Chemical Destabilization of Fresh and Spent Cutting Oil Emulsions: Differences between an Ecofriendly and Two Commercial Synthetic Lubricants

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

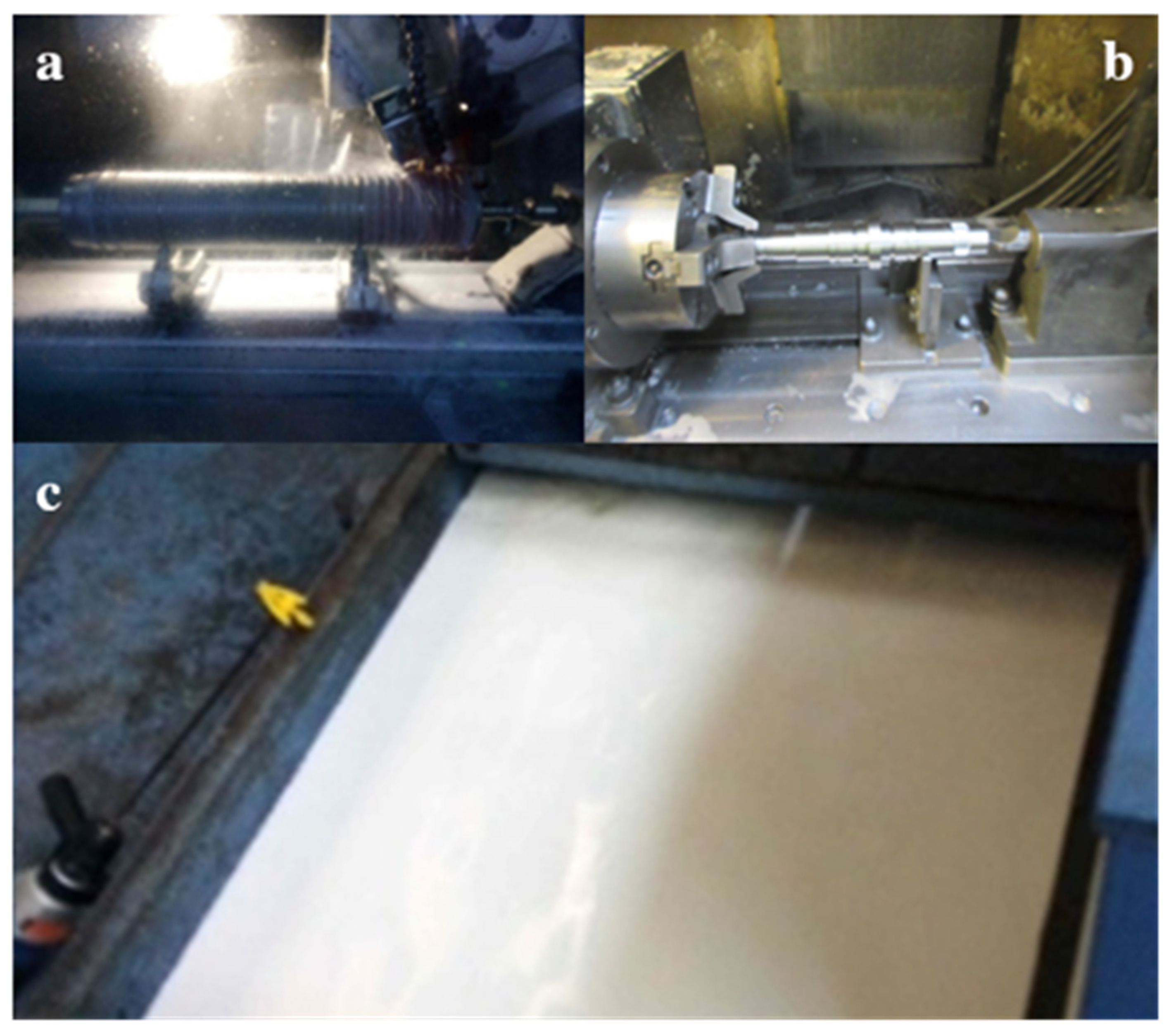

2.2. Experimental Apparatus and Procedures

2.3. Analytical Methods

3. Results

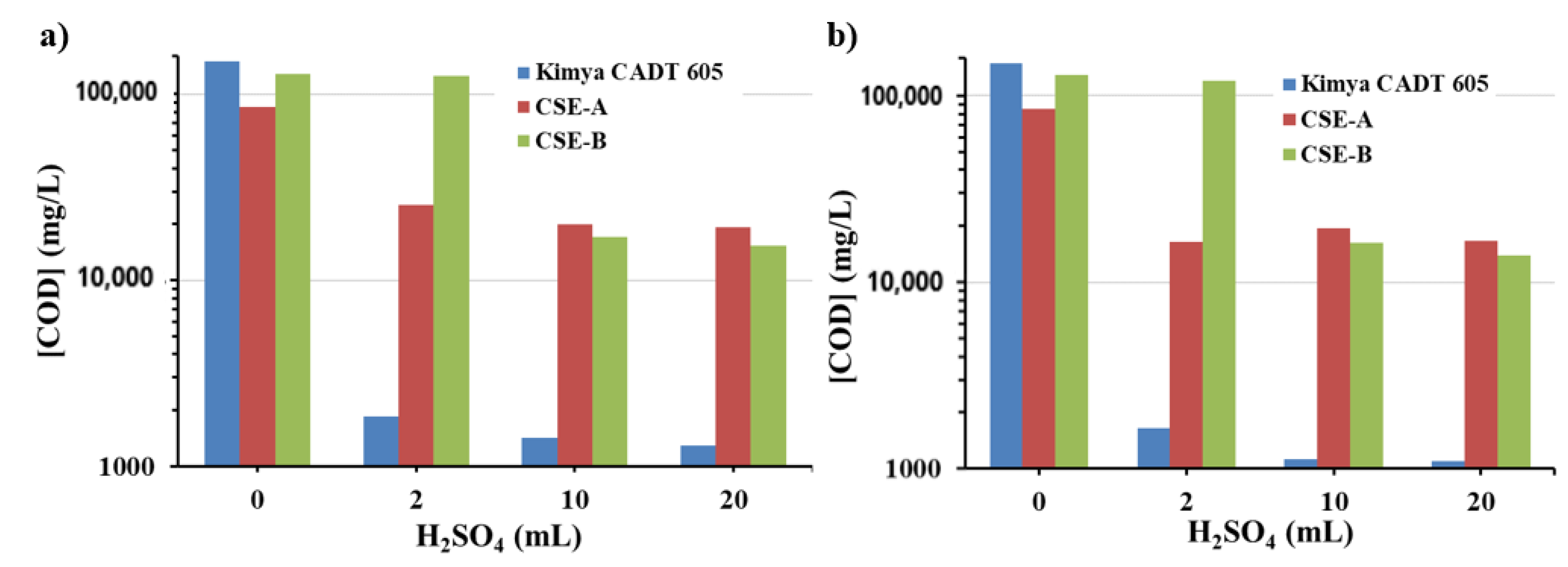

3.1. Chemical Parameters of the Fresh Emulsions

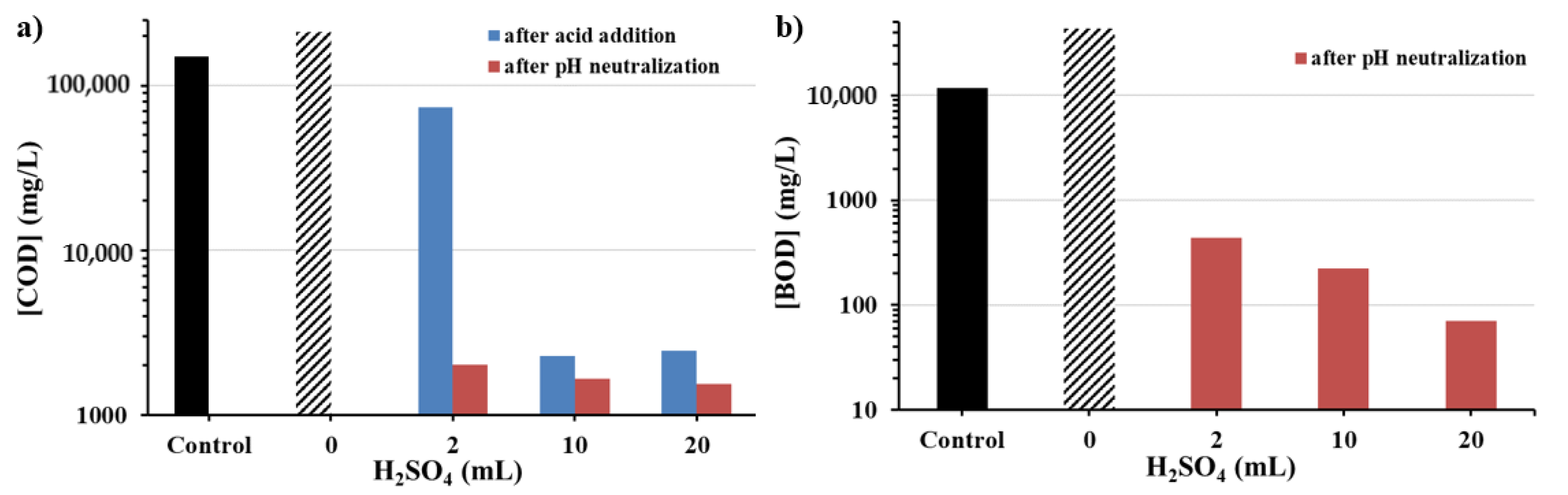

3.2. Chemical Parameters of CADT 605 Spent Emulsion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maisano, M.; Cappello, T.; Natalotto, A.; Vitale, V.; Parrino, V.; Giannetto, A.; Oliva, S.; Mancini, G.; Cappello, S.; Mauceri, A.; et al. Effects of petrochemical contamination on caged marine mussels using a multi-biomarker approach: Histological changes, neurotoxicity and hypoxic stress. Mar. Environ. Res. 2017, 128, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Karmakar, G.; Ghosh, P.; Sharma, B.K. Chemically modifying vegetable oils to prepare green lubricants. Lubricants 2017, 5, 44. [Google Scholar] [CrossRef]

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef]

- Mancini, G.; Panzica, M.; Fino, D.; Cappello, S.; Yakimov, M.M.; Luciano, A. Feasibility of treating emulsified oily and salty wastewaters through coagulation and bio-regenerated GAC filtration. J. Environ. Manag. 2017, 203, 817–824. [Google Scholar] [CrossRef] [PubMed]

- Viotti, P.; Di Palma, P.R.; Aulenta, F.; Luciano, A.; Mancini, G.; Papini, M.P. Use of a reactive transport model to describe reductive dechlorination (RD) as a remediation design tool: Application at a CAH-contaminated site. Environ. Sci. Pollut. Res. 2014, 21, 1514–1527. [Google Scholar] [CrossRef] [PubMed]

- Luciano, A.; Mancini, G.; Torretta, V.; Viotti, P. An empirical model for the evaluation of the dissolution rate from a DNAPL-contaminated area. Environ. Sci. Pollut. Res. 2018, 25, 33992–34004. [Google Scholar] [CrossRef]

- Ghosh, P.; Karmakar, G. Evaluation of sunflower oil as a multifunctional lubricating oil additive. Int. J. Ind. Chem. 2014, 5, 7. [Google Scholar] [CrossRef]

- Ghosh, P.; Hoque, M.; Karmakar, G. Castor oil as potential multifunctional additive in the formulation of eco-friendly lubricant. Polym. Bull. 2018, 75, 501–514. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiža, R.; Mandziuk, I.; Kupcinskas, A.; Prisyazhna, K.; Grigoriev, A.; Kavaliova, I.; Revo, S. Tribological properties of beef tallow as lubricating grease. Ind. Lubr. Tribol. 2017, 69, 645–654. [Google Scholar] [CrossRef]

- Boyde, S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem. 2012, 4, 293–307. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants. A review for oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Syahir, A.Z.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam, M.A.; Alabdulkarem, A.; Gulzar, M.; Khuong, L.S.; Harith, M.H. A review on bio-based lubricants and their applications. J. Clean. Prod. 2017, 168, 997–1016. [Google Scholar] [CrossRef]

- Angulo, B.; Fraile, J.M.; Gil, L.; Herrerías, C.I. Bio-lubricants production from fish oil residue by transesterification with trimethylolpropane. J. Clean. Prod. 2018, 202, 81–87. [Google Scholar] [CrossRef]

- Mandziuk, I.A.; Prisyazhna, K.O. Industrial lubricants based on renewable raw materials. Report 1. Properties of the natural acylglycerols. J. Chem. Technol. 2015, 23, 32–37. [Google Scholar] [CrossRef][Green Version]

- do Valle, C.P.; Rodrigues, J.S.; Fechine, L.M.U.D.; Cunha, A.P.; Malveira, J.Q.; Luna, F.M.T.; Ricardo, N.M.P.S. Chemical modification of Tilapia oil for biolubricant applications. J. Clean. Prod. 2018, 191, 158–166. [Google Scholar] [CrossRef]

- Salimon, J.; Salih, N.; Yousif, E. Biolubricants: Raw materials, chemical modifications and environmental benefits. Eur. J. Lipid Sci. Technol. 2010, 112, 519–530. [Google Scholar] [CrossRef]

- Salimon, J.; Abdullah, B.M.; Yusop, R.M.; Salih, N. Synthesis, reactivity and application studies for different biolubricants. Chem. Cent. J. 2014, 8, 16. [Google Scholar] [CrossRef]

- Council Regulation (EC). No 440/2008 Laying Down Test Methods Pursuant to Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH); European Union: Brussels, Belgium, 2008. [Google Scholar]

- Bensadok, K.; Belkacem, M.; Nezzal, G. Treatment of cutting oil/water emulsion by coupling coagulation and dissolved air flotation. Desalination 2007, 206, 440–448. [Google Scholar] [CrossRef]

- Benito, J.M.; Cambiella, A.; Lobo, A.; Gutiérrez, G.; Coca, J.; Pazos, C. Formulation, characterization and treatment of metalworking oil-in-water emulsions. Clean Technol. Environ. 2010, 12, 31–41. [Google Scholar] [CrossRef]

- Giannopoulos, D.; Kolaitis, D.I.; Togkalidou, A.; Skevis, G.; Founti, M.A. Quantification of emissions from the co-incineration of cutting oil emulsions in cement plants–Part I: NOx, CO and VOC. Fuel 2007, 86, 1144–1152. [Google Scholar] [CrossRef]

- Soković, M.; Mijanović, K. Ecological aspects of the cutting fluids and its influence on quantifiable parameters of the cutting processes. J. Mater. Process. Technol. 2001, 109, 181–189. [Google Scholar] [CrossRef]

- Vasanth, D.; Pugazhenthi, G.; Uppaluri, R. Cross-flow microfiltration of oil-in-water emulsions using low cost ceramic membranes. Desalination 2013, 320, 86–95. [Google Scholar] [CrossRef]

- Islam, M.S.; McCutcheon, J.R.; Rahaman, M.S. A high flux polyvinyl acetate-coated electrospun nylon 6/SiO2 composite microfiltration membrane for the separation of oil-in-water emulsion with improved antifouling performance. J. Membr. Sci. 2017, 537, 297–309. [Google Scholar] [CrossRef]

- Venault, A.; Chiang, C.H.; Chang, H.Y.; Hung, W.S.; Chang, Y. Graphene oxide/PVDF VIPS membranes for switchable, versatile and gravity-driven separation of oil and water. J. Membr. Sci. 2018, 565, 131–144. [Google Scholar] [CrossRef]

- Karhu, M.; Leiviskä, T.; Tanskanen, J. Enhanced DAF in breaking up oil-in-water emulsions. Sep. Purif. Technol. 2014, 122, 231–241. [Google Scholar] [CrossRef]

- Demirbas, E.; Kobya, M. Operating cost and treatment of metalworking fluid wastewater by chemical coagulation and electrocoagulation processes. Process. Saf. Environ. 2017, 105, 79–90. [Google Scholar] [CrossRef]

- Amin, M.M.; Mofrad, M.M.G.; Pourzamani, H.; Sebaradar, S.M.; Ebrahim, K. Treatment of industrial wastewater contaminated with recalcitrant metal working fluids by the photo-Fenton process as post-treatment for DAF. J. Ind. Eng. Chem. 2017, 45, 412–420. [Google Scholar] [CrossRef]

- Sykora, J.L.; Smith, E.J.; Synak, M. Effect of lime neutralized iron hydroxide suspensions on juvenile brook trout (Salvelinus fontinalis, Mitchill). Water Res. 1972, 6, 935–950. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse; Metcalf & Eddy Inc. McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Suárez, S.; Roca, X.; Gasso, S. Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: Application to the Spanish context. J. Clean. Prod. 2016, 117, 150–159. [Google Scholar] [CrossRef]

- Worm, M.; Kang, B.; Dingels, C.; Wurm, F.R.; Frey, H. Acid-labile amphiphilic PEO-b-PPO-b-PEO copolymers: Degradable poloxamer analogs. Macromol. Rapid Commun. 2016, 37, 775–780. [Google Scholar] [CrossRef] [PubMed]

- Xiang, W.; Tardy, B.; Bai, L.; Stubenrauch, C.; Rojas, O.J. Measuring the interfacial behavior of sugar-based surfactants to link molecular structure and uses. In Biobased Surfactants Synthesis, Properties, and Applications, 2nd ed.; AOCS Press: Urbana, IL, USA, 2019; pp. 387–412. [Google Scholar]

- Petrella, A.; Petrella, M.; Boghetich, G.; Petruzzelli, D.; Calabrese, D.; Stefanizzi, P.; De Napoli, D.; Guastamacchia, M. Recycled waste glass as aggregate for lightweight concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2007, 160, 165–170. [Google Scholar] [CrossRef]

- Petrella, A.; Petrella, M.; Boghetich, G.; Petruzzelli, D.; Ayr, U.; Stefanizzi, P.; Calabrese, D.; Pace, L.; Guastamacchia, M. Thermo-acoustic properties of cement-waste-glass mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2009, 162, 67–72. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Rizzi, V.; Cosma, P.; Race, M.; De Vietro, N. Lead ion sorption by perlite and reuse of the exhausted material in the construction field. Appl. Sci. 2018, 8, 1882. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Liuzzi, S.; Ayr, U.; Cosma, P.; Rizzi, V.; Petrella, M.; Di Mundo, R. Use of cellulose fibers from wheat straw for sustainable cement mortars. J. Sustain. Cem. Based Mater. 2019, 8, 161–179. [Google Scholar] [CrossRef]

- Aïtcin, P.C.; Flatt, R.J. Science and Technology of Concrete Admixtures; Woodhead Publishing: Cambridge, UK, 2015; pp. 195–218. [Google Scholar]

- Feneuil, B.; Pitois, O.; Roussel, N. Effect of surfactants on the yield stress of cement paste. Cem. Concr. Res. 2017, 100, 32–39. [Google Scholar] [CrossRef]

- Decreto Legislativo No 152/2006. In Norme in Materia Ambientale; Italian Parliament: Rome, Italy, 2006.

- Ranade, V.V.; Bhandari, V.M. Industrial Wastewater Treatment, Recycling and Reuse; Butterworth-Heinemann, Elsevier: Oxford, UK, 2014. [Google Scholar]

| Emulsion Type | Oil Content (% w/w) | COD (mg/L) | BOD5 (mg/L) | NIS (mg/L) |

|---|---|---|---|---|

| CSE-A | 5 | 85,000 | 4100 | 6000 |

| CSE-B | 5 | 128,600 | 9900 | 7500 |

| Kimya CADT 605 | 5 | 149,700 | 11,650 | <0.2 |

| Kimya CADT 605 spent emulsion | 5.8 | 212,653 | 43,350 | 74 |

| Limits for Discharge in Sewers | Limits for Discharge in Surface Water Bodies | Undiluted Treated Emulsion | Diluted Treated Emulsion | |||||

|---|---|---|---|---|---|---|---|---|

| 2 mL H2SO4 | 10 mL H2SO4 | 20 mL H2SO4 | 2 mL H2SO4 | 10 mL H2SO4 | 20 mL H2SO4 | |||

| [COD] (mg/L) | 500 | 160 | 2043 | 1670 | 1545 | 102 | 84 | 77 |

| [BOD5] (mg/L) | 250 | 40 | 439 | 223 | 70 | 22 | 11 | 3.5 |

| [NIS] (mg/L) | 4 | 2 | 30 | 27 | 25 | 1.5 | 1.35 | 1.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spasiano, D.; Petrella, A.; Lacedra, V. Chemical Destabilization of Fresh and Spent Cutting Oil Emulsions: Differences between an Ecofriendly and Two Commercial Synthetic Lubricants. Sustainability 2020, 12, 5697. https://doi.org/10.3390/su12145697

Spasiano D, Petrella A, Lacedra V. Chemical Destabilization of Fresh and Spent Cutting Oil Emulsions: Differences between an Ecofriendly and Two Commercial Synthetic Lubricants. Sustainability. 2020; 12(14):5697. https://doi.org/10.3390/su12145697

Chicago/Turabian StyleSpasiano, Danilo, Andrea Petrella, and Vito Lacedra. 2020. "Chemical Destabilization of Fresh and Spent Cutting Oil Emulsions: Differences between an Ecofriendly and Two Commercial Synthetic Lubricants" Sustainability 12, no. 14: 5697. https://doi.org/10.3390/su12145697

APA StyleSpasiano, D., Petrella, A., & Lacedra, V. (2020). Chemical Destabilization of Fresh and Spent Cutting Oil Emulsions: Differences between an Ecofriendly and Two Commercial Synthetic Lubricants. Sustainability, 12(14), 5697. https://doi.org/10.3390/su12145697