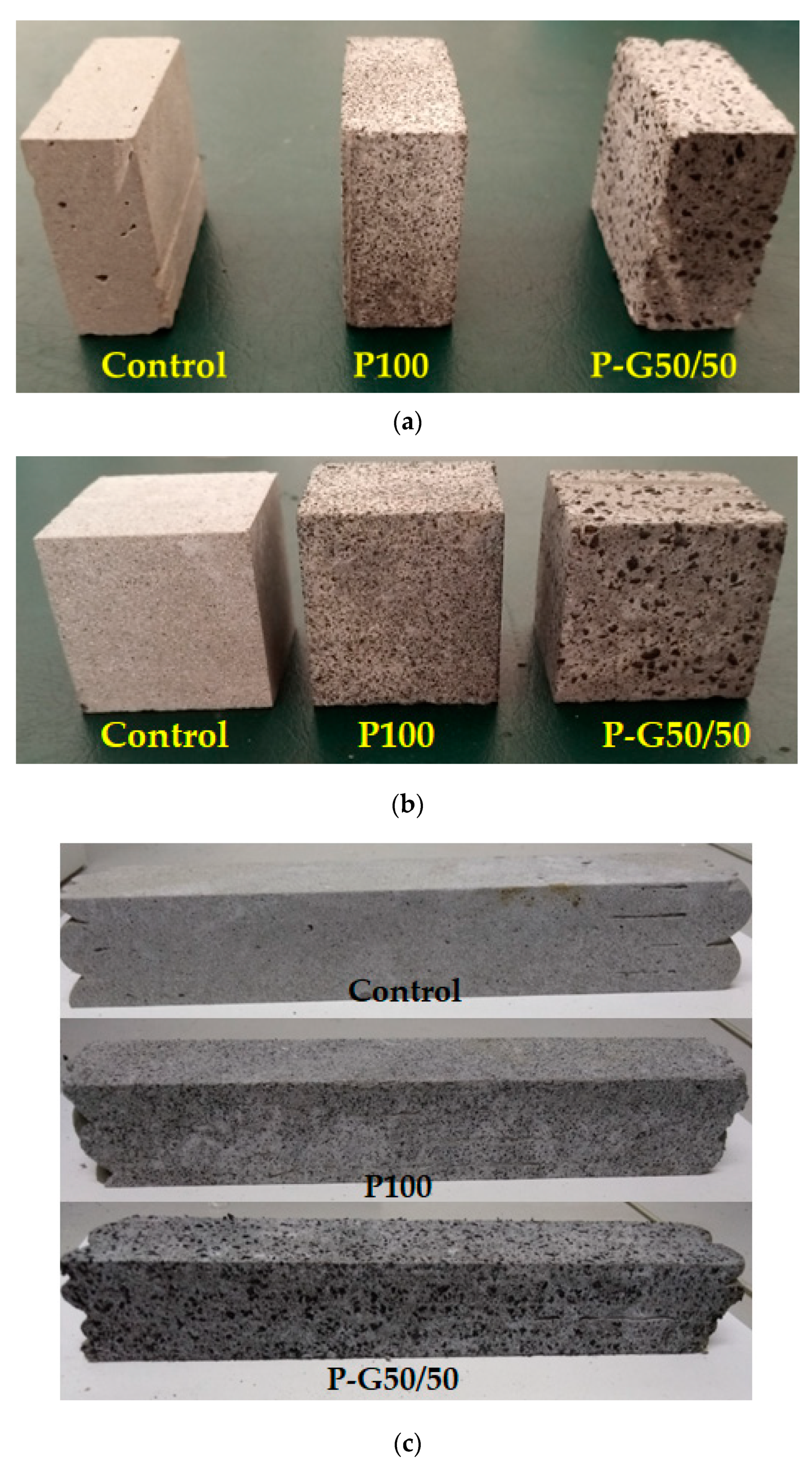

- Control mix: Standard cement mortar (100% sand) used as the basis for the preparation of the rubberized mixes and for comparison purposes.

- P100 mix: Rubberized cement mortar obtained by total replacement of the sand with rubber powder.

- P-G50/50 mix: Rubberized cement mortar obtained by total replacement of the sand with an equal proportion of rubber powder and rubber granules.

2. Materials and Methods

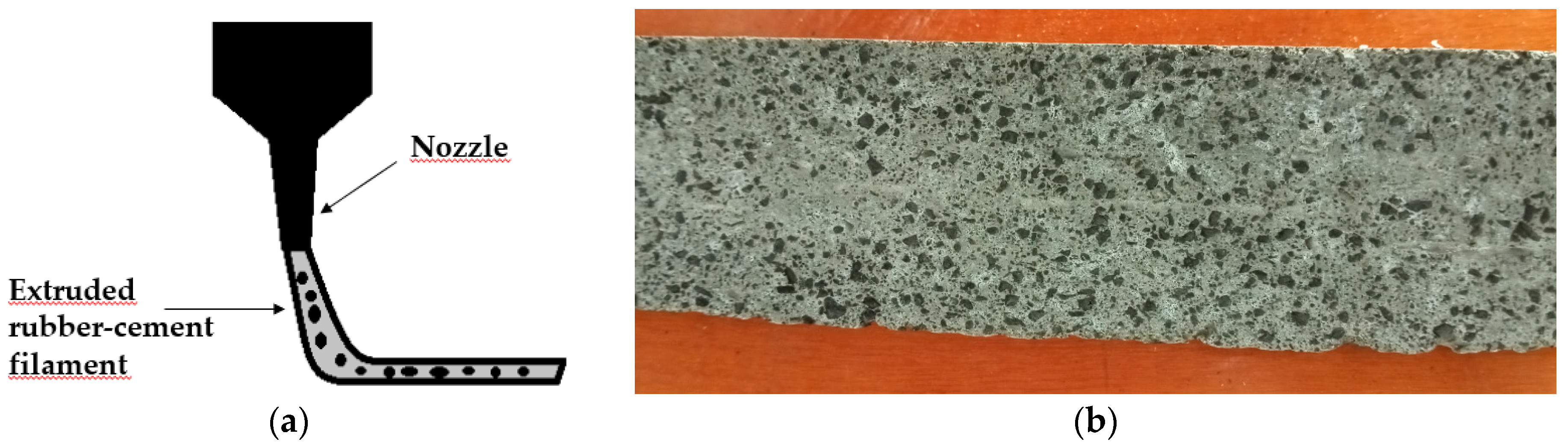

2.1. Materials, Print Process, and Samples Preparation

- Type I Portland cement: 800 kg

- Limestone sand (maximum size of 0.4 mm): 1100 kg

- Water: 300 kg

- Relation water to cement (w/c ratio): 0.375

- Silica fume: 120 kg

- Chemical additives (expansive agent, superfluidifying and reducer additives): 32 kg.

2.2. Testing Program

2.2.1. Physical Characterization: Bulk Density and Permeable Porosity

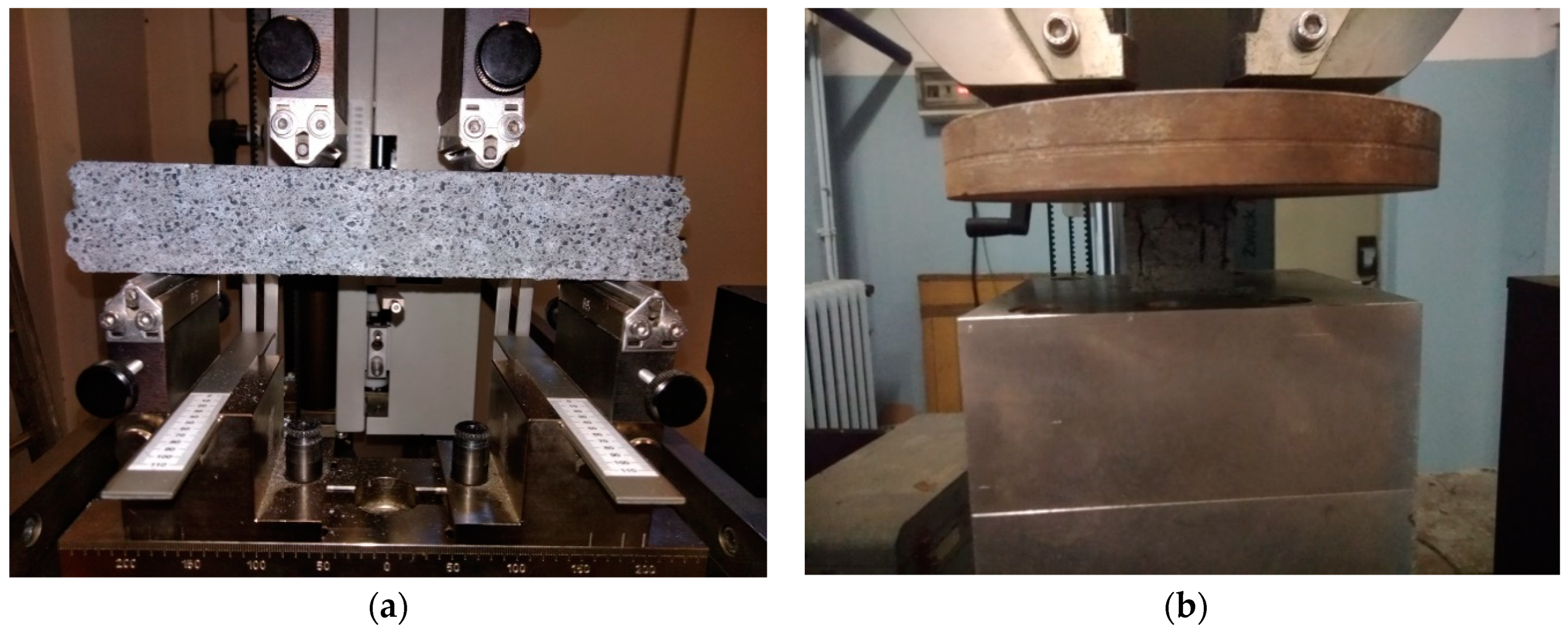

2.2.2. Mechanical Characterization: Four-Point Flexural and Uni-Axial Compressive Tests

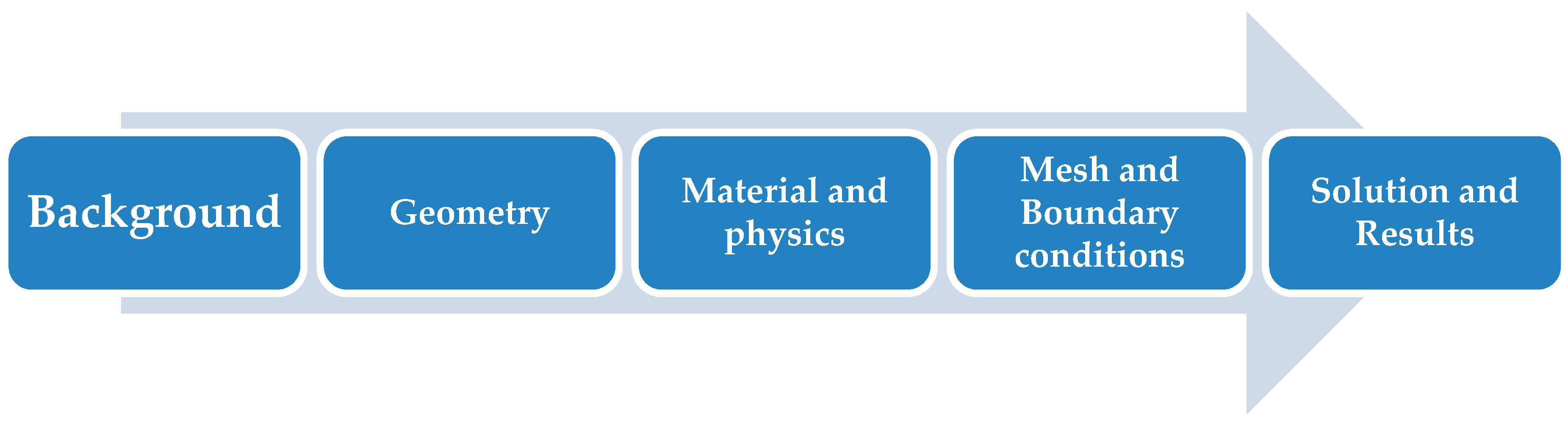

2.3. Finite Element Method (FEM)-Based Mechanical Analysis of Rubber-Cement Bricks

- Easy modeling of complex shapes and irregular geometries

- Determine how critical factors could affect the investigated structure and why failures might occur

- Identify any design vulnerabilities and use the numerical results to develop a new design or perform topological optimization.

2.3.1. Background

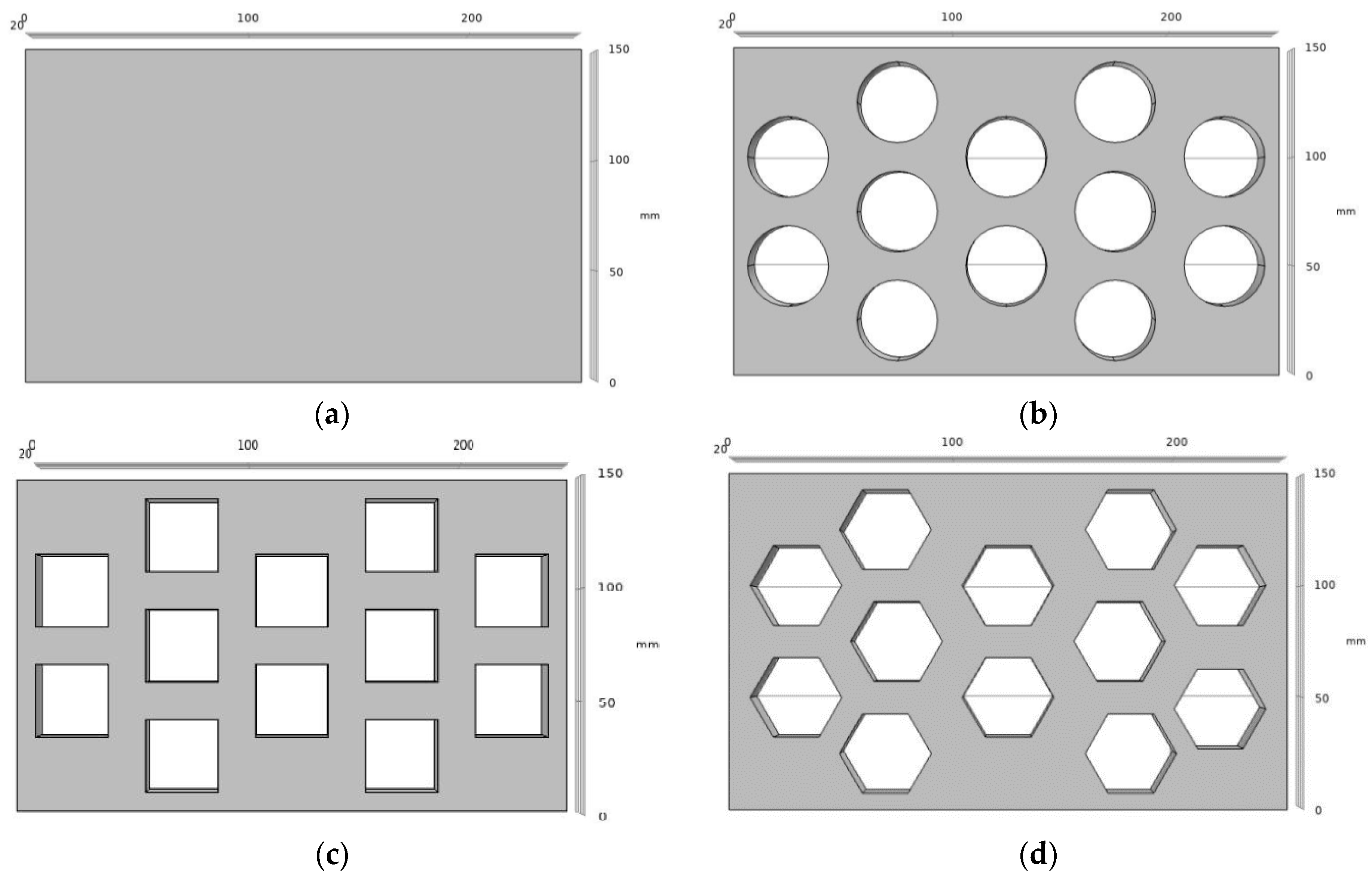

2.3.2. Geometry

2.3.3. Material and Physics

2.3.4. Mesh and Boundary Conditions

3. Results

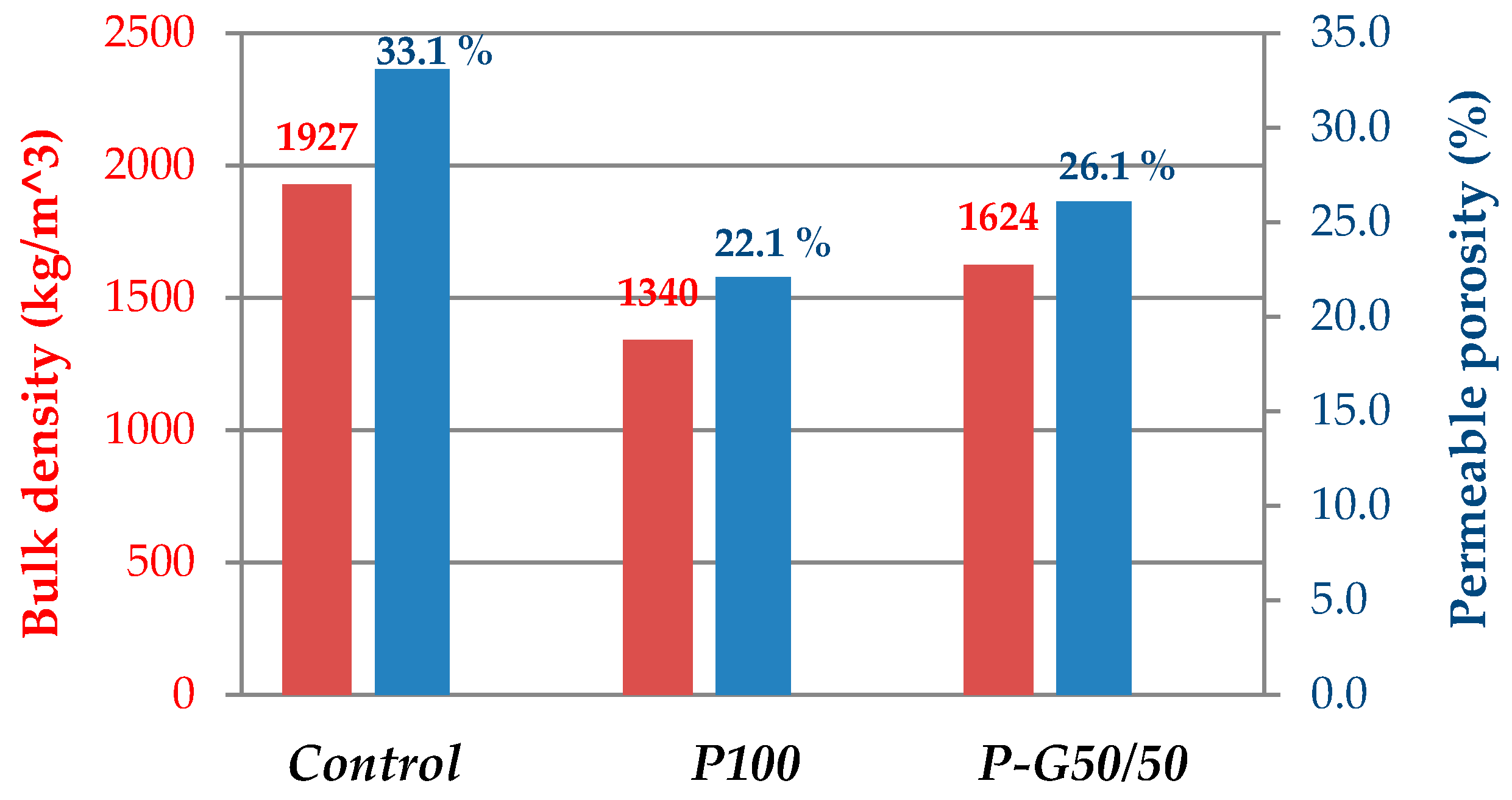

3.1. Physical Characterization: Bulk Density and Permeable Porosity

- As shown in Table 1, the mix design of the rubberized compounds requires less water amount than the control mixture. This aspect involves a lower capillary porosity in the hardened rubber-cement material

- Porous mineral aggregates were replaced with non-porous rubber particles. This factor reduces the rate of permeable voids in the material.

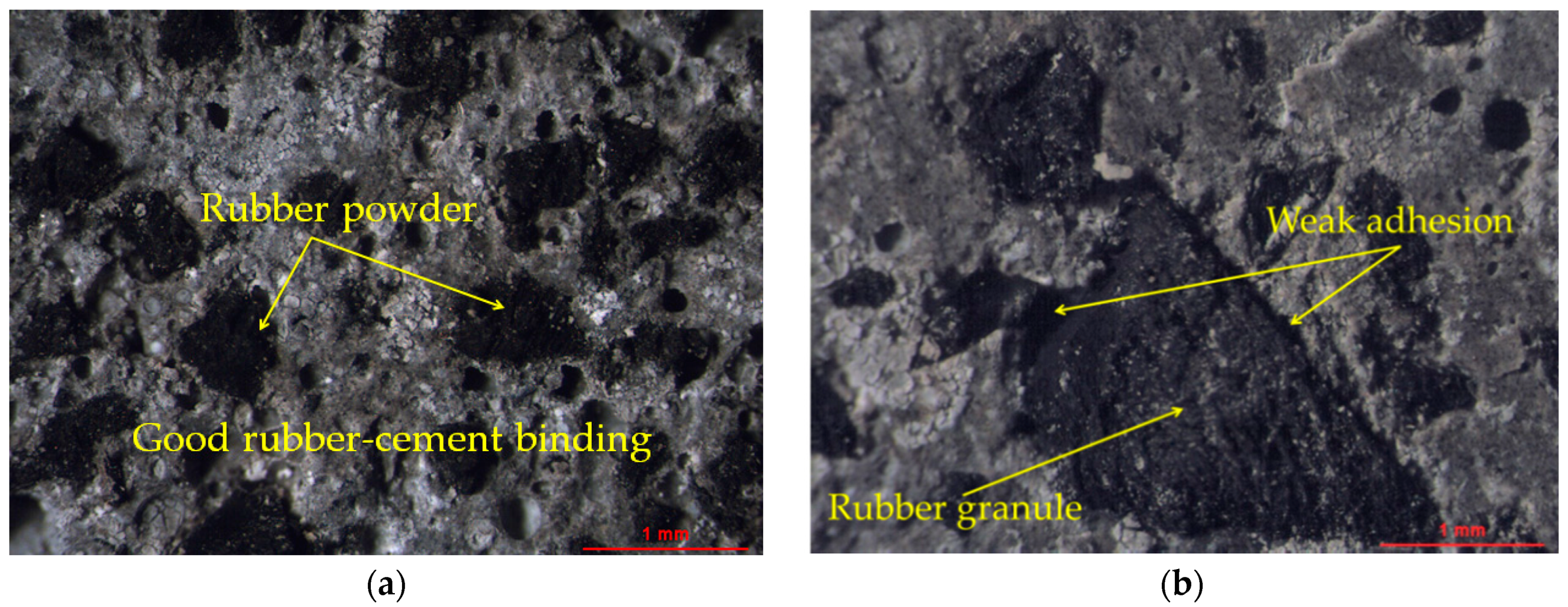

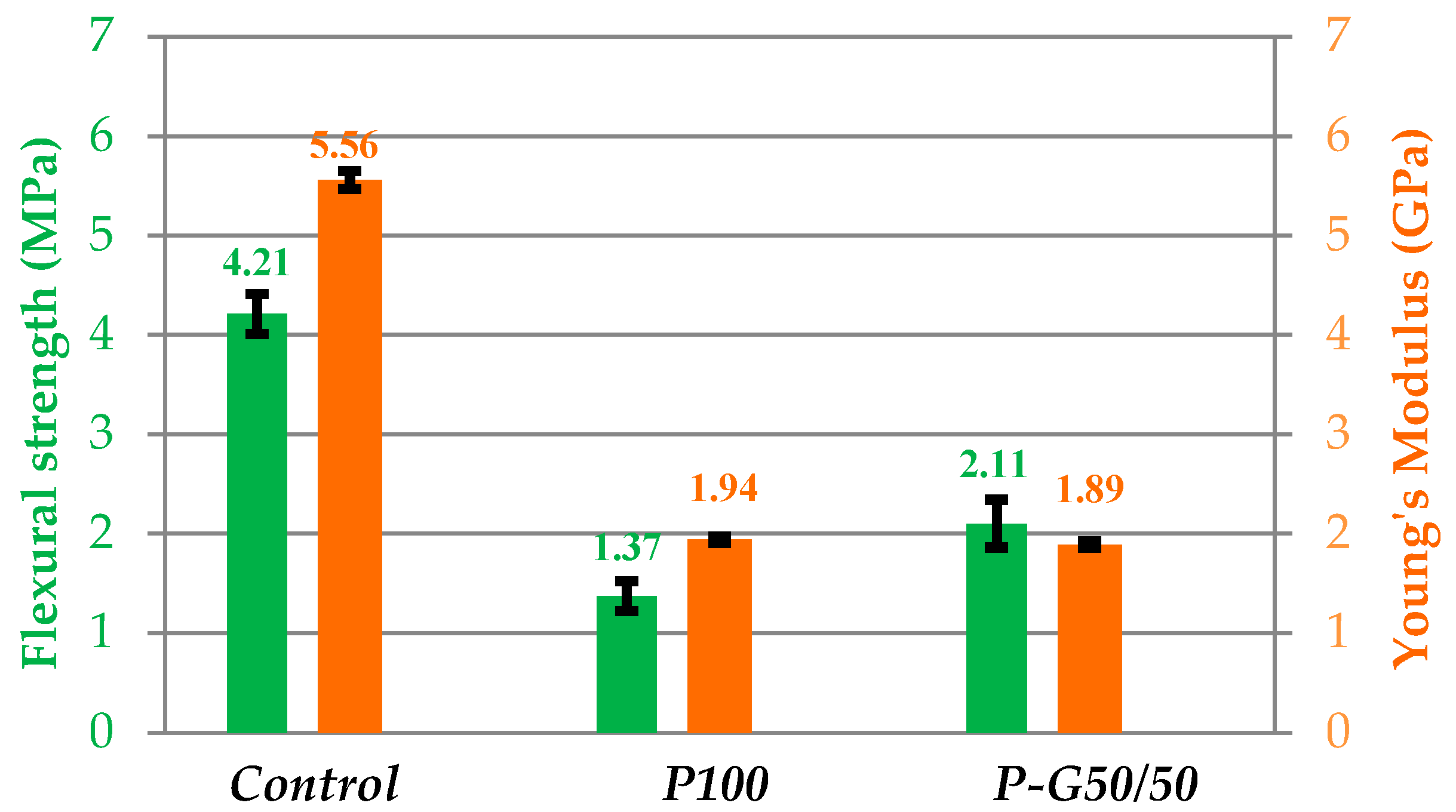

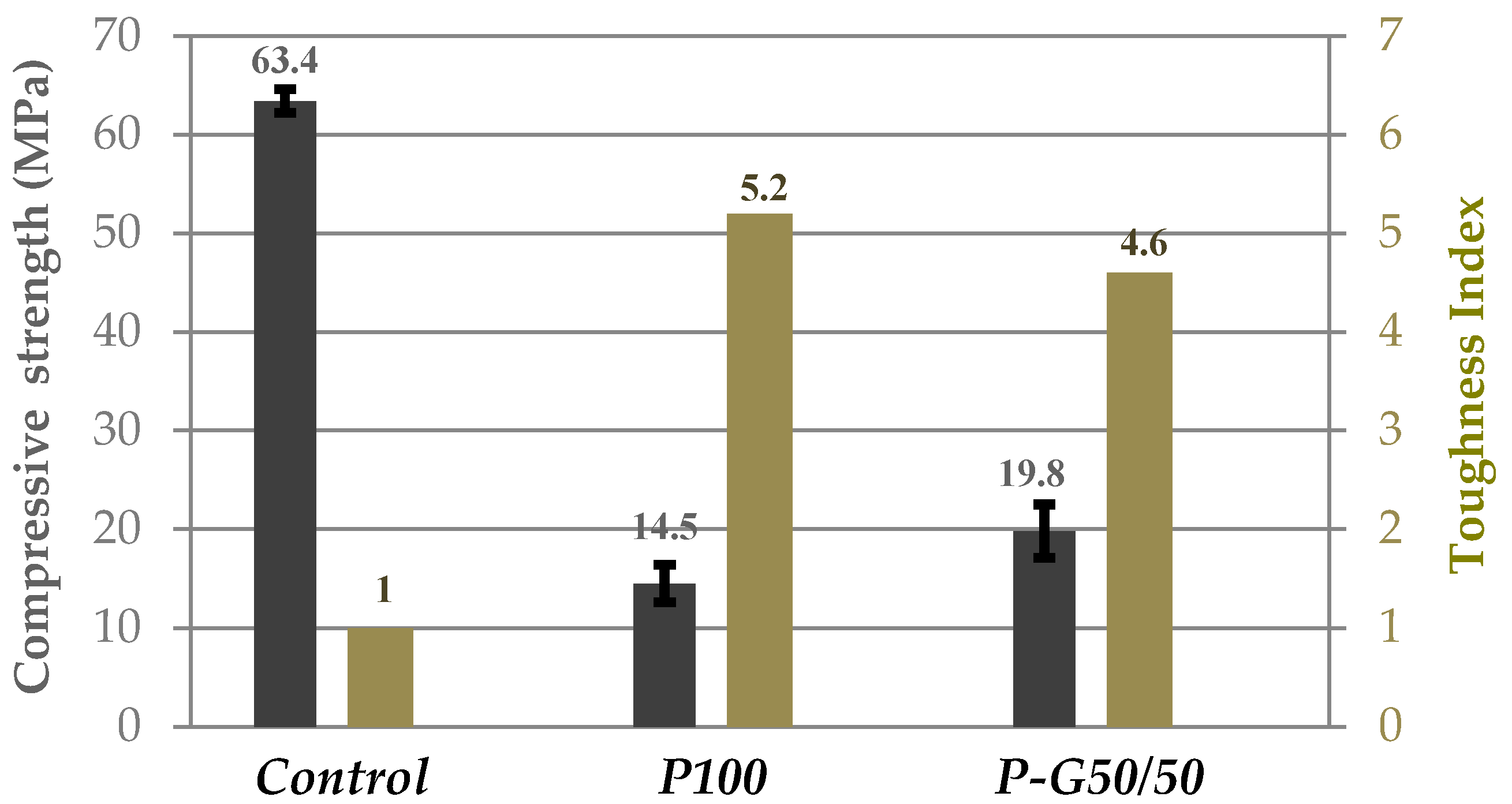

3.2. Mechanical Characterization: Four-Point Flexural and Uni-Axial Compressive Tests

- Weak adhesion between rubber particles and cement paste. This implies an ineffective load transfer mechanism between cement matrix and rubber fillers.

- Lower mechanical strength of the polymer aggregates than the cement matrix. Such performance discrepancy makes rubber particles as structural weakness sources.

- The non-polar character of the rubber fillers increases the air content in the mixtures (then decrease in bulk density), promoting the worsening in mechanical strength.

3.3. FEM-Based Mechanical Analysis: Solution and Results

4. Comparative Analysis of Tire Rubber-Cement Compounds Made by Casted and 3D Printing Methods

- Lightweight: The low density of rubberized mortars enables reduction dead-weight of structures and dimensions of building components (façade panels, slabs, block, non-structural elements). Weight reduction may reduce pre-cast elements transportation costs (less expensive handling and transporting equipment) as well as provide slender and spacious construction [56].

- Thermal insulation: The use of tire rubber in lightweight mortar allows the production of building materials with improved thermal efficiency. Pelisser et al. [57] evaluated the thermal performances of mortar panels, mainly for use in facades and signs. The addition of rubber aggregates gave the component a 15% higher thermal resistance than the standard material. This improved thermal insulation feature contributes to the achievement of energy efficiency, reducing operating costs through lower energy consumption.

- Vibroacoustic insulation: Lightweight rubber-cement mortars can be used for acoustic performance qualification in buildings for the impact and airborne noises. Concerning the sound transmission through a structure, rigid partitions that deform slightly before the vibration transmit the sound waves in a very short time. Elastomeric properties of tire rubber aggregates improve the material deformability, promoting the sound attenuation. Tutikian et al. [58] showed that the total replacement of mineral aggregates with polymeric aggregates results in an impact noise reduction of up to 15 dB.

- However, the possibility of using these compounds in AM methods represents an advanced technological upgrade. Preliminary comparison between the features of printable and casted rubberized mixes highlights some interesting effects brought by 3D printing, which can be key points in state-of-the-art context.

- Material rheology and physical-mechanical properties.

4.1. Sample Manufacturing Method and Material Homogeneity

4.2. Constructability

5. Discussion

5.1. Material Characterization

- The total sand-rubber replacement does not alter the proper mixtures printability. Working on the w/c ratio, it was possible to obtain rheological properties suitable for AM process. Mix designs of rubberized compounds show a lower water amount than the “standard” fresh mortar. This evidence implies less capillary porosity in hardened rubber-cement material.

- Rubber powder-based mix (P100) is slightly less porous and more compact than the “hybrid” mix (50% rubber powder—50% rubber granules). Due to the complex surface texture, the fine rubber fraction develops an optimal interface bond with the cement matrix. Conversely, coarse polymer aggregates provide weaker adhesion with cement, promoting voids in the ITZ.

- The incorporation of tire rubber particles as aggregates in cement-based compounds decrease the bulk density in cement mixtures. Density reduction is lower in rubberized compound with polymer particles of combined sizes (P-G50/50 mix) than that of mix with 100% rubber powder. The presence of rubber granules in the mixture significantly reduces the rate of trapped air. On the other hand, the high specific surface of rubber powder promotes the tendency to absorb gas, with a consequent decrease in the unit weight of the material.

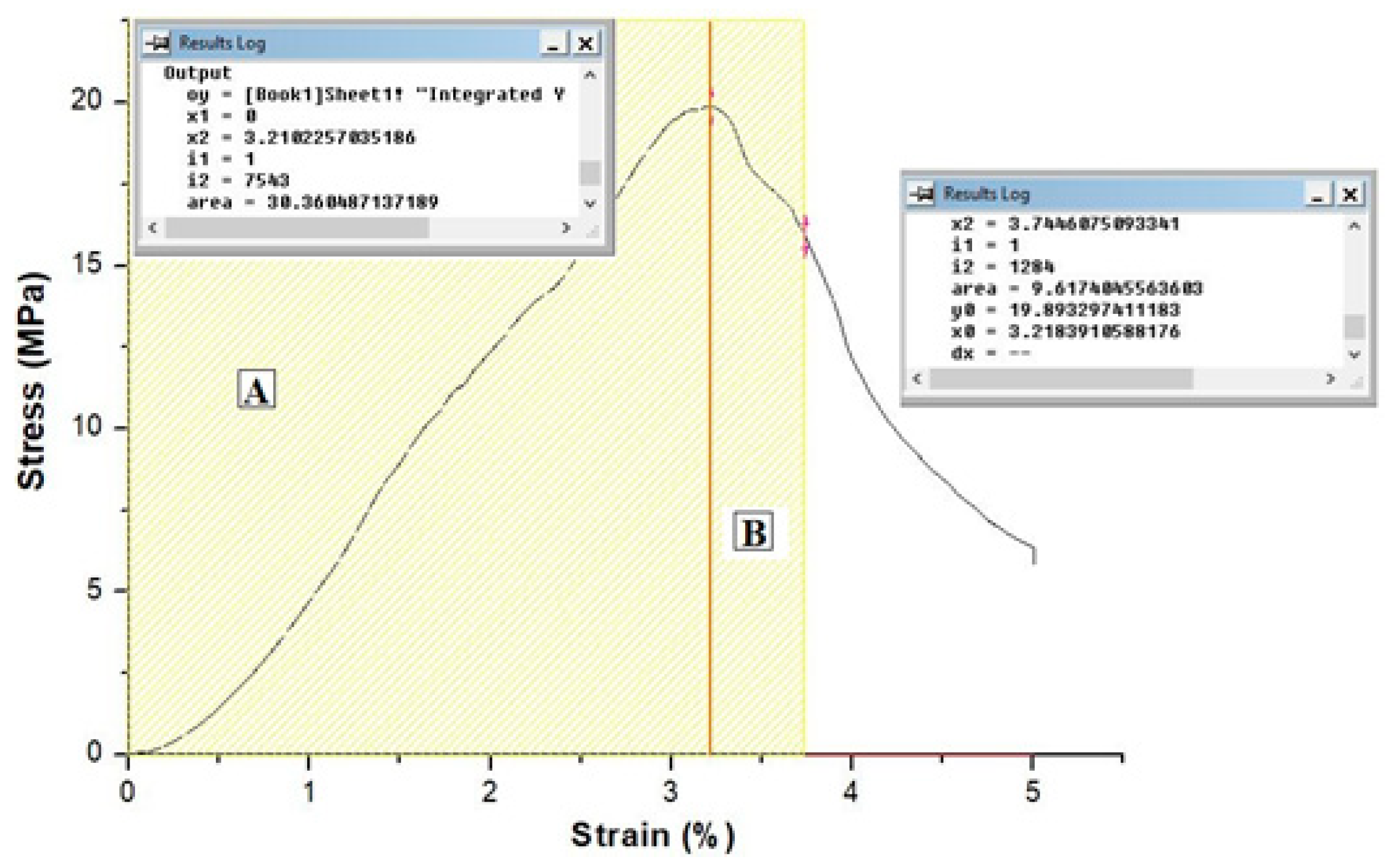

- In terms of mechanical properties, the rubberized samples showed a decrease in compressive strength, flexural strength, and Young’s modulus compared to the “neat” material. The lowest strength reduction was related to P-G50/50 sample. This result can be attributed to the positive synergy between the two rubber fillers. Rubber powder ensures the material compaction and therefore an efficient load transfer among cement matrix and rubber aggregates. Rubber granules reduce the quantity of trapped air in the material and provide a hindering action to cracks propagation. Rubberized mortar was more deformable than Control sample, but the particles size didn’t affect the elastic behavior.

- High Ti values suggest that the rubber-modified cement materials have greater cracking and fracture resistance to static load than Control mix.

5.2. FEM-Based Mechanical Analysis

5.3. Casted and Printed Rubber-Cement Compounds: Comparative Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Purdue University Materials Engineering. Available online: https://engineering.purdue.edu/MSE/aboutus/whatsmaterials (accessed on 20 March 2020).

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Hamouda, H. Effect of superplasticizer on workability of concrete containing crumb rubber. Civ. Environ. Res. 2015, 7, 35–43. [Google Scholar]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Chou, L.H.; Lu, C.K.; Chang, J.R.; Lee, M.T. Use of waste rubber as concrete additive. Waste Manag. Res. 2007, 25, 68–76. [Google Scholar] [CrossRef] [PubMed]

- El-Sherbini, Y.; Abdel-Gawad, A.K.; Shalaby, A.; El-Gammal, A. Compressive strength of concrete utilizing waste tire rubber. J. Emerg. Trends Eng. Appl. Sci. 2010, 1, 96–99. [Google Scholar]

- Valente, M.; Sibai, A. Rubber/crete: Mechanical properties of scrap to reuse tire-derived rubber in concrete; A review. J. Appl. Biomater. Funct. Mater. 2019, 17, 1–8. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Pang, S.S.; Eggers, J. Investigation into waste tire rubber-filled concrete. J. Mater. Civ. Eng. 2004, 16, 187–194. [Google Scholar] [CrossRef]

- Corbella, D.; Fernandez, F.; Hernández-Olivares, F.; Armisen, P. New designs of the ceramic bricks of horizontal hexagonal hollow. Res. Interact. Des. 2016, 84. [Google Scholar] [CrossRef]

- Guzman, A.D.M.; Munno, M.G.T. Design of a brick with sound absorption properties based on plastic waste & sawdust. IEEE Access 2015, 3, 1260–1271. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Method for the Enhancement of Buildability and Bending Resistance of 3D Printable Tailing Mortar. Int. J. Concr. Struct. Mater. 2018, 12, 37. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- ASTM C 67-03a. Standard Test Method for Sampling and Testing Bricks and Structural Clay Tile; American Society for Testing and Material: Philadelphia, PA, USA, 2003. [Google Scholar]

- Sambucci, M.; Marini, D.; Valente, M. Tire Recycled Rubber for More Eco-Sustainable Advanced Cementitious Aggregate. Recycling 2020, 5, 11. [Google Scholar] [CrossRef]

- ASTM C 1202. Standard Test Method for Electrical Indication of Concrete’S Ability to Resist Chloride Ion Penetration; Annual Book of ASTM Standards, Vol. 04.02; American Society for Testing and Materials: Philadelphia, PA, USA, 2002. [Google Scholar]

- ASTM C348-08. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM C109/C109M. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); American Society for Testing and Materials: West Conshohocken, PA, USA, 1999. [Google Scholar]

- ASTM C1018-97. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading) (Withdrawn 2006); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Khaloo, A.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire-rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef]

- Diaz, J.J.D.C.; Rabanal, F.Á.; Nieto, P.G.; Lopez, M.S. Sound transmission loss analysis through a multilayer lightweight concrete hollow brick wall by FEM and experimental validation. Build. Environ. 2010, 45, 2373–2386. [Google Scholar] [CrossRef]

- Bednarz, Ł.; Górski, A.; Jasieńko, J.; Rusiński, E. Simulations and analyses of arched brick structures. Autom. Constr. 2010, 20, 741–754. [Google Scholar] [CrossRef]

- Díaz, J.J.D.C.; Nieto, P.G.; Biempica, C.B.; Gero, M.P. Analysis and optimization of the heat-insulating light concrete hollow brick walls design by the finite element method. Appl. Therm. Eng. 2007, 27, 1445–1456. [Google Scholar] [CrossRef]

- IEEE Innovation at Work. Available online: https://innovationatwork.ieee.org/the-advantages-of-fem/ (accessed on 1 May 2020).

- Khatam, H.; Chen, L.; Pindera, M.J. Elastic and plastic response of perforated metal sheets with different porosity architectures. J. Eng. Mater. Technol. 2009, 131. [Google Scholar] [CrossRef]

- Cabezas, J.J.F. Mechanical properties of load bearing walls made of Uruguayan hollow ceramic bricks. Rev. Constr. 2015, 14, 15–21. [Google Scholar] [CrossRef][Green Version]

- Lacarrière, B.; Lartigue, B.; Monchoux, F. Numerical study of heat transfer in a wall of vertically perforated bricks: Influence of assembly method. Energy Build. 2003, 35, 229–237. [Google Scholar] [CrossRef]

- Sutcu, M.; Díaz, J.J.D.C.; Rabanal, F.P.Á.; Gencel, O.; Akkurt, S. Thermal performance optimization of hollow clay bricks made up of paper waste. Energy Build. 2014, 75, 96–108. [Google Scholar] [CrossRef]

- Lourenço, P.B.; Vasconcelos, G.; Medeiros, P.; Gouveia, J. Vertically perforated clay brick masonry for loadbearing and non-loadbearing masonry walls. Constr. Build. Mater. 2010, 24, 2317–2330. [Google Scholar] [CrossRef]

- Baronio, G.; Binda, L.; Charola, A.E. Deterioration of bricks with and eithout perforation due to salt crystallization. In Proceedings of the 7th International Brick Masonry Conference, Melbourne, Australia, 17–20 February 1985; Volume 1, p. 223. [Google Scholar]

- Willam, K.J.; Warnke, E.P. Constitutive models for the triaxial behavior of concrete. In Proceedings of the International Association Bridge Structures Engineering Seminar on Concrete Structures Subjected to Triaxial Stresses, Bergamo, Italy, 17–19 May 1974; Volume 19, pp. 1–30. [Google Scholar]

- Díaz, J.J.D.C.; Nieto, P.G.; Rabanal, F.Á.; Martínez-Luengas, A.L. Design and shape optimization of a new type of hollow concrete masonry block using the finite element method. Eng. Struct. 2011, 33, 1–9. [Google Scholar] [CrossRef]

- Musmar, M.A.; Rjoub, M.I.; Hadi, M.A. Nonlinear finite element analysis of shallow reinforced concrete beams using SOLID65 element. ARPN J. Eng. Appl. Sci. 2014, 9, 85–89. [Google Scholar]

- Hejazi, M.; Moayedian, S.M.; Daei, M. Structural analysis of Persian historical brick masonry minarets. J. Perform. Constr. Facil. 2016, 30. [Google Scholar] [CrossRef]

- Civiconcepts. Available online: https://civiconcepts.com/2019/12/tensile-strength-of-concrete-test-result (accessed on 2 May 2020).

- Shang, H.S.; Song, Y.P. Experimental study of strength and deformation of plain concrete under biaxial compression after freezing and thawing cycles. Cem. Concr. Res. 2006, 36, 1857–1864. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber–an overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Tiamlom, K. Expansion under water and drying shrinkage of rubberized concrete mixed with crumb rubber with different size. Constr. Build. Mater. 2012, 29, 520–526. [Google Scholar] [CrossRef]

- Valadares, F.; Bravo, M.; de Brito, J. Concrete with used tire rubber aggregates: Mechanical performance. ACI Mater. J. Am. Concr. Inst. 2012, 109, 283. [Google Scholar]

- RILEM. Functional Classification of Lightweight Concretes: Recommendation LC2, 2nd ed.; RILEM: Paris, France, 1978; pp. 281–282. [Google Scholar]

- Ünal, O.; Uygunoğlu, T.; Yildiz, A. Investigation of properties of low-strength lightweight concrete for thermal insulation. Build. Environ. 2007, 42, 584–590. [Google Scholar] [CrossRef]

- Ghizdăveț, Z.; Ștefan, B.M.; Nastac, D.; Vasile, O.; Bratu, M. Sound absorbing materials made by embedding crumb rubber waste in a concrete matrix. Constr. Build. Mater. 2016, 124, 755–763. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.H.; Chen, G.M.; Xie, Z.H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Bivanti, M.; Shtrepi, L.; Astolfi, A.; Volpatti, G.; Zampini, D. Pervious concrete as sound absorption material: Theoretical models used as a simple predictive tools for designers. RIA 2019, 43, 1–13. [Google Scholar]

- Skripkiunas, G.; Grinys, A.; Janavicius, E. Porosity and durability of rubberized concrete. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 1243–1253. [Google Scholar]

- Skripkiūnas, G.; Grinys, A.; Černius, B. Deformation properties of concrete with rubber waste additives. Mater. Sci. 2007, 13, 219–223. [Google Scholar]

- Pelisser, F.; Zavarise, N.; Longo, T.A.; Bernardin, A.M. Concrete made with recycled tire rubber: Effect of alkaline activation and silica fume addition. J. Clean. Prod. 2011, 19, 757–763. [Google Scholar] [CrossRef]

- Sofi, A. Effect of waste tyre rubber on mechanical and durability properties of concrete–A review. Ain Shams Eng. J. 2018, 9, 2691–2700. [Google Scholar] [CrossRef]

- Grinys, A.; Sivilevičius, H.; Daukšys, M. Tyre rubber additive effect on concrete mixture strength. J. Civ. Eng. Manag. 2012, 18, 393–401. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials 2016, 9, 172. [Google Scholar] [CrossRef]

- Li, L.J.; Tu, G.R.; Lan, C.; Liu, F. Mechanical characterization of waste-rubber-modified recycled-aggregate concrete. J. Clean. Prod. 2016, 124, 325–338. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef] [PubMed]

- American Society for Testing and Materials. Specification for Load Bearing Concrete Masonry Units; ASTM: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Astiaso Garcia, D.; Cumo, F.; Tiberi, M.; Sforzini, V.; Piras, G. Cost-Benefit Analysis for Energy Management in Public Buildings: Four Italian Case Studies. Energies 2016, 9, 522. [Google Scholar] [CrossRef]

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- Pelisser, F.; Barcelos, A.; Santos, D.; Peterson, M.; Bernardin, A.M. Lightweight concrete production with low Portland cement consumption. J. Clean. Prod. 2012, 23, 68–74. [Google Scholar] [CrossRef]

- Tutikian, B.F.; Nunes, M.F.O.; Leal, L.C.; Marquetto, L. Impact sound insulation of lightweight concrete floor with EVA waste. Build. Acoust. 2012, 19, 75–88. [Google Scholar] [CrossRef]

- Atahan, A.; Yücel, A.Ö. Crumb rubber in concrete: Static and dynamic evaluation. Constr. Build. Mater. 2012, 36, 617–622. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Du, Q.; Wu, H. Effects of rubber particles on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 2015, 91, 145–149. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928. [Google Scholar] [CrossRef]

| Mix Design | P100 | P-G50/50 |

|---|---|---|

| Cement [kg/m3] | 800 | 800 |

| Water [kg/m3] | 260 | 250 |

| w/c ratio | 0.325 | 0.312 |

| Sand [kg/m3] | 0 | 0 |

| Silica fume [kg/m3] | 120 | 120 |

| Rubber pwd. [kg/m3] | 300 | 150 |

| Rubber gran. [kg/m3] | 0 | 160 |

| Additives [kg/m3] | 32 | 32 |

| Material Property | Symbol | Property Group | Evaluation |

|---|---|---|---|

| Density | ρ | Basic | Experimental |

| Porosity | P | Basic | Experimental |

| Young’s modulus | E | Basic | Experimental |

| Uniaxial compressive strength | σc | Basic/WW criterion | Experimental |

| Uniaxial tensile strength | σt | WW criterion | Empirical |

| Biaxial compressive strength | σbc | WW criterion | Empirical |

| Material Property | Symbol | Value | Property Group | Evaluation |

|---|---|---|---|---|

| Density | ρ | 1624 kg/m3 | Basic | Experimental |

| Porosity | P | 0.261 | Basic | Experimental |

| Young’s modulus | E | 1.89 GPa | Basic | Experimental |

| Uniaxial compressive strength | σc | 19.8 MPa | Basic/WW criterion | Experimental |

| Uniaxial tensile strength | σt | 2.38 MPa | WW criterion | Empirical |

| Biaxial compressive strength | σbc | 23.8 MPa | WW criterion | Empirical |

| Brick Design | σc (MPa) | Strength Reduction Rate | E (GPa) | Young’s Modulus Reduction Rate |

|---|---|---|---|---|

| Std. brick | 21.2 | - | 1.87 | - |

| CS brick | 15.1 | 28.8% | 1.22 | 34.8% |

| SS brick | 13.4 | 36.8% | 1.22 | 34.8% |

| HS brick | 15.0 | 29.2% | 1.21 | 35.3% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valente, M.; Sambucci, M.; Sibai, A.; Musacchi, E. Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis. Sustainability 2020, 12, 5993. https://doi.org/10.3390/su12155993

Valente M, Sambucci M, Sibai A, Musacchi E. Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis. Sustainability. 2020; 12(15):5993. https://doi.org/10.3390/su12155993

Chicago/Turabian StyleValente, Marco, Matteo Sambucci, Abbas Sibai, and Ettore Musacchi. 2020. "Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis" Sustainability 12, no. 15: 5993. https://doi.org/10.3390/su12155993

APA StyleValente, M., Sambucci, M., Sibai, A., & Musacchi, E. (2020). Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis. Sustainability, 12(15), 5993. https://doi.org/10.3390/su12155993