Abstract

According to the Law for the Use of Renewable Energies and the Financing of Energy Transition, Mexico’s goal for 2024 is to generate 35% of its energy from non-fossil sources. Each year, up to 2630 tons of residual biomass from the zapote industry are dismissed without sustainable use. The main purposes of this study were to determine the elemental chemical analysis of the zapote seed and its energy parameters to further evaluate its suitability as a solid biofuel in boilers for the generation of thermal energy in a tropical climate. Additionally, energy, economic, and environmental assessments of the installation were carried out. The results obtained show that zapote seed has a higher heating value (18.342 MJ/kg), which makes it appealing for power generation. The Yucatan Peninsula is the main zapote-producing region, with an annual production of 11,084 tons. If the stone of this fruit were used as biofuel, 7860.87 MWh could be generated and a CO2 saving of 1996.66 tons could be obtained. Additionally, replacing a 200 kW liquefied petroleum gas (LPG) boiler with a biomass boiler using zapote seed as a biofuel would result in a reduction of 60,960.00 kg/year of CO2 emissions. Furthermore, an annual saving of $7819.79 would be obtained, which means a saving of 53.19% relative to the old LPG installation. These results pave the way toward the utilization of zapote seed as a solid biofuel and contribute to achieving Mexico’s energy goal for 2024 while promoting sustainability in universities.

1. Introduction

The increase in the worldwide population, which is expected to exceed 11 billion by the end of the century, together with economic and social development, has led to an increase in energy demand [1,2]. Despite progressive growth and the falling costs of renewable energy sources, coal, oil, and gas remain the mainstay of the steadily growing energy consumption on a global scale [3]. The energy transition to a low-carbon economy is also threatened by geopolitical and commercial tensions, and by declining investment in clean energy, according to a study published by Capgemini in collaboration with De Pardieu Brocas Maffei and Vaasa ETT. As a result, the concentrations of the main greenhouse gases (GHG) that trap heat in the atmosphere once again reached record levels in 2018: carbon dioxide (CO2) increased by 147%, methane (CH4) by 259%, and nitrous oxide (N2O) by 123%. These increases make climate change more acute as temperatures rise and extreme weather events multiply [4].

Climate change represents by far one of the major threats facing our society [5]. On 12 December 2015, at the Conference of Parties 21 (COP21) in Paris, all signatory countries came to a historic agreement to promote and accelerate the necessary measures in the fight against climate change, which included accelerating the energy transition to a sustainable low-carbon economy. The purpose of the Paris Agreement was to establish a coordinated global response to the threat of climate change and to conclude a global agreement on the reduction of greenhouse gases (GHGs), which intends to limit the increase in global temperature this century to below 2 °C compared to pre-industrial levels and to maintain ongoing efforts to further reduce the rise in temperature to 1.5 °C. Furthermore, the agreement seeks to enhance the capacity of countries to address the effects of climate change and to ensure that economic streams produce low greenhouse gas (GHG) emissions [6,7].

According to the International Energy Agency, more than a third of the world’s energy is consumed in buildings, 70% of which is used to meet heating and cooling requirements [8]. Buildings are one of the main sources of greenhouse gas emissions, and for this reason, more effort is needed to understand the energy consumption patterns in buildings and to establish strategies for energy saving at the district level [9,10]. To reduce these emissions (up to 20% since 1990) and promote the use of renewable energies, among other measures, the European Directive 2010/31/EU introduced the definition of a nearly zero energy building (NZEB) and appeals for deployment in public institutions by 31 December 2018, whereas it extends to the identical date in 2020 for privately owned buildings [11,12,13]. The principal feature of low-energy buildings is that their energy demand must be equal to their energy generated, that is, they must be able to produce the same energy or more than they will consume over a whole year. Furthermore, the energy produced must be in situ or in the closest environment and using renewable energies [14].

Mexico has clear goals regarding the use and exploitation of renewable energies, and Mexican universities, in the context of their social and environmental liability, cannot remain on the sidelines of this commitment. According to the Law for the Use of Renewable Energies and the Financing of Energy Transition, Mexico’s goal for 2024 is to generate 35% of its energy from non-fossil sources. To achieve this goal, Mexico would have to increase the share of renewables by 400 percent in less than 10 years. In Mexico, there are a large number of renewable resources with enormous potential for energy generation. We can highlight the high levels of solar radiation, a multitude of dams and reservoirs for the generation of hydroelectric energy, potential for the development of geothermal energy, areas with intense wind activity, and the generation of large quantities of agricultural and industrial waste, as well as solid urban waste [15,16].

Renewable energies are almost unlimited resources that nature provides us with and that we must take advantage of due to their sustainable nature. Another important advantage is that these resources are indigenous and increase a country’s energy resilience by decreasing its dependence on energy imports. They also increase the diversification of the energy supply and boost the growth of new technologies and job creation [17]. Under the term of renewable energy, different heterogeneous categories of technologies can be grouped. Some technologies can generate electricity and heat, as well as mechanical energy, while others can produce solid, liquid, or gaseous fuels that meet multiple energy needs. On the other hand, while some technologies can be implemented within rural and urban environments at the same place of consumption (centralized), others are generated at a distance and therefore require large transport networks (decentralized) [18,19].

Among the available renewable energies, the use of biomass for heating has experienced great growth in the last decade. Biomass is becoming more and more important as an alternative to traditional fossil fuels, such as coal or oil derivatives, since it is a more accessible and a better-distributed geographical resource, its theoretical balance of CO2 emissions is considered to be zero, and it is renewable, among other advantages [20]. Biomass can be defined as the organic substances that have their origin in the carbon compounds formed in photosynthesis and that can be used as an energy source. Under this definition, many materials can be considered biomass. Solid biofuel sources are usually divided into those of primary nature and those of secondary nature. In the former, which includes energy crops and forest biomass extracted for energy purposes, their management and use are mainly oriented toward energy production. In the sources of secondary origin, in what is generally called residual biomass, we find agricultural by-products (straw, cane, and fruit prunings), forest by-products (remains from forestry interventions, such as branches and trees with no commercial value), and industrial by-products (sawdust, fruit shells and stones, etc.). Both primary and secondary biomass can be used either via direct combustion or thermochemical processes, such as pyrolysis and gasification [21]. Additionally, both primary and secondary sources can be used for the generation of thermal energy in boilers and district heating networks, as well as for the generation of electrical energy in biomass plants.

Heating and domestic hot water generation are the most widespread thermal applications of biomass, though it is also used for cooling and power generation. Biomass can be used to generate the thermal energy necessary to power an air-conditioning system (heating and cooling), either at a centralized level (single-family house or block of flats) or at a decentralized district level (several buildings) [22,23]. Implementing a distribution network to supply not only housing estates and other residential dwellings but also public buildings, industries, etc., is known as “district heating”, and involves transporting the thermal energy over a distance through ducts that are not structurally integrated into a single building [24].

A recent Reuters Business Insight report estimates that the contribution of bioenergy to the world’s primary energy supply could reach 50% by 2050. Bioenergy projects are largely conditioned by the location and availability of biomass resources, although in recent years, the market for standardized biofuels has developed considerably. Within the applications of biomass for heating, its use in boilers to replace fossil fuels has experienced a great boom in the last decade, mainly due to the significant energy and economic savings obtained [25].

Among the most commonly used fuels for biomass boilers are pellets, mostly from the wood and forestry industries that generate waste in the form of sawdust and chips. However, due to the increase in the price of this biofuel in recent years, it is necessary to investigate new forms of bioenergy that allow for reducing costs on the one hand and alleviating the pressure on the wood industry on the other. The European standard EN 14961-1 promotes the use of new forms of biofuels, and studies have already shown the potential of certain fruit shells and stones for generating heat [26,27,28,29].

Today, Mexico is a country that depends heavily on fossil fuels for the production of its primary energy. If we pay attention to its energy production between the years 2007 and 2017, this amounted to 8935 PJ, of which 88.2% was referred to fossil fuels, 7.2% was renewable energy (1.31% obtained from biomass), 3.4% was from coal, and 1.2% was nuclear energy [30].

If we focus on primary energy production in Mexico from biomass, the main sources are firewood, occupying 5.2%, and sugarcane bagasse with 0.9%. A large part of the energy production from sugar cane bagasse (50%) is used by the sugar industry for the production of its energy [31].

According to the Mexican Secretary of Energy (SENER), 45% of the waste obtained from crops is used as fertilizer or for cooking and heating houses in rural areas [31].

Honorato-Salazar et al. [32] studied the available agricultural residues in Mexico from twenty crops. They estimated that there is between 17.5 and 58.1 megatons of dry matter produced per year (Mt DM/yr). The corresponding bioenergy potential ranges from 313.4 PJ/yr to 1039.4 PJ/yr.

The zapote mamey (Pouteria sapota, also called Lucuma mammosa) is a tree species of the Sapotaceae family. The zapote mamey tree is an ornamental, perennial tree that can reach a height of up to 40 m and a diameter at breast height of more than 1 m. The trunk is straight and may have buttresses. The external bark is cracked and falls off into rectangular pieces, brownish-gray to brownish-black in color, with a thickness of 10 to 20 mm. The leaves are arranged in a spiral and agglomerate at the tips of the branches. The fruits are berries that are up to 20 cm long, ovoid, reddish-brown in color, and rough in texture. The mesocarp is sweet, fleshy, orange to reddish, with small amounts of latex when unripe. It usually contains a seed that is up to 10 cm long, ellipsoid, and black to dark brown. The percentage in weight of the seed ranges from 8% to 16% of the total weight of the fruit [33].

Its exact origin is difficult to determine since it was already being cultivated throughout tropical America before the arrival of Europeans. Its natural range probably extends from southern Mexico to Nicaragua, Belize, and northern Honduras. In Mexico, the original areas of distribution are likely to have been in Veracruz, Tabasco, and northern Chiapas; however, it is now found in all southern Mexican states. It is cultivated from Florida (USA) to Brazil and Cuba. It has also been introduced to the Philippines, Indonesia, Malaysia, and Vietnam. It is a plant that is widely distributed in its place of origin, from southern Mexico to Guatemala and Belize, where it is found both wild and cultivated [34].

In Mexico, production has been concentrated since 2006, mainly in the states of Yucatan and Guerrero, but the states of Chiapas, Michoacan, Veracruz, and Campeche are consolidating their participation in production every year. The trend in the production of Mamey in Mexico has had a greater momentum from 2006 to 2008; after that period of growth, the upward trend has been constant but slow [33]. Figure 1 shows the zapote production in the main states of Mexico.

Figure 1.

Zapote production in the main states of Mexico.

The fruit is eaten raw or made into smoothies, ice cream, and fruit bars. It can be used to produce jam and jelly. Some beauty products use pressed oilseed to produce what is known as sapayul oil. However, the food and cosmetics zapote industries produce large amounts of waste, which is thrown away without making environmentally responsible use of it.

The main purposes of this study were to determine the elemental chemical analysis of the zapote seed and its energy parameters to further evaluate its suitability as a solid biofuel in boilers for the generation of thermal energy in a tropical climate. Additionally, energy, economic, and environmental assessments of the installation were carried out.

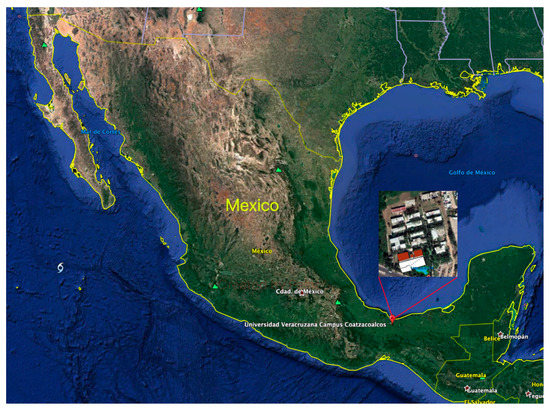

2. Case Study

The heavy chemistry laboratory of the Faculty of Engineering of the University of Veracruz in Mexico was taken as a case study (Figure 2). The Veracruzana University (UV) was founded in 1944 and became autonomous in 1996. It is located in the state of Veracruz on the Gulf of Mexico. It has five regional headquarters: Xalapa, Veracruz, Orizaba-Córdoba, Poza Rica-Tuxpan, and Coatzacoalcos-Minatitlán. In terms of the number of students it serves, it is among the five largest public state universities of higher education in Mexico.

Figure 2.

Location of the Faculty of Engineering of the University of Veracruz.

The dimensions of the chemistry laboratory (Figure 3) are 35 × 15 × 3 m, and among the equipment, the laboratory has two evaporators and a reactor for the dehydration of food. These equipment are fed by one 200 kW liquefied petroleum gas (LPG) boiler to produce steam. It consumes 200 L of LPG to produce 400 kg/h of saturated steam. Figure 4 shows the evaporator–condenser assembly.

Figure 3.

University of Veracruz heavy chemistry lab.

Figure 4.

Evaporator–condenser assembly.

Figure 5 shows the LPG boiler used to produce the steam needed.

Figure 5.

Liquefied petroleum gas (LPG) boiler used for steam production.

Initially, an energy audit was conducted, which served as the basis for the technical study. Subsequently, all the required data was gathered to assess the feasibility of substituting the current LPG boiler with a biomass boiler that would use zapote seeds as fuel.

2.1. Climatological Data

The city of Coatzacoalcos in the state of Veracruz (Mexico) has a tropical, warm, and humid climate characterized by a short dry season and heavy rainfall. The average annual temperature is 25 °C and the average rainfall is 2471 mm per year. Table 1 shows the most relevant climatic data for the city of Coatzacoalcos in the state of Veracruz.

Table 1.

Climatic data of Veracruz state.

2.2. Overview of the Existing Heating System

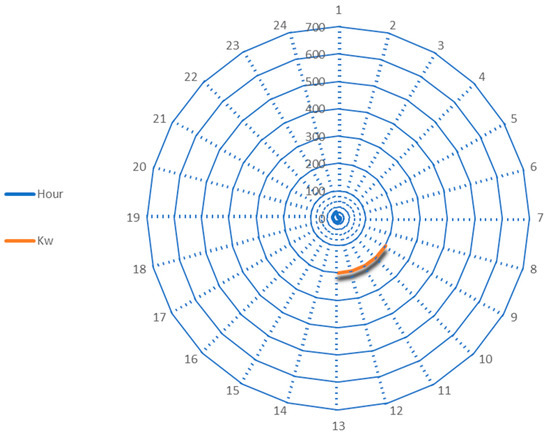

The 200 kW LPG boiler operates for approximately 4 h daily and an annual average of 300 days. Therefore, the thermal power demanded is 240,000 kWh.

Figure 6 shows the operating diagram of the LPG boiler.

Figure 6.

Running chart of the LPG boiler.

3. Materials and Methods

Regarding the use of zapote seeds as biofuel, 2000 g of this waste was collected for the determination of its chemical composition and the evaluation of its energy parameters (Figure 7).

Figure 7.

Zapote mamey (Pouteria mammosa L).

The UNE-EN 14961-1 standard “Solid biofuels–Specifications and fuel classes—Part 1: General requirements,” was used to assign the biomass quality parameters and the standard UNE-EN 15148 was used for the determination of the volatile matter. These standards have been developed by the Spanish Association for Standardisation and Certification (AENOR).

Table 2 shows the standards and measuring equipment used.

Table 2.

Standards and the measuring equipment used in this study.

3.1. Humidity

The moisture content was determined by drying the fuel at a temperature of 105 ± 2 °C in a MEMMERT UFE 700 oven and carrying out three to five complete hourly air swaps. After a period of permanence that should not exceed 24 h to avoid releasing volatiles, the sample was weighed again. The difference in mass corresponded to the sample’s moisture content.

The percentage of moisture in biofuel is a major factor when determining its energy efficiency. This is because for the heat to be available, the water must first be evaporated, where the greater the moisture percentage, the lesser the calorific value of the fuel. Furthermore, a high moisture content leads to the appearance of slag that tends to accumulate in the flue pipes, leading to corrosion and clogging problems. Most combustion reactions are complete with biomass moisture contents below 30%, with a maximum heat transfer at 10% moisture [35].

3.2. Elemental Composition

Except for the fraction corresponding to moisture and ash, the biomass is mainly made up of carbon (C), hydrogen (H), nitrogen (N), oxygen (O), sulfur (S), and chlorine (Cl) compounds. The elemental composition provides the relative amounts of these chemical elements.

For the calculation of the carbon, hydrogen, and nitrogen content, a given mass of the sample is burnt in an oxygen-containing atmosphere, resulting in ash and gaseous products of combustion (carbon dioxide, water vapor, elemental nitrogen, sulfur oxides, and hydrogen halides) [36]. Using instrumental techniques and the LECO Tru Spec CHN 620-100-400 analyzer, the mass fraction of carbon, hydrogen, and nitrogen in the gas stream was quantitatively determined.

The ultimate analysis of the biomass is required to evaluate the performance of biofuel and also allows for the estimation of its calorific value through the use of analytical expressions. It is also indicative of its environment-related burden since nitrogen turns to N2 and NOx, the last of which is one of the main greenhouse gases. The carbon content also helps to evaluate CO2 emissions.

3.3. Ash Content

Ash is the inorganic and non-combustible fraction of biomass formed due to the minerals it contains, some of which are sodium, potassium, chlorine, and phosphorus. The ash is considered an indicator of the efficiency of the biofuel because the more residue it leaves when burned, the greater the problems of clogging and corrosion in the installation [37].

For its determination, a muffle oven (NABERTHERM LVT 15/11) was used, quantifying the residual mass after the sample was burned under controlled conditions of weight, time, and temperature.

3.4. Chlorine and Sulfur Content

The chlorine and sulfur contents are other indicators of the quality of a biofuel. After combustion, chlorine is transformed into chlorides, which cause corrosion problems in the installation. On the other hand, sulfur is transformed into sulfur oxide, which is one of the main precursors of SOx emissions into the atmosphere [38].

The standard EN 15289 was followed for its determination. A calorimetric pump (Tirator Mettler Toledo G20) was utilized to determine the chlorine content in the combustion washing water using silver nitrate. For the sulfur, a tubular furnace (LECO TruSpec S 630-100-700 Analyzer) was used for the combustion of the sample at high temperature (1350 °C) and further gas quantification.

3.5. Higher Heating Value (HHV) and Lower Heating Value (LHV)

By breaking the bonds of organic compounds, by direct combustion of biomass, or by combustion of products obtained from it through physical or chemical transformations, carbon dioxide and water, among other substances, are obtained and energy is released in the process. The quality of a biofuel depends on the amount of heat it can release in the energy conversion process; this amount of heat relative to the unit of mass is the power or calorific value.

Depending on how the calorific value of the biomass is measured, the higher heating value (HHV) and lower heating value (LHV) can be defined. The HHV is the total amount of heat released in the combustion of 1 kg of biomass considering the energy needed to evaporate the water since it is assumed that the water vapor will be completely condensed, while the LHV is the heat released during the combustion of 1 kg of biofuel without considering the energy consumed to evaporate the water since it is considered that water vapor does not condense and therefore this energy is not transformed into useful heat power and is lost.

Whereas the HHV is determined by experimentation using a calorimetric pump according to the UNE-EN 14918 standard, the LHV can be calculated from it by using the following expression [39,40,41]:

3.6. Volatile Matter (VM)

The volatile matter content is determined by the loss of mass, less that due to moisture, when the biofuel undergoes a process of heating due to high temperature without being in contact with air. It can come from the organic or inorganic fraction of the biomass. Volatile matter conditions the design of the installation. The higher the volatile content of the biomass, the better the ignition at low temperatures will be since the reactivity is improved and the combustion process is enriched.

3.7. Fixed Carbon (FC)

Fixed carbon is the non-volatile part found in the crucible when the volatile materials have been determined. The quantity of fixed carbon is not obtained from the weight of the waste but is obtained using the equation:

The VM/FC ratio is known as the combustibility index. If the VM/FC ratio increases, the degree of reactivity of the biomass also increases; therefore, the greater this quotient, the easier the ignition and the lower time needed for complete combustion.

3.8. RETScreen Analysis

The analysis was carried out using the RETScreen software, which has been used to analyze and assess several bioenergy projects. RETScreen is software developed by the Natural Resource of Canada, which helped with the analysis of zapote seed as a source of energy [42]. The biomass heating project analysis that RETScreen uses is presented in Figure 8.

Figure 8.

Bioenergy process in RETScreen.

This process starts by specifying the biomass selected, which in this case was zapote seed. The model calculates the building’s (or buildings’) heating requirements. The next phase considers the heating load, where in this stage, all information about zapote seed is given. Finally, the energy delivered and fuel consumption is calculated. This final stage uses the load and demand information of the biomass heating system and/or the peak load heating system.

4. Results and Discussion

In this section, the results of the zapote seed’s physical, chemical, and energy parameter analyses are presented and compared with the quality parameters of other standardized solid biofuels to evaluate the use of this agro-industrial waste as a solid biofuel in thermal energy generation systems. An energy, environmental, and economic balance of the thermal system is also presented.

4.1. Zapote Seed Values

In this section, we present the quality indicators of the zapote seed, for which 2000 g of a sample of this waste from surrounding industries were collected and analyzed in the laboratory. Table 3 shows the mean value, the standard deviation, the maximum value, and the minimum value, which determined the parametric distribution.

Table 3.

Chemical and energy indicators derived from zapote seed profiling (parameters calculated on a dry basis, except for moisture).

As shown in Table 3, the main problem with zapote seed for use as a biofuel is its high moisture content of over 50%. Due to this, instability in the thermochemical process is produced that diminishes the efficiency of the combustion since it is necessary to evaporate the water first such that the heat is available; as a result, the net calorific value of the biomass is reduced and causes problems of jamming and corrosion in the thermal installation due to the emission of tars. Furthermore, environmental pollution increases as a result of inefficient conversion processes in which carbon monoxide and volatile organic compounds are generated.

The endothermic limit of biomass is 65% humidity; above this value, not enough energy is released to satisfy the evaporation requirement and produce heat. Above a 50% moisture content, some combustion systems will require a support fuel, such as natural gas or LPG. Therefore, in most heat transfer processes, humidities below 30% are required, with an optimum performance occurring at 10% humidity.

In our case study, a drying system needed to be implemented to reduce the humidity of the seed to around 10% before it was used for direct combustion in a boiler. The drying of the biomass can be done naturally in piles or forced with industrial drying systems.

On the other hand, the use of biomass via thermochemical conversion generates a solid residue or ash that comes from the mineral matter of the original plants, as well as from that which may have been added during the collection process. As it is an inert fraction, the energy available in any fuel is reduced in proportion to its ash content.

Therefore, ash is the inorganic fraction of biomass that is mainly composed of metallic oxides, such as calcium oxide (CaO), sodium oxide (Na2O), potassium oxide (K2O), phosphorus oxide (P2O5), aluminum oxide (Al2O3), iron oxide (Fe2O3), silicon oxide (SiO2), and magnesium oxide (MgO), with the oxides being either in the form of salts or organically associated compounds.

Calcium oxide (CaO) and silica (SiO2) affect the abrasion of the plant components due to the dragging of the ashes toward the gas outlet. Alkaline metals (K and Na) react with phosphorus and silica, which can cause slag deposits that prevent the correct transfer of heat, even generating problems in the correct operation of the installation. Furthermore, alkaline and alkaline-earth metals influence the melting temperature of the ashes, and consequently, the greater or lesser adhesion of the deposits that are formed. Potassium and sodium also react with chlorine in the gas phase (HCl) to form corresponding chlorides that can be deposited on the pipe surfaces and cause corrosion.

In the case of the zapote seed, its ash content varies between 2.49% and 2.35%, which indicates that despite being a moderate value, it is below other standardized solid fuels, such as almond shell pellets (3.35%) or oak wood pellets (3.32%) [43].

The deviation in the results depends on multiple parameters. In addition to the number of repetitions and samples analyzed, it also depends on the part of the plant analyzed. For example, waste fractions, as in the case study, usually have a higher ash content (due to impurities that may be introduced during collection and transport). On the other hand, the reproducibility of the results depends significantly on the type of plant, the growth conditions, the use of fertilizers, and the type of soil, which is related to the level of soluble inorganic elements (e.g., sandy soils give rise to less ash compared to clay soils). It can be seen that C3 plants, such as zapote, tend to have a higher water intake compared to C4 plants, and therefore have a higher ash content.

Table 4 contrasts the physicochemical indicators of the quality of various commercial biofuels and industrial wastes versus those of zapote seed to assess the applicability of this by-product in boilers.

Table 4.

Comparison between zapote seed and other biofuels.

As reflected in the comparison, zapote seed had a higher ash content than other standardized fuels, which would suggest that the problems associated with corrosion and maintenance costs of the installation could be greater.

When analyzing the calorific value of the zapote seed, we found that it was in the range of 18.320–18.364 MJ/kg, which was higher than the energy value of other standardized fuels, such as olive stone (17.884 MJ/kg) or almond shell (18.200 MJ/kg), which shows the energy potential of this residual biomass. The last row of the table shows the variation of HHV as a percentage, varying from −2.5% to +9.2%.

Other parameters that indicate the quality of biofuel are its chlorine and sulfur contents. Sulfur has a corrosive effect on the installation and causes the emission of SOx gases that contribute to global warming and cause acid rain. The sulfur content of the zapote seed (0.05%) was very low, similar to the sulfur content of almond shell and lower than that of olive stone (0.110%), which shows that corrosion problems and SOx emissions would be lessened by the use of this biofuel.

The chlorine content has a decisive influence on the corrosion of the plant since the reaction with potassium and sodium produces chlorides that have a dissociative catalytic action in the system. The chlorine content of the zapote seed (0.06%) was very low, similar to that of other agro-industrial wastes, such as olive stone (0.06%) or mango stone (0.07%), but lower than that of almond shells (0.2%), which shows that corrosion problems in thermal installations could be lessened by using this biofuel.

Another important quality parameter of biofuel is its volatile matter content. As can be seen, zapote seed had a higher volatile matter content than other solid biofuels. This high volatility and low fixed carbon content suggest that it produces less corrosion and boiler fouling. On the other hand, the combustibility index or VM/FC ratio was significantly higher than that of other solid fuels. This fact was due to greater reactivity of the fuel and facilitated ignition, even at low temperatures, reducing the residence state until the complete combustion.

It is necessary to take into account that not only is the zapote seed interesting because of its energy potential but also for its carbon neutrality. This is because it is assumed that the plant is capable of retaining more carbon during its life cycle than it releases during combustion, making the carbon cycle neutral.

Zapote waste can be collected from industries processing this fruit in the surrounding area in such a way that it both contributes to the sustainable environmental treatment of this waste and a significant fall in CO2 emissions.

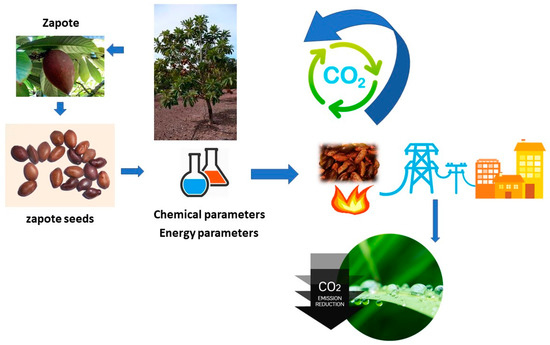

4.2. Energy and Environmental Assessment

Biomass is considered to be theoretically CO2 neutral because its combustion does not contribute to the increase of the greenhouse effect. This is because the carbon that is released during the combustion of biomass is the same that was continuously absorbed and released by the plants for their growth (Figure 9). The CO2 emissions generated from biomass energy do not alter the balance of atmospheric carbon concentration since it comes from carbon removed from the atmosphere in the same biological cycle, and therefore do not increase the greenhouse effect. Its use contributes to reducing CO2 emissions into the atmosphere whenever it replaces fossil fuel.

Figure 9.

CO2-saving scheme using zapote seed as biofuel.

Once the energy parameters of the zapote seed had been calculated, the next phase of this study was to calculate the savings in CO2 emissions in the heavy chemistry laboratory of the Faculty of Engineering of the University of Veracruz, derived from the use of this seed as biofuel. Furthermore, the savings in CO2 emissions that would be produced in the states of Mexico that produce zapote were calculated.

The first step was to calculate the energy (MWh) that could be obtained from the zapote seeds, considering the residues that would be obtained from all the zapote production in the main producing states of Mexico. This was done using Equation (2) and the results are given in Figure 10:

where:

Figure 10.

Bioenergy potential in the main producer states of Mexico using zapote seed as biofuel (MWh).

- Ep: energy obtained from the zapote seed (MWh);

- RH: considering 10% humidity in zapote seed;

- Pzapote: zapote production (kg);

- HHV: higher heating value (18.342 MJ/kg);

- fs: % of seed in a whole zapote (15%);

- Fc: unit conversion factor (0.000277778 Wh/J).

Once the energy that would be obtained by using zapote seed as a biofuel was calculated, the savings in CO2 emissions that this would represent compared to the use of LPG were calculated. As discussed in a previous section, biomass is a clean, environmentally friendly source of energy since it produces zero CO2 emissions. The mass (kg/year) of CO2 emitted by the combustion of liquefied petroleum gas (LPG) was calculated using:

where:

- : kg/year of CO2 emitted by the combustion of liquefied petroleum gas (LPG).

- : consumption of liquefied petroleum gas (LPG) per year (kWh/year).

- CO2 emission factor of liquefied petroleum gas (LPG) (kg/kWh).

Table 5 shows the CO2 emission factor for biomass and LPG and the total CO2 emissions reduced annually using zapote seed as biofuel.

Table 5.

CO2 emission (kg/kWh) of LPG and zapote seed [47].

The use of a biomass boiler in the heavy chemistry laboratory of the Faculty of Engineering of the University of Veracruz in Mexico would save 60,960.00 kg/year of CO2 emissions.

Figure 11 shows the CO2 savings in the main producer states of Mexico using zapote seed as biofuel (t).

Figure 11.

CO2 Savings in the main producer states of Mexico using zapote seed as biofuel (t).

4.3. Economical Profit

The economic viability assessment of the project to replace the former gas boiler with a biomass boiler fed by zapote seed was made by taking into consideration the following data:

- The number of annual operating hours of the installation.

- Calculation of the LPG (L) and biomass (kg) required to satisfy the energy demand.

- Lower heating value (LHV) of both the zapote seed and LPG.

- Current market prices of both types of fuel (biomass and LPG).

The thermal demand of the installation was calculated by taking into account the fact that the 200 kW LPG boiler works four hours a day for an average of 300 days a year. Under this scenario, the annual consumption of the installation is 240,000 kW/h.

The market for biomass boilers for heat generation at both residential and industrial levels is booming due to the rising cost of fossil fuels, which are also severely taxed in most countries. To determine the economic savings that would be achieved with the new biomass heating plant compared to the old LPG boiler, it was first necessary to calculate the amount of fuel required in both cases to meet the annual thermal demand. From the values of the calorific value of LPG and its density, it was calculated that 37,696.73 L of LPG are needed annually to meet the energy demand. Considering the current market price of LPG ($0.39/L) [48], a total annual cost of $14,701.72 was calculated for the LPG installation. Table 6 shows the economic analysis of the LPG installation and the zapote seed boiler.

Table 6.

Economic analysis of the LPG installation and the zapote seed boiler.

Once the calorific value of the biomass (LHV) had been determined and knowing the annual thermal demand of the installation (kWh), the amount of biomass necessary to satisfy it could be obtained from the following expression:

From this expression, it was calculated that 63,424.95 kg of zapote seed will be consumed, and considering that the price per kilo of this residual biomass, once treated and transported to the point of consumption, is $0.108/kg, an annual saving of $7,819.79 will be made, which represents a 53.19% saving compared to the old LPG installation.

Some financial parameters were calculated, such as the internal rate of return (IRR), payback, and benefit/cost ratio (B/C).

The IRR represents the ideal interest yield provided by the project, considering all costs and benefits. The IRR can be calculated when all the cash flow is at time 0 and the costs are equal to the incomes.

Payback is the time that the investment takes to recoup its initial investment; this analysis considers the cash flows from its inception, as well as the leverage of the project.

B/C is the ratio of the net benefits to the costs of the project. Net benefits represent the present value of the annual revenue and savings minus the annual costs, while the cost is defined as the project equity.

Table 7 presents the financial results and its feasibility.

Table 7.

Financial analysis.

As seen in Table 7, the financial analysis describes the viability of the project, where the IRR is predicted to be 7%, which is a competitive market rate; the payback period is predicted to be 9.8 years to recover its investment, and the B/C is predicted to be 1.13, which means that the benefits are 13% higher than the costs.

A sensitivity or what-if analysis was also done and is presented in Table 8.

Table 8.

Sensitivity analysis of zapote seed. The bold amounts indicate the range of profitability of the project.

In Table 8, it can be seen that $6,849.89 is the base of the project, that is, the feasibility of the project requires 63,424.95 kg of zapote seed at 0.108 USD per kilogram; if the price and quantity increase in different scenarios, then the project can be rejected. The bold amounts indicate the range of profitability of the project.

4.4. Energy Policy

The implications of the Mexican Law of Promotion and Development of Bioenergetics (LPDB) that can be taken into account in this paper are the promotion and development of bioenergetics to contribute to the energy diversification and sustainable development as conditions that guarantee support for the Mexican countryside. This law has three main objectives [49]:

- Promote the production of inputs for bioenergetics from agricultural, forestry, algae, biotechnological, and enzymatic processes in the Mexican countryside without jeopardizing the country’s food security and sovereignty.

- Develop the production, commercialization, and efficient use of bioenergetics to contribute to the reactivation of the rural sector, the generation of employment, and a better quality of life for the population, particularly those with high and very high marginality.

- To seek the reduction of polluting emissions and greenhouse gases into the atmosphere in accordance with international instruments contained in the Treaties to which Mexico is a party.

According to the Secretary of Agriculture and Rural Development, Ministry of Agriculture and Rural Development (SAGARPA), Mexico is the leader in the production of zapote mamey, with only five states in Mexico producing it [30]. The benefits shown in this study can be proposed to SAGARPA and use the LPDB to increase the market opportunity for small producers and increase the production overall. This necessitates an adequate credit policy for this sector, which includes low interest rates, especially during the first few years, as well as flexibility in the terms and forms of payment.

Considering the results of this study, beginning with a sustainable proposal to universities along with the five producer states of zapote mamey regarding their boiler equipment, this experience can be shared with other institutions with similar conditions.

5. Conclusions

Biomass projects are an interesting alternative to fossil fuels where resources are widely available. Due to its carbon-neutral condition and low price, biomass boilers are having an increasing presence in international markets. According to the Law for the Use of Renewable Energies and the Financing of Energy Transition, Mexico’s goal for 2024 is to generate 35% of its energy from non-fossil sources.

Zapote mamey is one of the most widely grown fruits in Mexico, with an annual production of 17,515 t. Zapote industry waste could be used to generate power and reduce CO2 emissions; while the CO2 emissions of LPG are 0.254 kg/kWh, the zapote seed emissions will be theoretically 0. Replacing a 200 kW LPG boiler with a biomass boiler fed with dry zapote seeds in the heavy chemistry laboratory of the Faculty of Engineering of the University of Veracruz in Mexico would mean a reduction in CO2 emissions of 60,960.00 kg/year.

The use of zapote seed as a biofuel has important advantages in the fight against climate change:

- It reduces the emissions of CO2, NOx, and HCl and emissions of sulfur and particles.

- Reduces boiler maintenance and the danger of toxic fuel gas leaks.

- Jobs are generated in the agro-food industry to produce food, waste is used to generate thermal energy, and the planting of these crops aids the fight against erosion and soil degradation.

Comparing the annual costs of these two sources of energy, the amount saved was predicted to be $US7,819.79, which means an annual saving of 53.19%. The total investment of the project was estimated to be $US67,530.48. According to financial results, the project was predicted to be attractive, with its financial variables showing a predicted IRR of 7%, a payback period of 9.8 years, and a B/C ratio of 1.13.

A sensitivity or what-if analysis was carried out because the price and quantity of zapote seed are sensitive to changes. In this case, the project can be accepted if the maximum quantity required increases to 79,281.19 kg but the price decreases 25% (to 0.081 USD), or the maximum price increases 25% to 0.135 USD and the quantity decreases 25% (to 47,568.71 kg).

Regarding policy implications, this study shows that there is a market opportunity for small producers and overall increases in production, which necessitates an adequate credit policy for this sector, including low interest rates, especially during the first few years, as well as flexibility in the terms and forms of payment.

These results pave the way toward the utilization of zapote seed as a solid biofuel, contribute to achieving Mexico’s energy goal for 2024, and promote sustainability in universities.

One of the main limitations of this study was the humidity of the zapote seeds. In future work, the possibility of designing dryers for these seeds, built in an environmentally sustainable way, will be studied.

Author Contributions

Conceptualization, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M.; methodology, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M.; formal analysis, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M.; investigation, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M.; resources, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M.; writing—original draft preparation, M.-A.P.-M., Q.H.-E., F.R.-M., and A.-J.P.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors thank MS. Florentino Sanchez Padilla for his support in obtaining the university laboratory data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Perea-Moreno, M.-A.; Manzano-Agugliaro, F.; Perea-Moreno, A.-J. Sustainable energy based on sunflower seed husk boiler for residential buildings. Sustainability 2018, 10, 3407. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Waste-to-energy nexus for circular economy and environmental protection: Recent trends in hydrogen energy. Sci. Total Environ. 2020, 713, 136633. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.J.; Forster, P.M.; Allen, M.; Fuglestvedt, J.; Millar, R.J.; Rogelj, J.; Zickfeld, K. Current fossil fuel infrastructure does not yet commit us to 1.5 C warming. Nat. Commun. 2019, 10, 101. [Google Scholar] [CrossRef] [PubMed]

- Wold Energy Markets Observatory 2019. Available online: https://www.capgemini.com/news/world-energy-markets-observatory-2019/ (accessed on 25 March 2020).

- Jung, J.; Petkanic, P.; Nan, D.; Kim, J.H. When a girl awakened the world: A user and social message analysis of greta thunberg. Sustainability 2020, 12, 2707. [Google Scholar] [CrossRef]

- Lima, M.A.; Mendes, L.F.R.; Mothé, G.A.; Linhares, F.G.; de Castro, M.P.P.; da Silva, M.G.; Sthel, M.S. Renewable energy in reducing greenhouse gas emissions: Reaching the goals of the Paris agreement in Brazil. Environ. Dev. 2020, 33, 33. [Google Scholar] [CrossRef]

- Johannsdottir, L.; McInerney, C. Calls for Carbon Markets at COP21: A conference report. J. Clean. Prod. 2016, 124, 405–407. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2019. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 26 March 2020).

- De la Cruz-Lovera, C.; Perea-Moreno, A.-J.; De la Cruz-Fernández, J.-L.; Alvarez-Bermejo, J.A.; Manzano-Agugliaro, F. Worldwide research on energy efficiency and sustainability in public buildings. Sustainability 2017, 9, 1294. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Hamburg, A.; Kuusk, K.; Mikola, A.; Kalamees, T. Realisation of energy performance targets of an old apartment building renovated to nZEB. Energy 2020, 194, 116874. [Google Scholar] [CrossRef]

- Kim, D.; Cho, H.; Koh, J.; Im, P. Net-zero energy building design and life-cycle cost analysis with air-source variable refrigerant flow and distributed photovoltaic systems. Renew. Sustain. Energy Rev. 2020, 118, 109508. [Google Scholar] [CrossRef]

- Ferrara, M.; Monetti, V.; Fabrizio, E. Cost-optimal analysis for nearly zero energy buildings design and optimization: A critical review. Energies 2018, 11, 1478. [Google Scholar] [CrossRef]

- Harkouss, F.; Fardoun, F.; Biwole, P.H. Optimal design of renewable energy solution sets for net zero energy buildings. Energy 2019, 179, 1155–1175. [Google Scholar] [CrossRef]

- Pérez-Denicia, E.; Fernández-Luqueño, F.; Vilariño-Ayala, D.; Manuel Montaño-Zetina, L.; Alfonso Maldonado-López, L. Renewable energy sources for electricity generation in mexico: A review. Renew. Sustain. Energy Rev. 2017, 78, 597–613. [Google Scholar] [CrossRef]

- Vidal-Amaro, J.J.; Østergaard, P.A.; Sheinbaum-Pardo, C. Optimal energy mix for transitioning from fossil fuels to renewable energy sources - the case of the mexican electricity system. Appl. Energy 2015, 150, 80–96. [Google Scholar] [CrossRef]

- Ram, M.; Aghahosseini, A.; Breyer, C. Job creation during the global energy transition towards 100% renewable power system by 2050. Technol. Forecast. Soc. Chang. 2020, 151, 119682. [Google Scholar] [CrossRef]

- Perea-Moreno, M.-A.; Hernandez-Escobedo, Q.; Perea-Moreno, A.-J. Renewable energy in urban areas: Worldwide research trends. Energies 2018, 11, 577. [Google Scholar] [CrossRef]

- Mousavi, N.; Kothapalli, G.; Habibi, D.; Das, C.K.; Baniasadi, A. A novel photovoltaic-pumped hydro storage microgrid applicable to rural areas. Appl. Energy 2020, 262, 114284. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; López-Ochoa, L.M.; López-González, L.M.; Las-Heras-Casas, J.; Xiberta-Bernat, J. Evolution and perspectives of the bioenergy applications in Spain. J. Clean. Prod. 2019, 213, 553–568. [Google Scholar] [CrossRef]

- Las-Heras-Casas, J.; López-Ochoa, L.M.; Paredes-Sánchez, J.P.; López-González, L.M. Implementation of biomass boilers for heating and domestic hot water in multi-family buildings in Spain: Energy, environmental, and economic assessment. J. Clean. Prod. 2018, 176, 590–603. [Google Scholar] [CrossRef]

- Carlon, E.; Schwarz, M.; Prada, A.; Golicza, L.; Verma, V.K.; Baratieri, M.; Gasparella, A.; Haslinger, W.; Schmidl, C. On-site monitoring and dynamic simulation of a low energy house heated by a pellet boiler. Energy Build. 2016, 116, 296–306. [Google Scholar] [CrossRef]

- Perea-Moreno, A.J.; Perea-Moreno, M.Á.; Hernandez-Escobedo, Q.; Manzano-Agugliaro, F. Towards forest sustainability in Mediterranean countries using biomass as fuel for heating. J. Clean. Prod. 2017, 156, 624–634. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Perea-Moreno, A.J.; Perea-Moreno, M.Á.; Dorado, M.P.; Manzano-Agugliaro, F. Mango stone properties as biofuel and its potential for reducing CO2 emissions. J. Clean. Prod. 2018, 190, 53–62. [Google Scholar] [CrossRef]

- Sánchez, F.; San Miguel, G. Improved fuel properties of whole table olive stones via pyrolytic processing. Biomass Bioenergy 2016, 92, 1–11. [Google Scholar] [CrossRef]

- Perea-Moreno, A.-J.; Aguilera-Ureña, M.-J.; Manzano-Agugliaro, F. Fuel properties of avocado stone. Fuel 2016, 186, 358–364. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation. Part I: Ultimate analysis data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- Secretaría de Energía (SENER), 2018. Sistema de Información Energética. Balance Nacional de Energía: Producción Deenergía Primaria. Available online: http://sie.energia.gob.mx/bdiController.do?action=temas.Dfgdfg (accessed on 9 May 2019).

- Secretaría de Energía (SENER), 2012. Iniciativa Para el Desarrollode las Energías Renovables en México. Energía de la Biomasa. PwC. Available online: http://rembio.org.mx/wp-content/uploads/2014/10/iniciativa-renovable-sener.pdf (accessed on 10 May 2020).

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioproc. Technol. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- Comité Sistema Producto Mamey de Guerrero, A.C. Available online: http://dev.pue.itesm.mx/sagarpa/estatales/EPT%20COMITE%20SISTEMA%20PRODUCTO%20MAMEY%20GUERRERO/PLAN%20RECTOR%20QUE%20CONTIENE%20PROGRAMA%20DE%20TRABAJO%202012/PR%20Mamey%20Gro.%202012.pdf (accessed on 23 March 2020).

- Alexiades, M.N.; Shanley, P. Productos Forestales, Medios de Subsistencia y Conservación: Estudios de Caso Sobre Sistemas de Manejo de Productos Forestales no Maderables; CIFOR: Bogor, Indonesia, 2004. [Google Scholar]

- Mata-Sánchez, J.; Pérez-Jiménez, J.A.; Díaz-Villanueva, M.J.; Serrano, A.; Núñez-Sánchez, N.; López-Giménez, F.J. Statistical evaluation of quality parameters of olive stone to predict its heating value. Fuel 2013, 113, 750–756. [Google Scholar] [CrossRef]

- Farias, R.D.; García, C.M.; Palomino, T.C.; Andreola, F.; Lancellotti, I.; Barbieri, L. Valorization of agro-industrial wastes in lightweight aggregates for agronomic use: Preliminary study. Environ. Eng. Manag. J. 2017, 16, 1691–1700. [Google Scholar] [CrossRef]

- Grabke, H.J.; Reese, E.; Spiegel, M. The effects of chlorides, hydrogen chloride, and sulfur dioxide in the oxidation of steels below deposits. Corros. Sci. 1995, 37, 1023–1043. [Google Scholar] [CrossRef]

- Riedl, R.; Dahl, J.; Obernberger, I.; Narodoslawsky, M. Corrosion in fire tube boilers of biomass combustion plants. In Proceedings of the China International Corrosion Control Conference, Beijing, China, 26–28 October 1999. [Google Scholar]

- Khan, A.; De Jong, W.; Jansens, P.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Senelwa, K.; Sims, R.E. Bioenergy, Fuel characteristics of short rotation forest biomass. Biomass Bioenergy 1999, 17, 127–140. [Google Scholar] [CrossRef]

- Nasser, R.A.-S.; Aref, I.M. Fuelwood characteristics of six acacia species growing wild in the southwest of Saudi Arabia as affected by geographical location. BioResources 2014, 9, 1212–1224. [Google Scholar] [CrossRef]

- RETScreen, Natural Resource of Canada. 2019. Available online: https://www.nrcan.gc.ca/maps-tools-publications/tools/data-analysis-software-modelling/retscreen/7465 (accessed on 2 October 2019).

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Sepúlveda, F.J.; Rojas, C.V. Characterization and combustion behaviour of commercial and experimental wood pellets in south west Europe. Fuel 2015, 142, 199–207. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Biomass sources for thermal conversion. Techno-economical overview. Fuel 2017, 195, 182–189. [Google Scholar] [CrossRef]

- Gómez, N.; Rosas, J.G.; Cara, J.; Martínez, O.; Alburquerque, J.A.; Sánchez, M.E. Slow pyrolysis of relevant biomasses in the mediterranean basin. Part 1. Effect of temperature on process performance on a pilot scale. J. Clean. Prod. 2016, 120, 181–190. [Google Scholar] [CrossRef]

- González, J.F.; González-García, C.M.; Ramiro, A.; Gañán, J.; González, J.; Sabio, E.; Román, S.; Turegano, J. Use of almond residues for domestic heating: Study of the combustion parameters in a mural boiler. Fuel Process. Technol. 2005, 86, 1351–1368. [Google Scholar] [CrossRef]

- Factores de Emisión de CO2 y Coeficientes de Paso a Energía Primaria de Diferentes Fuentes de Energía Final Consumidas en el Sector de Edificios en España. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros%20documentos/Factores_emision_CO2.pdf (accessed on 8 January 2020).

- Gobierno de México. Precios al Público de Gas LP Reportados Por Los Distribuidores. Available online: https://www.gob.mx/cre/documentos/precios-al-publico-de-gas-lp-reportados-por-los-distribuidores (accessed on 2 April 2020).

- Mexican Law of Promotion and Development of Bioenergetics (LPDB). Available online: http://www.diputados.gob.mx/LeyesBiblio/pdf/LPDB.pdf (accessed on 11 May 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).