An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment

Abstract

1. Introduction

1.1. Sustainable Development

1.2. Sustainable Coal Coking Process

- the presence of a high temperature of combustion products and blast force that could affect persons present on the plant premises;

- it may cause the outbreak of a fire;

- it may become an initiator of dust explosion in a confined space under the impact of a preliminary blast when dust becomes “blown off” from the places where it had become settled and formed a large cloud [3].

- making an assessment of explosion hazard and carrying out a correct classification of areas and premises;

- applying adequate prevention from accidental explosions and from consequences of an explosion;

- selecting appropriate devices in the investment process (especially electrical appliances), including installations with explosion-proofing.

- Zone 20—space in which the explosive atmosphere in the form of an airborne cloud of flammable dust occurs permanently, frequently, or over long periods;

- Zone 21—space in which the explosive atmosphere in the form of an airborne cloud of flammable dust may occur at times during normal operation;

- Zone 22—space in which the explosive atmosphere in the form of an airborne cloud of flammable dust does not occur during normal operation, and even if it does, it does not continue for a long time.

2. Materials

3. Methods

3.1. Minimum Ignition Temperatures of Dust

3.2. Explosion Parameters of the Tested Dust Consistent with Standard EN 14034

3.3. Thermal Gravimetric Analysis (TGA)

3.4. Heat of Combustion

4. Results

5. Risk Analysis in a Typical Coking Plant

- generation of coal coking products;

- processing coal coking products;

- production of briquettes and solid fuels from coal;

- wholesale of liquid, solid, gaseous fuels and derivative products,

- generation of gaseous fuels;

- distribution of gas fuels in a network system.

- bunker, charge coal used to produce a mixture of a specific composition;

- furnace plant, in chambers of coking batteries the process of high-temperature degassing of the coal mixture takes place;

- coal derivatives—the purification process of raw coking gas is performed and recovery of coal-derivative products.

- acceptance and unloading of charge coal;

- storage of coal;

- production of the coal mixture and its transport to coal towers;

- intake of mixture and loading of chambers;

- operation of batteries of coking furnaces;

- receipt and quenching of coke;

- sorting and loading of coke.

- (1)

- identification of hazards connected with the release of hazardous substances at the level of installations or an installation node;

- (2)

- identification of potential emergency scenarios;

- (3)

- identification and assessment of security and protection means in the context of their impact on the possibility of occurrence of emission, fire, explosion (frequency and magnitude of anticipated consequences of emission, fire, explosion and the risk level);

- (4)

- initial proposal for additional safety means and an assessment of their impact on the risk level.

- (1)

- frequency of occurrence of the hazard connected with the release of a hazardous substance;

- (2)

- magnitude of consequences arising from such a hazard (in each case, the worst possible consequences that a given hazard may cause are adopted) [4].

5.1. Classification of Coke Dust Explosion Hazard Zones

5.2. Characterisation of Ignition Sources for Coke Dust

6. Discussion

- Perform an inventory of devices installed in the delimited explosion hazard zones. Next, verification should be done on whether those devices fulfil the necessary requirements with respect to explosion safety, among others, with a view to category, explosion group, and temperature class.

- Change the categorization, amend the range, or, to eliminate the explosion hazard zones, as well as to minimize potential explosion effects, a dusting reduction system should be installed on belt conveyors and coke boosters with the use of water fog.

- Assure that the coke booster in sections of furnace and sorting facilities is made airtight, as well as the dump to the coking plant in the sorting unit, because each lack of tightness increases the likelihood of creating an explosive atmosphere.

- There is a need for devising, deploying, and following procedures for maintaining the cleanliness of the entire installation (among others, technological belt conveyors, parts of building structures including devices contained inside) in the whole plant to prevent the occurrence of coke dust layers. With this in mind, employees should regularly control cleanliness of the facilities in which dust may occur.

- Within the designated gas explosion hazard zones, appropriate protection means are to be adopted to ensure protection from static electricity, or adopt another technical solution aimed at the discharge of electrostatic charges.

7. Conclusions

- The maximum admissible temperature on the surface of a device used in conditions in which layers of coke dust exist depends to a large extent on the thickness of the compiled dust. For a coke dust layer of a thickness of 50 mm, this temperature is threefold lower.

- Consequently, in plants where the analyzed dust occurs, attention should be paid to the type of devices installed in delimited explosion hazard zones, and, in particular, it is necessary to verify whether the abovementioned devices fulfil the relevant requirements related to explosion safety.

- Before locating equipment in a zone where dust may be present, it is necessary to delimit the category, explosion class, and maximum admissible temperature on surface of a devices.

- The rate of coke oxidation is significantly affected by such factors as: coke fragmentation, contents of mineral substances in the coal, hygroscopic moisture, and carbon content; the greater the coal fragmentation, the higher the risk of ignition in the environment. Another parameter that has a great impact on ignition of coke dust is its content of hygroscopic moisture. Moisture is the cause of oxidation of pyrite and other exothermic reactions. Hygroscopic moisture in the process of self-heating is a negative factor, because the greater its content in coal, the higher the risk of ignition.

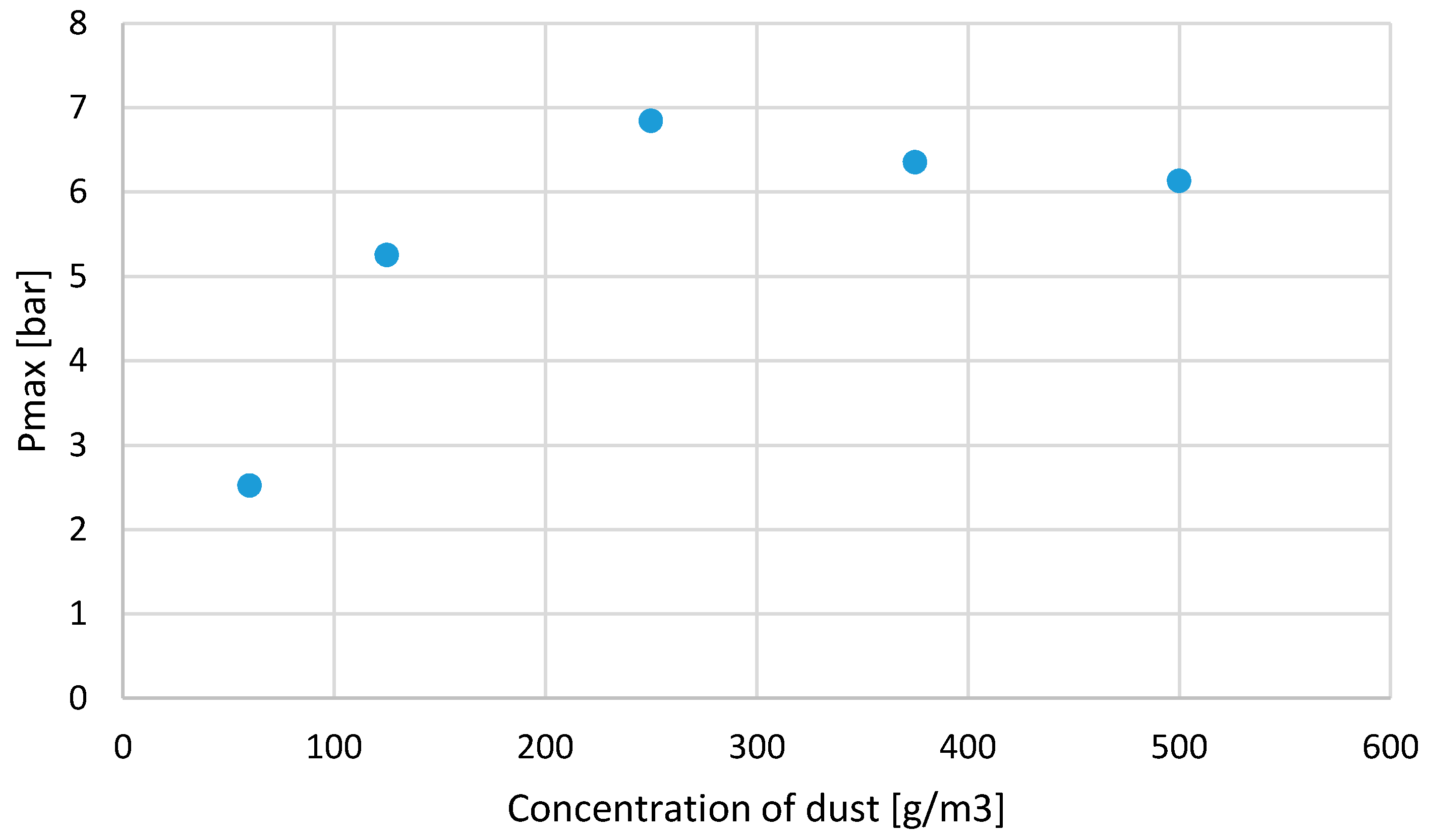

- The maximum explosion pressure of tested coke dust amounted to 6.84 bar, and the KSt value was 64.2 bar m/s, which corresponds with explosion hazard class 1, and the obtained KSt value is close to the value found in literature for coal.

- The PHA method is helpful to determine the legitimacy of using additional means aimed at ensuring explosion safety and it allows a qualitative evaluation of their impact on the risk level to bring down the risk in delimited zones to an acceptable level.

- Minimizing the explosion risk may consequently result in minimizing the risk of releasing contaminants and products of thermal decomposition into the environment. If crucial explosion parameters are known, it is possible to prevent coking technology from having a negative influence on sustainable development in process safety.

Funding

Conflicts of Interest

References

- United Nations. A/RES/70/1 Transforming our world: The 2030 Agenda for Sustainable Development, General Assembly Distr.: General 21 October 2015 Seventieth Session Agenda Items 15 and 116 15-16301. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 13 May 2020).

- Bartknecht, W. Explosions—Course, Prevention, Protection; Springer-Verlag: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Cybulski, W. Wybuchy Pyłu Węglowego i Ich Zwalczanie; Śląsk: Katowice, Poland, 1973. [Google Scholar]

- Eckhoff, R.K. Dust Explosions in the Process Industries, 3rd ed.; Gulf Professional Publishing: New York, NY, USA, 2003. [Google Scholar]

- Eckhoff, R.K. Differences and similarities of dust and gas explosions: A critical evaluation of the European ATEX directives in relation to dust. J. Loss. Prevent. Proc. 2006, 19, 553–560. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Understanding Dust Explosions. The Role of Power Science and Technology. J. Loss. Prevent. Proc. 2009, 22, 105–116. [Google Scholar] [CrossRef]

- Taveau, J. Dust Explosion Propagation and Isolation. J. Loss. Prevent. Proc. 2017, 48, 320–330. [Google Scholar] [CrossRef]

- Wilson, L.; McCutcheon, D. Industrial Safety and Risk Management; University of Alberta Press: Edmonton, AB, Canada, 2003. [Google Scholar]

- Hardy, C.C. Wildland fire hazard and risk: Problems, definitions, and context. For. Ecol. Manag. 2005, 211, 73–82. [Google Scholar] [CrossRef]

- Manzinia, G.; Gramazio, P.; Guastella, S.; Liciottic, C.; Baffonid, G.L. The fire risk in photovoltaic installations—Checking the PV modules safety in case of fire. In Proceedings of the 69th Conference of the Italian Thermal Engineering Association, ATI 2014, Milan, Italy, 10–13 September 2014. [Google Scholar]

- Pollack, K.M.; Poplin, G.S.; Griffin, S.; Peate, W.; Nash, V.; Nied, E.; Gulotta, J.; Burgess, J.L. Implementing risk management to reduce injuries in the U.S. Fire Service. J. Saf. Res. 2017, 60, 21–27. [Google Scholar] [CrossRef] [PubMed]

- HSE. Fire, Explosion and Risk Assessment Topic Guidance. Hazard Installations Directorate; Health & Safety Executive: London, UK, 2003.

- Bidabadi, M.; Mohebbi, A.K.; Poorfar, S.; Hochgreb, C.; Lin, S.; Biouki, M.; Hajilou, M. Modeling Quenching Distance and Flame Propagation Speed Through an Iron Dust Cloud with Spatially Random Distribution of Particles. J. Loss. Prevent. Proc. Ind. 2016, 43, 138–146. [Google Scholar] [CrossRef]

- Bidabadi, M.; Hajilou, A.K.; Poorfar, S.H.; Yosefi, S.R.; Zadsirjan, S. Modeling Flame Propagation of Micron-Sized Iron Dust Particles in Media with Spatially Discrete Sources. Fire Saf. J. 2014, 69, 111–116. [Google Scholar] [CrossRef]

- Bidabadi, S.H.; Yosefi, A.K.; Poorfar, M.; Hajilou, S.R.; Zadsirjan, S. Modeling Combustion of Magnesium Dust Cloud in Heterogeneous Media. Combust. Explos. Shock Waves 2014, 50, 658–663. [Google Scholar] [CrossRef]

- International Association of Oil & Gas Producers. Consequence Modelling. Report No. 434-7: 40, 201; Available online: https://www.iogp.org/bookstore/product/risk-assessment-data-directory-consequence-modelling/ (accessed on 13 May 2020).

- Kong, D.; Lu, S.; Xie, Q.; Kong, D.; Lo, S.; Lu, S.; Lo, S.; Kang, Q. Fuzzy Risk Assessment for Life Safety Under Building Fires. Fire Technol. 2014, 50, 977–991. [Google Scholar] [CrossRef]

- Van den Schoora, F.; Middhab, P.; Van den Bulcka, E. Risk analysis of LPG (liquefied petroleum gas) vehicles in enclosed car parks. Fire Saf. J. 2013, 57, 58–68. [Google Scholar] [CrossRef]

- van der Voort, M.M.; Klein, A.J.J.; Maaijer, M.; van den Berg, A.C.; van Deursen, J.R.; Versloot, N.H.A. A quantitative risk assessment tool for the external safety of plants with a dust explosion hazard. J. Loss. Prevent. Proc. 2007, 20, 375–386. [Google Scholar] [CrossRef]

- Abuswer, M.; Amyotte, P.R.; Khan, F. A quantitative risk management framework for dust and hybrid mixture explosions. J. Loss. Prevent. Proc. 2013, 26, 283–289. [Google Scholar] [CrossRef]

- Skjold, T. Review of the DESC project. J. Loss. Prevent. Proc. 2007, 20, 291–302. [Google Scholar] [CrossRef]

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Frank, W.L. Dust explosion prevention and the critical importance of housekeeping. Process Saf. Prog. 2004, 23, 175–184. [Google Scholar] [CrossRef]

- DeFriend, S.; Dejmek, M.; Porter, L.; Deshotels, B.; Natvig, B. A risk-based approach to flammable gas detector spacing. J. Hazard. Mater. 2007, 159, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Hansen, O.R.; Hinze, P.; Engel, D.; Davis, S. Using computational fluid dynamics (CFD) for blast wave predictions. J. Loss Prev. Proc. 2010, 23, 885–906. [Google Scholar] [CrossRef]

- Middha, P.; Engel, D.; Hansen, O.R. Can the addition of hydrogen to natural gas reduce the explosion risk. Int. J. Hydrogen Energy 2011, 36, 2628–2636. [Google Scholar] [CrossRef]

- Amyotte, P.; Abuswer, M.; Di Benedetto, A.; Russo, P. Determination of hybrid mixture explosion severity. In Proceedings of the 13th International Symposium on LOSS prevention and Safety Promotion in the process Industries, Brugge, Belgium, 6–9 June 2010. [Google Scholar]

- Directive 94/9/EC of the European Parliament and the Council of 23 March 1994 on the Approximation of the Laws of the Member States Concerning Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres. Available online: https://euoag.jrc.ec.europa.eu/files/attachments/directive_94_9_ec.pdf (accessed on 13 May 2020).

- EN 50281, Part 2-1 (2002). Electrical Apparatus for Use in the Presence of Combustible Dust—Part 2-1: Test Methods—Methods of Determining the Minimum Ignition Temperature of Dust. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030056650 (accessed on 13 May 2020).

- ISO/IEC 80079, Part 20-2 (2016). Explosive Atmospheres—Part 20-2: Material Characteristics—Combustible Dusts Test Methods—Technical Corrigendum 1. Available online: https://www.iso.org/standard/66564.html (accessed on 13 May 2020).

- EN 14034, Part 1. (2011). Determination of Explosion Characteristics of Dust Clouds—Part 1: Determination of the Maximum Explosion Pressure Pmax of Dust Clouds. Available online: https://www.researchgate.net/publication/282893830_Determination_Of_The_Maximum_Explosion_Pressure_And_The_Maximum_Rate_Of_Pressure_Rise_During_Explosion_Of_Wood_Dust_Clouds (accessed on 13 May 2020).

- EN 14034, Part 2. (2011). Determination of Explosion Characteristics of Dust Clouds—Part 2: Determination of the Maximum Rate of Explosion Pressure Rise (dp/dt) Max of Dust Clouds. Available online: https://infostore.saiglobal.com/en-us/Standards/EN-14034-2-2006-A1-2011-328536_SAIG_CEN_CEN_756384/ (accessed on 13 May 2020).

- EN ISO 11358, Part 1 (2014). Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. Available online: https://www.iso.org/standard/59710.html (accessed on 13 May 2020).

- EN ISO 1716 (2018). Reaction to Fire Tests for Products. Determination of the Gross Heat of Combustion (Calorific Value). Available online: https://www.iso.org/standard/70177.html (accessed on 13 May 2020).

- Vincoli, J.W. Basic Guide to System Safety, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- EN IEC 60079 (2017) Explosive Atmospheres—Part 0: Equipment—General Requirements. Available online: https://standardscatalog.ul.com/standards/en/standard_60079-0_6 (accessed on 13 May 2020).

- Kordylewski, W. Spalanie i Paliwa; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2005. [Google Scholar]

- Sampson, G.R.; Richmond, A.P.; Brewster, G.A.; Gasbarro, A.F. Cofiring of wood chips with coal in interior Alaska. For. Prod. J. 1991, 41, 53–56. [Google Scholar]

- Frazzitta, S.; Annamalai, K.; Sweeten, J. Performance of a Burner with Coal and Coal-Bio-Solid Fuel Blends. J. Propuls. Power 1999, 15, 181–186. [Google Scholar] [CrossRef]

| Parameter Type | Value | |

|---|---|---|

| Minimal ignition temperature of a dust layer (MITDL) (°C) | Thickness of dust layer [mm] | |

| 5 | >400 °C | |

| 12.5 | >400 °C | |

| 25 | >400 °C | |

| 50 | 400 °C | |

| Minimal ignition temperature of a cloud dust (MITDC) (°C) | 610 | |

| Maximum explosion pressure pmax (bar) of a dust cloud, at dust concentration for pmax 250 (g/m3) | 6.84 | |

| The maximum rate of explosion pressure rise (dp/dt)max of dust clouds (bar/s) at dust concentration for (dp/dt)max 250 (g/m3) | 236.89 | |

| Parameter KSt max. (bar m)/s | 64.2 | |

| Heat of combustion (kJ/g) | 27.03 | |

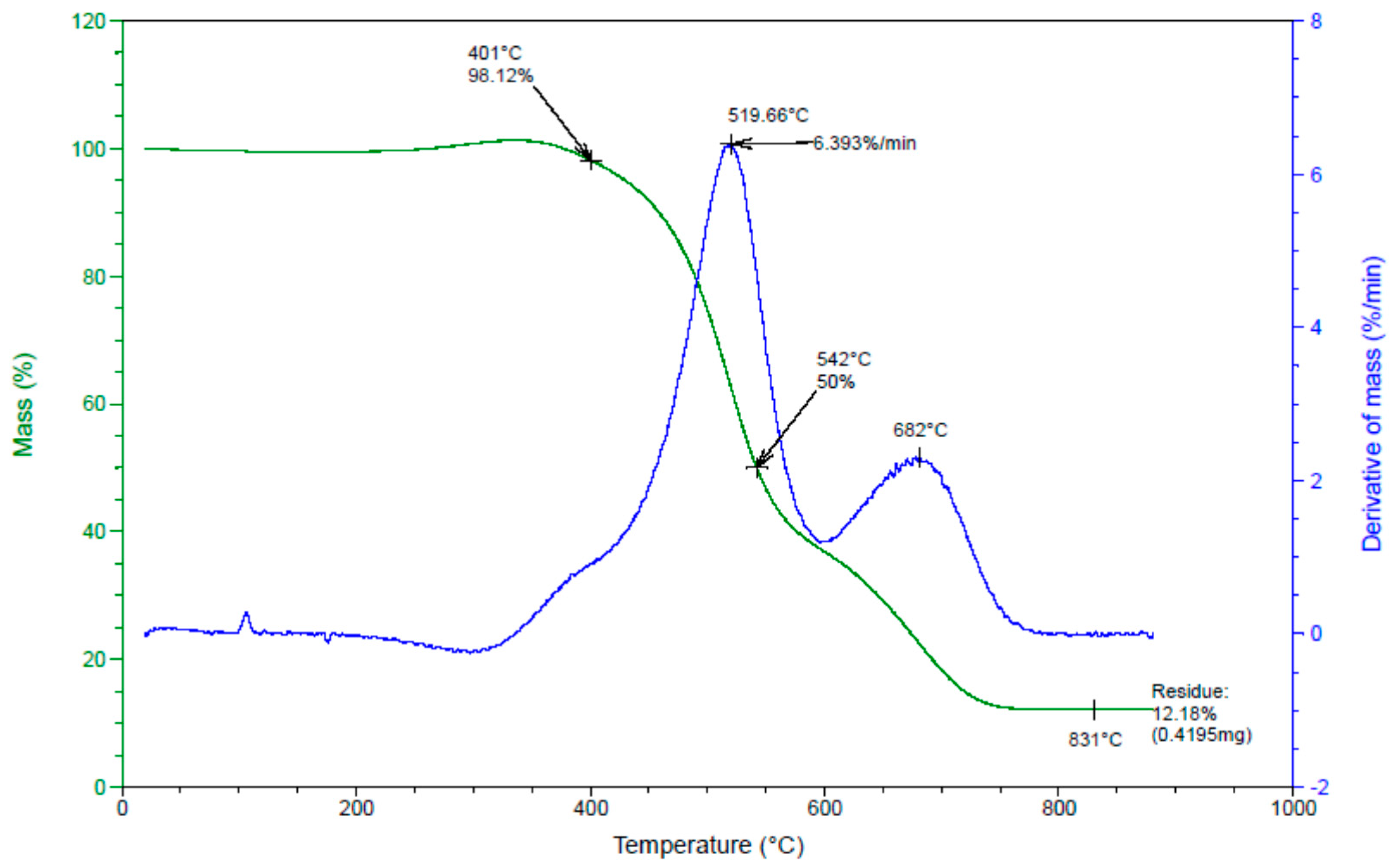

| Tested Parameters | Coke Dust |

|---|---|

| Temperature of thermal-decomposition beginning (°C) | 401 |

| Temperature of 50% mass loss (°C) | 542 |

| Final temperature of thermal decomposition (°C) | 750 |

| Mass residue after combustion (%) | 12.18 |

| Maximum mass-loss rate (%/min) | 6.4 |

| Temperature of maximum mass-loss rate (°C) | 520 |

| The Probability of Explosion (P)/Level | Category Effects (E) from 1 to 5 | ||||

|---|---|---|---|---|---|

| Negligible/1 | Low/2 | Medium/3 | High/4 | Catastrophe/5 | |

| Certain event/5 | TA | TNA | TNA | NA | NA |

| Possible/4 | TA | TA | TNA | TNA | NA |

| Exceptional/3 | A | TA | TA | TNA | TNA |

| Small/2 | A | A | TA | TA | TNA |

| Very small/1 | A | A | A | TA | TA |

| The Probability of Explosion | Description/Frequency |

|---|---|

| Certain event | 100–101 [1/year] |

| Possible | 10-1–10-2 [1/year] |

| Exceptional | 10-2–10-3 [1/year] |

| Small | 10-3–10-4 [1/year] |

| Very small | Below 10-4 [1/year] |

| Short Description | Description | Destruction [%] | |

|---|---|---|---|

| 1 | Negligible | No damage | 0–1 |

| 2 | Low | Small damage requiring minor repair | >1–10 |

| 3 | Medium | Medium damage requiring repair of parts | >10–25 |

| 4 | High | Significant damage requiring greater expenditure and renovation | >25–60 |

| 5 | Catastrophe | Major damage, including building structure | >60–100 |

| Process/Location | Type of Danger | Frequency of Occurrence | Zone | Range of Zone |

|---|---|---|---|---|

| Belt conveyors | Coke dust | If it occurs, it lasts a short time | 22 | Within 0.5 m around the conveyor belt vertically and horizontally |

| Coke discharge area | Coke dust | If it occurs, it lasts a short time | 22 | Area within the coke discharge area Inside the coke semitrailer |

| Coke sorting equipment | Coke dust | If it occurs, it lasts a short time | 22 | Inside the fine coke sorter |

| Dangerous/Initiating Event | Effects | Preventive Measures | Safety Systems (Proposal) | P | E | R | Recommendations/Remark |

|---|---|---|---|---|---|---|---|

| Explosion of a combustible mixture (coke dust–air) due to the air being blown up by the air in the dust room | 1.The outbreak. 2. Possible propagation of explosion inside the room. 3. Possible human sacrifices. 4. Damage to the installation, material losses. 5. Stop the installation. | Constant monitoring of technological installations. - Filter unit in the sorting plant. - Installation of central vacuuming in a sorting plant | Within 0.4 m around the conveyor belt vertically and horizontally | 2 | 5 | TNA | Additional security measures should be introduced (cleaning, wetting) |

| Ignition Source | Description | Probability of an Effective Ignition Source (Frequency in the Range of 1 to 3) |

|---|---|---|

| Hot surfaces | ||

| Electrical devices and equipment | If normal equipment is used within the designated explosion hazard zones—not intended for use in these spaces | 2 (possible) |

| Electrical devices and equipment | If there are devices working in explosive spaces, together with documentation confirming the correct selection of these devices, e.g., light sources for lamps in explosion-proof setup | 3 (very small) |

| Coke sorting equipment | Coke dust | If it occurs, it lasts a short time |

| Flame and hot gases (including hot particles) | ||

| Human error, e.g., flame of a match (temp. 600 to 700 °C) | Smoking ban in inadmissible places | 3 (very low) |

| Human error, e.g., burning cigarette butt, (temp. 400 to 670 °C) | Smoking ban in inadmissible places | 3 (very low) |

| Human error, e.g., flame of a gas burner (temp. of ca. 3000 °C)—overhaul and repair works | Preparing the working area and execution of fire hazardous works after obtaining a written usage permit | 3 (very low) |

| Sparks generated mechanically | ||

| Work tools capable of generating a mechanical spark | On the area of designated explosion hazard zones, the employees use non-sparking tools. | 3 (very low) |

| Generated during modernization works | Preparing the working area and execution of fire hazardous works after obtaining a written usage permit | 3 (very low) |

| Electrical appliances | ||

| Overload, overheating, flashover (electrical fittings) | If on the area of delimited explosion hazard zones the used devices are in common finishing, they are unsuitable for operation in those zones. | 2 (possible) |

| Overload, overheating, flashover (electrical fittings) | If on the area of delimited explosion hazard zones the used devices are explosion-proof | 3 (very low) |

| Stray voltage, cathode anticorrosion protection | ||

| Stray voltage in the event of damage to the electrical system or lightning strike | Electrical wiring ground of installation, technical inspections, and constant supervision over the technical efficiency of electrical wiring ground and lightning protection systems | 3 (very low) |

| Static electricity | ||

| Sparkover between man and device or installation | Required documentation to confirm the adoption of installation electrical wiring ground | Sparkover between man and device or installation |

| Lightning strike | ||

| Lightning | Lightning protection, periodical technical inspections | 3 (very low) |

| Electromagnetic waves with a radio frequency (RF) 104—3 × 1011 Hz | ||

| Not identified | Lack of sources in literature | 3 (very low) |

| Electromagnetic waves from 3 × 1011 Hz to 3 × 1015 Hz | ||

| Not identified | Lack of sources in literature | 3 (very low) |

| Ionizing radiation | ||

| Not identified | Lack of sources in literature | 3 (very low) |

| Ultrasound | ||

| Not identified | Lack of sources in literature | 3 (very low) |

| Adiabatic compression and impact waves | ||

| Not identified | Lack of sources in literature | 3 (very low) |

| Exothermal reactions, including self-ignition of dusts | ||

| Not identified | Cleaning procedures including removal of settled dust at least once every 6–7 h, installation of a wetting system for dust or coal input | 2 (possible) |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Półka, M. An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment. Sustainability 2020, 12, 4130. https://doi.org/10.3390/su12104130

Półka M. An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment. Sustainability. 2020; 12(10):4130. https://doi.org/10.3390/su12104130

Chicago/Turabian StylePółka, Marzena. 2020. "An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment" Sustainability 12, no. 10: 4130. https://doi.org/10.3390/su12104130

APA StylePółka, M. (2020). An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment. Sustainability, 12(10), 4130. https://doi.org/10.3390/su12104130