Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression

Abstract

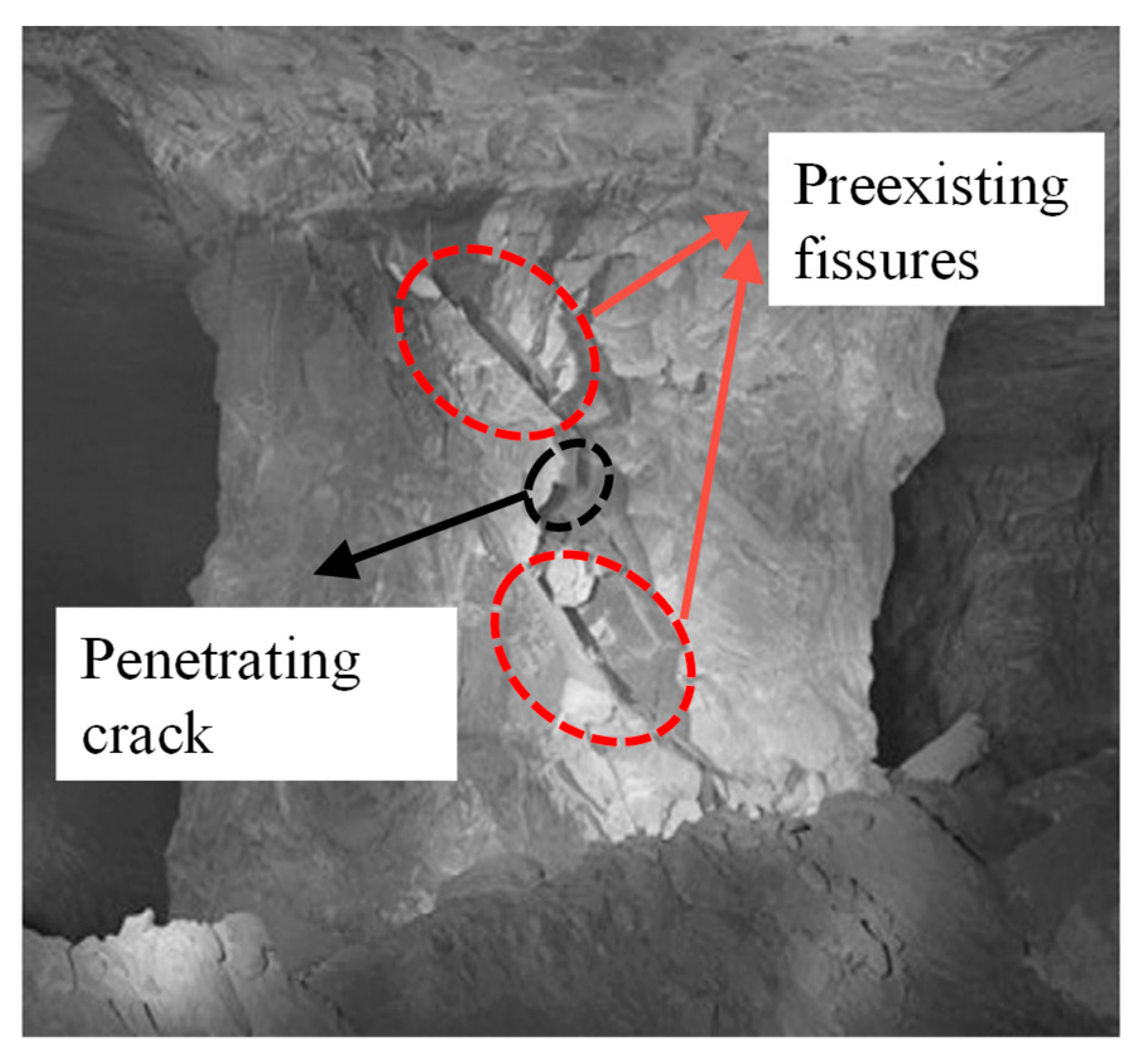

:1. Introduction

2. Laboratory Tests

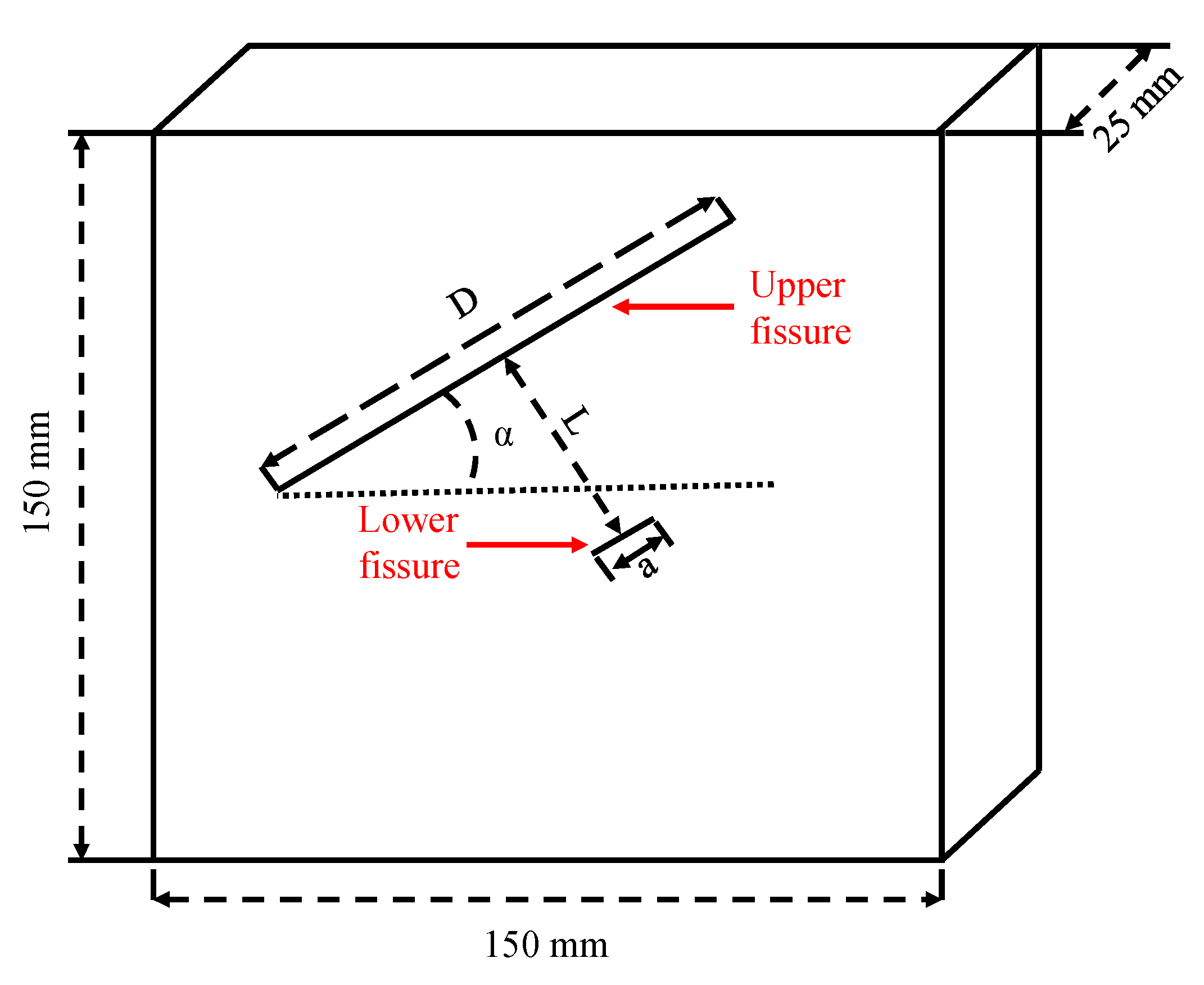

2.1. Prefabricated Parallel Double Fissures Space Design

2.2. Specimen Preparation

2.3. Test Equipment

3. Laboratory Results and Discussion

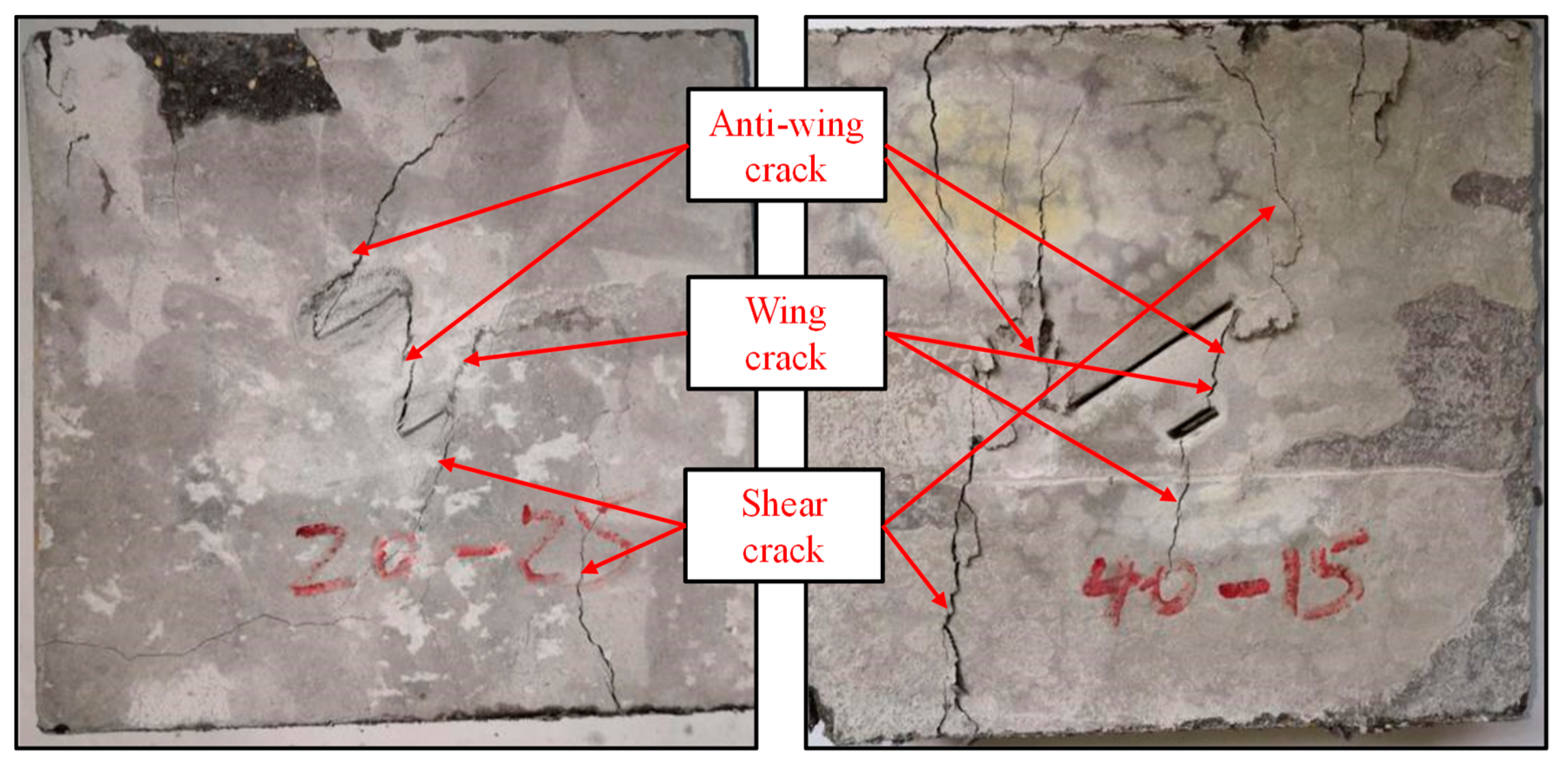

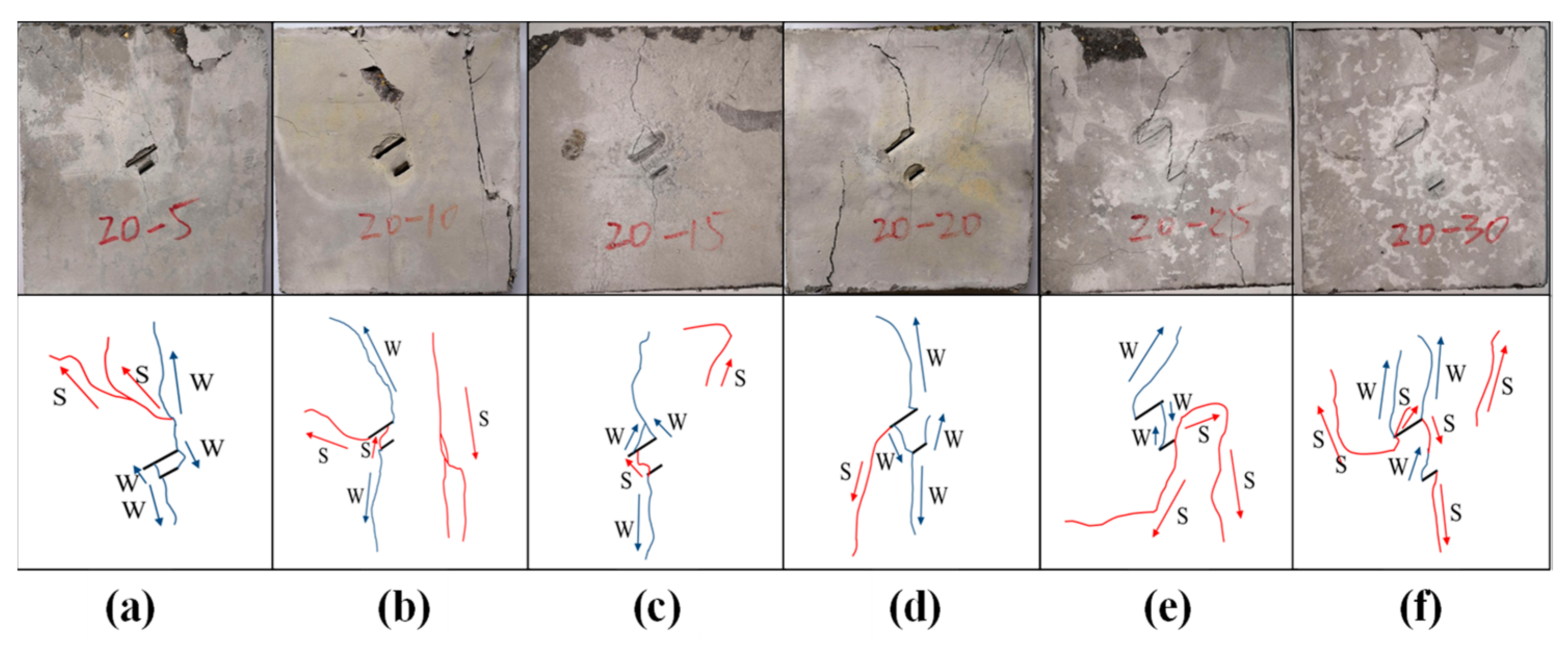

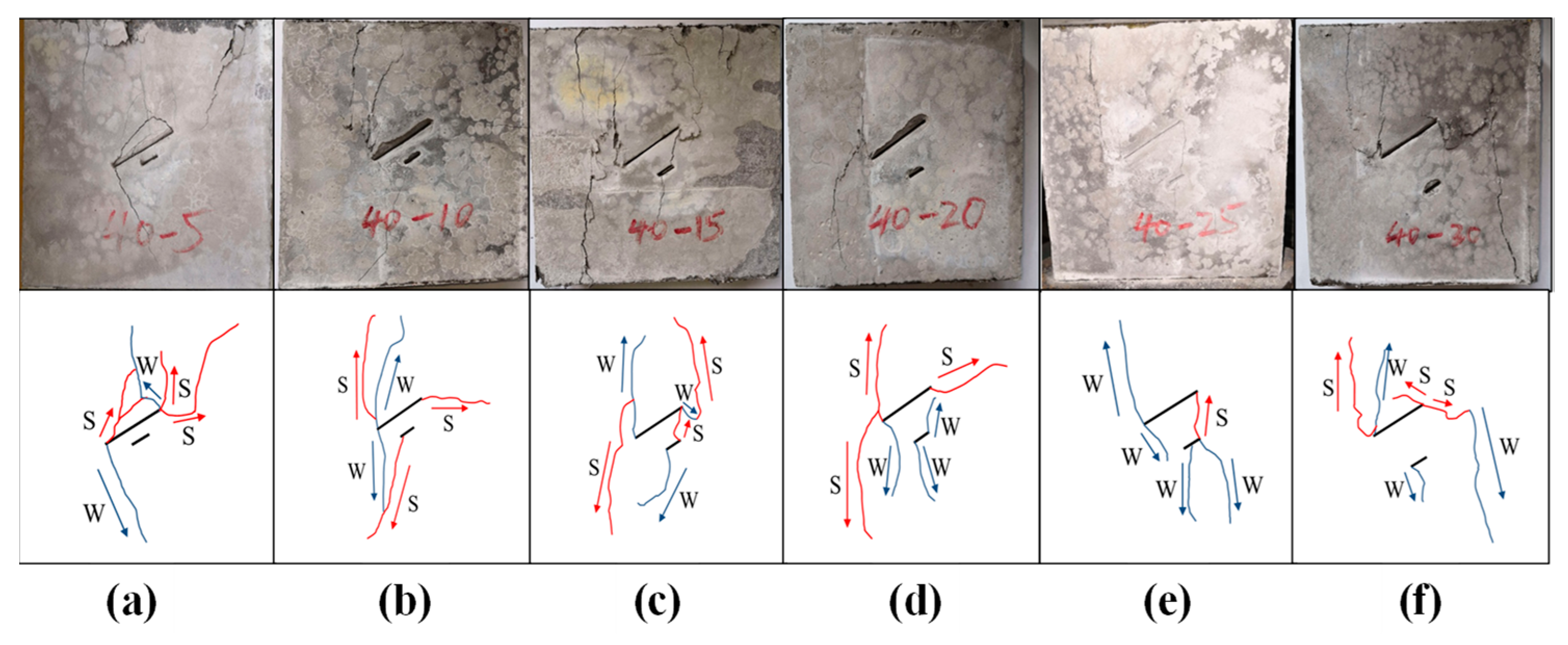

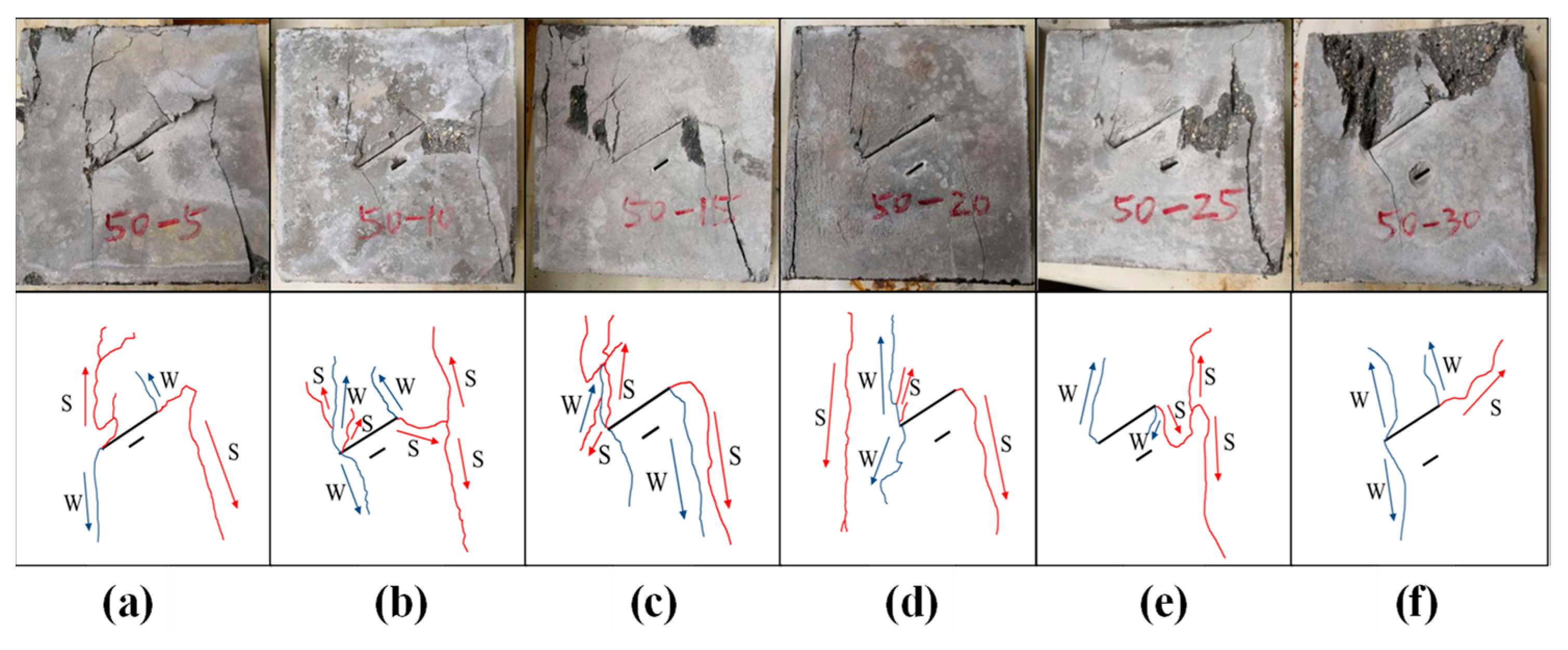

3.1. Crack Propagation Mode and External Morphology

3.2. The Axial Stress–Strain Curves of Specimens with Parallel Double Fissures under Uniaxial Compression

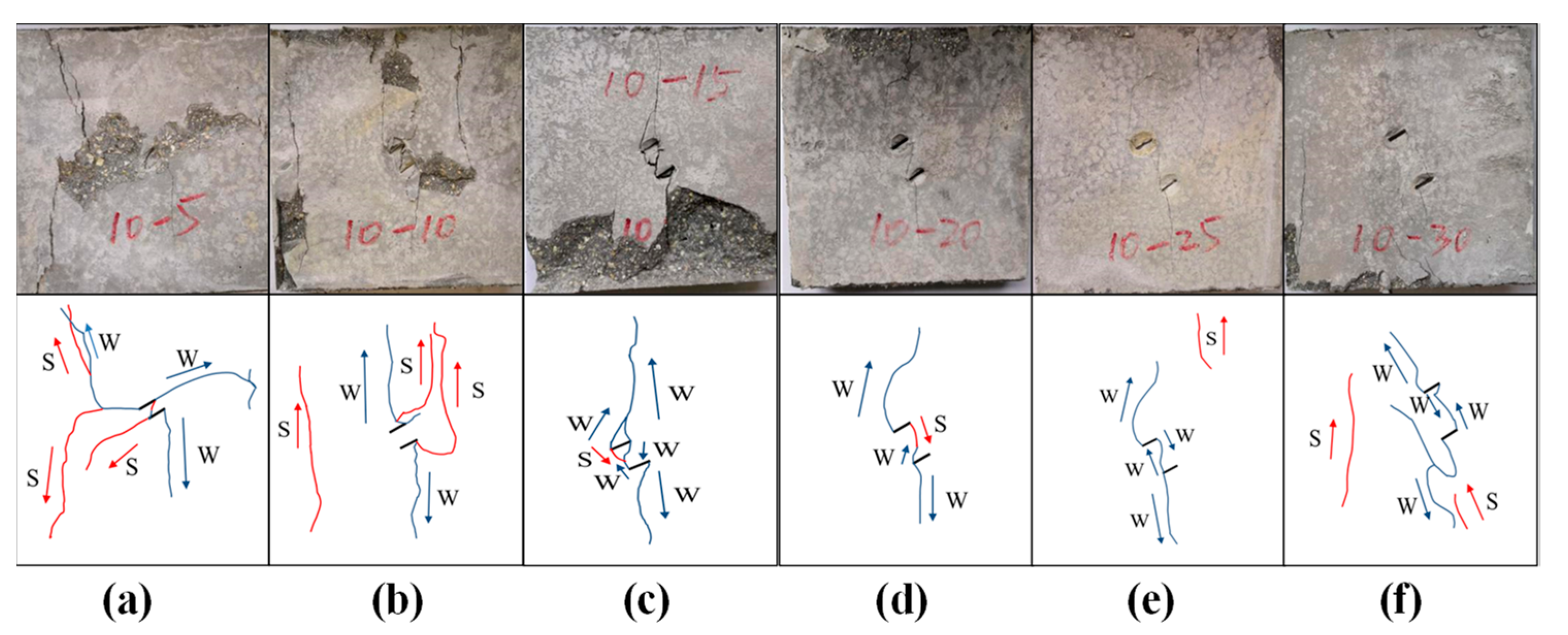

3.3. Crack Propagation Mode of Specimens under Uniaxial Compression until Failure

- When the length difference is 40 mm, no propagation appears at the lower fissure, but the upper generates new cracks. No matter how the spacing changes, the lower fissure will not expand. The effect of the spacing on the lower propagation can’t be seen by experiments (see Figure 11).

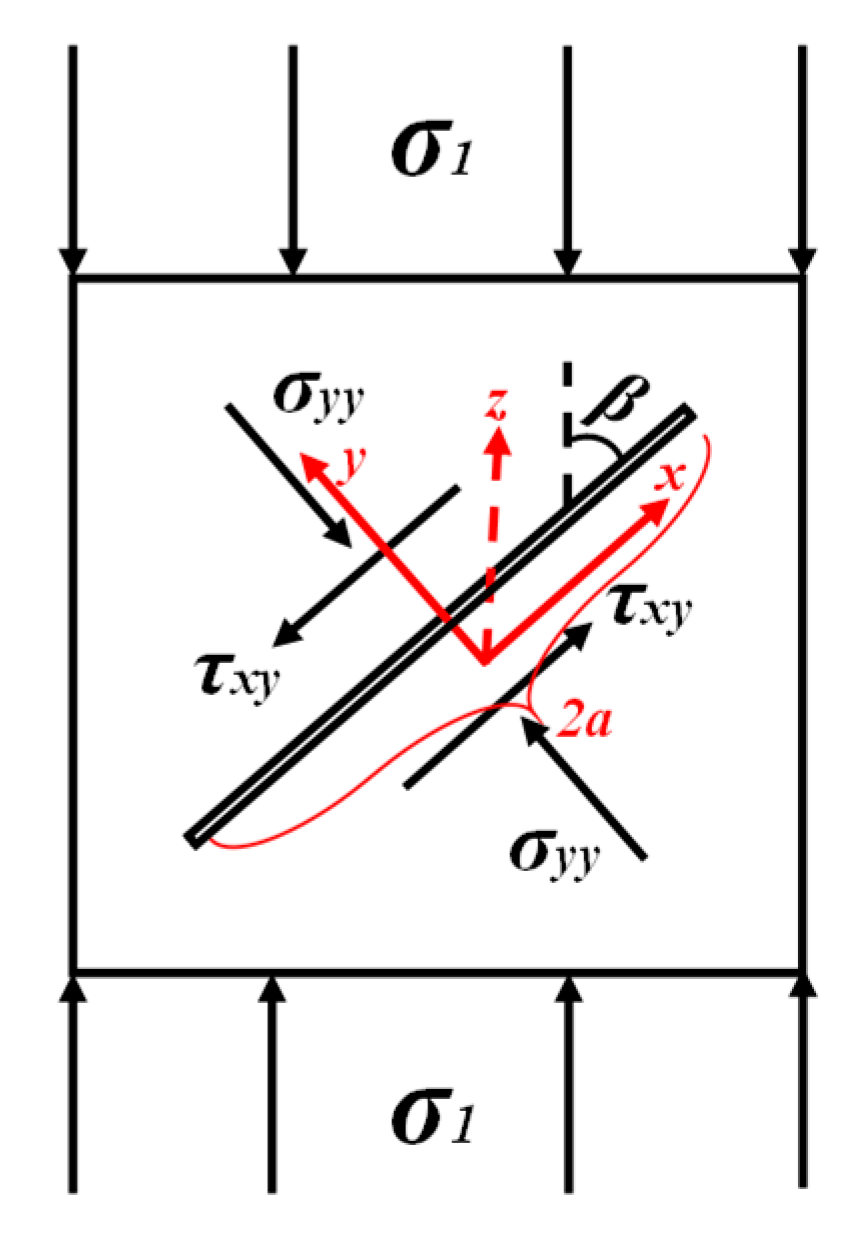

3.4. Mechanical Properties of Crack Propagation

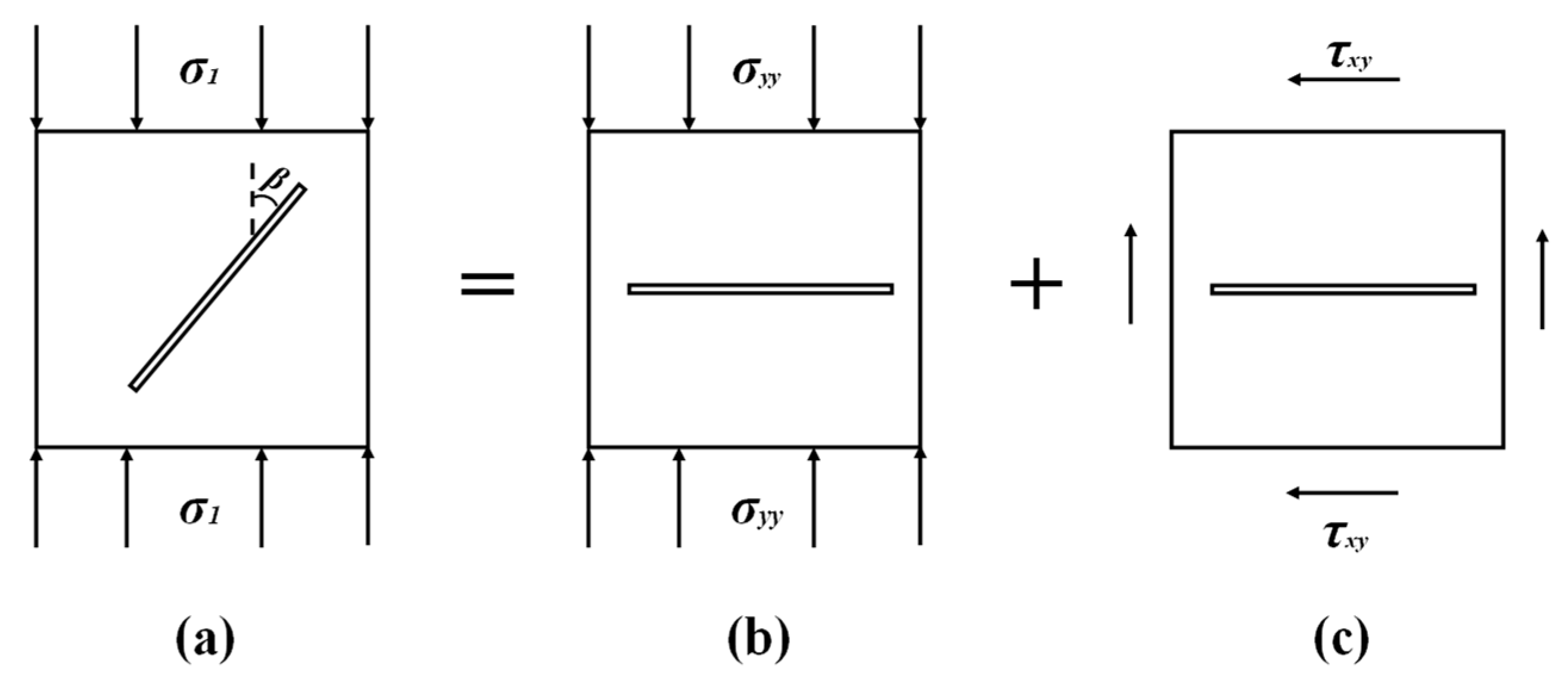

3.4.1. Fracture Strength Analysis of Fissures

3.4.2. Crack Propagation Analysis under Uniaxial Compression

4. Conclusions

- According to the uniaxial compression tests, we found that the initial crack runs along the normal direction of the prefabricated fissure. Meanwhile, the new cracks are generated in three forms, including coplanar shear cracks, diagonal shear cracks and wing-type cracks.

- Based on the theoretical study of the fracture mechanics, we deduced the stress intensity factor formula for the tip of the prefabricated lower fissure. By plugging the physical data into the formula, we obtained the theoretical results. The theoretical results agree well with the tests, which confirm the experiment setting.

- Synthesizing the theoretical and laboratory results, we worked out how the fissures’ length difference and spacing affect the crack propagation of the prefabricated fissures.

- No matter how the length difference and spacing change, new cracks are always generated from the upper fissure.

- The lower fissure’s propagation generates cracks less obviously as the length difference increases. With an increase to 40 mm, it does not occur at all

- The decrease of spacing weakens the lower fissure’s propagation. As it was reduced to 5mm, the propagation stopped.

- Compared to the fissure spacing, the length difference has more significant effects on the lower fissure’s propagation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. Sci. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Dong, W.; Wu, Z.M.; Zhou, X.M.; Wang, N.; Kastiukas, G. An experimental study on crack propagation at rock-concrete interface using digital image correlation technique. Eng. Fract. Mech. 2017, 171, 50–63. [Google Scholar] [CrossRef]

- Yang, S.Q.; Dai, Y.H.; Han, L.J.; Jin, Z.Q. Experimental study on mechanical behavior of brittle marble samples containing different flaws under uniaxial compression. Eng. Fract. Mech. 2009, 76, 1833–1845. [Google Scholar] [CrossRef]

- Zhou, X.P.; Cheng, H.; Feng, Y.F. An Experimental Study of Crack Coalescence Behaviour in Rock-Like Materials Containing Multiple Flaws Under Uniaxial Compression. Rock Mech. Rock Eng. 2014, 47, 1961–1986. [Google Scholar] [CrossRef]

- Feng, P.; Dai, F.; Liu, Y.; Xu, N.W.; Du, H.B. Coupled effects of static-dynamic strain rates on the mechanical and fracturing behaviors of rock-like specimens containing two unparallel fissures. Eng. Fract. Mech. 2019, 207, 237–253. [Google Scholar] [CrossRef]

- Zhou, X.P.; Li, L.H.; Berto, F. Cracking behaviors of rock-like specimens containing two sets of preexisting cross flaws under uniaxial compression. J. Test. Eval. 2019, 47, 838–867. [Google Scholar] [CrossRef]

- Zhou, X.P.; Zhang, J.Z.; Yang, L.H.; Cui, Y.L. Internal morphology of cracking of two 3-d pre-existing cross-embedded flaws under uniaxial compression. Geotech. Test. J. 2018, 41, 20170189. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Mechanism of brittle fracture of rock: Part II—Experimental studies. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 407–423. [Google Scholar] [CrossRef]

- Wu, Q.H.; Li, X.B.; Weng, L.; Li, Q.F.; Zhu, Y.J.; Luo, R. Experimental investigation of the dynamic response of prestressed rockbolt by using an SHPB-based rockbolt test system. Tunn. Undergr. Sp. Technol. 2019, 93, 103088. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, L.Y.; Wang, W.J.; Wan, W.; Ma, W.H. Separation of elastoviscoplastic strains of rock and a nonlinear creep model. Int. J. Geomech. 2018, 18, 04017129. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, L.Y.; Wang, W.J.; Tang, J.Z.; Lin, H.; Wan, W. Transient pulse test and morphological analysis of single rock fractures. Int. J. Rock Mech. Min. Sci. 2017, 91, 139–154. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int. J. Fract. 2011, 168, 227–250. [Google Scholar] [CrossRef]

- Yang, S.Q.; Liu, X.R.; Jing, H.W. Experimental investigation on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 63, 82–92. [Google Scholar] [CrossRef]

- Yang, S.Q.; Liu, X.R. Experimental investigation on dilatancy behavior of marble with pre-existing fissures under different confining pressures. Chin. J. Geotech. Eng. 2012, 34, 2188–2197. [Google Scholar]

- Yang, S.Q.; Yang, Z.; Zhang, P.C.; Tian, W.L. Experiment and peridynamic simulation on cracking behavior of red sandstone containing a single non-straight fissure under uniaxial compression. Theor. Appl. Fract. Mech. 2020, 108, 102637. [Google Scholar] [CrossRef]

- Yang, S.Q. Crack coalescence behavior of brittle sandstone samples containing two coplanar fissures in the process of deformation failure. Eng. Fract. Mech. 2011, 78, 3059–3081. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Ranjith, P.G. Failure mechanical and acoustic behavior of brine saturated-sandstone containing two pre-existing flaws under different confining pressures. Eng. Fract. Mech. 2018, 193, 108–121. [Google Scholar] [CrossRef]

- Zhou, X.P.; Li, G.Q.; Ma, H.C. Real-time experiment investigations on the coupled thermomechanical and cracking behaviors in granite containing three pre-existing fissures. Eng. Fract. Mech. 2020, 224, 106797. [Google Scholar] [CrossRef]

- Su, H.J.; Jing, H.W.; Zhao, H.H. Experimental study on the influence of longitudinal fissure on mechanics charac teristic of sandstone. J. Min. Saf. Eng. 2014, 31, 644–649. [Google Scholar]

- Miao, S.; Pan, P.-Z.; Wu, Z.; Li, S.; Zhao, S. Fracture analysis of sandstone with a single filled flaw under uniaxial compression. Eng. Fract. Mech. 2018, 204, 319–343. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S.; Yang, X.; Xia, K.; Liu, J.; Guo, S.; Wang, S. The coalescence and strength of rock-like materials containing two aligned X- type flaws under uniaxial compression. Geomech. Eng. 2019, 17, 47–56. [Google Scholar]

- Kou, M.; Liu, X.; Tang, S.; Wang, Y. 3-D X-ray computed tomography on failure characteristics of rock-like materials under coupled hydro-mechanical loading. Theor. Appl. Fract. Mech. 2019, 104, 102396. [Google Scholar] [CrossRef]

- Ha, Y.D.; Lee, J.; Hong, J.-W. Fracturing patterns of rock-like materials in compression captured with peridynamics. Eng. Fract. Mech. 2015, 144, 176–193. [Google Scholar] [CrossRef]

- Theocaris, P.S. Ductile branching modes in stable propagating cracks: An experimental study. Eng. Fract. Mech. 1990, 36, 477–493. [Google Scholar] [CrossRef]

- Wei, M.D.; Dai, F.; Xu, N.W.; Zhao, T. Stress intensity factors and fracture process zones of ISRM-suggested chevron notched specimens for mode I fracture toughness testing of rocks. Eng. Fract. Mech. 2016, 168, 174–189. [Google Scholar] [CrossRef]

- Einstein, H.H.; Hirschfeld, R.C.; Nelson, R.A.; Bruhn, R.W. Model Studies of Jointed-Rock Behavior. In Proceedings of the 11th U.S. Symposium on Rock Mechanics (USRMS), Berkeley, CA, USA, 16–19 June 1969; p. 22. [Google Scholar]

- Zhou, T.; Zhu, J.B.; Ju, Y.; Xie, H.P. Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng. Fract. Mech. 2019, 205, 190–204. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, L.Y.; Wang, W.J.; Pu, C.Z.; Wan, W.; Tang, J.Z. Cracking and Stress–Strain Behavior of Rock-Like Material Containing Two Flaws Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 2665–2687. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wan, W.; Wang, W.J.; Wang, M.; Peng, Q.Y. Fracture experiments on ordered multi-crack body in rock-like materials under uniaxial compression and numerical simulation of wing cracks. Yantu Gongcheng Xuebao/Chin. J. Geotech. Eng. 2013, 35, 2097–2109. [Google Scholar]

- Pu, C.Z.; Cao, P.; Zhao, Y.L.; Zhang, X.Y.; Liu, Y.K. Numerical analysis and strength experiment of rock-like materials with multi-fissures under uniaxial compression. Rock Soil Mech. 2010, 31, 3661–3666. [Google Scholar]

- Jin, J.; Cao, P.; Pu, C. Influence of flaw parameters on damage mode and strength of rock-like materials. J. Cent. South Univ. 2014, 45, 529–535. [Google Scholar]

- Liu, X.; Liu, A.; Li, X. Experimental study of columnar jointed sandstone-like material with preset filling. Chin. J. Rock Mech. Eng. 2014, 33, 772–777. [Google Scholar]

- Zhang, B.; Li, S.C.; Yang, X.Y.; Zhang, D.F.; Yang, W.M. Uniaxial compression tests on mechanical properties of rock mass similar material with cross-cracks. Yantu Lixue/Rock Soil Mech. 2012, 33, 3674–3679. [Google Scholar]

- Qian, X.K.; Liang, Z.Z.; Liao, Z.Y.; Wang, K. Numerical investigation of dynamic fracture in rock specimens containing a pre-existing surface flaw with different dip angles. Eng. Fract. Mech. 2020, 223, 106675. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Xu, X. Numerical simulation of propagation and coalescence of flaws in rock materials under compressive loads using the extended non-ordinary state-based peridynamics. Eng. Fract. Mech. 2016, 163, 248–273. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Zhang, X.P. Crack coalescence study based on the bonded-particle model approach. In Proceedings of the ISRM International Symposium-EUROCK 2012, Stockholm, Sweden, 28–30 May 2012; p. 10. [Google Scholar]

- Modiriasari, A.; Jiang, L.; Yoon, H.; Bobet, A.; Pyrak-Nolte, L.J. Effect of Layering on Cracking Initiation and Propagation under Uniaxial Compression. In Proceedings of the Agu Fall Meeting, New Orleans, LA, USA, 11–15 December 2017. [Google Scholar]

- Afolagboye, L.O.; He, J.; Wang, S. Crack Initiation and Coalescence Behavior of Two Non-parallel Flaws. Geotech. Geol. Eng. 2017, 36, 105–133. [Google Scholar] [CrossRef]

- Zhou, X.P.; Zhang, J.Z.; Wong, L.N.Y. Experimental Study on the Growth, Coalescence and Wrapping Behaviors of 3D Cross-Embedded Flaws Under Uniaxial Compression. Rock Mech. Rock Eng. 2018, 51, 1379–1400. [Google Scholar] [CrossRef]

- Afolagboye, L.O.; He, J.; Wang, S. Experimental study on cracking behaviour of moulded gypsum containing two non-parallel overlapping flaws under uniaxial compression. J. Mech. 2017, 33, 394–405. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Shou, Y. The modeling of crack propagation and coalescence in rocks under uniaxial compression using the novel conjugated bond-based peridynamics. Int. J. Mech. Sci. 2017, 614–643. [Google Scholar] [CrossRef]

- Singh, R.N.; Whittaker, B.N.; Sun, G. Rock fracture mechanics. In Rock Fracture Mechanics; Elsevier: Amsterdam, The Netherlands, 1992; p. 275. [Google Scholar]

- Xiang, W.; Yang, H.T. The method of caustics applied in fracture mechanics(determination of stress intensity factor KI). Acta Mech. Solida Sinica 1984, 23, 498–548. [Google Scholar]

- Irwin, G.R. Linear fracture mechanics, fracture transition, and fracture control. Eng. Fract. Mech. 1968, 1, 241–257. [Google Scholar] [CrossRef]

- Marquis, G. Failure Modes and Fatigue Strength of Improved HSS Welds. Eng. Fract. Mech. 2001, 77, 2051–2062. [Google Scholar] [CrossRef]

- Wang, M.; Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock Mech. Min. Sci. 2019, 123, 104094. [Google Scholar] [CrossRef]

- Xie, H.P.; Li, L.Y.; Peng, R.D.; Ju, Y. Energy analysis and criteria for structural failure of rocks. J. Rock Mech. Geotech. Eng. 2009, 1, 11–20. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y. Griffith’s criterion for mixed mode crack propagation. Eng. Fract. Mech. 1987, 26, 683–689. [Google Scholar] [CrossRef]

- Margolin, L.G. A generalized Griffith criterion for crack propagation. Eng. Fract. Mech. 1984, 19, 539–543. [Google Scholar] [CrossRef]

- Rychlewski, J. On Hooke’s law. J. Appl. Math. Mech. 1984, 48, 303–314. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Peng, Q.Y.; Wan, W.; Wang, W.J.; Zhang, S.G. Seepage-fracture coupling mechanism of rock masses cracking propagation under high hydraulic pressure and numerical verification. Yantu Lixue/Rock Soil Mech. 2014, 35, 556–564. [Google Scholar]

- Wu, Q.H.; Chen, L.; Shen, B.T.; Dlamini, B.; Li, S.Q.; Zhu, Y.J. Experimental Investigation on Rockbolt Performance Under the Tension Load. Rock Mech. Rock Eng. 2019, 52, 4605–4618. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, Y.X.; Wang, W.J.; Tang, L.; Liu, Q.; Cheng, G. Modeling of rheological fracture behavior of rock cracks subjected to hydraulic pressure and far field stresses. Theor. Appl. Fract. Mech. 2019, 101, 59–66. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Z.M.; Dong, Y.Q.; Zhou, L. Study of mixed-mode I/II fractures using single cleavage semicircle compression specimens under impacting loads. Eng. Fract. Mech. 2017, 177, 33–44. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, L.Y.; Liao, J.; Wang, W.J.; Liu, Q.; Tang, L.M. Experimental study of fracture toughness and subcritical crack growth of three rocks under different environments. Int. J. Geomech. 2020, 20, 04020128. [Google Scholar] [CrossRef]

- Kpegba, K.W.; Ottavy, N.; Souchet, R. Stress intensity factors in two-dimensional crack problems by using the Superimposed Meshes Method. Eng. Fract. Mech. 1996, 54, 113–125. [Google Scholar] [CrossRef]

- Hooft, G.T. Dimensional regularization and the renormalization group. Nucl. Phys. 1973, 61, 455–468. [Google Scholar] [CrossRef] [Green Version]

- Pal, S.; Ibrahim, R.N.; Raman, R.K.S. Threshold stress intensity factor and crack growth rate for stress corrosion cracking of simulated heat affected zone in caustic solution. Eng. Fract. Mech. 2011, 78, 13–26. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, Y.X.; Wang, W.J.; Wang, W.J.; Tang, J.Z. Modeling of non-linear rheological behavior of hard rock using triaxial rheological experiment. Int. J. Rock Mech. Min. Sci. 2017, 93, 66–75. [Google Scholar] [CrossRef]

| Specimen Number (D-L) | Upper Fissure Length (mm) | Fissure Spacing (mm) | Specimen Number (D-L) | Upper Fissure Length (mm) | Fissure Spacing (mm) |

|---|---|---|---|---|---|

| 10–5 | a | 0.5a | 30–20 | 3a | 2a |

| 10–10 | a | a | 30–25 | 3a | 2.5a |

| 10–15 | a | 1.5a | 30–30 | 3a | 3a |

| 10–20 | a | 2a | 40–5 | 4a | 0.5a |

| 10–25 | a | 2.5a | 40–10 | 4a | a |

| 10–30 | a | 3a | 40–15 | 4a | 1.5a |

| 20–5 | 2a | 0.5a | 40–20 | 4a | 2a |

| 20–10 | 2a | a | 40–25 | 4a | 2.5a |

| 20–15 | 2a | 1.5a | 40–30 | 4a | 3a |

| 20–20 | 2a | 2a | 50–5 | 5a | 0.5a |

| 20–25 | 2a | 2.5a | 50–10 | 5a | a |

| 20–30 | 2a | 3a | 50–15 | 5a | 1.5a |

| 30–5 | 3a | 0.5a | 50–20 | 5a | 2a |

| 30–10 | 3a | a | 50–25 | 5a | 2.5a |

| 30–15 | 3a | 1.5a | 50–30 | 5a | 3a |

| Specimen Number (D-L) | σmax (Mpa) | Specimen Number (D-L) | σmax (Mpa) | Specimen Number (D-L) | σmax (Mpa) | Specimen Number (D-L) | σmax (Mpa) |

|---|---|---|---|---|---|---|---|

| 10–5 | 41.30 | 40–10 | 24.38 | 20–20 | 32.56 | 40–25 | 19.17 |

| 20–5 | 32.70 | 50–10 | 18.60 | 30–20 | 30.68 | 50–25 | 18.18 |

| 30–5 | 28.50 | 10–15 | 39.10 | 40–20 | 28.51 | 10–30 | 39.15 |

| 40–5 | 18.95 | 20–15 | 34.00 | 50–20 | 20.08 | 20–30 | 31.53 |

| 50–5 | 19.10 | 30–15 | 26.24 | 10–25 | 38.35 | 30–30 | 28.87 |

| 10–10 | 43.61 | 40–15 | 31.25 | 20–25 | 32.26 | 40–30 | 24.38 |

| 20–10 | 33.85 | 50–15 | 24.41 | 30–25 | 27.08 | 50–30 | 17.14 |

| 30–10 | 27.14 | 10–20 | 43.92 |

| Specimen Number (D-L) | ||||

|---|---|---|---|---|

| 20–5 | 3.13 | 2.95 | 2.60 | 2.32 |

| 30–5 | 3.16 | 2.95 | 2.77 | 2.32 |

| 40–5 | 2.42 | 2.95 | 2.13 | 2.32 |

| 50–5 | 2.73 | 2.95 | 2.39 | 2.32 |

| 20–10 | 3.42 | 3.36 | 2.69 | 2.39 |

| 30–10 | 3.18 | 3.36 | 2.64 | 2.39 |

| 40–10 | 3.25 | 3.36 | 2.74 | 2.39 |

| 50–10 | 2.74 | 3.36 | 2.34 | 2.39 |

| 20–15 | 3.62 | 3.30 | 2.70 | 2.19 |

| 30–15 | 3.25 | 3.30 | 2.55 | 2.19 |

| 40–15 | 4.23 | 3.30 | 3.51 | 2.19 |

| 50–15 | 3.64 | 3.30 | 3.07 | 2.19 |

| 20–20 | 3.64 | 3.92 | 2.59 | 2.44 |

| 30–20 | 4.10 | 3.92 | 2.98 | 2.44 |

| 40–20 | 4.13 | 3.92 | 3.20 | 2.44 |

| 50–20 | 3.21 | 3.92 | 2.52 | 2.44 |

| 20–25 | 3.60 | 3.46 | 2.56 | 2.11 |

| 30–25 | 3.62 | 3.46 | 2.63 | 2.11 |

| 40–25 | 2.85 | 3.46 | 2.21 | 2.11 |

| 50–25 | 2.90 | 3.46 | 2.28 | 2.11 |

| 20–30 | 3.77 | 3.63 | 2.50 | 2.17 |

| 30–30 | 3.90 | 3.63 | 2.81 | 2.17 |

| 40–30 | 3.62 | 3.63 | 2.74 | 2.17 |

| 50–30 | 2.77 | 3.63 | 2.15 | 2.17 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Wan, W.; Zhao, Y.; Peng, W. Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression. Sustainability 2020, 12, 5188. https://doi.org/10.3390/su12125188

Chen W, Wan W, Zhao Y, Peng W. Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression. Sustainability. 2020; 12(12):5188. https://doi.org/10.3390/su12125188

Chicago/Turabian StyleChen, Wei, Wen Wan, Yanlin Zhao, and Wenqing Peng. 2020. "Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression" Sustainability 12, no. 12: 5188. https://doi.org/10.3390/su12125188

APA StyleChen, W., Wan, W., Zhao, Y., & Peng, W. (2020). Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression. Sustainability, 12(12), 5188. https://doi.org/10.3390/su12125188