Value Analysis Model to Support the Building Design Process

Abstract

1. Introduction

2. Research Method

2.1. Overall Approach

2.2. Problem Identification and Motivation: Literature Review

2.2.1. Value

2.2.2. Customer

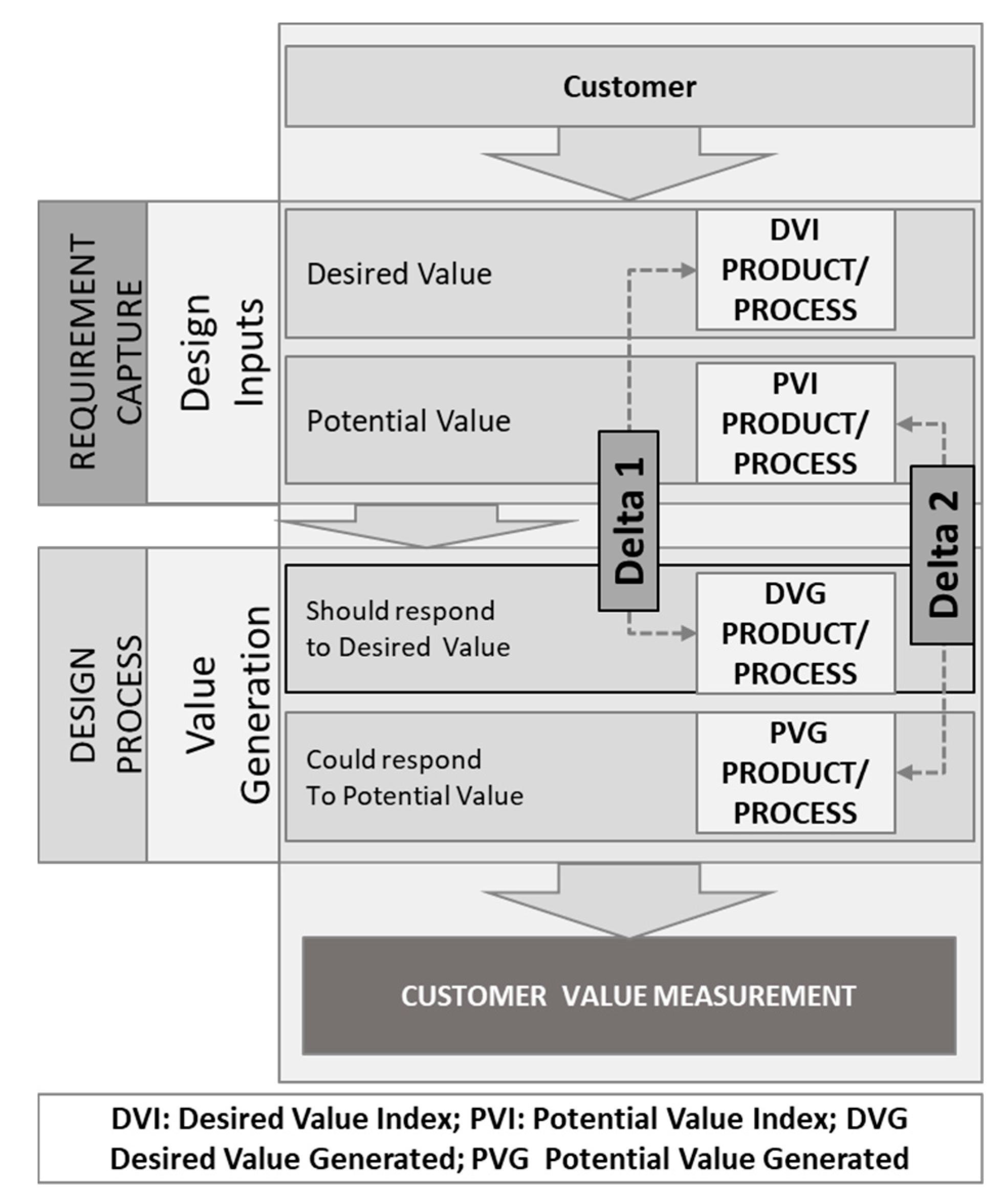

2.2.3. Generation and Loss of Value

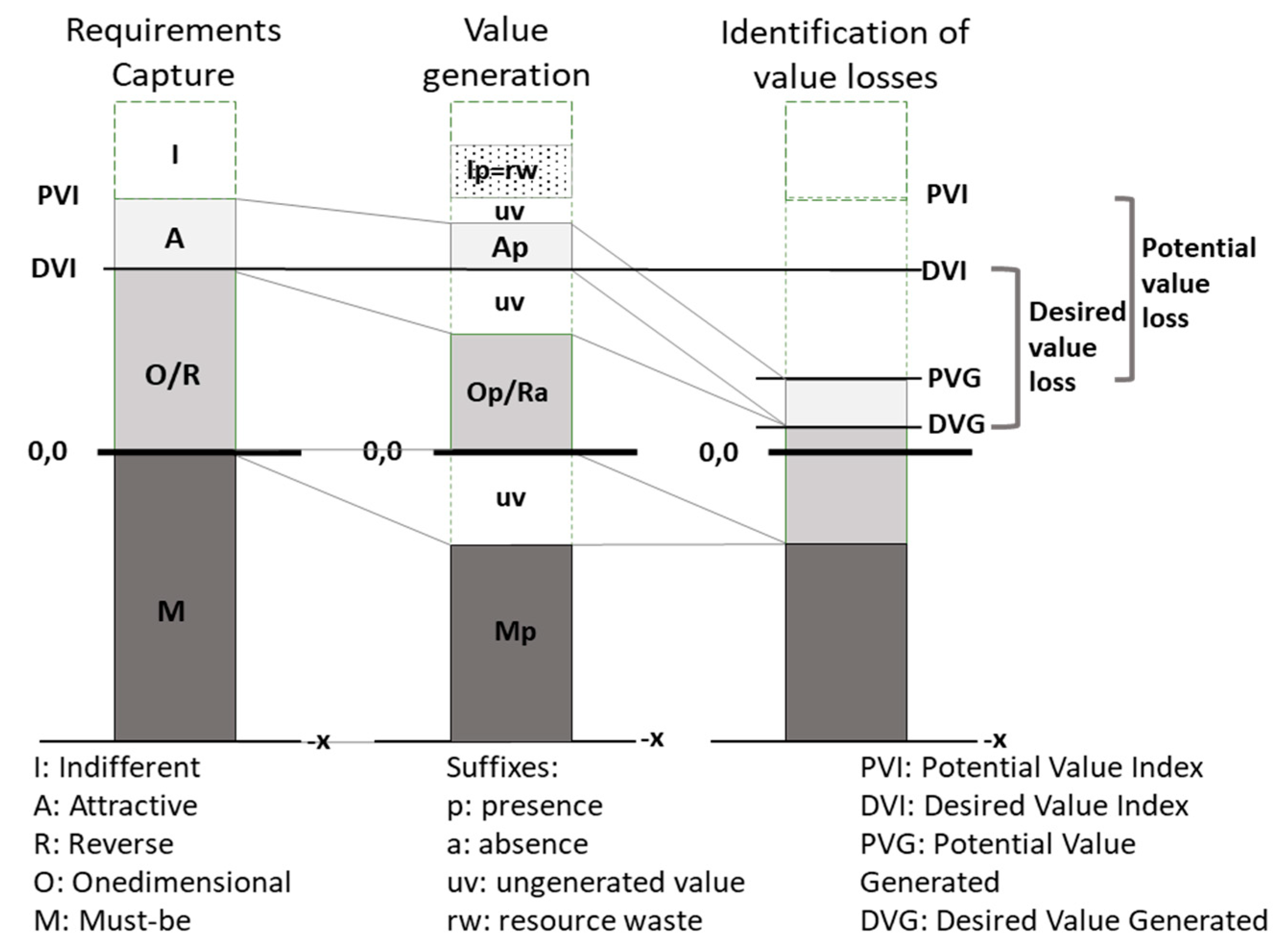

- Requirements capture: Ensuring that all customer requirements, both explicit and implicit, have been captured as the first step in generating value.

- Requirements flow-down: Ensuring that all relevant customer requirements are retained in all phases of production and are not lost when progressively transformed into design solutions, production plans, and products.

- Comprehensive requirements: Ensuring that all requirements relate to all customer roles.

- Production subsystem capacity: Ensuring the capacity of the production system to produce products as needed.

- Value measurement: Through metrics, ensuring that value is generated for the customer.

- Minimization of the life cycle cost.

- Pursuit of the satisfaction of customers’ needs.

- Pursuit of value maximization.

- Requirements capture.

- Requirements flow-down.

- Pursuit of integrated solutions for the fulfillment of requirements.

- Assurance of the capacity and performance of the production system.

- Verification that the requirements are met.

- Value measurement through metrics.

- Identification of value losses.

2.2.4. Value-Related Methods in the Architecture, Engineering, and Construction (AEC) Industry

2.2.5. Point of Departure

2.3. Draft 1

2.4. Draft 2

2.5. Draft 3

3. Results

3.1. Value Analysis Model (VAM)—General Overview

3.2. Requirements Capture—Design Inputs

3.2.1. Customer Identification

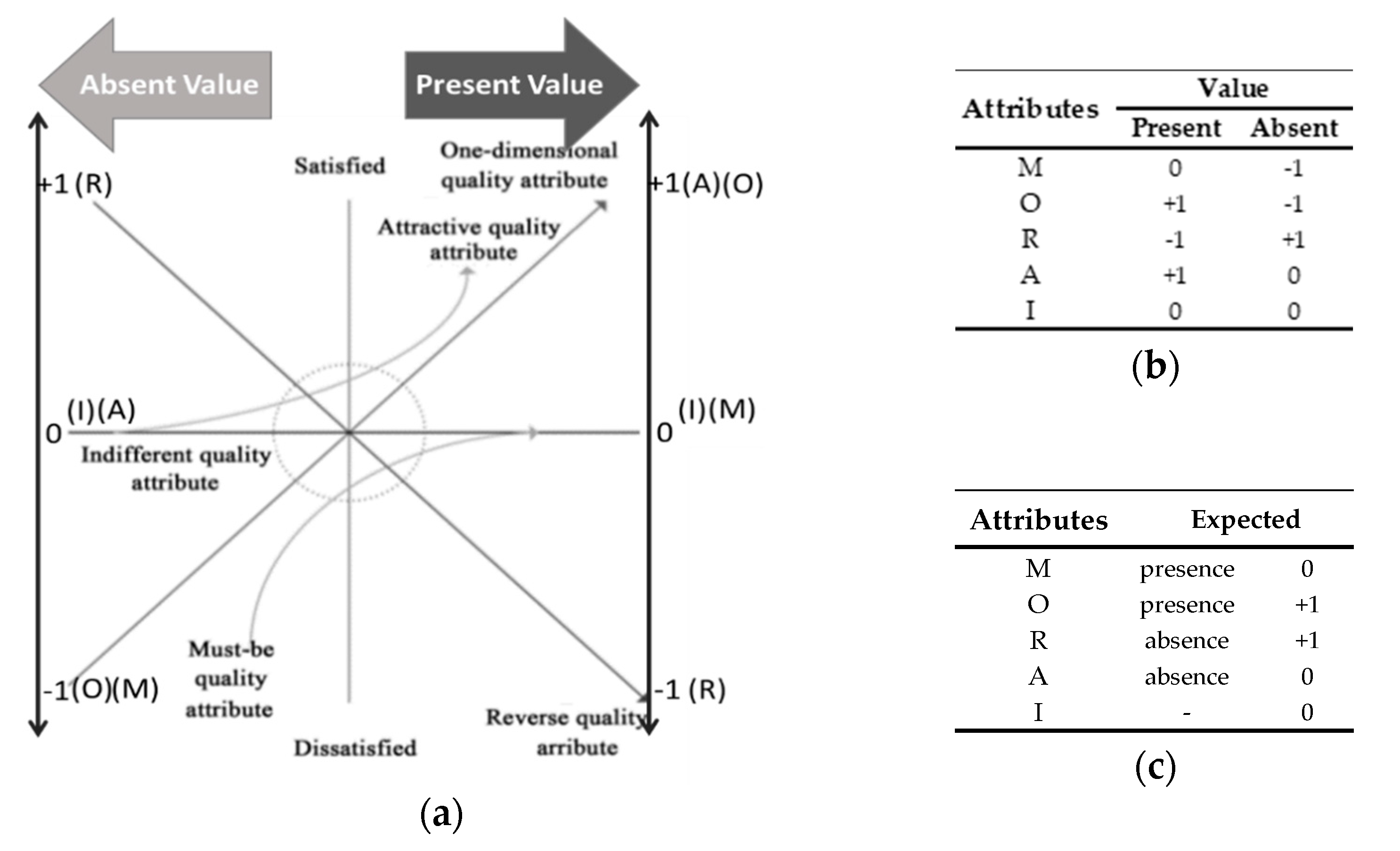

3.2.2. Attribute List Creation

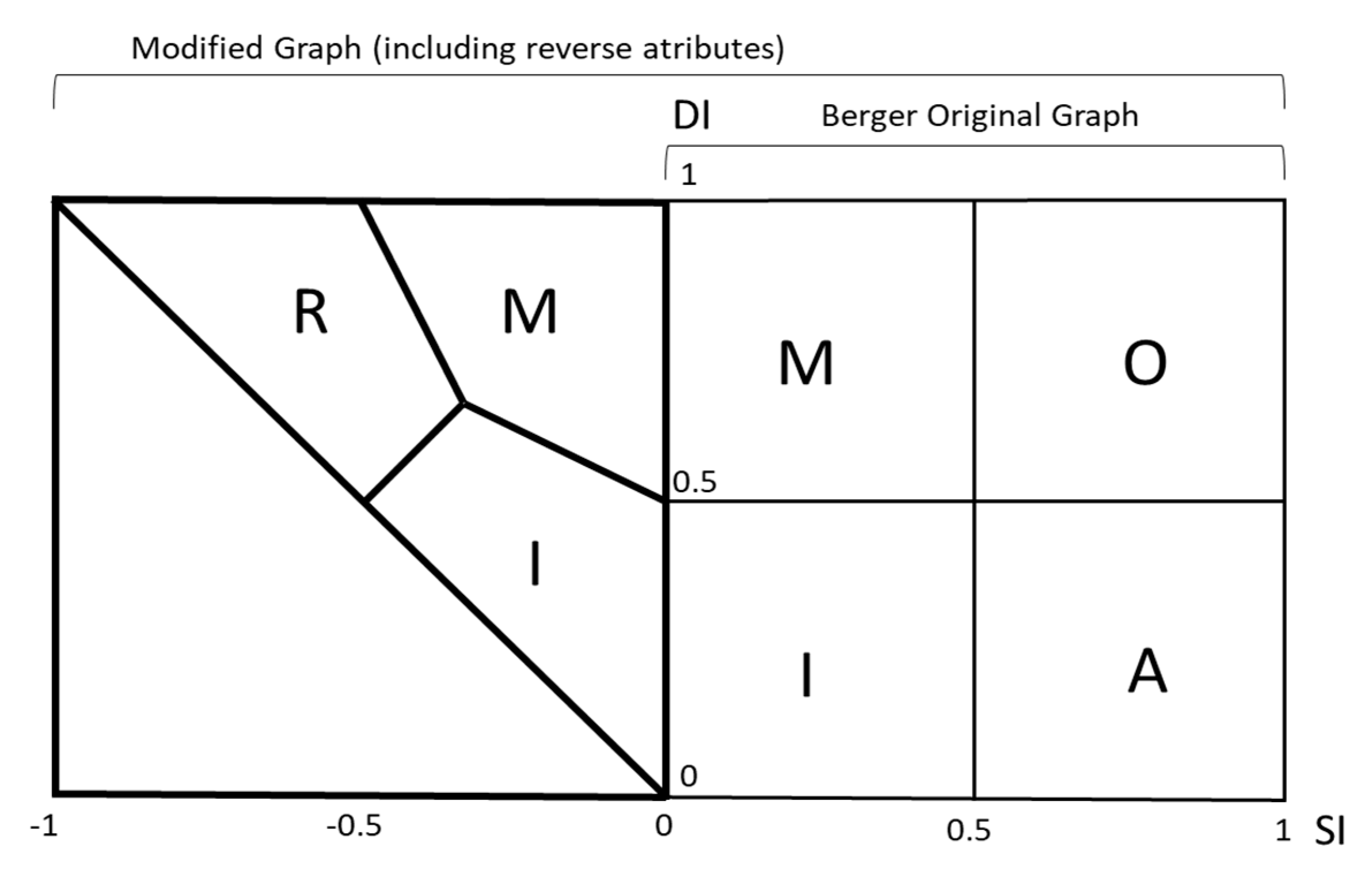

3.2.3. Attribute Classification

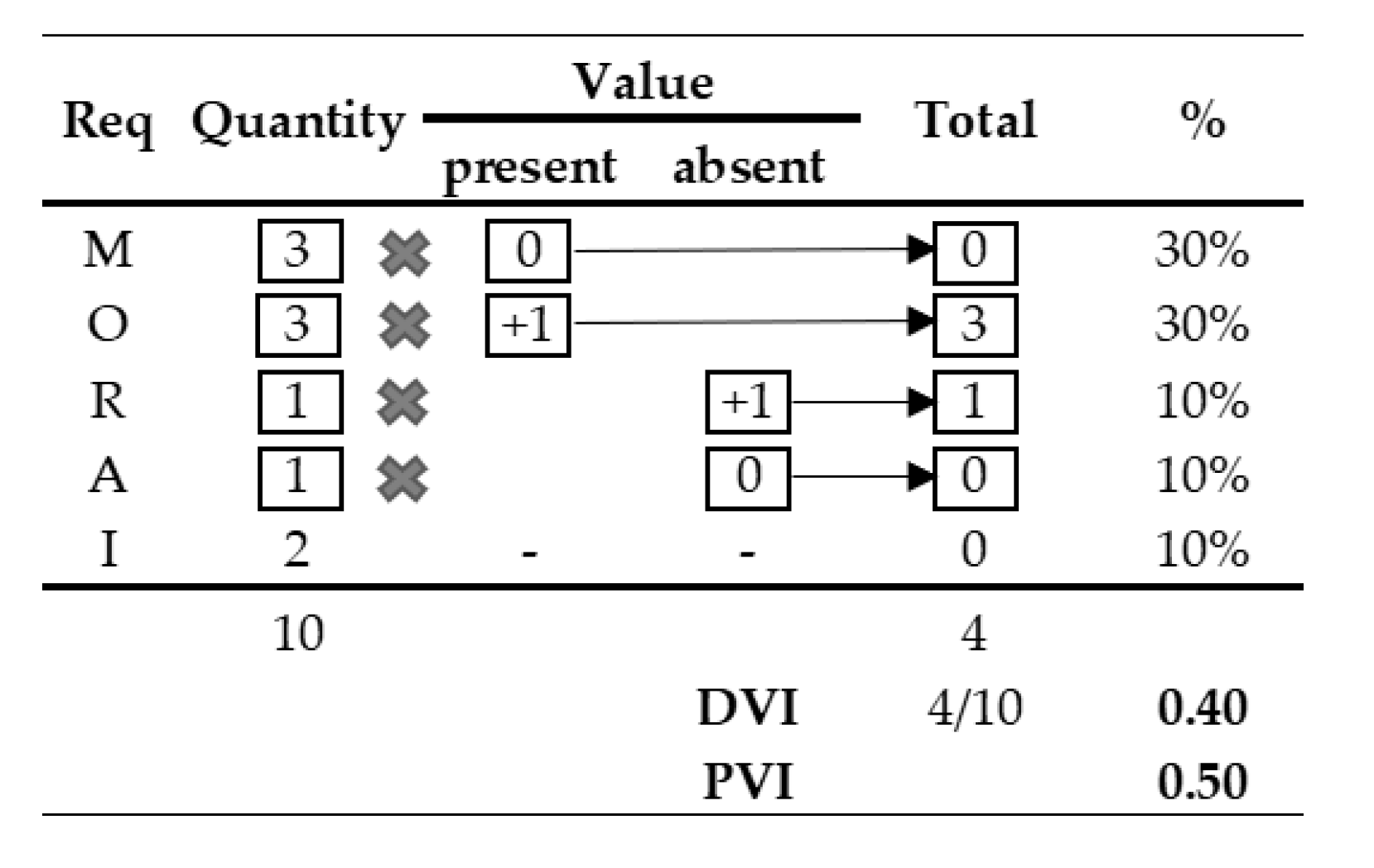

3.2.4. Attribute Valuation

3.2.5. Calculation of Indexes

3.3. Design Process—Value Generation

3.3.1. Generated Value Indexes (GVI) Calculation

3.3.2. Comparison of Generated Value with Desired and Potential Value

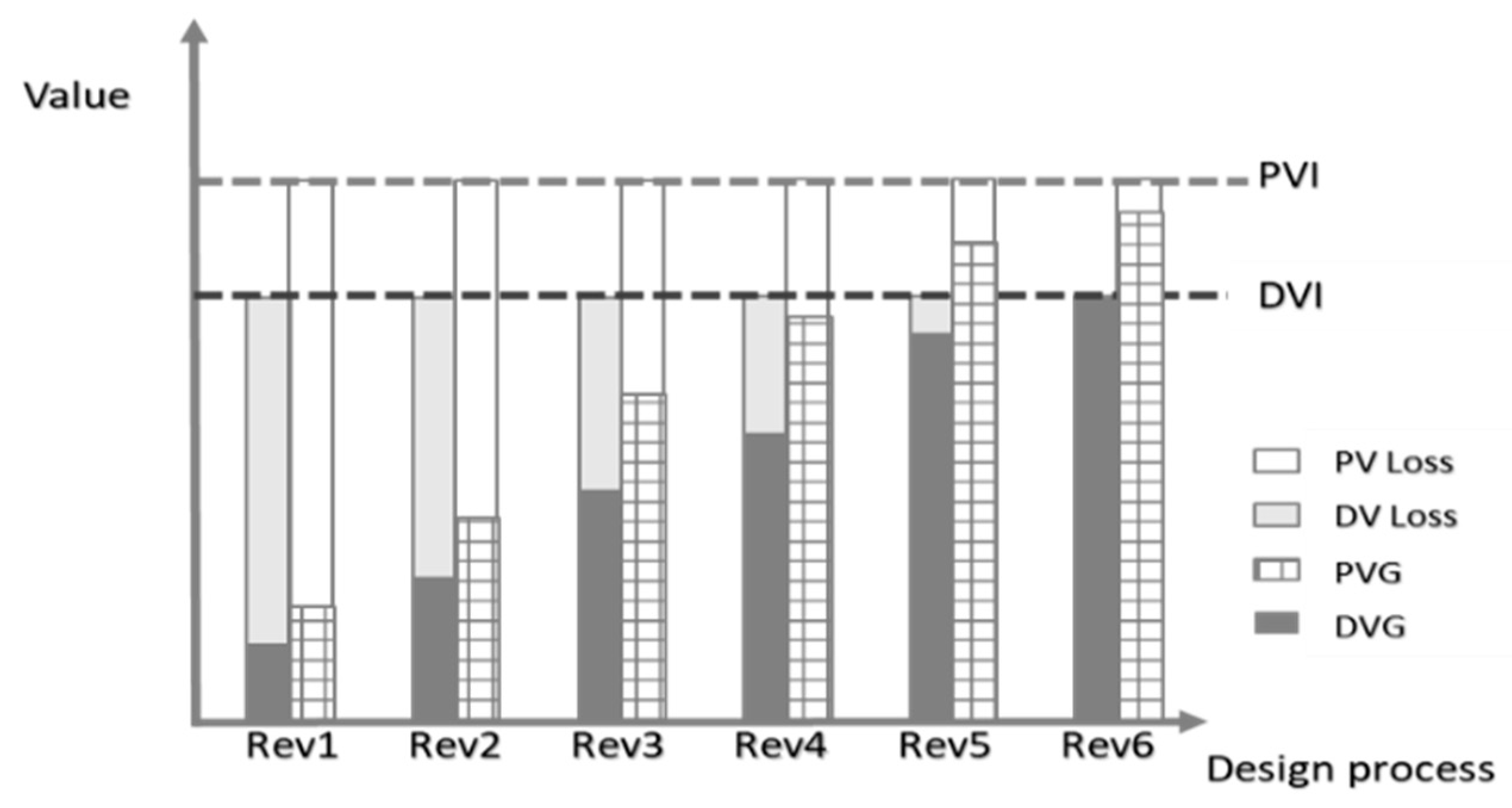

3.4. Value Evolution Over Time

3.4.1. Determination of the Number of Revisions

3.4.2. Comparison with Other Reviews

3.5. Consideration of Multiple Customers

4. Analysis of a Practical Implementation

5. Conclusions

5.1. Summary

5.2. Contributions

5.3. Limitations

5.4. Future Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gunby, M.; Damnjanovic, I.; Anderson, S.; Joyce, J.; Nuccio, J. Identifying, communicating, and responding to project value interests. J. Manag. Eng. 2013, 29, 50–59. [Google Scholar] [CrossRef]

- Ballard, G. Project budgets be based on worth or cost? In Proceedings of the 20th Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; p. 10. [Google Scholar]

- Koskela, L. An exploration towards a production theory and its application to construction. Ph.D. Thesis, Helsinki University of Technolog, Helsinki, Finland, 2000. [Google Scholar]

- The Standish Group. Chaos Report. Project Smart UK. United Kingdom. 2014. Available online: https://www.projectsmart.co.uk/white-papers/chaos-report.pdf (accessed on 8 May 2020).

- Díaz, H.; Alarcón, L.F.; Mourgues, C.; García, S. Multidisciplinary Design Optimization through process integration in the AEC industry: Strategies and challenges. Autom. Constr. 2017, 73, 102–119. [Google Scholar] [CrossRef]

- Bustos Chocomeli, O. Factores Latentes en la Desviación de Presupuestos en Proyectos de Arquitectura. Un Análisis Empírico. Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2015. [Google Scholar] [CrossRef]

- Knotten, V.; Svalestuen, F.; Hansen, G.; Lædre, O. Design management in the building process—A review of current literature. Procedia Econ. Financ. 2015, 21, 120–127. [Google Scholar] [CrossRef]

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Process model for client requirements processing in construction. Bus. Process Manag. J. 2000, 6, 251–279. [Google Scholar] [CrossRef]

- Bonnier, K.; Kalsaas, B.; Ose, A. Waste in design and engineering. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015; pp. 463–472. [Google Scholar]

- Kumar, V.; Whitney, P. Daily Life, not markets: Customer-centered design. J. Bus. Strategy 2007, 28, 46–58. [Google Scholar] [CrossRef][Green Version]

- Arge, K. Understanding and Competence in the Project’s Time Phase. In Project Report Sintef; Sintef: Oslo, Norway, 2008. [Google Scholar]

- Womack, J.; Jones, D. Lean Thinking; Simon and Schuster: New York, NY, USA, 2012; ISBN 978-84-9875-199-4. [Google Scholar]

- Spiten, T.; Haddadi, A.; Støre-Valen, M.; Lohne, J. Enhancing Value for end-users. A Case study of end-user involvement. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 153–162. [Google Scholar]

- Miron, L.; Kaushik, A.; Koskela, L. Target Value Design: The challenge of value generation. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015; pp. 815–825. [Google Scholar]

- Fischer, G.; Lemke, A.; McCall, R.; Morch, A. Making Argumentation Serve Design. Hum. Comput. Interact. 1991, 6, 393–419. [Google Scholar] [CrossRef]

- Bølviken, T.; Rooke, J.; Koskela, L. The Wastes of Production in Construction—A TFV Based Taxonomy. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 23–27 June 2014; pp. 811–822. [Google Scholar]

- Love, P.; Lopez, R.; Edwards, D. Reviewing the past to learn in the future making sense of design errors and failures in construction. Struct. Infrastruct. Eng. 2013, 2479, 675–688. [Google Scholar] [CrossRef]

- Kano, N.; Seraku, N.; Takahashi, F.; Tsuji, S. Attractive quality vs. must be quality. J. Jpn. Soc. Qual. Control 1984. [Google Scholar]

- Tanaka, T. Target costing at Toyota. J. Cost Manag. 1993, 4–11. [Google Scholar]

- Holmström, J.; Ketokivi, M.; Hameri, A.P. Bridging practice and theory: A design science approach. Decis. Sci. 2009, 40, 65–87. [Google Scholar] [CrossRef]

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A design science research methodology for information systems research. J. Manag. Inf. Syst. 2007, 24, 45–77. [Google Scholar] [CrossRef]

- Hevner, A.R. A Three Cycle View of Design Science Research A Three Cycle View of Design Science Research. Scand. J. Inf. Syst. 2007, 19, 87–92. [Google Scholar]

- Huang, J. Application of Kano Model in Requirements Analysis of Y Company’s Consulting Project. Am. J. Ind. Bus. Manag. 2017, 7, 910–918. [Google Scholar] [CrossRef][Green Version]

- Novak, V. Managing Sustainability Value in Design: A Systems Approach in Environmental Design and Planning. Ph.D. Thesis, Virginia Polytechnic Institute, Blacksburg, VA, USA, 2012. [Google Scholar]

- Rachwan, R.; Abotaleb, I.; Elgazouli, M. The Influence of Value Engineering and Sustainability Considerations on the Project Value. Procedia Environ. Sci. 2016, 34, 431–438. [Google Scholar] [CrossRef]

- AFNOR. French Standard NF EN 12973; Association Francaise de Normalisation: Paris, France, 2000; ISBN 2008012425. [Google Scholar]

- Kelly, J.; Male, S.; Graham, D. Value Management of Construction Projects; Blackwell Publishing Company: Hoboken, NJ, USA, 2008; ISBN 978-1-405-17348-3. [Google Scholar]

- Saxon, R. Be Valuable; Report of Value Task Group; Constructing Excellence: London, UK, 2005. [Google Scholar]

- Drevland, F.; Lohne, J.; Klakegg, O.J. Defining an Ill-defined Concept-Nine Tenets on the Nature of Value. Lean Constr. J. 2018, 31–46. [Google Scholar]

- Eskerod, P.; Ang, K. Stakeholder Value Constructs in Megaprojects: A Long-Term Assessment Case Study. Proj. Manag. J. 2017, 48, 60–75. [Google Scholar] [CrossRef]

- Bolar, A.; Tesfamariam, S.; Sadiq, R. Framework for prioritizing infrastructure user expectations using Quality Function Deployment (QFD). Int. J. Sustain. Built Environ. 2017, 6, 16–29. [Google Scholar] [CrossRef]

- Gallarza, M.; Arteaga-Moreno, F.; Servera-Francés, D.; Fayos-Gardó, T. Participar como voluntario en eventos especiales: Comparación entre el valor esperado y percibido. Innovar. J. 2016, 26, 47–60. [Google Scholar] [CrossRef]

- Kowaltowski, D.; Granja, A. The concept of desired value as a stimulus for change in social housing in Brazil. Habitat Int. 2011, 35, 435–446. [Google Scholar] [CrossRef]

- Tucker, J.; Pearce, A.; Bruce, R.; McCoy, A.; Mills, T. The perceived value of green professional credentials to credential holders in the US building design and construction community. Constr. Manag. Econ. 2012, 30, 963–979. [Google Scholar] [CrossRef]

- Lee, B.; Paredis, C. A conceptual framework for value-driven design and systems engineering. Procedia CIRP 2014, 21, 10–17. [Google Scholar] [CrossRef]

- Camisón, C.; Cruz, S.; González, T. Gestión de la Calidad: Conceptos, Enfoques, Modelos y Sistemas; Pearson Educación: Madrid, Spain, 2006; ISBN 9788420542621. [Google Scholar]

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Establishing and processing client requirements—A key aspect of concurrent engineering in construction. Eng. Constr. Archit. Manag. 2000, 7, 15–28. [Google Scholar] [CrossRef]

- Drevland, F.; Tillmann, P. Value for Whom? In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 16–22 July 2018; pp. 261–270. [Google Scholar] [CrossRef]

- Leinonen, J.; Huovila, P. The house of the rising value. In Proceedings of the 8th Annual Conference of the International Group for Lean Construction, Brigthon, UK, 17–19 August 2000. [Google Scholar]

- Zhang, Y.; Tzortzopoulos, P.; Kagioglou, M. Evidence-Based Design in Healthcare: A Lean Perspective with an emphasis on value generation. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 53–62. [Google Scholar]

- Rybkowski, Z.; Shepley, M.; Ballard, G. Target value design: Applications to newborn intensive care units. Heal. Environ. Res. Des. J. 2012, 5, 5–23. [Google Scholar] [CrossRef]

- Yin, Y.; Qin, S.; Holland, R. Development of a design performance measurement matrix for improving collaborative design during a design process. Int. J. Product. Perform. Manag. 2011, 60, 152–184. [Google Scholar] [CrossRef]

- Volkova, T.; Jākobsone, I. Design thinking as a business tool to ensure continuous value generation. Intellect. Econ. 2016. [Google Scholar] [CrossRef]

- Westcott, M.; Sato, S.; Mrazek, D.; Wallace, R.; Vanka, S.; Bilson, C.; Hardin, D. The DMI Design Value Scorecard: A New Design Measurement and Management Model. Des. Manag. Rev. 2014, 24, 10–16. [Google Scholar] [CrossRef]

- Heikkilä, V.; Paasivaara, M.; Lasssenius, C.; Damian, D.; Engblom, C. Managing the requirements flow from strategy to release in large-scale agile development: A case study at Ericsson. Empir. Softw. Eng. 2017, 22, 2892–2936. [Google Scholar] [CrossRef]

- Porter, M. Competitive Advantage; The Free Press: New York, NY, USA, 1985. [Google Scholar]

- Farías, P.; Fistrovic, B. Las preferencias del consumidor usando el método de Máximas Diferencias. Rev. Adm. Empres. 2016, 56, 138–151. [Google Scholar] [CrossRef][Green Version]

- Franco, J.; Picchi, F. Lean design in building projects: Guiding principles and exploratory collection of good practices. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 113–122. [Google Scholar]

- Amini, P.; Falk, B.; Schmitt, R. A Framework for Value-optimized Design of Product Features. Procedia CIRP 2016, 57, 386–391. [Google Scholar] [CrossRef]

- Menezes, A.; Cripps, A.; Bouchlaghem, D.; Buswell, R. Predicted vs. actual energy performance of non-domestic buildings: Using post-occupancy evaluation data to reduce the performance gap. Appl. Energy 2012, 97, 355–364. [Google Scholar] [CrossRef]

- Zhang, Z.; Hamledari, H.; Billington, S.; Fischer, M. 4D beyond construction: Spatio-temporal and life-cyclic modeling and visualization of infrastructure data. J. Inf. Technol. Constr. 2018, 23, 285–304. [Google Scholar]

- Zimina, D.; Ballard, G.; Pasquire, C. Target value design: Using collaboration and a lean approach to reduce construction cost. Constr. Manag. Econ. 2014, 30, 383–398. [Google Scholar] [CrossRef]

- Borgianni, Y. Verifying dynamic kano’s model to support new product/service development. J. Ind. Eng. Manag. 2018, 11, 569–587. [Google Scholar] [CrossRef]

- Kron, C.; Von der Haar, R. Target costing for the development of office buildings. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 43–52. [Google Scholar]

- Pandolfo, A.; Rojas, J.; Kurek, J.; Pandolfo, L.; Lublo, R.; Guimarães, J.; Reinehr, R. Aplicación del modelo de evaluación de proyectos habitacionales para la medición de la satisfacción de las necesidades del usuario. Rev. Ing. Constr. 2008, 23, 42–51. [Google Scholar] [CrossRef]

- García, S.; Solís, J. 3Cv+2: Quality model for dwelling construction. Rev. Ing. Constr. 2008, 23, 102–111. [Google Scholar]

- Haddadi, A.; Johansen, A.; Andersen, B. A Conceptual Framework to Enhance Value Creation in Construction Projects. Procedia Comput. Sci. 2016, 100, 565–573. [Google Scholar] [CrossRef]

- Salvatierra, J.; Pasquire, C.; Miron, L. Exploring Value Concept through the IGLC Community: Nineteen Years of Experience. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Lin, G.; Shen, Q. Measuring the performance of value management studies in construction: Critical review. J. Manag. Eng. 2007, 23, 2–9. [Google Scholar] [CrossRef]

- Berger, C.; Blauth, R.; Boger, D.; Buss, D.; Dambolena, I.; Graham, A.; Graves, S.; Horwitz, P.; Langone, L.; Mayersohn, J.; et al. Kano’s Methods for Understanding Customer-defined Quality. Cent. Qual. Manag. J. 1993, Fall, 37. [Google Scholar]

- Witell, L.; Lofgren, M.; Dahlgaard, J. Theory of attractive quality and the Kano methodology—The past, the present, and the future. Total Qual. Manag. Bus. Excell. 2013, 24, 1241–1252. [Google Scholar] [CrossRef]

- Arroyave, C.; Maya, A.; Orozco, C. Aplicación de la metodología QFD en el proceso de ingeniería de requisitos. Bachelor’s Thesis, Universidad EAFIT, Medellín, Colombia, 2007. [Google Scholar]

- Díaz, H. Optimización Multidisciplinaria de Diseño Mediante el uso de Herramientas PIDO y BIM como Soporte a la Metodología Target Value Design en Proyectos de Vivienda. Ph.D. Thesis, Pontificia Universidad Católica de Chile, Santiago, Chile, 2017. [Google Scholar]

- Ballard, G.; Rybkowski, Z. Overcoming the hurdle of first cost: Action Research in target costing. In Proceedings of the Construction Research Congress, Seattle, WA, USA, 5–7 April 2009; pp. 1038–1047. [Google Scholar]

- Rischmoller, L.; Alarcón, L.; Koskela, L. Improving Value Generation in the Design Process of Industrial Projects Using CAVT. J. Manag. Eng. 2006. [Google Scholar] [CrossRef]

- Tauriainen, M.; Marttinen, P.; Dave, B.; Koskela, L. The Effects of BIM and Lean Construction on Design Management Practices. Procedia Eng. 2016, 164, 567–574. [Google Scholar] [CrossRef]

- Song, J.; Migliaccio, G.C.; Wang, G.; Lu, H. Exploring the Influence of System Quality, Information Quality, and External Service on BIM User Satisfaction. J. Manag. Eng. 2017, 33, 1–10. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M. Virtual Design and Construction: Themes, Case Studies and Implementation Suggestions; CIFE Working Paper 097; Versión 14; Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- Matzler, K.; Hinterhuber, H.; Franz, B.; Sauerwein, E. How to delight your customers. J. Prod. Brand Manag. 1996, 5, 6–18. [Google Scholar] [CrossRef]

- Giménez, Z.; Mourgues, C.; Alarcón, L.; Mesa, H. Proposal of a Model for Measuring Value in the Design Process. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 1–7 July 2019; pp. 49–62. [Google Scholar] [CrossRef]

- Hernández, R.; Fernández, C.; Baptista, P. Metodología de Investigación; Mc. Graw Hill Education: Mexico City, Mexico, 2014. [Google Scholar]

| Methods | Influential Factors Within the Value Generation Process | Relationship with Quality, Constructability, Productivity | Reference | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimization of the Life Cycle Cost | Pursuit of Satisfaction of the Customer’s Needs | Pursuit of Value Maximization | Requirements Capture | Requirements Flow-Down | Pursuit of Integral Solutions for the Fulfillment of Requirements | Assurance of the Capacity and Performance of the Production System | Verification That the Requirements Are Met | Value Measurement through Metrics | Identification of Value Losses | |||

| Post-occupancy evaluation (POE) | X | X | X | X | [27,50] | |||||||

| Value Management/ Engineering | X | X | X | [25,59] | ||||||||

| Kano Model | X | X | X | [23,60,61] | ||||||||

| Quality Function Deployment (QFD) | X | X | X | X | X | X | [31,62,63] | |||||

| Target Costing | X | X | X | X | X | [54,64] | ||||||

| Virtual Design and Construction (VDC) | X | X | X | X | X | X | X | X | [5,65,66,67] | |||

| Target Value Design (TVD) | X | X | X | X | X | X | X | [41,52] | ||||

| Assessment of Housing Projects | X | X | X | X | X | [55] | ||||||

| 3Cv + 2 | X | X | X | X | X | [56] | ||||||

| Framework for Enhancing Value Creation in Construction Projects | X | X | [57] | |||||||||

| Owner Value Interest Model | X | X | X | X | [1] | |||||||

| Stated Preferences | X | X | X | [33] | ||||||||

| Design Thinking | X | X | X | X | X | [43] | ||||||

| Profession | Occupation | Experience |

|---|---|---|

| Ph.D. Civil Engineer | Senior professor at a public university in Venezuela | 33 years of experience in construction management and quality |

| Ph.D. Civil Engineer | Senior professor at a public university in Spain | 28 years of experience in construction management |

| Ph.D. Civil Engineer | Project Manager. Bogotá, Colombia | 10 years of experience in construction |

| Ph.D. Civil Engineer | Corporate quality leader. USA | 13 years of experience in lean design and construction |

| MSc. Architect | Leader in Lean design and integrated project delivery (IPD). USA | 25 years of experience in lean design |

| Ph.D. Civil Engineer | Associate professor at a public university in Brazil | 30 years of experience in construction management and economics |

| Civil Engineer | Talent development manager/LCI instructor. Perú | 14 years of experience in lean design and construction |

| MSc. Civil Engineer | Lean consultant. USA | 34 years of experience in design and construction |

| Functional | Dysfunctional | ||||

|---|---|---|---|---|---|

| Like | Must-be | Neutral | Live-with | Dislike | |

| Like | Q | A | A | A | O |

| Must-be | R | I | I | I | M |

| Neutral | R | I | I | I | M |

| Live-with | R | I | I | I | M |

| Dislike | R | R | R | R | Q |

| Req | Must be | One-d | Reverse | Attract. | Indiffer. | Quest | Total | % 1st Response | Class. | Berger Original | Modified CS | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | O | R | A | I | Q | T | Kano | SI | DI | CS | SI-R | DI-R | CS-R | ||

| R1 | 7 | 9 | 1 | 19 | 5 | 0 | 41 | 46% | A | 0.70 | 0.40 | A | 0.66 | 0.41 | A |

| R2 | 24 | 11 | 0 | 4 | 1 | 1 | 41 | 59% | M | 0.38 | 0.88 | M | 0.38 | 0.88 | M |

| R3 | 17 | 20 | 0 | 2 | 2 | 0 | 41 | 49% | O-M? | 0.54 | 0.90 | O | 0.54 | 0.90 | O |

| R4 | 3 | 8 | 2 | 6 | 21 | 1 | 41 | 51% | I | 0.37 | 0.29 | I | 0.30 | 0.33 | I |

| R5 | 19 | 17 | 0 | 4 | 1 | 0 | 41 | 46% | M-O? | 0.51 | 0.88 | O | 0.51 | 0.88 | O |

| R6 | 27 | 3 | 1 | 5 | 4 | 1 | 41 | 66% | M | 0.21 | 0.77 | M | 0.18 | 0.78 | M |

| R7 | 13 | 9 | 0 | 14 | 3 | 2 | 41 | 34% | A-M? | 0.59 | 0.56 | O | 0.59 | 0.56 | O |

| R8 | 29 | 4 | 0 | 7 | 1 | 0 | 41 | 71% | M | 0.27 | 0.80 | M | 0.27 | 0.80 | M |

| R9 | 0 | 0 | 19 | 0 | 22 | 0 | 41 | 54% | R-I? | 0.00 | 0.00 | I | −0.46 | 0.46 | I |

| R10 | 0 | 0 | 31 | 0 | 10 | 0 | 41 | 76% | R | 0.00 | 0.00 | I | −0.76 | 0.76 | R |

| Value Losses | Percentage of Value Losses | Percentage of Value Fulfillment | |

|---|---|---|---|

| Desired Value | DVL = DVI-DVG | ||

| Potential Value | PVL = PVI-PVG | ||

| DVI: Desired value index PVI: Potential value index DVG: Desired value generated PVG: Potential value generated | DVL: Desired value loss PVL: Potential value loss | DVLP: Desired value loss percentage PVLP: Potential value loss percentage DVFP: Desired value fulfillment percentage PVFP: Potential value fulfillment percentage | |

| Attributes List | |

|---|---|

| 1 | High percentage of repetitive elements |

| 2 | Low cost variability |

| 3 | Good cost/quality ratio |

| 4 | Good value for money/square meters |

| 5 | Good location |

| 6 | Sellable/competitive design |

| 7 | Aesthetic |

| 8 | Easy to build |

| 9 | Functional |

| 10 | Differentiating image |

| 11 | Innovative |

| 12 | Materials available on the market |

| 13 | Durable materials |

| 14 | Easy to install materials |

| 15 | Product stable to earthquakes and other events |

| 16 | Profitable product |

| 17 | Compliant with regulations |

| 18 | That meets the customer’s requirements |

| 19 | To maintain its value over time |

| 20 | To improve the quality of life of the community |

| 21 | To improve the customer’s quality of life |

| 22 | No reclaims |

| 23 | Presenting cutting-edge technology |

| 24 | Sustainable/energy efficient |

| Customer | Total | |||

|---|---|---|---|---|

| Owner | Designers | Builders | ||

| w | 42% | 28% | 31% | 100% |

| DVI | 0.79 | 0.32 | 0.29 | 0.51 |

| PVI | 1.00 | 0.69 | 0.42 | 0.73 |

| Project 1 | ||||

| DVG | 0.10 | −0.11 | −0.11 | −0.02 |

| PVG | 0.22 | 0.14 | −0.04 | 0.12 |

| DVFP | 13% | −34% | −38% | −4% |

| PVFP | 22% | 20% | −10% | 16% |

| DVL | 0.69 | 0.42 | 0.40 | 0.53 |

| PVL | 0.78 | 0.55 | 0.46 | 0.62 |

| DVLP | 87% | 134% | 138% | 104% |

| PVLP | 78% | 80% | 110% | 84% |

| Project 2 | ||||

| DVG | 0.39 | 0.07 | 0.07 | 0.20 |

| PVG | 0.54 | 0.34 | 0.16 | 0.37 |

| DVFP | 49% | 23% | 24% | 40% |

| PVFP | 54% | 49% | 39% | 50% |

| DVL | 0.40 | 0.24 | 0.22 | 0.30 |

| PVL | 0.46 | 0.35 | 0.26 | 0.37 |

| DVLP | 51% | 77% | 76% | 60% |

| PVLP | 46% | 51% | 61% | 50% |

| Process—Project 2 | ||||

|---|---|---|---|---|

| Designer | ||||

| % Present | V. Pre | V. Abs | Score | |

| M | 69% | 0 | −1 | −2.80 |

| O | 69% | 1 | −1 | 2.27 |

| A | 80% | 1 | 0 | 3.99 |

| I | 69% | 0 | 0 | 0.00 |

| R | −1 | 1 | 0.00 | |

| DVL | 0.27 | DVG | −0.02 | |

| PVL | 0.31 | PVG | 0.14 | |

| DVLP | 109% | DVFP | −9% | |

| PVLP | 69% | PVFP | 31% | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giménez, Z.; Mourgues, C.; Alarcón, L.F.; Mesa, H.; Pellicer, E. Value Analysis Model to Support the Building Design Process. Sustainability 2020, 12, 4224. https://doi.org/10.3390/su12104224

Giménez Z, Mourgues C, Alarcón LF, Mesa H, Pellicer E. Value Analysis Model to Support the Building Design Process. Sustainability. 2020; 12(10):4224. https://doi.org/10.3390/su12104224

Chicago/Turabian StyleGiménez, Zulay, Claudio Mourgues, Luis F. Alarcón, Harrison Mesa, and Eugenio Pellicer. 2020. "Value Analysis Model to Support the Building Design Process" Sustainability 12, no. 10: 4224. https://doi.org/10.3390/su12104224

APA StyleGiménez, Z., Mourgues, C., Alarcón, L. F., Mesa, H., & Pellicer, E. (2020). Value Analysis Model to Support the Building Design Process. Sustainability, 12(10), 4224. https://doi.org/10.3390/su12104224