Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof

Abstract

1. Introduction

2. Experimental Design

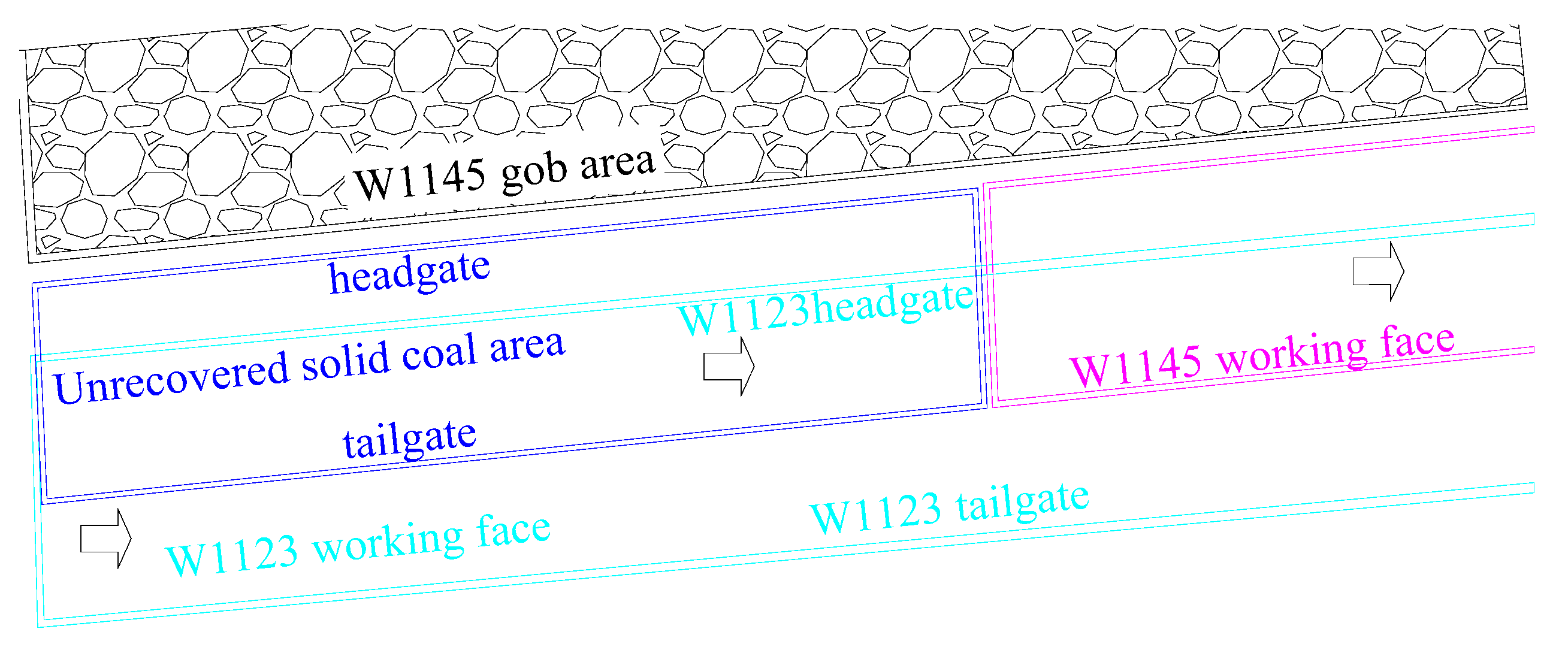

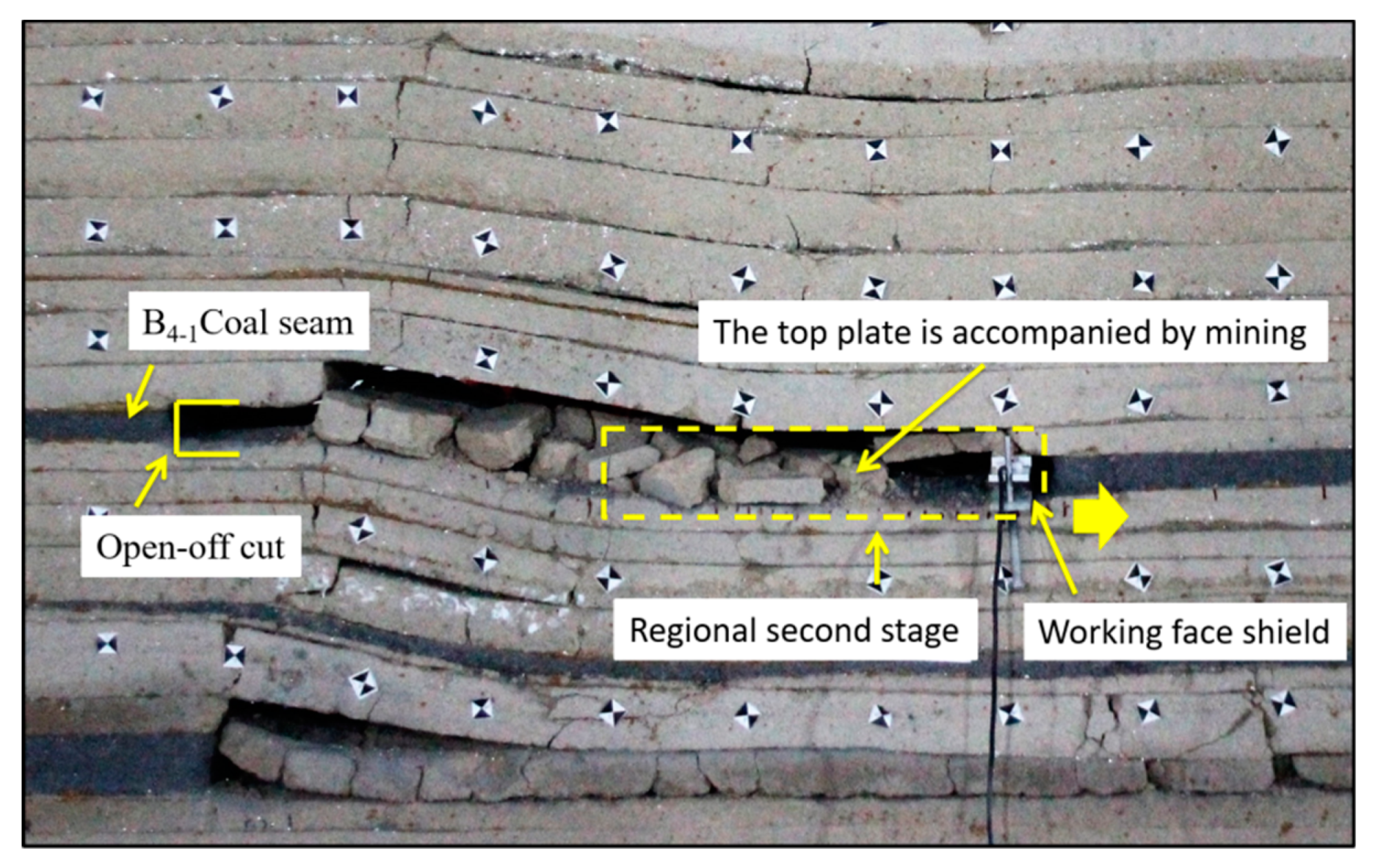

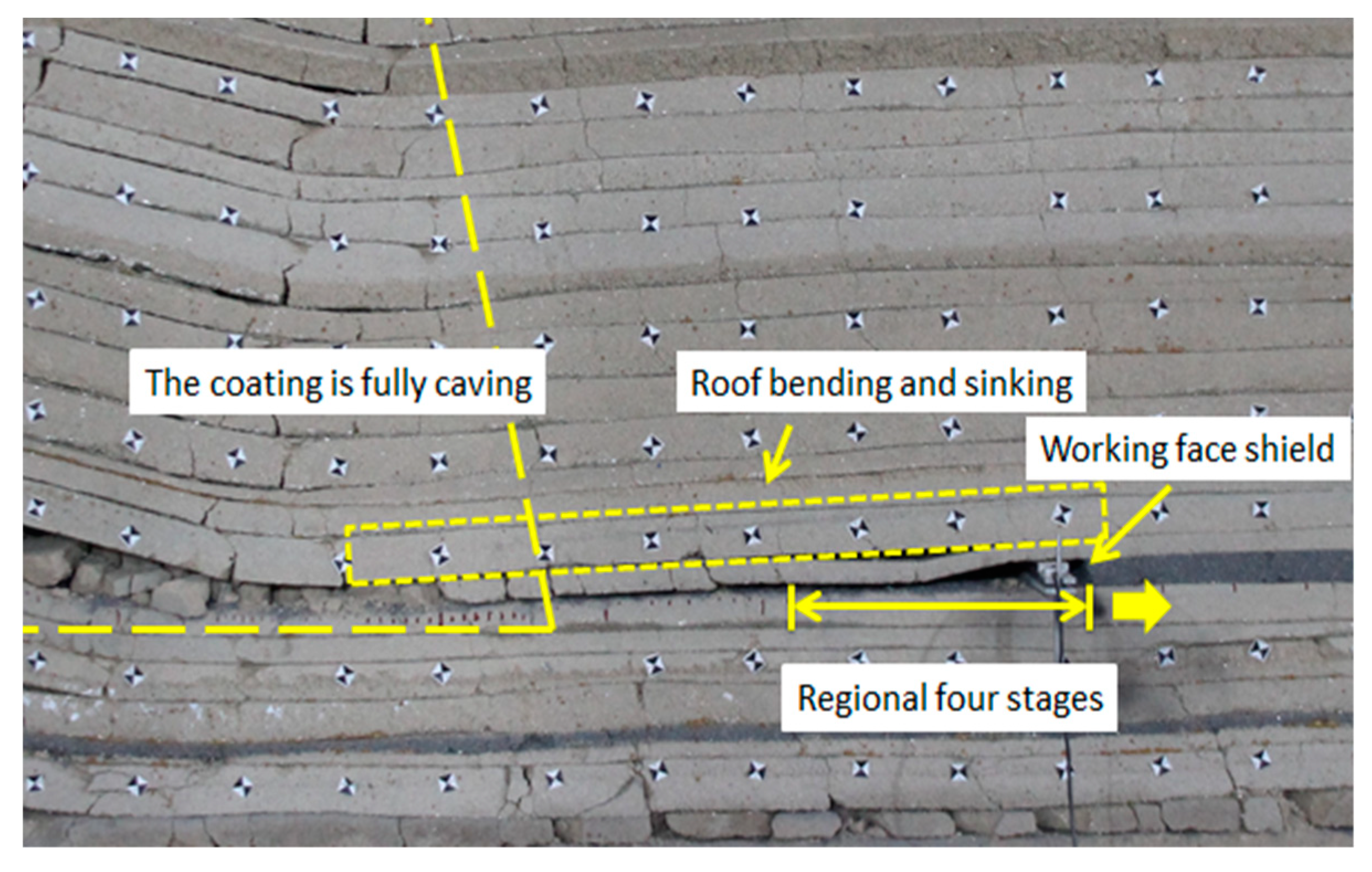

2.1. Engineering Background

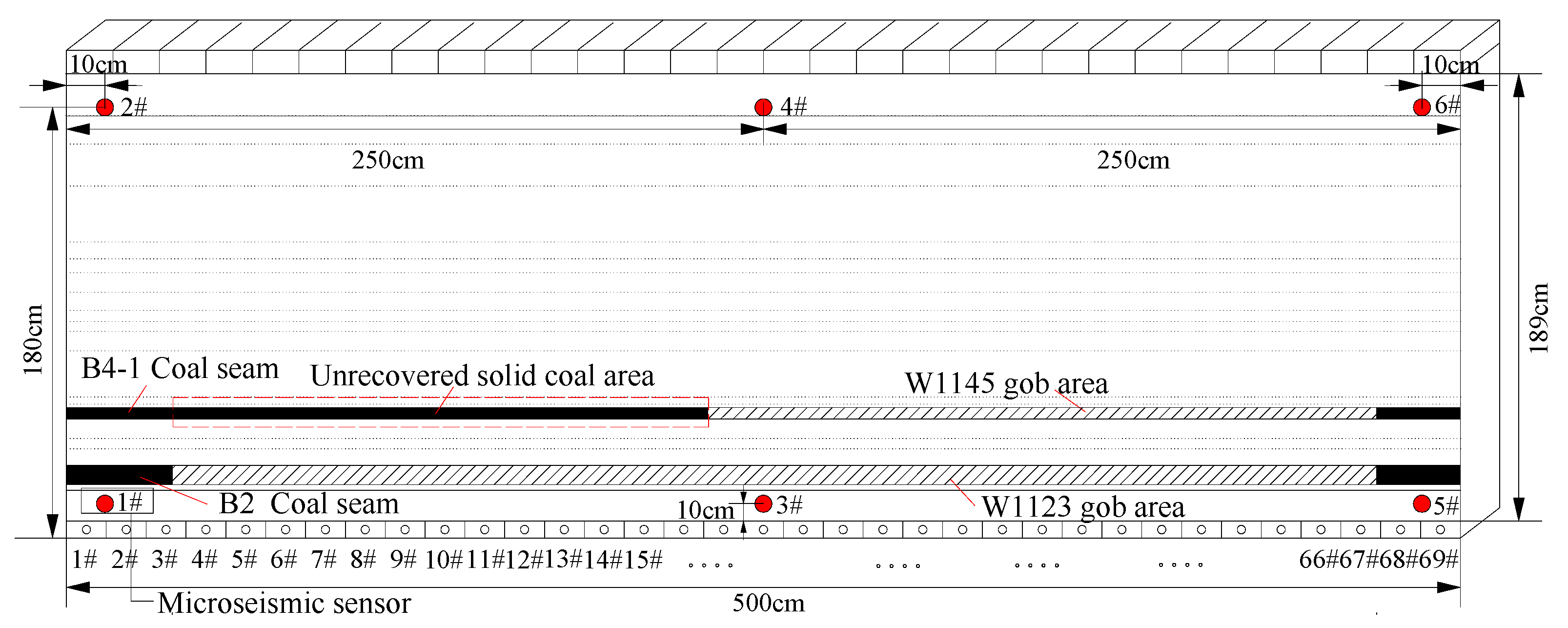

2.2. Model Desgin

2.3. Experimental Scheme

3. Advancing Speed of Energy Release from Upward Mining Overlying Rocks and Effect of Stoping Time

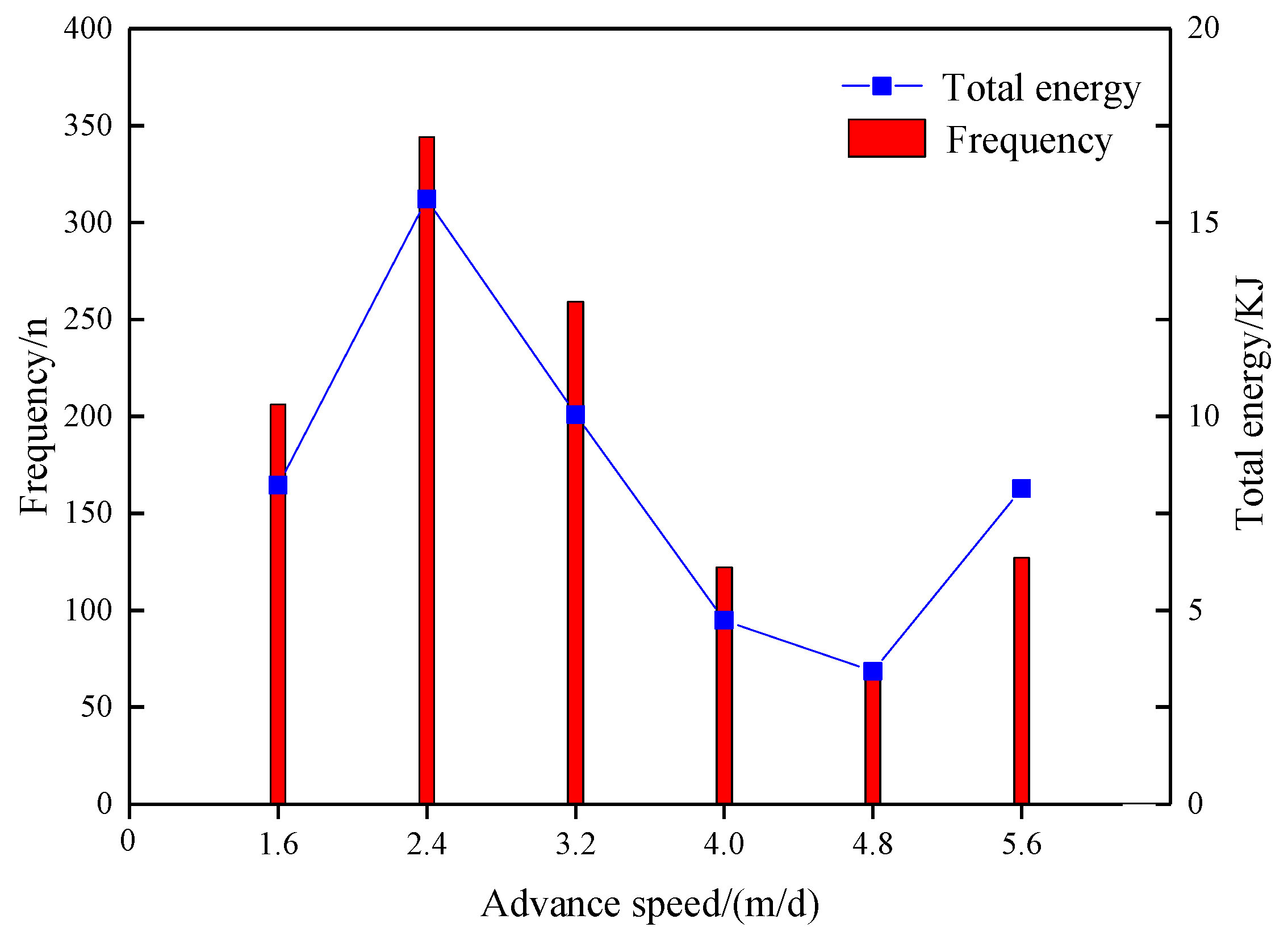

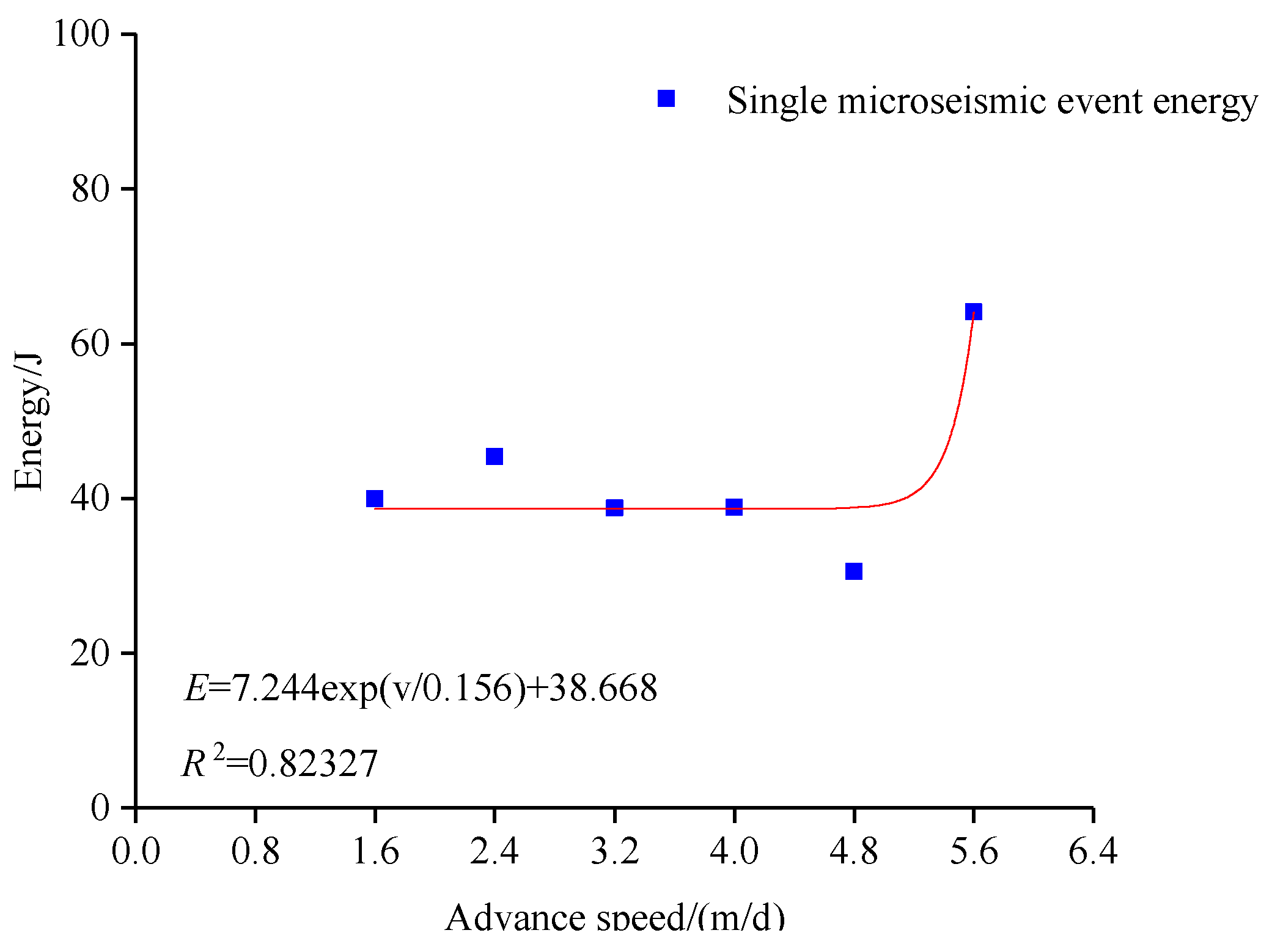

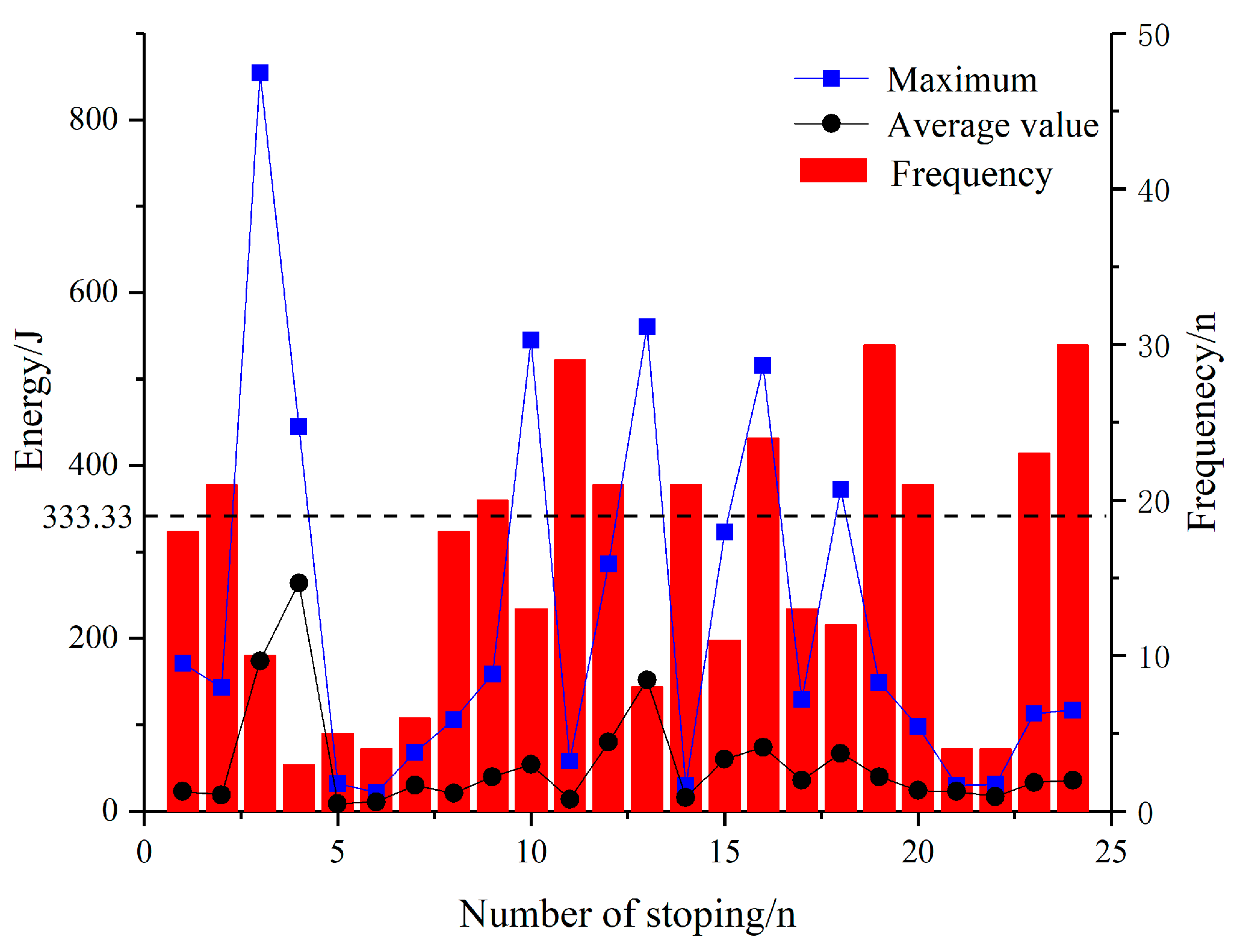

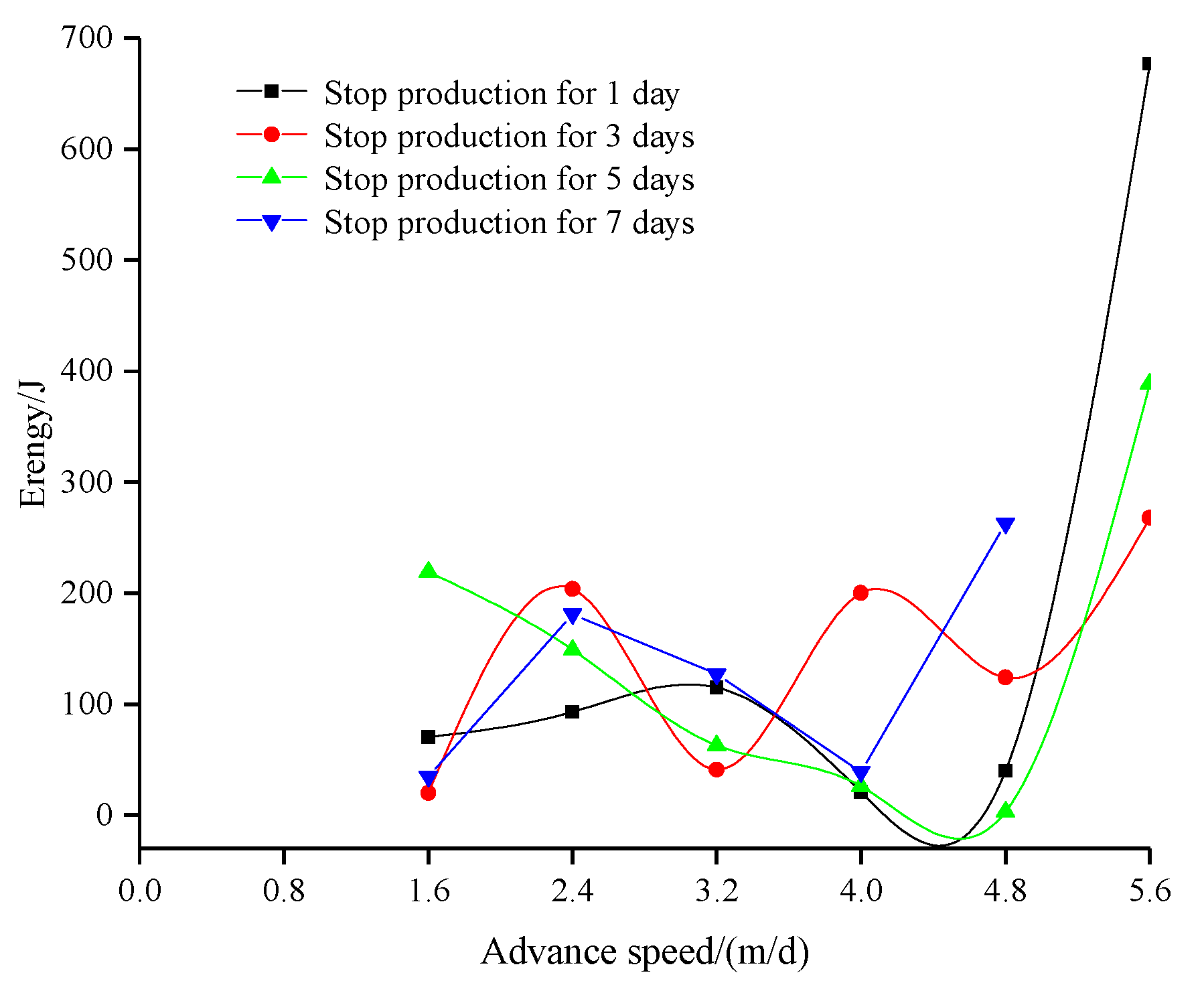

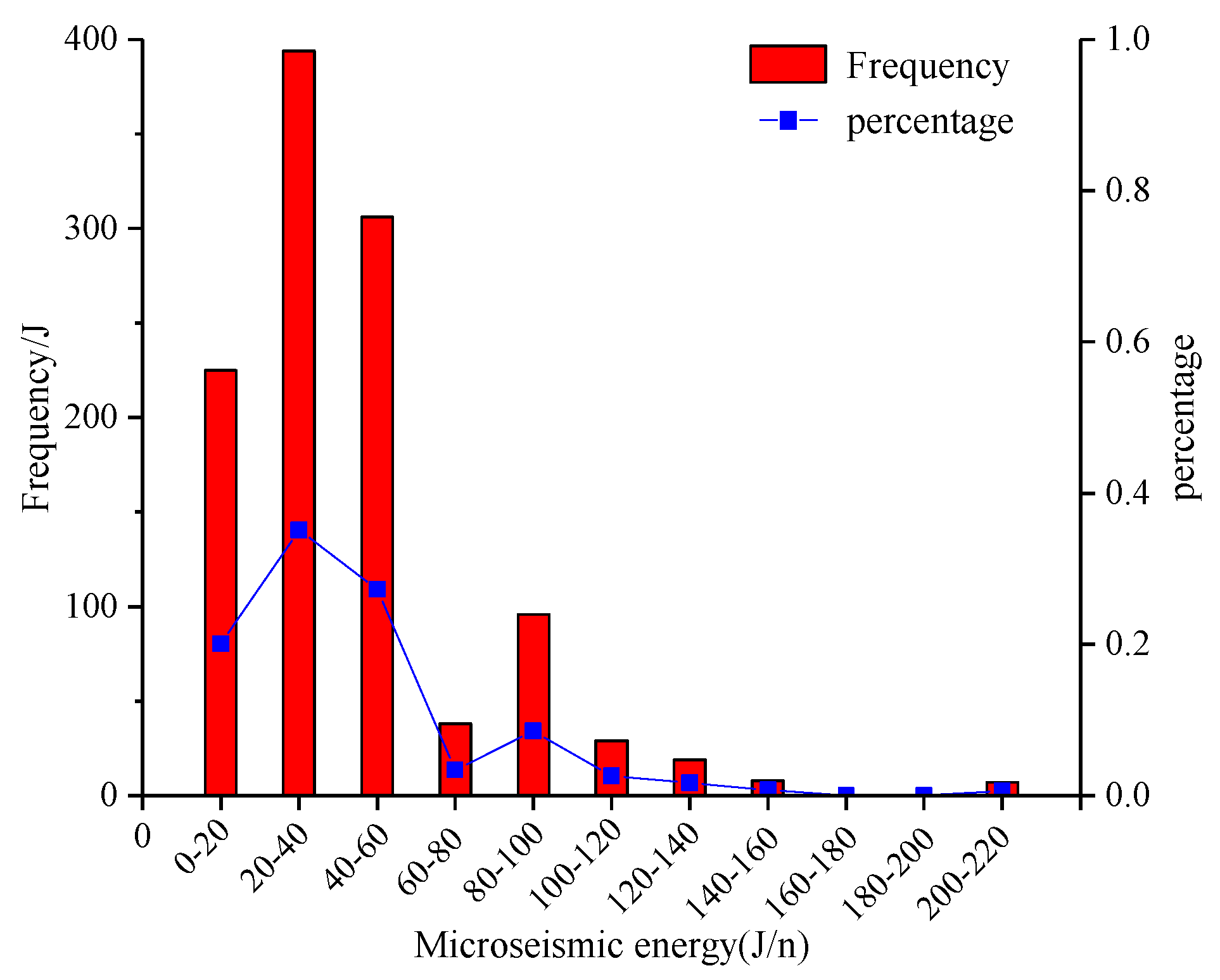

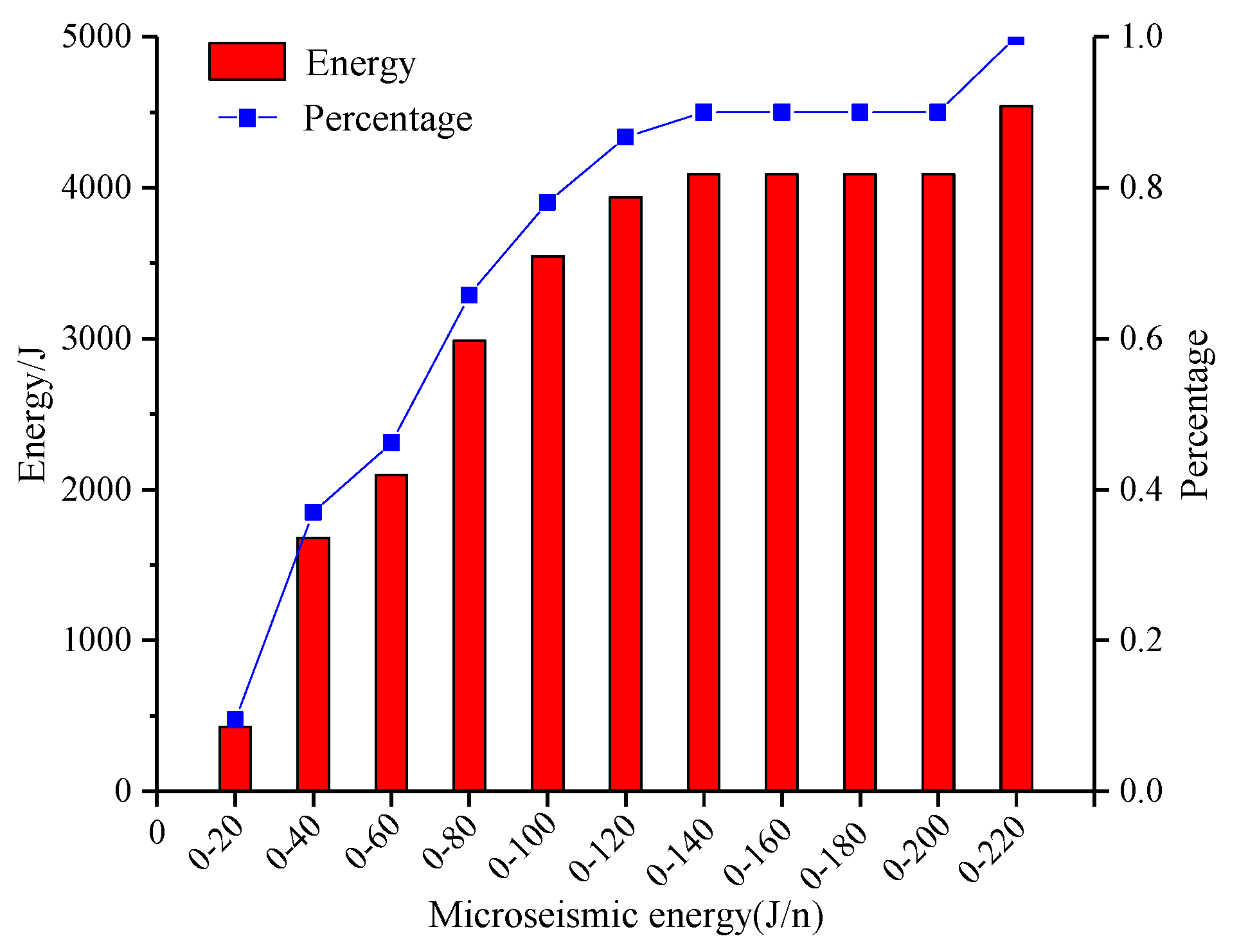

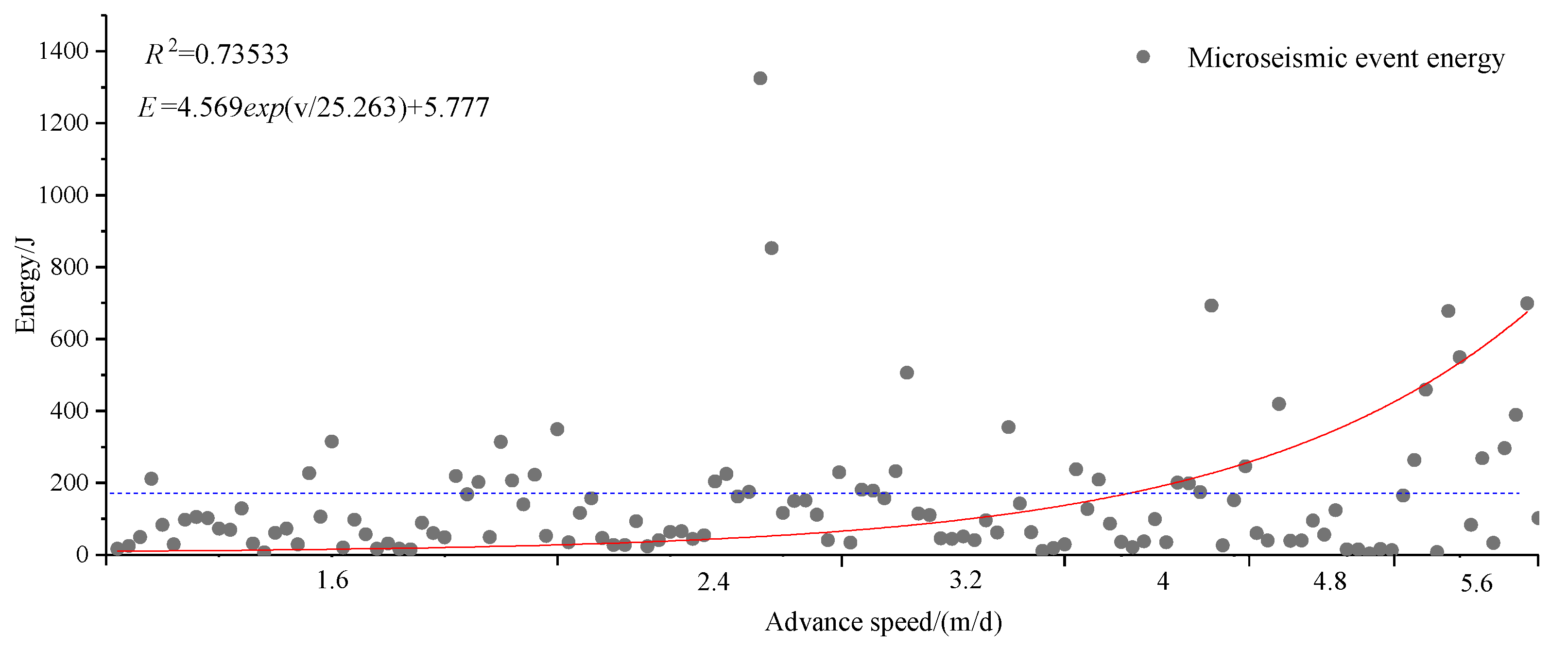

3.1. Evolution Law of Microseisms between Regions with Different Advance Speed

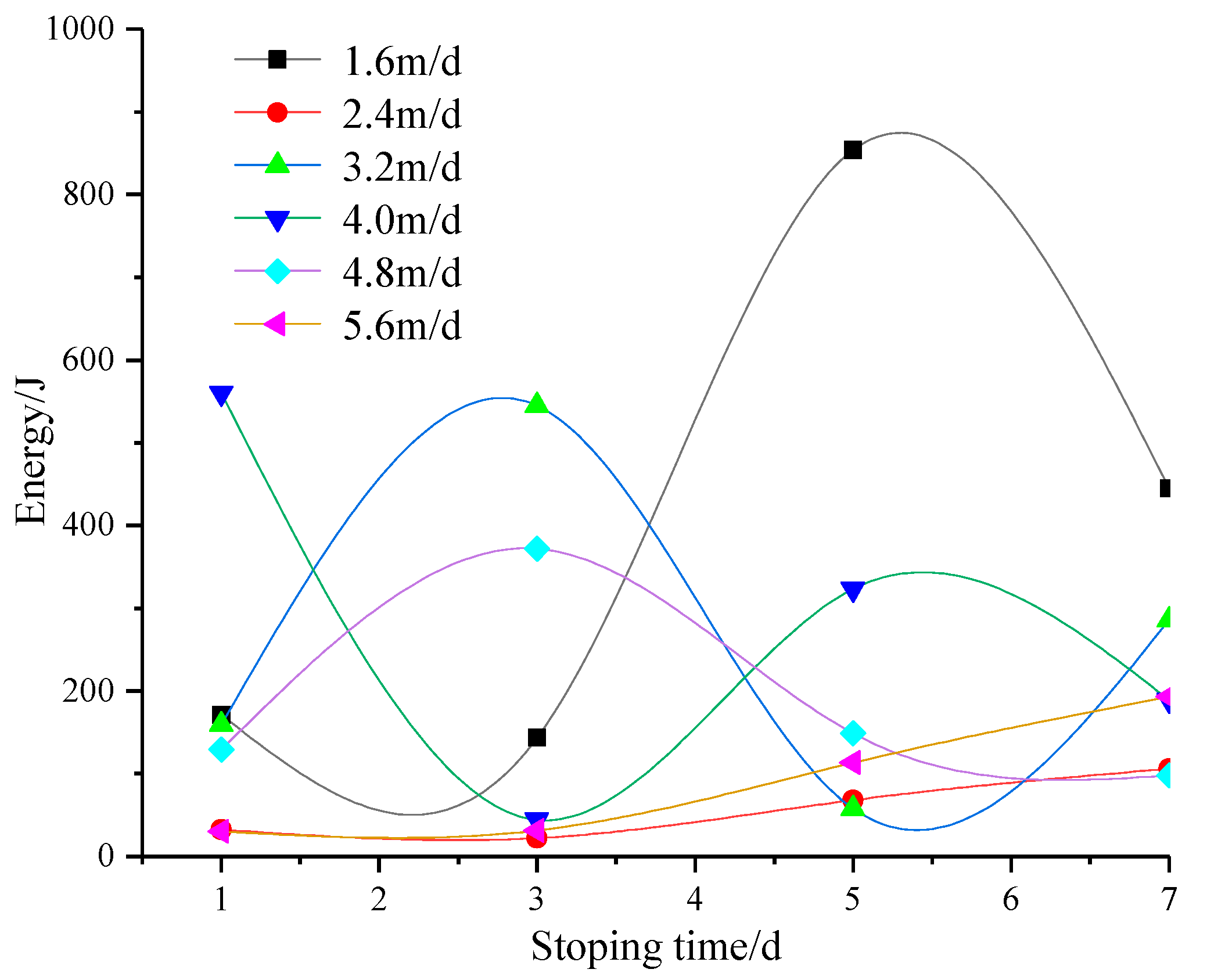

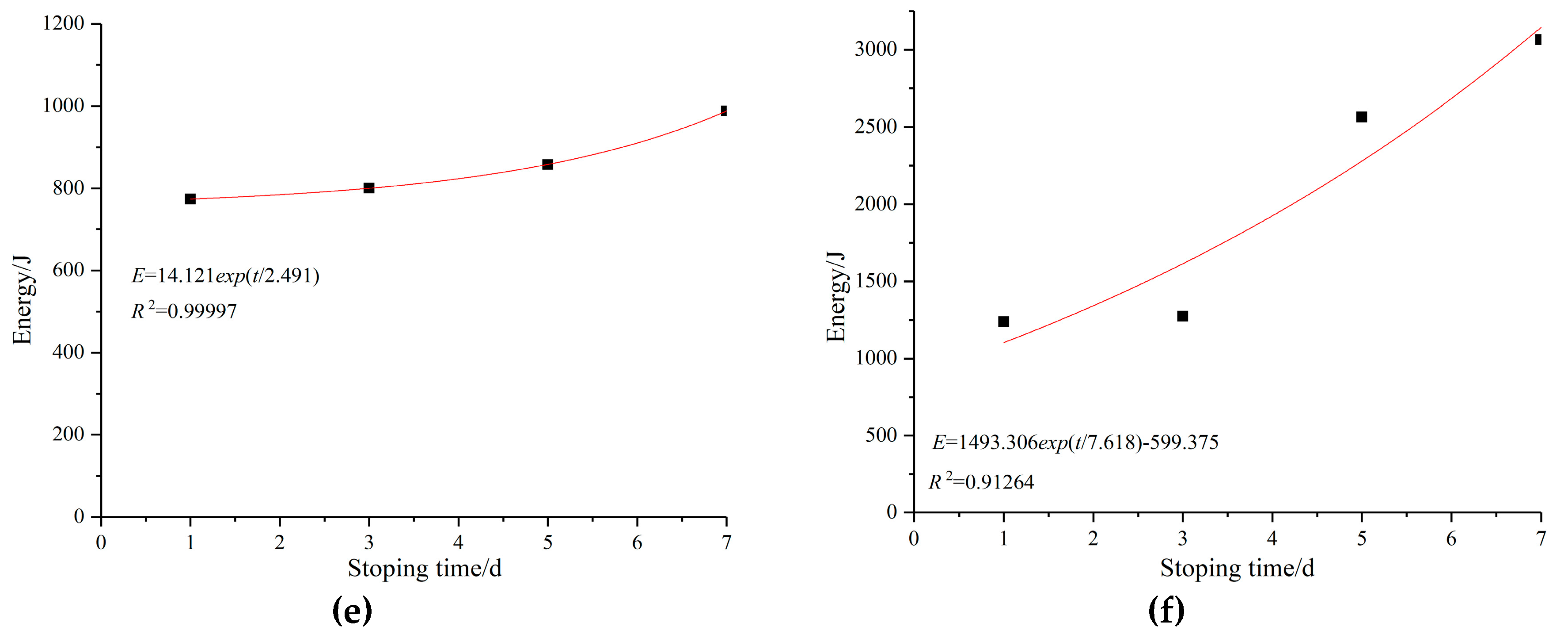

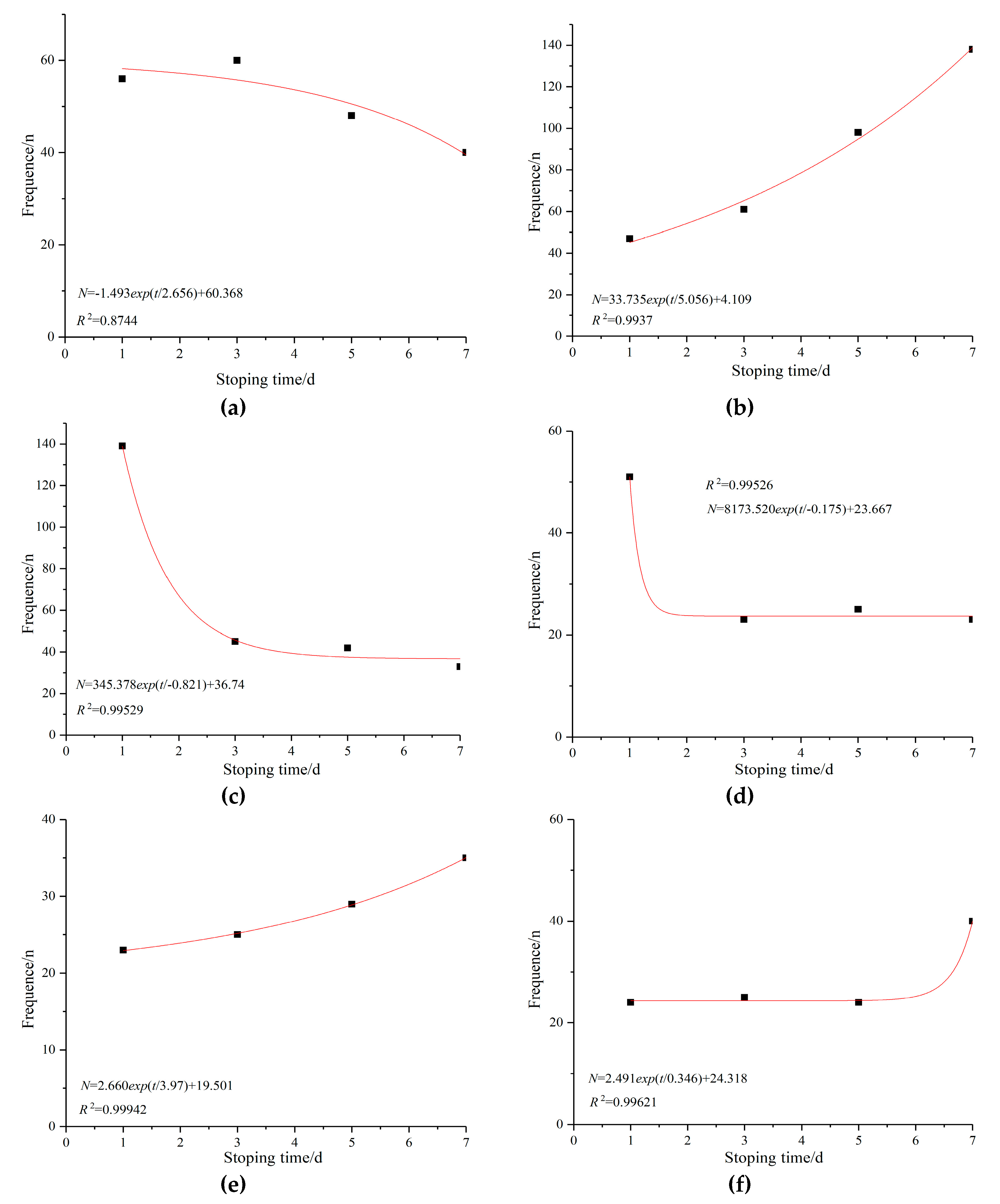

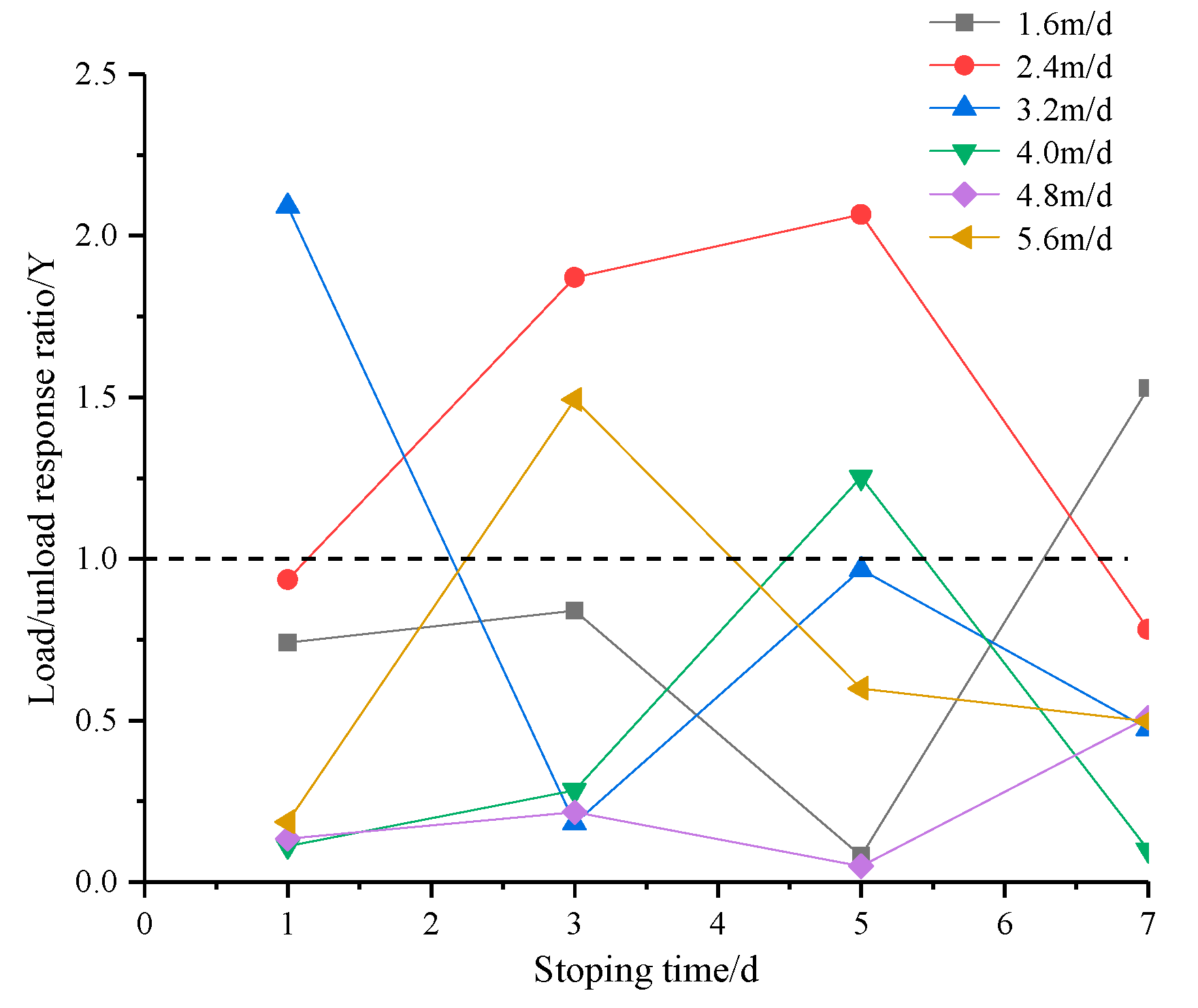

3.2. Microseismic Evolution Law under the Same Advancement Speed and Different Stoping Times

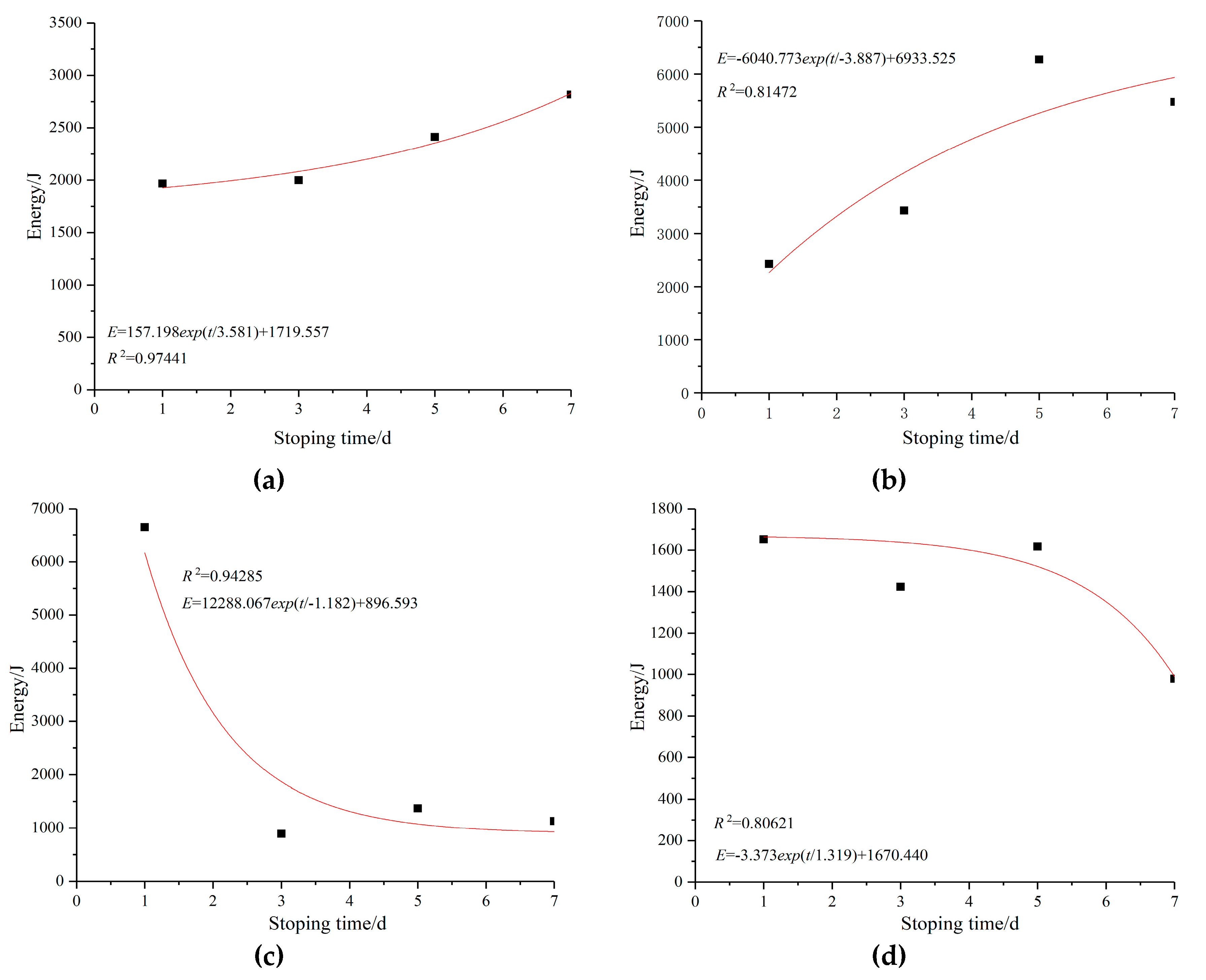

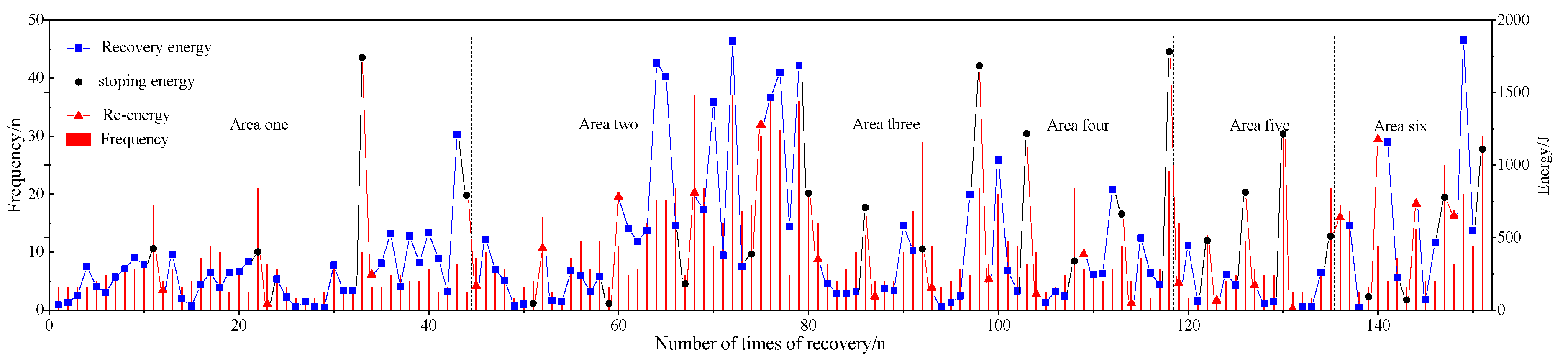

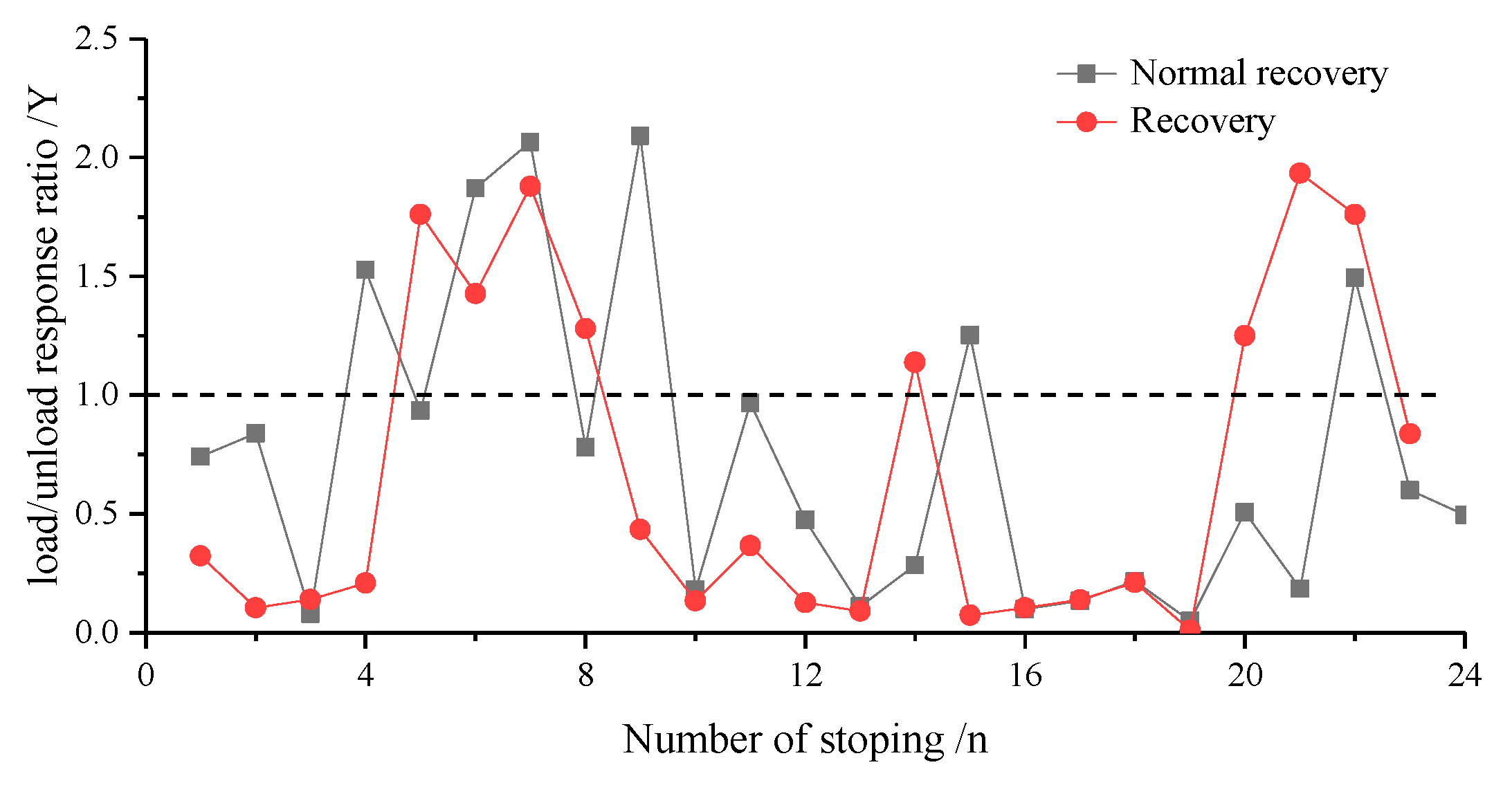

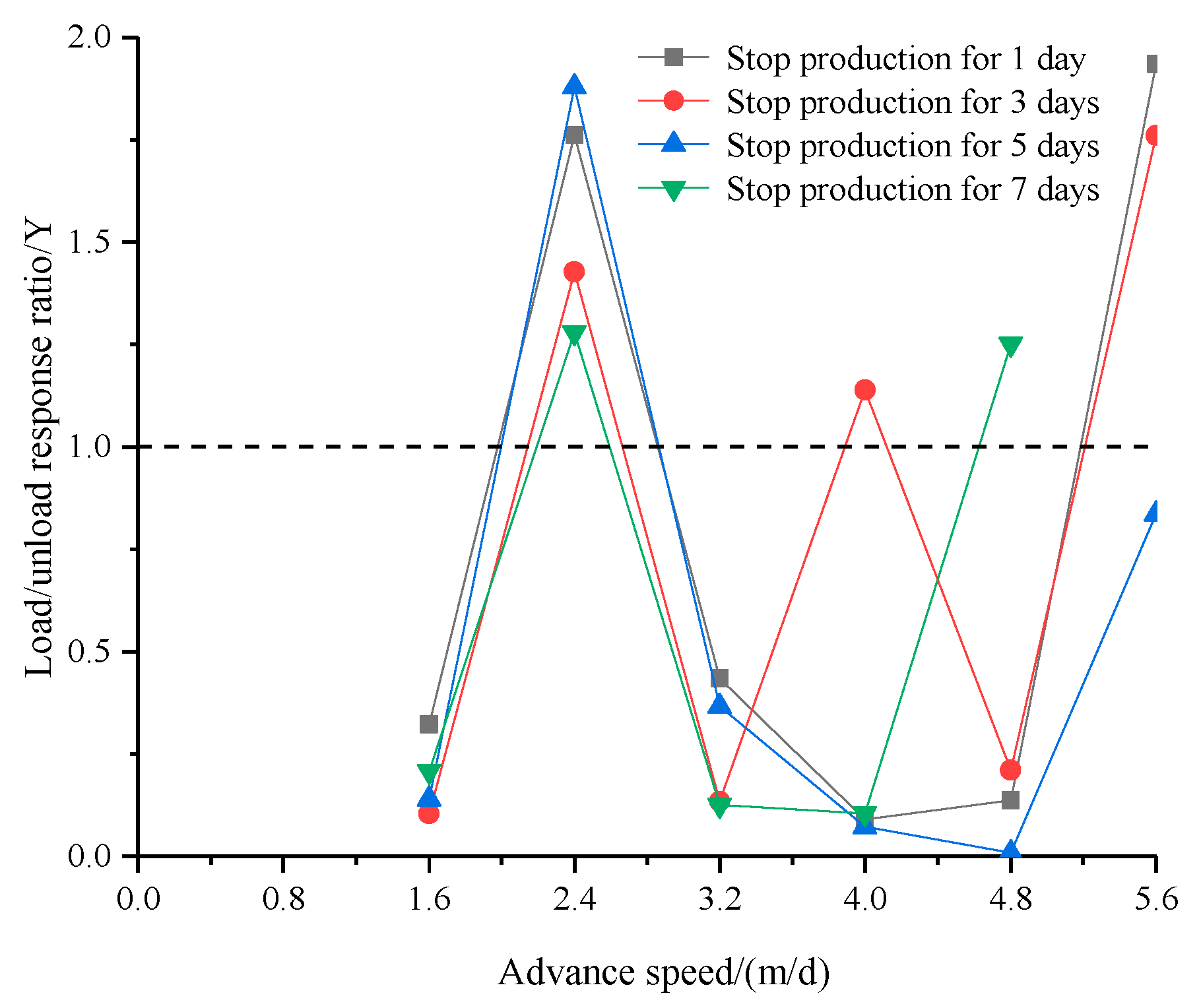

3.3. Time Effect of Stoping Production and Resuming Mining at Different Advancing Speed

4. Mechanism of Rock Burst Caused by the Effect of Working Face Advancing Speed and Stoping Time

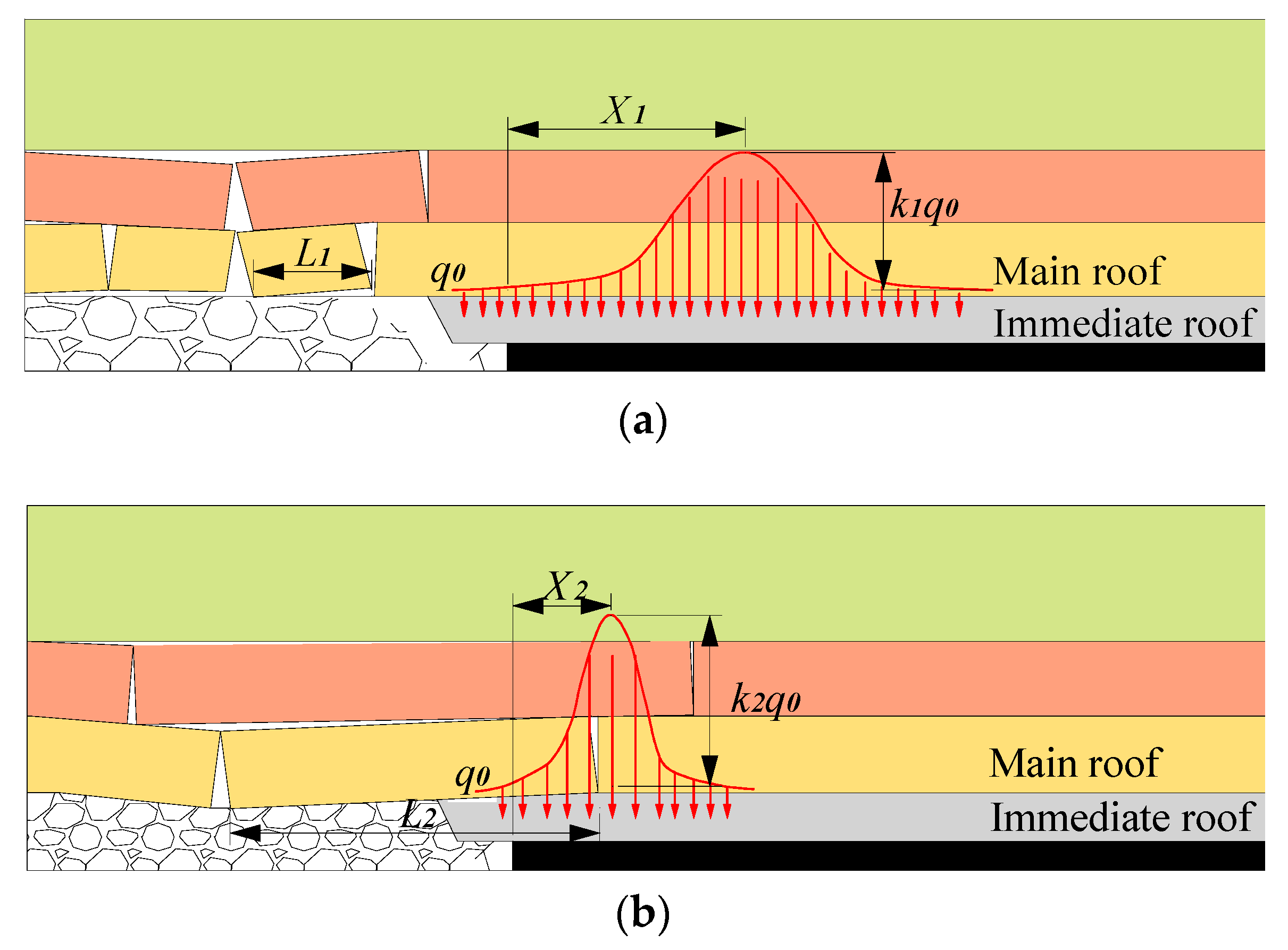

4.1. Mechanism of Rock Burst Caused by Change of Advancing Speed

4.2. Impact Ground Pressure Caused by Coordinated Change of Advancement Speed and Stoping Time

5. Coordinated Control and Disaster Reduction of Advancement Speed and Stoping Time

5.1. Determination of Safety Mining Indicators

5.2. Coordinated Control During Production Suspension and Recovery

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, Y.D.; Zao, Y.X. State of the art: Investigation on mechanism forecast and control of coal bumps in China. Chin. J. Rock Mech. Eng. 2015, 34, 2188–2204. [Google Scholar]

- Pan, Y.S.; Li, Z.H.; Zhang, M.T. Distribution, type, mechanism and prevention of rock burst in China. Chin. J. Rock Mech. Eng. 2003, 22, 1844–1851. [Google Scholar]

- Dou, L.M.; He, X.Q.; He, H.; He, J.; Fan, J. Spatial structure evolution of overlying strata and inducing mechanism of rock burst in coal mine. Trans. Nonferrous Met. Soc. China 2014, 24, 1255–1261. [Google Scholar] [CrossRef]

- Shan, P.F.; Lai, X.P. Numerical Simulation of the Fluid-Solid Coupling Process During the Failure of a Fractured Coal-Rock Mass Based on the Regional Geostress Characteristics. J. Transp. Porous Media 2018, 124, 1061–1079. [Google Scholar] [CrossRef]

- Shan, P.F.; Lai, X.P. Influence of CT scanning parameters on rock and soil images. J. Vis. Commun. Image Represent. 2019, 58, 642–650. [Google Scholar] [CrossRef]

- Dou, L.M.; He, X.Q. Technique of classification forecasting rock burst in coal mines. J. China Univ. Min. Technol. 2007, 36, 717–722. [Google Scholar]

- Cai, M.F.; Ji, H.G.; Wang, J.A. Study of the time-spacestrength relation for mining seismicity at Laohutai coal mine and its prediction. Int. J. Rock Mech. Min. Sci. 2005, 42, 145–151. [Google Scholar] [CrossRef]

- Simser, B.P. Rock burst management in Canadian hard rock mines. J. Rock Mech. Geotech. Eng. 2019, 11, 1036–1043. [Google Scholar] [CrossRef]

- Dou, L.M.; Lu, C.P.; Mu, Z.L.; Gao, M.S. Prevention and forecasting of rock burst hazards in coal mines. Min. Sci. Technol. 2009, 19, 585–591. [Google Scholar] [CrossRef]

- Li, H.T.; Song, L.; Zhou, H.W.; Jiang, Y.D.; Wang, H.W. Evaluation method and application of coal burst performance under the effect of loading rate. J. China Coal Soc. 2015, 40, 2763–2771. [Google Scholar]

- Wang, J.C.; Wang, Z.H. Impact effect of dynamic load induced byhard roof in high intensity working face. Chin. J. Rock Mech. Eng. 2015, 34, 1844–1851. [Google Scholar]

- Zhao, T.B.; Guo, W.Y.; Han, F.; Gu, S.T. Analysis on energy accumulation and release of roofunder influence of mining speed. Coal Sci. Technol. 2018, 46, 37–44. [Google Scholar]

- Wang, J.N.; Jiao, S.H.; Xie, G.X. Study on influence of mining rate on stress environment in surrounding rock of mechanized top caving working face. Chin. J. Rock Mech. Eng. 2006, 25, 1118–1124. [Google Scholar]

- Wang, L.; Xie, G.X. Influence of Mining Velocity on Dynamic Disasters in the Coal and Rock Mass at a Fully Mechanized Working face. J. China Univ. Min. Technol. 2010, 39, 70–74. [Google Scholar]

- Yang, S.L.; Wang, Z.H.; Jiang, W.; Yang, J.H. Advancing rate effect on rock and coal failure format in high-intensity working face. J. China Coal Soc. 2016, 41, 586–594. [Google Scholar]

- Dou, L.M.; Jiang, Y.D.; Cao, A.Y.; Liu, H.S.; Gong, S.F.; Cai, W.; Zhu, G.A. Monitoringand pre-warning of rock burst hazard with technology of stress fieldand wave field in underground coalmines. Chin. J. Rock 2017, 36, 803–811. [Google Scholar]

- Dou, L.M.; Mu, Z.L.; Li, Z.L.; Cao, A.Y.; Gong, S.Y. Research progress of monitoring, forecasting, andprevention of rock burst in underground coal mining in China. Int. J. Coal Sci. Technol. 2014, 1, 278–288. [Google Scholar] [CrossRef]

- Dou, L.M.; Chen, T.J.; Gong, S.Y.; He, H.; Zhang, S.B. Rock burst hazard determination by using computed tomography technology in deep workface. Saf. Sci. 2012, 50, 736–740. [Google Scholar] [CrossRef]

- He, X.Q.; Chen, W.X.; Nie, B.S.; Mitri, H. Electromagnetic emission theory and its application to dynamic phenomena in coal-rock. Int. J. Rock Mech. Min. Sci. 2011, 48, 1352–1358. [Google Scholar] [CrossRef]

- Liu, J.H.; Sun, H.; Tian, Z.J.; Jiang, F.X.; Li, D.; Wang, Y.; Zhu, Q.J. Effect of advance speed on rock burst in coal mines and its dynamic control method. J. China Coal Soc. 2018, 43, 1858–1865. [Google Scholar]

- Chen, T. Analysis of the relationship between advancing speed and periodical weighting span in fully mechanized working face. Coal Min. Technol. 1999, 34, 33–35. [Google Scholar]

- Brodny, J. Tests of friction joints in mining yielding supports under dynamic load. Arch. Min. Sci. 2011, 56, 303–318. [Google Scholar]

- Szurgacz, D.; Brodny, J. Tests of Geometry of the Powered Roof Support Section. Energies 2019, 12, 3945. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of the Influence of Dynamic Load on the Work Parameters of a Powered Roof Support’s Hydraulic Leg. Sustainability 2019, 11, 2570. [Google Scholar] [CrossRef]

- Cui, F.; Zhang, T.H.; Lai, X.P.; Cao, J.T.; Shan, P.F. Study on the evolution law of overburden breaking angle under repeated mining and the application of roof pressure relief. Energies 2019, 12, 4513. [Google Scholar] [CrossRef]

- Li, Y.S. Rock burst mechanism and its preliminary application. China Coll. Min. Technol. 1985, 3, 42–48. [Google Scholar]

- Cui, F.; Yang, Y.B.; Lai, X.P.; Cao, J.T. Similar material simulation experimental study on rock bursts induced by keystratum breaking based on microseismic monitoring. Chin. J. Rock Mech. Eng. 2019, 38, 803–814. [Google Scholar]

- Guo, Z. The relativity between testing condition and mechanical characteristics of rocks. Hydrogeol. Eng. Geol. 1995, 1, 15–19. [Google Scholar]

- Yin, X.C.; Yin, X.F.; Yu, H.Z.; Zhang, H.H.; Yan, D.Y. Preliminary study on mining induced earthquake prediction in terms of loading-unloading response ratio. Earthquake 2004, 24, 25–30. [Google Scholar]

- Yin, X.C.; Liu, Y. Load-unload response ratio-An interplay between earthquake prediction and mechanics. Adv. Mech. 2013, 43, 555–580. [Google Scholar]

| Mining Area | Area 1 | Area 2 | Area 3 | Area 4 | Area 5 | Area 6 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specific range (cm) | 0–32 | 32–63.2 | 63.2–95.2 | 95.2–127.2 | 127.2–158.4 | 158.4–192 | |||||||

| Daily advancement (m/d) | 1.6 | 2.4 | 3.2 | 4 | 4.8 | 5.6 | |||||||

| Advance speed (cm/d) | 0.8 | 1.2 | 1.6 | 2 | 2.4 | 2.8 | |||||||

| Number of mining per stage (n) | 40 | 26 | 20 | 16 | 13 | 12 | |||||||

| production pause time (d) | 1/3/5/7 | 1/3/5/7 | 1/3/5/7 | 1/3/5/7 | 1/3/5/7 | 1/3/5/7 | |||||||

| Number of times of recovery (n) | Stage 1 | 1–10 | 1 | 1–6 | 1 | 1–5 | 1 | 1–4 | 1 | 1–3 | 1 | 1–3 | 1 |

| Stage 2 | 11–20 | 3 | 7–13 | 3 | 6–10 | 3 | 5–8 | 3 | 4–6 | 3 | 4–6 | 3 | |

| Stage 3 | 21–30 | 5 | 14–20 | 5 | 11–15 | 5 | 9–12 | 5 | 7–9 | 5 | 7–9 | 5 | |

| Stage 4 | 31–40 | 7 | 21–26 | 7 | 16–20 | 7 | 13–16 | 7 | 10–13 | 7 | 10–12 | 7 | |

| Working Face | Advance Speed | Short Stopping Time | Long Stopping Time |

|---|---|---|---|

| normal mining | low speed | Y value is low | Y value increases |

| high speed | Y value is higher | Y value decreases | |

| repeated mining | low speed | Y value is low | Y value increases |

| high speed | Y value is higher | Y value decreases |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, F.; Yang, Y.; Lai, X.; Jia, C.; Shan, P. Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof. Sustainability 2020, 12, 37. https://doi.org/10.3390/su12010037

Cui F, Yang Y, Lai X, Jia C, Shan P. Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof. Sustainability. 2020; 12(1):37. https://doi.org/10.3390/su12010037

Chicago/Turabian StyleCui, Feng, Yanbin Yang, Xingping Lai, Chong Jia, and Pengfei Shan. 2020. "Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof" Sustainability 12, no. 1: 37. https://doi.org/10.3390/su12010037

APA StyleCui, F., Yang, Y., Lai, X., Jia, C., & Shan, P. (2020). Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof. Sustainability, 12(1), 37. https://doi.org/10.3390/su12010037