Abstract

Starting from an experimental activity, the paper describes research analysis that has been conducted on a real case construction with the aim to design its adaptation as a nearly zero energy building in three possible alternative scenarios: (i) a lab for students’ activities in the Lecco University Campus of Politecnico di Milano; (ii) an Alpine shelter for the implementation of a sustainable mountain tourism in Zermatt; (iii) an emergency shelter for poor communities in Burkina Faso. The use of an easily disassembled and lightweight steel structure coupled with dry-layered technologies allows a tailor-made envelope design, ensuring high thermal comfort, very low energy use, and limited construction times. The three case studies have been designed starting from the same architectural/structural concept. A detailed analysis, by means of finite element method and dynamic building thermal simulations, has been performed to predict the overall performances of each case study. The results show: (i) high replicability of the concept; (ii) high customization of the envelope technologies; (iii) high energy efficiency; and (iv) high thermal comfort of the architecture. The useful energy requirement in all the three analyzed scenarios is minimized and equal to 14.13, 23.88, and 41.83 kWh/m2 year, respectively, for the students’ lab, the Alpine shelter and the emergency shelter. According to this study the energy needs can be covered by renewable energy produced on site, making the architectural concept an interesting modular lightweight solution for a nearly zero energy building with high potential for replicability.

1. Introduction

The increasing awareness on climate changes and the latest EPBD recast 844/2018/UE [1] are stimulating new approaches in the building design process, renewable energies integration and their upcycle at the end-of-life through the concept of nearly zero energy buildings (nZEB) [2,3], which are the main stream quality in the architecture, engineering and construction industry. Various researches and assessments [4] illustrate a worrying environmental trend at a global level that are tightly linked to the process of industrialization, which implies a significant increase in the use of energy, materials and related CO2 emissions, and intensifying the competition for raw materials [5]. The EU buildings stock is relatively old, with more than 40% of them built before 1960 and 90% before 1990 [6]. To be in compliance with the EU decarbonization target [7], building renovation must become a very current practice in the next years, rather than new construction. Moreover, since buildings must keep their efficiency over time, a long-term vision for building renovation must be designed [8,9].

In this context, designers should not only seek to lower the operating energy through better insulation and by the production of energy on-site [10,11], but also lower the embodied energy of building materials, allowing their dismounting with possible reuse. The environmental impact of the building materials used arises at various stages of a building lifespan: construction, operation and demolition; for these reasons, designers should also consider the overall resources efficiency [12]. The operating energy accounts for more than 80% of the total energy use [13], its relative analysis has dominated building energy researches for many years when compared to the analysis of the embodied energy. In the last decade, the significant role of embodied energy and emissions has been recognized as a relevant topic [14,15]. This is mainly due to: (i) the increasingly restrictive building regulation [16] and more energy efficient building technologies [17], the percentage of operational energy and its related carbon emissions are expected to decrease in the future [18]; (ii) the increasing use of building materials characterized by high quantity of embodied energy stored (e.g., thermal insulator materials) [19,20] and (iii) the development and commercialization of reliable and easy to use tools to deal with Life Cycle Assessment (LCA) concept and embodied energy issues.

In light of this, the buildings design should take into account the “3R-process: reduce—reuse—recycle”. This approach can lead to architectures with low environmental impact as a whole, that represent the basis of the design for disassembly approach (DfD). The approach has been applied with high success in several real cases, showing, on one hand the high potential of success, and on the other hand how the overall design process must be modified with respect to the actual construction practice [21,22]. This DfD concept was first defined in the 1990s, but the general idea was introduced earlier with the Crystal Palace at Sydenham, built in London for the Great Exhibition of 1851. Made of cast iron and glass, the building was designed to be temporary, simple, and easy to transport. After the Exhibition the modular structure was packed up and moved to South London for reassembly, and it remained there until its destruction, in 1936, due to a fire. Several other examples have been developed during the Modernist movement [23]. In 1923, Le Corbusier introduced the concept of “house as a machine for living” as a mass-produced architecture based on rationalization through prefabrication [9]. In 1932, the term was first used in the same way by Frank Lloyd Wright introducing the “assembled house” concept, consisting of modular units. Following some of the ideas of Modernism, Richard Buckminster Fuller developed the idea of “dymaxion house”, as an example of a modular lightweight and high energy efficient construction. Starting from this example, the concept has been in the latest years further developed showing several benefits, including easy repair or upgrade if needed to extend its useful life, recycling at the end of its life span and reuse in case of change in needs. The DfD is also known as technical metabolism: this endless cycle turns the reused and recycled waste into “nutrients” for new buildings [24]. The key principles of DfD include: (i) proper documentation of materials and methods for deconstruction; (ii) design the accessible connections and jointing methods in order to ease the dismantling e.g., minimizing chemical or welding connections and using bolted, screwed and nailed connections for the assembly of prefabricated and/or modular structures; (iii) separate non-recyclable, non-reusable and non-disposable items, such as mechanical, electrical and plumbing; (iv) design simple structures and forms that allow the standardization of components and dimensions; and (v) design that reflects labor practices, productivity and safety [25]. From the social impact point of view the concept has a high potential in creating jobs for unskilled workers since, unlike demolition, there is no heavy equipment, nor specific tools or skills required. The approach has, moreover, the potential to revolutionize the future of architecture: closed-loop construction systems have not only a lower ecological footprint, but they also encourage innovation and produce unique aesthetics [26].

In this context, the paper reports the potential reuse of a temporary pavilion, “Delight the Light”, initially conceived as a press room for the event “in-Habits” during the Milan Design Week 2018, into a permanent nZEB open lab for university students at the Lecco Campus of Politecnico di Milano [27]. The present study investigates different building configurations for different climates (cold, temperate, and hot), highlighting the building modifications needed in order to ensure high comfort levels with minimum energy requirement. The concepts of disassembly, reuse, and recycle have been intrinsically presented, showing how the dry-layered envelope construction coupled with a modular steel frame structure can be successfully applied for different purposes. The modularity shows how the modules can be assembled into complete entities by combining them in several different ways. The paper also shows how the use of a lightweight structure with dry assembled materials is a fundamental requirement for the DfD approach, and how it forces the designer to think about all the phases of the building life since the very beginning of the project. All the different aspects were analyzed, ranging from the technological analysis to the energy performance, in order to verify the feasibility of the adaptation, increasing the envelope performances. In detail, three possible configurations have been studied, starting from the same architectural design: Alpine Shelter, open lab and emergency shelter.

2. Methodology

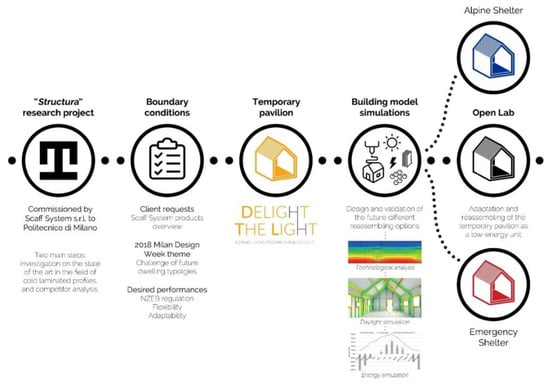

The present paper takes its inspiration from the results of a wider research work, called “Structura”, commissioned by Scaff System s.r.l. [28] to Politecnico di Milano. The company, a leader in the production of lightweight steel structures and mainly used for logistic purposes (e.g., industrial free-standing modular storage systems) and industrial buildings, set up a research program to extend the use of its brand products to the architectural building sector. The first step to envisage new market branches was a detailed investigation on the state of the art in the field of cold laminated profiles, as well as a competitor analysis, in order to compare the different Scaff System technical solutions to the main competitive products on the market. On the wave of the “Structura” research project, the concept idea for the “Delight the Light” pavilion combines the results of Scaff System products overview with the 2018 Milan Design Week theme, focused on the challenge of future dwelling typologies. A holistic optioneering process has been then followed, taking into account nZEB regulations, client requests and the event needs, in order to study and verify the feasibility and construction of the pavilion in Milan. After the event, the unit has been disassembled and the building components have been brought to the Politecnico di Milano campus storage, in view of a future reassembling. For that purpose, different ideas have been proposed and considered, resulting in the recent adaptation of the temporary pavilion to its new function: an open lab for university students. On this premise, the present paper goes through all the steps that led to the final construction of the unit, analyzing and discussing the various adaptation options that have been proposed as well as the results of the different building model simulations performed, which proved to be essential for the reach of the low-energy target. The whole approach is outlined in Figure 1.

Figure 1.

Schematic representation of the analysis methodology and its evolution step by step.

3. The “Delight the Light” Temporary Pavilion

The “Delight the Light” pavilion was developed for Officina Tamborrino (Scaff System brand) in compliance with the 2018 Milan Design Week event theme called “What about the future of the dwelling typologies?” On that wave, the unit has been designed to concretely answer to the need of a dwelling typology for the future: born as a temporary structure but meant to have a new life after the event. During the Design Week, the pavilion proved to be an excellent working space with the perfect daylighting during the day, and a fascinating light-house during the night, welcoming journalists as well as the technical staff of the Design Diffusion World (DDN) magazine in the prestigious setting of Castello Sforzesco, nearby the city center (Figure 2).

Figure 2.

“Delight the Light” temporary pavilion at 2018 Milan Design Week (INHABITS event–Milano Design Village).

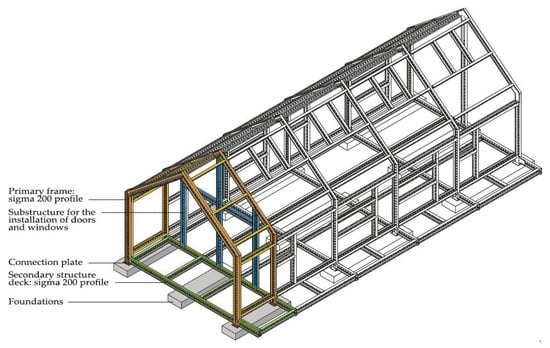

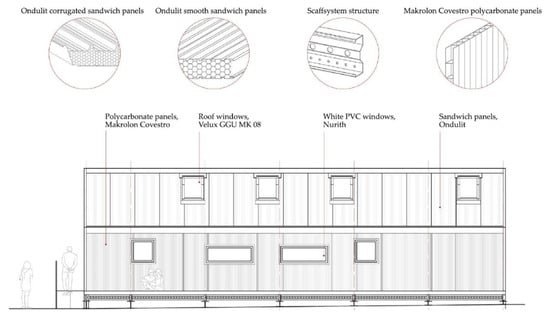

The pavilion has been designed as a modular, flexible and easy-to-assemble hut-shaped unit (Figure 3), that features innovative technological solutions and materials, such as a lightweight steel frame structure (Figure 4) and dry-layered envelopes, with sandwich panels and polycarbonate claddings, as exemplified in Figure 5.

Figure 3.

Construction of the “Delight the Light” temporary pavilion.

Figure 4.

Structural design of the modular unit.

Figure 5.

Identification of the main envelope elements featured in the “Delight the Light” pavilion.

The chosen materials, solutions and technologies have allowed the building to reach the expected internal comfort, as well as the acoustic and low-energy targets. Besides, the structural solution adopted has proved to be the best option for temporary or emergency units, resulting in very quick and efficient assembly/disassembly procedures.

Structural Flexibility and Modularity

Besides being quick to assemble, the pavilion is also very focused on high energy efficiency. The glazed portions and roof windows support natural ventilation and ensure a high influx of natural light and significant passive energy gains in the winter season. At the same time, ventilated facades, PV and solar panels allow the unit to be more self-sustaining.

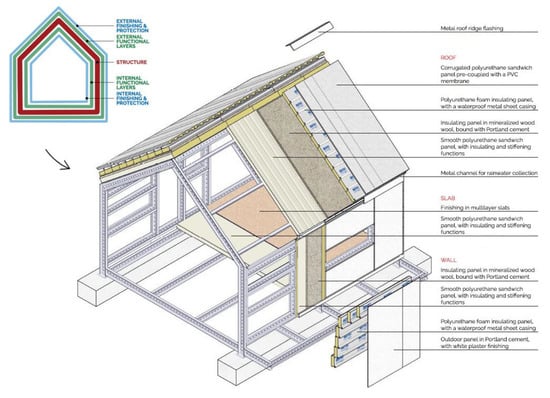

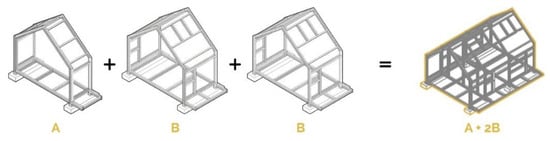

The pavilion also features dry-layered envelopes, composed by addition of independent layers, chosen to give focused performances, pre-engineered and built on site with dry and mechanical connectors. Dry-layered systems are conceived as composed of distinct and independent units: external envelope, structure, and internal envelope (Figure 6). In that way, to ensure optimal flexibility and adaptability, the building envelope can be designed and assembled ad hoc, according to the climate, location and function of the unit, and the pavilion itself is conceived as a sum of different smaller modules, “Module A” (1.6 m × 4.7 m, for a total of 7.5 m2) and “Module B” (2.7 m × 4.7 m, for a total of 12.7 m2), as represented in Figure 7.

Figure 6.

Dry-layered systems: axonometric representation of one of the various suitable dry-layered technological solutions for the pavilion.

Figure 7.

Key concepts in the unit design are its modularity, flexibility and ease to assemble.

4. From a Temporary Pavilion to Low Energy Permanent Buildings

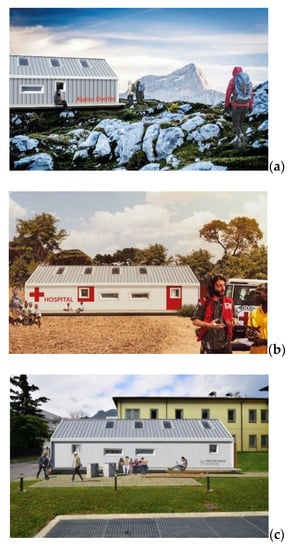

As mentioned at the beginning of the present paper, the final aim of the “Delight the Light” temporary pavilion was to make the most of its peculiar features, referring especially to its modularity, adaptability and ability to disassemble, in order to avoid its permanent dismantling after the 2018 Milan Design Week, in favor of a better and brighter future as a low-energy permanent building. For that purpose, this paper presents not only the actual re-adaptation of the temporary pavilion into an open lab for university students in Lecco, Italy (subchapter 4.2), but also two other scenarios in extremely diverse climates: an Alpine shelter in Zermatt, Switzerland and, considering the results of previous research work [29] as well as the constant great need for quick-assembly emergency units in the region, an emergency shelter in Pô, Burkina Faso (Figure 8a–c). For each of these scenarios, the thermal behavior of the slab, roof and wall stratigraphies has been optimized taking into account the three very different climate conditions, focusing, in particular, on achieving excellent winter performances in the Alpine climate of Zermatt (CH), optimal summer performances in the extremely hot weather of Pô (BF), and taking into consideration both seasons in the temperate climate of Lecco (IT).

Figure 8.

Render views of the three different scenarios analyzed, respectively: (a) Alpine shelter in Zermatt, Switzerland; (b) Emergency shelter in Pô, Burkina Faso; (c) open lab in Lecco, Italy.

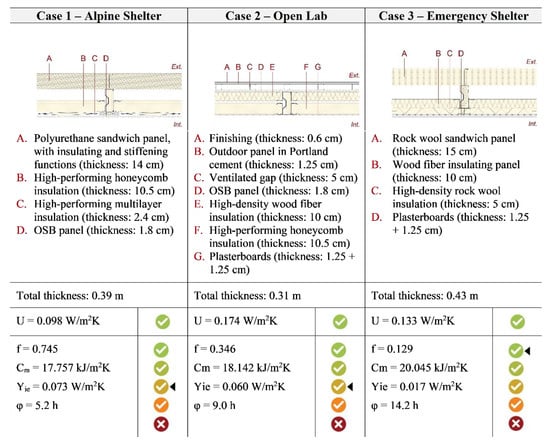

4.1. Building Envelope Design

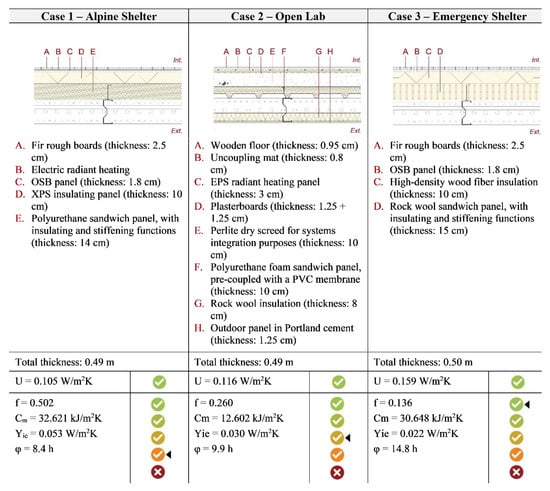

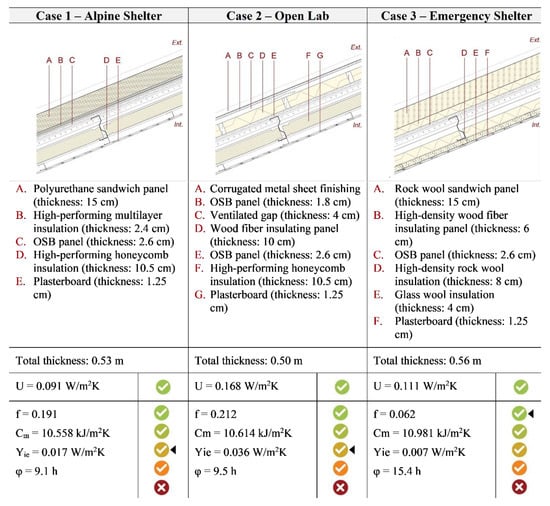

As mentioned above, thanks to its modularity and disassemblability, the unit can be designed to adapt to many different climates and countless functions, such as housing, commercial, classroom, emergency unit, building extension, tourist facility, and so forth. In this perspective, starting from the same architectural design of the “Delight the Light” pavilion and keeping the modular steel structure as a constant, several different technological solutions have been studied and proposed, as exemplified in Figure 9, Figure 10 and Figure 11, respectively for slabs, roofs and walls. With a view to implementing those strategies in future re-adaptations of the pavilion, for each building envelope, the main thermal parameters have been calculated and listed in the respective tables below, amongst those: heat transfer coefficient U (W/m2K), decrement factor f (-), internal areal heat capacity Cm (kJ/m2K), periodic thermal transmittance Yie (W/m2K), and time lag φ (h).

Figure 9.

Dry-layered slab: performances evaluated according to the two main Italian Ministerial Decrees for energy performances calculation and minimum requirements for buildings, D.M. 26/06/15 and D.M. 26/06/09.

Figure 10.

Dry-layered slab: performances evaluated according to D.M. 26/06/15 and D.M. 26/06/09.

Figure 11.

Dry-layered wall: performances evaluated according to D.M. 26/06/15 and D.M. 26/06/09.

Considering the actual re-adaptation of the pavilion, to be reassembled as an Open Lab for university students in Lecco (IT), the performance evaluation of the different stratigraphies has been made according to the two main Italian Ministerial Decrees for energy performances calculation and minimum requirements for buildings: D.M. 26/06/15 and D.M. 26/06/09 [30] (Table 1), for winter and summer performances respectively.

Table 1.

Summer performance evaluation (D.M. 26/06/09).

Therefore, the building envelope design has been carried out considering on one hand the performance parameters and on the other hand the climate context and the specific use of the building altogether. In the Alpine weather of Zermatt (CH), for example, the roof and wall stratigraphy’s implement high-performing thermo-reflective insulation materials derived from aerospace technologies, assuring high levels of thermal insulation in minimum thicknesses.

As far as the different materials used for the calculation of the building envelope parameters shown above, their main thermal properties are listed in Table 2, Table 3 and Table 4, respectively for slabs, roofs and walls layers. All the properties of the different materials have been found on their respective technical sheets, provided by the manufacturer and therefore representative of their real properties.

Table 2.

Slab materials and thermal properties.

Table 3.

Roof materials and thermal properties.

Table 4.

External wall materials and thermal properties.

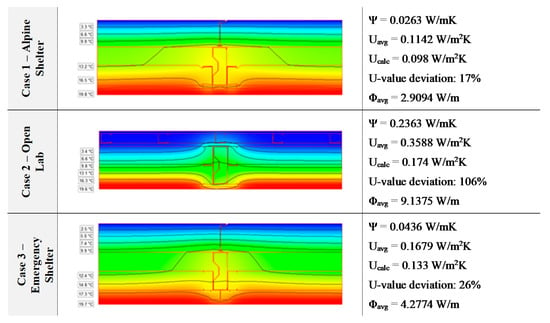

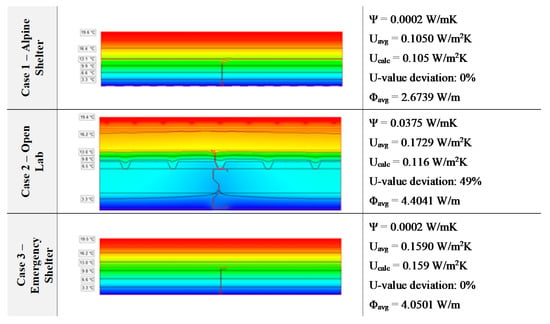

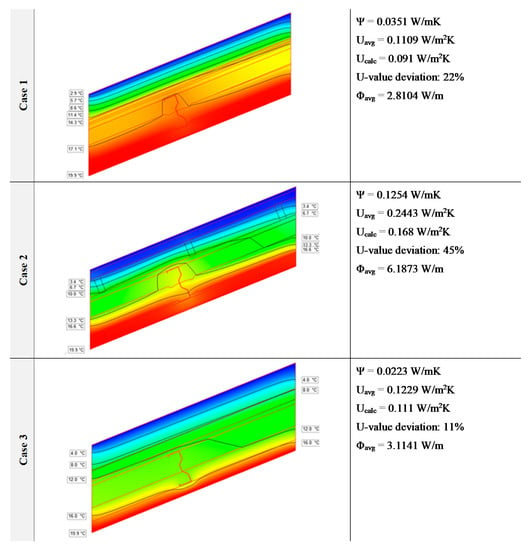

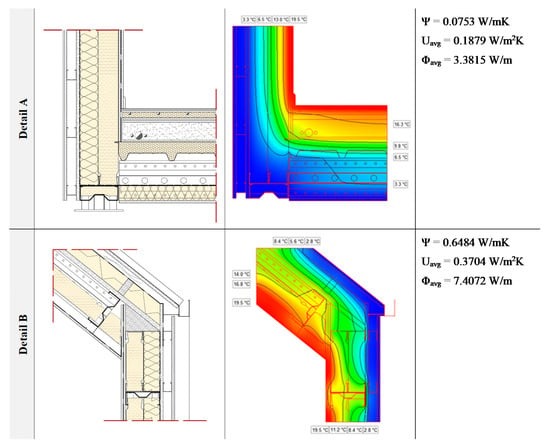

With the aim of reaching a low-energy target for the unit, finite elements calculations of the various scenarios shown above have been carried out in order to verify the thermo-hygrometric performances of the different solutions, previously calculated only through static calculations on homogeneous layers. The FEM (finite element model) analysis has been performed using the software Dartwin Mold Simulator 5 [31], according to the current legislation (ISO 10211:2008–ISO 13788:2013), with baseline conditions such as local climatic parameters, with critical temperature (0 °C–20 °C) and critical relative humidity level (80%). The software allows to calculate the linear thermal transmittance of any thermal bridge, directly from the drawing, as well as to evaluate the heat loss due to thermal bridges in walls, roofs, pillars, slabs, window openings and any other building structure; the Dartwin Mold Simulator FEM analysis also allows to prevent critical mistakes during the design phase, evaluating in advance the risk of mold growth on building surfaces, and highlighting any area that can be affected by surface or interstitial condensation.

FEM thermal calculation results are shown in Figure 12, Figure 13 and Figure 14, respectively for external wall, slab and roof solutions. Considering the envelope technology, composed by the integration of non-homogenous layers, the FEM analysis is a fundamental approach for optimizing the performance of the building component. In all three case studies, the thermal transmittances obtained through FEM analysis (Uavg) have been compared to the values calculated according to the EN ISO 6946:2018 [32] (Ucalc), in order to get a more readily comparable deviation rate: this process revealed small deviations in “Case 1” and “Case 3” (ranging from 0% to 22%, and 0% to 26%, respectively), but also a remarkable deviation value in “Case 2” (between 45% and 106%, therefore resulting in bigger Uavg-values). The same reasoning applies for the comparison on liner thermal transmittances (Ψ) between the three cases, that shows low values in “Case 1” and “Case 3” (always lower than 0.05 W/mK, almost nil in the case of slabs in particular), but again, greater values in “Case 2” (especially for wall and roof stratigraphies, that show values of about 0.24–0.25 W/mK). The presence of a diffuse steel structure, in fact, can lead to a diffuse thermal bridge formation, difficult to detect using the standard calculation. The presence of thermal bridges reduces the overall resistance of the technical element increasing the heat flux concentration with high probability of local material degradation.

Figure 12.

Wall FEM thermal analysis.

Figure 13.

Slab FEM thermal analysis.

Figure 14.

Roof FEM thermal analysis.

4.2. The Open Lab Case Study

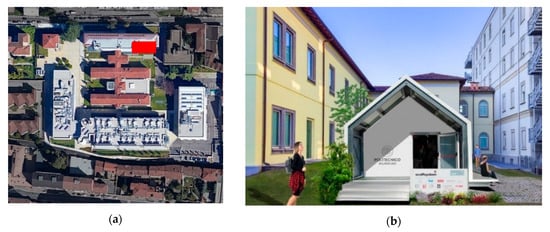

The present paragraph focuses on the actual re-adaptation of the temporary pavilion, exploring some of the additional studies and analysis that were conducted, such as the different seasonal schematic designs of the unit, to ensure the optimization of all passive and active strategies, the cross section of the building, for constructive design purposes as well as to check the consistency of the envelope stratigraphies chosen, and the FEM analysis of the two most critical section details. The unit, in fact, will be converted into an open lab for university students, in the Lecco campus of Politecnico di Milano (Figure 15). The 70 sqm pavilion’s unique design blends in perfectly with the existing campus buildings, while contributing to the regeneration of secluded areas available to the students.

Figure 15.

(a) Satellite view of the Politecnico di Milano, Lecco campus; (b) render of the open lab.

A very detailed and specific design process has been followed with the aim of reusing the majority of the existing elements, while optimizing passive strategies and implementing on-site renewable energy production, in order to reach the low-energy target.

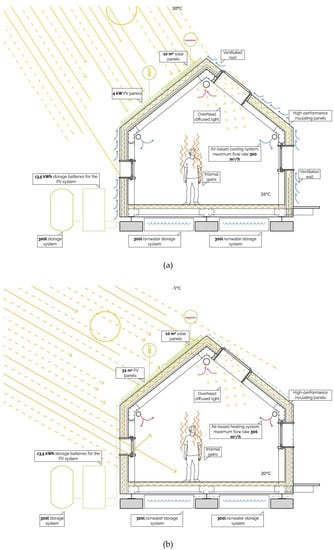

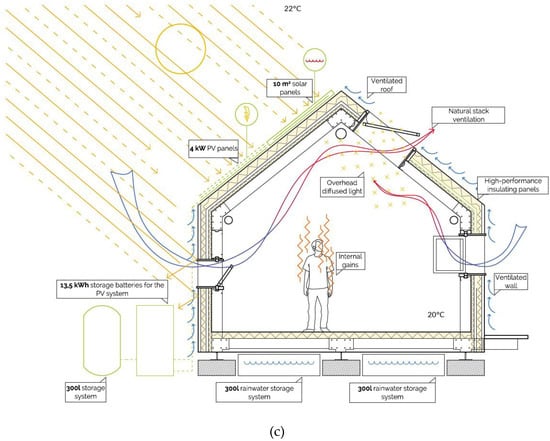

The main solutions adopted are outlined in the schematic designs in Figure 16, respectively for summer, winter, and mid-season. Thanks to the strategies outlined in the schematic designs, as well as to the high-performing envelope solutions studied above, the unit is able to adapt and meet the changing needs of the different seasons, benefitting from free solar gains to cut energy need during winter, and reducing them in the summertime through the use of movable solar screens on the glazing areas, lessening the need for active cooling systems. In the intermediate seasons, the open lab can also take advantage of natural stack and cross ventilation, in order to obtain optimal CO2 levels and to expel exhaust air. The unit also implements air-based heating and cooling systems, in order to adjust both temperature and humidity, achieving high levels of internal comfort. The 10 m2 solar panel system is designed to meet the building needs for sanitary water, while an electrical heat pump, connected to 4 kW of photovoltaic panels and 13.5 kWh of storage batteries, provides the additional energy required for the optimal operation of the building, reaching the low-energy target with zero local CO2 emissions.

Figure 16.

Schematic design, respectively: summer (a), winter (b) and mid-season (c).

As far as the chosen envelope strategies, the unit features dry-layered slab, roof and walls, presented as “Case 2” in Figure 9, Figure 10 and Figure 11, composed by addition of independent and selected layers, in order to give focused performances while maintaining the overall lightness. The thermal behavior of all three stratigraphies is optimized for the local climate, taking into account both winter and summer climate conditions, with excellent heat transfer coefficient U values, ranging from 0.116 to 0.174 W/m2K, great periodic thermal transmittance Yie, varying between 0.030 and 0.060 W/m2K, and good time shift φ, ranging between 9.0 and 9.9 h.

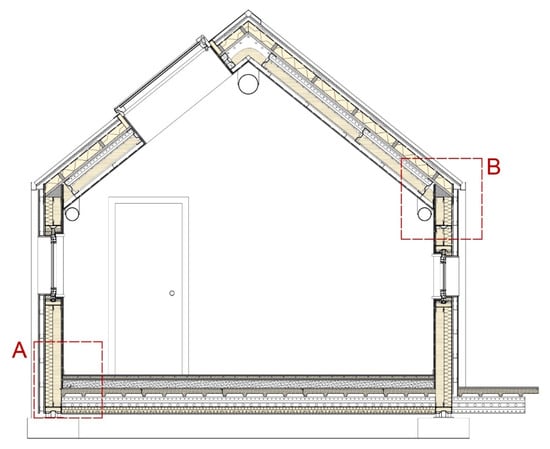

Finite elements calculations of the most critical details have also been performed, in order to verify the thermo-hygrometric performances of the open lab envelopes, previously calculated only through static calculations on homogeneous layers. As previously mentioned, the analysis has been carried out using the software Dartwin Mold Simulator 5 [31], according to the current legislation (ISO 10211:2008–ISO 13788:2013), with baseline conditions such as local climatic parameters, with critical temperature (0 °C–20 °C) and critical relative humidity level (80%). FEM thermal analysis has been conducted on the most critical section details, as highlighted in Figure 17; the FEM calculation results are shown in Figure 18.

Figure 17.

Open Lab cross section.

Figure 18.

FEM thermal analysis of the most critical section details, highlighted in Figure 17.

5. Performance Analysis of the Units

This section introduces the building model characteristics considered when analyzing the unit through dynamic simulations, for energy need estimation purposes. TRNSYS v18 [33] simulation environment has been used in order to study and evaluate the effect of both thermal inertia and resistivity of the previously designed envelope technologies. All the different simulations have been carried out on a yearly basis with a 60-min time step, to show in detail the responses of the building system to internal and external loads. The 60-min time step has been selected according to the ISO 52016-1:2017. The main goal of the hourly calculation method is to take into account the influence of hourly and daily variations in weather, operation (solar blinds, thermostats, needs, occupation, accumulation, etc.) and their dynamic interactions for heating and cooling. The building model has been considered to be working in free-floating temperature variation, in order to analyze the impact of the technological and architectural design in reference to the specific climate contexts and the different human-building interactions.

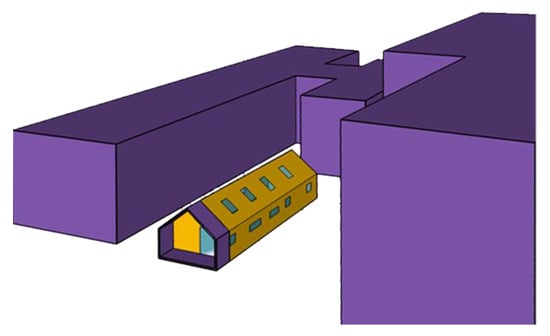

The building geometry has been modeled using the Trnsys3d plug-in for SketchUp, considering the unit as a single thermal zone. As exemplified in Figure 19 for the open lab in the Lecco campus, the different unit models have been placed in their new respective contexts, in order to take—within simulation assessments—also of their specific climatic contexts and of potential surrounding buildings, that would impact with both massing and shadows on the thermal and daylight performances of the units.

Figure 19.

SketchUp model of the open lab unit, for thermal and lighting analysis purposes.

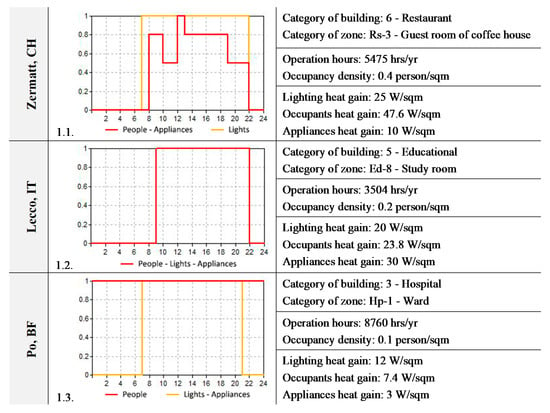

All the different schedules and boundary conditions of the buildings for energy calculation purposes, especially in terms of space usage and internal heat gains, have been set in accordance with ISO 18523-1:2016 [34], as shown in Figure 20.

Figure 20.

Energy calculation boundary conditions, respectively internal heat gains schedules, and ISO 18523-1:2016 reference space usage.

6. Results and Discussion

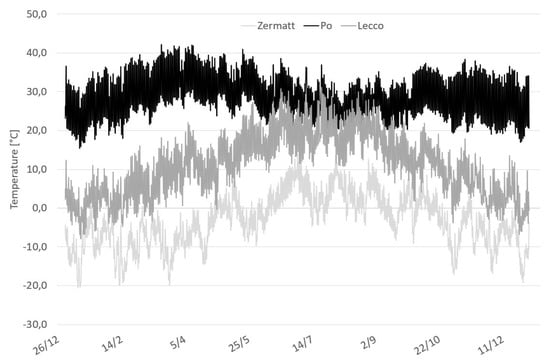

The following section presents the results of the simulations that have been carried out on all three case studies previously identified. The approach considers the implementation of several energy conservation measures, aiming to increase the thermal comfort and to reduce the energy needs. The overall efficiency of the building has been analyzed considering its response to the yearly environmental conditions, in all three uses mentioned above: laboratory for university students, alpine shelter, and emergency shelter. The building performance analysis has been carried out in different locations, representative of alpine, temperate and hot climate conditions. The overview of these climates is presented in Figure 21, comparing the yearly trend of temperatures in Zermatt (Switzerland), Lecco (Italy) and Pô (Burkina Faso). The climate files (Typical Meteorological Year—TMY) have been downloaded from the Meteonorm database [35]. The climate of Pô is classified, according to Köppen and Geiger [36], as tropical Savanna: the average annual temperature is 28.6 °C, the warmest month—on average—is April, with a mean temperature of 32.6 °C, and the coolest month—on average—is August, with a mean temperature of 26 °C. Lecco is located in the Northern Italy, and its climate is classified as Cfa (Humid subtropical climate). The yearly average temperature is 12.3 °C, July is the warmest month of the year with an average temperature of 22.2 °C, while January is the coldest month with a minimum temperature between −7 and −10 °C. Zermatt is located at 1617 m above the sea level, its climate is cold and temperate, classified as Dfb (warm-summer humid continental climate). The annual average is −3.6 °C, the minimum temperature is registered in January (−20 °C), whereas August is the hottest month with a monthly value of 4 °C.

Figure 21.

Annual temperatures trend in Lecco (IT), Zermatt (CH) and Pô (BF).

The response of the building has been analyzed in a “free-floating” mode at first, and with the implementation of the available ECM, the ideal plant system for heating, cooling and dehumidification afterwards. The concept of “free-floating” is very common in building simulations, it refers to a specific running mode where no temperature controls (such as heating and cooling systems) are applied to the thermal zones. In this respect, the “free-floating” simulations allow to analyze and compare the response of the building envelope to the climatic conditions, as well as to evaluate the impact of the passive heating/cooling strategies applied to the building. The comfort expectation has been studied according to the EN 15251:2007 [37], that considers the running mean ambient air temperature as external condition. For outdoor running mean temperatures below 15 °C, values for mechanically cooled buildings have been applied, according to the EN 7730:2005 [38]. Both the comfort conditions and the energy demands have been calculated using a dynamic simulation approach, taking into account the thermal properties of the envelope, the use of the building and its new location. Lighting systems were designed to guarantee adequate indoor illuminance values, considering different furniture configurations and the effect of natural and artificial lighting. The thermal comfort analysis has been carried out according to the Fanger approach. This comfort method combines quantitative environmental and individual variables. The predicted mean vote (PMV) indicates how the occupants judge the indoor climate; using PMV index, the percentage of people dissatisfied (PPD index) can be predicted. The qualitative analysis is supported by a quantitative measurement that takes into account the overall number of discomfort hours located outside of the comfort ranges. The overall approach of the Fanger model is described in the EN ISO 7730:2005.

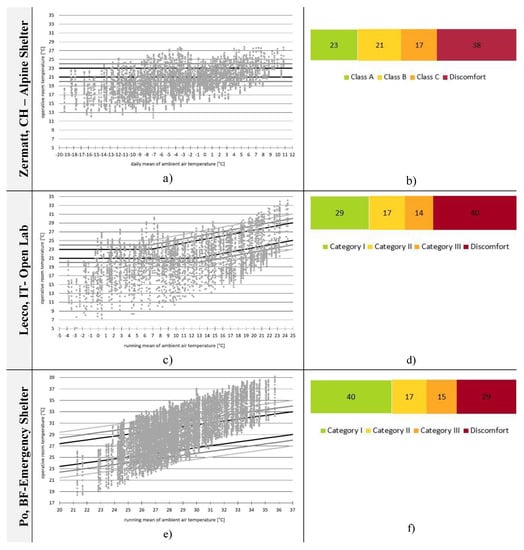

The simulations results demonstrate that the new life of the “Delight the Light” solution can be considered as a low energy intensity building with high thermal comfort. Figure 22 shows the final comfort graphs considering the free-floating regime after the application of the ECMs (shading, ventilation, schedule of use, etc.) and the building envelope analysis. The foot-print classifications (% of time) based on the comfort model of Fanger (EN 15,251 and EN 7730) highlight the percentage of comfort hours for the Category I, II and III. In detail, Category II has been reached for 44%, 46% and 57% of the occupied hours, respectively for Zermatt, Lecco and Po case studies. The applied energy efficient design principles encompass all the available techniques of creating a “healthy” interaction between indoor and outdoor climate conditions in buildings using as little energy as possible. Figure 22 shows the response of the building to the local climate conditions: winter months are clearly more energy intensive if compared to summer season, also because of the shading effect of the surrounding. The pitched roof has been designed to host a PV power plant, in order to guarantee a local renewable energy production. The PV system, with a 3-kW peak power, has been located on the south-east oriented pitch, due to the shading effect of the building. The PV model has been implemented in the overall building model; therefore the combined performance has been calculated with the TRNSYS software.

Figure 22.

Thermal comfort analysis according to the Fanger method: ISO 7730 for Alpine Shelter, combination of ISO 7730 and EN 15251 for open lab, and EN 15251 for the emergency shelter. The qualitative comfort graphs (a,c,e) are supported by detailed foot-print analysis (b,d,f).

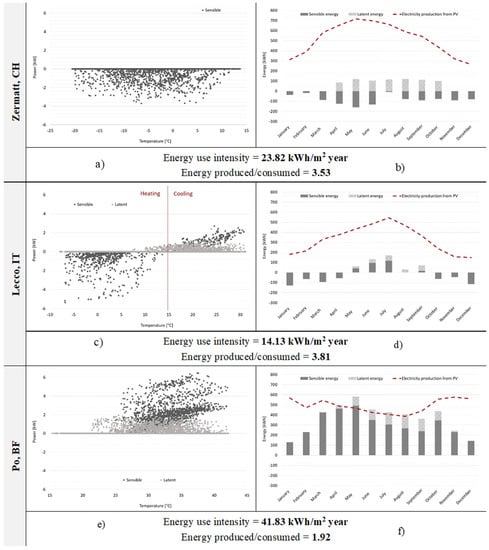

As presented in Figure 23, the annual energy consumption is equal to 23.82 kWh/m2 year for the Alpine shelter (heating and humidity control), 14.13 kWh/m2 year for the open lab (heating, cooling and humidity control), and 41.83 kWh/m2 year for the emergency shelter (cooling and humidity control).

Figure 23.

Simulation results: building power needs [kW] (a,c,e) both sensible (dark grey) and latent (light grey)—versus outside ambient air temperature [°C]; monthly energy balance [kWh] (b,d,f) absorbed by the building (columns) and produced by the PV panels (dashed red line).

The maximum power intensity required in all the analyzed cases is low and range from 4 kW (heating) for the alpine shelter to 6 kW for the open lab (heating) and for the emergency shelter (cooling). The low power requirement allows the installation of a small power size plant system (e.g., small electrical heat pump), reducing the cost and the architectural integration. Reducing the electrical energy consumption allows in fact to reduce the size of the Photovoltaic system as well.

The overall energy demand (useful energy) for the three different climates contexts has been calculated by adding up the hourly energy demand, giving a total of 1745 kWh/year for the Alpine shelter, 1035 kWh/year for the open lab, and 3063 kWh/year for the emergency shelter. The PV production potential has been calculated considering the specific climate context. Zermatt climate shows a PV production equal to 6161 kWh/year, bigger than the ones in Pô and Lecco, respectively 5881 kWh/year and 3941 kWh/year. Considering the annual energy balance, it is clear how the designed PV plant system allows reaching the nZEB goal (both on an annual and a monthly basis) for all the case studies mentioned.

7. Conclusions

The paper describes as a case study an example of a nearly zero Energy buildings redesign of a building that was initially conceived as a temporary exposition pavilion. The upcycled construction is a permanent nZEB open lab for university students at the Lecco Campus of Politecnico di Milano (IT). Two other potential reuses have been considered and presented, the Alpine shelter and the emergency shelter. All three case studies have been developed considering the advantages of the dry-layered steel technology, characterized by modularity, lightness, adaptability, and by the possibility to be easily dismounted, mounted, and transported. This first feature is fundamental to guarantee future uses with very limited impact on the built environment. Considering the implementation of a multilayer envelope technology with diffused steel structures connected with the main load structure, the thermal bridges and consequentially the potential degradation of the different envelope layers—in terms of both aesthetical quality and performance has been reduced. The verification of the envelope performance (roof, wall and floor) has been verified through FEM analysis calculating the U value and the temperature level of different material’s layer.

As demonstrated by the simulation results, the use of passive heating cooling strategies coupled with a tailor-made envelope technology, composed by resistive and massive layers, protects the inner space modulating the energy fluxes to the environment. The maximum power intensity required in all the analyzed cases is thus low and range from 4 kW (heating) for the Alpine shelter to 6 kW for the open lab (heating) and for the emergency shelter (cooling).

The three case studies presented have also been analyzed by means of dynamic thermal simulations to show the performance of the models. The annual energy consumption is equal to 23.82 kWh/m2 year for the Alpine shelter (for heating and humidity control), 14.13 kWh/m2 year for the open lab (heating, cooling and humidity control), and 41.83 kWh/m2 year for the emergency shelter (cooling and humidity control). The 3-kW peak photovoltaic power plant system (12 m2 of surface roof area) can cover the annual electrical energy needs with a total production of 3941, 6161 and 5881 kWh/year respectively for the open lab, Alpine shelter and the emergency shelter. The annual load-match index has been verified and it is equal to 3.53, 3.81 and 1.92 respectively for Lecco (IT), Zermatt (CH) and PO Climate. The comfort analysis shows the high level of user satisfaction that can be reached without the implementation of any active cooling/heating system.

The conceived technology presented in this paper is very promising and leads to unlimited configurations and uses. The open lab will be reassembled in the university campus soon, allowing the optimization of the remounting phase (list of actions, plug and play joints, etc.). Moreover, a monitoring campaign will be designed for energy performance verification and the results will be presented in a future work.

Author Contributions

Conceptualization, G.S. and D.B.; methodology, G.S.; investigation, G.S., M.I. data curation and formal analysis G.S, D.B. and M.M.S.; writing—original draft preparation, G.S., D.B. and M.M.S writing—review and editing, G.S., D.B., M.M.S., supervision, G.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| DfD | Design for Disassembly |

| ECM | Energy Conservation Measures |

| EPBD | Energy Performance of Buildings Directive |

| FEM | Finite Element Method |

| LCA | Life Cycle Assessment |

| nZEB | nearly Zero Energy Building |

| PV | Photovoltaic |

References

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency (Text with EEA Relevance). Available online: http://data.europa.eu/eli/dir/2018/844/oj (accessed on 20 June 2020).

- Sesana, M.M.; Salvalai, G. Overview on life cycle methodologies and economic feasibility for nZEBs. Build. Environ. 2013, 67, 211–216. [Google Scholar] [CrossRef]

- Sartori, I.; Napolitano, A.; Voss, K. Net zero energy buildings: A consistent definition framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef]

- IPCC. Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15/ (accessed on 20 June 2020).

- Radhi, H. Evaluating the potential impact of global warming on the UAE residential buildings—A contribution to reduce the CO2 emissions. Build. Environ. 2009, 44, 2451–2462. [Google Scholar] [CrossRef]

- Artola, I.; Rademaekers, K.; Williams, R.; Yearwood, J. Boosting Building Renovation: What potential and value for Europe? Dir. Gen. Intern. Policies Policy Dep. A Econ. Sci. Policy 2016. [Google Scholar] [CrossRef]

- De Cian, E.; Keppo, I.; Bollen, J.; Carrara, S.; Förster, H.; Hübler, M.; Kanudia, A.; Paltsev, S.; Sands, R.D.; Schumacher, K. European-LED climate policy versus global mitigation action: Implications on trade, technology, and energy. Clim. Chang. Econ. 2013, 4 (Suppl. 1), 1340002. [Google Scholar] [CrossRef]

- Sesana, M.M.; Salvalai, G. A review on Building Renovation Passport: Potentialities and barriers on current initiatives. Energy Build. 2018, 173, 195–205. [Google Scholar] [CrossRef]

- Sesana, M.M.; Rivallain, M.; Salvalai, G. Overview of the available knowledge for the data model definition of a building renovation passport for non-residential buildings: The ALDREN project experience. Sustainability 2020, 12, 642. [Google Scholar] [CrossRef]

- Attia, S. Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and Implementation; Elsevier: Cambridge, MA, USA, 2018. [Google Scholar]

- Amponsah, N.Y.; Lacarrière, B.; Jamali-Zghal, N.; Le Corre, O. Impact of building material recycle or reuse on selected emergy ratios. Resour. Conserv. Recycl. 2012, 67, 9–17. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002; ISBN 0-86547-587-3. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Salvalai, G.; Masera, G.; Sesana, M.M. Italian local codes for energy efficiency of buildings: Theoretical definition and experimental application to a residential case study. Renew. Sustain. Energy Rev. 2015, 42, 1245–1259. [Google Scholar] [CrossRef]

- Salvalai, G.; Sesana, M.M.; Iannaccone, G. Deep renovation of multi-storey multi-owner existing residential buildings: A pilot case study in Italy. Energy Build. 2017, 148, 23–36. [Google Scholar] [CrossRef]

- Engelmann, P.; Kalz, D.; Salvalai, G. Cooling concepts for non-residential buildings: A comparison of cooling concepts in different climate zones. Energy Build. 2014, 82, 447–456. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings-towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Brambilla, A.; Salvalai, G.; Tonelli, C.; Imperadori, M. Comfort analysis applied to the international standard “Active House”: The case of RhOME, the winning prototype of Solar Decathlon 2014. J. Build. Eng. 2017, 12, 210–218. [Google Scholar] [CrossRef]

- Brambilla, A.; Salvalai, G.; Imperadori, M.; Sesana, M.M. Nearly zero energy building renovation: From energy efficiency to environmental efficiency, a pilot case study. Energy Build. 2018, 166, 271–283. [Google Scholar] [CrossRef]

- Silva, M.F.; Jayasinghe, L.B.; Waldmann, D.; Hertweck, F. Recyclable architecture: Prefabricated and recyclable typologies. Sustainability 2020, 12, 1342. [Google Scholar] [CrossRef]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Procedia Eng. 2015, 118, 1296–1304. [Google Scholar] [CrossRef]

- Addis, W.; Schouten, J. Design for Reconstruction-Principles of Design to Facilitate Reuse and Recycling; CIRIA: London, UK, 2004; ISBN 086017607X. [Google Scholar]

- Guy, G.B. Design for disassembly in the built environment. In Proceedings of the 4th International Congress on Sustainability Science and Engineering, ICOSSE, Balatonfüred, Hungary, 26–29 May 2015. [Google Scholar]

- Salvalai, G.; Imperadori, M.; Sesana, M.M.; Baccaro, M.; Del Favero, L.; Tagliabue, A. Re-designing a temporary pavilion into a NZEB open lab for a university campus. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 10th International Conference IAQVEC 2019: Indoor Air Quality, Ventilation and Energy Conservation in Buildings, Bari, Italy, 5–7 September 2019. [Google Scholar]

- Scaffsystem. Available online: http://www.scaffsystem.it/ (accessed on 26 April 2020).

- Diletta, B. Centre Tournesol. Progetto di un Villaggio Rurale Clever-Tech a Po, in Burkina Faso; Politecnico di Milano: Milan, Italy, 2019. [Google Scholar]

- Fabbri, K. Linee guida nazionali per la certificazione energetica. In PONTE-Mensile di Progett Gest e Tec del Costr; Ponte: Florence, Italy, 2009. [Google Scholar]

- Dartwin. Available online: https://www.dartwin.it/it/ (accessed on 26 April 2020).

- EN ISO 6946:2018. Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. Available online: https://www.iso.org/standard/65708.html (accessed on 20 June 2020).

- TRNSYS. Transient System Simulation Tool. 2013. Available online: Http://WwwTrnsysCom/ (accessed on 20 June 2020).

- BS ISO 18523-1:2016. Energy Performance Ofbuildings—Schedule Andcondition of Building, Zoneand Space Usage for Energy Calculation. Part 1: Non-Residential Buildings. Available online: https://www.iso.org/standard/62765.html (accessed on 26 April 2020).

- Meteonorm. Meteonorm: Irradiation Data for Every Place on Earth; Meteotest: Bern, Switzerland, 2016. [Google Scholar]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007. [Google Scholar] [CrossRef]

- BS EN 15251. Indoor Environ Input Parameters Des Assess Energy Perform Build. 2007. Available online: https://meteonorm.com/assets/downloads/broschuere-mn-7.1.pdf (accessed on 26 April 2020).

- ISO. ISO 7730: Ergonomics of the thermal environment Analytical determination and interpretation of thermal comfort using calculation of the PMV and PPD indices and local thermal comfort criteria. Management 2005, 3, 605–615. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).