1. Introduction

Concrete materials are the most widely used in urban infrastructure. The materials should comply with the principles of sustainability [

1,

2,

3] and be friendly to climate and environment. The urban heat island effect (UHIE) is defined as the temperature difference between rural and urban areas that is mainly caused by urban construction and intense human activities. It is shown that the annual average temperature of urban areas is 0.5–3 °C higher than that of the suburbs, and even 6 °C higher during summer [

4,

5,

6]. UHIE has been considered as one of the major problems in urbanization and industrialization of human civilization [

7]. It has increased the occurrences of extreme weather such as heavy precipitation and storms [

8,

9], accelerated global warming, raised the energy demand of cities [

10,

11,

12], elevated environmental pollution, damaged human health, and even contributed to mortality rates [

13,

14].

UHIE is a natural imbalance due to human activities. Natural underlying surfaces with good cooling capacity have decreased gradually with urban development while artificial underlying surfaces with poor heat dissipation have continuously increased, which has resulted in an increase in the amount of heat stored in the urban system. Civil engineering materials such as cement concrete and asphalt concrete have been widely used in urban road construction, and bring remarkable features such as high-absorptivity, low-calorific capacity and impermeability [

15]. The thermal properties of pavements make a significant contribution to UHIE.

The external environment and pavement characteristics are the major factors that influence the pavement temperature field. There is natural convection between pavement and the external environment [

16]. Thermal radiation transfer also occurs, which includes mainly solar radiation during the daytime and atmospheric long-wave radiation [

17,

18]. Environmental conditions such as air temperature, solar radiation, wind speed and other factors are difficult to control, so researchers adjusted pavement characteristics to ease UHIE. Obviously, the performance of pavement materials plays an important role, which affects the internal temperature variation and heat transfer capacity of the pavement [

19].

Many measures have been tried to control the UHIE through improving the performance of pavement materials. High-albedo coating is verified as an effective anti-UHIE technology, which can lower the pavement temperature by increasing the solar-reflective rate of pavements [

20,

21]. Some materials such as water-cooled, porous and thermal resistance materials were also developed to improve stability of pavement temperature [

22,

23]. Some researchers have developed new materials to moderate the thermal conditions of pavements through promoting the evaporation and the water exchange between ground surface and deep soil [

24,

25]. For instance, porous materials can help alleviate heat accumulation [

26] because the strong drainage performance of the porous materials can significantly lower the pavement’s thermal conductivity [

27].

Understanding the potential contributing effects of pavement materials to UHIE is helpful in making reasonable choices in pavement design. This paper presents a study focusing on how pavement materials affect UHIE in a natural environment. Three typical pavement materials—cement concrete, dense asphalt concrete and porous asphalt mixture—were selected to evaluate their temperature variation in the natural environment where the temperature is constantly changing. The effects of these commonly used pavement materials on UHIE were compared according to the experimental results.

2. Materials and Methods

Three types of pavement materials were selected for the test. The pavement materials were a cement concrete (C25, P.O 42.5), a porous asphalt mixture (PAC13, 90#, 20%) and a dense asphalt concrete (AC13, 90#).

The raw materials of the cement concrete included water, Portland cement (Type 42.5), sand, limestone and additives. The raw materials of the asphalt concrete included limestone powder, limestone, 90# petroleum asphalt and high viscosity modified asphalt. The mix proportions of the three specimens are shown in

Table 1,

Table 2 and

Table 3, respectively.

The volume indexes of asphalt mixture AC13 and PAC13 including asphalt content (AC), air void content (AV), voids in mineral aggregate (VMA), and voids filled with asphalt (VFA) are shown in

Table 4.

The production process of the cement concrete was as follows: firstly, according to the proportion, add cement, sand and aggregates into the mixer to mix evenly, and then add water to mix evenly. Then, take out the mixture and put it into the mold, place the mold on the vibration table to vibrate and smooth the surface. Finally, after it had been cured in the laboratory for 24 h, the specimens were demolded and placed in the standard curing room with 20 ± 3 °C and 95% relative humidity for 28 days.

The production process of the asphalt concrete was as follows: firstly, put all kinds of mineral materials in 105 °C oven and dry for 6 h. Secondly, the dry graded coarse and fine aggregates are weighed according to the design grading requirements, mixed evenly in a metal plate, the mineral powder shall be placed in a metal basin, and then heated to 165 °C in an oven. Take the specified weight of asphalt and heat it to 150 °C in an oven. Thirdly, heat the mixer and keep it at 150 °C, pour the heated coarse and fine aggregate and asphalt into the mixer in turn and mix for 1~1.5 min; suspend mixing, add the heated mineral powder and continue mixing until it is even, and the total mixing time is 3 min. Fourthly, put the mixture into the mold and compact it with a rotary compactor at a compaction temperature of 145 °C. Finally, demold the specimen and place it in the natural environment to cool down.

The production process of the PAC13 was the same as that for the AC13.

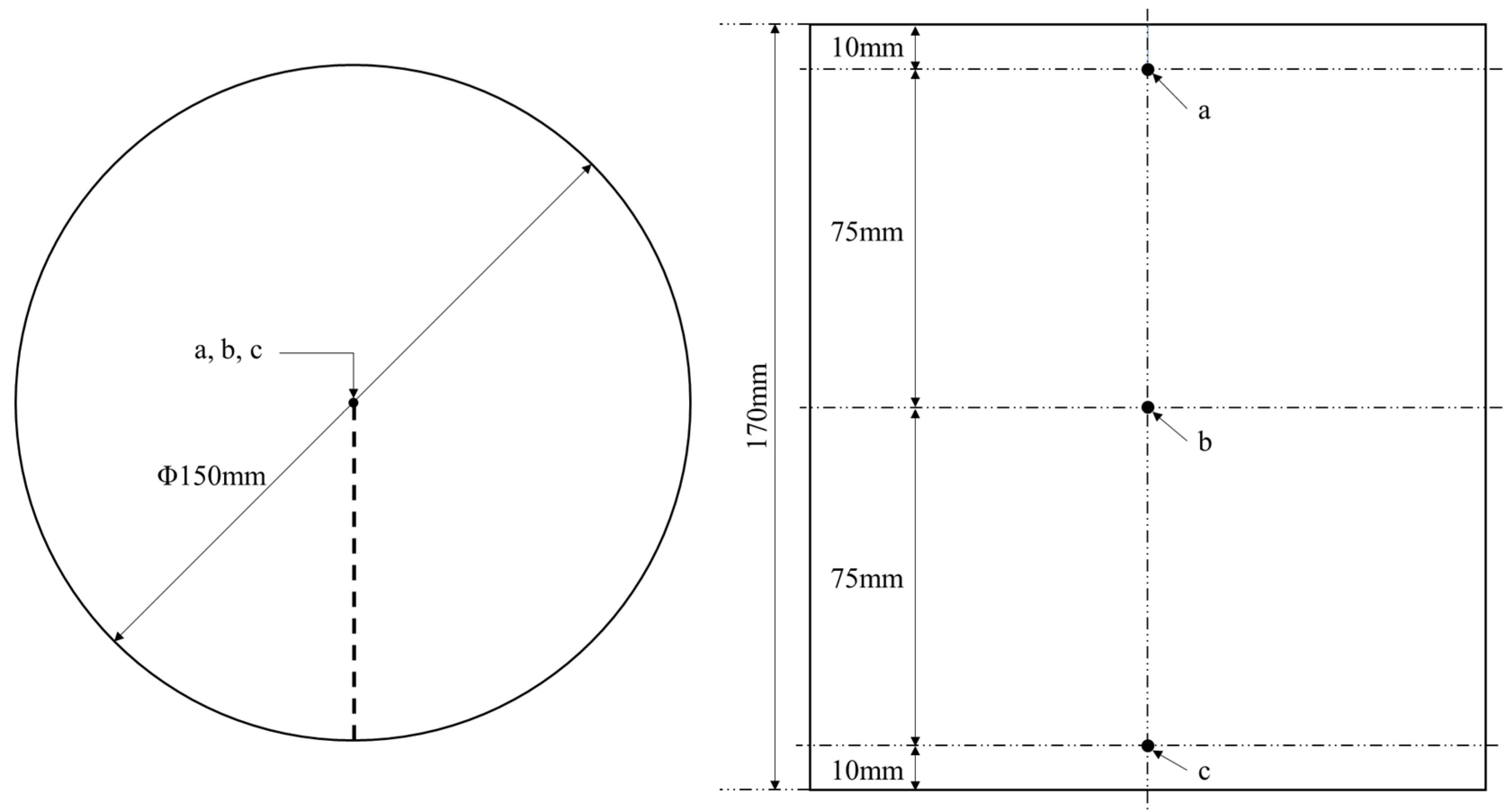

Cylinder samples were made with a diameter of 150 mm and a height of 170 mm. All specimens were placed in a sunny and dry place for seven days before they were tested. Each specimen was attached to 3 thermal sensors by drilling holes in it, which were located in the center of the sections 1, 8.5 and 16 cm below the top surface.

Figure 1 illustrates the locations of the thermal sensors.

The DS18B20 digital temperature sensor was selected to monitor the air temperature and the temperature inside the specimens. As shown in

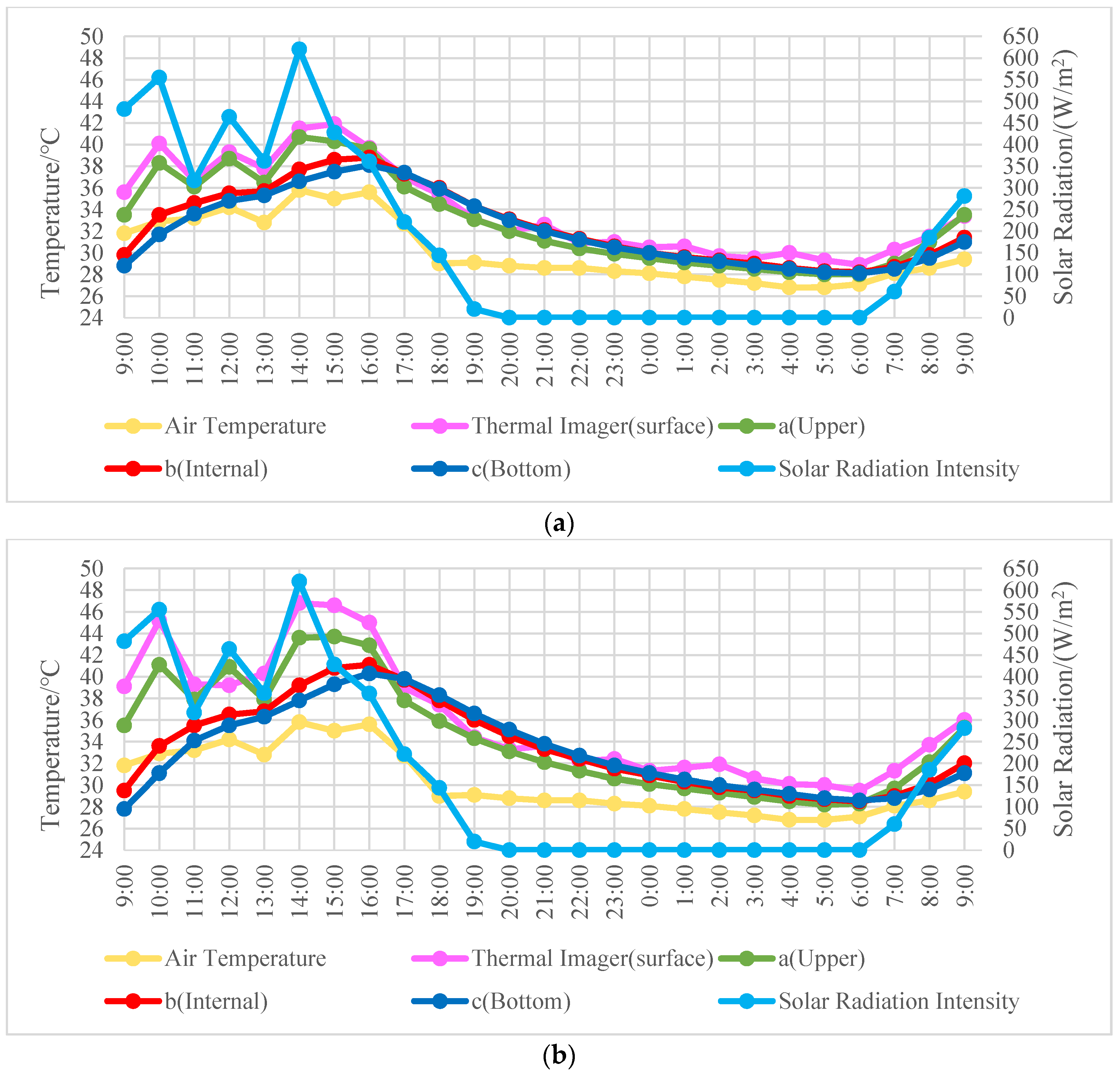

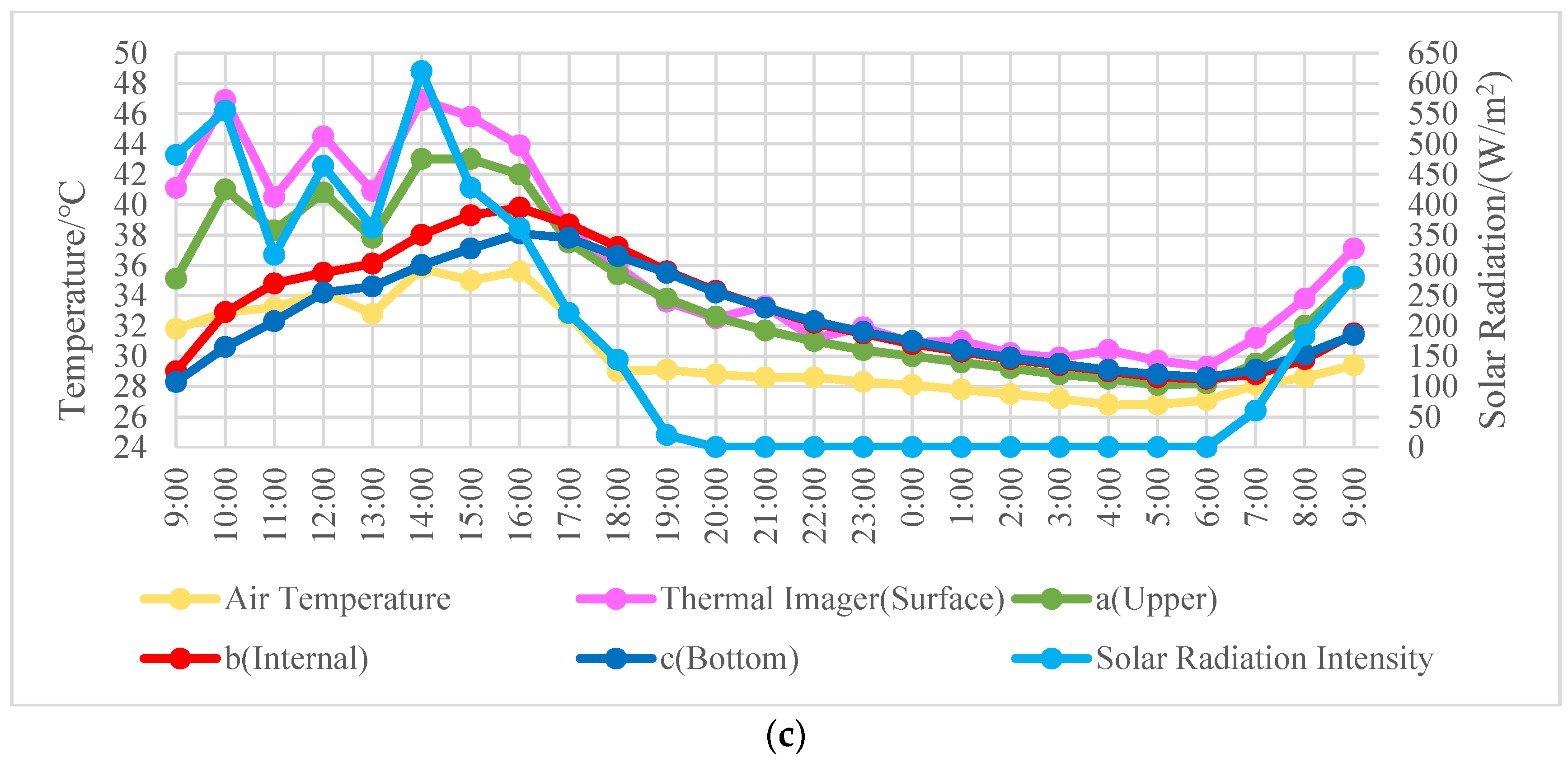

Figure 2, sensors at site a, site b and site c were used to measure the temperature of the upper part, the middle part and the bottom part of the specimen, respectively. At the designated height of the specimens, holes were drilled from the side of the specimens in the direction perpendicular to the axis. The drilling depth was 75mm, and the drilling diameter was slightly larger than the outer diameter of the sensor probe. The temperature sensor probe was put in the designated position, and then the gap between the drilling hole and the data line was sealed with epoxy resin. At the same time, a temperature sensor was placed above the specimens in the test to measure the air temperature. All the 10 temperature sensors were connected in parallel and connected to a computer via an RS485 converter. In addition, a Fluke Ti10 thermal imager and an irradiometer were employed to measure the surface temperature of the specimens and the intensity of solar radiation, respectively.

The sides and bottom of all the three specimens were wrapped with thermal insulation to avoid heat transfer from these locations.

Figure 2 depicts the wrapped and instrumented specimens. The wrapped and instrumented specimens were placed in an open field with natural sunlight and kept a certain distance from each other. Firstly, the specimens were placed in the open field for a week to reach a balance in the environment. Then the temperature monitoring started.

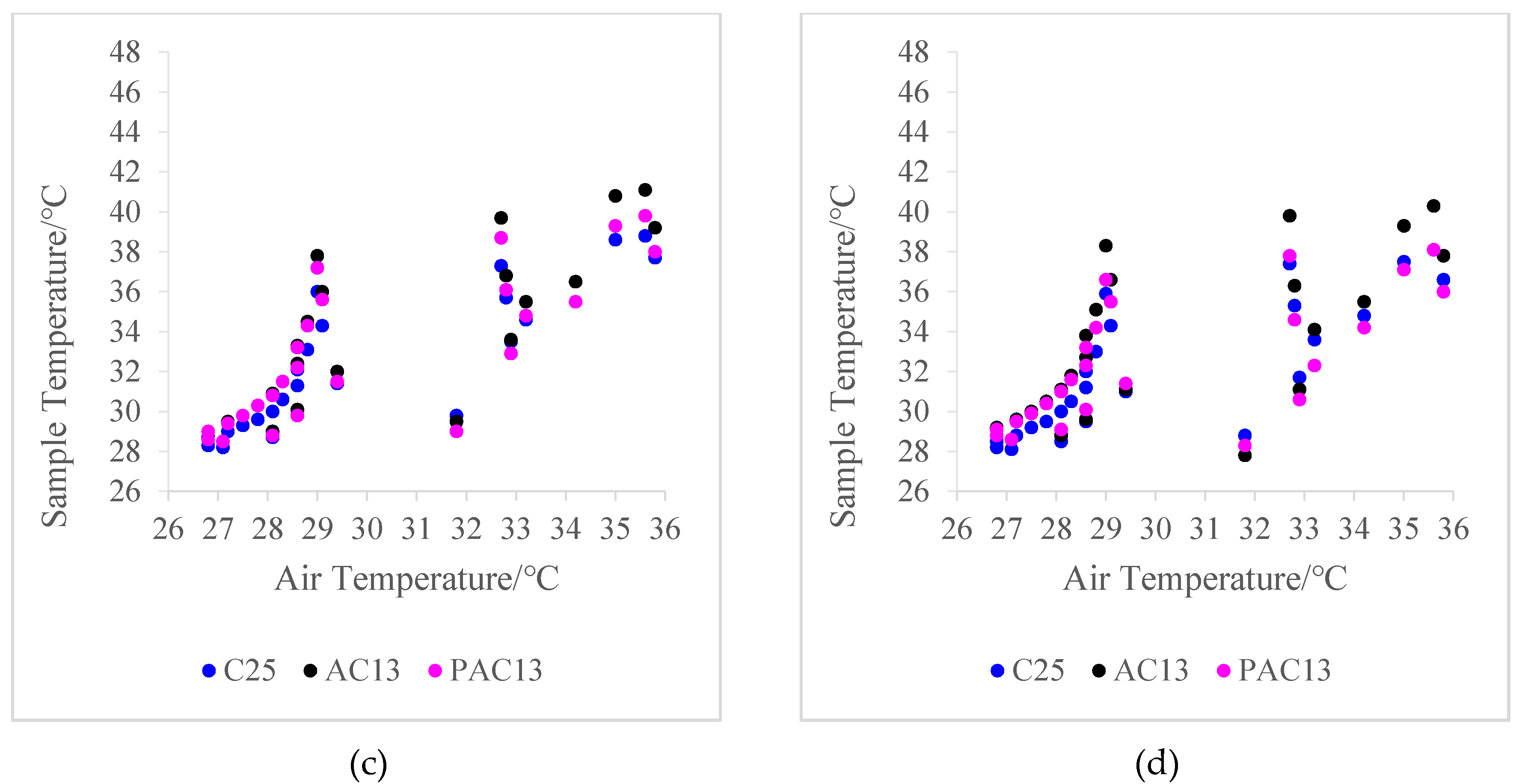

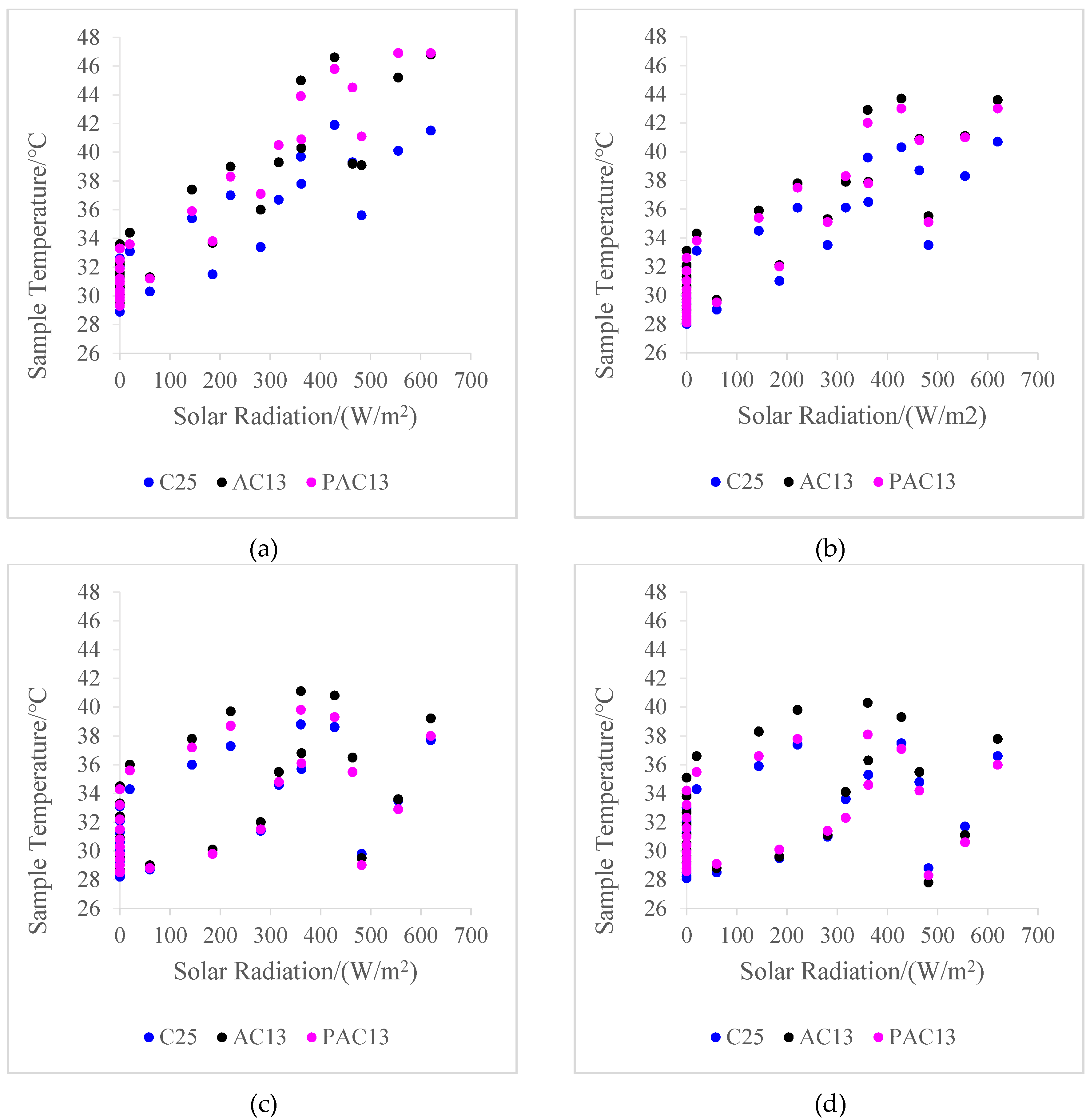

The air temperature, the solar radiation intensity and the temperature of the surface, the upper part, the middle part and the bottom part of the specimens were monitored in the test. The test system automatically recorded the temperature data obtained by the temperature sensors each 10 min. The surface temperature and the solar radiation intensity were also measured by the infrared thermal imager and the irradiometer, respectively, every hour during the test period. The test period was divided into cycles of 24 h and the test results of each cycle with stable outdoor conditions and complete data records were selected for further analysis.

4. Conclusions

This paper presents a study focusing on the potential of pavement materials to contribute to the UHIE. Three typical pavement materials, a cement concrete, a dense asphalt concrete and a porous asphalt mixture, were selected for evaluation in an open field for their anti-UHIE properties. Some conclusions can be drawn as follows.

- (1)

The temperature inside pavement specimens distinctly depends on the depth, which varies with the air temperature but is mostly higher than it. The temperature at surface is the highest, followed by that at the upper part, the middle part and the bottom part. After the solar radiation is absorbed by the pavement, the pavement transmits the heat to the air through radiation, conduction and convection, which is the main source of heat in the air. The solar radiation directly absorbed by the atmosphere makes the effect of air heating very small. Generally, the pavement surface temperature will be higher than the air temperature

- (2)

The temperature of pavement specimens at the upper part is highly sensitive to environmental conditions. The solar radiation in the daytime significantly correlates to the temperature of pavement surface and the upper part. The correlation becomes weak at the middle and bottom of the pavement specimens.

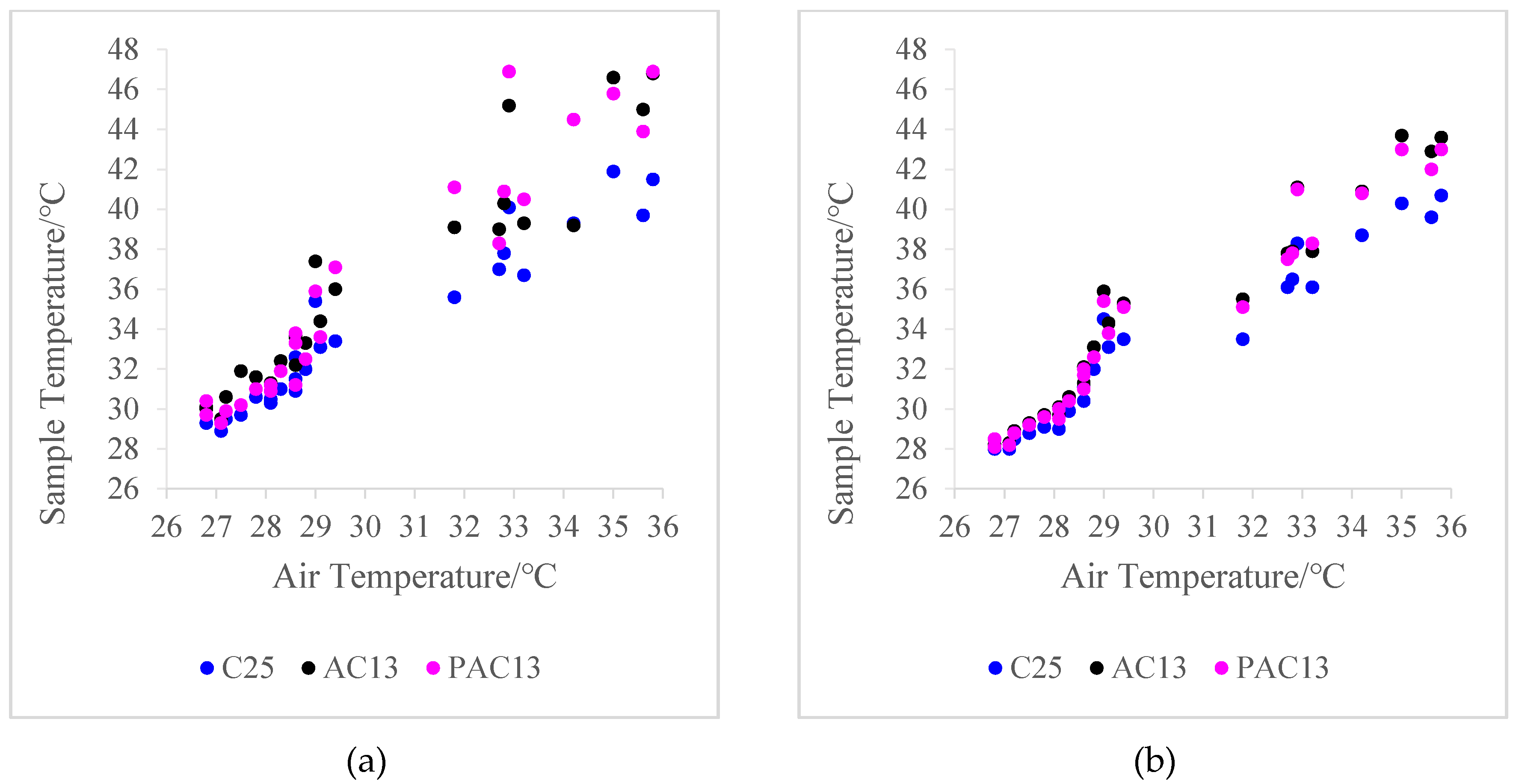

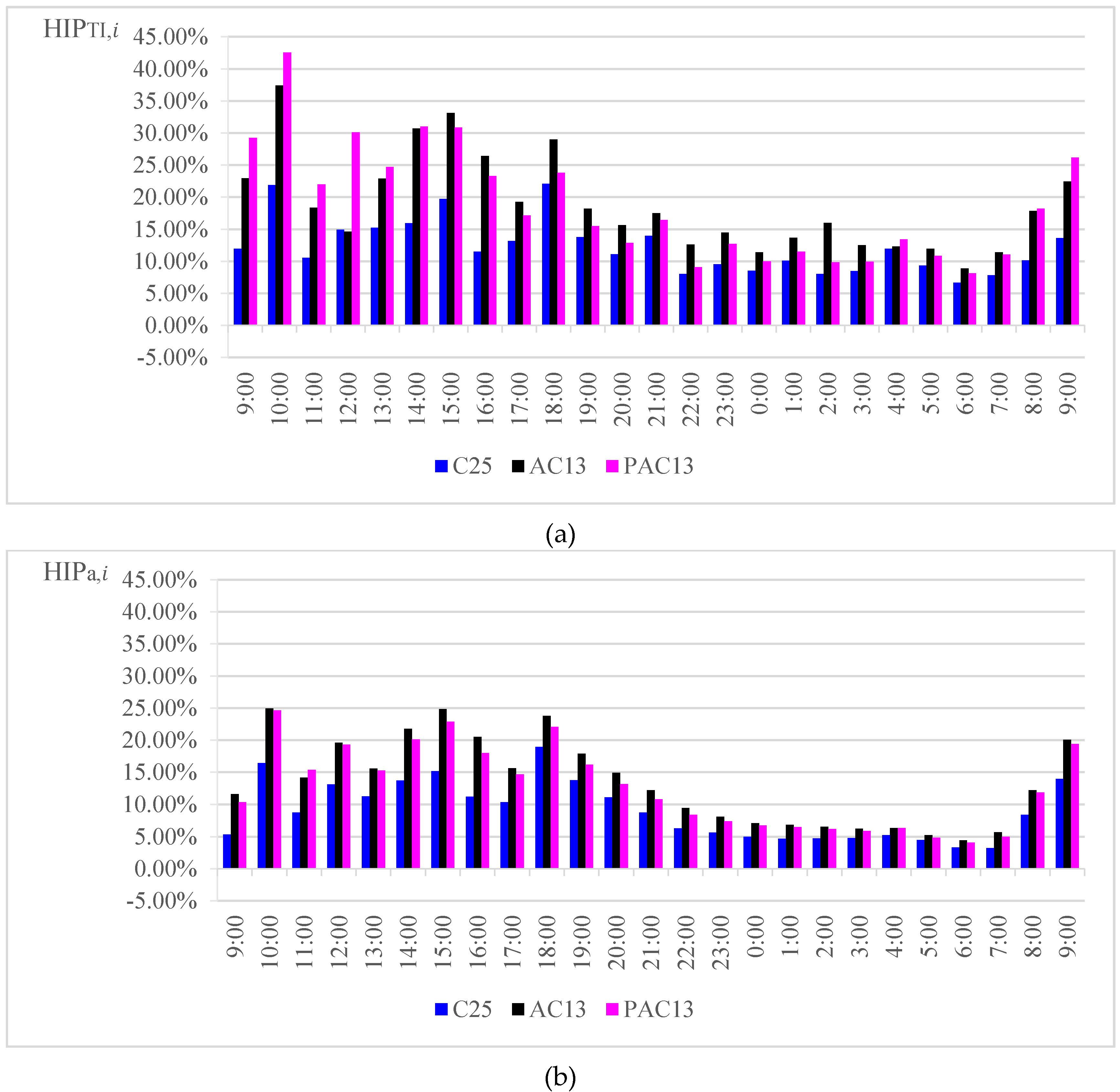

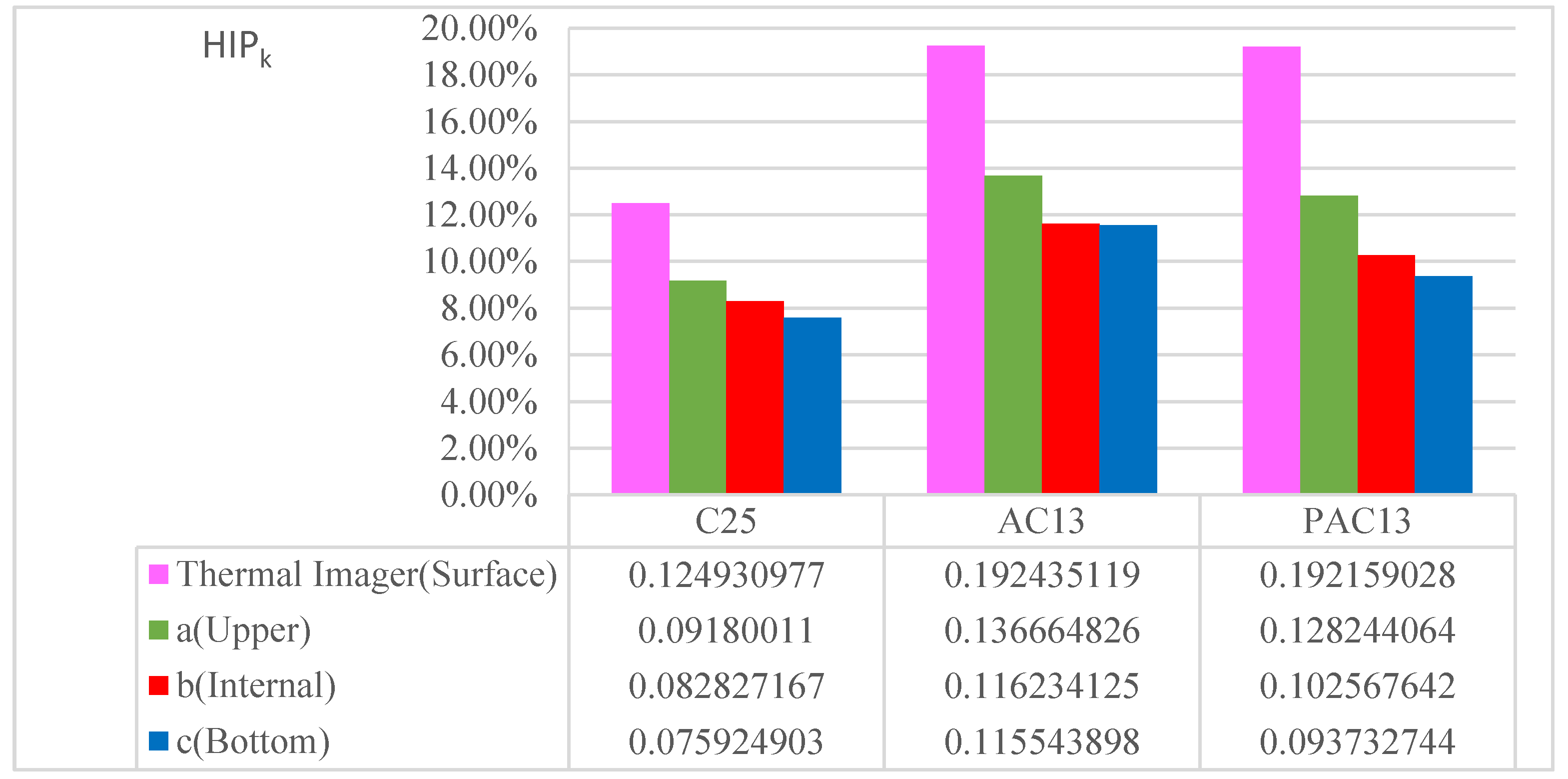

- (3)

The heat island potentials of pavement materials can be effectively evaluated by the indicators of and , and the lower values of them show better anti-UHIE performance of the materials. Among the three materials tested in this paper, the anti-UHIE performance of cement concrete is significantly higher than that of the asphalt mixtures, and the porous asphalt mixture is slightly better than the dense asphalt concrete in anti-UHIE.

The results derived from this study are preliminary but show it is feasible to use the proposed approach to estimate the UHIE of different pavement materials. HIP is obtained by analyzing the data of materials’ internal and environmental temperature and solar radiation. It is relatively convenient to be used in long-term temperature monitoring in engineering. In future research, we will use HIP to analyze the impact of various climate events on the long-term characteristics of UHIE and verify the reliability of HIP analysis. In addition, data-based analysis methods can consider more environmental factors such as air humidity and material moisture content, which are not difficult to obtain, and will optimize the calculation method of HIP.