Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards

Abstract

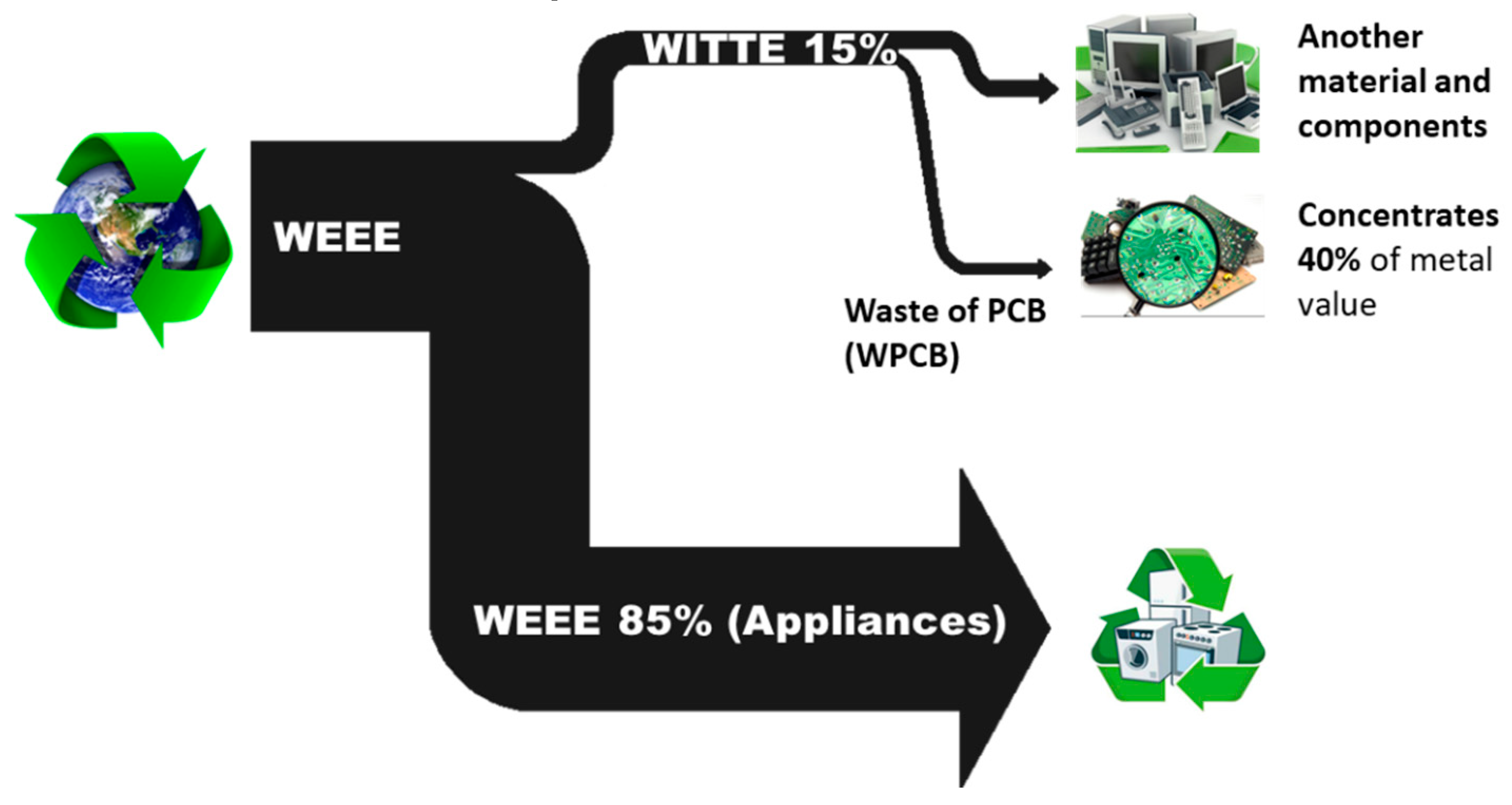

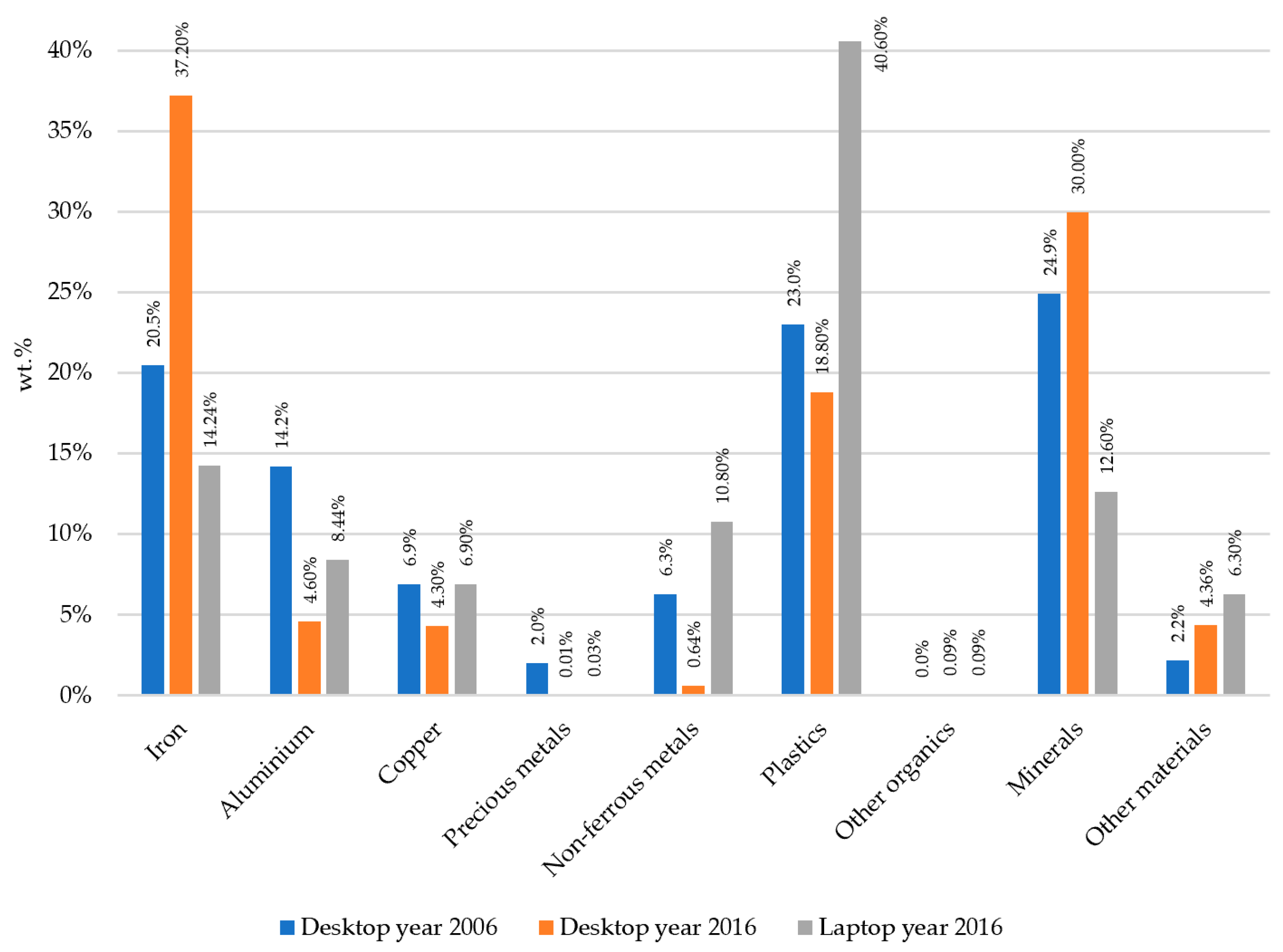

1. Introduction

- Category 1 covers large household appliances (fridges, washing machines, air conditioners, etc.);

- Category 2 covers small household appliances (vacuum cleaners, toasters, fryers, etc.);

- Category 3 covers IT and telecommunication equipment (ITTE) (PCs, tablets, notebooks, smartphones, etc.);

- Category 4 covers consumer equipment (e.g., TVs, stereo systems, digital cameras, etc.).

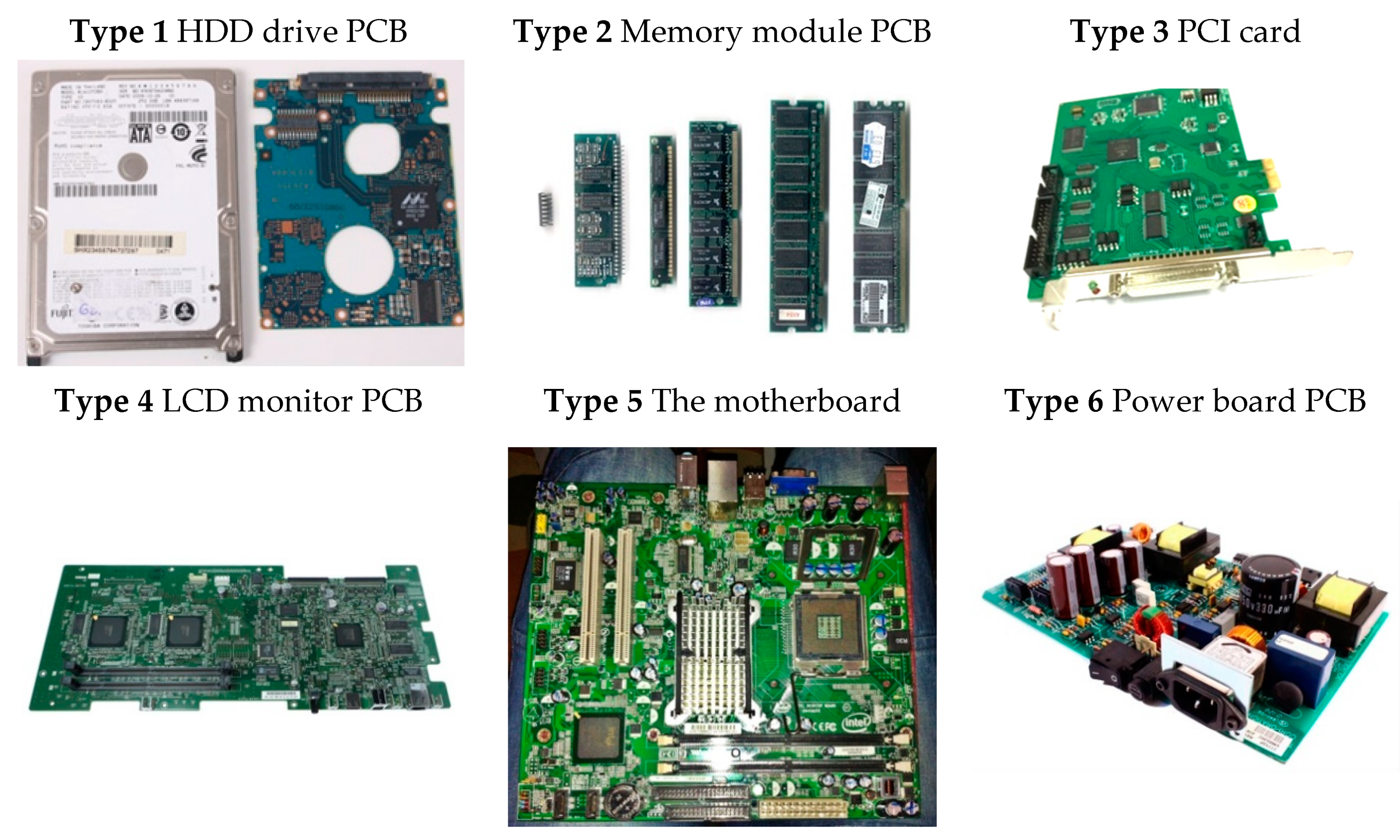

2. Recycling Techniques of WPCBs

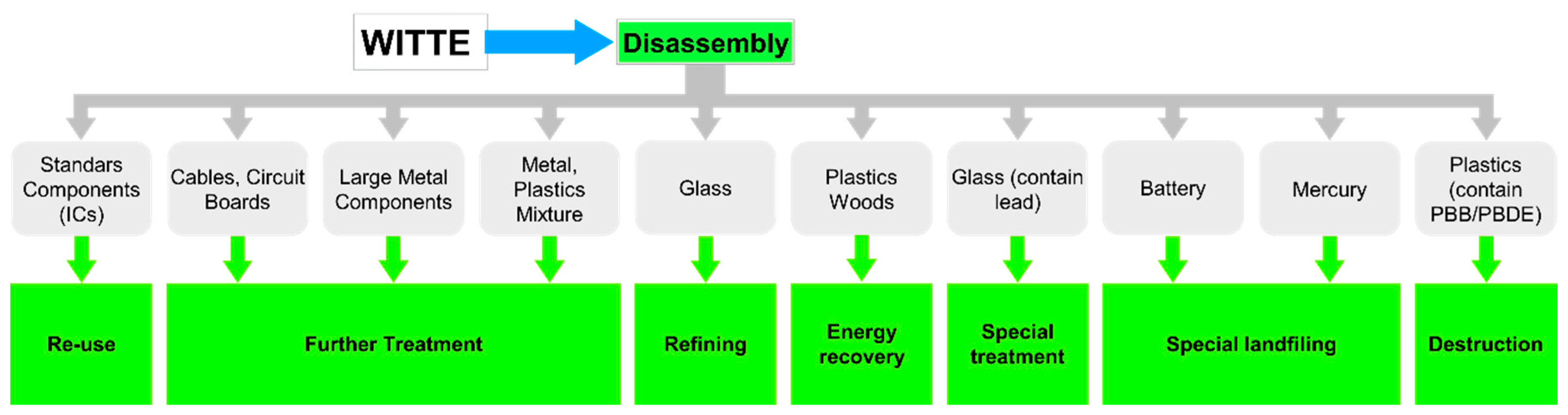

2.1. Disassembly Process

- Input and output product analysis. During the first phase, reusable, important, and hazardous components and materials are specified. Optimum disassembly is defined after preliminary cost analysis.

- Assembly analysis. Attachment components, part hierarchy, and previous assembly sequences are analyzed during the second phase.

- Uncertainty issues analysis. Defective parts or joints in the incoming material or product upgrading/downgrading during use may cause disassembly instability and damage to disassembly.

- Determination of the dismantling strategy. The final phase determines whether non-destructive or destructive disassembly is going to be used.

2.2. Mechanical Recycling Techniques

- Washing, drying, and comminution. The disassembled materials from PCBs are washed for the removal of adhered impurities and dried. This process minimizes the particle surface contamination that could affect the reproducibility and efficiency of the tribo-charging mechanism [72]. The polymers are then ground in a knife mill. These activities result in wastewater (from the washing process) and dust, noise, and vibrations (from the grinding process). Therefore, further measures are required in order to reduce the environmental impact.

- Sieving. The particle size directly affects the tribo-electrostatic separation [73]. Thus, a granulometric separation is carried out, using sieves coupled to a vibratory agitator. The environmental impact thereof consists of sound, vibrations, and dust.

- Secondary washing and drying. Disassembled PCB particles can acquire surface charges during the comminution and sieving processes. This affects the charging efficiency as well as the quality and quantity of products resulting from the overall process [74]. One way to neutralize this parasitic charging is to apply subsequent washing and drying, in order to neutralize the disassembled PCB particles. Hence, the environmental impact is diminished to wastewater and drying energy consumption only.

2.3. Electro-Mechanical Separation Methods

2.3.1. Shredding, Washing, and Sieving

2.3.2. Magnetic Separation

2.3.3. Eddy Current Separators

2.3.4. Corona Electrostatic Separator

- Middling materials of the separation system and additionaltreatment. Due to the feeding process, non-uniform electrical field, and space charge distribution, a considerable number of particles don’t gain sufficient charge and goes in to the middling products. Furthermore, certain unintended factors, such as changes in ambient conditions, often increase the middling products.

- Nonconductive material impurity and additional treatment. Since the particle mixture consists mainly of nonmetals, certain metals are covered with nonmetals. Such particles bind to the sheet, move with it, and eventually goes with the particles that are not conductive. This contributes not only to metal loss, but also to the impurity of the non-conductive materials. If the particle dimensions are <0.6 mm, it is possible to achieve complete separation between metals and non-metals for comminuted PCB waste [101].

- Stability of the separation process. For the following reasons, the results are unstable [102]: The metal concentration variability in the feeding material; the temperature and humidity fluctuations; the electrostatic separation sensitivity to the particle size; and the accumulation of dust on the corona electrode. For example, under laboratory conditions, the granule mixture can be sorted into several size groups. Nevertheless, this is not valid in industrial applications, where particles belonging to different size groups are always a concern.

- Agreement between efficiency of production and quality of separation. Higher feed rates and higher roll speeds are required to increase the production capacity. However, a higher roll speed could lead to poor quality of separation [103] due to the creation of a large quantity of middling products.

- Feeding granule mixture superficial moisture. The mixture of feeding granules absorbs the moisture in the area.

2.3.5. Triboelectrostatic Separation

2.4. Gravity Separation

2.5. Chemical Recycling Techniques

2.6. Electrochemical Processes

2.7. Thermal Recycling Methods

2.7.1. Pyrolysis Process

2.7.2. Thermal Treatment

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hazra, A.; Das, S.; Ganguly, A.; Das, P.; Chatterjee, P.; Murmu, N.; Banerjee, P. Plasma Arc Technology: A Potential Solution toward Waste to Energy Conversion and of GHGs Mitigation. In Waste Valorisation and Recycling; Springer: Singapore, 2019; pp. 203–217. [Google Scholar] [CrossRef]

- Ning, C.; Lin, C.S.K.; Hui, D.C.W.; Mckay, G. Waste Printed Circuit Board (PCB) Recycling Techniques; Springer International Publishing: Basel, Switzerland, 2017; Volume 375. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-Waste: An Overview on Generation, Collection, Legislation and Recycling Practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Suresh, S.S.; Bonda, S.; Mohanty, S.; Nayak, S.K. A Review on Computer Waste with Its Special Insight to Toxic Elements, Segregation and Recycling Techniques. Process Saf. Environ. Prot. 2018, 116, 477–493. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Hadi, P.F.; D’Adamo, I.; Li, J.; Rosa, P.; Terzi, S.; Wei, G.; Zeng, X. Modelling the correlations of e-waste quantity with economic increase. Sci. Total Environ. 2018, 613–614, 46–53. [Google Scholar] [CrossRef] [PubMed]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor—2017; United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA): Bonn, Germany; Geneva, Switzerland; Vienna, Austria, 2017. [Google Scholar]

- Liu, H.; Wu, X.; Dou, D.; Tang, X.; Leong, G.K. Determining Recycling Fees and Subsidies in China’s WEEE Disposal Fund with Formal and Informal Sectors. Sustainability 2018, 10, 2979. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Koh, L.; Rosa, P. A profitability assessment of European recycling processes treating printed circuit boards from waste electrical and electronic equipments. Renew. Sustain. Energ Rev. 2016, 64, 749–760. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Hasan, M.; Mishra, Y.K.; Pandey, A.K.; Tiwar, B.N.; Kuhad, R.C.; Gupta, V.K.; Thakur, V.K. Environmentally sound system for E-waste: Biotechnological perspectives. Curr. Res. Biotechnol. 2019, 1, 58–64. [Google Scholar] [CrossRef]

- Reuter, M.A.; Hudson, C.; Van Schaik, A.; Heiskanen, K.; Meskers, C.; Hagelüken, C. UNEP. Metal Recycling: Opportunities, Limits, Infrastructure, A Report of the Working Group on the Global Metal Flows to the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2013. [Google Scholar]

- Dwivedy, M.; Mittal, R.K. An Investigation into E-Waste Flows in India. J. Clean. Prod. 2012, 37, 229–242. [Google Scholar] [CrossRef]

- Needhidasan, S.; Samuel, M.; Chidambaram, R. Electronic Waste—An Emerging Threat to the Environment of Urban India. J. Environ. Health Sci. Eng. 2014, 12, 36. [Google Scholar] [CrossRef]

- Betts, K.; Rajagopal, R.R.; Rajarao, R.; Sahajwalla, V.; Bernstad, A.; la Cour Jansen, J.; Aspegren, H.; Camelino, S.; Rao, J.; Padilla, R.L.; et al. Producing Usable Materials from E-Waste. Environ. Sci. Technol. 2008, 42, 6782–6783. [Google Scholar] [CrossRef]

- Yu, J.; Williams, E.; Ju, M.; Yang, Y. Forecasting Global Generation of Obsolete Personal Computers. Environ. Sci. Technol. 2010, 44, 3232–3237. [Google Scholar] [CrossRef]

- Cruz-Sotelo, S.E.; Ojeda-Benítez, S.; Jáuregui Sesma, J.; Velázquez-Victorica, K.I.; Santillán-Soto, N.; García-Cueto, O.R.; Concepción, V.A.; Alcántara, C. E-Waste Supply Chain in Mexico: Challenges and Opportunities for Sustainable Management. Sustainability 2017, 9, 503. [Google Scholar] [CrossRef]

- Habib Al Razi, K.M. Resourceful Recycling Process of Waste Desktop Computers: A Review Study. Resour. Conserv. Recycl. 2016, 110, 30–47. [Google Scholar] [CrossRef]

- Williams, E.; Kahhat, R.; Allenby, B.; Kavazanjian, E.; Kim, J.; Xu, M. Environmental, Social, and Economic Implications of Global Reuse and Recycling of Personal Computers. Environ. Sci. Technol. 2008, 42, 6446–6454. [Google Scholar] [CrossRef] [PubMed]

- Kiddee, P.; Naidu, R.; Wong, M.H. Electronic Waste Management Approaches: An Overview. Waste Manag. 2013, 33, 1237–1250. [Google Scholar] [CrossRef]

- Bernstad, A.; la Cour Jansen, J.; Aspegren, H. Property-Close Source Separation of Hazardous Waste and Waste Electrical and Electronic Equipment—A Swedish Case Study. Waste Manag. 2011, 31, 536–543. [Google Scholar] [CrossRef]

- Steubing, B.; Böni, H.; Schluep, M.; Silva, U.; Ludwig, C. Assessing Computer Waste Generation in Chile Using Material Flow Analysis. Waste Manag. 2010, 30, 473–482. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Duan, H.; Hou, K.; Li, J.; Zhu, X. Examining the Technology Acceptance for Dismantling of Waste Printed Circuit Boards in Light of Recycling and Environmental Concerns. J. Environ. Manag. 2011, 92, 392–399. [Google Scholar] [CrossRef]

- Duan, H.; Li, J.; Liu, Y.; Yamazaki, N.; Jiang, W. Characterization and Inventory of PCDD/Fs and PBDD/Fs Emissions from the Incineration of Waste Printed Circuit Board. Environ. Sci. Technol. 2011, 45, 6322–6328. [Google Scholar] [CrossRef]

- Richter, H.; Lorenz, W.; Bahadir, M. Examination of Organic and Inorganic Xenobiotics in Equipped Printed Circuits. Chemosphere 1997, 35, 169–179. [Google Scholar] [CrossRef]

- Faraji, F.; Golmohammadzadeh, R.; Rashchi, F. Fungal bioleaching of WPCBs using Aspergillus niger: Observation, optimization and kinetics. J. Environ. Manag. 2018, 217, 775–787. [Google Scholar] [CrossRef] [PubMed]

- Becci, A.; Amato, A.; Fonti, V.; Karaj, D.; Beolchini, F. An innovative biotechnology for metal recovery from printed circuit boards. Resour. Conserv. Recycl. 2020, 153, 104549. [Google Scholar] [CrossRef]

- Işıldara, A.; van Hullebusch, E.D.; Lenzd, M.; Laing, G.D.; Marra, A.; Cesaro, A.; Panda, S.; Akcil, A.; Kucuker, M.A.; Kuchta, K. Biotechnological strategies for the recovery of valuable and critical raw materials from waste electrical and electronic equipment (WEEE)—A review. J. Hazard. Mater. 2019, 362, 467–481. [Google Scholar] [CrossRef]

- Ogunseitan, O.A.; Schoenung, J.M.; Saphores, J.-D.M.; Shapiro, A.A. The Electronics Revolution: From E-Wonderland to E-Wasteland. Science 2009, 326, 670–671. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Yang, Y.; Xu, Z. PM10 and PM2.5 and Health Risk Assessment for Heavy Metals in a Typical Factory for Cathode Ray Tube Television Recycling. Environ. Sci. Technol. 2013, 47, 12469–12476. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, A.; Wang, T.; Qu, G.; Shao, J.; Yuan, B.; Wang, Y.; Jiang, G. Influence of E-Waste Dismantling and Its Regulations: Temporal Trend, Spatial Distribution of Heavy Metals in Rice Grains, and Its Potential Health Risk. Environ. Sci. Technol. 2013, 47, 7437–7445. [Google Scholar] [CrossRef]

- Song, Q.; Wang, Z.; Li, J.; Yuan, W. Life Cycle Assessment of Desktop PCs in Macau. Int. J. Life Cycle Assess. 2013, 18, 553–566. [Google Scholar] [CrossRef]

- Man, M.; Naidu, R.; Wong, M.H. Persistent Toxic Substances Released from Uncontrolled E-Waste Recycling and Actions for the Future. Sci. Total Environ. 2013, 463–464, 1133–1137. [Google Scholar] [CrossRef]

- Verma, H.R.; Singh, K.K.; Mankhand, T.R. Comparative Study of Printed Circuit Board Recycling by Cracking of Internal Layers Using Organic Solvents-Dimethylformamide and Dimethylacetamide. J. Clean. Prod. 2017, 142, 1721–1727. [Google Scholar] [CrossRef]

- Hanafi, J.; Jobiliong, E.; Christiani, A.; Soenarta, D.C.; Kurniawan, J.; Irawan, J. Material Recovery and Characterization of PCB from Electronic Waste. Procedia-Soc. Behav. Sci. 2012, 57, 331–338. [Google Scholar] [CrossRef]

- Yamane, L.H.; de Moraes, V.T.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of WEEE: Characterization of Spent Printed Circuit Boards from Mobile Phones and Computers. Waste Manag. 2011, 31, 2553–2558. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, A.K.; Li, J.; Koh, L.; Ogunseitan, O.A. Circular economy and electronic waste. Nat. Electron. 2019, 2, 86–89. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.E.; Janke, T. Characterization of the non-metal fraction of the processed waste printed circuit boards. Waste Manag. 2018, 75, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Guo, J.; Xu, Z. Recycling of Waste Printed Circuit Boards: A Review of Current Technologies and Treatment Status in China. J. Hazard. Mater. 2009, 164, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Stone, R. Confronting a Toxic Blowback from the Electronics Trade. Science 2009, 325, 1055. [Google Scholar] [CrossRef] [PubMed]

- Rios, P.; Stuart, J.A.; Grant, E. Plastics Disassembly versus Bulk Recycling: Engineering Design for End-of-Life Electronics Resource Recovery. Environ. Sci. Technol. 2003, 37, 5463–5470. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Z. Disposing and Recycling Waste Printed Circuit Boards: Disconnecting, Resource Recovery, and Pollution Control. Environ. Sci. Technol. 2015, 49, 721–733. [Google Scholar] [CrossRef]

- Huang, J.; Chen, M.; Chen, H.; Chen, S.; Sun, Q. Leaching Behavior of Copper from Waste Printed Circuit Boards with Brønsted Acidic Ionic Liquid. Waste Manag. 2014, 34, 483–488. [Google Scholar] [CrossRef]

- Franke, C.; Kernbaum, S.; Seliger, G. Remanufacturing of Flat Screen Monitors. In Innovation in Life Cycle Engineering and Sustainable Development; Brissaud, D., Tichkiewitch, S., Zwolinski, P., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 139–152. [Google Scholar]

- Isernia, R.; Passaro, R.; Quinto, I.; Thomas, A. The Reverse Supply Chain of the E-Waste Management Processes in a Circular Economy Framework: Evidence from Italy. Sustainability 2019, 11, 2430. [Google Scholar] [CrossRef]

- Parajuly, K.; Wenzel, H. Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability 2017, 9, 768. [Google Scholar] [CrossRef]

- Becker, W.; Simon-Hettich, B.; Honicke, P. Toxicology and Ecotoxicology Investigations for Liquid Crystal and Disposal of LCDs; Merck brochure, Merck KGaA, Liquid Crystals Division and Institute of Toxicology 64271: Darmstadt, Germany, 2003. [Google Scholar]

- Bi, X.; Simoneit, B.R.T.; Wang, Z.; Wang, X.; Sheng, G.; Fu, J. The Major Components of Particles Emitted during Recycling of Waste Printed Circuit Boards in a Typical E-Waste Workshop of South China. Atmos. Environ. 2010, 44, 4440–4445. [Google Scholar] [CrossRef]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Takashi Kameya, T. A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef] [PubMed]

- Puttlitz, K.J.; Stalter, K.A. Handbook of Lead-Free Solder Technology for Microelectronic Assemblies; CRC Press: Marcel Dekker, NY, USA, 2004. [Google Scholar]

- Syed, S. Recovery of Gold from Secondary Sources—A Review. Hydrometallurgy 2012, 115–116, 30–51. [Google Scholar] [CrossRef]

- Vats, M.C.; Singh, S.K.; Vats, M.C.; Singh, S.K. Assessment of Gold and Silver in Assorted Mobile Phone Printed Circuit Boards (PCBs): Original Article. Waste Manag. 2015, 45, 280–288. [Google Scholar] [CrossRef] [PubMed]

- Camelino, S.; Rao, J.; Padilla, R.L.; Lucci, R. Initial Studies about Gold Leaching from Printed Circuit Boards (PCB’s) of Waste Cell Phones. Procedia Mater. Sci. 2015, 9, 105–112. [Google Scholar] [CrossRef]

- Namias, J. The Future of Electronic Waste Recycling in the United States: Obstacles and Domestic Solutions; Columbia University: New York, NY, USA, 2013; Available online: http://www.seas.columbia.edu/earth/wtert/sofos/Namias_Thesis_07-08-13.pdf (accessed on 10 December 2019).

- Hadi, P.; Xu, M.; Lin, C.S.K.; Hui, C.-W.; McKay, G. Waste printed circuit board recycling techniques and product utilization. J. Hazard. Mater. 2015, 283, 234–243. [Google Scholar] [CrossRef]

- D’Adamo, I.; Ferella, F.; Gastaldi, M.; Maggiore, F.; Rosa, P.; Terzi, S. Towards sustainable recycling processes: Wasted printed circuit boards as a source of economic opportunities. Resour. Conserv. Recycl. 2019, 149, 455–467. [Google Scholar] [CrossRef]

- Ferella, F.; de Michelis, I.; Scocchera, A.; Pelino, M.; Vegliò, F. Extraction of metals from automotive shredder residue: Preliminary results of different leaching systems. Chin. J. Chem. Eng. 2015, 23, 417–424. [Google Scholar] [CrossRef]

- Cui, J.; Forssberg, E. Mechanical Recycling of Waste Electric and Electronic Equipment: A Review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Disassembly Sequence Planning for Products with Defective Parts in Product Recovery. Comput. Ind. Eng. 1998, 35, 161–164. [Google Scholar] [CrossRef]

- Rousis, K.; Moustakas, K.; Stylianou, M.; Papadopoulos, A.; Loizidou, M. Management of Waste from Electrical and Electronic Equipment: The Case of Television Sets and Refrigerators. J. Environ. Eng. Sci. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Gupta, S.M.; McLean, C.R. Disassembly of Products. Comput. Ind. Eng. 1996, 31, 225–228. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in Environmentally Conscious Manufacturing and Product Recovery: A Survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Kuo, T.C. Disassembly Sequence and Cost Analysis for Electromechanical Products. Robot. Comput. Integr. Manuf. 2000, 16, 43–54. [Google Scholar] [CrossRef]

- Feldmann, K.; Trautner, S.; Meedt, O. Innovative Disassembly Strategies Based on Flexible Partial Destructive Tools. Annu. Rev. Control 1999, 23, 159–164. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Scharke, H.; Hucht, A. Flexible Robot-Based Disassembly Cell for Obsolete TV-Sets and Monitors. Robot. Comput. Integr. Manuf. 1999, 15, 247–255. [Google Scholar] [CrossRef]

- Moroni, M.; Lupo, E.; Pelle, V.; Pomponi, A.; Marca, F. Experimental Investigation of the Productivity of a Wet Separation Process of Traditional and Bio-Plastics. Separations 2018, 5, 26. [Google Scholar] [CrossRef]

- Marca, F.L.; Moroni, M.; Cherubini, L.; Lupo, E.; Cenedese, A. Separation of Plastic Waste via the Hydraulic Separator Multidune under Different Geometric Configurations. Waste Manag. 2012, 32, 1306–1315. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. The Valorization of Plastic Solid Waste (PSW) by Primary to Quaternary Routes: From Re-Use to Energy and Chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129. [Google Scholar] [CrossRef]

- Meng, L.; Wang, Z.; Zhong, Y.W.; Guo, L.; Gao, J.T.; Chen, K.Y.; Cheng, H.J.; Guo, Z.C. Supergravity separation for recovering metals from waste printed circuit boards. Chem. Eng. J. 2017, 326, 540–550. [Google Scholar] [CrossRef]

- Meng, L.; Guo, L.; Guo, Z. Separation of metals from metal-rich particles of crushed waste printed circuit boards by low-pressure filtration. Waste Manag. 2019, 84, 227–234. [Google Scholar] [CrossRef] [PubMed]

- Silveira, A.V.M.; Cella, M.; Tanabe, E.H.; Bertuol, D.A. Application of Tribo-Electrostatic Separation in the Recycling of Plastic Wastes. Process Saf. Environ. Prot. 2018, 114, 219–228. [Google Scholar] [CrossRef]

- Lee, J.-K.; Shin, J.-H. Triboelectrostatic Separation of Pvc Materials from Mixed Plastics for Waste Plastic Recycling. Korean J. Chem. Eng. 2002, 19, 267–272. [Google Scholar] [CrossRef]

- Tilmatine, A.; Medles, K.; Younes, M.; Bendaoud, A.; Dascalescu, L. Roll-Type Versus Free-Fall Electrostatic Separation of Tribocharged Plastic Particles. IEEE Trans. Ind. Appl. 2010, 46, 1564–1569. [Google Scholar] [CrossRef]

- Wu, G.; Li, J.; Xu, Z. Triboelectrostatic Separation for Granular Plastic Waste Recycling: A Review. Waste Manag. 2013, 33, 585–597. [Google Scholar] [CrossRef]

- Jiang, W.; Jia, L.; Zhen-ming, X. A New Two-Roll Electrostatic Separator for Recycling of Metals and Nonmetals from Waste Printed Circuit Board. J. Hazard. Mater. 2009, 161, 257–262. [Google Scholar] [CrossRef]

- Hubau, A.; Chagnes, A.; Minier, M.; Touzé, S.; Chapron, S.; Guezennec, A.-G. Recycling-oriented methodology to sample and characterize the metal composition of waste Printed Circuit Boards. Waste Manag. 2019, 91, 62–71. [Google Scholar] [CrossRef]

- Ruan, J.; Qin, B.; Huang, J. Controlling measures of micro-plastic and nano pollutants: A short review of disposing waste toners. Environ. Int. 2018, 118, 92–96. [Google Scholar] [CrossRef]

- Moyo, T.; Chirume, B.H.; Petersen, J. Assessing alternative pre-treatment methods to promote metal recovery in the leaching of printed circuit boards. Resour. Conserv. Recycl. 2020, 152, 104545. [Google Scholar] [CrossRef]

- Hagelüken, C. Metals Recovery from E-Scrap in a Global Environment Technical Capabilities, Challenges & Experience Gained. In Proceedings of the 6th session of OEWG Basel Convention, Basel, Geneva, 7 Setember 2007; Volume 7. [Google Scholar]

- Chancerel, P.; Meskers, C.E.M.; Hagelüken, C.; Rotter, V.S. Assessment of Precious Metal Flows during Preprocessing of Waste Electrical and Electronic Equipment. J. Ind. Ecol. 2009, 13, 791–810. [Google Scholar] [CrossRef]

- Gu, F.; Summers, P.A.; Hall, P. Recovering materials from waste mobile phones: Recent technological developments. J. Clean. Prod. 2019, 238, 117657. [Google Scholar] [CrossRef]

- Moltó, J.; Font, R.; Gálvez, A.; Conesa, J.A. Pyrolysis and Combustion of Electronic Wastes. J. Anal. Appl. Pyrolysis 2009, 84, 68–78. [Google Scholar] [CrossRef]

- Sethurajan, M.; van Hullebusch, E.D.; Fontana, D.; Akcil, A.; Deveci, H.; Batinic, B.; Leal, J.P.; Gasche, T.A.; Kucuker, M.A.; Kuchta, K.; et al. Recent advances on hydrometallurgical recovery of critical and precious elements from end of life electronic wastes—A review. Crit. Rev. Environ Sci. Techno. 2019, 49, 212–275. [Google Scholar] [CrossRef]

- Zhu, X.N.; Nie, C.C.; Wang, S.S.; Xie, Y.; Zhang, H.; Lyu, X.J.; Qiu, J.; Li, L. Cleaner approach to the recycling of metals in waste printed circuit boards by magnetic and gravity separation. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Ladou, J.; Lovegrove, S. Export of Electronics Equipment Waste. Int. J. Occup. Environ. Health 2008, 14, 1–10. [Google Scholar] [CrossRef]

- Mohabuth, N.; Hall, P.; Miles, N. Investigating the Use of Vertical Vibration to Recover Metal from Electrical and Electronic Waste. Miner. Eng. 2007, 20, 926–932. [Google Scholar] [CrossRef]

- Habib, M.; Miles, N.J.; Hall, P. Recovering Metallic Fractions from Waste Electrical and Electronic Equipment by a Novel Vibration System. Waste Manag. 2013, 33, 722–729. [Google Scholar] [CrossRef]

- Settimo, F.; Bevilacqua, P.; Rem, P. Eddy Current Separation of Fine Non-Ferrous Particles from Bulk Streams. Phys. Sep. Sci. Eng. 2004, 13, 15–23. [Google Scholar] [CrossRef]

- Schlett, Z.; Claici, F.; Mihalca, I.; Lungu, M. A New Static Separator for Metallic Particles from Metal–Plastic Mixtures, Using Eddy Currents. Miner. Eng. 2002, 15, 111–113. [Google Scholar] [CrossRef]

- Schubert, H.G.; Warlitz, G. Sorting Metal/Non-Metal Mixtures Using a Corona Electrostatic Separator. Aufbereit.-Tech. 1994, 35, 449–456. [Google Scholar]

- Ruan, J.; Qian, Y.; Xu, Z. Environment-Friendly Technology for Recovering Nonferrous Metals from e-Waste: Eddy Current Separation. Resour. Conserv. Recycl. 2014, 87, 109–116. [Google Scholar] [CrossRef]

- Li, J.; Shrivastava, P.; Gao, Z.; Zhang, H.-C. Printed Circuit Board Recycling: A State-of-the-Art Survey. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 33–42. [Google Scholar]

- Guo, J.; Cao, B.; Guo, J.; Xu, Z. A Plate Produced by Nonmetallic Materials of Pulverized Waste Printed Circuit Boards. Environ. Sci. Technol. 2008, 42, 5267–5271. [Google Scholar] [CrossRef]

- Kellner, R. Integrated Approach to E-Waste Recycling. In Electronic Waste Management; The Royal Society of Chemistry: London, UK, 2009; pp. 111–160. [Google Scholar] [CrossRef]

- Hamerski, F.; Krummenauer, A.; Bernardes, A.M.; Veit, H.M. Improved settings of a corona-electrostatic separator for copper concentration from waste printed circuit boards. J. Environ. Chem. Eng. 2019, 7, 102896. [Google Scholar] [CrossRef]

- Liu, W.; Liang, C.; Qin, W.Q.; Jiao, F. A New Technology for Recovery of Metals from Waste Printed Circuit Boards. Appl. Mech. Mater. 2014, 675–677, 698–703. [Google Scholar] [CrossRef]

- Li, J.; Lu, H.; Guo, J.; Xu, Z.; Zhou, Y. Recycle Technology for Recovering Resources and Products from Waste Printed Circuit Boards. Environ. Sci. Technol. 2007, 41, 1995–2000. [Google Scholar] [CrossRef]

- Veit, H.M.; Diehl, T.R.; Salami, A.P.; Rodrigues, J.S.; Bernardes, A.M.; Tenório, J.A.S. Utilization of Magnetic and Electrostatic Separation in the Recycling of Printed Circuit Boards Scrap. Waste Manag. 2005, 25, 67–74. [Google Scholar] [CrossRef]

- Aman, F.; Morar, R.; Kohnlechner, R.; Samuila, A.; Dascalescu, L. High-Voltage Electrode Position: A Key Factor of Electrostatic Separation Efficiency; IEEE Transactions on Industry Applications: New Jersey, NJ, USA, 2004; Volume 40. [Google Scholar] [CrossRef]

- Samuila, A.; Urs, A.; Iuga, A.; Morar, R.; Aman, F.; Dascalescu, L. Optimization of Corona Electrode Position in Roll-Type Electrostatic Separators. IEEE Trans. Ind. Appl. 2005, 41, 527–534. [Google Scholar] [CrossRef]

- Lu, H.; Li, J.; Guo, J.; Xu, Z.M. Pulverization Characteristics and Pulverizing of Waste Printed Circuit Boards (Printed Wiring Boards) Based on Resource Utilization. J. Shanghai Jiaotong Univ. 2007, 4, 551–556. [Google Scholar]

- Dascalescu, L.; Samuila, A.; Mihalcioiu, A.; Bente, S.; Tilmatine, A. Robust Design of Electrostatic Separation Processes. IEEE Trans. Ind. Appl. 2005, 41, 715–720. [Google Scholar] [CrossRef]

- Medles, K.; Tilmatine, A.; Miloua, F.; Bendaoud, A.; Younes, M.; Rahli, M.; Dascalescu, L. Set Point Identification and Robustness Testing of Electrostatic Separation Processes. IEEE Trans. Ind. Appl. 2007, 43, 618–626. [Google Scholar] [CrossRef]

- Higashiyama, Y.; Asano, K. Recent Progress in Electrostatic Separation Technology. Part. Sci. Technol. 1998, 16, 77–90. [Google Scholar] [CrossRef]

- Kiewiet, C.W.; Bergougnou, M.A.; Brown, J.D.; Inculet, I.I. Electrostatic Separation of Fine Particles in Vibrated Fluidized Beds. IEEE Trans. Ind. Appl. 1978, IA–14, 526–530. [Google Scholar] [CrossRef]

- Iuga, A.; Samuila, A.; Morar, R.; Bilici, M.; Dascalescu, L. Tribocharging Techniques for the Electrostatic Separation of Granular Plastics from Waste Electric and Electronic Equipment. J. Part. Sci. Technol. 2015, 34, 45–54. [Google Scholar] [CrossRef]

- Benabboun, A.; Tilmatine, A.; Brahami, Y.; Bendimerad, S.E.; Miloudi, M.; Medles, K. Experimental Investigation of Electrostatic Separators of Plastic Particles Using Different Charging Devices. Sep. Sci. Technol. 2014, 49, 464–468. [Google Scholar] [CrossRef]

- Sohaili, J.; Muniyandi, S.K.; Mohamad, S.S. A Review on Printed Circuit Board Recycling Technology. Int. J. Sci. Eng. Res. 2012, 3, 12–18. [Google Scholar]

- Iuga, A.; Samuila, A.; Neamtu, V.; Morar, R.; Beleca, R.; Das, S.; Dascalescu, L. Removal of Metallic Particles from Acrylonitrile Butadiene Styrene Wastes Using Electrostatic Separation Methods. IEEE Trans. Ind. Appl. 2011, 47, 322–330. [Google Scholar] [CrossRef]

- Bendaoud, A.; Tilmatine, A.; Medles, K.; Rahli, M.; Huzau, M.; Dascalescu, L. Characterisation of Dual Corona-Electrodes for Electrostatic Processes Applications. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; Volume 3, pp. 1552–1558. [Google Scholar] [CrossRef]

- Iuga, A.; Calin, L.; Neamtu, V.; Mihalcioiu, A.; Dascalescu, L. Tribocharging of Plastics Granulates in a Fluidized Bed Device. J. Electrostat. 2005, 63, 937–942. [Google Scholar] [CrossRef]

- Park, C.H.; Park, J.K.; Jeon, H.S.; Chun, B.C. Triboelectric Series and Charging Properties of Plastics Using the Designed Vertical-Reciprocation Charger. J. Electrostat. 2008, 66, 578–583. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, G.; Pan, D.; Wang, W.; Wu, Y.; Zuo, T. Overview of the Recycling Technology for Copper-Containing Cables. Resour. Conserv. Recycl. 2017, 126, 132–140. [Google Scholar] [CrossRef]

- Veit, H.M.; Bernardes, A.M.; Ferreira, J.Z.; Tenório, J.A.S.; Malfatti, C. de F. Recovery of Copper from Printed Circuit Boards Scraps by Mechanical Processing and Electrometallurgy. J. Hazard. Mater. 2006, 137, 1704–1709. [Google Scholar] [CrossRef] [PubMed]

- Jeon, H.S.; Park, C.H.; Cho, B.G.; Park, J.K. Separation of PVC and Rubber from Covering Plastics in Communication Cable Scrap by Tribo-Charging. J. Sep. Sci. Technol. 2009, 44. [Google Scholar] [CrossRef]

- Li, J.; Wu, G.; Xu, Z. Tribo-Charging Properties of Waste Plastic Granules in Process of Tribo-Electrostatic Separation. Waste Manag. 2015, 35, 36–41. [Google Scholar] [CrossRef]

- Miloudi, M.; Dascalescu, L.; Li, J.; Medles, K.; Tilmatine, A. Improved Overall Performances of a Tribo-Aero-Electrostatic Separator for Granular Plastics from Waste Electric and Electronic Equipment. IEEE Trans. Ind. Appl. 2015, 51, 4159–4165. [Google Scholar] [CrossRef]

- Aksa, W.; Medles, K.; Rezoug, M.; Boukhoulda, M.F.; Bilici, M.; Dascalescu, L. Two Stage Electrostatic Separator for the Recycling of Plastics from Waste Electrical and Electronic Equipment. J. Electrostat. 2013, 71, 681–688. [Google Scholar] [CrossRef]

- Dascalescu, L.; Zeghloul, T.; Iuga, A. Chapter 4-Electrostatic Separation of Metals and Plastics from Waste Electrical and Electronic Equipment. In WEEE Recycling; Chagnes, A., Cote, G., Ekberg, C., Nilsson, M., Retegan, T., Eds.; Elsevier: Amsterdam, Netherlands, 2016; pp. 75–106. [Google Scholar] [CrossRef]

- Zelmat, M.E.; Tilmatine, A.; Touhami, S.; Bendaoud, A.; Medles, K.; Ouiddir, R.; Dascalescu, L. Experimental Investigation of a New Tribo-Aeroelectrostatic Separation Process for Micronized Plastics from WEEE. IEEE Trans. Ind. Appl. 2017, 53, 4950–4956. [Google Scholar] [CrossRef]

- Cangialosi, F.; Crapulli, F.; Intini, G.; Liberti, L.; Notarnicola, M. Modelling of Tribo-Electrostatic Separation for Industrial by-Products Recycling. WIT Trans. Ecol. Environ. 2006, 92, 101–110. [Google Scholar] [CrossRef]

- Zhang, C. Completely Bounded Banach-Mazur Distance. Proc. Edinburgh Math. Soc. 1997, 40, 247–260. [Google Scholar] [CrossRef][Green Version]

- He, J.; Duan, C. Recovery of metallic concentrations from waste printed circuit boards via reverse floatation. Waste Manag. 2017, 60, 618–628. [Google Scholar] [CrossRef] [PubMed]

- Freitas, M.B.J.G.; Celante, V.G.; Pietre, M.K. Electrochemical Recovery of Cobalt and Copper from Spent Li-Ion Batteries as Multilayer Deposits. J. Power Sources 2010, 195, 3309–3315. [Google Scholar] [CrossRef]

- Sepúlveda, A.; Schluep, M.; Renaud, F.G.; Streicher, M.; Kuehr, R.; Hagelüken, C.; Gerecke, A.C. A Review of the Environmental Fate and Effects of Hazardous Substances Released from Electrical and Electronic Equipments during Recycling: Examples from China and India. Environ. Impact Assess. Rev. 2010, 30, 28–41. [Google Scholar] [CrossRef]

- Lee, J.; Pandey, B.D. Bio-Processing of Solid Wastes and Secondary Resources for Metal Extraction—A Review. Waste Manag. 2012, 32, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Qiu, K. A New Technology for Recycling Materials from Waste Printed Circuit Boards. J. Hazard. Mater. 2010, 175, 823–828. [Google Scholar] [CrossRef]

- Traversi, R.; Becagli, S.; Calzolai, G.; Chiari, M.; Giannoni, M.; Lucarelli, F.; Nava, S.; Rugi, F.; Severi, M.; Udisti, R. A Comparison between PIXE and ICP-AES Measurements of Metals in Aerosol Particulate Collected in Urban and Marine Sites in Italy. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2014, 318, 130–134. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Koh, L.; Rosa, P. Recycling of WEEEs: An economic assessment of present and future e-waste streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- De Marco, I.; Caballero, B.M.; Chomón, M.J.; Laresgoiti, M.F.; Torres, A.; Fernández, G.; Arnaiz, S. Pyrolysis of Electrical and Electronic Wastes. J. Anal. Appl. Pyrolysis 2008, 82, 179–183. [Google Scholar] [CrossRef]

- Yang, H.; Liu, J.; Yang, J. Leaching Copper from Shredded Particles of Waste Printed Circuit Boards. J. Hazard. Mater. 2011, 187, 393–400. [Google Scholar] [CrossRef]

- Liang, G.; Tang, J.; Liu, W.; Zhou, Q. Optimizing Mixed Culture of Two Acidophiles to Improve Copper Recovery from Printed Circuit Boards (PCBs). J. Hazard. Mater. 2013, 250–251, 238–245. [Google Scholar] [CrossRef]

- Birloaga, I.; De Michelis, I.; Ferella, F.; Buzatu, M.; Vegliò, F. Study on the Influence of Various Factors in the Hydrometallurgical Processing of Waste Printed Circuit Boards for Copper and Gold Recovery. Waste Manag. 2013, 33, 935–941. [Google Scholar] [CrossRef] [PubMed]

- Bigum, M.; Brogaard, L.; Christensen, T.H. Metal Recovery from High-Grade WEEE: A Life Cycle Assessment. J. Hazard. Mater. 2012, 207–208, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Yeh, C.-H.; Xu, Y. Sustainable Planning of E-Waste Recycling Activities Using Fuzzy Multicriteria Decision Making. J. Clean. Prod. 2013, 52, 194–204. [Google Scholar] [CrossRef]

- Ghosh, B.; Ghosh, M.K.; Parhi, P.; Mukherjee, P.S.; Mishra, B.K. Waste Printed Circuit Boards Recycling: An Extensive Assessment of Current Status. J. Clean. Prod. 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Fogarasi, S.; Imre-Lucaci, F.; Ilea, P.; Imre-Lucaci, Á. The Environmental Assessment of Two New Copper Recovery Processes from Waste Printed Circuit Boards. J. Clean. Prod. 2013, 54, 264–269. [Google Scholar] [CrossRef]

- Lister, T.E.; Wang, P.; Anderko, A. Recovery of Critical and Value Metals from Mobile Electronics Enabled by Electrochemical Processing. Hydrometallurgy 2014, 149, 228–237. [Google Scholar] [CrossRef]

- Kim, E.; Kim, M.; Lee, J.; Jeong, J.; Pandey, B.D. Leaching Kinetics of Copper from Waste Printed Circuit Boards by Electro-Generated Chlorine in HCl Solution. Hydrometallurgy 2011, 107, 124–132. [Google Scholar] [CrossRef]

- Casas, J.M.; Acuña-Goycolea, P.; Crisóstomo, G.; Cifuentes, L. Processing of a Ferric Anolyte Produced by a Copper Electrowinning Cell Based on Reactive Electro Dialysis. Miner. Eng. 2008, 21, 525–532. [Google Scholar] [CrossRef]

- Fogarasi, S.; Imre-Lucaci, F.; Imre-Lucaci, Á.; Ilea, P. Copper Recovery and Gold Enrichment from Waste Printed Circuit Boards by Mediated Electrochemical Oxidation. J. Hazard. Mater. 2014, 273, 215–221. [Google Scholar] [CrossRef]

- Diaz, L.A.; Lister, T.E.; Parkman, J.A.; Clark, G.G. Comprehensive Process for the Recovery of Value and Critical Materials from Electronic Waste. J. Clean. Prod. 2016, 125, 236–244. [Google Scholar] [CrossRef]

- Imre-Lucaci, F.; Fogarasi, S.; Ilea, P.; Tamasan, M. Copper Recovery from Real Samples of WPCBs by Anodic Dissolution. Environ. Eng. Manag. J. 2012, 11, 1439–1444. [Google Scholar] [CrossRef]

- Ping, Z.; ZeYun, F.; Jie, L.; Qiang, L.; Guang Ren, Q.; Ming, Z. Enhancement of Leaching Copper by Electro-Oxidation from Metal Powders of Waste Printed Circuit Board. J. Hazard. Mater. 2009, 166, 746–750. [Google Scholar] [CrossRef] [PubMed]

- Imre-Lucaci, Á.; Nagy, M.; Imre-Lucaci, F.; Fogarasi, S. Technical and environmental assessment of gold recovery from secondary streams obtained in the processing of waste printed circuit boards. Chem. Eng. J. 2017, 309, 655–662. [Google Scholar] [CrossRef]

- Kumari, A.; Jha, M.K.; Lee, J.; Singh, R.P. Clean Process for Recovery of Metals and Recycling of Acid from the Leach Liquor of PCBs. J. Clean. Prod. 2016, 112, 4826–4834. [Google Scholar] [CrossRef]

- Lei, J.; Yuan, G.; Weerachanchai, P.; Lee, S.W.; Li, K.; Wang, J.Y.; Yang, Y. Investigation on Thermal Dechlorination and Catalytic Pyrolysis in a Continuous Process for Liquid Fuel Recovery from Mixed Plastic Wastes. J. Mater. Cycles Waste Manag. 2018, 20, 137–146. [Google Scholar] [CrossRef]

- Zabłocka-Malicka, M.; Szczepaniak, W.; Rutkowski, P.; Ochromowicz, K.; Leśniewicz, A.; Chęcmanowski, J. Decomposition of the ISA-Card under Steam for Valorized Polymetallic Raw Material. J. Anal. Appl. Pyrolysis 2018, 130, 256–268. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, G.; Li, A.; Wang, L. Economic Analysis of Waste-to-Energy Industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef]

- Othman, N.; Mohd Sidek, L.; Ahmad Basri, E.N.; Muhd Yunus, M. Electronic Plastic Waste Management in Malaysia: The Potential of Waste to Energy Conversion. In Proceedings of the 2009 3rd International Conference on Energy and Environment (ICEE), Malacca, Malaysia, 7–8 December 2009. [Google Scholar] [CrossRef]

- Jayaraman, K.; Vejayon, S.; Raman, S.; Mostafiz, I. The proposed e-waste management model from the conviction of individual laptop disposal practices—An empirical study in Malaysia. J. Clean. Prod. 2019, 208, 688–696. [Google Scholar] [CrossRef]

- Szałatkiewicz, J. Energy Recovery from Waste of Printed Circuit Boards in Plasmatron Plasma Reactor. Pol. J. Environ. Stud. 2014, 23, 277–281. [Google Scholar]

- Altarawneh, M.; Ahmed, O.H.; Jiang, Z.T.; Dlugogorski, B.Z. Thermal Recycling of Brominated Flame Retardants with Fe2O3. J. Phys. Chem. A 2016, 120, 6039–6047. [Google Scholar] [CrossRef]

- Imai, T.; Hamm, S.; Rothenbacher, K.P. Comparison of the Recyclability of Flame-Retarded Plastics. Environ. Sci. Technol. 2003, 37, 652–656. [Google Scholar] [CrossRef] [PubMed]

- Kasper, A.C.; Gabriel, A.P.; de Oliveira, E.L.B.; de Freitas Juchneski, N.C.; Veit, H.M. Electronic Waste Recycling BT-Electronic Waste: Recycling Techniques; Veit, H.M., Moura Bernardes, A., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 87–127. [Google Scholar] [CrossRef]

- Long, L.; Sun, S.; Zhong, S.; Dai, W.; Liu, J.; Song, W. Using Vacuum Pyrolysis and Mechanical Processing for Recycling Waste Printed Circuit Boards. J. Hazard. Mater. 2010, 177, 626–632. [Google Scholar] [CrossRef] [PubMed]

- Evangelopoulos, P.; Kantarelis, E.; Yang, W. Investigation of the Thermal Decomposition of Printed Circuit Boards (PCBs) via Thermogravimetric Analysis (TGA) and Analytical Pyrolysis (Py–GC/MS). J. Anal. Appl. Pyrolysis 2015, 115, 337–343. [Google Scholar] [CrossRef]

- Xiang, D.; Mou, P.; Wang, J.; Duan, G.; Zhang, H.C. Printed Circuit Board Recycling Process and Its Environmental Impact Assessment. Int. J. Adv. Manuf. Technol. 2007, 34, 1030–1036. [Google Scholar] [CrossRef]

- Havlik, T.; Orac, D.; Petranikova, M.; Miskufova, A. Hydrometallurgical Treatment of Used Printed Circuit Boards after Thermal Treatment. Waste Manag. 2011, 31, 1542–1546. [Google Scholar] [CrossRef]

- Fujita, T.; Ono, H.; Dodbiba, G.; Yamaguchi, K. Evaluation of a Recycling Process for Printed Circuit Board by Physical Separation and Heat Treatment. Waste Manag. 2014, 34, 1264–1273. [Google Scholar] [CrossRef]

- Tuncuk, A.; Stazi, V.; Akcil, A.; Yazici, E.Y.; Deveci, H. Aqueous Metal Recovery Techniques from E-Scrap: Hydrometallurgy in Recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

- Moberg, Å.; Johansson, M.; Finnveden, G.; Jonsson, A. Printed and Tablet E-Paper Newspaper from an Environmental Perspective—A Screening Life Cycle Assessment. Environ. Impact Assess. Rev. 2010, 30, 177–191. [Google Scholar] [CrossRef]

| Electronic Parts of PCB | Weight/Piece (g) | Ag (g/Kg) | Au (g/Kg) | Pd (g/Kg) | Pt (g/Kg) | Cu (g/Kg) | Al (g/Kg) |

|---|---|---|---|---|---|---|---|

| Aluminum capacitor | 5.551 | 0 | 0.001 | 0.0001 | 0.001 | 7.4 | 670 |

| Tantalum capacitor | 0.27 | 0 | 0.14 | 0 | 0 | 0.22 | 1.3 |

| Ceramic capacitor | 0.218 | 0.06 | 0.036 | 0 | 0 | 510 | 0.25 |

| Smallest capacitor | 0.006 | 100 | 0.008 | 35 | 5 | 2.4 | 1.3 |

| Electronic resistance | 1.625 | 57.602 | 3.601 | 2.509 | 0 | 380.4 | 34.94 |

| Plastic IC chip | 9.913 | 12.2 | 15.398 | 0.083 | 0.264 | 901 | 4.879 |

| Central processing units (without metal film) | 6.02 | 0.055 | 0.517 | 0.075 | 0 | 500 | 0 |

| Integrated Graphics Processor (IGP) | 4.13 | 0.032 | 0.501 | 0.041 | 0 | 171 | 0 |

| Integrated Drive Electronics Connector | 0.681 | 0.016 | 0.37 | 0.007 | 0 | 770 | 8.8 |

| Small Computer System Interface Connector | 0.882 | 0.002 | 0.7 | 0 | 0.052 | 0.21 | 110 |

| Processes | Separation Criteria | Principles of Separation | Sorting Task | Workable Particle Size Range |

|---|---|---|---|---|

| Shredding, washing, sieving | Shredding: Mechanical forces. Sieving: Vibratory. | Washing: To remove the adhered impurities. Sieving: Using sieves coupled to a vibratory agitator. | Shredding: Crushing and grinding. Washing: Separation the impurities from the useful material. Sieving: Particle size separation. | 3–5 mm |

| Magnetic separation | Magnetic field. | The use of magnets to separate magnetic materials from mixtures. | Separation ferromagnetic metals from non-ferrous metals and other non-magnetic waste. | 3–5 mm |

| Eddy current separation | Electric conductivity and density. | The use of a powerful magnetic field to separate non-ferrous metals. | Non-ferrous metal/non-metal separation. | >5 mm |

| Corona electrostatic separation | Electric conductivity. | Different charges of particles resulting in different forces between particles. | Metal/non-metal separation. | 0.1–5 mm (10 mm for laminar particles) |

| Triboelectrostatic separation | Dielectric constant. | Tribo-charge with different charges (+ or −) of the components’ force directions. | Separation of plastics (non-conductors). | <5 (10) mm |

| Density Separation Process | Workable Piece Sizes (mm) | Plastics Waste | Aluminum Scrap | Cable Scrap | Electronic Scrap | Light Steel Scrap |

|---|---|---|---|---|---|---|

| Sink-float separation—Liquids |  |  |  | |||

| Sink-float separation—Gravity separator | 5–150 |  |  | |||

| Sink-float separation—Hydrocyclone | <50 |  | ||||

| Sink-float separation—Aero-chutes | 0.7–3 |  | ||||

| Sink-float separation—Fluidized bed trough separation | 0.7–5 |  | ||||

| Sorting by hydraulic jigs | 2–20 |  | ||||

| Sorting by pneumatic jigs | <3 |  | ||||

| Sorting in Aero-chutes | 0.6–2 |  | ||||

| Sorting in Aero-tables | <4 |  | ||||

| Up-stream hydraulic separation | 5–150 |  |  | |||

| Up-stream pneumatic separation | <300 |  |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vermeșan, H.; Tiuc, A.-E.; Purcar, M. Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability 2020, 12, 74. https://doi.org/10.3390/su12010074

Vermeșan H, Tiuc A-E, Purcar M. Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability. 2020; 12(1):74. https://doi.org/10.3390/su12010074

Chicago/Turabian StyleVermeșan, Horațiu, Ancuța-Elena Tiuc, and Marius Purcar. 2020. "Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards" Sustainability 12, no. 1: 74. https://doi.org/10.3390/su12010074

APA StyleVermeșan, H., Tiuc, A.-E., & Purcar, M. (2020). Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability, 12(1), 74. https://doi.org/10.3390/su12010074