1. Introduction

Taken together, wind and hydropower provide the greatest proportion of all renewable energies to the grid in Spain, contributing 49.5% and 34.20%, respectively, in 2018 [

1]. At 178.8 GW, wind power represents 18.8% of the total installed power generation capacity in the European Union (EU), and, with an installed capacity of 23.5 GW [

2,

3], Spain is second only to Germany in this respect. In terms of hydropower, Spain is ranked twentieth in the world and the fifth in the EU with a total installed capacity of 17.08 GW [

4].

One of the critical elements in both technologies is the oil used for lubrication. The potential drawbacks related to the use of lubricant oil include the need to change it regularly, which entails a break in generation and can cause significant economic losses, given the direct impact on the number of working hours of generation and related maintenance issues. Furthermore, in environmental terms, lubricant oil must be managed as a dangerous waste, with inherent risks of spillage during handling.

In a hydropower plant, lubricant oil is used both in turbines and for the regulation of mechanical systems. A turbine transforms potential energy into kinetic energy, which causes the electric generator to rotate. This rotation transforms the kinetic energy into electrical power. The turbine–generator group is made up of static and rotating parts. The bearings are an essential element in the system and are submerged in lubricant oil to avoid premature wear due to friction. In this sense, a thin layer of lubricant oil is the only thing that separates the fixed and rotating elements. The regulatory system consists of pipes that contain lubricant oil, which adjust the movement of mechanical elements through the increase or decrease of pressure. The regulatory system of the turbine-generator include tanks that contain between 3000 and 80,000 L [

5] of oil.

One of the critical parts of the wind turbine is the gearbox, which consists of a gear assembly that increases the speed of the shaft. The shaft connects the input with the output of the wind turbine. At the same time, the gearbox is the part that suffers the most significant mechanical loss. To minimise the friction within the gear assembly and improve its performance, the gears are submerged in lubricant oil. A gearbox uses between 200 and 400 L of oil [

6,

7], depending on the size of the wind turbine. As in the case of hydropower generation, any problem that causes the wind turbine to stop leads to an economic loss.

To be able to adapt to the needs of each application, lubricant oils are required to have particular characteristics and properties. Lubricant oils are made of a base, which is usually between 75% and 95% oil. The remaining 5% consists of the additives that are responsible for determining the final characteristics of the oil. In this work, we follow the oil classification standard in the industry, to make it useful for stakeholders. This classification is based on the type of base oil utilised for the formulation of products [

8]:

Mineral oil-based lubricants

Synthetic oils

Biodegradable, environmentally friendly oils (based on esters or fatty oils)

The mineral oil is a direct petroleum by-product usually produced in petrochemical plants. This kind of oil is the primary oil used in regulation and lubrication of turbines in hydropower plants. Synthetic oils can be based on several types of chemical compounds such as esters, diesters, polyalphaolefins, polyalkeleneglycols, silicones, alkyl benzenes or polyphenyl ethers [

8]. Synthetic oil has a higher viscosity than mineral oil, and this is important given the high stress in the gears.

It is possible to formulate biodegradable oils from both selected mineral base oils and synthetic oils. However, vegetable oils and synthetic ester-based products are regarded as highly biodegradable and are preferred in those applications where spillage in soil and water is expected [

8]. However, it has a disadvantage in that, if it is mixed with water, the oil breaks down more quickly than other mineral oils, which then affects the mechanical elements; it is also more expensive than mineral oil.

There exist studies on the impact of the use of different oils on the performance of the gearbox [

9] of a wind turbine. In addition, there exist works that evaluate the CO

2 emissions associated with wind power plants [

10]. However, studies combining both issues are more difficult to find. Therefore, to address this gap, here we undertake an analysis based on the evaluation of the different lubricant oils described above. We present a lifecycle assessment (LCA) [

11] for each one of their applications.

To this end, we use as a case study two hydropower plants and wind farms in Spain owned by Naturgy Energy Group S.A. [

12], representing a broad range of hydropower and wind farm facilities. Naturgy is a multinational energy company with a generation mix of 12.6% hydropower and 8.6% wind power. In the following sections, we describe the data sources used in this study; we then present the results, followed by a discussion, before finally offering some key conclusions for policy makers and other interested parties.

2. Data and Methodology

For the LCA described here, the input data were obtained from the sources listed in

Table 1. Naturgy uses mineral oil for regulation in hydropower plants, synthetic oil in wind turbines (specifically in the gearbox) and biodegradable oil for particular applications where there is a danger of spillage, for example in the cleaning grille of the hydropower plant.

For the LCA, we followed the methodology recommended by UNE-EN ISO 14040:2006 [

20]. Assessment of the environmental and economic impacts focused on comparative analysis of different types of oil. To study the lubricant oil in a hydropower plant, we assessed the lubrication of the bearings and the regulation system. For the wind turbines, we assessed the lubrication of the gearbox. The main factors considered were the energy used in manufacturing and recycling, changes of equipment required due to wear, types of oils, the amount of waste produced when replacing them, reduction of the potential impact in case of spillage, transport, power generation, CO

2 emissions and the cost of each type of oil.

Table 2 summarises the relevant information.

Some processes were not included in the LCA, because they are associated with the lifetime of the lubricant oil or because their contribution to the global assessment is low compared with those listed previously [

21]. These process are:

The manufacture of the equipment and the infrastructure required for the extraction and transport of crude oil and seeds

The production of fertilisers, seeds and weed-killers

Management of the waste produced during the extraction of biodegradable oil

The energy balance during the extraction of petroleum (e.g., obtaining natural gas and other derivatives of petroleum)

Link and aggregation of additives in the different types of oil

To perform the study, we defined a functional unit (FU) to be the reference unit that forms the basis for comparisons made between different systems. The FU must be defined in the goals and scoping phase of an LCA [

22]. For this study, we defined the FU as the amount of mineral, synthetic and biodegradable oil in terms of the energy used in kWh/l, the associated CO

2 emissions in terms of kg/L, and the cost in terms of €/L for the Belesar and Velle hydropower plants, and the gearbox of the wind turbine V90-20MW during their lifetime.

2.1. Hydropower

The hydropower plants selected for the LCA were Belesar and Velle, located in the Miño-Sil River basin (a heavily intervened catchment [

23]) in the northwest of the Iberian Peninsula. Belesar is located at longitude 7.74 W and latitude 42.66 N. Velle is located downstream at longitude 7.85 W and latitude 42.36 N. Both plants are managed by Naturgy. Belesar has 310 MW of installed power generation capacity with three Francis turbines, which need 57,800 L of oil for lubrication and regulation. Velle has 86.5 MW of installed capacity with two Kaplan turbines, and, of the hydropower plants managed by Naturgy it uses the greatest amount of lubricant oil, 70,200 L. In both hydropower plants, the mineral oil used is “Cepsa HD turbines 68”. The lifetime of this type of hydropower plant is between 40 and 80 years [

24], depending on the type of dam and its construction. For the purposes of our study, we considered a lifetime of 50 years. Belesar and Velle became operational in 1963 and 1967, respectively. Belesar was refurbished between 2007 and 2009, and Velle between 2012 and 2014 [

12].

Table 3 shows the mineral oil requirements of Belesar and Velle and

Table 4 shows the mineral oil consumption for 2013–2017, together with the mean consumption for the period and extrapolated values for the lifetime of the hydropower plant (50 years).

2.2. Wind

Naturgy has 1012 MW of installed wind power capacity in Spain, with a total of 1227 turbines. In México and Australia, Naturgy has 330 MW with 145 wind turbines [

12]. For this study, we selected the VESTAS V90-2MW model of wind turbine, being the one most commonly used by Naturgy and broadly adopted in the market. The VESTAS V90-2MW contains a gearbox that requires 400 L of lubricant oil to operate. The oil used by Naturgy in this type of wind turbine is the synthetic “Cepsa Aerogear Synt 320”. The regulation for wind turbines set out in UNE-EN 61400-1:2006 [

25] indicates a number of different characteristics including design, installation, operation and maintenance under specific environmental conditions and offers a range of values for the lifetime of these turbines. According to these regulations, the Spanish Association for Standardization and Certification (AENOR) [

26] indicates a lifetime of 20 years accounting for fatigue. The main mechanical component of the wind turbine is the gearbox. We evaluated the lubrication of the gearbox, which has an average expected life of seven years [

27]. It is therefore necessary to make three complete changes of lubricant oil in the gearbox during the lifetime of the wind turbine. Consumption data for the synthetic oil “Cepsa Aerogear Synt 320” used in the VESTAS V90-2MW turbine in several wind farms owned by Naturgy are shown in

Table 5.

The annual mean consumption (last twenty years) of oil (127 wind turbines) is calculated following the steps set out in

Appendix A.1. The mean annual consumption of oil in these 127 wind turbines is 13,513 L/year, and for each wind turbine the figure is 106.4 L/year.

2.3. Energy Consumption and Associated Emissions during the Production of Mineral Oil

Here, we split the analysis of the production in three steps: extraction, transport and production in the refinery.

Table 6 shows the values of the energy used in the extraction and transport of crude oil according to widely adopted practice [

21].

For each kg of crude oil, less than 2% is used for the production of mineral oil [

13]. For this reason, the energy used to produce a kg of mineral oil is 2% of the total value in

Table 6, i.e., 0.021 kWh/kg. The energy used to obtain it is 10.15 kWh/L (the data for oil refining were provided by the Spanish Research Centre for Energy, Environment and Technology (CIEMAT) [

28]. These data were obtained from the refinery in Algeciras in Cádiz, because this is the biggest refinery in Spain).

The emissions associated with the production of mineral oil were computed using the emissions calculator of the Ministry for the Ecological Transition [

29]. The emission factor for converting kWh to kgCO

2 is 0.385. The associated emissions are thus: 10.15 kWh/L × 0.385 = 3.91 kgCO

2/L. The emissions resulting from extraction and transport are insignificant compared with those related to the energy used in the manufacturing of the oil.

2.4. Data on Energy and Associated Emissions for the Production of Biodegradable Oil

Data on the energy and emissions involved in the use of biodegradable oil with a vegetable base were obtained from sources related to colza and sunflower farming [

30]. According to published data on the energy values related to the production of colza [

31,

32,

33], the value is 2131 MJ/t. For the case of sunflower oil, the value is higher, at 4365 MJ/t [

32]. These values include the energy required to transport the crop from farms to extraction plants. Data on the energy necessary to process the colza and sunflower oil were obtained from Group Bunge-Ibérica [

34], as shown in

Table 7.

In this study, we used the average of the values obtained for the two oils, colza and sunflower, which was 20.90 MJ/kg. This result was then converted into kWh per litre of oil produced: 6.37 kWh/L. The emissions produced per litre of biodegradable oil were obtained using the calculator of MITECO [

29].The conversion factor from kWh to kgCO

2 is 0.385, meaning that the associated emissions are 2.45 kgCO

2/L.

2.5. Data on Energy and Associated Emissions for the Production of Synthetic Oil

We used a specific type of synthetic oil broadly adopted in the energy production sector: Cepsa Aerogear synt 320. This oil has a basis of polyalphaolefins (PAOS) and ester. The synthetic ester comes from fatty acid and alcohol [

35], and PAOS are obtained from ethylene. Ethylene is obtained from refineries or natural gas. For these reasons, in the assessment for the production of synthetic oil, we considered a value halfway between those used for mineral and biodegradable oil, as shown in

Table 8. The emissions associated with energy used in terms of kgCO

2 are

kgCO

2/L.

2.6. Data on Energy and Associated Emissions Associated to the Transport and Recycling of Lubricant Oil

In calculating the energy use and emissions produced during the transport and recycling of the lubricant oil, we considered hydropower plants and wind farms to follow a similar process in terms of receiving and recycling the oil. The data for this were obtained from SIGAUS [

36]. The data obtained for the trip to the recycling plant can be seen in

Table 9, which shows the average trip length for three different scenarios. In this study, we selected the average of these three types of trips.

Assuming each truck has a diesel engine and makes urban trips, the emission factor is 490.73 gCO

2/km [

37]. The emissions of CO

2 are thus the product of 87.2 km and 490.73 gCO

2/km, which equates to 42.73 kgCO

2. The equivalent energy is 110.98 kWh, obtained using the calculator of MITECO [

29]. The associated emissions per litre are then obtained by dividing the total energy, 110.98 kWh, by the number of litres transported each time, 5000 L, giving a result of 0.02 kWh/L. The consumption of energy for each kg of recycled oil [

19] is 742,000 BTU per barrel of oil used. Thus, the energy used to recycle the oil is 1.35 kWh/L, and after adding the emissions from the associated transport to the recycling plant we obtained 1.37 kWh/L. The associated emissions are 0.53 kgCO

2/L (see

Appendix A.2).

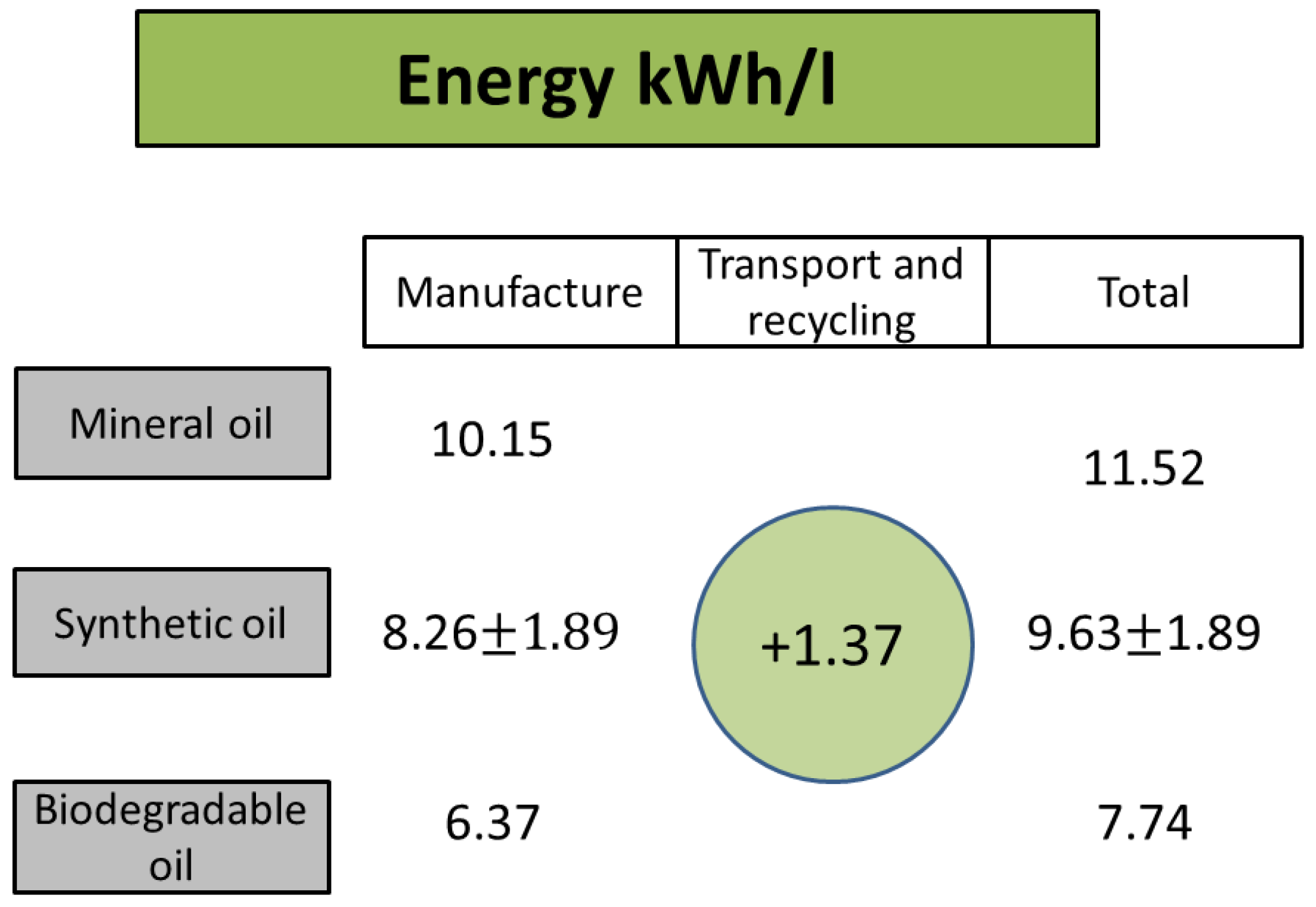

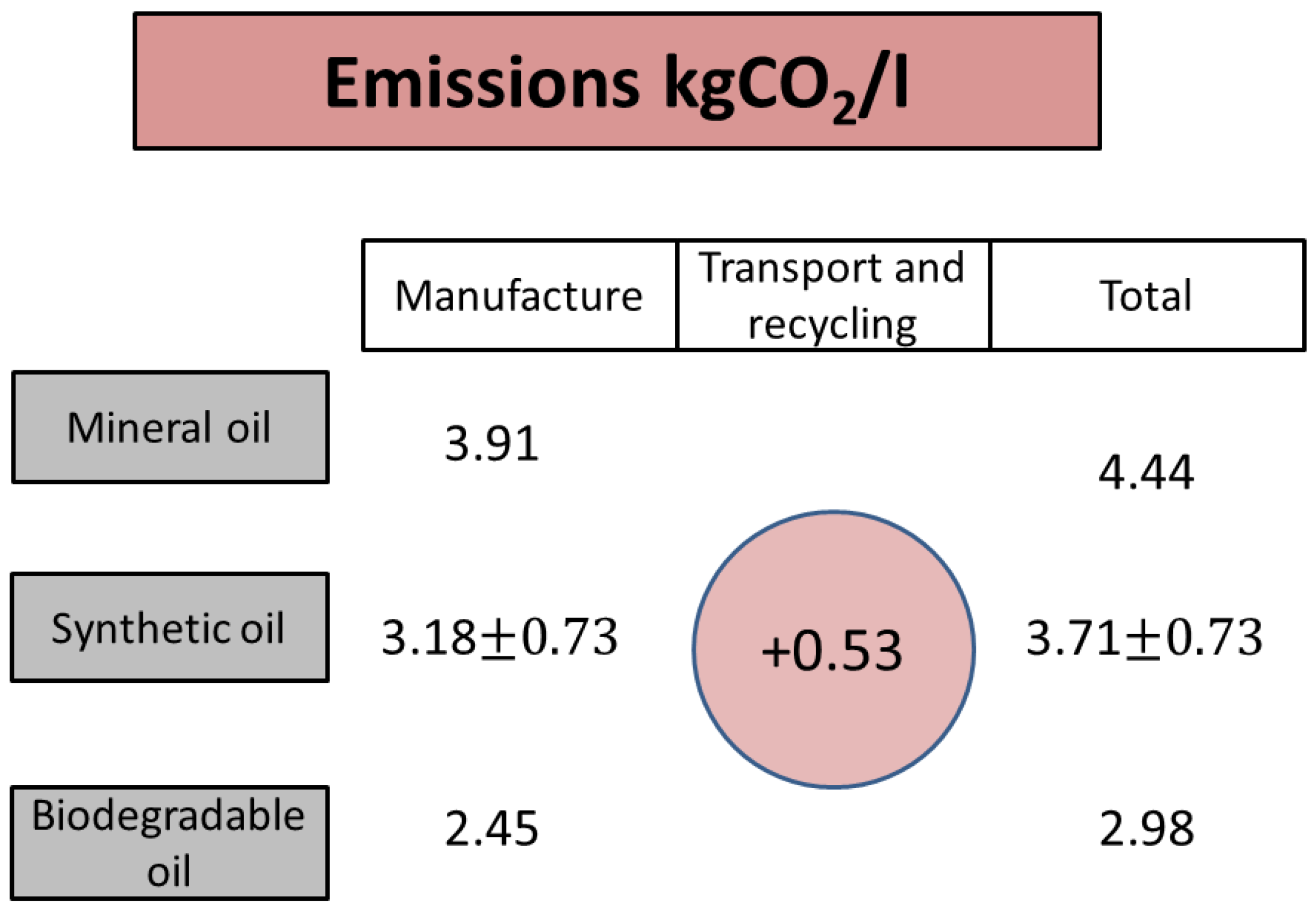

2.7. Comparison of Energy and Emissions for the Manufacture, Transport and Recycling Stages in the Use of the Lubricant Oil

Figure 1 and

Figure 2 also summarise the energy requirements and the associated emissions involved in producing one litre of biodegradable, mineral and synthetic oil.

From an environmental point of view, the production of biodegradable oil uses 33% less energy than mineral oil and proportionally less CO

2 per litre. However, its use is sub-optimal in that the biodegradable oil does not maintain the proper lubrication of the machinery for as long as mineral or synthetic oil [

38].

2.8. Economic Data of Lubricant Oils

An economic analysis allows comparisons to be made between the different types of oils used by Naturgy. The price per litre in each case is shown in

Table 10.

Table 11 and

Table 12 show the economic data for the different types of oils as applied to the hydropower plants of Belesar and Velle.

As a part of this study, we undertook an analysis regarding the cost of replacing the oil in the multiplier (with average life of eight years) using the synthetic oil Castrol Optigear Synthetic 320 at a cost of 14.75 €/L, which is double that of the oil Cepsa Aerogear Synt 320 (and currently used by Naturgy in this type of wind turbine).

Table 13 shows an assessment of the cost. It was considered that the average life of a gearbox is eight years, and in the table the cost of the gearbox is taken to be the average for a restored gearbox and a new gearbox. In

Table 14, we show the cost per year of the lubricant oil Castrol Optigear.

The relationship between the energy consumed in the production of the oil and the energy dispatched to the grid provides an assessment that reflects the significance and profitability of these components in power generation. In

Figure 3, the relationship is shown between the energy required to produce the oil consumed during a single year for the Belesar and Velle hydropower plants, as well as the wind turbine V90-2MW (kWh/year), and the energy dispatched to the grid (kWh/year).

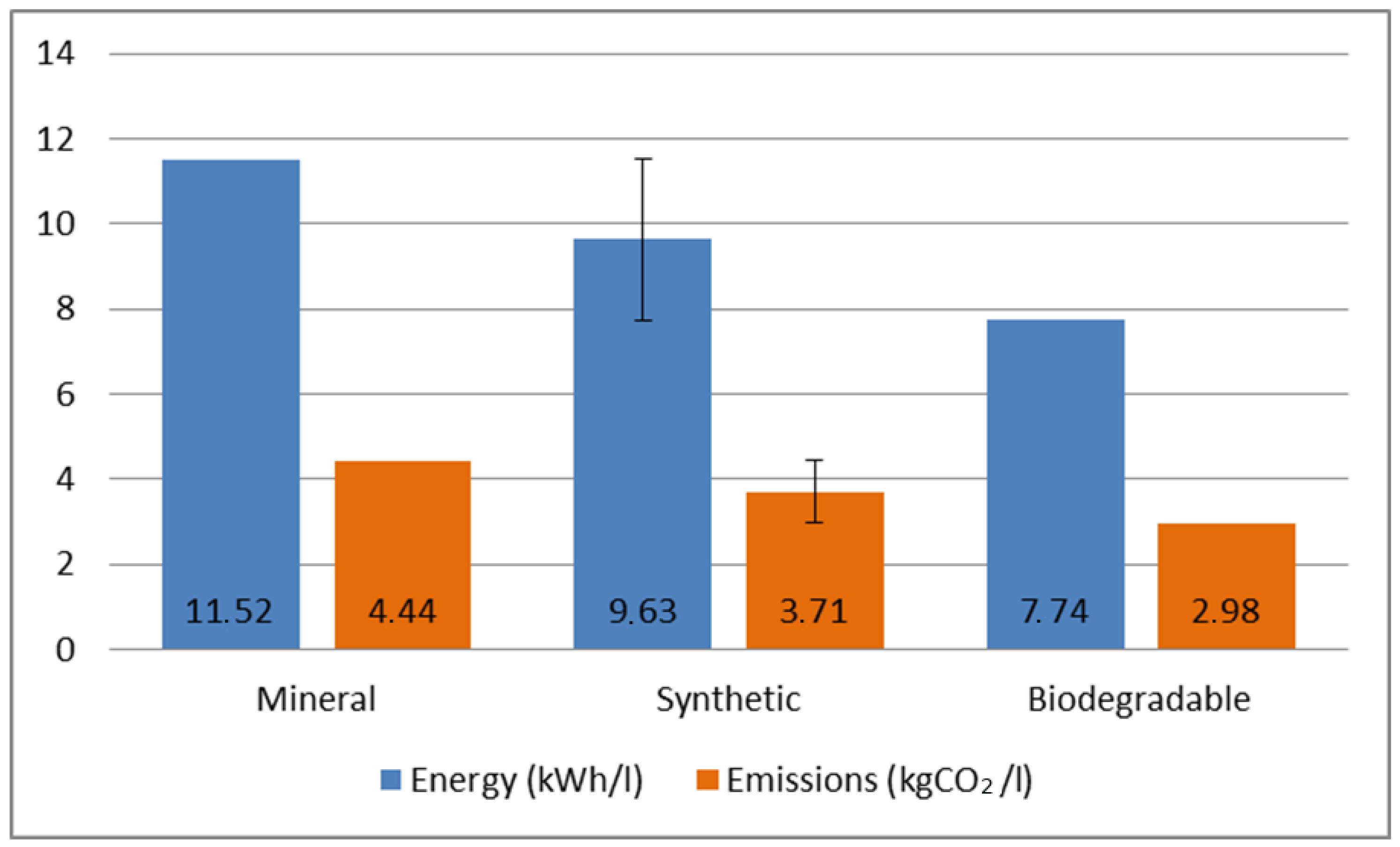

3. Results

Although the production and use of biodegradable oil emit less CO

2, it may not be used in many lubrication systems because it can lose its chemical properties in contact with water. Mineral oil requires the greatest amount of energy for processing and therefore its emissions of CO

2 are higher, given that the refining process requires a large amount of energy to convert petroleum to oil (see

Figure 4).

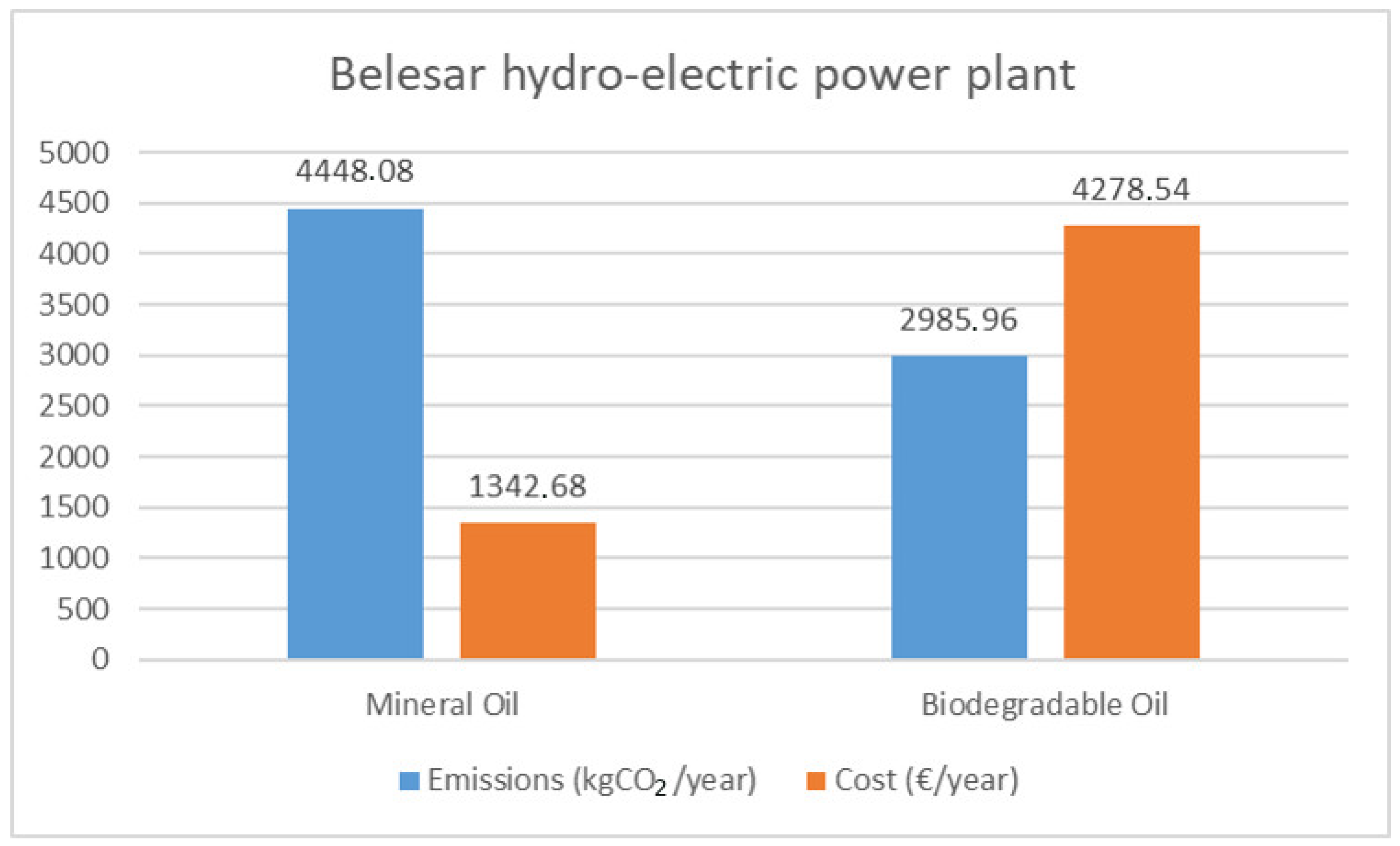

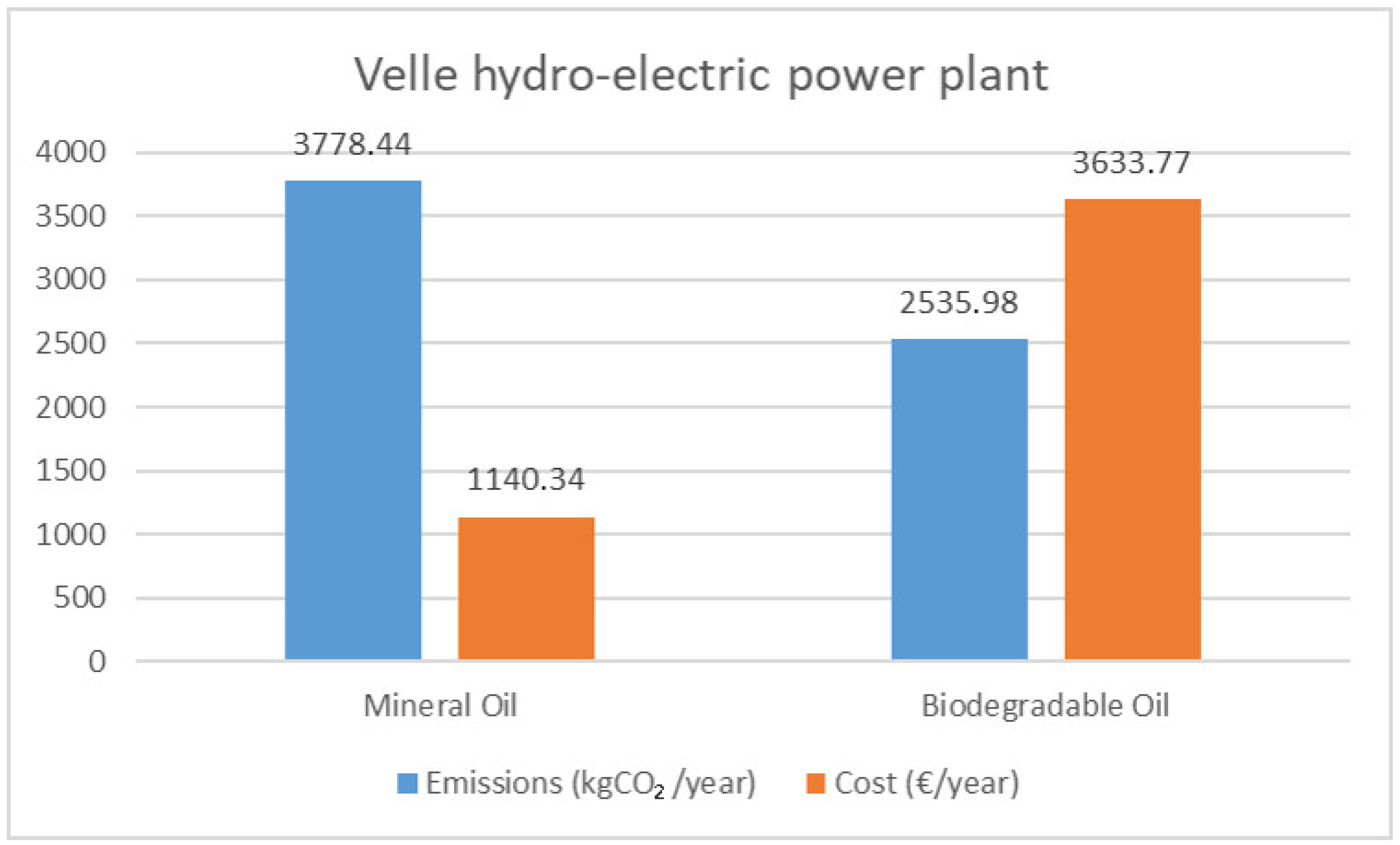

Using the data for Belesar and Velle hydropower power plants (

Table 11 and

Table 12), we compared the costs to the emissions of CO

2 (

Figure 5 and

Figure 6). Our results show that the use of biodegradable oil instead of mineral oil causes 33% less CO

2 emissions, but the cost is 319% higher than when using mineral oil.

One major disadvantage of biodegradable oil lies in the fact that, on contact water, it degrades more rapidly than mineral oil, losing its essential characteristics and thus affecting the operation of the mechanical plant.

For this reason, the use of biodegradable oil is only necessary for those places in the hydropower plant where there exists a risk of release of oil into the river (i.e., the cleaning grilles and the sluice gate), because in these places there is no retention system in place. For lubrication in the main moving parts of the plant, as long as the cost of biodegradable oil is appreciably higher than that of the mineral oil, hydropower plants will continue to use mineral oil.

As far as the wind turbines are concerned, our analysis yields further useful information. As shown in

Table 13 and

Table 14, it is possible to make an assessment of the durability of the gearbox (of the wind turbine Aero V90-2MW) using the lubricant oil Castrol Optigear. We showed that, if the lifetime of the gearbox can be extended from seven to eight years, i.e., an extra year of operation, it would generate savings of:

This result relates to the operation of a single wind turbine. Given that Naturgy currently operates 127 wind turbines of this model (Aero V90-2MW), the total savings could be:

We note that with these savings comes a potential increase in the durability of the equipment and a decrease in the required frequency of oil changes. These results offer the possibility of environmental benefits, driving innovation and thus more responsible consumption.

Figure 3 shows that for each kWh necessary to produce the amount of lubricant oil consumed in one year, Belesar HP produces more than 55,000 times more energy, Velle HP produces near to 19,000 times more energy and a single wind turbine V90-2MW produces more than 3300 times energy over the same period of time. Taking into account also that wind power and hydropower do not have associated emissions of CO

2, we conclude that there is a clear net gain inherent in the production of lubricant oil with regard to their use in renewable energy.

4. Conclusions

In this study, we analylitered from the environmental, economic, and technical points of view the use of mineral, synthetic, and biodegradable oil in wind and hydropower turbines. Our results show that biodegradable oil (vegetable based) is associated with a small amount of energy (kWh) and has lower equivalent carbon emissions (kgCO2) for its manufacture and recycling (33% less than mineral oil and 20% lower than the synthetic oil, in terms of both energy and associated emissions in this case).

A comparison between the oils used for wind power (synthetic) and for hydropower (mineral) turbines shows that, per litre, the synthetic oil is five times more expensive for wind than the mineral oil is for hydropower. Furthermore, for wind power, a greater amount of oil is required per GWh. Typically, although mineral oils biodegrade, the processes involved are slow and may be only partial. Biodegradable oils tend to biodegrade more rapidly and more completely [

39,

40]. The use of biodegradable oil in a hydropower plant could entail its more frequent replacement than the use of mineral oil. As shown in

Figure 3, just one substitution of the biodegradable oil in the mechanism causes more emissions than the use of mineral oil. Furthermore, the replacement of the oil in the system implies the interruption of energy production during the process. Biodegradable oil is recommended if there is a significant risk of spillage. However, the higher cost of biodegradable vs. natural mineral oil and problems when it comes into contact with water are the main barriers to its wider adoption. For sites where there is no potential for environmental impact during its use, economic considerations carry greater weight than sustainability.

The possible use of other types of synthetic oil in the gearbox of a wind turbine could provide savings up to 1300 € per turbine. With this financial incentive, it is recommended for future studies to experiment with other types of synthetic oil, in order to assess properly the assumption of increased durability of the turbine. The evaluation of the lubricant oil from an energy point of view shows particular relevance concerning the energy necessary to produce it and the power released to the grid.

Finally, as a further step in this kind of works in the future, it would be interesting to study the impact on the results of considering a broader range of oils. For example, it would be relevant to evaluate a potential impact on the results here obtained with vegetable-based biodegradable oil when considering instead a biodegradable synthetic oil.