1. Introduction

The high dynamics of orders, where customers are increasingly striving for highly personalized products, reduces the differences between different types of production systems with relation to high flexibility and efficient cost-time investment [

1]. The flexibility of small and medium-sized manufacturing companies with job-shop production type [

2] has recently faced the challenge of achieving sustainable financial growth in a globally competitive environment. For the sake of success, they are experiencing an increase in the introduction of collaborative workplaces into existing or newly proposed production systems. Collaborative workplaces that include a collaborative machine (most often a collaborative robot) into the production system introduce variables that need to be evaluated properly for its effective introduction [

3]. From a global economic point of view, it is not enough to evaluate only the financial impacts of collaborative workplaces. Their impact on the environment and the social aspect of employees and the environment also need to be considered [

4]. This article presents research work based on the research question of the impact of collaborative workplaces on the sustainable viability of manufacturing systems. The importance of evaluating a research question refers to the importance of knowing and making use of collaborative workplaces in high flexible manufacturing, in order to achieve the financial, environmental and social positive impacts of the manufacturing process.

A detailed knowledge of the impact of collaborative workplaces on the manufacturing system and beyond is more complex than that regarding fully automated workplaces (use of industrial robots), because when considering financial and environmental aspects, it is important to consider human-machine (robot) collaboration and the related social aspect. Over the past decade, researchers have explored the impact of collaborative workplaces on the manufacturing process, but not in relation to their sustainable viability and the three previously mentioned aspects. Collaborative workplaces should provide a significantly higher level of security, with a continuous collaboration between the collaborative machine and the worker. This raises various research issues, such as the safe speeds and accelerations of the collaborative machine [

5,

6]. A higher level of safety requires the use of advanced sensing control systems, in order to know the precise position of the worker and the collaborative machine in real-time [

7]. The need to integrate security protocols and upgraded management systems differentiates collaborative workplaces significantly from fully automated and robotic jobs, since collaborative workplaces allow for a higher degree of flexibility than fully automated and robotic jobs, with the desired cost-effective investment [

8]. In the time of Industry 4.0 and the transition to collaborative workplaces that offer a high degree of flexibility and value for money investment, the advantage of collaborative workplaces is their wide availability, their connectivity to the cyber-physical environment and the relatively simple introduction into an existing or newly proposed manufacturing process [

9]. Researchers are faced with constraints on the conditions of cooperation between humans and the collaborative machine, but are concerned primarily with the safety and economic impact of the collaborative workplace, as a subset of the manufacturing system [

10]. However, the area of collaborative workplace influence on the overall manufacturing system and its financial, environmental and social viability has not been evaluated and researched yet. Therefore, a thorough examination of the impact of collaborative machines on human co-workers [

11] is crucial in times of mass personalization-oriented manufacturing and the need to achieve short delivery times with efficient cost-time investment. Reference [

11] describes how the collaborative machine influences human workers from different perspectives: appearance of the collaborative machine (mainly robots), responsibility of human workers toward the robot and importance of a better understanding of the realistic human-robot collaboration workstation (HRCW) scenario in the manufacturing environment.

This research work presents a simulation modeling method, which is used to evaluate the impact of a collaborative workplace on the sustainable viability of the manufacturing system [

12]. The advantage of using a simulation modeling method and a simulation scenario approach is the possibility of evaluating in detail the various parameters of a real-world manufacturing system [

13]. For the purpose of credible numerical and graphical results’ elevation, a method using data-driven simulation models is selected based on the use of input data from a real-world manufacturing system. The advantage of using data-driven simulation models is the interactivity between different optimization and evaluation methods [

14]. The methods used in the present research work provide a comprehensive research approach, where the key task is to evaluate the impact of collaborative workplaces on the sustainable viability of manufacturing systems from the standpoint of various indicators [

15]. The literature presented by other researchers deals with the presented research problem separately, in smaller subgroups, only with concepts and some with practical instructions [

16]. The main limitations of the present work are related to the connectivity of the individual subassemblies and the lack of a complete evaluation method that can be used in a real manufacturing system. In research [

17], the researchers present the well-structured influence of flexible manufacturing systems on the sustainable suitability of contract manufacturing, thus providing guidance for further development in relation to collaborative workplaces. As mentioned earlier, the link between collaborative workplaces and their impact on sustainable eligibility in Industry 4.0, from the perspective of organizational and environmental regulations and the global competitiveness of small and medium-sized enterprises (SMEs), is crucial [

18,

19]. The presented simulation modeling method enables the evaluation of different characteristics of the manufacturing system and complements the current area of highly flexible manufactured systems on the cost-time investment influence [

20].

At a time when customer needs for personalized products re-emphasize the importance of massively optimized and, thus, sustainably justified manufacturing, researchers are concerned with three key areas. Impacts on sustainable eligible manufacturing include environmental, economic and social impacts on a sustainable eligible system. Job-shop production, given the customers’ needs, tends to reduce processing times, while ensuring high manufacturing flexibility with short delivery time. In doing so, the proposed research question arises. How can one evaluate appropriate processing times so that the short delivery times will be reached and the manufacturing system will be sustainably justified? In the present research work, we show how to introduce collaborative workplaces into high-mix low-volume production to shorten previous processing times, influence cost-time investments and actually integrate energy efficiency into a manufacturing society.

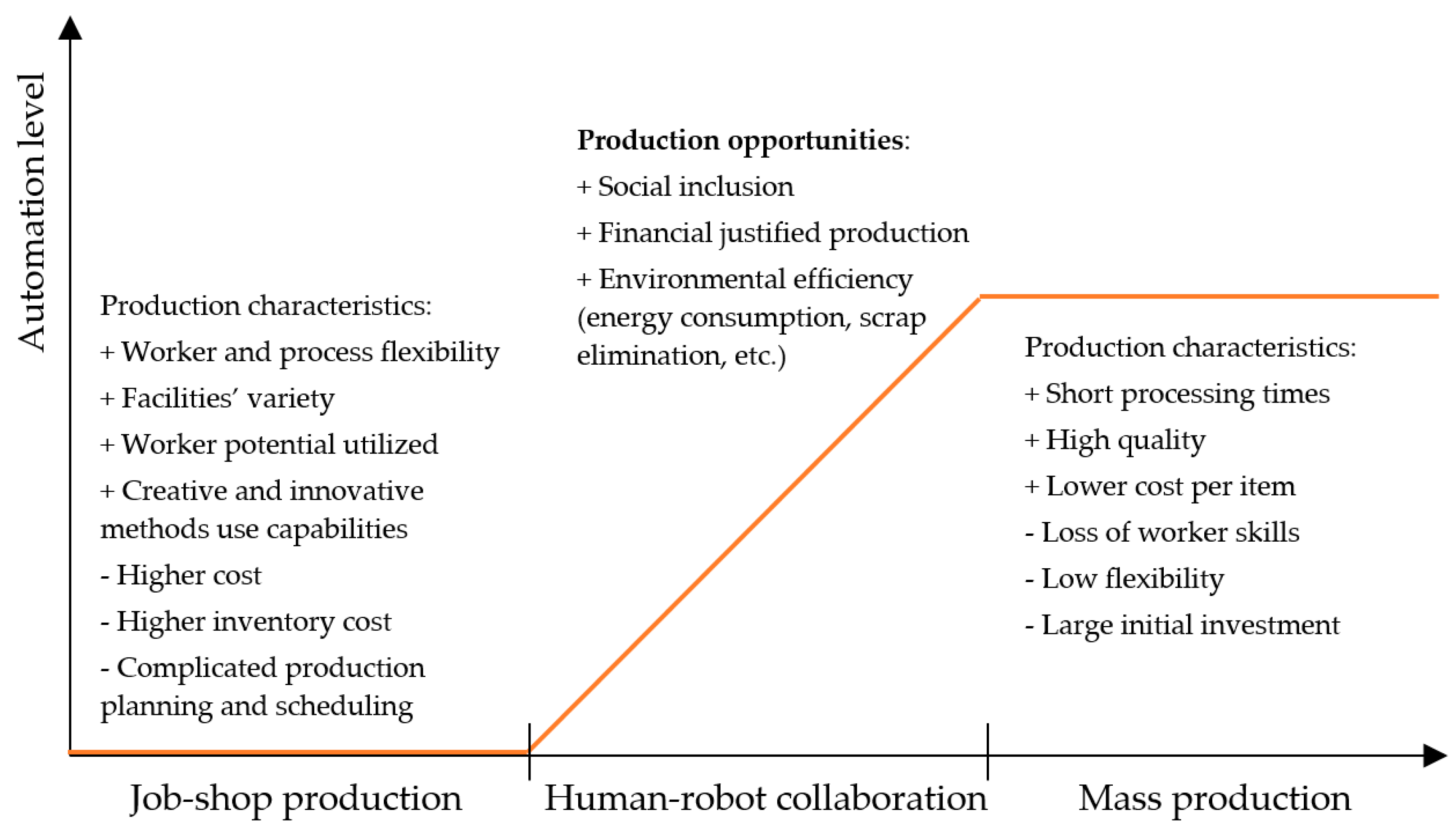

The impact of job-shop production on sustainable eligibility has not been well researched, since the complexity of manufacturing planning and scheduling of job-shop production depends largely on the flexibility that this type of production provides. The impact of environmental, economic and social considerations on the sustainable viability of job-shop production is particularly crucial in the introduction of collaborative workplaces, in order to ensure value-based production systems from a symmetry standpoint. Collaborative workplaces, in this research work, are defined as Human-Robot Collaboration (HRC). In

Figure 1 we propose new production opportunities when introducing collaborative workplaces into job-shop (mass customization) production, to ensure a shorter processing time and an efficient cost-time investment and still preserve manufacturing flexibility.

The research presented in this article is divided into the following sections: the second section presents the research problem of determining the impact of a collaborative workplace on the sustainable viability of a manufacturing system. Starting from the introductory research question, the third section presents a new approach to simulation modeling with the corresponding block diagram. The real-world data are entered as the basis of the simulation model, the application of the simulation scenario approach to manual workplaces and a comparative simulation model for collaborative workplaces. The numerical and graphical results are presented in section four, and the results and parallels are given in relation to the research question posed. Observations are made in relation to the test data set, and a numerical analysis of the performance of the simulation model in a one-month three-shift production is performed. The final, sixth section presents the results, compares them with existing research and assesses individual advantages and limitations. A proposal for further research is made, focusing on possible applications of the proposed methods.

2. Problem Description—Metal Products Manufacturing Process Description

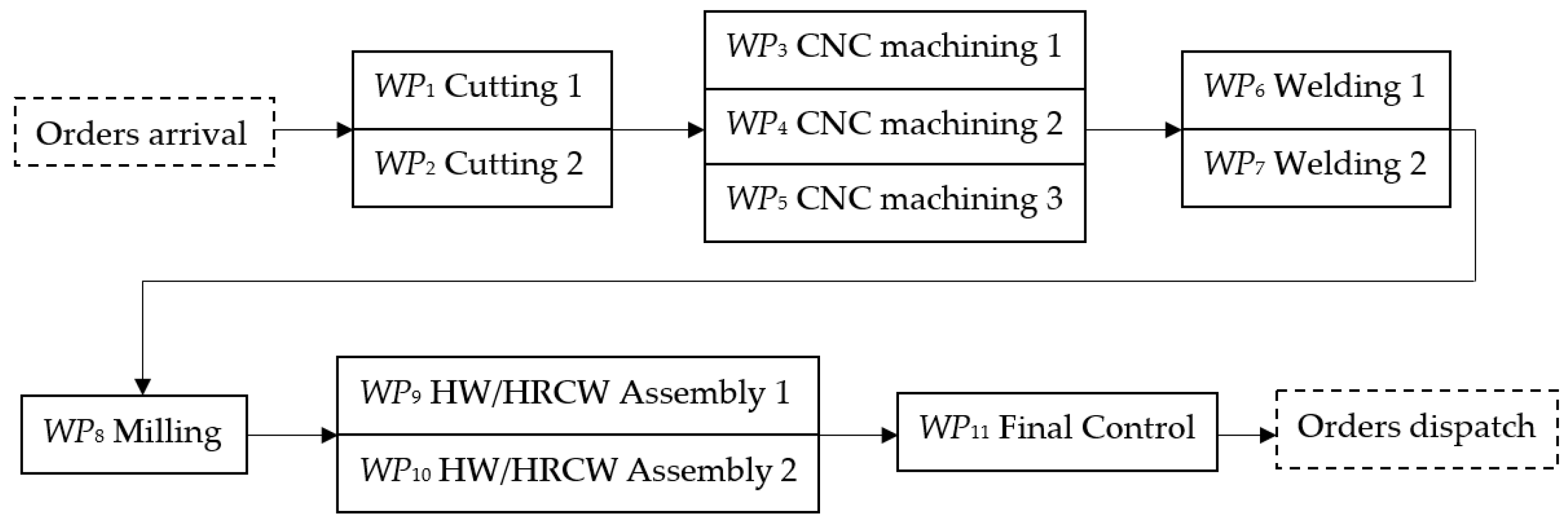

We take into account and as an example the metal products manufacturing industry. A company is confronted with the increase of new orders from global customers. As a result, the company had to eliminate the bottleneck within the manufacturing process shown in

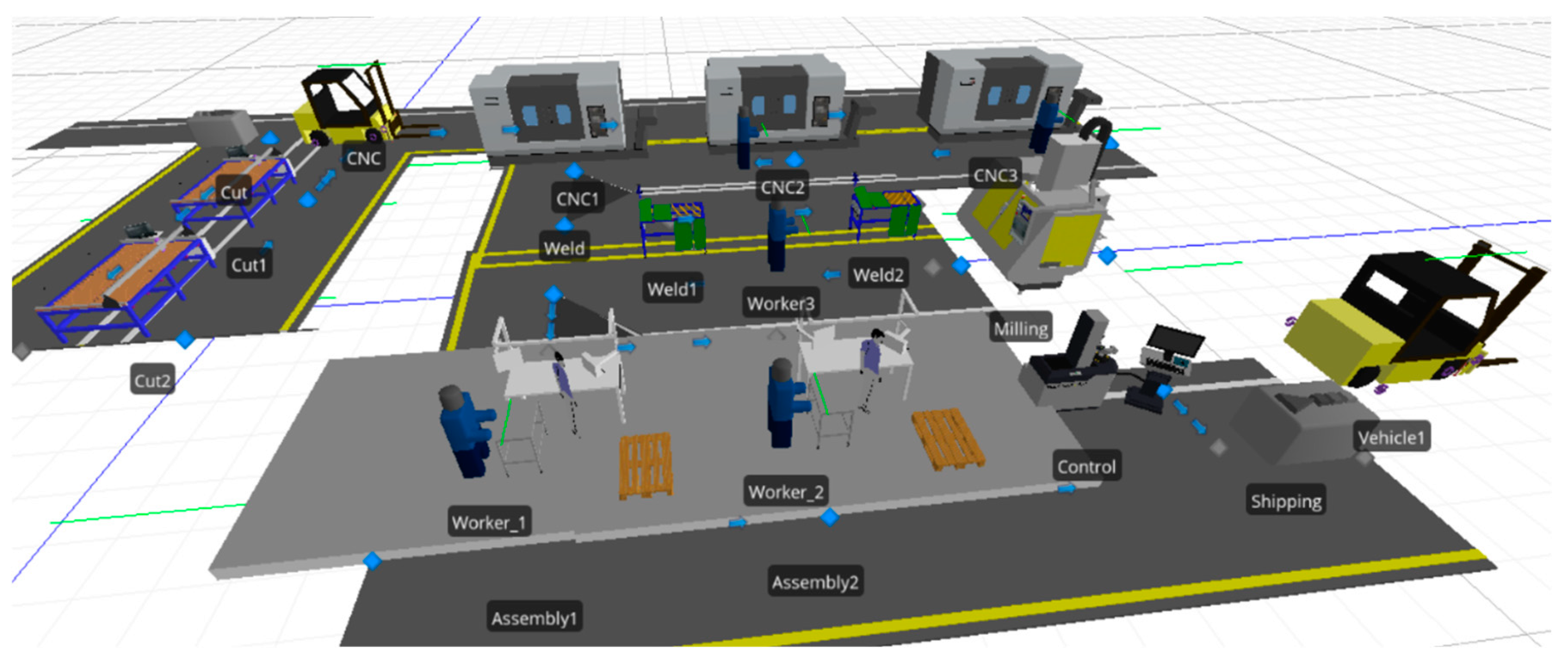

Figure 2. The manufacturing process consists of eleven workplaces (

WPs): the first two

WPs represent raw material cutting (

WP1 and

WP2), the next three

WPs represent machining with multipurpose CNC machines (

WP3,

WP4 and

WP5), followed by two

WPs with manual welding (

WP6 and

WP7) and one milling site (WP

8). Once the machining has been completed, the process of manually assembling the individual components (or the proposed HRCW) into the finished product is carried out in two

WPs (

WP9 and

WP10). The process of final inspection is represented by

WP11.

The previous operating experience has shown that the production bottleneck is caused by two manual human assembly workstations (HW) (WP9 and WP10). The research problem therefore concerned the introduction of a collaborative workstation (human-robot collaboration workstation, HRCW) into the existing manufacturing system at the assembly workstation (WP9 and WP10). The introduction of HRCW in relation to HW must be evaluated in terms of covering the financial, social and environmental aspects.

In the second part, the section presents the multidisciplinary research problem of evaluating collaborative workplaces and their influence on the manufacturing sustainability and their importance and integration opportunities into the existing or newly proposed manufacturing systems. A proposal is made to integrate collaborative workplaces into high-mix low-volume production types, with the possibility of overcoming the constraints of that type of production compared to mass production. The proposed integration model, combining and integrating the positive attributes of highly customized production with the positive characteristics of mass production and eliminating individual constraints, is shown in

Figure 1.

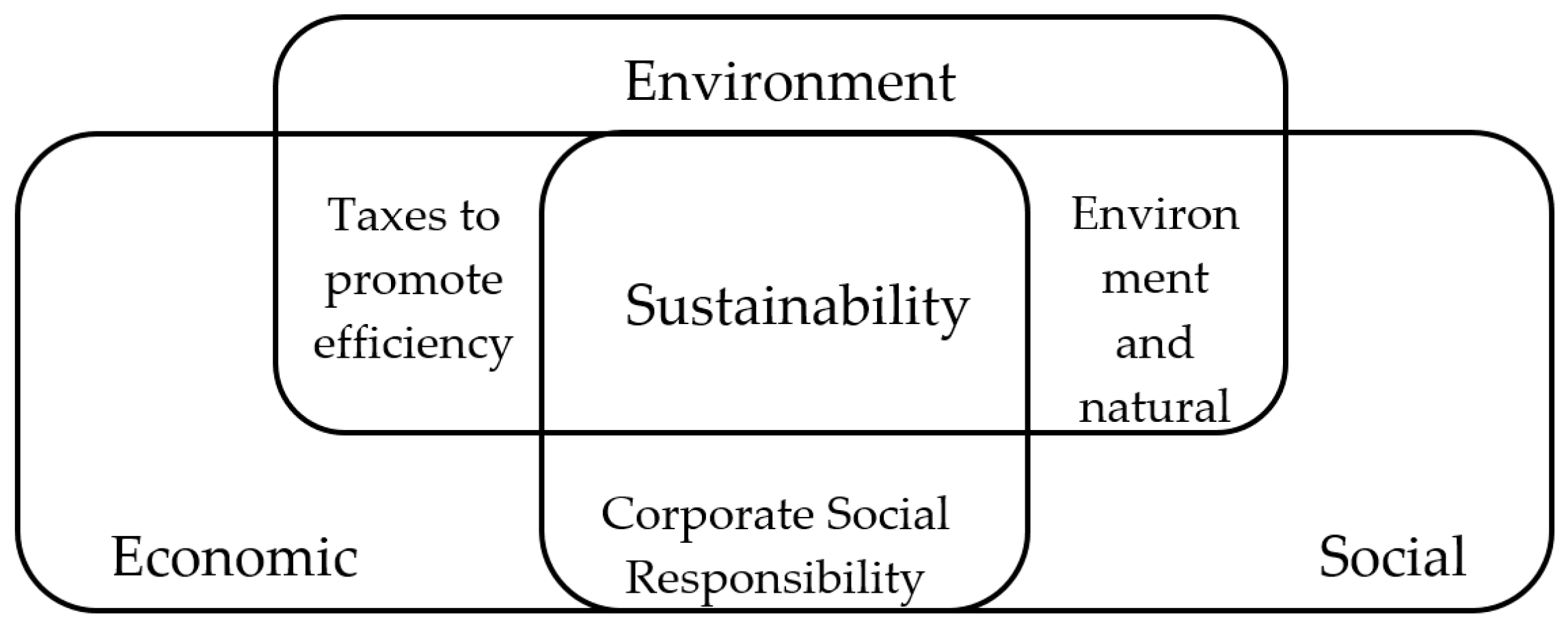

2.1. Sustainable Manufacturing

Sustainable Manufacturing is, in the time of Industry 4.0 and collaborative workplaces (mainly HRC), a wide and increasingly important research field, due to the urgency of assessing the influence of HRC on the financial, social and environmental viewpoints of Sustainable Manufacturing. The integration of collaborative workplaces into the manufacturing types of high-mix, low-volume and reduced limitations regarding mass production manufacturing systems is not well researched. Sustainable Manufacturing is a process developing long-lasting products with a comprehensive life-cycle consideration, aiming to ensure minimum negative environmental impacts and minimize the consumption of natural resources and energy. To ensure global growth, SMEs must be economically sound and societally beneficial. Sustainable oriented manufacturing can only be fulfilled with an innovative and creative thinking approach. The encouragement of innovation and creative thinking promotes the accelerated growth of SME’s and new life-cycle product design. Societal and corporate responsibility correlated with economic growth and taxes to promote efficiency depend on an SME’s openness to new manufacturing process designs. The three main foundations for Sustainable Manufacturing are presented in

Figure 3, as a multidisciplinary research field.

Due to the environmental changes, manufacturing processes must be oriented to minimizing negative environmental impacts and promoting global awareness. The interdisciplinary nature of Sustainable Manufacturing must concern preserving energy and eliminating carbon dioxide emissions. Preserving natural resources, related to material waste management and new methods for remanufacture and scrap improvement in manual or HRC workplaces, enables repairability and disassembly with minimal manufacturing costs. Appropriate new product designs must ensure the safety of employees, communities and consumers, as well as long-lasting products. The main global research focus of Sustainable Manufacturing is to introduce a new holistic optimized life-cycle of manufacturing systems, processes, products and services. Sustainable Manufacturing ensures more sustainable products. In this case, the manufacturing processes must be optimized in the way of cost, time and flexibility, which will increase an enterprise’s total, social and environmental justification. In the present research work, Sustainable Manufacturing is evaluated as the optimization of high-mix low-volume manufacturing systems with three main objectives assessing manual workplaces and HRC workplaces.

2.2. Collaborative Workplaces

A collaborative workplace can be defined when two entities or objects help us achieve the same goal in the same workplace. In our case, we are talking about a collaborative human-robot workplace, hereafter referred to as the Human-Robot Collaboration Workplace (HRCW). In the past, the focus was on industrial robotics, which put robots in the forefront, replacing workers in the pursuit of a variety of difficult, dangerous and non-ergonomic tasks. Most often, robots are used to manipulate heavy loads at different positions and to manipulate objects in positions that are unpleasant and dangerous to the worker, such as manipulating toxic or hot objects. The efficiency of industrial robots is proven by performing monotonous operations that are uncomfortably repetitive and require high precision and repeatability with a proper quality assurance. The advantages of robots relate to robustness, speed and a high degree of reproducibility, ensuring a faster execution of tasks with better quality and, consequently, at a lower cost than those executed by humans. We must not forget that industrial robots reach significantly longer Mean Time Between Failures (MTBF) times, of more than 50,000 h. It should be noted that in reality these times are shorter due to software failures, human errors and failures of various electrical components within the robot’s workplace. However, with these benefits come the key limitations of industrial robots, which relate to the flexibility and security of collaboration in direct human contact. With a view to eliminating these limitations, the rise of so-called collaborative workplaces and collaborative robots intended for direct human-robot contact can be traced in the last decade. Collaborative robots provide safety by working directly with humans in accordance with the International Standard ISO EN 10218. Properly equipped collaborative robots and associated equipment in the ISO/TS 15066 Standard set, together with ordinary limit velocities and accelerations, define safe collaborative tools. With the arrival of collaborative workplaces directly into the human field of operations, the main benefits of collaborative workplaces related to Sustainable Manufacturing are:

Socio-economic viability, which guarantees sustainable and globally competitive production, linked to the regulation of labor prices and the ability to apply for collaborative jobs in small, medium and large enterprises.

Improving the quality of products that relate to the high reproducibility of robotic movements in managing repetitive tasks. This reduces the cost of final control and process scrap ejection.

Labor operations of collaborative workplaces can speed up the processing times of the manual operations previously performed by the worker. Evenly high-occupied job capacities enable short order flow times with dynamic order arrivals and short due dates.

Collaborative machines embody industrial robots in the field of Ergonomically Irregular Movements, in difficult and dangerous environments or in human-unfriendly work operations. Such improvements to the work environment can lead to a reduction in occupational injuries and permanent illness for workers. A high level of safety in collaborative workplaces reduces the number of security situations and simplifies the rules followed by the worker.

For safety reasons, the ISO EN 10218 Standard of collaborative machines with associated sensor equipment, grips and other equipment is classified into four basic functions of collaborative machines (safety-rated monitoring stop, hand guiding, speed and separation monitoring and power and force limiting).

From the four main characteristics of the collaborative machines, we find that their use in high-mix low-volume production is even more suitable for providing shorter orders’ flow times and the ability to adapt quickly to specific orders’ specifications and ensure the high quality of finished products. Given these capabilities, we can conclude that the introduction of Human-Robot Collaborative Workplaces (HRCW) is justified from a financial investment standpoint, as evidenced by previously published scientific research [

8]. However, cost-time investment is not the only aspect that we want to evaluate when evaluating the impact of a collaborative workplace on Sustainable Manufacturing. In order to evaluate the impact of the collaborative workplace on the sustainable viability production comprehensively, our research also defines the environmental and social aspects of collaborative workplaces. The biggest issue when introducing collaborative workplaces is the social aspect of such a modernization in the manufacturing processes. The direct impact of the collaborative machine on humans, including its social and emotional aspects, remains unknown.

The introduction of robots into mass production systems enables the production of a large number of identical products, since the robots are capable of performing monotonous and ergonomically difficult operations with short processing time. In mass production systems without fully automated and robotic systems, customer demand cannot be met [

9]. However, when it comes to collaborative workplaces within high-mix low-volume production, the social aspect of introducing a collaborative machine to an existing job is completely different. Current research is focused on the examination of the ethical and legal dimensions of collaborative systems. The main research questions are related to safety issues, while the ethical aspect is strongly related to the issues of working with robots [

6]. As mentioned above, legal issues are being addressed professionally with new standards and protocols for the use of collaborative machines and associated jobs. On ethical issues, however, we face research questions about the impact of the robots on humans, the ability to collaborate and the impact of the collaborative HRCW workplace on the performance and efficiency of the manufacturing system. The aspect of downsizing and the introduction of collaborative workplaces into bespoke manufacturing systems have thus become very important research issues.

3. Simulation Modeling

An analysis of the collaborative workplace impact on an existing manufacturing system in which the assembly operation is performed manually, with two workers in a single workplace, was performed using a simulation modeling approach. A comprehensive simulation modeling approach and simulation scenarios were used in order to evaluate the impact of collaborative workplaces on the sustainable viability of manufacturing. The simulation model captured the input data of a high-mix low-volume production type. The input data for the data-driven simulation model was provided by a smaller size company in the European Union.

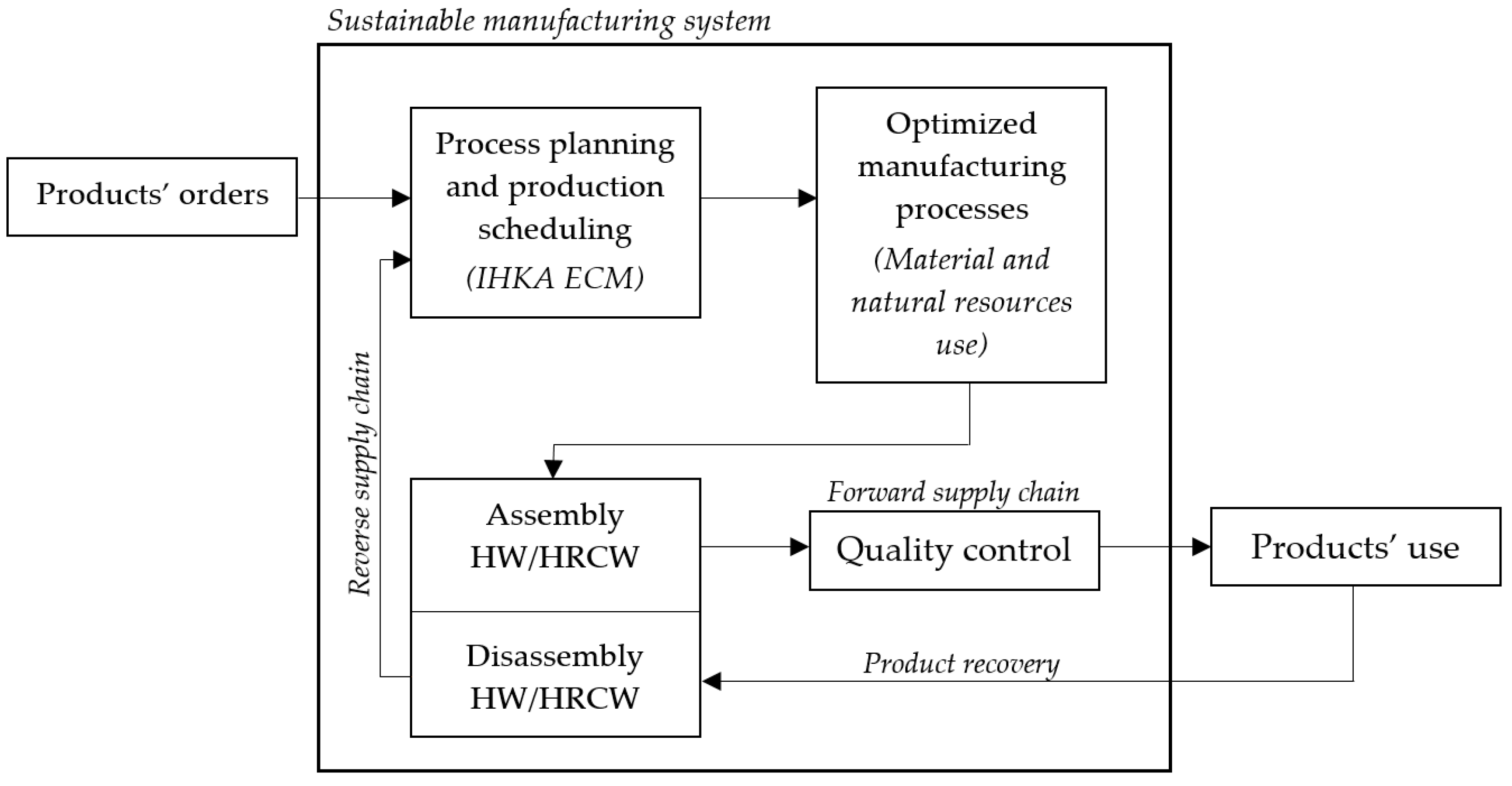

In order to fully address the research question,

Figure 4 represents the proposed block diagram of the problem under consideration from the viewpoint of providing a sustainably balanced manufacturing system.

The individual blocks represent the following characteristics:

The Product Orders block represents an input set of orders that summarizes the characteristics of high-mix low-volume production. Due to the wide range of capabilities, the proposed block diagram can be used for different types of manufacturing systems. In the present case, there are fifteen orders, with different numbers of operations and different ranges, and the ordered product pieces vary from ten to twenty. A high-mix low-volume set of orders represents a typical order by European SME customers who need highly personalized products.

In order to ensure Sustainable Manufacturing in the introductory phase, it is necessary to optimize the order of the execution sequence according to the appropriately allocated operations to the available machines. The sequence of orders and the assignment of machines in the present research work was performed using the Evolutionary Computation (EC) method Improved Heuristc Kalman Algorithm (IHKA) [

21]. The use of EC methods provides the ability to perform a multicriteria optimization of scheduling and order planning, while ensuring an evenly occupied production capacity, eliminating bottlenecks and shortening order flow times.

An appropriate sequence of work orders, according to the allocated machines and work processes, enables an optimized manufacturing system. The proposed block diagram deals with a sustainably justified manufacturing system from three previously described points of view. The production scheduling and process planning block presented in the previously presented block enable an optimally arranged cost-time investment and, thus, the financial sustainability of the company. In the optimized manufacturing system, we propose a sustainable orientation based on the proper use of natural resources and energy consumption.

The Assembly/Disassembly allows for the validation of the social dimension of Sustainable Manufacturing. In this data block, the simulation model addresses the effects of the collaborative workplace (HRCW) in comparison to the manual assembly of the Human Workplace (HW). The impact of a collaborative workplace is evaluated using the three key parameters: orders production costs, average orders flow time and electricity consumption of the workplaces.

The Quality Control block completes the forward supply chain, which provides the customer with quality sustainable products.

The presented block diagram, however, does not end at the delivery and physical use of orders by the customer (Product use block). In return, it enables Product recovery, which further justifies all three main aspects of sustainably justified manufacturing.

Product upgrade and reuse enable the Reverse supply chain, in which a pre-shipped order is returned to the manufacturing system after upgrading, updating or recycling to a new product.

The simulation modeling approach presented is based on the block structure presented above, which addresses the sustainable viability of the manufacturing system comprehensively. In order to obtain credible results, the simulation model is based on the use of real-world manufacturing system input data correlated to the applied research questions that are found in all types of manufacturing systems. The following is an introduction to real-world manufacturing system characteristics, followed by a presentation of a simulation scenario approach that addresses the impact of collaborative workplaces on the existing manual workplace manufacturing operation.

3.1. Flexible Job-Shop Manufacturing System

The simulation model covers the manufacturing process of highly flexible production. The characteristics of highly flexible high-mix low-volume production, which, with a high capacity to adapt to the customers’ needs, optimizes the production process, are defined mathematically as NP-hard [

22]. The simulation model covers eleven workplaces (

WP) inside the manufacturing process, with the first two

WPs representing the raw material cutting operation (

WP1 and

WP2), the next three

WPs representing the operations with multipurpose CNC machines (

WP3,

WP4 and

WP5), followed by two

WPs of manual welding operations (

WP6 and

WP7) and a milling machining site (

WP8). After the machining is completed, the operation of assembling the individual components manually into the finished product is performed in two

WPs (

WP9 and

WP10). Two workers work in both

WPs. The final control operation is represented by

WP11.

Table 1 shows a three-order example with a corresponding workplace sequence and the process time of each individual operation. The workplace sequence is performed using the IHKA EC method, which sequences job operations according to the suitability and availability of workplaces (FJSSP optimization problem).

Due to the increase in customer orders and the awareness of the bottleneck represented by manual assembly in

WP9 and

WP10, the company decided to carry out a study on the ability to extend manual assembly

WPs and the potential introduction of collaborative machines to the existing two final assembly workplaces.

Figure 5 represents a simulation model of an existing manufacturing system with two manual assembly workplaces employing four workers.

The simulation model takes into account the three-shift work from Monday to Friday and an eight-hour warm-up period. In a single shift, WP9 and WP10 workstations stop for 30 min, during which workers take a lunch break. In the event of interruptions in the workplace due to employee breaks, they are replaced by an on-call worker who ensures the smoothness of the process. The cleaning and calibration of the machines is carried out by the maintenance team in each shift for a period of 15 min, when the worker in the individual workplace is having a 30 min brake. Transport between workplaces is carried out by forklifts whose average speed is 2 m/s and is limited to a maximum speed of 2.2 m/s due to the presence of workers and combined transport routes.

With the help of the company and the available literature, we determined the input parameters of the simulation model shown in

Table 2. The values of usage and idle costs were determined using the proposed method of machine (workplaces) classifying according to investment costs [

20]. The Eurostat EU-28 gross hourly rate for 2018, amounting to 27.4 EUR [

23], was used to determine the usage costs and idle costs of the

WP9 and

WP10 composition. Considering the fact that two workers are employed in a single job by a manual workplace, this value is doubled. In the case of manual jobs, the values of jobs are the same when performing operations and when jobs are waiting for a new operation.

The real-world two-dimensional model of the company served as a reference for determining the

xloc and

yloc coordinates of the workplaces in the manufacturing system. The determination of the collaborative workplace’s impact on the manufacturing sustainability can be determined from the financial eligibility (values of usage cost and idle cost of individual workplaces). The determination of the environmental aspect is determined by the input data on the electricity consumption of each workplace, which is determined by the methods given in the literature [

17]. The method proposed in the literature allows for the allocation of electricity consumption according to the size of the machines, divided into three main groups of basic investment costs. The power consumption of

WP9 and

WP10 was determined by the power supply value of the workplace assembly, which covers the illumination and power consumption of the power tool.

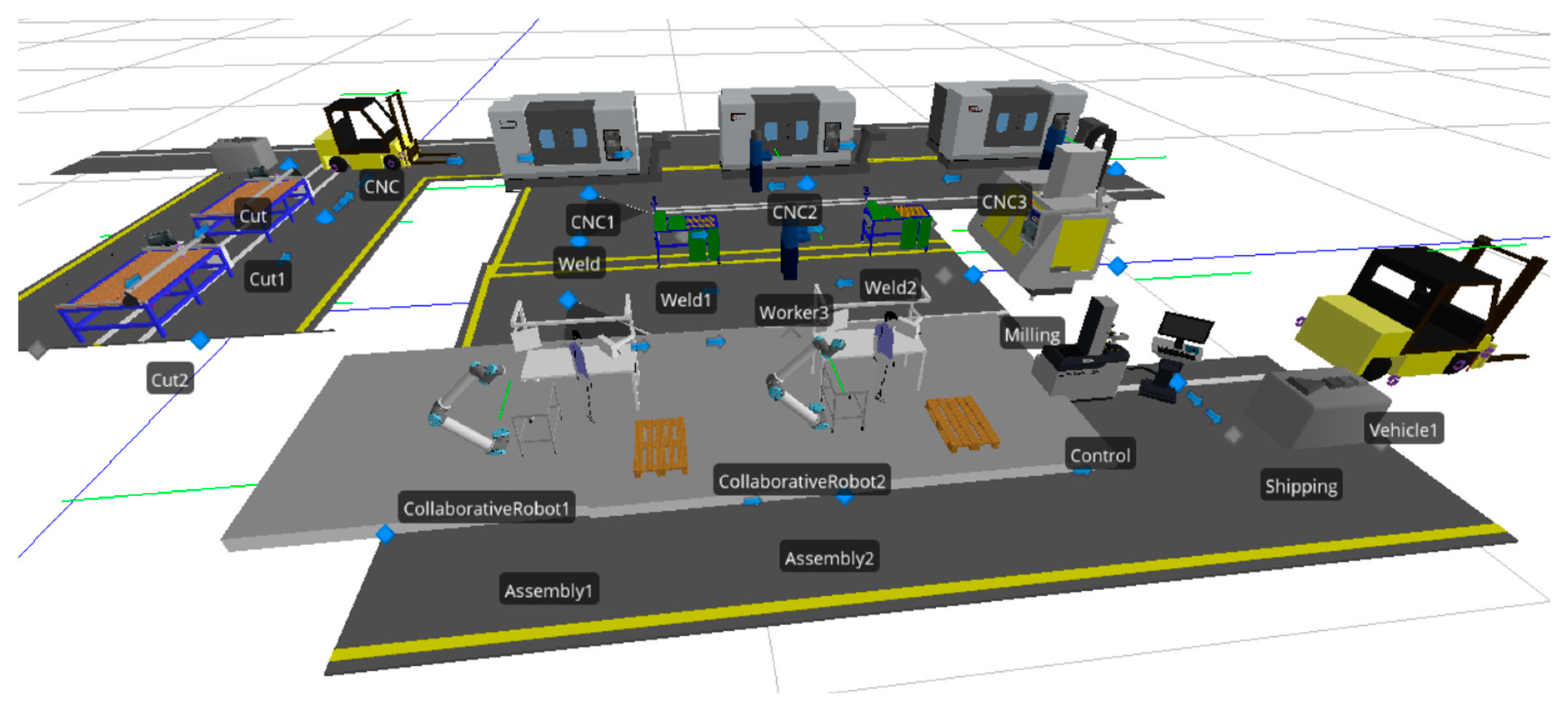

3.2. Collaborative Assembly Workplace Modeling

The increase in procurement by contracting authorities necessitated the extension of jobs in the final assembly, with the problem of recruiting skilled workers for manual jobs. Using the simulation model, the impact study and the assessment of the feasibility of introducing collaborative workplaces into the existing flexible job-shop production system were carried out. We installed a collaborative robot capable of performing previously known assembly operations at the previously presented

WP9 and

WP10 manual assembly jobs. A collaborative workplace called HRCW has 29.7% shorter processing times, according to a recalculation of the new assembly process times, than a workplace with two workers assembling manually. The introduction of collaborative workplaces ensures rapid custom production flexibility and eliminates manual assembly bottlenecks. The simulation model focuses on evaluating the impact of the collaborative workplace on the financial, environmental and social aspects of manufacturing. The manufacturing process is carried out in three shifts from Monday to Friday. In a single shift, workers have one 30-min lunch break. Human supervision of the manufacturing process is required. In the presented simulation model, collaborative robots require periodic maintenance service and inspection, which are terminologically implemented according to the manufacturer’s recommendations. The simulation model with the collaborative workplaces

WP9 and

WP10 is shown in

Figure 6.

Unlike the simulation model of the previously presented production system, the proposed impact of collaborative workplaces changes the financial values of operation usage and idle times for individual operations. The usage cost for

WP9 and

WP10 thus consists of the cost of one worker and the usage cost of the collaborative robot. According to the investment cost mentioned in the literature [

20], the UR3e collaborative robot is placed in the first group, with a usage cost of 30 EUR/h and an idle cost of 12 EUR/h. The total cost of a collaborative workplace with one employee earning 27.4 EUR/h amounts, therefore, to 57.4 EUR/h during operation and 39.4 EUR/h while waiting to execute the next operation. The positioning of workplaces in the manufacturing process with respect to the

xloc and

yloc coordinates remains unchanged. From the standpoint of additional costs, the introduction of collaborative robots into the existing manufacturing process is more favorable and easier than the introduction of industrial robots. Collaborative robots do not need a guardrail, they already have security sensor technology built in, and their management is quickly understandable, given the various possibilities of structured and graphical programming.

Table 3 shows the input data of the production process simulation model with collaborative workplaces related to changes in the electrical energy consumption of the

WP9 and

WP10 workplaces. Due to the added collaborative robot, classified in the first group according to investment costs [

20], the value of HRCW electricity consumption is the sum of 4 kWh of the collaborative robot in usage mode. In idle mode, this value is 0.5 kWh and half of the power of the previously presented workstation by manual assembly (0.5 kWh at usage time and 0.1 kWh at idle time). The total consumption of the collaborative workplace is, thus, 4.5 kWh when performing the operation and 0.7 kWh while waiting for the next operation.

4. Simulation Modeling Results

Simulation models involving manual assembly (Human Workplaces, HW) and the newly proposed collaborative workplaces (HRCW) have been evaluated using the simulation scenario approach. The reference simulation scenario used was a simulation model with workplaces

WP9 and

WP10, where the assembly of products is performed manually by four workers in two workplaces. A simulation model with two collaborative workplaces was proposed as a comparative simulation scenario, where one of the two workers on a single workplace was replaced by a collaborative robot. The numerical results in

Table 4 are the average values of twenty replicates of the simulation model in order to obtain credible results. Implementing a simulation model in multiple interactions and determining average values, in order to obtain credible results, is important from the standpoint of randomly determined values within the simulation model. These values relate to the implementation of the IHKA [

23] optimization algorithm, which, in the initial phase of the simulation model, determines the individual operations of orders into the available machines by the interactive method proposed in the literature [

14]. Functional dependencies are also used to determine the relationship between the investment cost of operation and the idle values [

20].

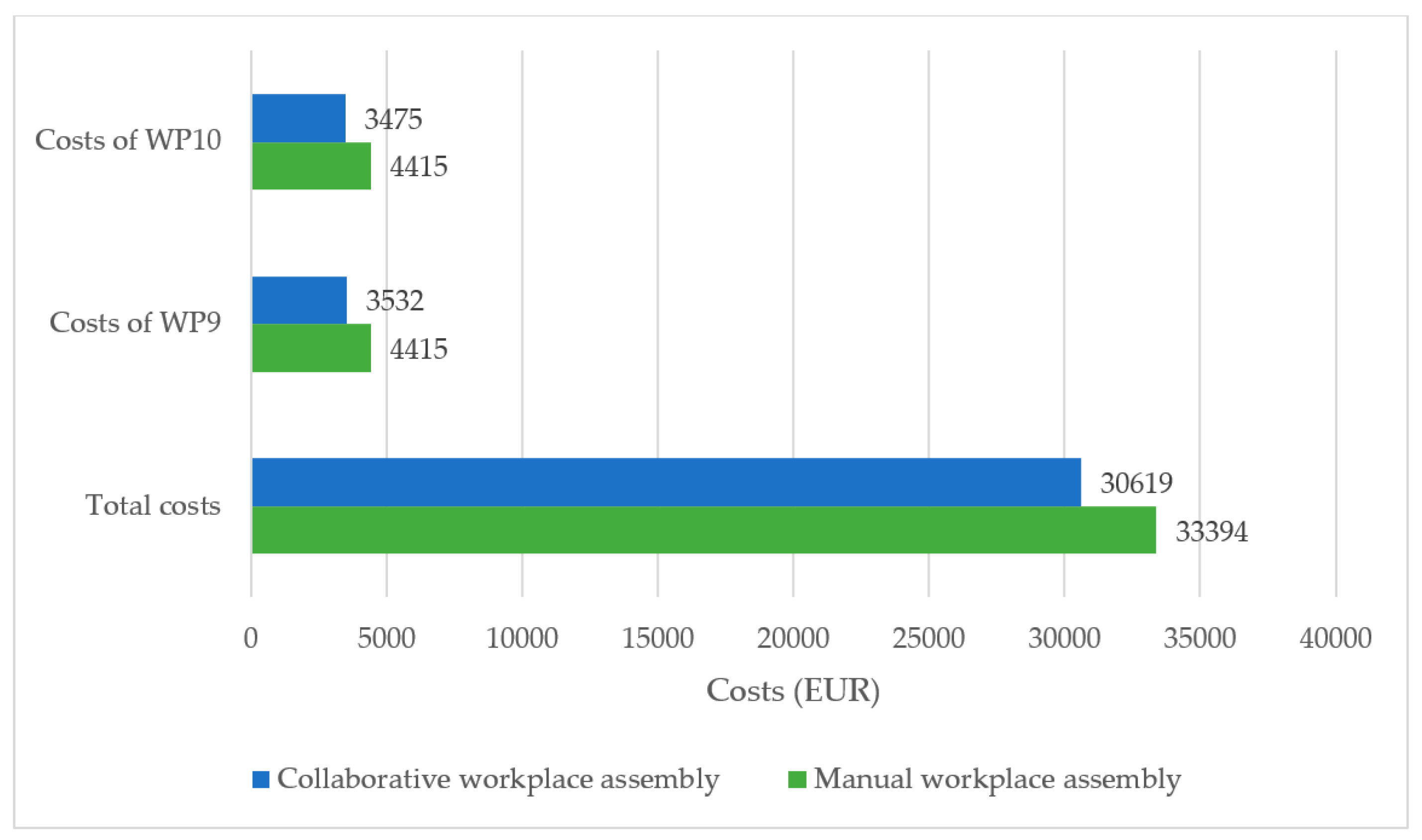

The evaluation of the production parameters was carried out using a data set that included fifteen orders, with a total of eighty-eight operations. The simulation time was determined by the production run in three shifts, from Monday to Friday, with an eight-hour warm-up period. The total cost of fifteen orders indicates that, in the case of HW jobs, the total cost of production is 8.3% higher than that obtained with the proposed introduction of collaborative HRCW workplaces, as the total amount of 33,394 EUR is 2775 EUR higher than for the two collaborative workplaces. The total cost is related to the cost of all orders in the manufacturing process. A properly optimized sequence of operations and uniformly high occupancy of the machines performed with the IHKA EC method yields plausible numerical results, since the parameters depend only on changes in the WP9 and WP10 workplaces, where the input parameters vary by workplace type—HW or HRCW.

A more detailed evaluation of the WP9 and WP10 jobs, which in the reference simulation scenario represented two manual assembly workplaces and a bottleneck in the production system, shows that the cost of collaborative workplace WP9 is 20% lower than that of the equivalent manual assembly workplace. The total cost of the manual WP9 workplace for fifteen orders is 4415 EUR, which is 883 EUR more than a collaborative workplace with a production cost of 3532 EUR. The numerical results of costs of the two manual workplaces, WP9 and WP10, confirm that they represent a bottleneck in the production process, since both are fully occupied at the time of procurement, confirming the equivalent amounts of the total cost of the two workplaces. Compared to the evaluation of the WP9 post, the difference between the MW and HRCW costs increased in the WP10 workplace. The collaborative WP10 workplace is 21.3% less expensive than the manual assembly workplace. The price of the workplace decreased from 4415 EUR at MW to 3475 EUR at HRCW. We attribute the differentiation of the operating costs of the WP9 and WP10 workplaces at HRCW to the vacant capacities that the collaborative workplaces still offer in this case. In this case, these two workplaces do not represent a bottleneck in the manufacturing system.

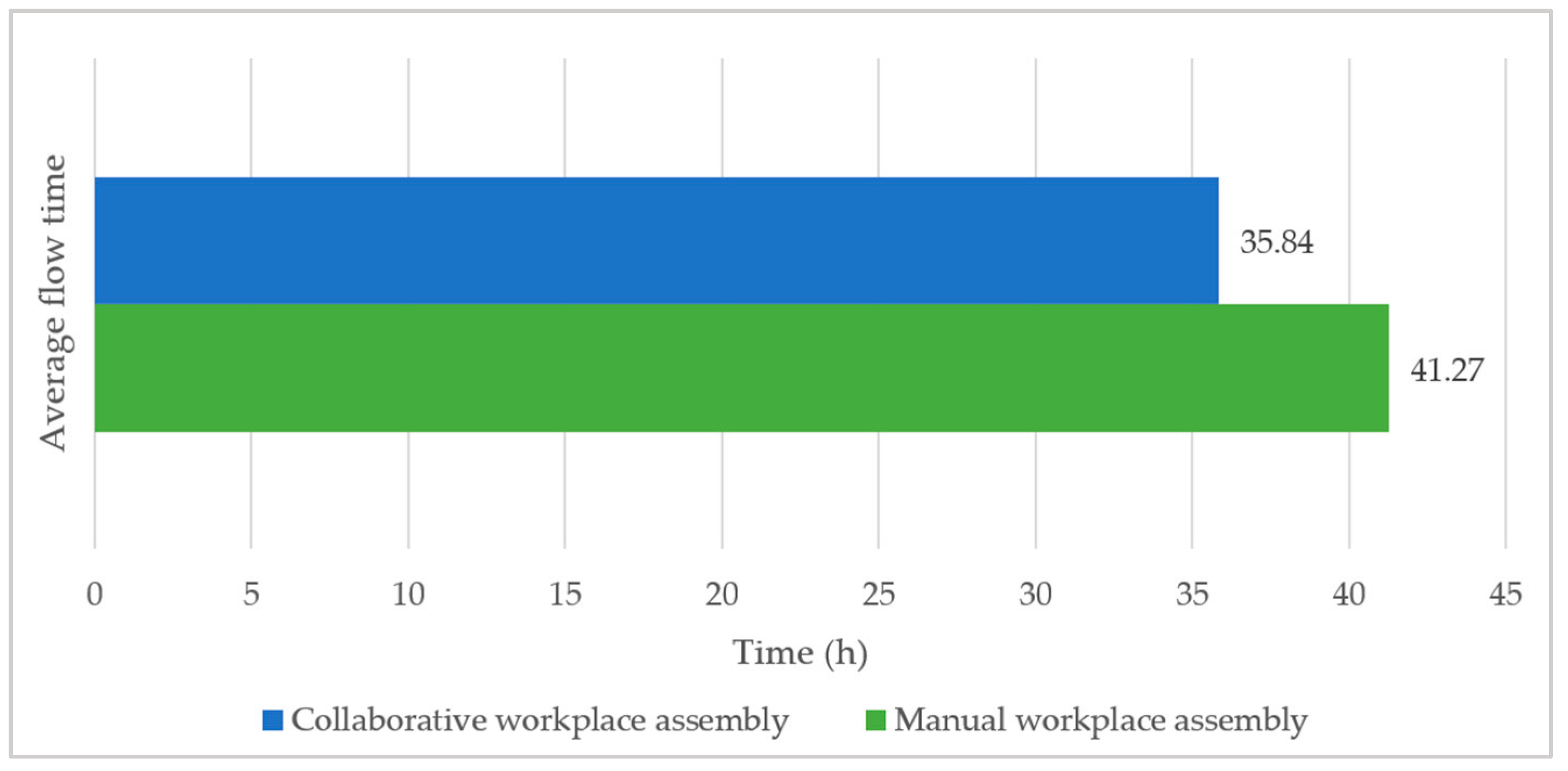

Due to the reduced processing time of workplaces WP9 and WP10, with the introduction of collaborative workplaces, the overall average flow time of fifteen orders is reduced by 13.2%. The order flow time for HW is 41.27 h, while for HRCW implementation it is 5.43 h less, which is 35.84 h. Reducing order flow time allows additional production capacity that can execute additional orders without additional upgrades to the manufacturing system.

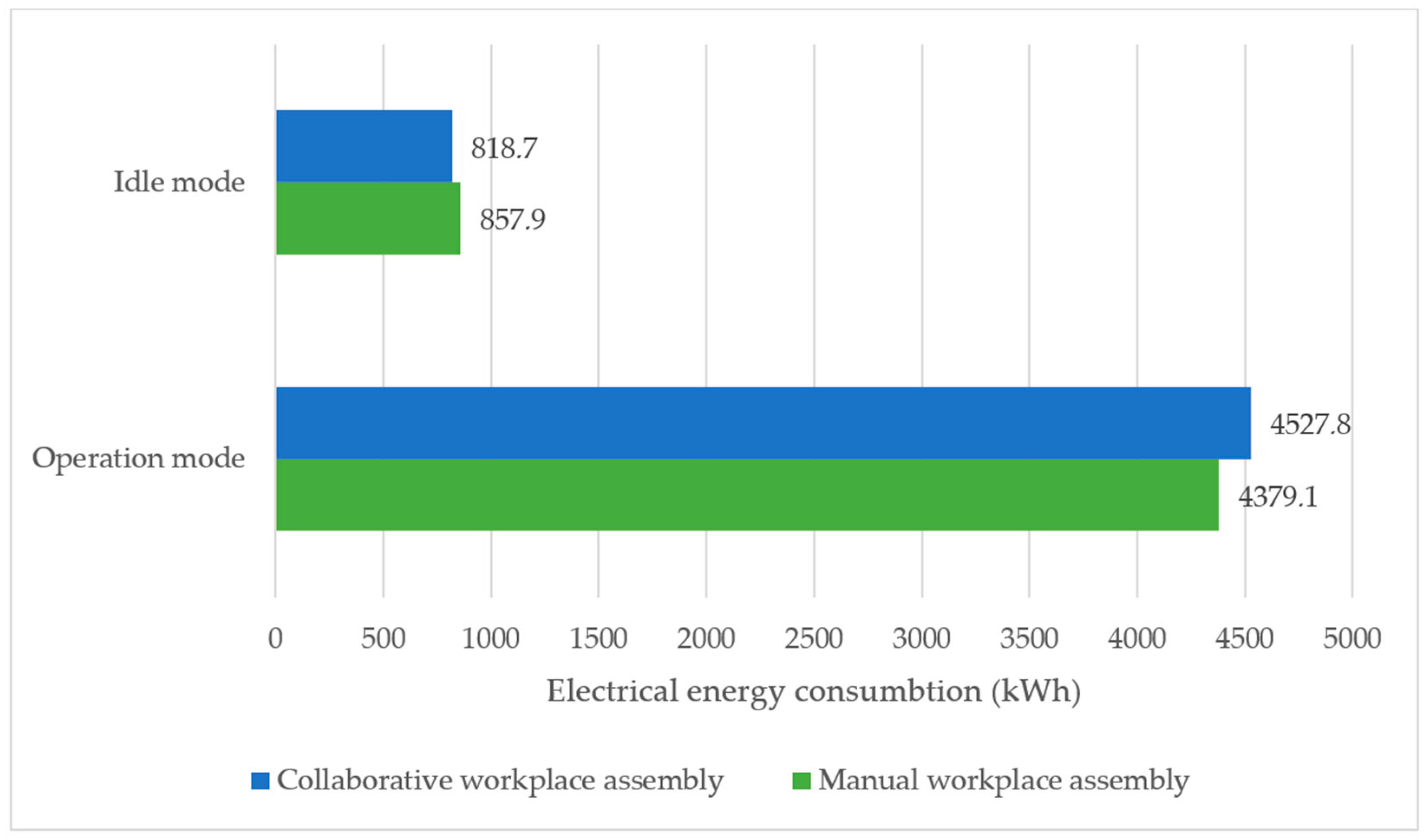

When evaluating electrical energy consumption, we find that HRCW electricity consumption increases from 4379.1 kWh to 4527.8 kWh, which is a 3.28% increase in electrical energy consumption. The increase in electrical energy consumption is reflected in the total electricity consumption of the HRCW workplace, which is 4.5 kWh during operation, compared to the 1 kWh electricity consumption in the HW workplace. The increase in electricity consumption of 3.28% is almost negligible, considering the basic difference in electricity consumption of individual workplaces, where there is a 450% increase at HRCW compared to HW. The negligible increase in the electricity consumption of the HRCW workplace is attributed to the shorter processing times of the HRCW workplace and the elimination of bottlenecks in the production system. The last row in

Table 4 represents electricity consumption while waiting for operations to be performed. Given that, in the case of HRCW, the system is balanced from an occupancy standpoint, and no bottlenecks occur in the manufacturing system, consequently, the workplaces (machines) wait less to perform the following operations. Total idle power consumption decreases from 857.9 kWh to 818.7 kWh, representing a 4.57% reduction in idle time when executing fifteen orders.

The numerical results in

Table 4 are represented graphically in

Figure 7,

Figure 8 and

Figure 9.

Figure 7 shows the total cost of operating workplaces. Dark blue represents an HRCW workplace and the green color represents a manual workplace (HW). When evaluating the total cost of workplaces, we find that the introduction of collaborative workplaces in highly flexible manufacturing is justified. The financial sustainability aspect is confirmed by an adequate cost-time investment, which is smaller in the HRCW workplace than in the HW workplace.

The corresponding financial investment value is confirmed by the lower operating values of the workplace, and the total shorter flow time confirms the shorter and more relevant investment of the collaborative workplace shown in

Figure 8.

The previously presented and evaluated numerical results of electrical energy consumption, which focus on evaluating the impact of a collaborative workplace on the environmental aspect of sustainable production, are shown graphically in

Figure 9. Proper production optimization with short flow times and the equally high utilization of workplaces with short waiting times allow for the efficient use of natural resources and energy. The differences between HW and HRCW collaborative workplaces are directly proportional to the shorter flow times and reduced idle times for operations. The proper scheduling of orders and individual operations in a manufacturing system with collaborative workplaces shortens the waiting times and prolongs the periods of active processing of operations.

Table 5 presents the numerical results of a simulation model that addresses the three-shift production of one month, from Monday to Friday. It covers twenty-one working days and takes into account an eight-hour warm-up period. The numerical results in the first row of

Table 5 show the production capacity in terms of the number of completed orders. For manual assembly workplaces, production capacities enable the completion of 165 orders, while the introduction of collaborative workplaces increases the value of completed orders by 18.2% and enables the completion of 195 orders in one month. Increasing production capacity through the introduction of HRCW workplaces enables a greater competitiveness of the company in the global market and shorter delivery times for individual orders, as evidenced by the numerical results discussed previously. By increasing the number of completed orders, the cost of producing an individual order is reduced. Reducing the cost of an individual order for high-mix low-volume production is crucial, as it is precisely the flexibility of this type of production that increases the costs of the orders considerably. Reducing the cost of the monthly production of these orders in the introduction of HRCW workplaces, depending on the individual order, saves 8.3%. The cost of manual assembly at two HW workplaces is 2226.3 EUR per order, compared to 2041.3 EUR when using collaborative HRCW workplaces. The numerical results of the simulation model of one-month three-shift production proves that introducing collaborative workplaces in highly flexible manufacturing processes enables the reduction of the negative financial, environmental and social impacts of these manufacturing types.

5. Conclusions

The presented research work represents a comprehensive simulation modeling approach in order to evaluate the impact of collaborative workplaces on the sustainable viability of manufacturing. The research focuses on the importance of examining the impact of collaborative workplaces on three key aspects of Sustainable Manufacturing (financial, environmental and social aspects). The introduction of collaborative workplaces has been increasingly present in the last decade in order to achieve more favorable cost-time investments and, thus, increase companies’ global competitiveness.

In our research work, we focused on the presentation of key theoretical and practical scientific state-of-the-art contributions. A state-of-the-art comprehensive simulation modeling approach enables the evaluation of the impact of collaborative workplaces on the sustainable viability of manufacturing systems. Initially, a new graph on the introduction of HRC workplaces is given, with a view to new production opportunities offered by implementing collaborative machines. Given the interdisciplinary nature of the research question, a new concept is introduced by linking the positive attributes of job-shop production with the positive properties of mass production. The individual advantages and limitations are outlined in terms of production systems opportunities that can be combined by introducing collaborative workplaces.

A sustainably justified manufacturing system is presented through a diagram as an interdisciplinary research problem, which, according to the simulation study, is divided into the three key aspects examined in the present research work. The three key aspects of sustainable production are addressed by parameters that represent the manufacturing system’s workplace cost, the consumption of electricity and the corresponding flow times in the context of high occupancy. Given that the manuscript examines the impact of collaborative workplaces on the sustainable viability of the manufacturing system, a description of the research problem and the classification of collaborative workplaces according to the four-level classification is offered at the beginning. The presentation of the scientific problem provides parallels between collaborative machines and their impact on the sustainable viability of production, which has not yet been explored in detail. As a suitable evaluation method, we propose the use of a simulation modeling approach and a simulation scenario approach that can evaluate the impact of collaborative workplaces on the sustainable viability of production. A new, state-of-the-art block diagram is given to evaluate the introduction of collaborative workplaces into an existing or newly proposed sustainable manufacturing system. The block diagram provides a comprehensive overview of the research problem and how to efficiently evaluate the impact of collaborative workplaces on the sustainable viability of the manufacturing system as a whole. The theoretically presented scientific contributions are supported by practical experiments of the previously presented research question. Two simulation scenarios have been constructed with the help of real-world manufacturing system input data and Eurostat statistics [

20,

21], which allow for the evaluation of manual and collaborative workplaces. The main scientific contribution of the proposed simulation modeling approach is its high adaptability and the wider applicability of the proposed scientific methods. The main practical findings on the impact of collaborative workplaces on sustainable eligibility relate to the parameters of workplace costs, order flow times and workplace electrical energy consumption. In order to ensure the credibility of the numerical results, a simulation study of the manufacturing system operation in a one-month three-shift cycle. The main results were related to the utilization parameters of the manufacturing system and the production capacity as well as to the reduction of order costs due to the high flexibility of the manufacturing system. The importance of the state-of-the-art contribution of the present work is reflected in the comprehensive consideration of the impact of the introduction of collaborative workplaces into an existing or newly proposed manufacturing system, following the guidelines of Sustainable Manufacturing. The present research work has certain limitations, related to the treatment of the SMEs’ manufacturing system types, which are of key importance for the European and global economies, and the proposed methods need to be adapted to other types of manufacturing systems. The research presented here is limited in that only certain parameters of sustainable manufacturing are taken into account. The paper focuses on parameters that describe the impact of the process and techniques on sustainable production and does not address the sustainable suitability of the products or orders. According to the literature [

24], most of the current research is focused on the product life-cycle and the assessment of sustainable manufacturing, so it is worthwhile exploring this perspective in the future. It should also be emphasized that the work presented here focuses on assessing the sustainable viability of the production system from a financial and environmental perspective. For these two aspects, the research work focuses on the study of the impact of workplace costs and electrical energy consumption when a community workplace is introduced in correlation with a manual (human) workplace. The research presented is not as concerned with the social impact of the introduction of a community workplace. In this respect, the research focuses primarily on securing a sufficient number of jobs (from a worker’s point of view), but further research should consider the study of the social impacts in relation to consumers, the local community and the global society. Given the research on social impacts presented in the literature [

25] and the importance of studying the social impact coefficient, which has not yet been studied in connection with the introduction of collaborative workplaces in manufacturing systems, this area allows for a further comprehensive consideration of this issue. Of particular importance is the assessment of the social impact on productivity and manufacturing performance. The high degree of credibility of the numerical and graphical results obtained and the new methods presented address the research problem as comprehensively as any published research work to date. Compared to other studies, dealing with the scientific problem in specific parts and considering only the influence of individual parameters on the sustainable viability of production, the present work is unique. Some researchers have studied the impact of the use of renewable energy sources and the reduction of CO2 emissions, not focusing on the introduction of new technologies into the existing manufacturing system, but using simulation modeling and Monte-Carlo methods to model only predictive algorithms [

25]. In doing so, they did not come up with solutions to evaluate impacts on sustainably justified production systems comprehensively, focusing only on an individual set. The existing literature also offers innovative models for evaluating the order life-cycle in a sustainably justifiable manufacturing system [

26]. In these cases, the authors provide general recommendations and an architectural model for how to evaluate the order life-cycle without observing how such a cycle affects the characteristics of the manufacturing system as a whole. Our research work also evaluates the impact of collaborative workplaces from a social point of view. However, unlike the researchers in the literature [

27] who discuss the social aspects of sustainable manufacturing, we do not link these aspects to collaborative workplaces, which, in the absence of an adequate workforce, make the impact of less demanding jobs more significant.

The introduction of collaborative workplaces presented here makes it possible to ensure the management of collaborative human-robot operations adequately, while addressing all key aspects of Sustainable Manufacturing.

According to the graph presented in

Figure 1, presenting production opportunities when introducing collaborative workplaces, the present simulation modeling approach demonstrates the feasibility of introducing collaborative workplaces and, thus, the ability to combine the positive characteristics of different product types into a more efficient and sustainable manufacturing system.

Future research plans: in order to extend the scientific work and to overcome the limitations in this field, the application of the present simulation modeling approach to other types of manufacturing systems and the holistic assessment of sustainable manufacturing, especially from a social point of view, will be pursued, as collaborative workplaces can occur in all types of manufacturing systems. An appropriate holistic assessment will enable sustainable viability and efficient time-cost investments for enterprises, taking into account workers, consumers, the local community and the global society. An appropriate evaluation of collaborative workplaces requires additional research to study the feasibility of their implementation and the direct impact of the collaborative machine on humans (a study of the social and emotional aspects), with the aim of achieving a fully balanced manufacturing system with an overall high efficiency.