Durability of Superheated Steam-Treated Light Red Meranti (Shorea spp.) and Kedondong (Canarium spp.) Wood against White Rot Fungus and Subterranean Termite

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material Preparation

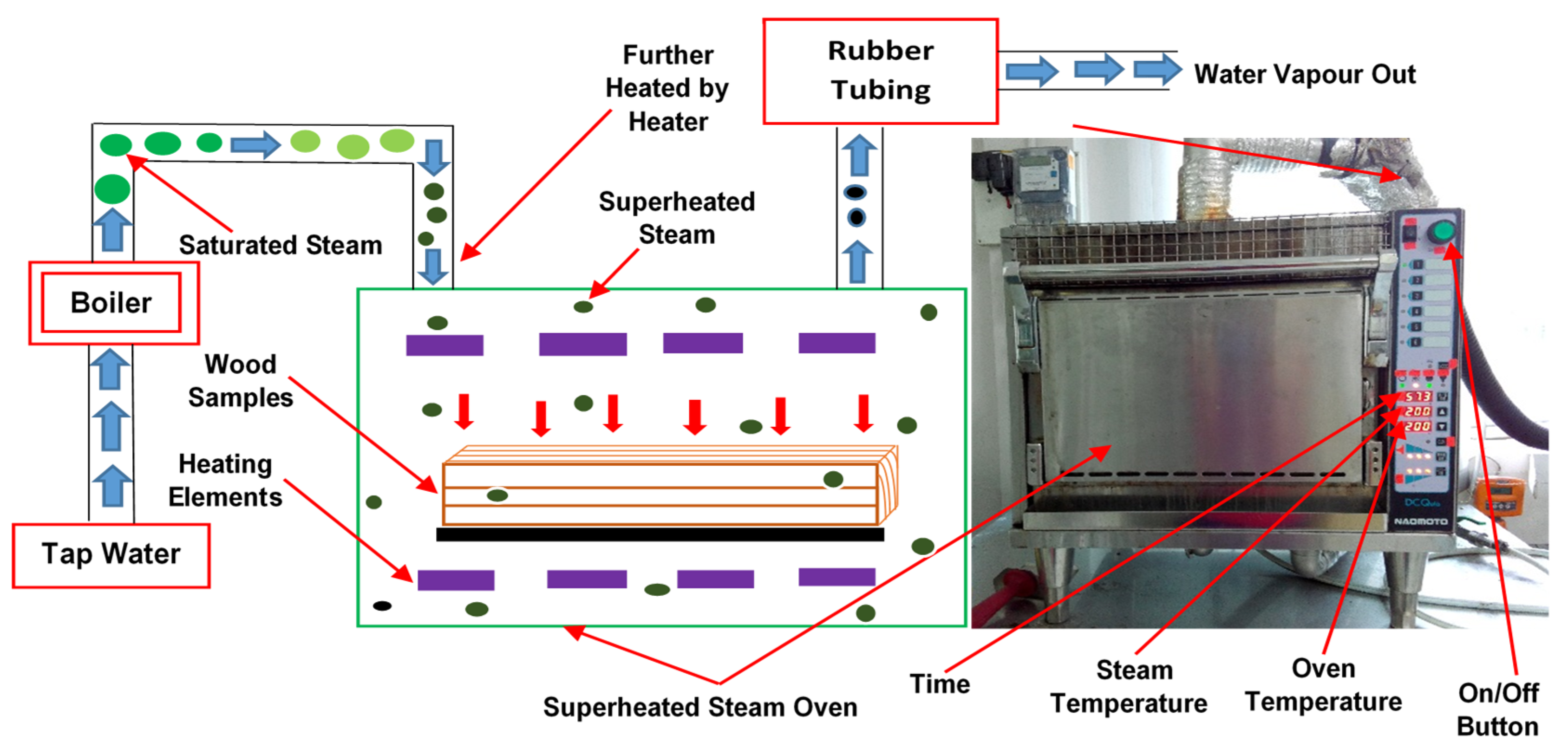

2.2. Optimizing of SHS Treatment Variables

2.3. Determination of Weight Loss and Equilibrium Moisture (EMC) after SHS Treatment

2.4. Evaluation of Chemical Properties

2.5. Evaluation of Biological Properties

2.5.1. Decay Resistance

2.5.2. Termite Resistance

2.6. Statistical Analysis

3. Results and Discussion

3.1. Weight Loss and EMC after SHS Treatment

3.2. Wet chemical Analysis

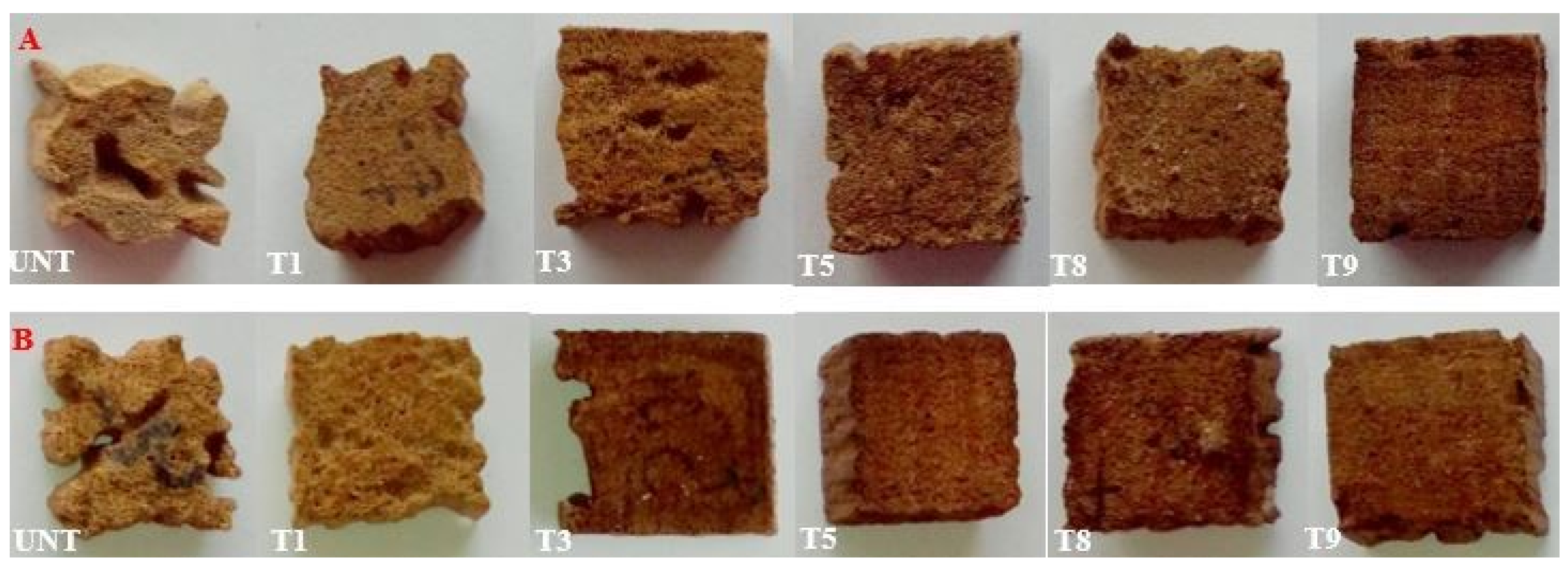

3.3. Fungal Decay

3.4. Termite Attack

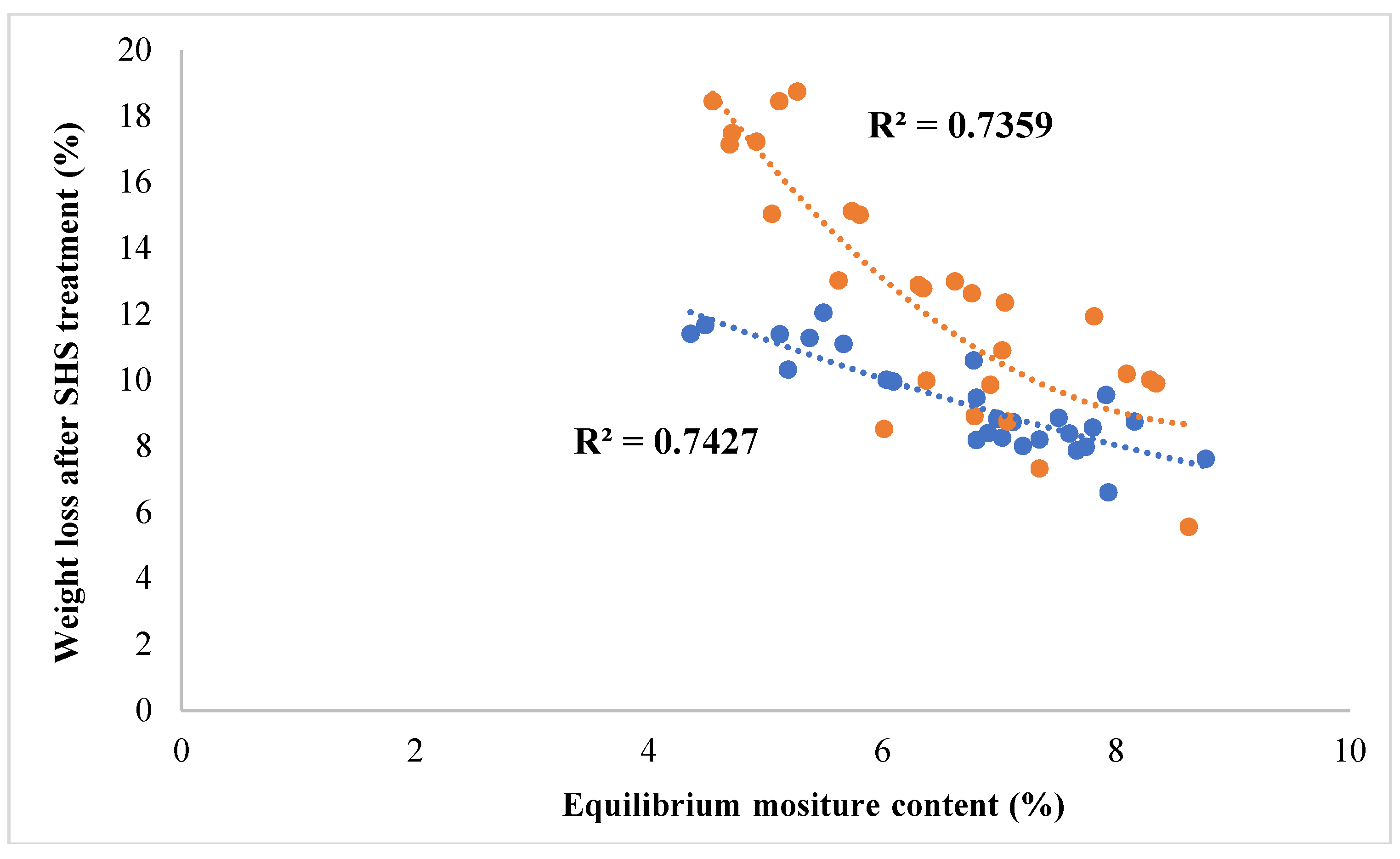

3.5. Correlation between Weight Loss and Equilibrium Moisture Content of Wood Speciemens

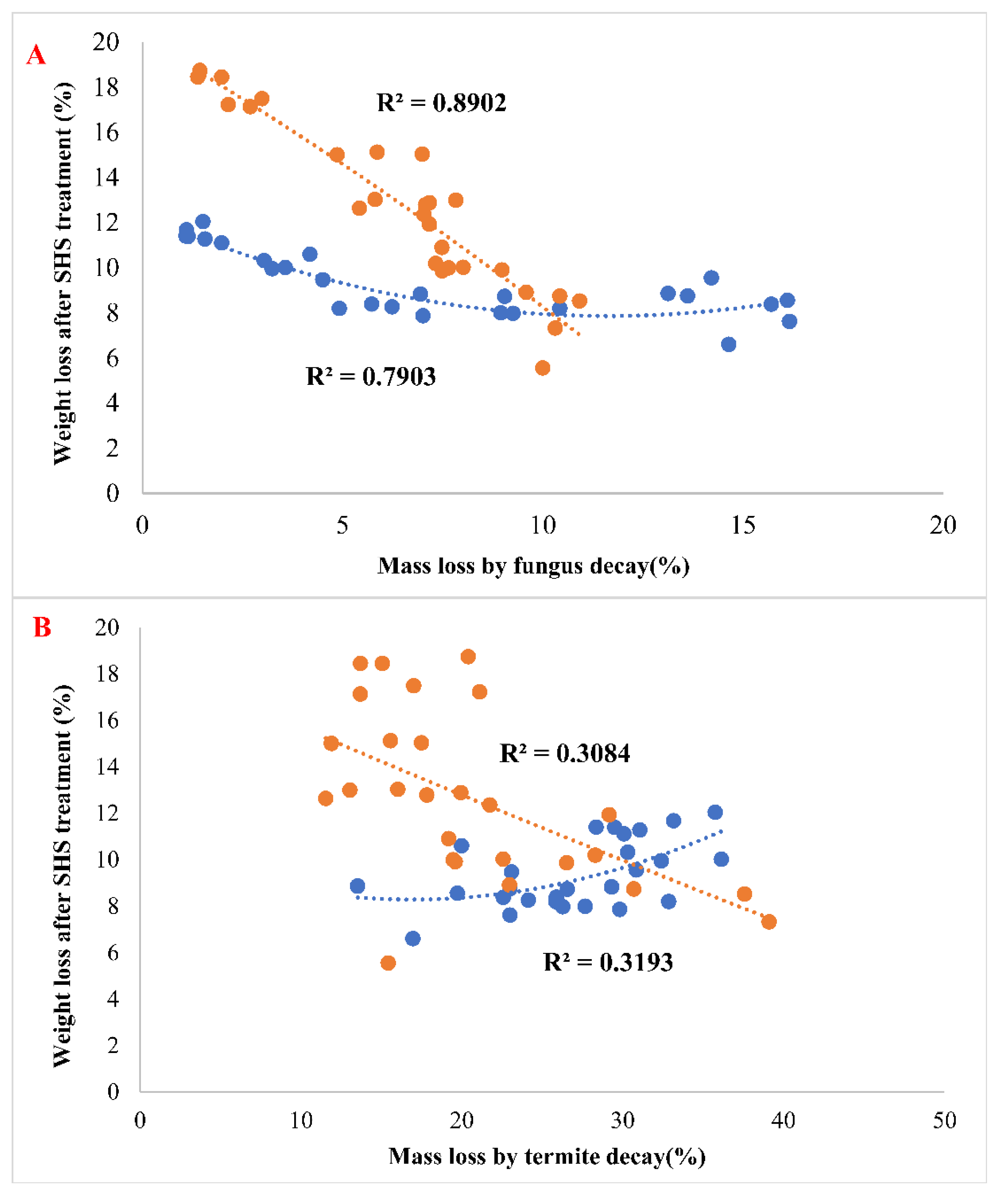

3.6. Correlation between Thermal-Induced Weight Loss of Wood Speciemens and Mass Loss

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thybring, E.E. Water relations in untreated and modified wood under brown-rot and white-rot decay. Int. Biodeterior. Biodegrad. 2017, 118, 134–142. [Google Scholar] [CrossRef]

- Mahapatro, G.K.; Chatterjee, D. Termites as structural pest: Status in Indian Scenario. Proc. Natl. Acad. Sci. India B 2018, 88, 977–994. [Google Scholar] [CrossRef]

- Rust, M.K.; Su, N.Y. Managing social insects of urban importance. Annu. Rev. Entomol. 2012, 57, 355–375. [Google Scholar] [CrossRef] [PubMed]

- Ngee, P.S.; Yoshimura, T.; Lee, C.Y. Foraging populations and control strategies of subterranean termites in the urban environment, with special reference to baiting. Jpn. J. Appl. Entomol. Zool. 2004, 15, 197–215. [Google Scholar]

- Kleindienst, Q.; Besserer, A.; Antoine, M.; Perrin, C.; Bocquet, J.; Bleron, L. Predicting the beech wood decay and strength loss in-ground. Int. Biodeterior. Biodegrad. 2017, 123, 96–105. [Google Scholar] [CrossRef]

- Morrell, J.J. Protection of Wood Based Materials. In Handbook of Environmental Degradation of Materials; Kutz, M., Ed.; William Andrew: Norwich, NY, USA, 2005; pp. 299–317. [Google Scholar]

- Takemoto, S.; Hwang, W.J.; Takeuchi, M.; Itoh, T.; Imamura, Y. Anatomical characterization of decayed wood in standing light red meranti and identification of the fungi isolated from the decayed area. J. Wood. Sci. 2008, 54, 233–241. [Google Scholar]

- Bami, M.L.; Kamarudin, M.S.; Saad, C.R.; Arshad, A.; Ebrahimi, M. Effects of canarium fruit (Canarium odontophyllum) oil as a dietary lipid source for juvenile mahseer (Tor tambroides) performance. Aquac. Rep. 2017, 6, 8–20. [Google Scholar] [CrossRef]

- Jackson, W.F. Durability of Malayan Timbers; Malayan Forest Service Trade Leaflet No. 28; Government Printing Department: Kuala Lumpur, Malaysia, 1965.

- Gascon-Garrido, P.; Oliver-Villanueva, J.V.; Ibiza-Palacios, M.S.; Militz, H.; Mai, C.; Adamopoulos, S. Resistance of wood modified with different technologies against Mediterranean termites (Reticulitermes spp.). Int. Biodeterior. Biodegrad. 2013, 82, 13–16. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Juliana, A.H.; Ang, A.F.; Tan, L.P.; Chin, K.L.; Paridah, M.T. Thermal treatment of wood using vegetable oils: A review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Ang, A.F.; Juliana, A.H.; Halis, R. Chemical, physico-mechanical properties and biological durability of rubberwood particleboards after post heat-treatment in palm oil. Holzforschung 2018, 72, 159–167. [Google Scholar] [CrossRef]

- Lee, S.H.; Zaidon, A.; Ang, A.F.; Juliana, A.H.; Lum, W.C.; Dahali, R.; Halis, R. Effects of two-step post heat-treatment in palm oil on the properties of oil palm trunk particleboard. Ind. Crop. Prod. 2018, 116, 249–258. [Google Scholar] [CrossRef]

- Boonstra, M.; Van Acker, J.; Kegel, E.; Stevens, M. Optimisation of a two-stage heat treatment process. Durability aspects. Wood Sci. Technol. 2007, 41, 31–57. [Google Scholar]

- Chaouch, M.; Dumarcay, S.; Petrissans, A.; Petrissans, M.; Gerardin, P. Effect of heat treatment intensity on some conferred properties of different European softwood and hardwood species. Wood Sci. Technol. 2013, 47, 663–673. [Google Scholar]

- Dubey, M.K.; Pang, S.; Chauhan, S.; Walker, J. Dimensional stability, fungal resistance and mechanical properties of radiata pine after combined thermomechanical compression and oil heat-treatment. Holzforschung 2016, 70, 793–800. [Google Scholar] [CrossRef]

- Gao, J.; Kim, J.S.; Terziev, N.; Daniel, G. Decay resistance of softwoods and hardwoods thermally modified by the Thermovouto type thermo-vacuum process to brown rot and white rot fungi. Holzforschung 2016, 70, 877–884. [Google Scholar]

- Gao, J.; Kim, J.S.; Terziev, N.; Cuccui, I.; Daniel, G. Effect of thermal modification on the durability and decay patterns of hardwoods and softwoods exposed to soft rot fungi. Int. Biodeterior. Biodegrad. 2018, 127, 35–45. [Google Scholar]

- Mburu, F.; Dumarcay, S.; Huber, F.; Petrissans, M.; Gerardin, P. Evaluation of thermally modified Grevillea robusta heartwood as an alternative to shortage of wood resource in Kenya: Characterisation of physicochemical properties and improvement of bio-resistance. Bioresour. Technol. 2007, 98, 3478–3486. [Google Scholar] [CrossRef]

- Lyon, F.; Thevenon, M.; Hwang, W.; Imamura, Y.; Gril, J.; Pizzi, A. Effect of an oil heat treatment on the leachability and biological resistance of boric acid impregnated wood. Ann. For. Sci. 2007, 64, 673–678. [Google Scholar] [CrossRef]

- Manola, R.D.; Garcia, C.M. Termite resistance of thermally-modified Dendrocalamus asper (Schultes f.) Backer ex Heyne. Insects 2012, 3, 390–395. [Google Scholar] [CrossRef]

- Oliver-Villanueva, J.; Gascón-Garrido, P.; Ibiza-Palacios, M.S. Evaluation of thermally-treated wood of beech (Fagus sylvatica L.) and ash (Fraxinus excelsior L.) against Mediterranean termites (Reticulitermes spp.). Eur. J. Wood Wood Prod. 2013, 71, 391–393. [Google Scholar] [CrossRef]

- Shi, J.L.; Kocaefe, D.; Amburgey, T.; Zhang, J. A comparative study on brown-rot fungus decay and subterranean termite resistance of thermally-modified and ACQ-C-treated wood. Holz. Roh. Werkst. 2007, 65, 353–358. [Google Scholar] [CrossRef]

- Surini, T.; Charrier, F.; Malvestio, J. Physical properties and termite durability of maritime pine (Pinus pinaster Ait), heat-treated under vacuum pressure. Wood Sci. Technol. 2012, 46, 487–501. [Google Scholar]

- Gradeci, K.; Labonnote, N.; Time, B.; Kohler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Sehlstedt-Persson, M.; Moren, T. Mould susceptibility of Scots pine (Pinus sylvestris L.) sapwood: Impact of drying, thermal modification, and copper-based preservative. Int. Biodeterior. Biodegrad. 2013, 85, 284–288. [Google Scholar] [CrossRef]

- Rasdianah, D.; Ashaari, Z.; Hidayah, A.; Lee, S.H. Effects of superheated steam treatment on the physical and mechanical properties of light red meranti and kedondong wood. J. Trop. For. Sci. 2018, 30, 384–392. [Google Scholar]

- Tang, Z.; Cenkowski, S.; Izydorczyk, M. Thin-layer drying of spent grains in superheated steam. J. Food Eng. 2005, 67, 457–465. [Google Scholar]

- Head, D.; Cenkowski, S.; Arntfield, S.; Henderson, K. Storage stability of oat groats processed commercially and with superheated steam. LWT Food Sci. Technol. 2011, 44, 261–268. [Google Scholar] [CrossRef]

- Mahmud, N.A.N.; Baharuddin, A.S.; Bahrin, E.K.; Sulaiman, A.; Naim, M.N.; Zakaria, R.; Hassan, M.A.; Nishida, H.; Shirai, Y. Enzymatic saccharification of oil palm mesocarp fiber (OPMF) treated with superheated steam. BioResources 2013, 8, 1320–1331. [Google Scholar]

- Umar, I.S.S.; Zaidon, A.; Lee, S.H.; Rasmina, H. Oil-heat treatment of rubberwood for optimum changes in chemical constituents and decay resistance. J. Trop. For. Sci. 2016, 28, 88–96. [Google Scholar]

- TAPPI Standard, T 257 cm-02. Sampling and Preparing Wood for Chemical Analysis; TAPPI: Atlanta, GA, USA, 2002. [Google Scholar]

- TAPPI Standard, T 204 cm-97. Wood Extractives in Ethanol-Benzene Mixture; TAPPI: Atlanta, GA, USA, 1997. [Google Scholar]

- TAPPI Standard, T 212 om-93. One Percent Sodium Hydroxide Solubility of Wood and Pulp; TAPPI: Atlanta, GA, USA, 1993. [Google Scholar]

- TAPPI Standard, T 222 om-02. Acid-Insoluble Lignin in Wood and Pulp; TAPPI: Atlanta, GA, USA, 2002. [Google Scholar]

- ASTM Standard D 1413-76. Reapproved. Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Roszaini, K.; Hale, M.D.; Salmiah, U. In-vitro decay resistance of 12 Malaysian broadleaf hardwood trees as a function of wood density and extractives compounds. J. Trop. For. Sci. 2016, 28, 533–540. [Google Scholar]

- Scheffer, T.C. Biological observations of significance for improved preservative treatment. Holzforschung 1964, 18, 88–94. [Google Scholar] [CrossRef]

- Bakar, E.S.; Hao, J.; Ashaari, Z. Durability of phenolic-resin-treated oil palm wood against subterranean termites a white-rot fungus. Int. Biodeterior. Biodegrad. 2013, 85, 126–130. [Google Scholar] [CrossRef]

- ASTM Standard D 3345-08. Standard Test Method for Laboratory Evaluation of Wood and other Cellulosic Materials for Resistance to Termites; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Candelier, K.; Thevenon, M.F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Zaman, A.; Alen, R.; Kotilainen, R. Thermal behavior of Scots pine (Pinus sylvestris) and silver birch (Betula pendula) at 200–230 °C. Wood Fiber Sci. 2000, 32, 138–143. [Google Scholar]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and ecotoxicity of heat treated pine wood extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef]

- Esteves, B.; Graca, J.; Pereira, H. Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 2008, 62, 344–351. [Google Scholar] [CrossRef]

- Tjeerdsma, B.; Boonstra, M.; Militz, H. Thermal Modification of Non-Durable Wood Species. Part 2. Improved Wood Properties of Thermally Treated Wood; Document no. IRG/WP 98-40124; International Research Group on Wood Protection: Stockholm, Sweden, 1998. [Google Scholar]

- Kishimoto, T.; Ueki, A.; Sano, Y. Delignification Mechanism during High-boiling solvent pulping part 3. structural changes in lignin analyzed by 13C-NMR spectroscopy. Holzforschung 2003, 57, 602–610. [Google Scholar] [CrossRef]

- Weiland, J.; Guyonnet, R. Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz. Roh. Werkst. 2003, 61, 216–220. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Fan, H.; Wang, J. Wood carbonization as a protective treatment on resistance to wood destroying fungi. Int. Biodeterior. Biodegrad. 2018, 129, 42–49. [Google Scholar] [CrossRef]

- Unsal, O.; Kartal, S.M.; Candan, Z.; Arango, R.A.; Clasuen, C.A.; Green, F. Decay and termite resistance, water absorption and swelling of thermally compressed wood panels. Int. Biodeterior. Biodegrad. 2009, 63, 548–552. [Google Scholar] [CrossRef]

- Dos Santos, D.V.B.; de Moura, L.F.; Brito, J.O. Effect of heat treatment on color, weight loss, specific gravity and equilibrium moisture content of two low market valued tropical woods. Wood Res. 2014, 59, 253–264. [Google Scholar]

- Li, T.; Cheng, D.; Avramidis, S.; Walinder, M.E.P.; Zhou, D. Response of hygroscopicity to heat treatment and its relation to durability of thermally modified wood. Constr. Build. Mater. 2017, 144, 671–676. [Google Scholar] [CrossRef]

- Thybring, E.E. The decay resistance of modified wood influenced by moiture exclusion and swelling reduction. Int. Biodeterior. Biodegrad. 2013, 82, 87–95. [Google Scholar] [CrossRef]

- Hakkou, M.; Petrissans, M.; Gerardin, P.; Zoulalian, A. Investigation of the reasons for fungal durability of heat-treated beech wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Rowell, R.M.; Ibach, R.E.; James, M. Understanding decay resistance, dimensional stability and strength changes in heat-treated and acetylated wood. Wood Mater. Sci. Eng. 2009, 4, 14–22. [Google Scholar] [CrossRef]

- Yao, J.; Taylor, F. Effect of high-temperature drying on the strength of southern pine dimension lumber. Forest Prod. J. 1979, 29, 49–51. [Google Scholar]

- Edlund, M.L.; Jermer, J. Durability of Some Alternatives to Preservative Treated Wood; Document NO. IRG/WP, 04-30353; International Research Group on Wood Protection: Stockholm, Sweden, 2004. [Google Scholar]

- Doi, S.; Aoyama, M.; Yamauchi, S.; Kurimoto, Y. Changes of decay and termite durabilities of Japanese larch (Larix leptolepis) wood due to high temperature kiln drying process. J. Wood Sci. 2005, 51, 526–530. [Google Scholar] [CrossRef]

- Doi, S.; Kurimoto, Y.; Ohmura, W.; Ohara, S.; Aoyama, M.; Yoshimura, T. Effects of heat treatments on the feeding behaviour of two subterranean termites. Holzforschung 1999, 53, 225–229. [Google Scholar] [CrossRef]

| Treatment | Temperature (°C) | Time (min) |

|---|---|---|

| T1 | 172 | 180 |

| T2 | 180 | 120 |

| T3 | 180 | 240 |

| T4 | 200 | 95 |

| T5 | 200 | 180 |

| T6 | 200 | 265 |

| T7 | 220 | 120 |

| T8 | 220 | 240 |

| T9 | 228 | 180 |

| Treatment | Weight Loss (%) | EMC (%) | ||

|---|---|---|---|---|

| LRM | KDD | LRM | KDD | |

| Untreated | - | - | 12.81 a | 11.66 a |

| T1 | 8.18 d | 8.19 d | 8.05 b | 6.81 c |

| T2 | 8.07 d | 9.30 d | 7.87 b | 8.26 b |

| T3 | 8.71 cd | 10.37 d | 7.56 c | 7.80 b |

| T4 | 8.06 d | 9.58 d | 7.43 bcd | 6.70 c |

| T5 | 7.76 d | 12.67 c | 6.97b c | 6.57 c |

| T6 | 9.41 bc | 12.88 bc | 6.80 d | 6.34 c |

| T7 | 10.09 b | 15.05 b | 5.77 c | 5.53 d |

| T8 | 11.47 a | 17.28 a | 5.51 e | 4.77 d |

| T9 | 11.48 a | 18.55 b | 4.65 f | 4.98 d |

| Treatment | Chemical Composition (%) | |||

|---|---|---|---|---|

| Holo-Cellulose | Alpha Cellulose | Hemi-Cellulose | Lignin | |

| Light red meranti | ||||

| Untreated | 74.62 ± 0.28 c | 42.51 ± 0.87 d | 32.11 ± 1.06 a | 23.05 ± 1.11 a |

| T1 | 73.53 ± 1.12 c | 41.62 ± 1.64 cd | 31.91 ± 2.19 a | 23.71 ± 1.81 a |

| T2 | 72.87 ± 1.01 c | 41.21 ± 0.96 cd | 31.66 ± 0.16 a | 25.25 ± 1.98 a |

| T3 | 67.01 ± 2.41 b | 40.14 ± 1.15 bcd | 26.87 ± 1.26 a | 31.15 ± 1.03 b |

| T4 | 65.86 ± 2.50 ab | 39.24 ± 1.34 abcd | 26.62 ± 3.38 a | 31.20 ± 1.17 b |

| T5 | 65.93 ± 1.28 ab | 38.43 ± 0.77 abc | 27.50 ± 2.04 a | 32.27 ± 1.34 bc |

| T6 | 66.15 ± 3.07 ab | 36.94 ± 2.46 ab | 29.21 ± 4.85 a | 30.44 ± 2.35 b |

| T7 | 65.02 ± 5.15 ab | 36.41 ± 3.52 a | 28.61 ± 8.02 a | 31.05 ± 1.02 b |

| T8 | 62.27 ± 3.91 ab | 35.76 ± 2.02 a | 26.51 ± 2.91 a | 34.24 ± 1.05 c |

| T9 | 61.91 ± 1.26 a | 36.58 ± 2.07 a | 25.33 ± 1.31 a | 34.44 ± 1.86 c |

| Kedondong | ||||

| Untreated | 76.42 ± 2.18 d | 44.33 ± 2.0 d | 32.09 ± 0.36 e | 21.94 ± 1.96 a |

| T1 | 71.89 ± 1.73 c | 43.21 ± 1.3 cd | 28.68 ± 0.7 de | 27.98 ± 1.88 b |

| T2 | 70.40 ± 3.99 bc | 42.71 ± 2.16 bcd | 27.69 ± 2.87 cd | 27.68 ± 1.97 b |

| T3 | 66.03 ± 1.78 ab | 41.86 ± 1.97 abcd | 24.17 ± 2.1 abc | 30.88 ± 1.98 bc |

| T4 | 65.91 ± 2.30 ab | 40.92 ± 2.83 abcd | 24.99 ± 0.98 abcd | 30.66 ± 2.02 bc |

| T5 | 62.43 ± 2.55 a | 39.31 ± 2.52 abc | 23.12 ± 1.98 ab | 33.41 ± 1.56 c |

| T6 | 61.24 ± 1.15 a | 39.63 ± 1.11 abc | 21.61 ± 2.22 a | 33.53 ± 2.48 c |

| T7 | 64.48 ± 2.53 a | 38.91 ± 0.79 ab | 25.57 ± 1.77 abcd | 30.93 ± 1.82 bc |

| T8 | 64.33 ± 2.94 a | 38.45 ± 3.56 a | 25.88 ± 4.34 bcd | 30.91 ± 3.17 bc |

| T9 | 63.29 ± 2.87 a | 37.73 ± 1.82 a | 25.56 ± 1.89 abcd | 32.10 ± 0.96 c |

| Treatment | Mass Loss (%) of Fungal Decay | |

|---|---|---|

| Light Red Meranti | Kedondong | |

| Untreated | 18.14 ± 2.39 f | 14.81 ± 1.55 e |

| T1 | 15.99 ± 0.25 ef | 10.55 ± 0.33 d |

| T2 | 13.80 ± 0.78 e | 8.72 ± 1.43 c |

| T3 | 10.10 ± 3.71 d | 7.61 ± 0.36 bc |

| T4 | 9.55 ± 0.78 d | 8.24 ± 1.16 c |

| T5 | 6.30 ± 0.62 c | 7.04 ± 0.07 bc |

| T6 | 4.54 ± 0.37 bc | 6.35 ± 1.29 b |

| T7 | 3.29 ± 0.27 ab | 5.91 ± 1.07 b |

| T8 | 1.69 ± 0.25 a | 2.61 ± 0.43 a |

| T9 | 1.11 ± 0.03 a | 1.60 ± 0.33 a |

| Treatment | Mass Loss (%) of Termite Resistance | |

|---|---|---|

| Light Red Meranti | Kedondong | |

| Untreated | 43.98 ± 12.51 b | 59.91 ± 7.74 c |

| T1 | 21.76 ± 9.08 a | 35.79 ± 18.58 b |

| T2 | 17.82 ± 11.06 a | 21.39 ± 12.66 a |

| T3 | 29.06 ± 13.25 ab | 23.35 ± 9.20 ab |

| T4 | 28.90 ± 15.76 ab | 22.98 ± 12.45 ab |

| T5 | 26.64 ± 7.89 a | 23.77 ± 6.40 ab |

| T6 | 22.97 ± 7.24 a | 13.53 ± 3.45 a |

| T7 | 32.94 ± 17.84 ab | 14.99 ± 3.72 a |

| T8 | 32.29 ± 14.60 ab | 17.27 ± 2.49 a |

| T9 | 30.33 ± 3.01 ab | 16.39 ± 5.66 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahali, R.; Lee, S.H.; Ashaari, Z.; Bakar, E.S.; Ariffin, H.; Khoo, P.S.; Bawon, P.; Salleh, Q.N. Durability of Superheated Steam-Treated Light Red Meranti (Shorea spp.) and Kedondong (Canarium spp.) Wood against White Rot Fungus and Subterranean Termite. Sustainability 2020, 12, 4431. https://doi.org/10.3390/su12114431

Dahali R, Lee SH, Ashaari Z, Bakar ES, Ariffin H, Khoo PS, Bawon P, Salleh QN. Durability of Superheated Steam-Treated Light Red Meranti (Shorea spp.) and Kedondong (Canarium spp.) Wood against White Rot Fungus and Subterranean Termite. Sustainability. 2020; 12(11):4431. https://doi.org/10.3390/su12114431

Chicago/Turabian StyleDahali, Rasdianah, Seng Hua Lee, Zaidon Ashaari, Edi Suhaimi Bakar, Hidayah Ariffin, Pui San Khoo, Paiman Bawon, and Qamariah Norhidayah Salleh. 2020. "Durability of Superheated Steam-Treated Light Red Meranti (Shorea spp.) and Kedondong (Canarium spp.) Wood against White Rot Fungus and Subterranean Termite" Sustainability 12, no. 11: 4431. https://doi.org/10.3390/su12114431

APA StyleDahali, R., Lee, S. H., Ashaari, Z., Bakar, E. S., Ariffin, H., Khoo, P. S., Bawon, P., & Salleh, Q. N. (2020). Durability of Superheated Steam-Treated Light Red Meranti (Shorea spp.) and Kedondong (Canarium spp.) Wood against White Rot Fungus and Subterranean Termite. Sustainability, 12(11), 4431. https://doi.org/10.3390/su12114431