Geotechnical Properties of Anthropogenic Soils in Road Engineering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Soil Properties and Sample Preparation

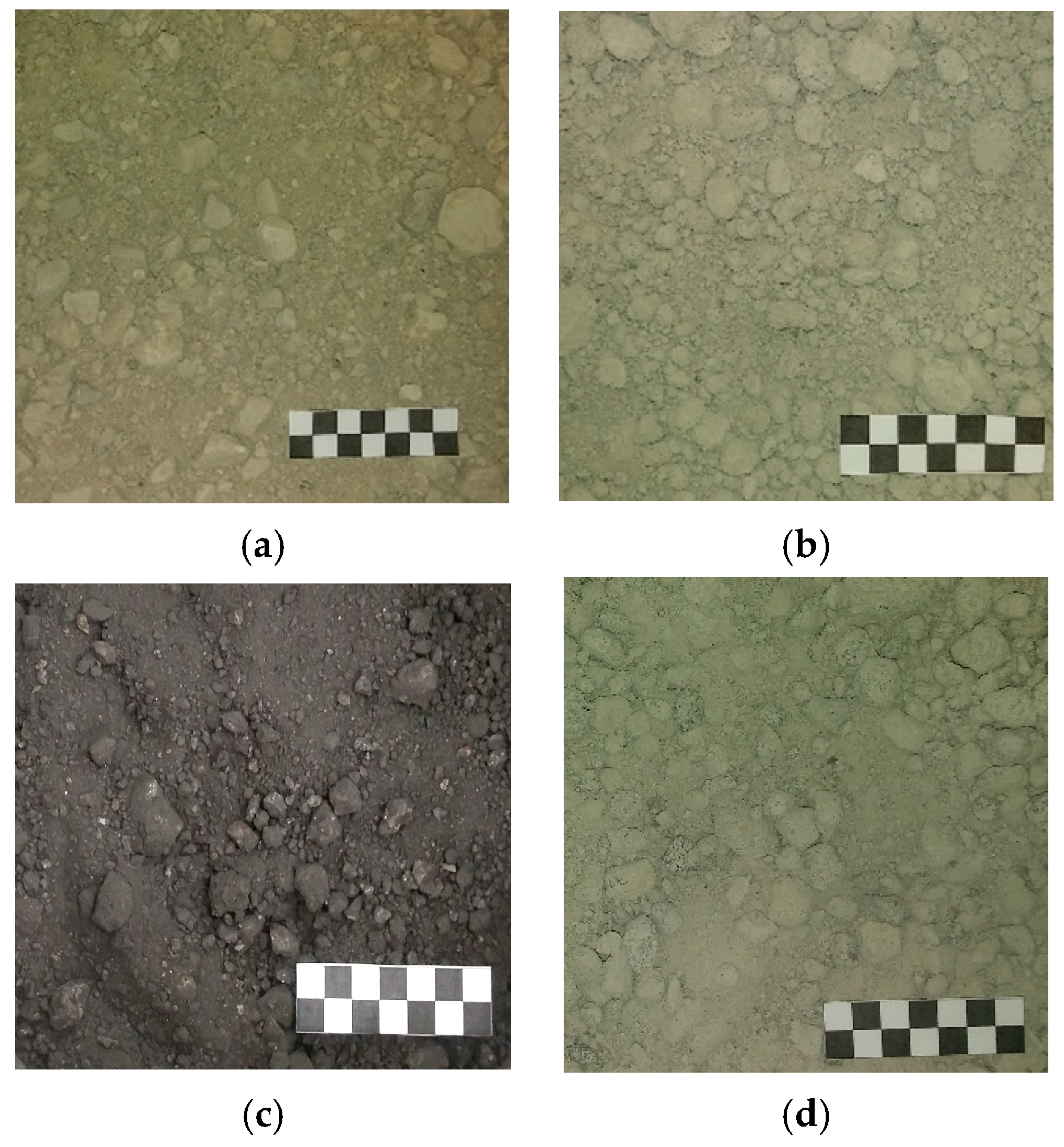

2.1.1. Crushed Limestone

2.1.2. Recycled Concrete Aggregate

2.1.3. Fly Ash and Bottom Ash Mix

2.1.4. Blast Furnace Slag

2.2. Static CBR Tests

2.3. Cyclic CBR Tests

2.4. Modified Oedometer Tests

3. Results

3.1. Soil Gradation Curve

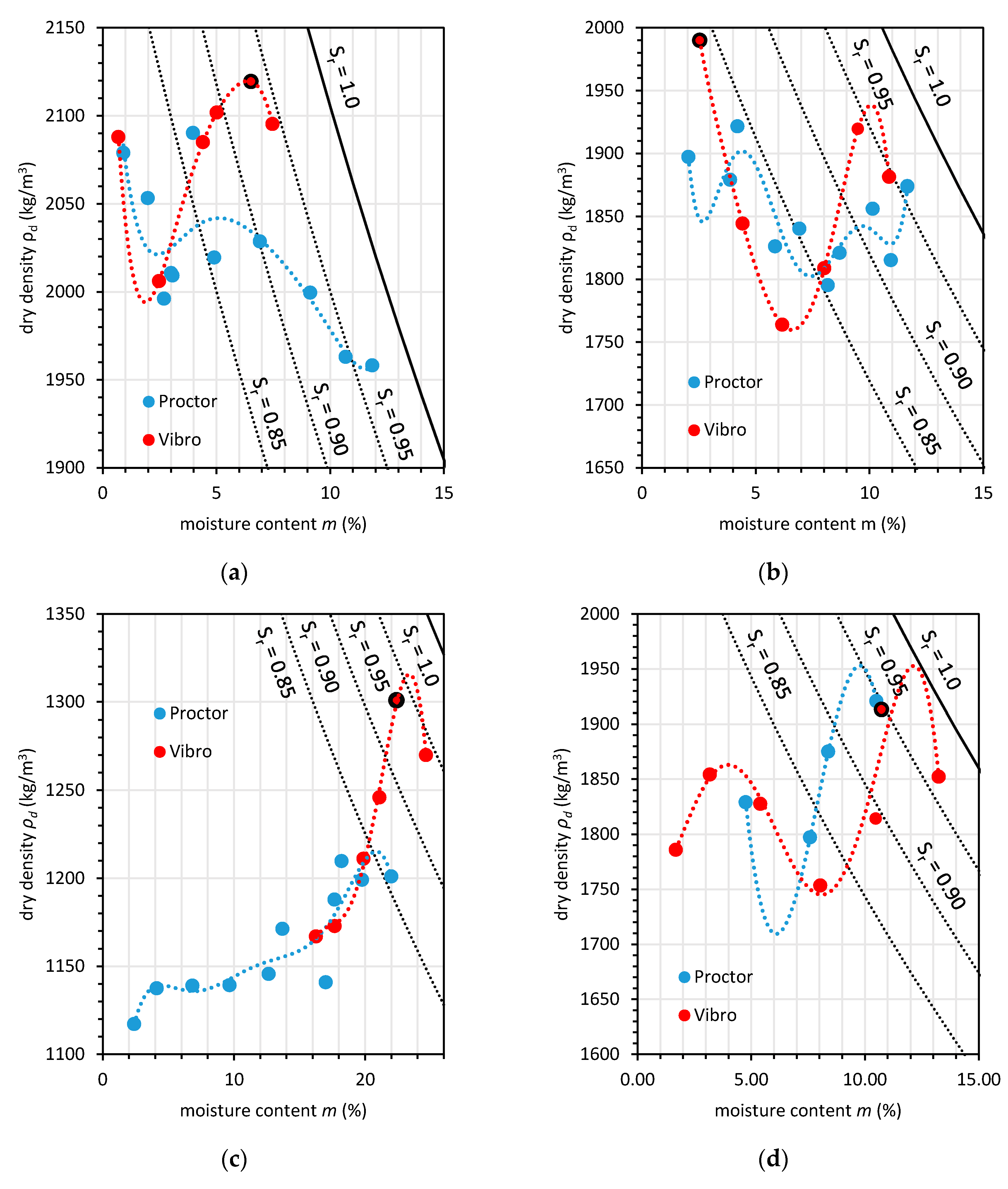

3.2. Optimum Moisture Content

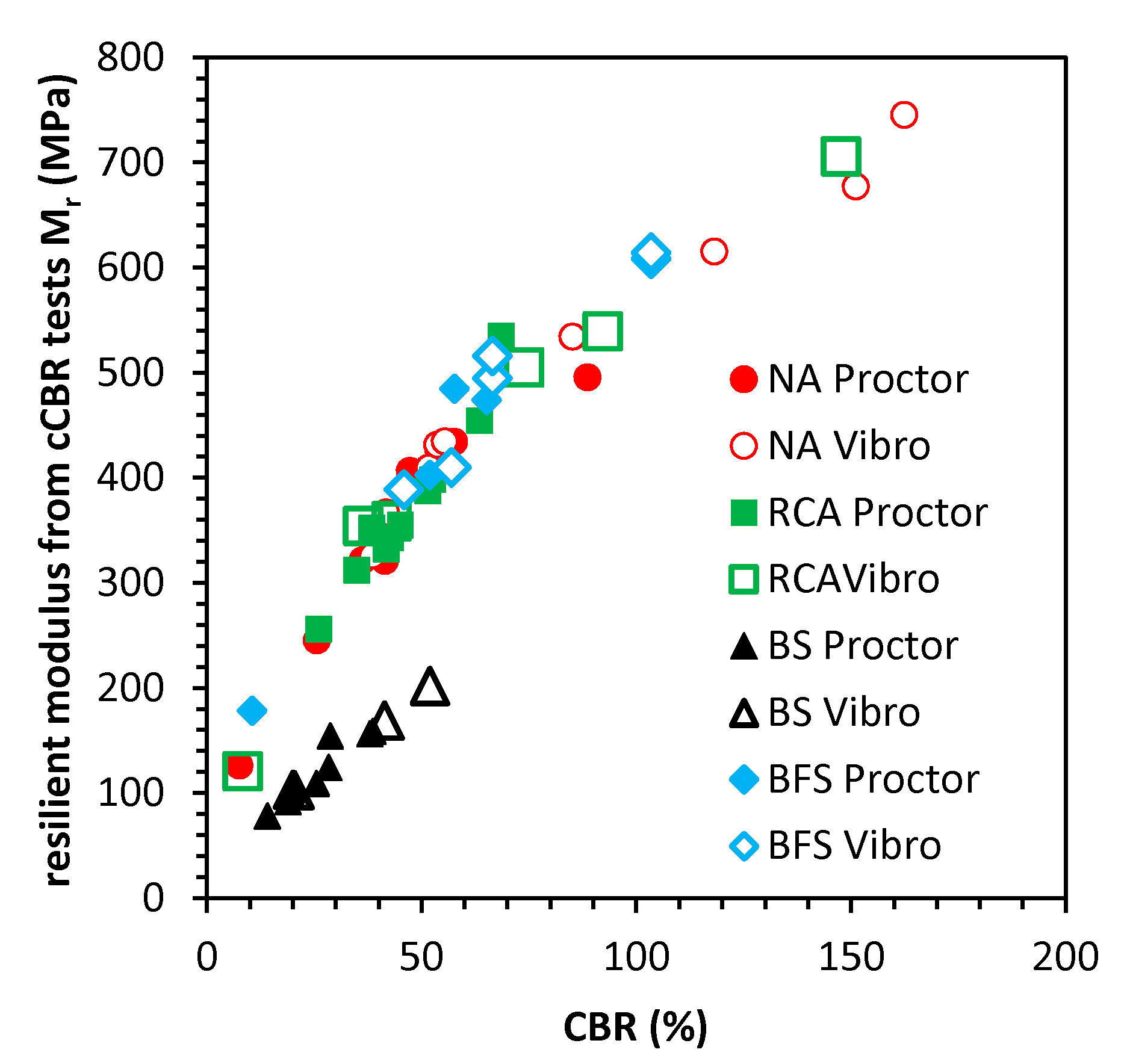

3.3. Static CBR Test Results

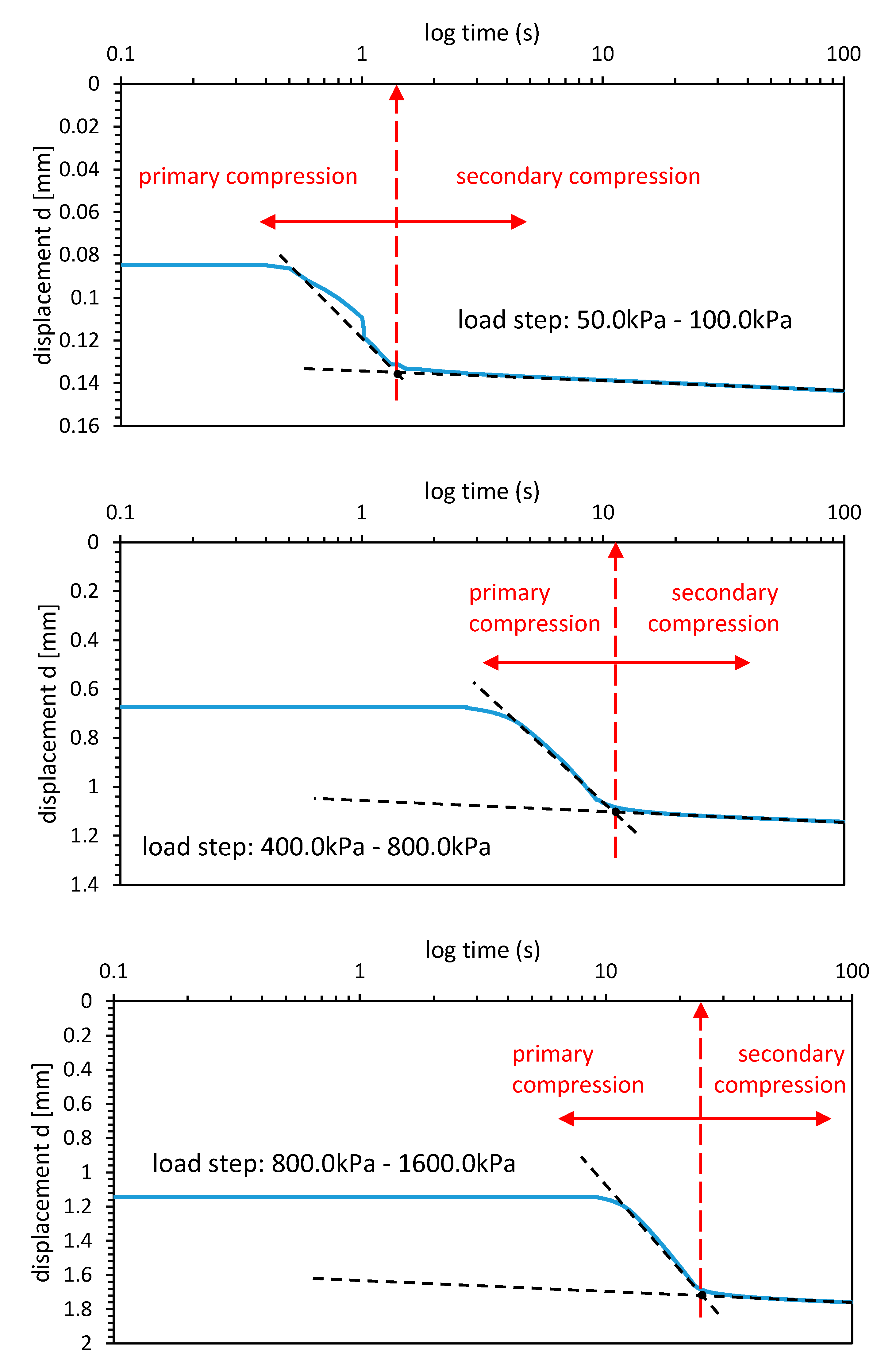

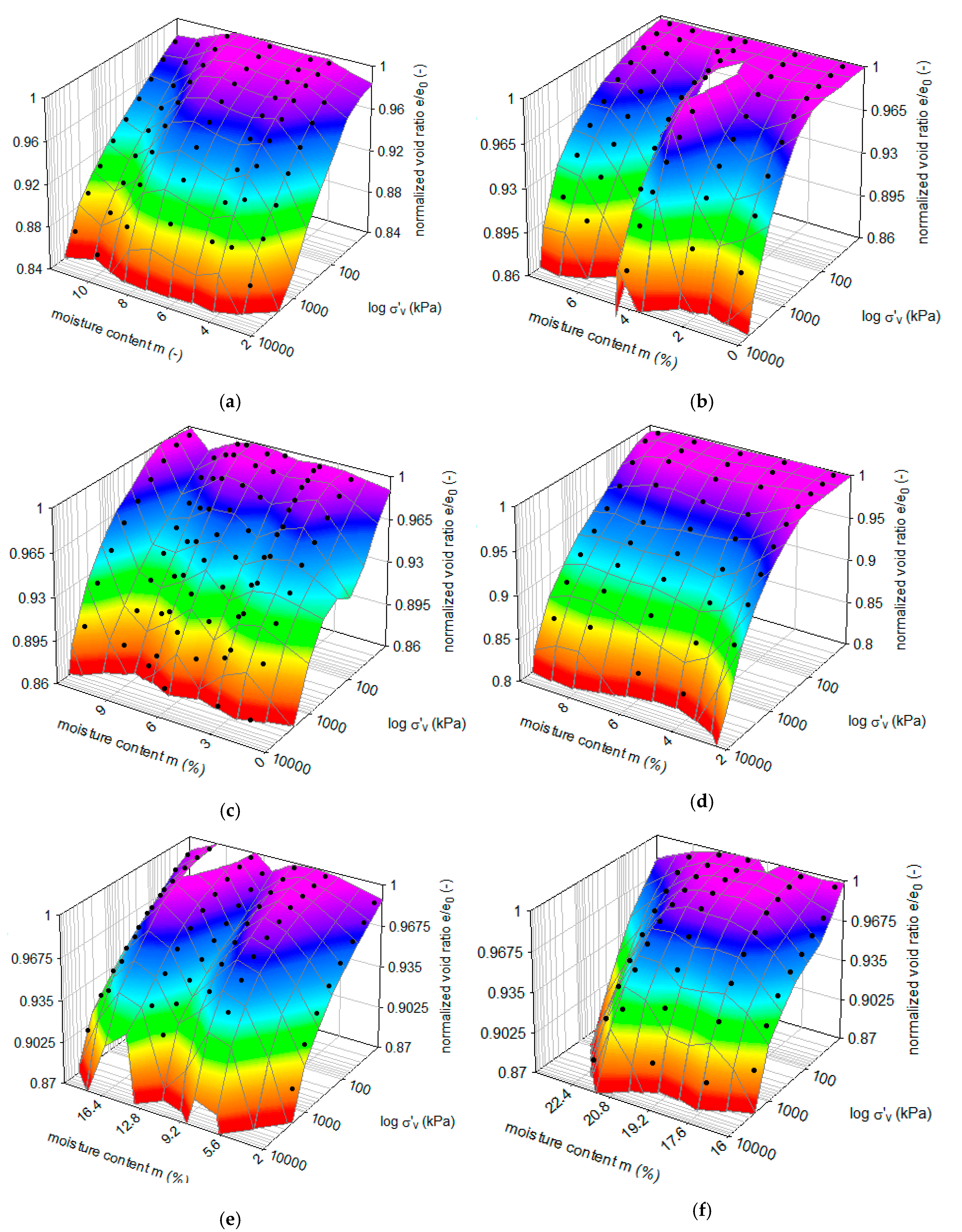

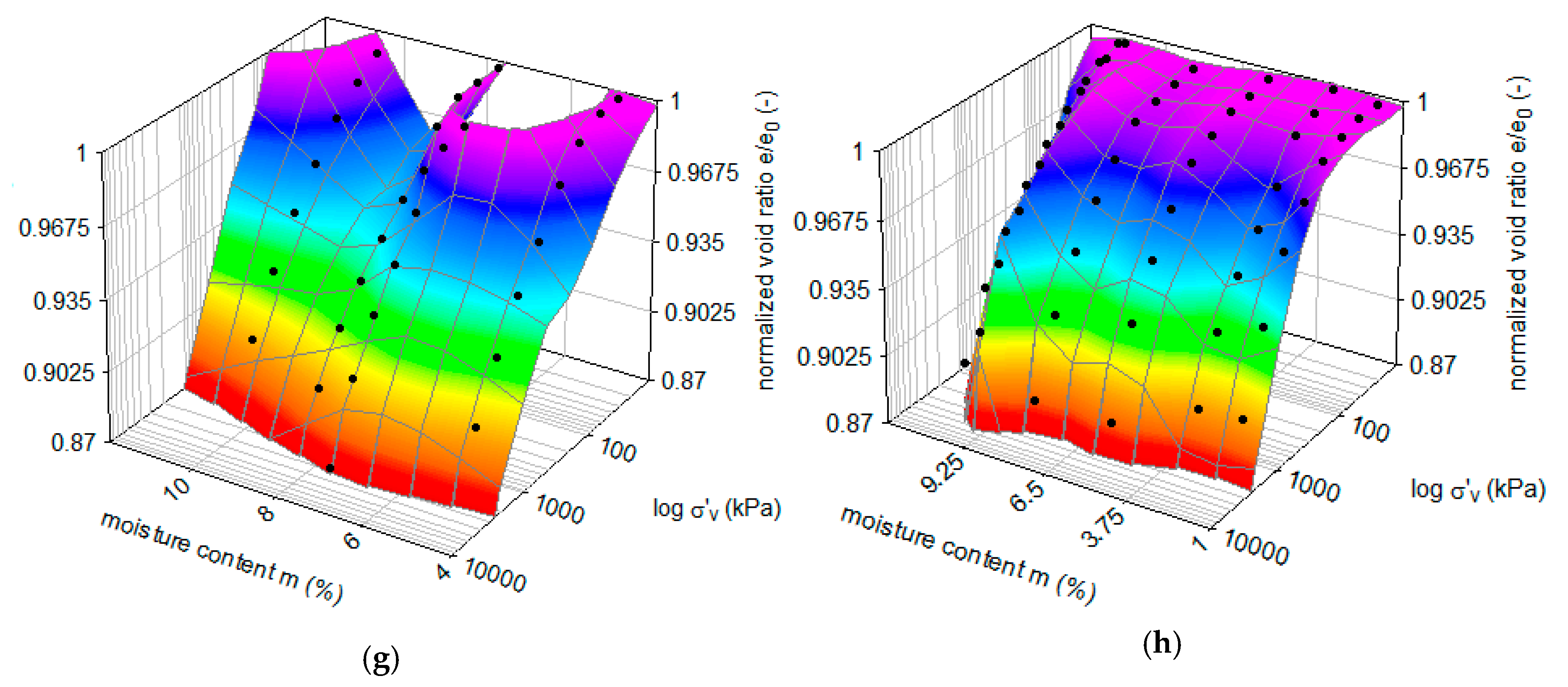

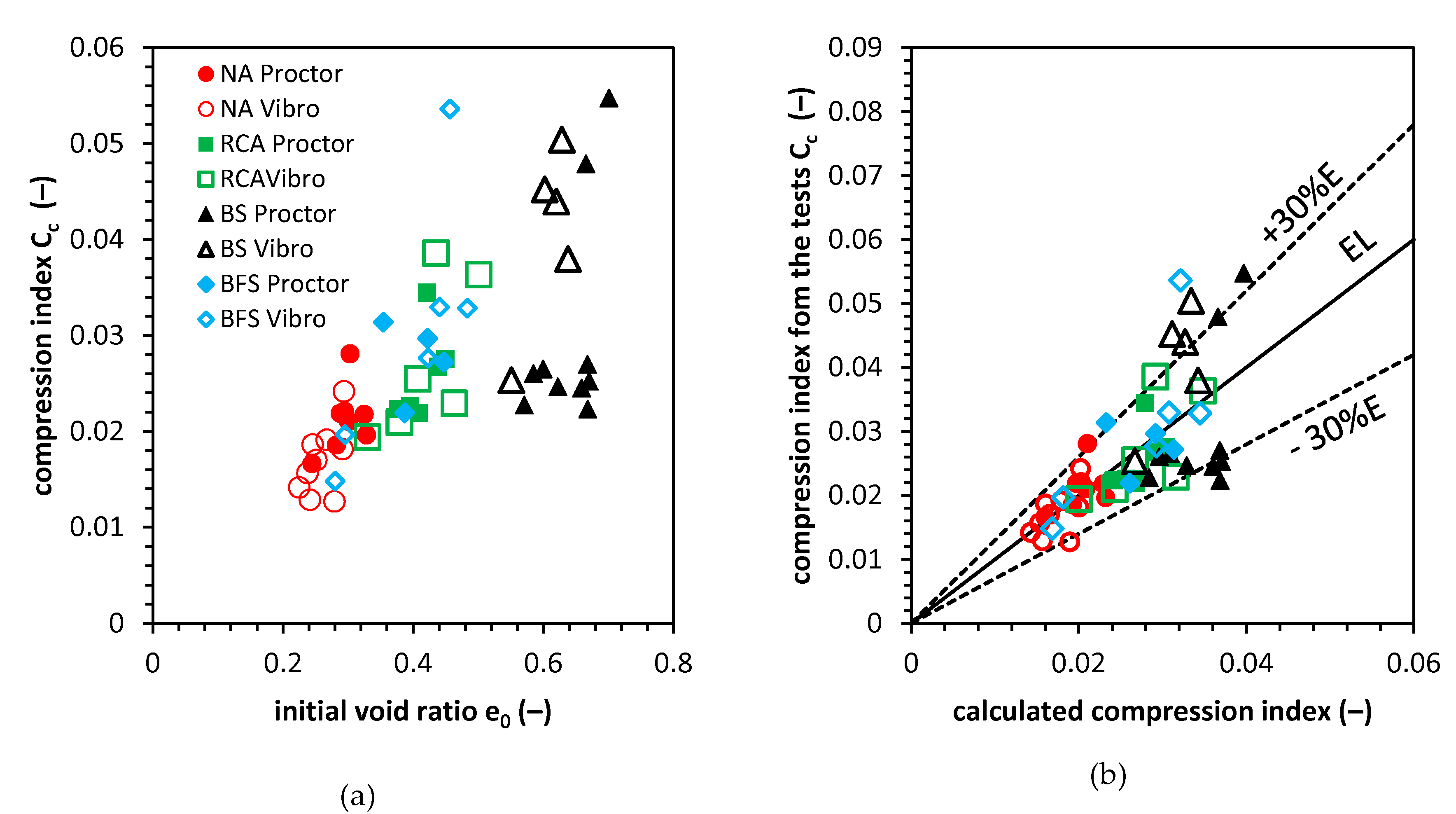

3.4. Oedometric Test Results

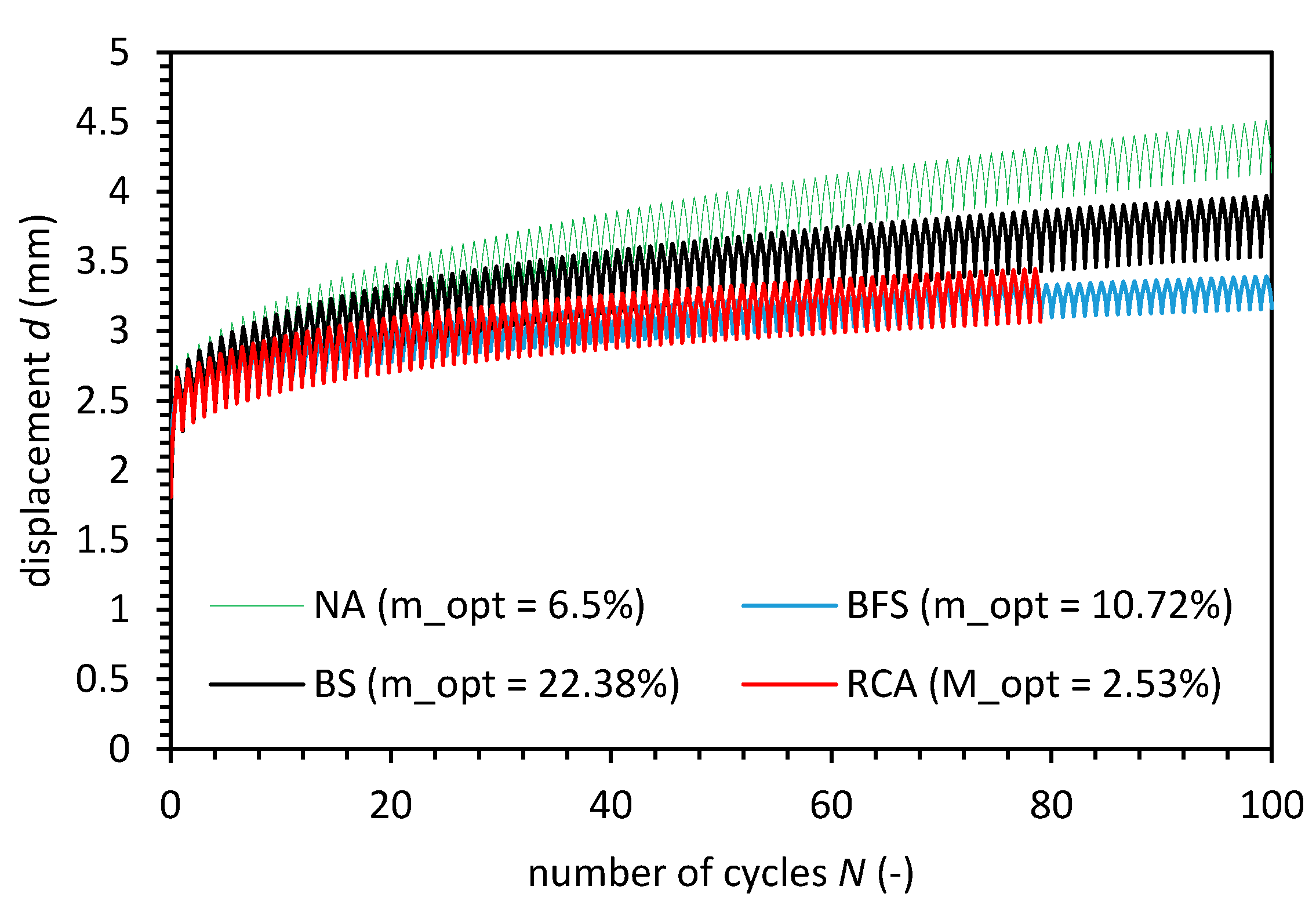

3.5. Cyclic CBR Test Results

4. Conclusions

- In this article, two methods of compaction were used: the impact compaction, which was conducted to the Proctor method, and the vibratory hammer compaction. The results clearly show that, for the vibratory compaction method, the compaction curve characteristics are more consistent, and the optimal moisture content can be found much easier than in the case of the Proctor method. The compaction curve shows that the highest dry density is achieved for the soil in the air-dry state (for RCA, in this state, the obtained dry density was the highest) and for nearly saturated soil (saturation ratio Sr ≈ 0.95). Therefore, we can recommend conducting compaction procedure on the anthropogenic soil in a wet state, which is more favorable since, in intermediate moisture content, the dry density in all cases was the lowest. The recommended compaction method is vibratory-compaction as well in all four tested soil cases. The higher dry density might be caused by higher energy of compaction imposed on the soil sample, despite the effort to be consistent with the Proctor method. Nevertheless, vibratory compaction has an additional advantage, which is grain breakage prevention. The impact method causes moderate (RCA and BFS)-to-high particle breakage, like in the case of BS. That can cause significant changes in the resulting gradation curve.

- The conducted static CBR tests have shown that, in the OMC, sandy gravel materials present exceptional CBR values. In the case of RCA and NA, the CBR value was over 100% (148% and 162%, respectively). The BFS reached 93%, which is also satisfactory for the subbase bearing capacity requirements. In the case of BS, the highest CBR value was 52%, which is not enough to use this material as a subbase, but as the subgrade. What is important to note is that the presented benefits are for samples compacted with vibratory methods. For the Proctor compacted samples, the CBR values are significantly lower. The CBR tests in this study were conducted in unsoaked conditions that have to be taken into account since, in soaked conditions, the CBR values are lower.

- The oedometric tests have revealed that the compaction effort creates the apparent preconsolidation pressure, which, on average, is between 270 and 370 kPa, and this characteristic is the same for all four soil types. We noted slightly higher values of σ’p for the fly ash and bottom ash mix and, in general, higher values of apparent preconsolidation pressure for vibro-compaction and air-dry moisture content.

- The compression tests have led to compression index CC estimation for all four soil types. The value of CC is in the range of the dense sands value reported in the literature. We observed a high correlation between the initial void ratio e0 and specific gravity SG. Therefore, two mathematical expressions were derived which were able to calculate the compression index based on e0, SG, and CBR value. We noted that a stronger correlation between initial void ratio as well as CBR value and compression index exists when the soil is denser and has higher bearing capacity. The reason for this is that more elastic soil responds to static loading when the void ratio is low, and there is no place for particle rearrangement. For example, for BS where initial void ratio was between 0.55 and 0.70, the CC value had the greatest inconsistency. Conversely, for NA where e0 was equal to 0.24 to 0.32, we observed the highest consistency of CC value.

- The cyclic CBR tests led us to calculate resilient modulus value for tested soil types. The highest Mr value corresponded to the highest CBR value and, therefore, to OMC. For NA, Mr was equal to 745 MPa, and for RCA, 705 MPa, for BS, 201 MPa, and BFS, 609 MPa. We compared Mr to CBR values, and we found a strong correlation between these two values. Based on that, we presented two equations for Mr calculation based on CBR value, which is dedicated to NA, RCA, and BS and second for BS. Both equations refer to well-known power functions form the Mechanistic-Empirical Pavement Design Guide, but the constants in this function and for the functions presented by us are different.

- The plastic displacement observed during the cCBR test has logarithmic characteristics. This phenomenon was accounted for by us as a secondary compression, which is time-dependent. We calculated the secondary compression index from cCBR tests, and we derived the formula for Cα_cCBR calculation based on the compression index value. The Cα_cCBR value can be later used for settlement calculation of a road layer. The plastic displacement accumulation rate was the greatest for NA, which means that the anthropogenic soils may be less susceptible to the rutting.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from CD waste its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Const. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Cristelo, N.; Vieira, C.S.; de Lurdes Lopes, M. Geotechnical and geoenvironmental assessment of recycled construction and demolition waste for road embankments. Proc. Eng. 2016, 143, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civil. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Agrela, F.; Barbudo, A.; Ramírez, A.; Ayuso, J.; Carvajal, M.D.; Jiménez, J.R. Construction of road sections using mixed recycled aggregates treated with cement in Malaga, Spain. Resour. Conserv. Recycl. 2012, 58, 98–106. [Google Scholar] [CrossRef]

- Herrador, R.; Pérez, P.; Garach, L.; Ordóñez, J. Use of recycled construction and demolition waste aggregate for road course surfacing. J. Transp. Eng. 2012, 138, 182–190. [Google Scholar] [CrossRef]

- Da Conceição Leite, F.; dos Santos Motta, R.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Construct. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P.V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S. Sustainable usage of construction and demolition materials in roads and footpaths. In Sustainability Issues in Civil Engineering; Springer: Singapore, 2017; pp. 3–13. [Google Scholar]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Sulewska, M.J. Analysis of changes in the system of identification and classification of soils. MATEC Web Conf. 2019, 262, 04003. [Google Scholar] [CrossRef]

- Akinmusuru, J.O. Potential beneficial uses of steel slag wastes for civil engineering purposes. Resour. Conserv. Recycl. 1991, 5, 73–80. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Adeyeri, J.B.; Ejohwomu, O.A. Effects of steel slag addition on the plasticity, strength, and permeability of lateritic soil. In Proceedings of the ICSDEC 2012: Developing the Frontier of Sustainable Design, Engineering, and Construction, Fort Worth, TX, USA, 7–9 November 2012; pp. 457–464. [Google Scholar]

- Gruchot, A. California bearing Ratio of composites from colliery spoils and fly ash. Przegląd Górniczy 2014, 2, 12–17. [Google Scholar]

- Gruchot, A.; Wójtowicz, A. Influence of loading and moisture content on the CBR ratio of ash-slag mixture. Przegląd Górniczy 2014, 4, 81–85. [Google Scholar]

- Yadu, L.; Tripathi, R.K. Stabilization of soft soil with granulated blast furnace slag and fly ash. Int. J. Res. Eng. Technol. 2013, 2, 115–119. [Google Scholar]

- Sas, W.; Głuchowski, A.; Szymański, A. Cyclic Behavior of Recycled Concrete Aggregate Improved with Lime and Gypsum Addition. In Proceedings of the Fourth International Conference on Geotechnique, Construction Materials and Environment, Brisbane, Australia, 19–21 November 2014; Volume 1, pp. 196–201. [Google Scholar]

- Arulrajah, A.; Piratheepan, J.; Ali, M.M.Y.; Bo, M.W. Geotechnical properties of recycled concrete aggregate in pavement sub-base applications. Geotech. Test. J. 2012, 35, 743–751. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M. Reclaimed asphalt pavement and recycled concrete aggregate blends in pavement subbases: Laboratory and field evaluation. J. Mater. Civil. Eng. 2014, 26, 349–357. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Construct. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Araya, A.; Molenaar, A.; Houben, L. Characterization of unbound granular materials using repeated load CBR and triaxial testing. In Paving Materials and Pavement Analysis; ASCE: Reston, VA, USA, 2010; pp. 355–363. [Google Scholar]

- Yang, G.Q.; Wang, X.Z.; Wang, J.X.; Du, X.L. Study on the Engineering Characteristic of California Bearing Ratio (CBR) of Expressway Subgrade Material. In Logistics: The Emerging Frontiers of Transportation and Development in China; ASCE: Reston, VA, USA, 2009; pp. 2590–2595. [Google Scholar]

- Li, N.; Wang, H.; Ma, B.; Li, R. Investigation of unbound granular material behavior using precision unbound material analyzer and repeated load triaxial test. Transp. Geotech. 2019, 18, 1–9. [Google Scholar] [CrossRef]

- Molenaar, A.A.; Araya, A.A.; Houben, L.J. Characterization of unbound base materials for roads using a new developed repeated load CBR test. In Proceedings of the 8th International Conference on Managing Pavement Assets, Santiago, Chile, 15–19 November 2011. [Google Scholar]

- Araya, A.A.; Huurman, M.; Molenaar, A.A.A. Integrating traditional characterization techniques in mechanistic pavement design approaches. In Transportation and Development Institute Congress 2011: Integrated Transportation and Development for a Better Tomorrow; ASCE: Reston, VA, USA, 2011; pp. 596–606. [Google Scholar]

- Sas, W.; Głuchowski, A.; Szymanski, A. The geotechnical properties of recycled concrete aggregate with addition of rubber chips during cyclic loading. Int. J. GEOMATE 2017, 12, 25–32. [Google Scholar] [CrossRef]

- Sas, W.; Głuchowski, A. Rutting prediction for stabilized soils based on the cyclic CBR test. Roads Bridges Drogi i Mosty 2013, 12, 411–423. [Google Scholar]

- Sas, W.; Głuchowski, A.; Szymański, A. Behavior of recycled concrete aggregate improved with lime addition during cyclic loading. Int. J. GEOMATE 2016, 10, 1662–1669. [Google Scholar] [CrossRef]

- Hight, D.W.; Stevens, M.G.H. An analysis of the California Bearing Ratio test in saturated clays. Geotechnique 1982, 32, 315–322. [Google Scholar] [CrossRef]

- Pan, T.; Tutumluer, E.; Anochie-Boateng, J. Aggregate morphology affecting resilient behavior of unbound granular materials. Transp. Res. Record. 2006, 1952, 12–20. [Google Scholar] [CrossRef]

- Mishra, D.; Tutumluer, E.; Butt, A.A. Quantifying effects of particle shape and type and amount of fines on unbound aggregate performance through controlled gradation. Transp. Res. Record. 2010, 2167, 61–71. [Google Scholar] [CrossRef]

- Kwon, J.; Kim, S.H.; Tutumluer, E.; Wayne, M.H. Characterisation of unbound aggregate materials considering physical and morphological properties. Int. J. Pavement Eng. 2017, 18, 303–308. [Google Scholar] [CrossRef]

- Mendoza, C.; Caicedo, B. Elastoplastic framework of relationships between CBR and Young’s modulus for granular material. Road Mater. Pavement Des. 2018, 19, 1796–1815. [Google Scholar] [CrossRef]

- Putri, E.E.; Rao, N.K.; Mannan, M.A. Evaluation of modulus of elasticity and modulus of subgrade reaction of soils using CBR test. J. Civil. Eng. Res. 2012, 2, 34–40. [Google Scholar] [CrossRef]

- Sneddon, I.N. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Nielson, F.D.; Bhandhausavee, C.; Yeb, K.-S. Determination of Modulus of Soil Reaction from Standard Soil Tests (Report No. 284); Highway Research Record: Washington, DC, USA, 1969; pp. 1–12. [Google Scholar]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Construct. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Koenders, E.A.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cement. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- ISO 17892-4:2016 Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. Available online: http://sklep.pkn.pl/pn-en-iso-17892-4-2017-01e.html (accessed on 18 January 2017).

- Kim, B.; Prezzi, M.; Salgado, R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. J. Geotech. Geoenviron. Eng. 2005, 131, 914–924. [Google Scholar] [CrossRef]

- Kumar, D.; Kumar, N.; Gupta, A. Geotechnical Properties of Fly Ash and Bottom Ash Mixtures in Different Proportions. Int. J. Sci. Res. 2014, 3, 9. [Google Scholar]

- Uliasz-Bocheńczyk, A.; Bąk, P. Management of waste from energy production—Waste combustion in Poland. IOP Conf. Ser. Mater. Sci. Eng. 2018, 427, 012019. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P.; Barnat-Hunek, D. Mechanical and microstructural properties of high performance concrete with burnt coal cinder. Izolacje 2015, 10, 1–7. [Google Scholar]

- Muhunthan, B.; Taha, R.; Said, J. Geotechnical Engineering Properties of Incinerator Ash Mixes. J. Air Waste Manag. Assoc. 2004, 54, 985–991. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grubeša, I.N.; Barisic, I.; Fucic, A.; Bansode, S.S. Characteristics and Uses of Steel Slag in Building Construction; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Gruyaert, E. Effect of Blast-Furnace Slag as Cement Replacement on Hydration Microstructure, Strength and Durability of Concrete. Ph.D. Thesis, University of Gent, Ghent, Belgium, 2011. [Google Scholar]

- Rahman, A.A.; Abo-El-Enein, S.A.; Aboul-Fetouh, M.; Shehata, K. Characteristics of Portland blast-furnace slag cement containing cement kiln dust and active silica. Arab. J. Chem. 2016, 9, 138–143. [Google Scholar] [CrossRef] [Green Version]

- Pal, S.C.; Mukherjee, A.; Pathak, S.R. Investigation of hydraulic activity of ground granulated blast furnace slag in concrete. Cement. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- ASTM D698-12e1. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). Annual Book of ASTM Standards, USA. 2008. Available online: https://www.techstreet.com/standards/astm-d5254-d5254m-92-2010e1?product_id=1751704 (accessed on 8 January 2010).

- Sas, W.; Głuchowski, A.; Gabryś, K.; Szymański, A. Application of cyclic CBR test for the estimation of resilient modulus in the pavement construction. In Proceedings of the XVI ECSMGE Geotechnical Engineering for Infrastructure and Development, Edinburgh, UK, 13–17 October 2015; pp. 3747–3752. [Google Scholar]

- Sas, W.; Głuchowski, A. Application of cyclic CBR test to approximation of subgrade displacement in road pavement. ACTA Sci. Polonorum Arch. 2013, 12, 51–61. [Google Scholar]

- WT–4 Unbound Mix for National Roads; Technical Specifications, Directive No 102 of Polish General Director of National Roads and Motorways; Polish General Director of National Roads and Motorways: Warsaw, Poland, 2010.

- Pavements constructed with Clay, Natural Stone or Concrete Pavers. Guide for the Design of Permeable Pavements Constructed with Concrete Paving Blocks and Flags, Natural Stone Slabs and Setts and Clay Pavers; BS 7533-13:2009; BSI: London, UK, 2009.

- AASHTO M 145-91 Standard Specification for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes; AASHTO: Washington, DC, USA, 2017.

- EN 933-11:2009 Tests for Geometrical Properties of Aggregates. Classification Test for the Constituents of Coarse Recycled Aggregate. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030205890 (accessed on 31 July 2009).

- Fomina, N.; Polyanskiy, M. Grain size distribution of aggregates of crushed concrete. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 97, p. 02018. [Google Scholar]

- EN 1997-2:2007 Geotechnical Design—Part 2: Ground Investigation and Testing. Available online: http://sklep.pkn.pl/pn-en-1997-2-2007e.html (accessed on 14 March 2007).

- ASTM D2487 Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International (ASTM): West Conshohocken, PA, USA, 2017.

- He, H.; Sandeep, C.S.; Senetakis, K. The interface behavior of recycled concrete aggregate: A microechanical grain-scale experimental study. Construct. Build. Mater. 2019, 210, 627–638. [Google Scholar] [CrossRef]

- Rowe, P.W.; Barden, L. A new consolidation cell. J. Geotech. 1996, 16, 162–170. [Google Scholar] [CrossRef]

- Chenari, R.J.; Fard, M.K.; Maghfarati, S.P.; Pishgar, F.; Machado, S.L. An investigation on the geotechnical properties of sand–EPS mixture using large oedometer apparatus. Construct. Build. Mater. 2016, 113, 773–782. [Google Scholar] [CrossRef]

- Fallenius, B.H. Bacis of Foundation Design; Pile Buck International, Inc.: Vero Beach, FL, USA, 2019. [Google Scholar]

- Duan, W.; Cai, G.; Liu, S.; Yuan, J.; Puppala, A.J. Assessment of Ground Improvement by Vibro-compaction Method for Liquefiable Deposits from In-Situ Testing Data. Int. J. Civ. Eng. 2019, 17, 723–735. [Google Scholar] [CrossRef]

- Becker, D.E.; Crooks, J.H.A.; Been, K.; Jefferies, M.G. Work as a Criterion for Determining in Situ and Yield Stresses in Clays. Can. Geotech. J. 1987, 24, 549–564. [Google Scholar] [CrossRef]

- Widodo, S.; Ibrahim, A. Estimation of primary compression index (Cc) using physical properties of Pontianak soft clay. Int. J. Eng. Res. Appl. 2012, 2, 2231–2235. [Google Scholar]

- Rendon-Herrero, O. Universal Compression Index Equation. J. Geotech. Eng. Div. 1980, 106, 1179–1199. [Google Scholar]

- Azzous, A.S.; Krizek, R.J.; Corotis, R.B. Regression Analysis of Soil Compressibility. Soils Foundat. 1976, 16, 19–29. [Google Scholar] [CrossRef] [Green Version]

| Dry Density ρd (kg/m3) | Specific Gravity SG (–) | Compaction Energy EC (J/cm3) | California Bearing Ratio (CBR) (%) | |

|---|---|---|---|---|

| Moisture m (%) | −0.565 0.00033 | −0.617 0.00006 | 0.0997 0.563 | −0.357 0.0323 |

| Dry Density ρd (kg/m3) | 0.987 0.0000 | 0.162 0.344 | 0.541 0.0006 | |

| Specific Gravity SG (–) | 0.162 0.346 | 0.518 0.0012 | ||

| Compaction Energy EC (J/cm3) | 0.373 0.02504 |

| Natural Aggregate (NA) | Recycled Concrete Aggregate (RCA) | Fly Ash and Bottom Ash (BS) | Blast Furnace Slag (BFS) | ||||

|---|---|---|---|---|---|---|---|

| Moisture (%) | σ’p (kPa) | Moisture (%) | σ’p (kPa) | Moisture (%) | σ’p (kPa) | Moisture (%) | σ’p (kPa) |

| Proctor Compaction | |||||||

| 0.91 | 305.35 | 2.04 | 310.33 | 2.39 | 341.46 | 4.75 | 302.73 |

| 1.98 | 324.23 | 3.87 | 293.26 | 4.11 | 310.76 | 7.58 | 277.87 |

| 2.70 | 341.04 | 4.20 | 310.33 | 6.84 | 346.43 | 8.38 | 315.59 |

| 3.00 | 276.91 | 5.85 | 277.82 | 9.67 | 312.49 | 10.50 | 297.15 |

| 3.07 | 297.33 | 6.92 | 309.47 | 12.64 | 281.09 | ||

| 3.97 | 346.43 | 8.17 | 312.57 | 13.69 | 315.08 | ||

| 4.90 | 337.24 | 8.68 | 311.06 | 16.99 | 326.34 | ||

| 6.91 | 281.09 | 10.14 | 276.80 | 17.67 | 324.23 | ||

| 9.13 | 348.20 | 10.94 | 312.02 | 18.20 | 341.04 | ||

| 10.68 | 310.76 | 11.66 | 292.00 | ||||

| 11.85 | 326.45 | 11.67 | 310.33 | ||||

| Vibratory Compaction | |||||||

| 0.69 | 367.34 | 2.53 | 342.14 | 16.26 | 367.74 | 1.68 | 500.62 |

| 2.48 | 329.53 | 4.42 | 294.84 | 17.67 | 367.81 | 3.18 | 320.03 |

| 4.41 | 401.26 | 6.16 | 315.08 | 19.88 | 335.82 | 5.40 | 360.61 |

| 5.01 | 262.80 | 8.01 | 245.11 | 21.09 | 347.98 | 8.03 | 340.89 |

| 6.52 | 315.99 | 9.49 | 302.72 | 22.39 | 285.57 | 10.48 | 315.99 |

| 7.46 | 330.21 | 10.86 | 294.84 | 10.72 | 310.76 | ||

| NA | RCA | BS | BFS | ||||

|---|---|---|---|---|---|---|---|

| Moisture (%) | CC (-) | Moisture (%) | CC (-) | Moisture (%) | CC (-) | Moisture (%) | CC (-) |

| Proctor Compaction | |||||||

| 0.91 | 0.00351 | 2.04 | 0.00424 | 2.39 | 0.00862 | 4.75 | 0.00397 |

| 1.98 | 0.00372 | 3.87 | 0.00393 | 4.11 | 0.00491 | 7.58 | 0.00415 |

| 2.70 | 0.00395 | 4.20 | 0.00419 | 6.84 | 0.00501 | 8.38 | 0.00391 |

| 3.00 | 0.00395 | 5.85 | 0.00419 | 9.67 | 0.00495 | 10.50 | 0.00394 |

| 3.07 | 0.00390 | 6.92 | 0.00484 | 12.64 | 0.00505 | ||

| 3.97 | 0.00374 | 8.17 | 0.00446 | 13.69 | 0.00501 | ||

| 4.90 | 0.00393 | 8.68 | 0.00443 | 16.99 | 0.00777 | ||

| 6.91 | 0.00387 | 10.14 | 0.00445 | 17.67 | 0.00489 | ||

| 9.13 | 0.00386 | 11.66 | 0.00411 | 18.20 | 0.00474 | ||

| 10.68 | 0.00398 | 11.67 | 0.00441 | ||||

| 11.85 | 0.00405 | ||||||

| Vibratory Compaction | |||||||

| 0.69 | 0.00430 | 2.53 | 0.003818 | 16.26 | 0.00788 | 1.68 | 0.00652 |

| 2.48 | 0.00387 | 4.42 | 0.004288 | 17.67 | 0.00782 | 3.18 | 0.00423 |

| 4.41 | 0.00364 | 6.16 | 0.004468 | 19.88 | 0.00761 | 5.40 | 0.00411 |

| 5.01 | 0.00359 | 8.01 | 0.004213 | 21.09 | 0.00787 | 8.03 | 0.00420 |

| 6.52 | 0.00383 | 9.49 | 0.004067 | 22.39 | 0.00746 | 10.48 | 0.00400 |

| 7.46 | 0.00399 | 10.86 | 0.004192 | 10.72 | 0.00400 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głuchowski, A.; Gabryś, K.; Soból, E.; Šadzevičius, R.; Sas, W. Geotechnical Properties of Anthropogenic Soils in Road Engineering. Sustainability 2020, 12, 4843. https://doi.org/10.3390/su12124843

Głuchowski A, Gabryś K, Soból E, Šadzevičius R, Sas W. Geotechnical Properties of Anthropogenic Soils in Road Engineering. Sustainability. 2020; 12(12):4843. https://doi.org/10.3390/su12124843

Chicago/Turabian StyleGłuchowski, Andrzej, Katarzyna Gabryś, Emil Soból, Raimondas Šadzevičius, and Wojciech Sas. 2020. "Geotechnical Properties of Anthropogenic Soils in Road Engineering" Sustainability 12, no. 12: 4843. https://doi.org/10.3390/su12124843

APA StyleGłuchowski, A., Gabryś, K., Soból, E., Šadzevičius, R., & Sas, W. (2020). Geotechnical Properties of Anthropogenic Soils in Road Engineering. Sustainability, 12(12), 4843. https://doi.org/10.3390/su12124843