Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise

Abstract

1. Introduction

2. Materials and Methods

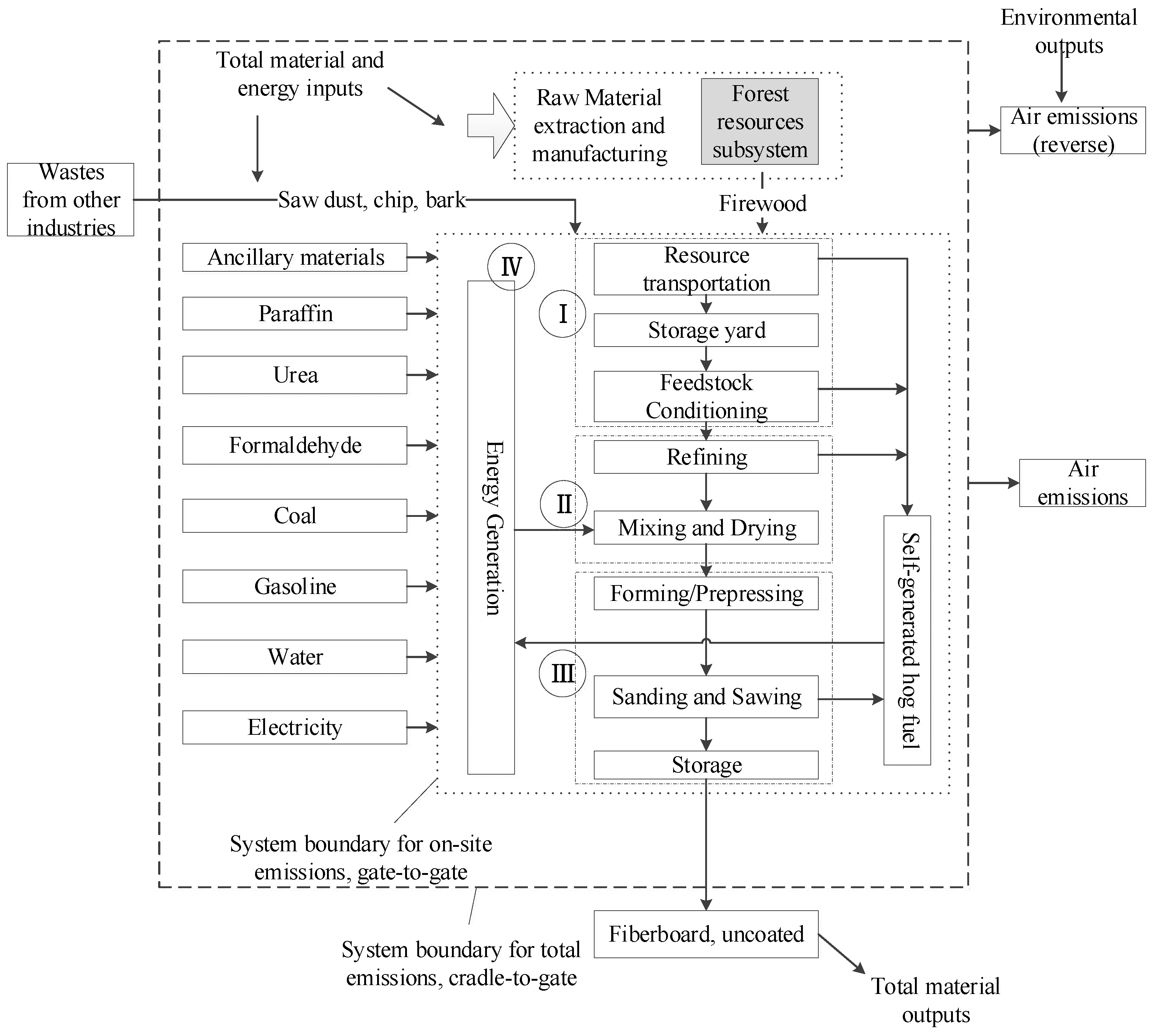

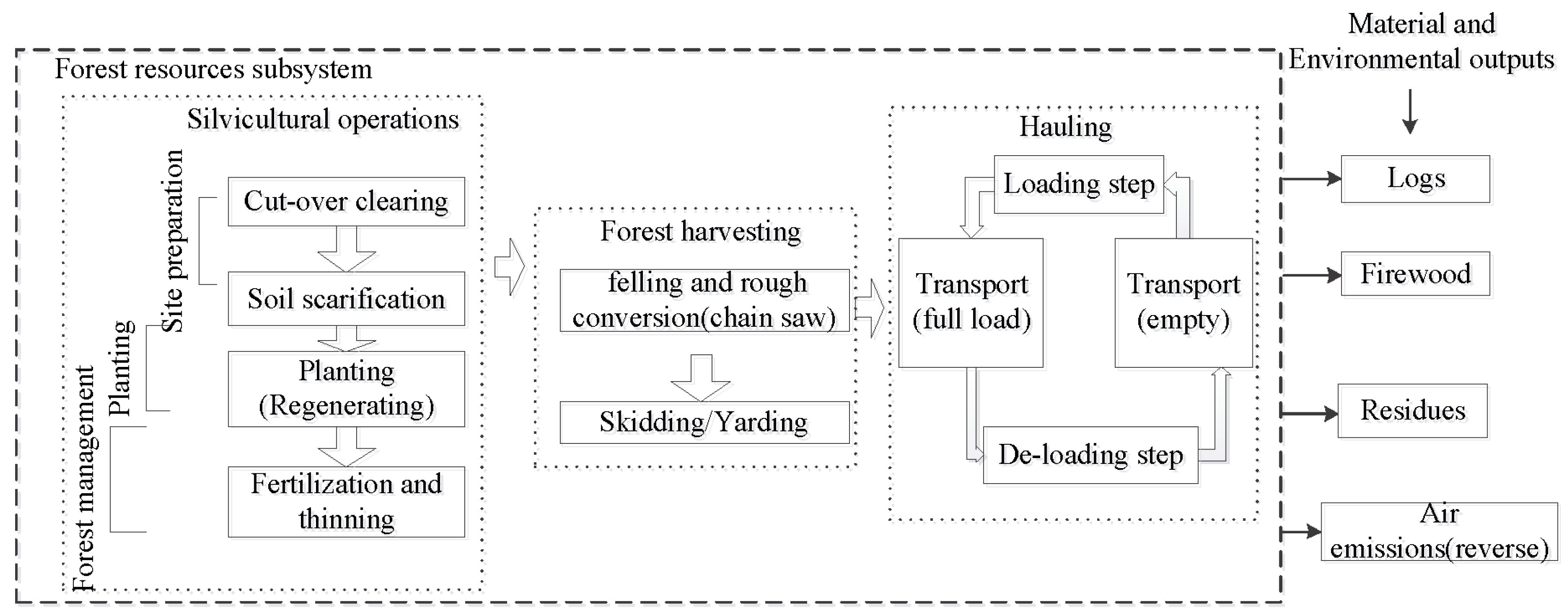

2.1. Case Study System Boundaries

2.2. Goal and Scope

2.3. Functional Unit and Allocation

2.4. System Boundaries

2.5. Biogenic Carbon

2.5.1. Calculation Principle

2.5.2. Models and Approach

3. Results and Discussion

3.1. Inventory of the Complex Forestry Enterprise

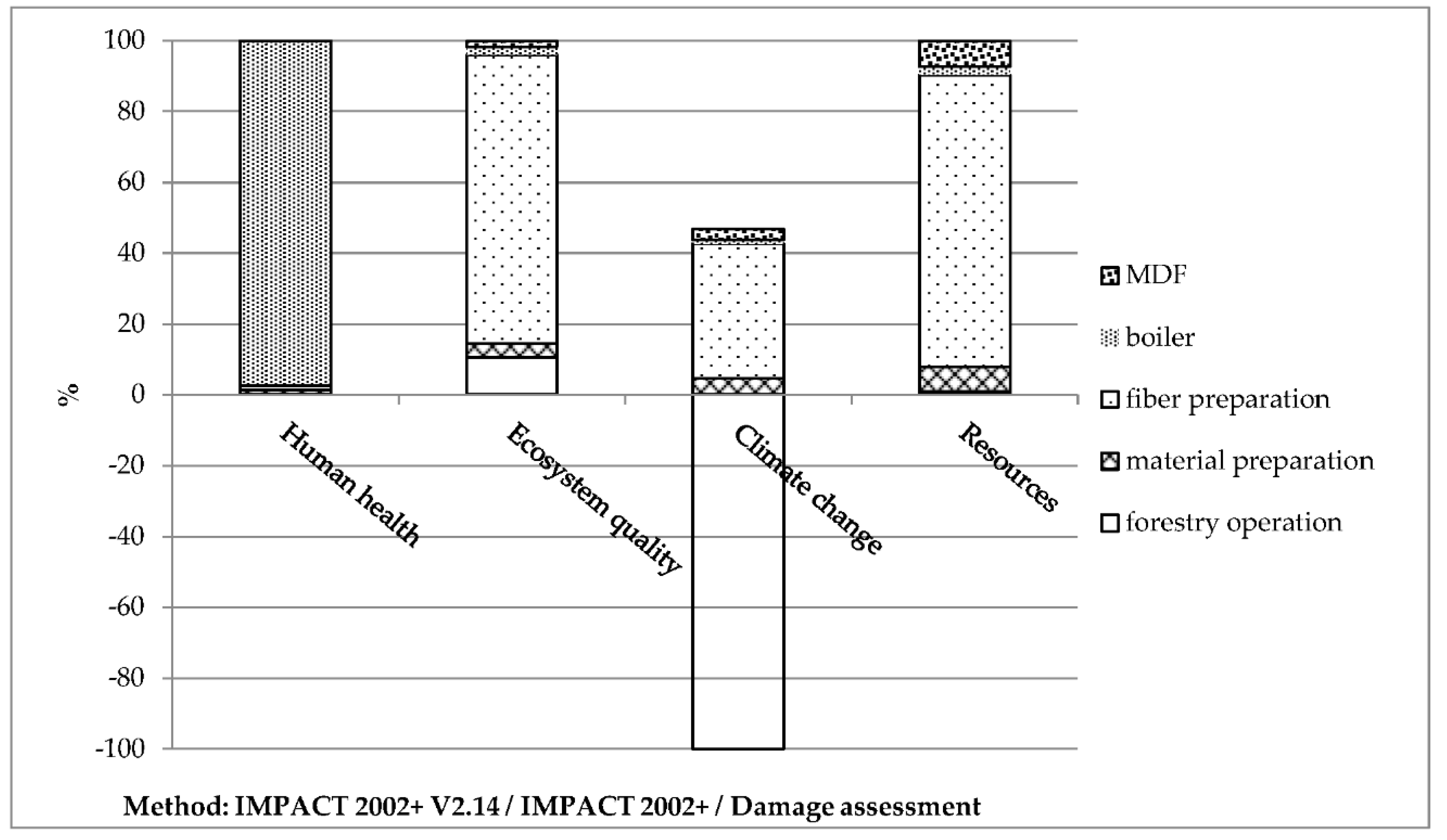

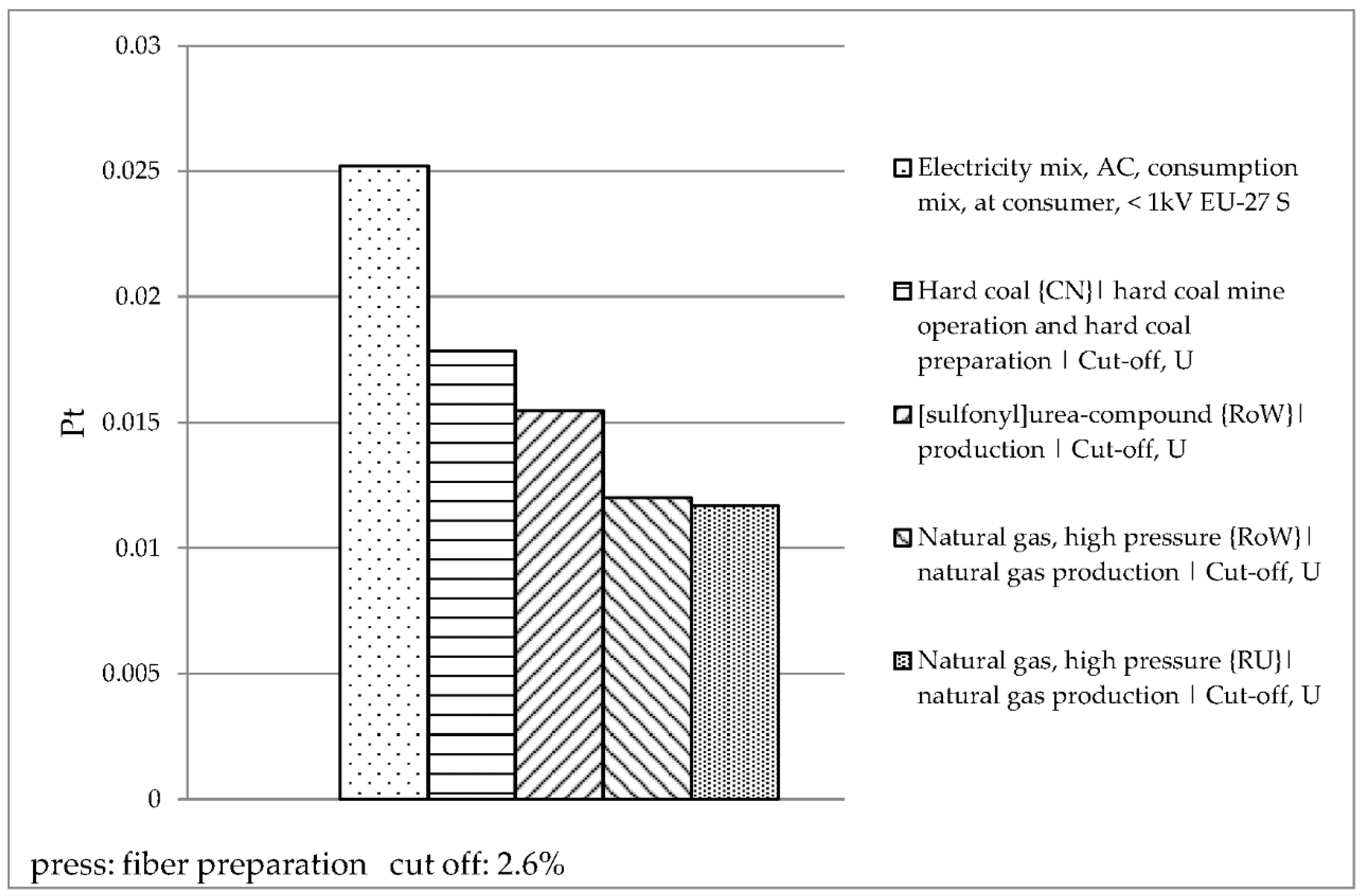

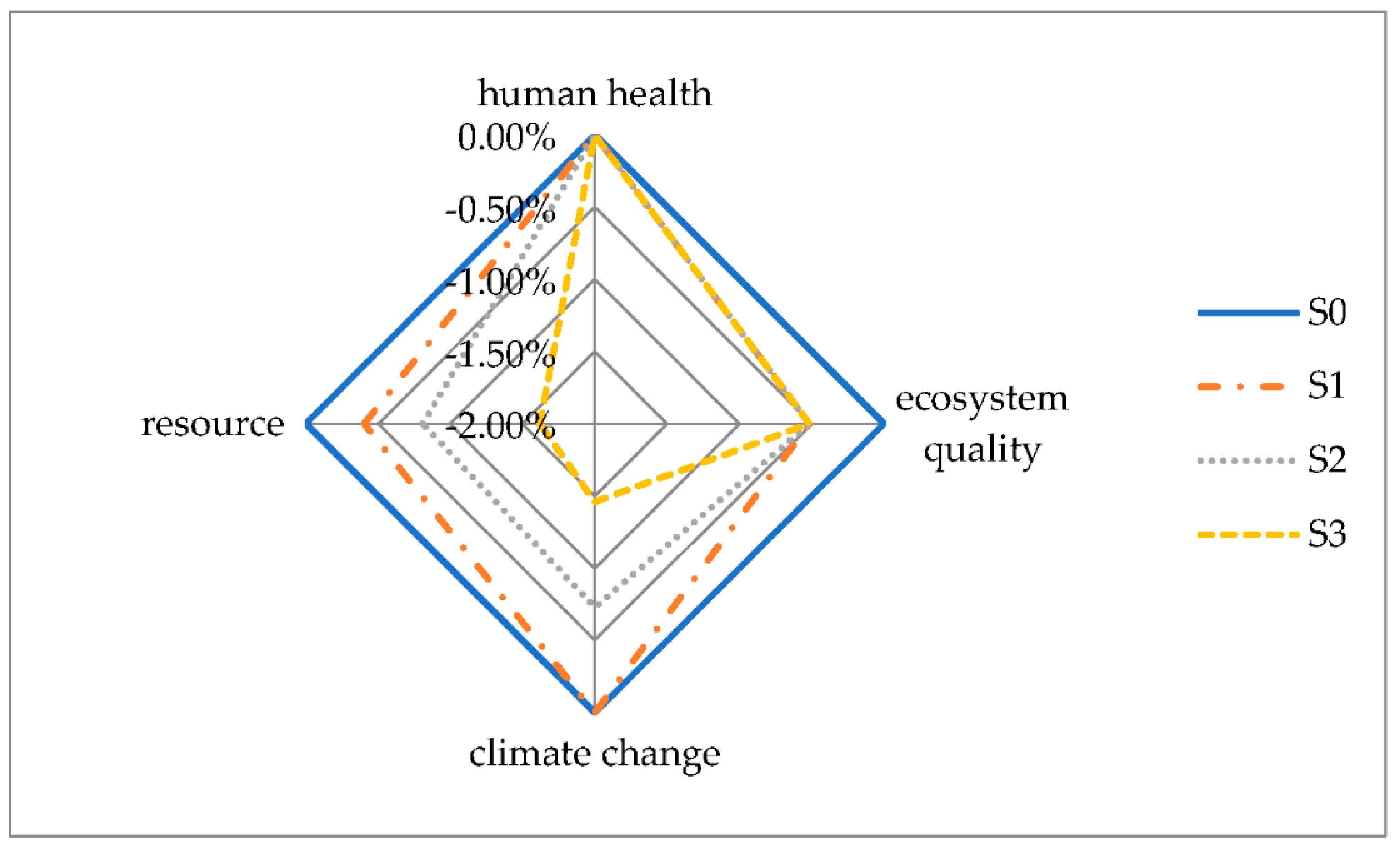

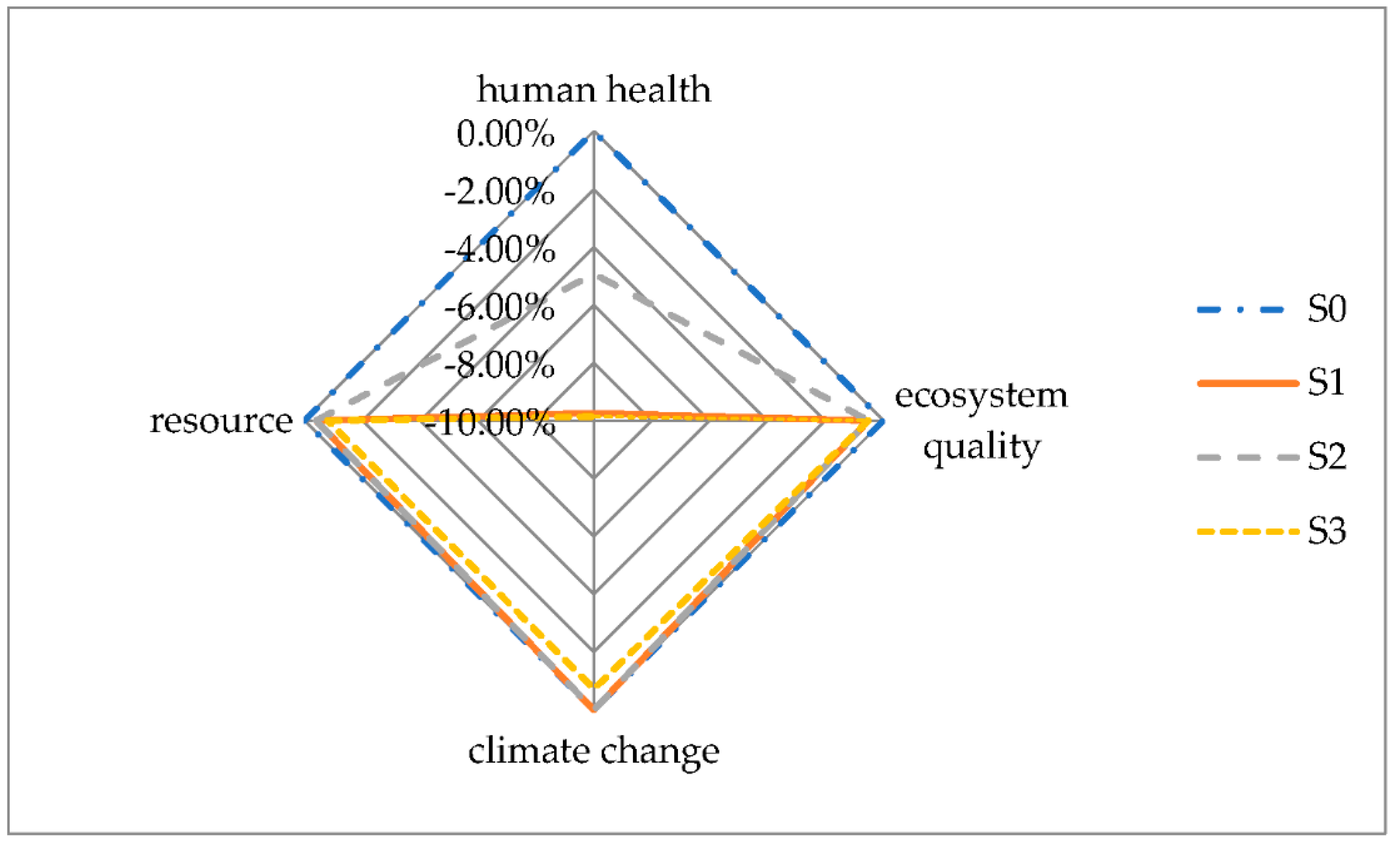

3.2. Life Cycle Impact Assessment of the Complex Forestry Enterprise

3.3. Proposals for Environmental Improvements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bocken, N. Sustainable Business: The New Business as Usual? J. Ind. Ecol. 2014, 18, 3–7. [Google Scholar] [CrossRef]

- Xie, H.; Zhang, Z. Research on collaborative motivation of forestry green supply chain. For. Econ. 2018, 12, 42–46. [Google Scholar]

- Ke, S.; Zhao, T. State of forest health, forest product production and ecological services in the united states. J. World For. Res. 2011, 24, 59–64. [Google Scholar]

- Food and Agriculture Organization. Classification and Definitions of Forest Products; Food and Agriculture Organization: Rome, Italy, 1982. [Google Scholar]

- Natural Capital Coalition. Natural Capital Protocol Forest Products Sector Guide. 2018. Available online: http://www.naturalcapitalcoalition.org (accessed on 28 February 2020).

- Xie, J.; Shen, W.; Cao, F. Spatial dynamic evolution mechanism of compound forest product value chain: An analysis framework based on system theory. Sci. Silvae Sin. 2016, 52, 106–117. [Google Scholar]

- Sahoo, K.; Bergman, R.; Alanya, S.; Gu, H.; Liang, S. Life cycle assessment of forest-based products: A review. Sustainability 2019, 11, 4722. [Google Scholar] [CrossRef]

- Song, Y.; Peng, H. Strategies of forestry carbon sink under forest insurance and subsidies. Sustainability 2019, 11, 4607. [Google Scholar] [CrossRef]

- Khoo, H.H.; Eufrasio-Espinosa, R.M.; Koh, L.S.C.; Sharratt, P.N.; Isoni, V. Sustainability assessment of biorefinery production chains: A combined LCA-supply chain approach. Clean. Prod. 2019, 235, 1116–1137. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Ma, Q.; Fan, S.; Jin, H.; Liu, H.; Liu, H. A social sustainability assessment model for manufacturing company based on S-LCA. Int. J. Sustain. Dev. Plan. 2019, 14, 172–182. [Google Scholar] [CrossRef]

- Bowers, T.; Puettmann, M.E.; Ganguly, I.; Eastin, I. Cradle-to-gate life-cycle impact analysis of glued-laminated (Glulam) timber: Environmental impacts from glulam produced in the US pacific northwest and southeast. J. For. Prod. 2017, 67, 368–380. [Google Scholar] [CrossRef]

- Handler, R.M.; Shonnard, D.R.; Lautala, P.T.; Abbas, D.; Srivastava, A. Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. J. Clean. Prod. 2014, 76, 64–73. [Google Scholar] [CrossRef]

- Abbas, D.; Handler, R.M. life-cycle assessment of forest harvesting and transportation operations in Tennessee. J. Clean. Prod. 2018, 176, 512–520. [Google Scholar] [CrossRef]

- Milota, M.; Puettmann, M.E. Life-cycle assessment for the cradle-to-gate production of softwood lumber in the pacific northwest and southeast regions. J. For. Prod. 2017, 67, 331–342. [Google Scholar] [CrossRef]

- Bergman, R.D.; Oneil, E.; Eastin, I.L.; Han, H.S. Life cycle impacts of manufacturing redwood decking in northern California. J. Wood Fiber Sci. 2014, 46, 322–339. [Google Scholar]

- Kouchaki, P.H.; Sharifi, M.; Mousazadeh, H.; Zarea-Hosseinabadi, H. Lifecycle assessment of manufacturing process in Islamic. J. Clean. Prod. 2016, 112, 351–358. [Google Scholar] [CrossRef]

- Jia, L.; Chu, J.; Ma, L.; Kumar, A. Life cycle assessment of plywood manufacturing process in China. Int. J. Environ. Res. Public Health 2019, 16, 2037. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Guan, X.; Guo, M.; Wang, J. Environmental load of solid wood floor production from larch grown at different planting densities based on a life cycle assessment. J. For. Res. 2018, 29, 1443–1448. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies. J. Renew. Sustain. Energy 2016, 53, 1486–1489. [Google Scholar] [CrossRef]

- D’Amato, D.; Gaio, M.; Semenzin, E. A review of LCA assessments of forest-based bioeconomy products and processes under an ecosystem services perspective. J. Sci. Total. Environ 2019, 12, 359–367. [Google Scholar] [CrossRef]

- Proto, A.R.; Bacenetti, J.; Macrì, G.; Zimbalatti, G. Roundwood and bioenergy production from forestry: Environmental impact assessment considering different logging systems. J. Clean. Prod. 2017, 165, 1485–1498. [Google Scholar] [CrossRef]

- Schweier, J.; Magagnotti, N.; Labelle, E.R.; Athanassiadis, D. Sustainability Impact Assessment of Forest Operations: A Review. Curr. For. Rep. 2019. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; Sage Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- JRC-IEA. International Reference Life Cycle Data System (ILCD) Handbook-General Guide for Life Cycle Assessment-Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, March 2010. [Google Scholar]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and consequential LCA in the ILCD handbook. Int. J. Life Cycle Assess. 2015, 21, 293–296. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björklund, A.; Ekman, A.; Potter, K.H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Janssen, M.; Strid, I. Review of methodological choices in LCA of biorefinery systems-key issues and recommendations. Biofuels Bioprod. Biorefin. 2015, 9, 606–619. [Google Scholar] [CrossRef]

- Zamagni, A.; Guinée, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and shadows in consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918. [Google Scholar] [CrossRef]

- Curran, M.A.; Mann, M.; Norris, G. The international workshop on electricity data for life cycle inventories. Clean. Prod. 2005, 13, 853–862. [Google Scholar] [CrossRef]

- Kajaste, R. Chemicals from biomass-managing greenhouse gas emissions in biorefinery production chains-a review. J. Clean. Prod. 2014, 75, 1–10. [Google Scholar] [CrossRef]

- Saraiva, A.B. System boundary setting in life cycle assessment of biorefineries: A review. Int. J. Environ. Sci. Technol. 2017, 14, 435–452. [Google Scholar]

- Maier, J.M.; Sowlati, T.; Salazar, J. Life cycle assessment of forest-based biomass for bioenergy: A case study in British Columbia, Canada. Resour. Conserv. Recycl. 2019, 146, 598–609. [Google Scholar] [CrossRef]

- Piekarski, C.M.; De Francisco, A.C.; Da Luz, L.M.; Kovaleski, J.; Silva, D.A.L. Life cycle assessment of medium-density fiberboard (MDF) manufacturing process in Brazil. Sci. Total. Environ. 2017, 575, 103–111. [Google Scholar] [CrossRef]

- Bergman, R.D.; Reed, D.L.; Taylor, A.M.; Harper, D.P.; Hodges, D.G. Cradle-to-gate life cycle assessment of switchgrass fuel pellets manufactured in the Southeastern United States. Wood Fiber Sci. J. Soc. Wood Sci. Technol. 2015, 47, 147–159. [Google Scholar]

- ISO14044: Environmental Management–Lifecycle Assessment–Requirements and guidelines; Institution British Standards: London, UK, 2006.

- Song, A.; Yang, S.; Sun, M. Guidelines for Calculating Greenhouse Gas Emissions Caused by Energy Consumption (Version 2.0); World Resources Institute: Beijing, China, 2012; Available online: http://www.ghgprotocol.org/calculation-tools/all-tools (accessed on 19 May 2020).

- Jungmeier, G.; McDarby, F.; Evald, A.; Hohenthal, C.; Petersen, A.-K.; Schwaiger, H.-P.; Zimmer, B. Energy aspects in LCA of forest products. Int. J. Life Cycle Assess. 2003, 8, 99–105. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Yang, H. Comparison of product carbon footprint protocols: Case study on medium-density fiberboard in china. Int. J. Environ. Res. Public Heal. 2018, 15, 2060. [Google Scholar] [CrossRef] [PubMed]

- Calvo Buendia, E.; Tanabe, K.; Kranjc, A.; Baasansuren, J.; Fukuda, M.; Ngarize, S.; Osako, A.; Pyrozhenko, Y.; Shermanau, P.; Federici, S. Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Volume 4, Agriculture, Forestry and Other Land Use. IPCC, 2019. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Cover.pdf (accessed on 19 May 2020).

- Chen, Y.; Wen, Z.; Xie, Y. Fair value measurement on forest carbon sink from the view of forest resources cultivation enterprises. Ecol. Econ. 2018, 34, 45–49. [Google Scholar]

- Zhang, Q.; Qin, H.; Huang, Y. Review of forest carbon measurement based on choice of Heilongjiang province. Resour. Dev. Market 2013, 29, 982–984. [Google Scholar]

- Li, Q.; Xu, Y. Accounting of forest biological assets based on forestry carbon sink project. Financ. Account. Mon. 2011, 11, 63–65. [Google Scholar]

- Xu, S.; Li, L.; Zhao, Y.; Xu, Z. Research progress of forest carbon sequestration in China. Guangdong Agric. Sci. 2014, 41, 218–222. [Google Scholar]

- Zhang, C.; Wang, L.; Song, Q.; Chen, X.; Gao, H.; Wang, X. Biomass carbon stocks and dynamics of forests in Heilongjiang Province from 1973 to 2013. China Environ. Sci. 2018, 12, 4678–4686. [Google Scholar]

- Fang, J.; Guo, Z.; Piao, S.L.; Chen, A. Terrestrial vegetation carbon sinks in China, 1981–2000. Sci. China Ser. D Earth Sci. 2007, 50, 1341–1350. [Google Scholar] [CrossRef]

- State Forestry Administration. Guidelines for Carbon Sink Measurement and Monitoring of Afforestation Projects [EB/OL]. Available online: http://www.forestry.gov.cn/ (accessed on 8 January 2011).

- Fu, Y.; Sun, Y. A study of the determination of organic carbon of vegetation. World For. Res. 2013, 26, 24–30. [Google Scholar]

- State Forestry Administration. LY/T2253-2014, Guidelines for Carbon Sink Measurement and Monitoring of Afforestation Projects; China Standards Press: Beijing, China, 2014.

- Oneil, E.; Maureen, E.P. A Life-cycle Assessment of Forest Resources of the Pacific Northwest, USA. For. Prod. J. 2017, 67, 316–330. [Google Scholar] [CrossRef]

- Humbert, S.; Schryver, A.D.; Bengoa, X.; Margni, M.; Jolliet, O. IMPACT 2002+: User Guide; Quantis: Lausanne, Switzerland, 2014. [Google Scholar]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Chene, S.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Eco-efficiency analysis of Spanish WWTPs using the LCA plus DEA method. Water Res. 2014, 68, 651–666. [Google Scholar] [CrossRef]

- Li, C. Effect of compound microbial fertilizer on early growth of Chinese fir. Mod. Agric. Sci. Technol. 2015, 17, 189–199. [Google Scholar]

- Xiang, Q. Effects of biofilmed bio-fertilizer on gas exchange and biomass accumulation of Masson Pine Seedlings. For. Sci. Technol. 2017, 46, 6–9. [Google Scholar]

- Jayasinghearachchi, H.; Seneviratne, G. Fungal solubilization of rock phosphate is enhanced by forming fungal–rhizobial biofilms. Soil Biol. Biochem. 2006, 38, 405–408. [Google Scholar] [CrossRef]

- Seneviratne, G.; Jayasekara, A.; De Silva, M.; Abeysekera, U.P. Developed microbial biofilms can restore deteriorated conventional agricultural soils. Soil Boil. Biochem. 2011, 43, 1059–1062. [Google Scholar] [CrossRef]

- Shang, B. Effect of slow-release fertilizer on the growth of Chinese fir seedlings. J. For. Sci. Technol. 2017, 38, 93–94. [Google Scholar]

- Li, Z.; Mo, Y. The effect of foliar fertilization on the growth of Chinese fir at seedling stage. For. Sci. Technol. 2017, 49, 48–50. [Google Scholar]

| Acronyms | Full Name |

|---|---|

| FAO | Food and Agriculture Organization of the United Nations |

| LCA | Life cycle assessment |

| ISO | International Organization for Standardization |

| SIA | Sustainability impact assessment |

| ALCA | Attributive life cycle assessment |

| CLCA | Contingency life cycle assessment |

| ILCD | International reference life cycle data system |

| FU | Function unit |

| MDF | Medium-density fiberboard |

| CODCr | Chemical oxygen demand measured by potassium dichromate (K2Cr2O7) as oxidant |

| BOD5 | Biochemical oxygen demand in 5 days |

| SS | Suspended solid |

| C-G | Cradle to gate |

| Tree Species | Equation | Parameter Value | Source of References | |

|---|---|---|---|---|

| Biomass equation | Chinese fir | W = aDb * | a = 0.0740, b = 2.39 | [44] |

| Masson Pine | W = a(D2H)b * | a= 0.00951, b = 1.138668 | [45] | |

| Tree species | Parameter value | Source of references | ||

| Carbon content | Chinese fir | 46.97% | [46] | |

| Masson Pine | 46.0% | [47] | ||

| Category | Item | Amount | Category | Item | Amount |

|---|---|---|---|---|---|

| Outputs I | biomass | 1 m3 | Material | electricity | 324.1 kWh |

| Material | seedling | 24.94 p | diesel | 1.23 L | |

| Emission (air) | CO2 | −2.59 t | wood fuel | 0.19 t | |

| Outputs II | MDF | 1 m3 | Emission (air) | particulates I | 0.33 kg |

| Material | chips | 0.1 t | formaldehyde I | 0.03 kg | |

| sawdust | 0.15 t | particulates II | 0.002 kg | ||

| bark | 0 t | formaldehyde II | 0.001 kg | ||

| fuelwood | 1.61 t | Emission (liquid) | CODCr | 2.524 g | |

| paraffin | 5.84 kg | BOD5 | 0.532 g | ||

| urea | 72.69 kg | SS | 1.465 g | ||

| formaldehyde | 109.95 kg | ammonia nitrogen | 0.076 g | ||

| lube oil | 7.82 kg | formaldehyde | 0.002 g | ||

| water | 1.13 L | Noise | - | 51.42 dB |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, W.; Xu, D. Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise. Sustainability 2020, 12, 4147. https://doi.org/10.3390/su12104147

Zhang X, Zhang W, Xu D. Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise. Sustainability. 2020; 12(10):4147. https://doi.org/10.3390/su12104147

Chicago/Turabian StyleZhang, Xuyao, Weimin Zhang, and Dayu Xu. 2020. "Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise" Sustainability 12, no. 10: 4147. https://doi.org/10.3390/su12104147

APA StyleZhang, X., Zhang, W., & Xu, D. (2020). Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise. Sustainability, 12(10), 4147. https://doi.org/10.3390/su12104147