Abstract

The efficient vehicle procurement is an important business segment of different companies with their own vehicle fleet. It has a significant influence on reducing transport and maintenance costs and on increasing the fleet’s energy efficiency. It is indispensable that managers consider various criteria from several aspects when procuring a vehicle. In that sense, we defined 13 relevant criteria and divided them into four multidisciplinary aspects: Construction-technical, financial, operational, and environmental. Decision-Making Trial and Evaluation Laboratory-Based Analytic Network Process (DANP) method was applied to evaluate the significance of defined criteria and aspects and their interdependency. It is established that the three most important criteria for vehicle procurement are vehicle price, vehicle maintenance, and vehicle selling price. The most important aspect is construction technical aspect, while the aspect of the environment is the least important. The Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) method was used to rank eight different vehicles, which were considered by vehicle fleet manager at the observed company. This model assists fleet managers in the selection of the most suitable vehicle for procurement, while significantly reducing decision-making time and simultaneously observing all necessary criteria and their weights. Moreover, we have considered 10 different scenarios to establish whether and how the rank of the observed alternatives would change.

1. Introduction

The vehicle procurement represents one of the significant activities of the fleet managers [1]. Transport and logistics companies often have a heterogeneous vehicle fleet, composed of different vehicle types and different construction-operation characteristics [2]. One of the main goals of the observed companies is to reduce transport and maintenance costs, as well as to increase the fleet’s energy efficiency in order to increase profit [3]. This paper analyzes the road vehicles procurement as one of the factors which contribute to the achievement of the defined goal. Besides choosing the right vehicle type during the procurement, an additional potential for achieving the defined goal is to choose the appropriate vehicle model within the selected type. However, the problem is that the managers during vehicle procurement often observe only certain criteria of certain aspects that they consider important, while other criteria and aspects that they insufficiently know about are neglected and considered insignificant. An additional problem is that managers evaluate the importance of observed criteria according to their (subjective) perceptions. All of the above leads to higher transport and maintenance costs and lower fleet’s energy efficiency, and thereby, to lower profit.

Vehicle procurement has been often covered in the literature as part of solving the fleet renewal or fleet replacement problem [4,5,6]. Some authors propose various models of integer programming to achieve efficient road vehicle fleet renewal or replacement [7,8,9]. Although the authors observed many different criteria, there is a lack of criteria that indirectly have an impact on transport and maintenance costs and energy efficiency. Moreover, the interdependent influences between criteria are not taken into account even though they exist in managers’ decision-making during the vehicle procurement process. The task of fleet renewal consists of defining the number and type of vehicles that are added to the fleet by procurement or that are removed from the fleet by selling [10], but there are only a few papers that deal with the decision which type and model of vehicle to procure. This is especially important for road vehicles since there are many different models of the same vehicle type (e.g., various models of van with gross vehicle weight up to 3.5 t) where each model has different characteristics which have an impact on transport and maintenance costs and energy efficiency. Besides that, although it gives good results, the integer programming is not commonly used by vehicle fleet managers, and it is not how they make a decision during the road vehicle procurement process. Considering the above-mentioned, the observed problem belongs to the Multi-Criteria Decision Making (MCDM).

In order to determine criteria weights, we used the Decision-Making Trial and Evaluation Laboratory-Based Analytic Network Process (DANP) method because the interdependent effects of the vehicle procurement criteria are non-reciprocal values. DANP method calculates non-weighted supermatrices by applying pairwise comparisons to the total impact matrix within the whole system, which better describes the real system [11]. The integration of the Decision-Making Trial and Evaluation Laboratory (DEMATEL) and Analytic Network Process (ANP) method is still widely used for solving different problems. The authors of [12] used integration of these two methods to establish the relationship between six important performance criteria and eighteen key performance indicators that describe the performance measurement system of any food supply chain, as well as to determine their ranking. Gudiel Pineda et al. [13] used the DANP method to obtain relative weights of the criteria important to evaluate the financial and operational performance of airlines. Hsu et al. [14], in their paper, observe multiple criteria regarding the quality of service for bike-sharing systems, as well as the relationships between them in order to better reflect the real-world situation and thus they used DANP method to determine the observed criteria relative weights. The authors of [15] have researched the inhibitors in the intermodal freight transport system, and they used grey-DEMATEL and ANP (gDANP) method to establish relationships between these inhibitors, as well as their relative weights. DANP method was used in [16] in order to determine relative weights and interdependency of 11 criteria from four clusters with an aim to support vehicle fleet managers in decision making on the selection of vehicle service centers. After that, we used the well-known Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) method to rank the observed vehicles. This method is one of the best in addressing the rank reversal problem [17]. The TOPSIS method as MCDM method was applied in [18], where authors used this method to integrate environmental, economic, and social dimensions in order to assess the sustainability of battery electric vehicles and to compare it with the sustainability of internal combustion engine vehicles. TOPSIS method was used in [19] for problem-solving in urban public transportation by ranking observed alternatives (electric buses) and evaluating them through seven different criteria. Additionally it was used in the selection of Brazilian furniture industry suppliers [20], an egg supplier for a Thai restaurant [21], evaluation of different fuel characteristics [22], vehicle manufacturer evaluation [23], performance evaluation of seven Indian industries based on financial ratio analysis taking into account 15 criteria [24], selection of the best railroad container terminal location out of 11 potentional ones observing seven different criteria [25], etc.

We are not aware of a model that selects the most suitable road vehicle while taking into account construction-technical, financial, operational, and environmental aspects of road vehicle, simultaneously from three points of view: Transport costs, maintenance costs, and energy efficiency. Thus, the main contribution of this paper is such a developed model for efficient vehicle procurement. This model is easily understandable for vehicle fleet managers since it describes better their perception in case there are multiple interdependent criteria. It significantly reduces decision making time, observing all necessary criteria and their weights. The aim of the model is to increase companies’ profit through a comprehensive and multidisciplinary approach. Additionally, we have conducted a literature review and engaged 50 experts to define relevant criteria for road vehicle procurement and their relative weights. Finally, this model is applicable for the selection of alternative fuel vehicles (AFVs) as well as for conventional (diesel) vehicles.

The paper is structured as follows. Section 2 comprises a literature review with the aim of defining the relevant vehicle procurement criteria. The developed model methodology is presented step-by-step in Section 3. The model implementation, obtained results, and discussion are presented in Section 4 and Section 5, while the conclusions are given in Section 6.

2. Vehicle Procurement Criteria

In this chapter, a literature review was conducted to identify significant aspects and criteria for vehicle procurement within the developed model that have a direct and indirect impact on transport and maintenance costs and fleet’s energy efficiency.

Many authors, while researching efficient fleet renewal/replacement, consider criteria such as the existence of new vehicle technologies, which includes vehicle equipment regarding safety and technical systems [26]. The same author points out the vehicle comfort and vehicle technical condition (age) as relevant criteria in order to increase the competitiveness of companies in the market. The older vehicles contribute to increased transport and maintenance costs [27], as well as to increased environmental costs [2]. The vehicle technical condition concerning the vehicle mileage is important in the calculation of the expected costs [6]. In order to increase a vehicle’s energy efficiency and reduce CO2 emission, vehicle manufacturers endeavor to reduce engine capacity [28,29]. It is established that the homogeneous fleet in air traffic has an influence on reducing transport and maintenance costs, pilots and technicians training costs, spare parts stock costs, and other costs [30]. Since this can be applied for road vehicles, the criterion compatibility with the existing vehicle fleet is also significant for our model. Vehicle price is considered in solving strategic fleet renewal in shipping and depends on the size, age and vessel technical condition [27]. This criterion is also used to calculate the life cycle costs of vehicles in [18]. For example, the electric commercial vehicles (ECVs) have approximately three times higher procurement costs in relation to conventional vehicles, and because of that, the fleet managers should not plan ECV procurement if the vehicle life cycle is shorter than 12 years [8]. Thus, government subsidies as a form of financing options when buying a vehicle are necessary for the electric vehicles to become more competitive [7]. The national and local financial subsidies were observed in taken into account in [18]. The criterion financing options when buying a vehicle in the form of vehicle leasing was taken into consideration in the developed model for fleet renewal with the aim to minimize AFVs’ expected and risk costs [9]. The discounted value of vehicle price, also as a form of financing options, should be contained within economic factors in the model for fleet replacement [8]. As the vehicle ages and its’ technical condition degrades, vehicle selling price decreases as well, while transport and maintenance costs tend to increase [31]. One of the factors that influence transport (operating) costs is fuel/energy consumption [18]. Fuel/energy consumption is the key parameter in stochastic processes because it depends on vehicle operation conditions and drivers’ skills [6]. With a decrease in fuel efficiency with diesel-fueled commercial vehicles, ECVs become much more competitive [8]. The fuel (energy) costs are about 62% lower for electric vans, about 37% lower for compressed natural gas (CNG) vans, and about 2% higher for biodiesel B30 vans, compared to diesel vans [32]. Some vehicle manufacturers and distributors, with a longer period of vehicle maintenance at their service centers, provide certain discounts on vehicle price [33]. In this way, fleet managers obtain lower initial vehicle procurement costs, but the overall maintenance costs are higher (due to the contracted extended maintenance in authorized service centers). While considering the AFVs, it is important to take into account the preventive maintenance costs since the electric vehicles have lower maintenance costs than conventional [8]. The maintenance costs are about 30% lower for electric vans and about 11% higher for biodiesel B30 and CNG vans compared to diesel vans [32]. This criterion is also observed in [18] for comparing battery electric vehicles and internal combustion engine vehicles. Besides all, legislation requirements, competition, and clients themselves play a remarkable role when procuring vehicles [33]. In that sense, in order to be in compliance with legislation requirements and to conduct efficient vehicle procurement, it is necessary to consider vehicle’s CO2 emissions. The CO2 emissions depend directly on the vehicle age and weight, so older or heavier vehicles emit more CO2 than newer or lighter vehicles [34]. The AFVs, such as electric vehicles, can significantly reduce harmful gas emissions, but only if electricity is generated from renewable energy sources [35]. CO2 emission is 50%-70% lower for electric vans, 28% lower for biodiesel B30, and about 5% lower for CNG vans compared to diesel vans [32]. The vehicle dimensions and weight sometimes represent a limitation for vehicle access to the transportation network, especially in dense urban environments [2]. In this sense, it is also necessary to take into account the criterion of vehicle’s compliance with the road-traffic infrastructure requirements on the transport network. This criterion can be quantified and measured through the vehicle turning diameter, which is of great importance in urban areas where diameters of road curves are smaller, and traffic lanes’ width is usually narrower. A potential to increase the fleet’s energy efficiency is much greater if managers optimize vehicle utilization and choose the right size and type of vehicle according to transport operations [36]. In that sense, we will observe vehicle’s compliance with the customers’ transport requirements as a criterion in our model.

Based on the literature review and authors’ own experience, we defined 13 relevant criteria and divided them into the four multidisciplinary aspects: Construction-technical, financial, operational, and environment (Table 1).

Table 1.

Preview of relevant criteria and aspects related to vehicle procurement.

3. Building an Evaluation Model for Vehicle Procurement

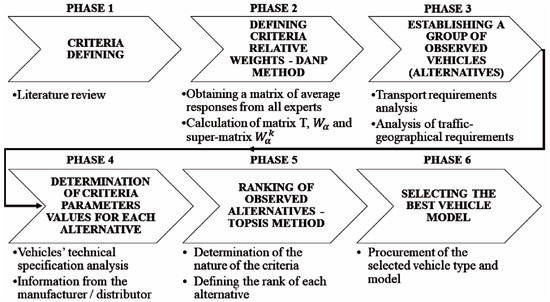

The procedure of the developed model for efficient vehicle procurement is shown in Figure 1. There are six phases that are described in the following subchapters.

Figure 1.

The procedure of the Multi-Criteria Decision Making (MCDM) model for efficient vehicle procurement.

3.1. Defining Criteria Relative Weights with DANP Method

DANP was used to determine the intensity of relevant criteria interdependencies, as well as to calculate the criteria significance to attaining the main goal of the observed companies. DANP shows the criteria interdependent effects as non-reciprocal values and calculates non-weighted supermatrices by applying pairwise comparisons (comparison of impact pairs) to the total impact matrix within the whole system, which better describes the real system [11]. The basic steps of DANP are [11]:

Step 1: Defining criteria (factors) and aspects (dimensions). In order to define the relevant criteria and aspects, it is necessary to conduct a scientific literature review in the considered area and conduct a survey.

Step 2: Calculation of direct-relation matrix-B. Matrix B represents the matrix of average responses of all H experts as follows:

where represents the answers of the expert k on the interaction of the ith and jth factors in the form of integer non-negative numbers within the n × n rank matrix.

Step 3: Calculation of normalized direct-relation matrix-X. Matrix X is calculated as follows:

where g is the normalization factor which is calculated as follows:

Step 4: Determining the total impact matrix-T. In order to determine the total impact matrix T, it is used the identity matrix I of rank n × n, as follows:

Step 5: Adjusting a threshold value-q. According to expert opinion, the threshold value q can be adjusted in order to disregard the criteria relationships with small impacts in the matrix T.

Step 6: Calculating the criteria influence and making the Influence Relation Map–IRM. On the basis of adopted threshold value q, the row and column sum values of the matrix T are calculated as follows

where a row sum values r indicates the overall influence of a given criterion on other criteria, and a column sum values s indicates the overall influence of other criteria on a given criterion. A sign ′ indicates a transposed matrix. The expression (r + s) shows the importance of criteria and aspects. The expression (r − s) sorts the criteria and aspects into cause and receive groups. With positive (r − s) value, a criterion (or aspect) is into the cause group. Otherwise, criterion (or cluster) is into the receive group.

Step 7: Obtaining the unweighted super-matrix-W. For this purpose, the total impact matrix-T is used. The matrix T actually represents the total impact matrix for criteria-. The normalized total impact matrix for criteria is calculated, according to Expression (6):

where Dm indicates the mth aspect and marks the nth criterion in the mth aspect. The matrix shows the normalized sub-matrix of the matrix with criteria impacts in the aspect D1.

The super-matrix W is calculated, as shown in Expression (7):

where indicates a transposition of the sub-matrix in the normalized total impact matrix for criteria , while I = 1,2,…m; j = 1,2,…m.

Step 8: Calculating the weighted super-matrix-. For this purpose, the total impact matrix for aspects is used. The matrix represents the sum of all impacts of every aspect in the matrix . The normalized total impact matrix for aspects is calculated, as shown in Expression (8)

where indicates the sum of all impacts from the sub-matrix of the total impact matrix for criteria and where denotes the sum of ith row in the super-matrix for aspects , while i = 1,2,…,m.

The super-matrix is calculated according to Expression (9):

Step 9: Obtaining the criteria relative weights. It is necessary to multiply the super-matrix by itself multiple times in order to calculate the limited weighted super-matrix with a stable convergence value, as shown in Expression (10):

where the number k denotes a positive integer number, which tends to infinity. Every vector of the limited super-matrix represents the relative weight of each criterion in relation to the defined goal.

3.2. Establishing a Group of Observed Vehicles–Defining Alternatives

Within this phase, the suitable vehicle types and models necessary for the realization of the transport process are defined. Since the observed companies are different regarding their characteristics, when defining a set of considered vehicles (alternatives) for procurement, it is necessary to take into account the following elements: The available company budget, the transport network specifics, the characteristics of the customers’ transport requirements, and legislation requirements.

Road characteristics (road curve diameter, traffic lanes width, existing traffic regulations, etc.) can be limiting factors for certain vehicle types and models. This is especially the case in urban areas with small road curve diameters and lane widths, with traffic restrictions for certain vehicles, such as trucks over 7.5 t gross vehicle weight (GVW) and vehicles with lower Euro standard than it is prescribed. Based on the analysis of customers’ transport requirements, the quantities and types of cargo most often transported by the company have to be determined, and therefore, the suitable types and models of vehicles are established (by type of vehicle’s cargo compartment, vehicle’s payload capacity). Legislation requirements (vehicle emission, noise, etc.) also represent limiting factors for certain vehicle categories when defining the vehicles set, especially for vehicles that operate in urban areas.

3.3. Determination of Criteria Parameters Values for Each Alternative

After defining a set of considered vehicles, it is necessary to determine for each vehicle the parameter values that quantitatively express each of the defined criteria, as noted in Table 1. These values of parameters are determined on the basis of the vehicles’ technical and operational data using vehicle specifications, available scientific and professional literature, information obtained from vehicle distributors, as well as from vehicle service centers. After determining the parameter value of the defined criteria for each vehicle, it is necessary to rank the considered vehicles by applying the TOPSIS method.

3.4. Ranking of Observed Alternatives with TOPSIS Method

TOPSIS method [37] was applied in order to rank the considered vehicles (alternatives) within the procuring process. The basic steps of the TOPSIS method are [37]:

Step 1: Construct the normalized decision matrix. Starting matrix is transformed into a normalized matrix where are normalized values obtained by normalization. i represents ith alternative considered Ai (1 ≤ i ≤ m) and j represents jth criterion Kj (1 ≤ j ≤ n). Normalization of starting matrix is carried out by vector normalization based on Equations (11) and (12):

Step 2: Construct the weighted normalized decision matrix. This step involves incorporating the relative weights of the criteria obtained with the DANP method on the basis of matrix, where j represents jth criterion and j = 1,…,n. Criteria relative weights are included in the decision matrix, which transforms the matrix into a weighted matrix based on Equation (13):

Step 3: Determine the ideal and anti-ideal solution. Ideal ) and anti-ideal ) solutions are vectors that are calculated, as shown in Equations (14) and (15):

Step 4: Calculate the separation measure. The alternative distance from ideal and anti-ideal solution is calculated by Euclidean distance in n-dimensional space of criteria as shown in Equation (16):

Step 5: Calculate the relative closeness to the ideal solution. This is calculated as follows (17):

where . The closer is to 1 the alternative is relatively closer to .

Step 6: Rank the preference order. A compromise solution is one or more alternatives that make the set determined in accordance with (18):

where the rank of alternatives (from best to worst) corresponds to the order of values ranked in descending order.

3.5. Selecting The Best Vehicle Model

After obtaining the best vehicle model for procurement, an analysis of the obtained results is carried out according to defined criteria. It is considered by which criteria the chosen alternative takes precedence over the other alternatives. In addition, the expected effects and losses of other alternatives are analyzed. Fleet managers consider the obtained results and make a decision on the choice of an appropriate vehicle for procurement. The presented model is a support for fleet managers in the road vehicle procurement process in order to reduce the transport and maintenance costs and increase the fleet’s energy efficiency.

4. Model Application

The developed model was applied at a company that owns a vehicle fleet for automotive spare parts distribution. According to the model’s second phase (Figure 1), the relative weights of the vehicle procurement criteria were calculated. In accordance with the other phases of the model, a set of vehicles (alternatives) was determined, as well as values of the observed parameters. Afterwards, the observed alternatives were ranked.

4.1. Calculating Criteria Relative Weights

Within Phase 2 of the developed model, a survey was conducted to gather experts’ opinions on the interdependencies between the defined criteria. The survey included 50 opinions of experts in this field. The demographic information of experts is shown in Table 2. The survey was conducted during the period from January to March 2019. The experts were informed about the model idea and therefore tasked to determine the interdependencies of 13 defined criteria with a score from 0 to 4 (from “no impact” to “very strong impact”). The inconsistent rate of 50 responses was less than 5%.

Table 2.

Demographic information of survey participants.

Based on the results of the survey and Equations (1)–(4), the total impact matrix-T was calculated, which simultaneously represents the total impact matrix for criteria − (Table 3). As can be seen from Table 3, the more important criteria are those with higher value of (r + c): Vehicle procurement price (F1), Vehicle maintenance (O2), and Engine characteristics (CT2). The criterion that influences the other criteria the most has the highest value of (r − s), and that is Environmental protection requirements (E1). The criterion with the lowest value of (r − s) is influenced the most by the other criteria, and that is Vehicle procurement price (F1).

Table 3.

Total impact matrix of criteria Tc and effects.

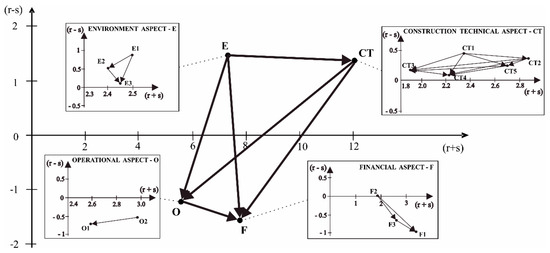

In order to show the interdependencies of aspects, the total impact matrix of aspects − was calculated (Table 4). As can be seen in Table 4, the Construction-technical aspect (CT) is very important. The aspect of the environment (E) has the most influence on other aspects, while the Financial aspect (F) is influenced the most by the other aspects.

Table 4.

Total impact matrix of aspects and effects.

Based on the calculated total caused and received effects, Figure 2 shows the Influence Relation Map (IRM), in order to clarify the relationships between defined criteria and aspects. As can be seen in Figure 2, aspect E has the highest value of (r − s), so it affects all other aspects. Aspect CT influences aspects O and F, while aspect F has the most received effects from the other aspects (Figure 2). When considering the impacts of criteria within one aspect such as e.g., CT aspect, the CT1 criterion affects all other criteria within CT aspect because it has the highest value of (r − c), while the CT4 criterion with the lowest value of (r − c) receives the most effects from the other criteria of CT aspect.

Figure 2.

Influence Relation Map (IRM) for vehicle procurement.

Based on Equation (10), a limited weighted super-matrix was calculated (Table 5). The vectors in super-matrix represent the relative weights of vehicle procurement criteria . As it is shown in Table 5, the criterion Vehicle procurement price (F1) has the highest relative weight, i.e., has the highest importance for the procurement of vehicles, in achieving the defined goal. Other significant criteria for vehicle procurement are: Vehicle maintenance (O2), Vehicle selling price (F3), and Fuel/energy Cost (O1). The most important vehicle procurement aspect is construction-technical aspect (CT), followed by financial (F), operational (O) and aspect of the environment (E), which has the least significance for the vehicle procurement process (Table 5).

Table 5.

Relative weights of criteria and aspects.

4.2. Establishing and Ranking the Vehicles and Selecting the Best Vehicle for Procurement

The observed company (Delmax Ltd.) has a heterogeneous fleet of 66 vehicles, with small pickup vehicles (GVW up to 2.5 t), vans (GVW up to 3.5 t), and trucks (GVW up to 15 t). The analysis of the operation data shows that the vehicles’ average annual mileage is 55,000 km. Based on the analysis of transport routes and history of customers’ transport requirements in the observed company, it was found that more than 90% of the transport routes pass through urban areas, and the weight of the transported cargo is between 800 and 1300 kg in more than 80% cases. According to the obtained results of conducted analyses, it was determined that possible vehicle types that can meet transportation requirements are: Vans with GVW up to 3.5 t and trucks with GVW up to 7.5 t. Regarding this, different types and models of vehicles from different manufacturers were considered in order to determine which vehicle model contributes the most to achieving the company’s goal. For the purpose of calculating the rank of alternatives, we have used the adjusted program code written in Python 3.7 [38].

Alternative A5 is a truck with a GVW up to 7.5 t, and the other alternatives are vans with a GVW up to 3.5 t (Table 6). Alternatives A1, A2, A3, and A4 are conventional (diesel) vans from different manufacturers, while the alternative A6 is an electric van. The alternatives A7 and A8 are a variation of the alternative A2 that use different alternative fuel CNG and biodiesel B30, respectively. Criteria values of the observed alternatives were determined based on the brochures from vehicle manufacturers’ websites and websites that advertise used vehicles, as well as from authorized maintenance services and vehicle dealers. These values were also determined based on the characteristics of the observed companies’ vehicle fleet and their transport requirements, considered the price of diesel is £1.08/lit and the price of electricity is £0.11/kWh. After determining the nature of each criterion (min./max.) the relative closeness of the observed alternatives to the ideal solution (Ci) was calculated on the basis of Equations (11)–(18), and the rank of each alternative was determined (Table 6).

Table 6.

Criteria values and rank of alternatives.

5. Results and Discussion

As it is shown in Table 6 the A2 (diesel van) is the first ranked alternative, while the A6 (electric van) is the second one. This vehicle has the lowest procurement price (about £30,000 lower than A6 and more than £1600 lower than the third ranked alternative, i.e., A3), which is the most important criterion. If a period of five years in operation (275,000 km) is observed, it can be seen that the sum of fuel/energy and maintenance costs is the lowest for the observed electric van (about £10,800), which is almost £13,000 less than for A2, about £11,000 less than for A3 and £4700 for CNG van. Regarding CO2 emission, it can be seen that A6 is the best alternative since it emits about 15 t of CO2 during a period of five years (well to wheel emission), which is 36 t less than the first ranked alternative and 88 t less than A5. However, if we observe overall transport and maintenance costs (sum of vehicle price, fuel/energy, and maintenance costs minus vehicle selling price) we can see that A2 has about £13,300 lower costs than A6. Besides the higher procurement price of alternative A3, the first ranked vehicle has one additional safety/technical system, twice as good compatibility with the existing vehicle fleet, higher vehicle selling price, as well as smaller vehicle turning diameter (which is very important in dense urban environments). Despite the fact that alternative A1 has the most safety-technical systems and equipment regarding vehicle comfort, it has very high maintenance costs (£495/year), which is the second most important criterion. Some of the reasons why the alternative A5 is the worst ranked are very high procurement, fuel/energy, and maintenance costs, as well as low payload utilization (33% of payload utilization means that this vehicle has 67% of free space while transporting goods, which means about 725,800 tonne-kilometer of loss compared to full payload utilization observed over a period of five years and 275,000 km traveled). It can be seen that electric van (A6) is second ranked mostly due to its high procurement price, zero compatibility with the existing vehicle fleet, and very low importance of criterion related to CO2 emission. Thus, we have considered different scenarios to establish whether and how the rank of the alternatives would change.

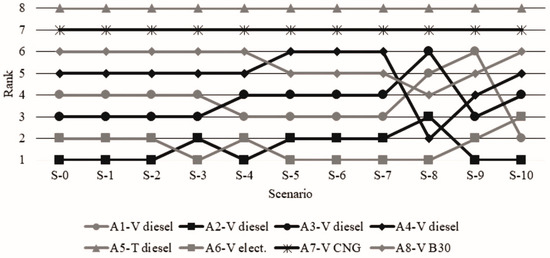

Scenario S-0 represents the existing scenario, while the S-1 represents the ranking of observed alternatives if the electric power is produced from renewable sources (zero emission of CO2 from well to wheel). S-2 and S-3 represent scenarios where there are subsidies of £15,000 and £20,000, whereby the use of renewable sources is significantly increased, respectively. Additionally, we have observed scenarios where the relative weights of criteria vehicle price (F1) and CO2 emission (E1) are the same (S-4), they have the same weights but the electric van emission is zero (S-5), where the importance of E1 criterion is twice as high as the importance of F1 (S-6), and where the relative weights of criteria F1 and E1 switch places (S-7). We have researched the rank of alternatives when the compatibility with the existing vehicle fleet of all alternatives is the same (S-8). Scenario S-9 represents the case where the number of safety technical systems is the same for all vehicles. Since the maintenance costs for alternative A1 are very high, in scenario S-10 we examined what would happen if these costs were the same as for the alternative A2. The ranks of alternatives for all of these scenarios are shown in Figure 3.

Figure 3.

Ranks of alternatives in different scenarios.

As can be seen from Figure 3, in our case study, scenarios S-1 and S-2 are the same as the basic scenario. If there are subsidies of £20,000 (about 30% of new electric vehicle price) and the electric energy production is mostly from renewable sources (S-3), A6 is the first ranked alternative. In scenario S-4 the only change is between alternatives A1 and A3. Scenarios S-5, S-6, and S-7 show that there are changes in rank between alternatives A2 and A6 (which is first ranked alternative in this case), between A1 and A3, as well as between A8 and A4. If the compatibility with the existing vehicle fleet of all alternatives is the same (S-8), then electric van is the first ranked alternative, and the second one is A4, while the first ranked alternative from the basic scenario (A2) is now the third ranked. The rank of alternatives A4 and A8 in scenario S-9 has improved, while the rank of alternative A1 has gone down from fourth to sixth. In the final scenario (S-10) it can be seen that the alternative A1 would be second ranked if its’ maintenance costs were lower, such as for the alternative A2. The rank of alternatives A5 and A7 is the same for all scenarios.

6. Conclusions

Vehicle procurement as a factor that contributes to making more profit in companies with their own vehicle fleet has been researched in this paper. We developed a model that selects the most suitable road vehicle while taking into account construction-technical, financial, operational, and environmental aspects of a road vehicle, simultaneously from three points of view: Transport costs, maintenance costs, and energy efficiency. Using the DANP method and engaging 50 experts from this field, we determined the criteria relative weights and their interdependency, which was ignored in most previous studies. The most important criteria for vehicle procurement are vehicle price (F1), vehicle maintenance (O2), vehicle selling price (F3), and fuel/energy costs (O1), while environmental protection requirements (E1) and vehicle comfort (CT3) are the least significant criteria. The TOPSIS method was used to rank the observed vehicles by their suitability. Besides the basic scenario, we have considered 10 more different scenarios to establish whether and how the rank of the observed alternatives would change.

On the basis of collected criteria parameter values observing five–year period and annual mileage of 55,000 km, the first ranked alternative (diesel van) has lower overall transport and maintenance costs (fuel/energy costs, maintenance costs, vehicle price and vehicle selling price) for £13,300 than second ranked alternative (electric van). In our case (observed company) the electric vehicle price should be about 30% lower (there should be subsidies) in order for this alternative to become the first ranked. We think there should be government subsidies, as well as the increase in usage of renewable energy sources, which will together encourage vehicle fleet managers to procure electric vehicles. For example, this difference in the vehicle price can be used to train the maintenance technicians and drivers, as well as to buy some spare parts and equipment to maintain electric vehicles. We can see that the sum of fuel/energy costs and vehicle maintenance costs of electric van are almost £15,000 lower, on average, than for diesel vans (observing five-year period). However, if overall transport and maintenance costs of electric van are observed, it can be seen that these costs are about £10,000 higher, on average, for five years in operation than for diesel vans.

This model is evaluated by road vehicle fleet managers as easy to understand and operate, while it gives extremely satisfying results in a short period of time. The managers said that without the model they were not aware of all criteria, and they did not observe all of them in previous vehicle procurements. Moreover, it was almost impossible for them to simultaneously observe all relevant criteria necessary for vehicle procurement, as well as their weights and parameters (vehicle data). With the model, the only thing managers should do is to provide vehicles’ data and import them into the model. Managers in the observed company during the vehicle procurement process have replaced two old, less suitable vans, with two new ones of the same manufacturer and the same model as the A2 alternative, based on the obtained results of the model. By choosing this alternative instead of second ranked alternative, this company saved about 20% of overall transport and maintenance costs. Moreover, this alternative has proven to be a better choice than all of the other ones as well, taking into account transport and maintenance costs and energy efficiency.

Since the criteria values of the observed alternatives should be determined based on the brochures from vehicle manufacturers’ websites and websites that advertise used vehicles, as well as from authorized maintenance services and vehicle dealers, the accuracy of the obtained information could affect the accuracy of derived results. Additionally, the limitation could represent the non-existence of parameter information that is needed for the model (e.g., vehicle CO2 emission), as well as a little longer time to collect all necessary data compared to the time when managers observed only a few criteria.

Author Contributions

Conceptualization, D.V.; formal analysis, M.S.; investigation, M.S.; methodology, D.V.; software, M.S.; supervision, D.V.; validation, D.S.; visualization, D.S.; writing—original draft, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This paper has been realized within the project “Development of the Model for Managing the Vehicle Technical Condition in Order to Increase its Energy Efficiency and Reduce Exhaust Emissions” (TR36010), supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia.

Acknowledgments

The authors wish to express their gratitude to all managers in the company Delmax Ltd. and vehicle service centers for providing all necessary information for this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alvarez, J.F.; Tsilingiris, P.; Engebrethsen, E.S.; Kakalis, N.M.P. Robust fleet sizing and deployment for industrial and independent bulk ocean shipping companies. INFOR 2011, 49, 93–107. [Google Scholar] [CrossRef]

- Hoff, A.; Andersson, H.; Christiansen, M.; Hasle, G.; Løkketangen, A. Industrial aspects and literature survey: Fleet composition and routing. Comput. Oper. Res. 2010, 37, 2041–2061. [Google Scholar] [CrossRef]

- Vujanović, D.; Momcilović, V.; Medar, O. Influence of an integrated maintenance management on the vehicle fleet energy efficiency. Therm. Sci. 2018, 22, 1525–1536. [Google Scholar] [CrossRef]

- Mørch, O.; Fagerholt, K.; Pantuso, G.; Rakke, J. Maximizing the rate of return on the capital employed in shipping capacity renewal. Omega 2017, 67, 42–53. [Google Scholar] [CrossRef]

- Patricksson, Ø.S.; Fagerholt, K.; Rakke, J.G. The fleet renewal problem with regional emission limitations: Case study from Roll-on/Roll-off shipping. Transp. Res. Part C Emerg. Technol. 2015, 56, 346–358. [Google Scholar] [CrossRef]

- Ansaripoor, A.H.; Oliveira, F.S.; Liret, A. A risk management system for sustainable fleet replacement. Eur. J. Oper. Res. 2014, 237, 701–712. [Google Scholar] [CrossRef]

- Figliozzi, M.A.; Boudart, J.A.; Feng, W. Economic and environmental optimization of vehicle fleets. Transp. Res. Rec. J. Transp. Res. Board 2011, 2252, 1–6. [Google Scholar] [CrossRef]

- Feng, W.; Figliozzi, M. An economic and technological analysis of the key factors affecting the competitiveness of electric commercial vehicles: A case study from the USA market. Transp. Res. Part C Emerg. Technol. 2013, 26, 135–145. [Google Scholar] [CrossRef]

- Ansaripoor, A.H.; Oliveira, F.S.; Liret, A. Recursive expected conditional value at risk in the fleet renewal problem with alternative fuel vehicles. Transp. Res. Part C Emerg. Technol. 2016, 65, 156–171. [Google Scholar] [CrossRef]

- Pantuso, G.; Fagerholt, K.; Wallace, S.W. Uncertainty in Fleet Renewal: A Case from Maritime Transportation. Transp. Sci. 2016, 50, 390–407. [Google Scholar] [CrossRef]

- Lee, W.S.; Huang, A.Y.; Chang, Y.Y.; Cheng, C.M. Analysis of decision making factors for equity investment by DEMATEL and Analytic Network Process. Expert Syst. Appl. 2011, 38, 8375–8383. [Google Scholar] [CrossRef]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M.I. Evaluating food supply chain performance using hybrid fuzzy MCDM technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Gudiel Pineda, P.J.; Liou, J.J.H.; Hsu, C.C.; Chuang, Y.C. An integrated MCDM model for improving airline operational and financial performance. J. Air Transp. Manag. 2018, 68, 103–117. [Google Scholar] [CrossRef]

- Hsu, C.C.; Liou, J.J.H.; Lo, H.W.; Wang, Y.C. Using a hybrid method for evaluating and improving the service quality of public bike-sharing systems. J. Clean. Prod. 2018, 202, 1131–1144. [Google Scholar] [CrossRef]

- Kumar, A.; Anbanandam, R. Analyzing interrelationships and prioritising the factors influencing sustainable intermodal freight transport system: A grey-DANP approach. J. Clean. Prod. 2020, 252, 119769. [Google Scholar] [CrossRef]

- Vujanović, D.B.; Momcilović, V.M.; Vasić, M.B. A hybrid multi-criteria decision making model for the vehicle service center selection with the aim to increase the vehicle fleet energy efficiency. Therm. Sci. 2018, 22, 1549–1561. [Google Scholar] [CrossRef]

- Sakthivel, G.; Ilangkumaran, M.; Gaikwad, A. A hybrid multi-criteria decision modeling approach for the best biodiesel blend selection based on ANP-TOPSIS analysis. Ain Shams Eng. J. 2015, 6, 239–256. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, G.; Li, T.; Wei, X. Comprehensive evaluation of the sustainable development of battery electric vehicles in China. Sustainability 2019, 11, 5635. [Google Scholar] [CrossRef]

- Hamurcu, M.; Eren, T. Electric Bus Selection with Multicriteria Decision Analysis for Green Transportation. Sustainability 2020, 12, 2777. [Google Scholar] [CrossRef]

- dos Santos, B.M.; Godoy, L.P.; Campos, L.M.S. Performance evaluation of green suppliers using entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Sureeyatanapas, P.; Sriwattananusart, K.; Niyamosoth, T.; Sessomboon, W.; Arunyanart, S. Supplier selection towards uncertain and unavailable information: An extension of TOPSIS method. Oper. Res. Perspect. 2018, 5, 69–79. [Google Scholar] [CrossRef]

- Hoseinpour, M.; Sadrnia, H.; Tabasizadeh, M.; Ghobadian, B. Evaluation of the effect of gasoline fumigation on performance and emission characteristics of a diesel engine fueled with B20 using an experimental investigation and TOPSIS method. Fuel 2018, 223, 277–285. [Google Scholar] [CrossRef]

- Sabaghi, M.; Mascle, C.; Baptiste, P. Application of DOE-TOPSIS technique in decision-making problems. IFAC-PapersOnLine 2015, 48, 773–777. [Google Scholar] [CrossRef]

- Anthony, P.; Behnoee, B.; Hassanpour, M.; Pamucar, D. Financial performance evaluation of seven Indian chemical companies. Decis. Mak. Appl. Manag. Eng. 2019, 2, 19–37. [Google Scholar] [CrossRef]

- Milosavljević, M.; Bursać, M.; Tričković, G. The selection of the railroad container terminal in Serbia based on multi criteria decision making methods. Decis. Mak. Appl. Manag. Eng. 2018, 1, 1–15. [Google Scholar] [CrossRef]

- Karagülle, A.Ö. The Evaluation of Fleet Structures in Turkish Aviation Industry from Strategic Management Point of View. Procedia–Soc. Behav. Sci. 2012, 58, 93–97. [Google Scholar] [CrossRef]

- Bakkehaug, R.; Eidem, E.S.; Fagerholt, K.; Hvattum, L.M. A stochastic programming formulation for strategic fleet renewal in shipping. Transp. Res. Part E Logist. Transp. Rev. 2014, 72, 60–76. [Google Scholar] [CrossRef]

- de Salvo Junior, O.; Vaz de Almeida, F.G. Influence of technologies on energy efficiency results of official Brazilian tests of vehicle energy consumption. Appl. Energy 2019, 241, 98–112. [Google Scholar] [CrossRef]

- Jiang, C.; Xu, H.; Srivastava, D.; Ma, X.; Dearn, K.; Cracknell, R.; Krueger-Venus, J. Effect of fuel injector deposit on spray characteristics, gaseous emissions and particulate matter in a gasoline direct injection engine. Appl. Energy 2017, 203, 390–402. [Google Scholar] [CrossRef]

- Merkert, R.; Hensher, D.A. The impact of strategic management and fleet planning on airline efficiency–a random effects tobit model based on dea efficiency scores. Transp. Res. Part A Policy Pract. 2011, 45, 686–695. [Google Scholar] [CrossRef]

- Riechi, J.; Mácian, V.; Tormos, B.; Avila, C. Optimal fleet replacement: A case study on a Spanish urban transport fleet. J. Oper. Res. Soc. 2017, 68, 886–894. [Google Scholar] [CrossRef]

- Low Carbon Vehicle Partnership, The Low Emission Van Guide; Guide for van operators; Cenex: Leicestershire, UK, 2019; pp. 5–27.

- Keles, P.; Hartman, J.C. Case study: Bus fleet replacement. Eng. Econ. A J. Devoted to Probl. Cap. Invest. 2004, 49, 253–278. [Google Scholar] [CrossRef]

- Mijailović, R. The optimal lifetime of passenger cars based on minimization of CO2 emission. Energy 2013, 55, 869–878. [Google Scholar] [CrossRef]

- Degirmenci, K.; Breitner, M.H. Consumer purchase intentions for electric vehicles: Is green more important than price and range? Transp. Res. Part D Transp. Environ. 2017, 51, 250–260. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M. Trends of energy efficiency in Finnish road freight transport 1995–2009 and forecast to 2016. Energy Policy 2010, 38, 7676–7686. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making; Lecture Notes in Economics and Mathematical Systems; Springer: Heidelberg, Germany, 1981; Volume 186, pp. 128–140. ISBN 978-3-642-48318-9. [Google Scholar]

- Papathanasiou, J.; Ploskas, N. TOPSIS. In Multiple Criteria Decision Aid; Pardalos, M., Du, D.-Z., Eds.; Springer Nature: Cham, Switzerland, 2018; Volume 136, pp. 1–30. ISBN 978-3-319-91646-0. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).