Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA

Abstract

1. Introduction

2. Materials and Methods

2.1. The Reason for Carrying Out the Study

2.2. The Perspective of the LCA Practitioner

2.3. The Functional Unit

2.4. The Intended Application of the Results

- Quantifying the impacts of a product or service, in order to use these values in another LCA study in which this product or service is used. Furthermore, quantified impacts can be used for the communication of environmental impacts, for example via environmental labeling, or periodic monitoring.

- Identifying opportunities to improve the environmental performance of the product or service, for example via innovation. For this type of application, a contribution analysis, or hotspot analysis aids in identifying the products and processes that contribute most to the environmental impacts of the functional unit.

- Making a decision to select between multiple alternative options. In the end, most LCA studies have the purpose to compare two alternative products or services that provide the same function. Furthermore, it is interesting to compare the impacts of a product before and after the application of an adjustment that is supposed to reduce the products’ environmental impacts.

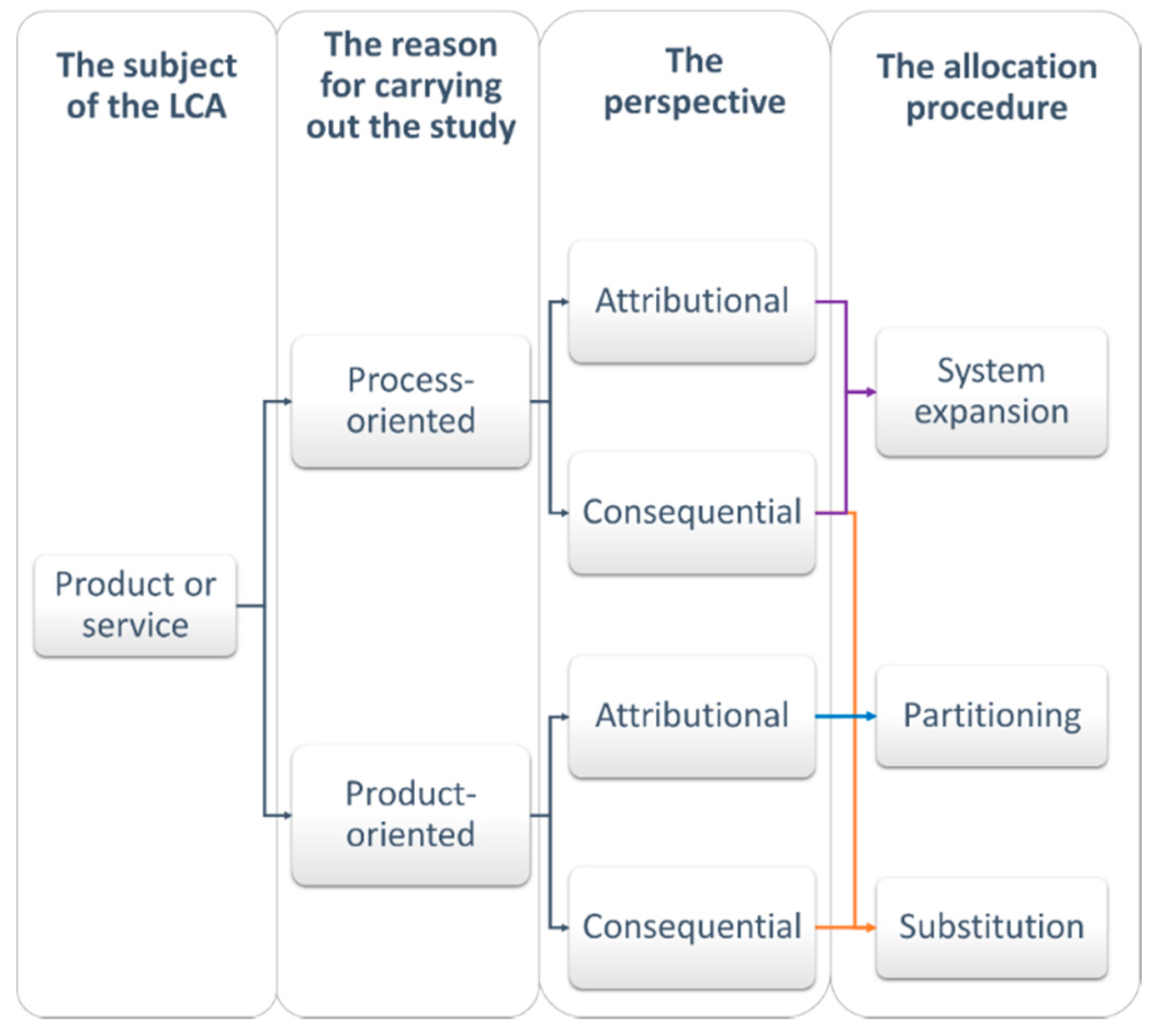

2.5. Relationship between the Elements of the Goal and Scope

3. Results

3.1. Updated Framework for Goal-Dependent Allocation

3.2. Archetypes of Goal and Scope Definitions

4. Discussion

4.1. Untangling System Expansion, Substitution, and the Cut-Off Approach

- Questions 1 and 2 of Table 3 cannot be answered via the operation of subtracting functions instead of the addition of functions.

- Equivalence between system expansion and substitution is only achieved for question 3, and only with regard to the absolute difference in environmental impacts (e.g., “the alternative system is accountable for 20 kg CO2-eq more than the system under study”). Any other comparison between the two product systems, such as percentages of improvements, is distorted due to the subtraction of functions instead of the addition of functions.

- The results can be easily misinterpreted by the suggestion that the alternative production routes are substituted, while in an attributional process-oriented LCA, a comparison between two product systems can be done for the mere purpose of benchmarking.

- Keeping the functional unit as “1 kg of recycled yttrium” suggests that a product-oriented LCA is conducted. Results are easily used for downstream studies in which yttrium is used, while the results do not refer to the cradle-to-gate impacts attributed to yttrium, as the applied approach is a process-oriented LCA.

- System expansion: Including the additional functions related to the co-products in the functional unit.

- Substitution: Allocation of inputs and outputs between the products and functions in a way that reflects economic relationships.

- In an attributional product-oriented LCA, when partitioning is applied, it could appear that the co-product or recycled product has a very low mass (for mass allocation) or economic revenue (for economic allocation) compared to the other co-products of the system. In that case, the allocation factor for the low-value product could approach, or be, 0%. With an allocation factor of 0%, the product becomes burden free, which is in line with the cut-off approach [3]. However, the cut-off approach is not appropriate when the allocation factor is low in an economic allocation due to the fact that the co-product, or recycled product, is produced in a low quantity, while the unit price is relatively high, as in this case the LCI per unit of product is non-negligible.

- In a consequential product-oriented or process-oriented LCA (questions 10–15), it is possible that the flows which are modeled by substitution generate relatively low impacts. In that case, it could be argued that the environmental consequences due to the multifunctional flow are negligible and are cut-off.

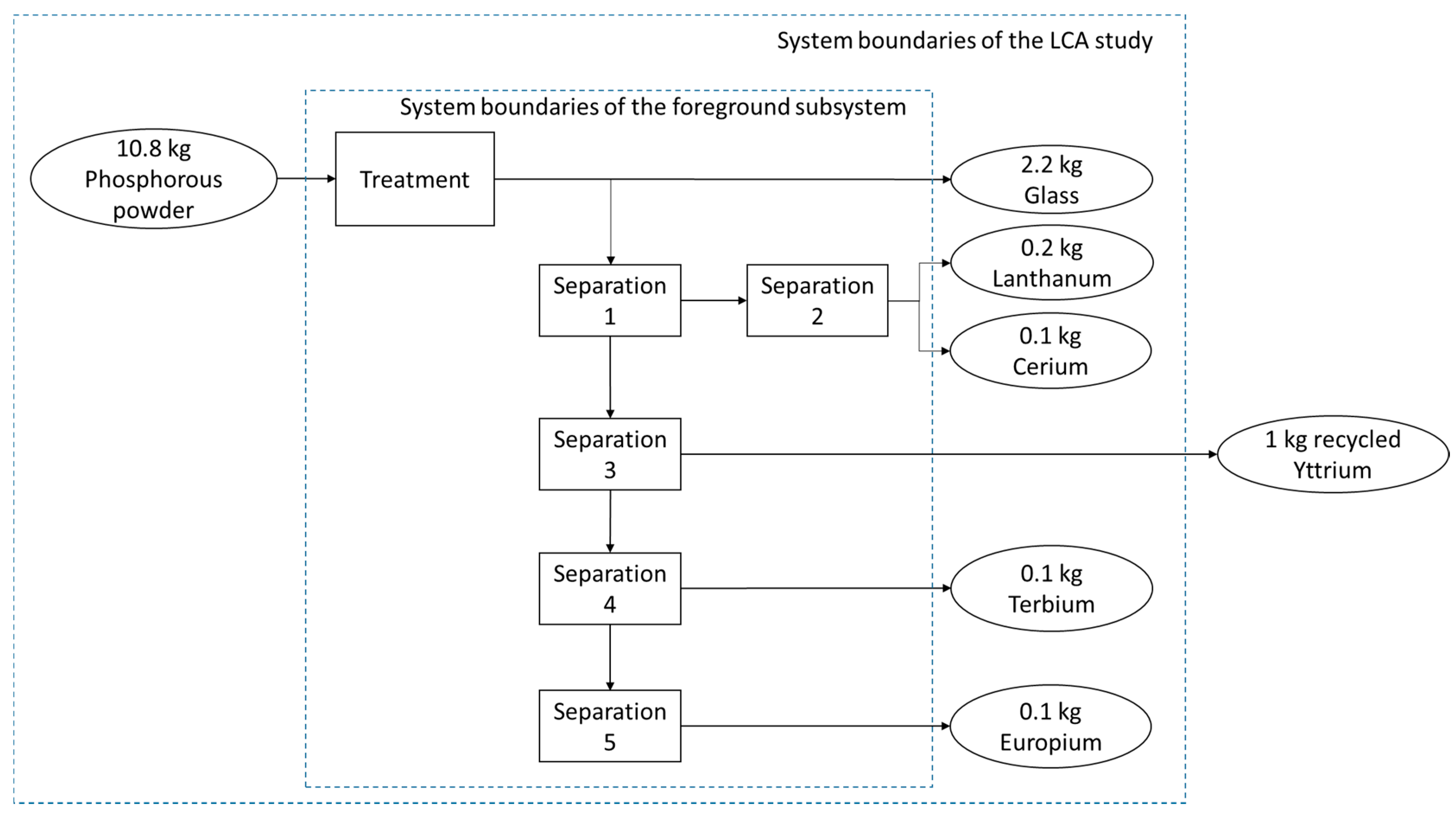

- Alternatively, if an LCA practitioner argues that the phosphorous powder is burden-free, because it is a waste, he/she might aim to conduct a process-oriented LCA where the flow of ingoing waste is a flow of interest. Instead of referring to this flow as “burden-free”, the flow should be included in the functional unit. As shown in Figure 3, functional flows do not “carry” an impact, as the overall impact of these flows is the subject of analysis.

4.2. Perspectives for the Use of Attributional and Consequential Approaches in Sustainability Assessments

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Critical review of guidelines against a systematic framework with regard to consistency on allocation procedures for recycling in LCA. Int. J. Life Cycle Assess. 2016, 21, 994–1008. [Google Scholar] [CrossRef]

- ISO. ISO 14044—Environmental Management—Life Cycle Assessment—Requirements and Guidelines; The International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a systematic framework for consistent allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Heijungs, R. Ten easy lessons for good communication of LCA. Int. J. LCA 2013, 19, 473–476. [Google Scholar] [CrossRef]

- Sonnemann, G.W.; Vigon, B.W. Global Guidance Principles for Life Cycle Assessment Databases—A Basis for Greener Processes and Products; United Nations Environment Programme: Paris, France, 2011. [Google Scholar]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability: International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; EUR 24708 EN; Publications Office of the European Union: Luxembourg, 2010.

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and consequential LCA in the ILCD handbook. Int. J. LCA 2016. [Google Scholar] [CrossRef]

- Morley, N.; Eatherley, D. Material Security—Ensuring Resource Availability for the UK Economy; C-Tech Innovation Ltd.: Cheshire, UK, 2008; ISBN 9781906237035. [Google Scholar]

- Bach, V.; Berger, M.; Finogenova, N.; Finkbeiner, M. Assessing the availability of terrestrial Biotic Materials in Product Systems (BIRD). Sustainability 2017, 9, 137. [Google Scholar] [CrossRef]

- Graedel, T.E.; Barr, R.; Chandler, C.; Chase, T.; Choi, J.; Christoffersen, L.; Friedlander, E.; Henly, C.; Jun, C.; Nassar, N.T.; et al. Methodology of metal criticality determination. Environ. Sci. Technol. 2012, 46, 1063–1070. [Google Scholar] [CrossRef]

- Bach, V.; Finogenova, N.; Berger, M.; Winter, L.; Finkbeiner, M. Enhancing the assessment of critical resource use at the country level with the SCARCE method—Case study of Germany. Resour. Policy 2017, 53, 283–299. [Google Scholar] [CrossRef]

- Kolotzek, C.; Helbig, C.; Thorenz, A.; Reller, A.; Tuma, A. A company-oriented model for the assessment of raw material supply risks, environmental impact and social implications. J. Clean. Prod. 2018, 176, 566–580. [Google Scholar] [CrossRef]

- Sonnemann, G.; Gemechu, E.D.; Adibi, N.; De Bruille, V.; Bulle, C. From a critical review to a conceptual framework for integrating the criticality of resources into Life Cycle Sustainability Assessment. J. Clean. Prod. 2015, 94, 20–34. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G. Economic allocation: Examples and derived decision tree. Int. J. LCA 2004, 9, 23–33. [Google Scholar] [CrossRef]

- Tan, Q.; Song, Q.; Li, J. The environmental performance of fluorescent lamps in China, assessed with the LCA method. Int. J. Life Cycle Assess. 2015, 20, 807–818. [Google Scholar] [CrossRef]

- Sud Ouest La Rochelle: Fermeture de L’atelier de Recyclage des Terres Rares de Solvay D’ici Fin. 2016. Available online: http://www.sudouest.fr/2016/01/15/la-rochelle-fermeture-de-l-atelier-de-production-de-solvay-d-ici-fin-2016-2243998-1391.php (accessed on 30 December 2016).

- Solvay Solvay Launches Its Rare Earth Recycling Activity in France. Available online: http://www.solvay.com/nl/media/press_releases/20120927-coleopterre.html (accessed on 14 March 2015).

- Lartigue-Peyrou, F. (Solvay, Brussels, Belgium). Personal communication, 2016.

- Azapagic, A.; Clift, R. Allocation of Environmental Burdens in Co-product Systems: Product-related Burdens (Part 1). J. Clean. Prod. 1999, 7, 101–119. [Google Scholar] [CrossRef]

- Weidema, B.P.; Ekvall, T.; Heijungs, R. Guidelines for Application of Deepened and Broadened LCA—Deliverable D18 of Work Package 5 of the CALCAS Project; ENEA: Roma, Italy, 2009. [Google Scholar]

- Schrijvers, D.; Tsang, M.; Castells, F.; Sonnemann, G. Life-Cycle Assessment. In Integrated Life-Cycle and Risk Assessment for Industrial Processes and Products; Sonnemann, G., Tsang, M., Schuhmacher, M., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 33–78. [Google Scholar]

- Frischknecht, R.; Benetto, E.; Dandres, T.; Heijungs, R.; Roux, C.; Schrijvers, D.; Wernet, G.; Yang, Y.; Messmer, A.; Tschuemperlin, L. LCA and decision making: When and how to use consequential LCA; 62nd LCA forum, Swiss Federal Institute of Technology, Zürich, 9 September 2016. Int. J. Life Cycle Assess. 2017, 22, 296–301. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology—Data Quality Guideline for the Ecoinvent Database Version 3; Ecoinvent Report 1 (v3); The Ecoinvent Centre: St. Gallen, Switzerland, 2013; Volume 3. [Google Scholar]

- Andrews, E.; Lesage, P.; Benoît, C.; Parent, J.; Norris, G.; Revéret, J.P. Life cycle attribute assessment: Case study of Quebec greenhouse tomatoes. J. Ind. Ecol. 2009, 13, 565–578. [Google Scholar] [CrossRef]

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L.; et al. Integrated method to assess resource efficiency—ESSENZ. J. Clean. Prod. 2016, 137, 118–130. [Google Scholar] [CrossRef]

- Neugebauer, S.; Forin, S.; Finkbeiner, M. From life cycle costing to economic life cycle assessment-introducing an economic impact pathway. Sustainability 2016, 8, 428. [Google Scholar] [CrossRef]

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- Sonderegger, T.; Berger, M.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral resources in life cycle impact assessment—Part I: A critical review of existing methods. Int. J. Life Cycle Assess. 2020. [Google Scholar] [CrossRef]

- Berger, M.; Sonderegger, T.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral resources in life cycle impact assessment: Part II—recommendations on application-dependent use of existing methods and on future method development needs. Int. J. Life Cycle Assess. 2020. [Google Scholar] [CrossRef]

- Drielsma, J.; Allington, R.; Brady, T.; Guinée, J.; Hammarstrom, J.; Hummen, T.; Russell-Vaccari, A.; Schneider, L.; Sonnemann, G.; Weihed, P. Abiotic Raw-Materials in Life Cycle Impact Assessments: An Emerging Consensus across Disciplines. Resources 2016, 5, 12. [Google Scholar] [CrossRef]

- Gemechu, E.D.; Helbig, C.; Sonnemann, G.; Thorenz, A.; Tuma, A. Import-based Indicator for the Geopolitical Supply Risk of Raw Materials in Life Cycle Sustainability Assessments. J. Ind. Ecol. 2016, 20, 154–165. [Google Scholar] [CrossRef]

- Moltesen, A.; Bonou, A.; Wangel, A.; Bozhilova-Kisheva, K.P. Social Life Cycle Assessment: An Introduction. In Life Cycle Assessment—Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer: Cham, Switzerland, 2018; p. 1215. [Google Scholar]

- Benoît Norris, C. Data for social LCA. Int. J. Life Cycle Assess. 2014, 19, 261–265. [Google Scholar] [CrossRef]

- Zamagni, A.; Amerighi, O.; Buttol, P. Strengths or bias in social LCA? Int. J. Life Cycle Assess. 2011, 16, 596–598. [Google Scholar] [CrossRef]

| Item of the Goal and Scope Definition | Parameters of Interest | Integration into Table 2 | LCA Modeling Approach |

|---|---|---|---|

| The reason for carrying out the study | The production/treatment | α | Process-oriented LCA |

| The consumption | Product-oriented LCA | ||

| The perspective of the LCA | Accountability for impacts | β | Attributional LCA |

| Consequences on global impacts | Consequential LCA | ||

| The functional unit | The subject of the LCA | γ | Partitioning/Substitution |

| The subject of the LCA and additional functions | System expansion |

| Intended Application of the Results | Research Question |

|---|---|

| Quantifying environmental impacts | What is/are the β of α of γ? |

| Identifying opportunities for improvement | How can we decrease the β of α of γ? |

| Decision-making | Does α of γ have (a) lower β than its alternative? |

| LCA Approach | Functional Unit | Research Question | Modeling Specifics |

|---|---|---|---|

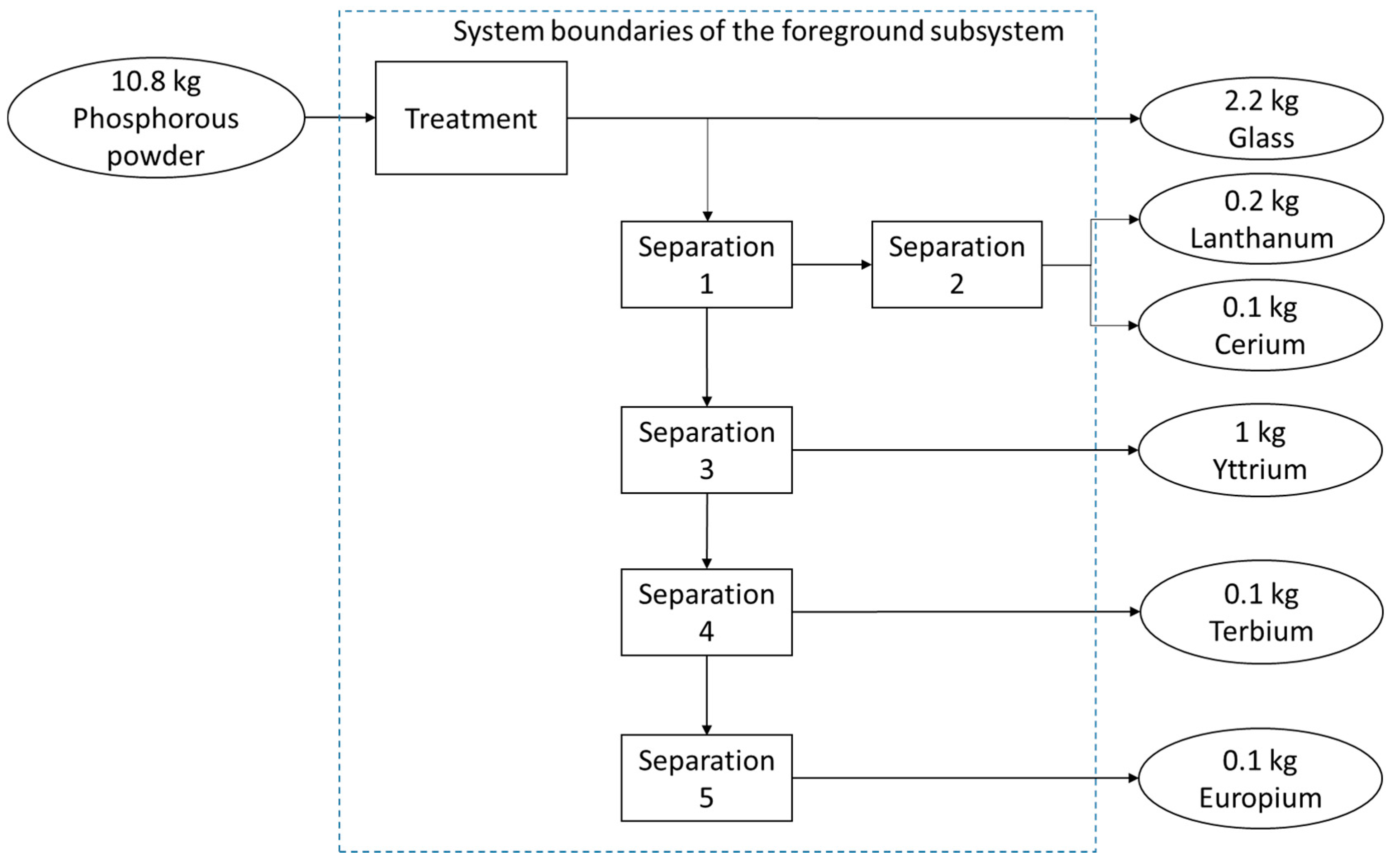

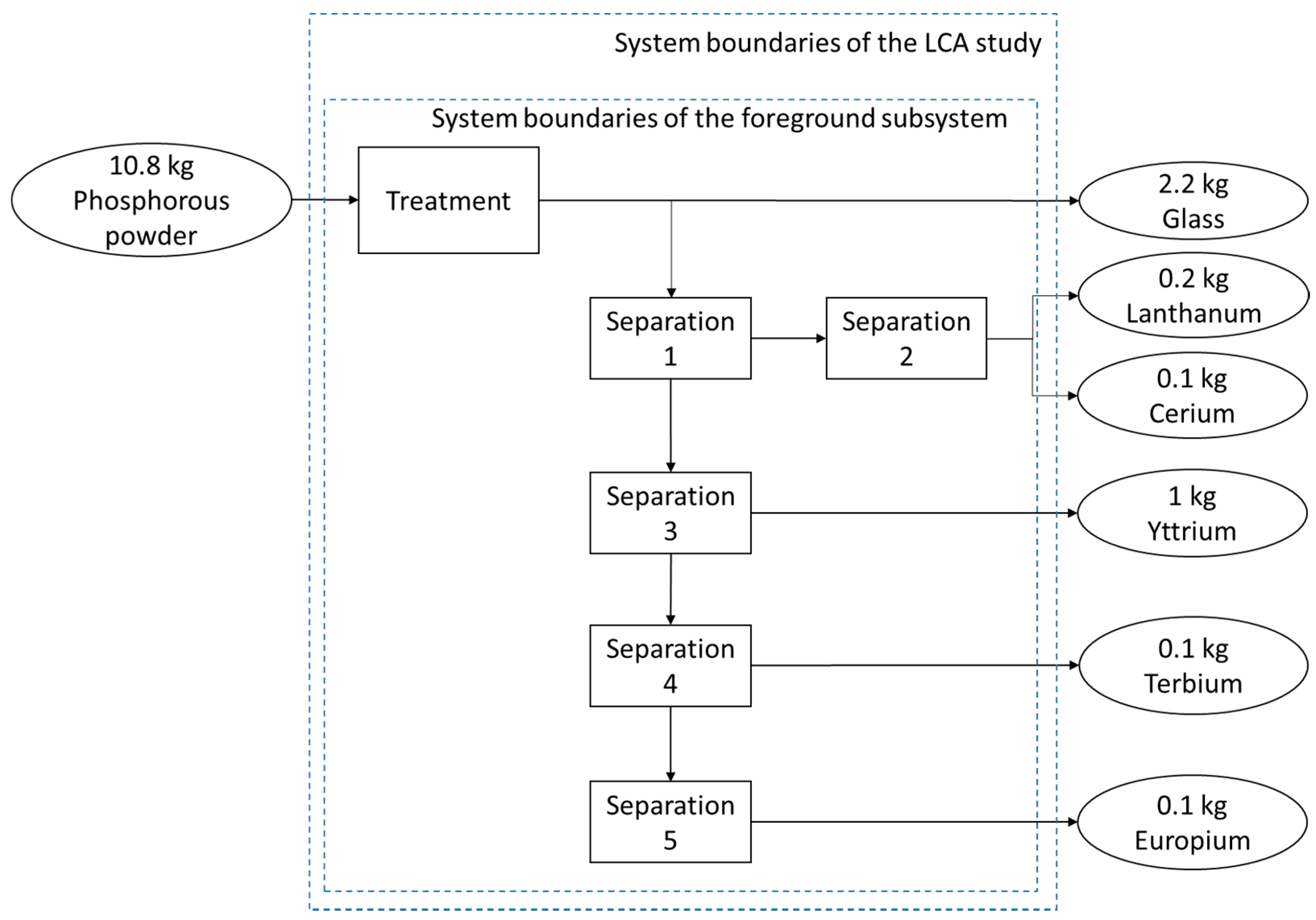

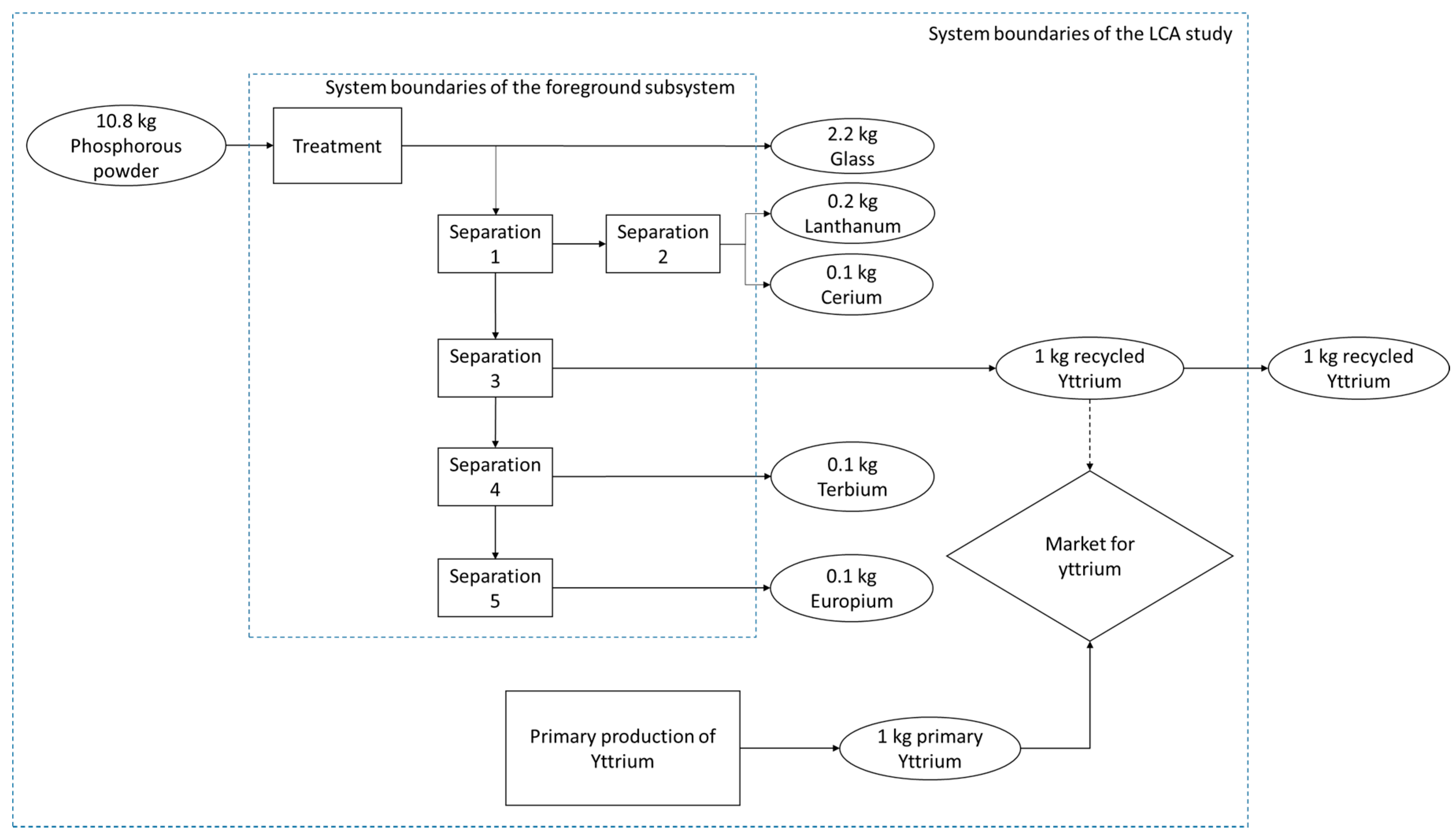

| Attributional process-oriented LCA | The treatment of 10.8 kg of phosphorous powder, and the production of 1 kg of yttrium, 2.2 kg of glass, 0.2 kg of lanthanum, 0.1 kg of cerium, 0.1 kg of terbium, and 0.1 kg of europium |

| Only the LCI of the foreground subsystem is calculated based on attributional background data. No allocation is necessary within the foreground subsystem, as system expansion is applied (Figure 3). |

| Attributional product-oriented LCA | The consumption of 1 kg of recycled yttrium |

| Partitioning must be applied to identify the cradle-to-gate inventory that is attributed to recycled yttrium. More information is required from the product system that supplies the phosphorous powder, as the recycling process is part of this product system (Figure 4). |

| Consequential process-oriented LCA | The treatment of 10.8 kg of phosphorous powder, and the production of 1 kg of yttrium, 2.2 kg of glass, 0.2 kg of lanthanum, 0.1 kg of cerium, 0.1 kg of terbium, and 0.1 kg of europium |

| Only the LCI of the foreground subsystem is calculated based on consequential background data. No allocation is necessary within the foreground subsystem, as system expansion is applied (Figure 3). |

| Consequential process-oriented LCA | The production of 1 kg of recycled yttrium |

| The LCI of the foreground subsystem is calculated based on consequential background data. The ingoing flow of phosphorous powder is modeled by the substitution of its marginal waste treatment process. The outgoing flows of glass, lanthanum, cerium, terbium, and europium are modeled by the substitution by their marginal users (Figure 4). |

| Consequential product-oriented LCA | The consumption of 1 kg of recycled yttrium |

| If the supply of recycled yttrium is constrained, the LCI represents the substitution of recycled yttrium by its marginal user. If the supply is unconstrained, the LCI of the foreground subsystem is calculated. The ingoing flow of phosphorous powder is modeled by the substitution of its marginal waste treatment process. The outgoing flows of glass, lanthanum, cerium, terbium, and europium are modeled by the substitution by their marginal users (Figure 5). |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schrijvers, D.; Loubet, P.; Sonnemann, G. Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA. Sustainability 2020, 12, 5587. https://doi.org/10.3390/su12145587

Schrijvers D, Loubet P, Sonnemann G. Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA. Sustainability. 2020; 12(14):5587. https://doi.org/10.3390/su12145587

Chicago/Turabian StyleSchrijvers, Dieuwertje, Philippe Loubet, and Guido Sonnemann. 2020. "Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA" Sustainability 12, no. 14: 5587. https://doi.org/10.3390/su12145587

APA StyleSchrijvers, D., Loubet, P., & Sonnemann, G. (2020). Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA. Sustainability, 12(14), 5587. https://doi.org/10.3390/su12145587