Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models

Abstract

1. Introduction

1.1. Background

1.2. Review Structure

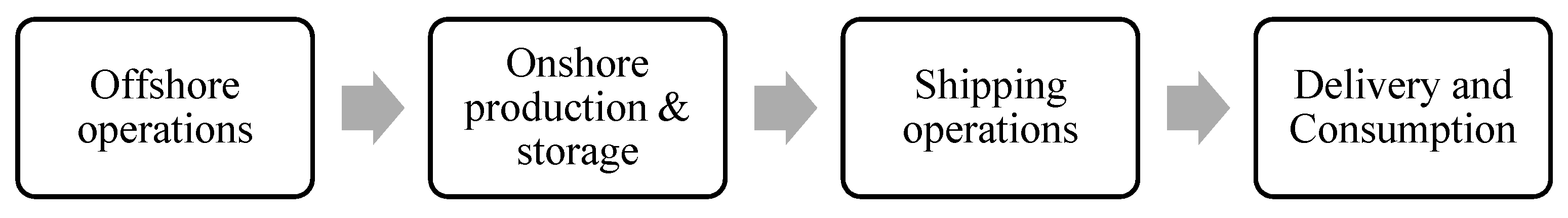

2. LNG Supply Chain Management

LNG Planning Levels

3. Sustainable Supply Chain Management

3.1. Environmental Dimensions

- Define the goal of the assessment and scoping of the study;

- Prepare the inventory of input and output for the processes that occur in the product’s life cycle;

- Assess the impact where the results of the inventory are transformed into an environmental impact profile for the product system;

- Interpret the impact according to the defined goal and scope of the study, including a sensitivity analysis of key elements in the assessment.

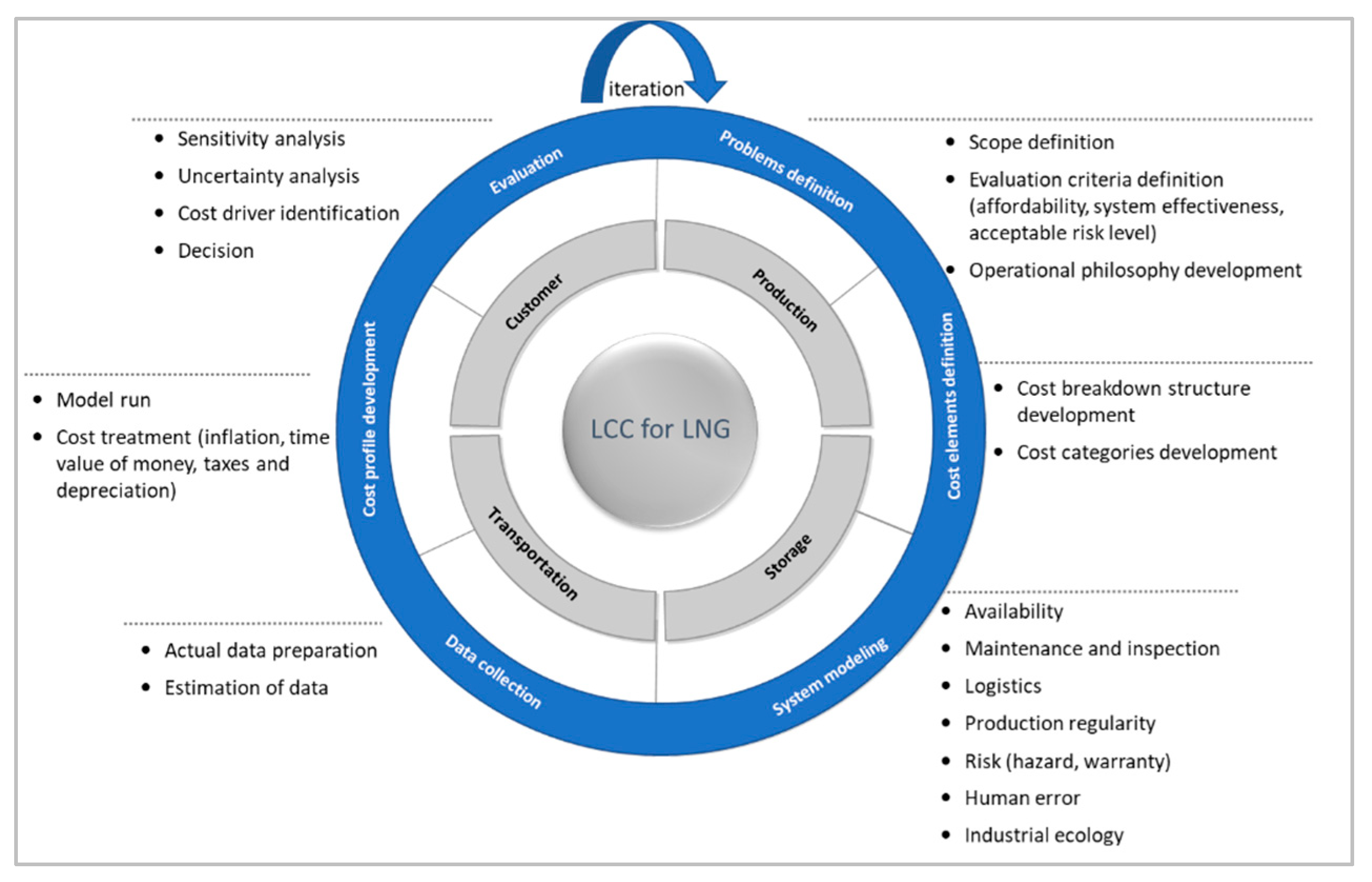

3.2. Economic Dimensions

3.3. Social Dimensions

3.4. Developing Sustainable Supply Chains

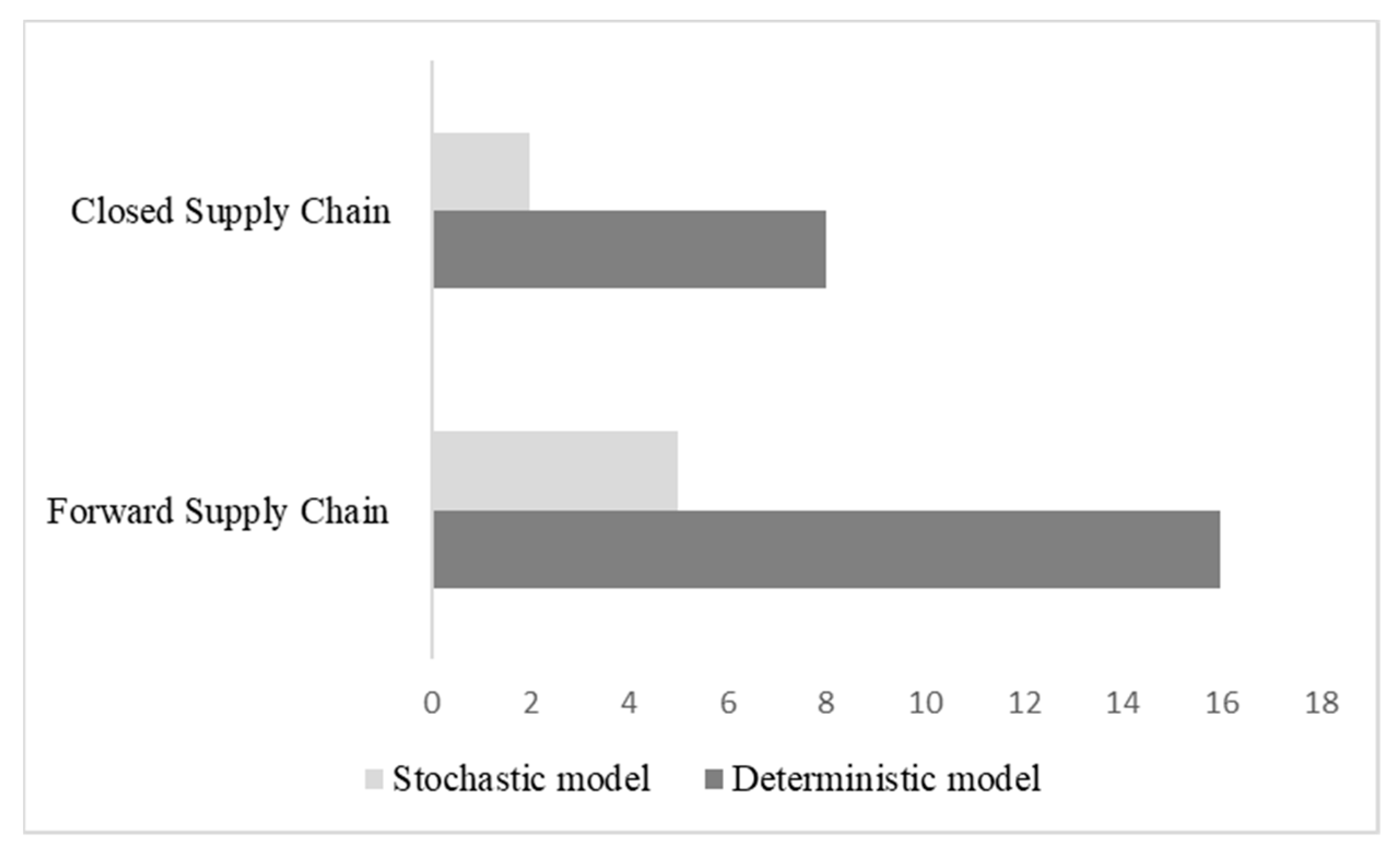

4. Review of Quantitative Models

4.1. Deterministic Models

4.1.1. Sustainable Forward/Open Supply Chain Management

Deterministic Models of LNG Supply Chain

4.1.2. Sustainable Closed-Loop Supply Chain Management

4.2. Stochastic Models

4.2.1. Sustainable Forward/Open Supply Chain Management

Stochastic Models for LNG Supply Chains

4.2.2. Sustainable Closed-Loop Supply Chain Management

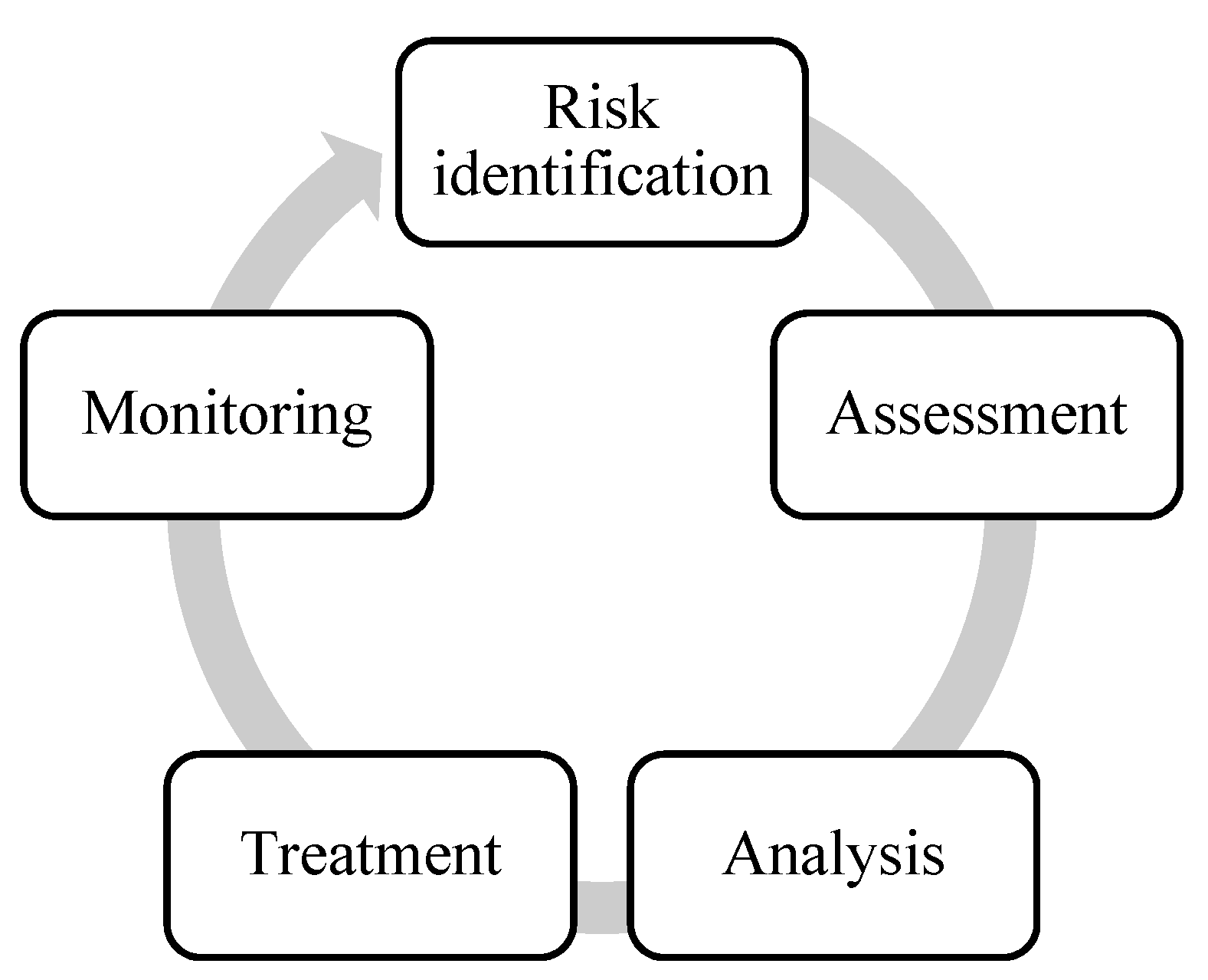

5. Sustainable Supply Chains and Resilience

6. Future Perspectives in LNG Supply Chain Management

- Fuel consumption of driving turbines and motors represents less than 0.2 g CO2/MJ HHV;

- Combustion of waste gases in flares represent between 0.1–0.5 g CO2/MJ HHV;

- Gas losses from venting connected with pre-treatments, maintenance processes and losses from equipment and pipes represent between 1–13 g CO2/MJ HHV;

- During LNG transportation, CO2 emissions represent between 1.04–2.11 g of CO2/MJ HHV.

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shively, B.; Ferrare, J. Understanding Today’s Natural Gas Business; Enerdynamics: Laporte, CO, USA, 2011. [Google Scholar]

- MIT Energy Initiative, the Future of Natural Gas. Available online: http://energy.mit.edu/research/future-natural-gas/ (accessed on 15 July 2019).

- Union of Concerned Scientists. Uses of Natural Gas. Available online: https://www.ucsusa.org/clean-energy/coal-and-other-fossil-fuels/uses-of-natural-gas#.W_w9H_ZuJPY (accessed on 23 July 2019).

- Eurogas. Gas: The Righ Choice for Heating in Europe. Available online: https://eurogas.org/uploads/media/Gas__the_right_choice_for_heating_in_Europe_PART_II_Brochure_140814.pdf (accessed on 2 July 2019).

- GIIGNL. The LNG Industry, GIIGNL Annual Report. Available online: https://giignl.org/sites/default/files/PUBLIC_AREA/About_LNG/5_LNG_Markets_And_Trade/giignl_2018_annual_report.pdf (accessed on 2 June 2019).

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply Chain Management: More Than a New Name for Logistics. Int. J. Logist. Manag. 1997, 8, 1–14. [Google Scholar] [CrossRef]

- Stevens, G. Integrating the Supply Chain. Int. J. Phys. Distrib. Mater. Manag. 1989, 19, 3–8. [Google Scholar] [CrossRef]

- Debo, L.; Savaskan, R.; Van Wassenhove, L. Reverse Logistics. In Quantitative Models for Closed-Loop Supply Chains; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Golar LNG. The LNG Supply Chain. Available online: http://www.golarlng.com/what-we-do/lng-supply-chain (accessed on 12 June 2019).

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Zhou, Z.; Cheng, S.; Hua, B. Supply chain optimization of continuous process industries with sustainability considerations. Comput. Chem. Eng. 2000, 24, 1151–1158. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Garcia, D.J.; You, F. Supply chain design and optimization: Challenges and opportunities. Comput. Chem. Eng. 2015, 81, 153–170. [Google Scholar] [CrossRef]

- Purba, R.; Diane, H. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2018, 25, 898–916. [Google Scholar]

- Pimenta, H.C.D.; Ball, P.D. Analysis of environmental sustainability practices across upstream supply chain management. Procedia CIRP 2015, 26, 677–682. [Google Scholar] [CrossRef]

- Leigh, M.; Li, X. Industrial ecology, industrial symbiosis and supply chain environmental sustainability: A case study of a large UK distributor. J. Clean. Prod. 2015, 106, 632–643. [Google Scholar] [CrossRef]

- Acquaye, A.; Ibn-Mohammed, T.; Genovese, A.; Afrifa, G.A.; Yamoah, F.A.; Oppon, E. A quantitative model for environmentally sustainable supply chain performance measurement. Eur. J. Oper. Res. 2018, 269, 188–205. [Google Scholar] [CrossRef]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- ISO 14067. Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14067:ed-1:v1:en (accessed on 15 July 2019).

- Hauschild, M.; Wenzel, H. Life cycle assessment—Environmental Assessment of Products. In A Systems Approach to the Environmental Analysis of Pollution Minimization; Lewis Publishers: Boca Raton, FL, USA, 2000; pp. 155–189. [Google Scholar]

- Wagner, M. The Influence of ISO 14001 and EMAS Certification on Environmental and Economic Performance of Firms: An Empirical Analysis. In Environmental Management Accounting—Purpose and Progress; Springer: Dordrecht, The Netherlands, 2003; Volume 146, pp. 367–386. [Google Scholar]

- Golicic, S.L.; Smith, C.D. A meta-analysis of environmentally sustainable supply chain management practices and firm performance. J. Supply Chain Manag. 2013, 49, 78–95. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations. Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Gotschol, A.; De Giovanni, P.; Esposito Vinzi, V. Is environmental management an economically sustainable business? J. Environ. Manag. 2014, 144, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Galuppo, L.; Gorli, M.; Scaratti, G.; Kaneklin, C. Building social sustainability: Multistakeholder processes and conflict management. Soc. Responsib. J. 2014, 10, 685–701. [Google Scholar] [CrossRef]

- Hutchins, M.J.; Sutherland, J.W. An exploration of measures of social sustainability and their application to supply chain decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Beske-Janssen, P.; Johnson, M.P.; Schaltegger, S. 20 Years of Performance Measurement in Sustainable Supply Chain Management—What Has Been Achieved? Supply Chain Manag. 2015, 20, 664–680. [Google Scholar] [CrossRef]

- UNEP. Guidelines for Social Life Cycle Assessment of Products; United Nations Environmental Programme: Paris, France, 2009. [Google Scholar]

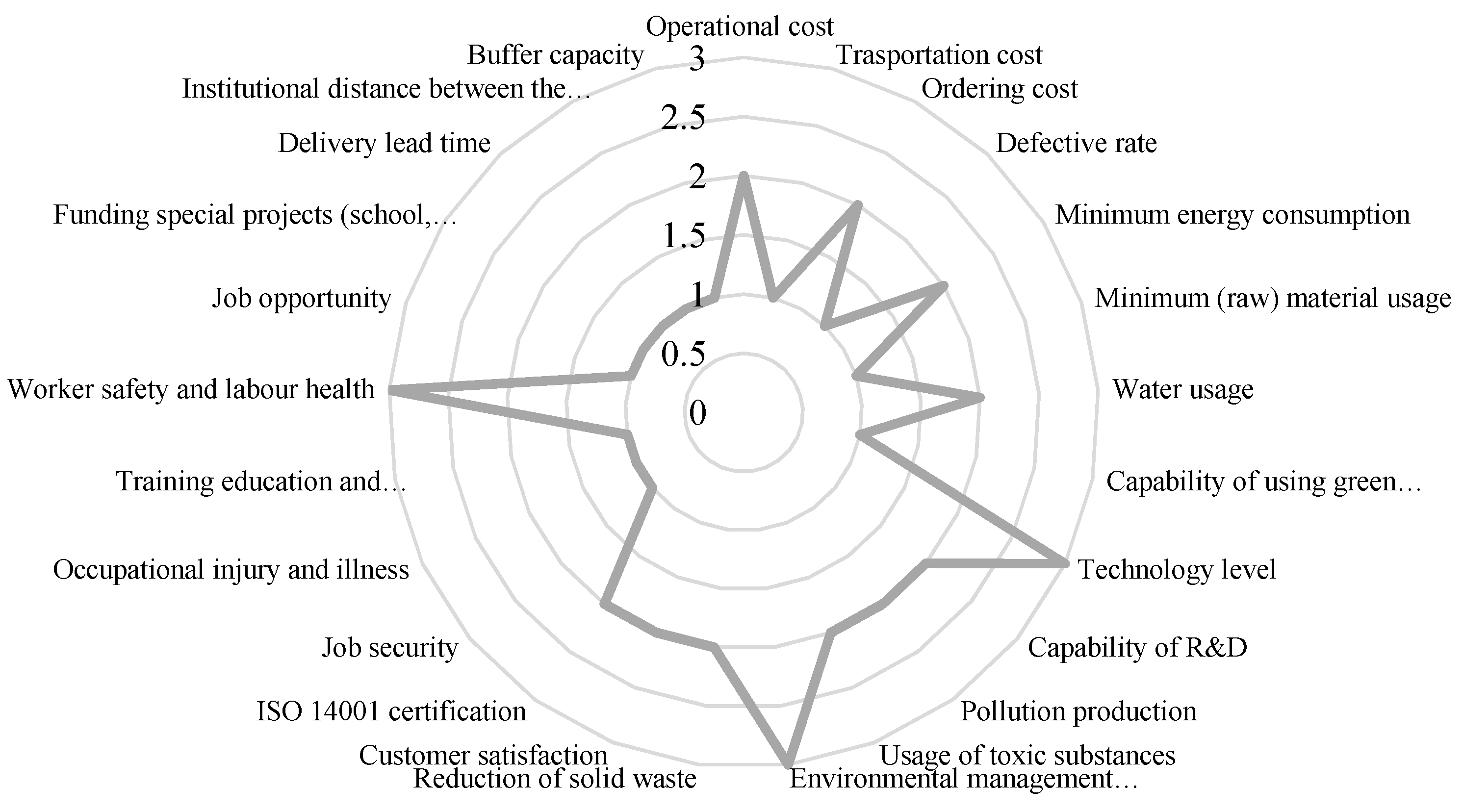

- Popovic, T.; Barbosa-Póvoa, A.; Kraslawski, A.; Carvalho, A. Quantitative indicators for social sustainability assessment of supply chains. J. Clean. Prod. 2018, 180, 748–768. [Google Scholar] [CrossRef]

- Popovic, T.; Carvalho, A.; Kraslawski, A.; Barbósa-Póvoa, A. Framework for assessing social sustainability in supply chains. Comput. Aided Chem. Eng. 2016, 38, 2019–2024. [Google Scholar]

- Mani, V.; Agarwal, R.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Childe, S.J. Social sustainability in the supply chain: Construct development and measurement validation. Ecol. Indic. 2016, 71, 270–279. [Google Scholar] [CrossRef]

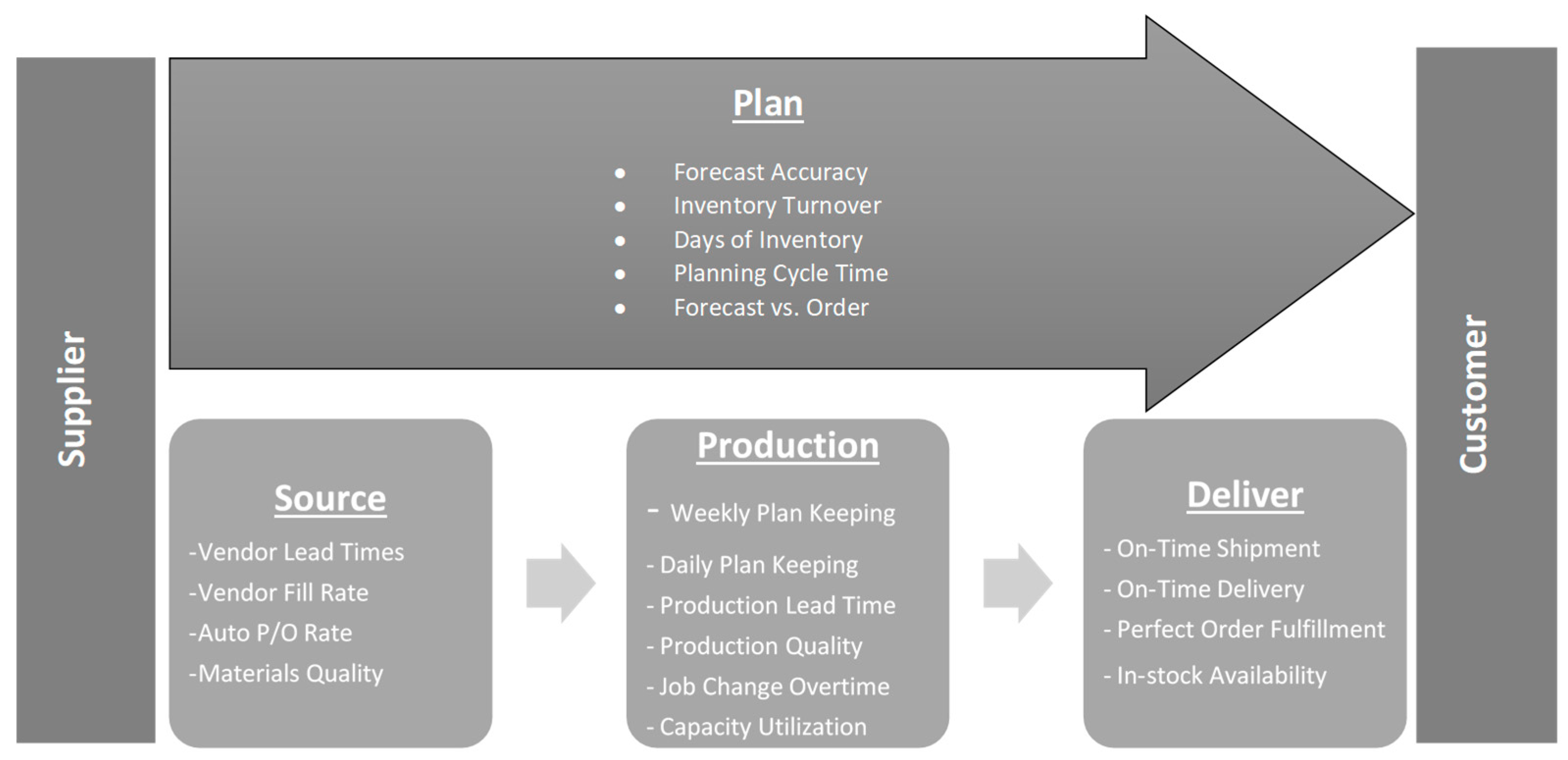

- Chae, B. Developing key performance indicators for supply chain: An industry perspective. Supply Chain Manag. 2009, 14, 422–428. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Gupta, R.; Dong, J. Multi-criteria evaluation of real-time key performance indicators of supply chain with the consideration of big data architecture. Comput. Ind. Eng. 2018, 128, 1076–1087. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. Indicators of sustainable development for industry: A general framework. Process Saf. Environ. Prot. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Sloan, T. Measuring the sustainability of global supply chains: Current practices and future directions. J. Glob. Bus. Manag. 2010, 6, 92–107. [Google Scholar]

- Agami, N.; Saleh, M.; Rasmy, M. Supply Chain Performance Measurement Approaches: Review and Classification. J. Organ. Manag. Stud. 2012, 2012, 1–20. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T.; Schaltegger, S.; Wagner, M. The sustainability balanced scorecard—Linking sustainability management to business strategy. Bus. Strategy Environ. 2002, 11, 269–284. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Cho, D.W.; Lee, Y.H.; Ahn, S.H.; Hwang, M.K. A framework for measuring the performance of service supply chain management. Comput. Ind. Eng. 2012, 62, 801–818. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; McGaughey, R.E. A framework for supply chain performance measurement. Int. J. Prod. Econ. 2004, 87, 333–347. [Google Scholar] [CrossRef]

- Erol, I.; Sencer, S.; Sari, R. A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecol. Econ. 2011, 70, 1088–1100. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C.; Jaber, M.Y. Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis. Sustain. Prod. Consum. 2016, 7, 1–15. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; Tirtiroglu, E. Performance Measures and Metrics in a Supply Chain Environment. Int. J. Oper. Prod. Manag. 2001, 21, 71–87. [Google Scholar] [CrossRef]

- ISO14031. Environmental Management—Environmental Performance Evaluation—Guidelines. Available online: https://www.iso.org/standard/52297.html (accessed on 10 July 2019).

- EMAS. Eco-Management and Audit Scheme. Official Journal of the European Union. Available online: http://data.europa.eu/eli/reg/2009/1221/oj (accessed on 10 September 2019).

- ILO. International Labour Organisation. Available online: http://www.ilo.org/global/standards/subjects-coveredby-international-labour-stand-ards/WCMS_230305/lang--en/index.htm (accessed on 5 June 2019).

- SA8000. Social Accountability 8000: International Standard. Available online: http://saintl.org/_data/n_0001/resources/live/SA8000%20Stan dard%202014.pdf (accessed on 10 August 2019).

- GRI. Global Reporting Initiative, Sustainability Reporting Guidelines. Available online: https://www.globalreporting.org/standards/g4/Pages/d efault.aspx (accessed on 10 July 2019).

- UNGC, United Nations Global Compact. Supply Chain Sustainability a Practical Guide for Continuous Improvement. Available online: https://www.unglobalcom-pact.org/docs/issues_doc/supply_chain/SupplyChainR ep_spread.pdf (accessed on 20 July 2019).

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Brandenburg, M.; Rebs, T. Sustainable supply chain management: A modelling perspective. Ann. Oper. Res. 2015, 229, 213–252. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Mele, F.D.; Kostin, A.M.; Guillén-Gosálbez, G.; Jiménez, L. Multiobjective model for more sustainable fuel supply chains. A case study of the sugar cane industry in argentina. Ind. Eng. Chem. Res. 2011, 50, 4939–4958. [Google Scholar] [CrossRef]

- Huang, Y.; Xie, F. Multistage optimization of sustainable supply chain of biofuels. Transp. Res. Rec. 2015, 2502, 89–98. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input–output analysis. AIChE 2011, 58, 1157–1180. [Google Scholar] [CrossRef]

- Pérez-Fortes, M.; Laínez-Aguirre, J.; Arranz-Piera, P.; Velo, E.; Puigjaner, L. Design of regional and sustainable bio-based networks for electricity generation using a multi-objective MILP approach. Energy 2012, 44, 79–95. [Google Scholar] [CrossRef]

- Andersson, K.; Eide, M.H.; Lundqvist, U.; Mattsson, B. The feasibility of including sustainability in LCA for product development. J. Clean. Prod. 1998, 6, 289–298. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Design of sustainable supply chains under the emission trading scheme. Int. J. Prod. Econom. 2012, 135, 37–49. [Google Scholar] [CrossRef]

- Gao, J.; You, F. Design a sustainable supply chain under uncertainty using life cycle optimisation and stochastic programming. Chem. Eng. Trans. 2017, 61, 151–156. [Google Scholar]

- Byrne, P.J.; Heavey, C.; Ryan, P.; Liston, P. Sustainable supply chain design: Capturing dynamic input factors. J. Simul. 2010, 4, 213–221. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Designing supply chains with sustainability considerations. Prod. Plan. Control 2011, 22, 727–741. [Google Scholar] [CrossRef]

- Ding, H.; Liu, Q.; Zheng, L. Assessing the economic performance of an environmental sustainable supply chain in reducing environmental externalities. Eur. J. Oper. Res. 2016, 255, 463–480. [Google Scholar] [CrossRef]

- Halati, A.; He, Y. Intersection of economic and environmental goals of sustainable development initiatives. J. Clean. Prod. 2018, 189, 813–829. [Google Scholar] [CrossRef]

- Neto, J.F.; Bloemhof-Ruwaard, J.M.; Van Nunen, J.A.E.E.; Van Heck, E. Designing and evaluating sustainable logistics networks. Int. J. Prod. Econ. 2008, 111, 195–208. [Google Scholar] [CrossRef]

- Ferretti, I.; Zanoni, S.; Zavanella, L.; Diana, A. Greening the aluminium supply chain. Int. J. Prod. Econ. 2007, 108, 236–245. [Google Scholar] [CrossRef]

- Brent, A. Integrating LCIA and LCM: Evaluating Environmental Performances for Supply Chain Management in South Africa. Manag. Environ. Qual. Int. J. 2005, 16, 130–142. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Berkol, Ç. Designing a sustainable supply chain using an integrated analytic network process and goal programming approach in quality function deployment. Expert Syst. Appl. 2011, 38, 13731–13748. [Google Scholar] [CrossRef]

- Chen, Z.; Andresen, S. A multiobjective optimization model of production-sourcing for sustainable supply chain with consideration of social, environmental, and economic factors. Math. Probl. Eng. 2014, 2014, 616107. [Google Scholar] [CrossRef]

- Boukherroub, T.; Ruiz, A.; Guinet, A.; Fondrevelle, J. An integrated approach for sustainable supply chain planning. Comput. Oper. Res. 2015, 54, 180–194. [Google Scholar] [CrossRef]

- Zubairu, N.; Dinwoodie, J. Supply Chain Initiatives: Antecedents for Liquefied Natural Gas Financial Performance. In Proceedings of the Logistics Research Network Annual Conference 2018, Plymouth, UK, 5–7 September 2018. [Google Scholar]

- Andersson, H.; Christiansen, M.; Fagerholt, K. Transportation planning and inventory management in the LNG supply chain. In Energy, Natural Resources and Environmental Economics; Springer: Berlin/Heidelberg, Germany, 2010; pp. 427–439. [Google Scholar]

- Grønhaug, R.; Christiansen, M. Supply chain optimization for the liquefied natural gas business. Innov. Distrib. Logist. 2010, 619, 195–218. [Google Scholar]

- Christiansen, M.; Fagerholt, K.; Ronen, D. Ship Routing and Scheduling: Status and Perspectives. Transp. Sci. 2004, 38, 1–18. [Google Scholar] [CrossRef]

- Grønhaug, R.; Christiansen, M.; Desaulniers, G.; Desrosiers, J. A Branch-and-Price Method for a Liquefied Natural Gas Inventory Routing Problem. Transp. Sci. 2010, 44, 400–415. [Google Scholar] [CrossRef]

- Andersson, H.; Christiansen, M.; Desaulniers, G. A new decomposition algorithm for a liquefied natural gas inventory routing problem. Int. J. Prod. Res. 2016, 54, 564–578. [Google Scholar] [CrossRef]

- Goel, V.; Furman, K.C.; Song, J.H.; El-Bakry, A.S. Large neighborhood search for LNG inventory routing. J. Heuristics 2012, 18, 821–848. [Google Scholar] [CrossRef]

- Goel, V.; Slusky, M.; Van Hoeve, W.J.; Furman, K.C.; Shao, Y. Constraint programming for LNG ship scheduling and inventory management. Eur. J. Oper. Res. 2015, 241, 662–673. [Google Scholar] [CrossRef]

- Stålhane, M.; Rakke, J.G.; Moe, C.R.; Andersson, H.; Christiansen, M.; Fagerholt, K. A construction and improvement heuristic for a liquefied natural gas inventory routing problem. Comput. Ind. Eng. 2012, 62, 245–255. [Google Scholar] [CrossRef]

- Rakke, J.G.; Stålhane, M.; Moe, C.R.; Christiansen, M.; Andersson, H.; Fagerholt, K.; Norstad, I. A rolling horizon heuristic for creating a liquefied natural gas annual delivery program. Transp. Res. Part C Emerg. Technol. 2011, 19, 896–911. [Google Scholar] [CrossRef]

- Al-Haidous, S.; Msakni, M.K.; Haouari, M. Optimal planning of liquefied natural gas deliveries. Transp. Res. Part C Emerg. Technol. 2016, 69, 79–90. [Google Scholar] [CrossRef]

- Mutlu, F.; Msakni, M.K.; Yildiz, H.; Sönmez, E.; Pokharel, S. A comprehensive annual delivery program for upstream liquefied natural gas supply chain. Eur. J. Oper. Res. 2016, 250, 120–130. [Google Scholar] [CrossRef]

- Andersson, H.; Christiansen, M.; Desaulniers, G.; Rakke, J.G. Creating annual delivery programs of liquefied natural gas. Optim. Eng. 2017, 18, 299–316. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; Van Der Laan, E.; Van Nunen, J.A.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Zegordi, S.H.; Nikbakhsh, E. A parallel variable neighborhood search for the multi-objective sustainable post-sales network design problem. Int. J. Prod. Econ. 2013, 145, 117–131. [Google Scholar] [CrossRef]

- Devika, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheuristics hybridization techniques. Eur. J. Oper. Res. 2014, 235, 594–615. [Google Scholar] [CrossRef]

- De Rosa, V.; Gebhard, M.; Hartmann, E.; Wollenweber, J. Robust sustainable bi-directional logistics network design under uncertainity. Int. J. Prod. Econ. 2013, 145, 184–198. [Google Scholar] [CrossRef]

- Faccio, M.; Persona, A.; Sgarbossa, F.; Zanin, G. Sustainable SC through the complete reprocessing of end-of-life products by manufacturers: A traditional versus social responsibility company perspective. Eur. J. Oper. Res. 2014, 233, 359–373. [Google Scholar] [CrossRef]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Haghighi, F.; Niaki, S.T.A. Modeling and solving a sustainable closed loop supply chain problem with pricing decisions and discounts on returned products. J. Clean. Prod. 2019, 207, 163–181. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M. Sustainable tire closed-loop supply chain network design: Hybrid metaheuristic algorithms for large-scale networks. J. Clean. Prod. 2018, 196, 273–296. [Google Scholar] [CrossRef]

- Juan, A.A.; Faulin, J.; Grasman, S.E.; Rabe, M.; Figueira, G. A review of simheuristics: Extending metaheuristics to deal with stochastic combinatorial optimization problems. Oper. Res. Perspect. 2015, 2, 62–72. [Google Scholar] [CrossRef]

- Awudu, I.; Zhang, J. Uncertainties and sustainability concepts in biofuel supply chain management: A review. Renew. Sustain. Energy Rev. 2012, 16, 1359–1368. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A mixed biomass-based energy supply chain for enhancing economic and environmental sustainability benefits: A multi-criteria decision making framework. Appl. Energy 2017, 206, 1088–1101. [Google Scholar] [CrossRef]

- Gao, J.; You, F. Economic and Environmental Life Cycle Optimization of Noncooperative Supply Chains and Product Systems: Modeling Framework, Mixed-Integer Bilevel Fractional Programming Algorithm, and Shale Gas Application. ACS Sustain. Chem. Eng. 2017, 5, 3362–3381. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A.; Onyeaghala, R. Stochastic optimization of sustainable hybrid generation bioethanol supply chains. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 1–28. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K. A multi-stage stochastic program for the sustainable design of biofuel supply chain networks under biomass supply uncertainty and disruption risk: A real-life case study. Transp. Res. Part E Logist. Transp. Rev. 2018, 118, 534–567. [Google Scholar] [CrossRef]

- Lee, D.H.; Dong, M.; Bian, W. The design of sustainable logistics network under uncertainty. Int. J. Prod. Econ. 2010, 128, 159–166. [Google Scholar] [CrossRef]

- Cardin, M.A.-A.; Ranjbar-Bourani, M.; de Neufville, R. Improving the Lifecycle Performance of Engineering Projects with Flexible Strategies: Example of On-Shore LNG Production Design. Syst. Eng. 2015, 18, 253–268. [Google Scholar] [CrossRef]

- Werner, A.; Uggen, K.T.; Fodstad, M.; Lium, A.; Egging, R. Stochastic Mixed-Integer Programming for Integrated Portfolio Planning in the LNG Supply Chain. Energy J. 2014, 35, 79–97. [Google Scholar] [CrossRef]

- Berle, Ø.; Norstad, I.; Asbjørnslett, B.E. Optimization, risk assessment and resilience in LNG transportation systems. Supply Chain Manag. 2013, 18, 253–264. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E.E.; Fagerholt, K.; Rönnqvist, M. Vessel routing and scheduling under uncertainty in the liquefied natural gas business. Comput. Ind. Eng. 2013, 64, 290–301. [Google Scholar] [CrossRef]

- Urciuoli, L.; Mohanty, S.; Hintsa, J.; Boekesteijn, E.G. The resilience of energy supply chains: A multiple case study approach on oil and gas supply chains to Europe. Supply Chain Manag. 2014, 19, 46–63. [Google Scholar] [CrossRef]

- Shuen, A.; Feiler, P.F.; Teece, D.J. Dynamic capabilities in the upstream oil and gas sector: Managing next generation competition. Energy Strategy Rev. 2014, 3, 5–13. [Google Scholar] [CrossRef]

- Badea, A.C.; Tarantola, S.; Bolado, R. Composite indicators for security of energy supply using ordered weighted averaging. Reliab. Eng. Syst. Saf. 2011, 96, 651–662. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Z.; Wang, G.; Li, H. Study on the impacts of natural gas supply cost on gas flow and infrastructure deployment in China. Appl. Energy 2016, 162, 1385–1398. [Google Scholar] [CrossRef]

- Li, X.; Armagan, E.; Tomasgard, A.; Barton, P.I. Stochastic pooling problem for natural gas production network design and operation under uncertainty. Aiche J. 2011, 57, 2120–2135. [Google Scholar] [CrossRef]

- Li, X.; Barton, P.I. Optimal design and operation of energy systems under uncertainty. J. Process Control 2015, 30, 1–9. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R.; Tiwari, M.K. Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Comput. Ind. Eng. 2005, 48, 327–356. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J. The design of a responsive sustainable supply chain network under uncertainty. Int. J. Adv. Manuf. Technol. 2015, 80, 427–445. [Google Scholar] [CrossRef]

- Chen, C.; Fan, Y. Bioethanol supply chain system planning under supply and demand uncertainties. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 150–164. [Google Scholar] [CrossRef]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- Krysiak, F.C. Risk management as a tool for sustainability. J. Bus. Ethics 2009, 85, 483–492. [Google Scholar] [CrossRef]

- Hallikas, J.; Karvonen, I.; Pulkkinen, U.; Virolainen, V.M.; Tuominen, M. Risk management processes in supplier networks. Int. J. Prod. Econ. 2004, 90, 47–58. [Google Scholar] [CrossRef]

- Giannakis, M.; Papadopoulos, T. Supply chain sustainability: A risk management approach. Int. J. Prod. Econ. 2016, 171, 455–470. [Google Scholar] [CrossRef]

- Valinejad, F.; Rahmani, D. Sustainability risk management in the supply chain of telecommunication companies: A case study. J. Clean. Prod. 2018, 203, 53–67. [Google Scholar] [CrossRef]

- Xu, M.; Cui, Y.; Hu, M.; Xu, X.; Zhang, Z.; Liang, S.; Qu, S. Supply chain sustainability risk and assessment. J. Clean. Prod. 2019, 225, 857–867. [Google Scholar] [CrossRef]

- Wieland, A.; Marcus Wallenburg, C. Dealing with supply chain risks: Linking risk management practices and strategies to performance. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H. Cooperative the Relational and Sources of Strategy Competitive Advantage. Acad. Manag. Rev. 2011, 23, 660–679. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Ramezankhani, M.J.; Torabi, S.A.; Vahidi, F. Supply chain performance measurement and evaluation: A mixed sustainability and resilience approach. Comput. Ind. Eng. 2018, 126, 531–548. [Google Scholar] [CrossRef]

- Zavitsas, K.; Zis, T.; Bell MG, H. The impact of flexible environmental policy on maritime supply chain resilience. Transp. Policy 2018, 72, 116–128. [Google Scholar] [CrossRef]

- Hohenstein, N.O.; Feisel, E.; Hartmann, E.; Giunipero, L. Research on the phenomenon of supply chain resilience: A systematic review and paths for further investigation. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 90–117. [Google Scholar] [CrossRef]

- Karl, A.A.; Micheluzzi, J.; Leite, L.R.; Pereira, C.R. Supply chain resilience and key performance indicators: A systematic literature review. Producao 2018, 28, 1–16. [Google Scholar] [CrossRef]

- Tamura, I.; Tanaka, T.; Kagajo, T.; Kuwabara, S.; Yoshioka, T.; Nagata, T.; Ishitani, H. Life cycle CO2 analysis of LNG and city gas. Appl. Energy 2001, 68, 301–319. [Google Scholar] [CrossRef]

- Balcombe, P.; Anderson, K.; Speirs, J.; Brandon, N.; Hawkes, A. Methane and CO2 Emissions from the Natural Gas Supply Chain: An Evidence Assessment. Available online: http://www.sustainablegasinstitute.org/publications/white-paper-1 (accessed on 10 September 2019).

- Kawauchi, Y.; Rausand, M. Life Cycle Cost (LCC) Analysis in Oil and Chemical Process Industries. Available online: https://www.researchgate.net/publication/228594034_Life_Cycle_Cost_LCC_Analysis_in_Oil_and_Chemical_Process_Industries (accessed on 5 September 2019).

| Author | Stage | Objectives | Models |

|---|---|---|---|

| Andersson et al. [73] | Shipping Operations | Minimise voyage operating cost, and over and under deliveries cost | Single objective MIP Optimisation method |

| Grønhaug & Christiansen [74] | Shipping Operations | Maximise revenue of selling LNG | Single objective MIP Optimisation method |

| Goel et al. [78] | Shipping Operations | Minimise lost production, stockout, and unmet demand | Single objective MIP–Rolling horizon heuristic |

| Stålhane et al. [80] | Shipping Operations | Minimise cost | Single objective MIP–Rolling horizon heuristic |

| Rakke et al. [81] | Shipping Operations | Minimise transportation and penalty costs | Single objective MIP–Rolling horizon heuristic |

| Al-Haidous et al. [82] | Shipping Operations | Minimise the number of vessels that satisfy all customers | Single objective MILP Optimisation method |

| Mutlu et al. [83] | Shipping Operations | Minimise cost | Single objective MIP–vessel routing heuristic |

| Andersson et al. [84] | Shipping Operations | Minimise cost | Single objective MIP–branch and cut algorithm |

| Reference | Stage | Objectives | Models |

|---|---|---|---|

| Werner et al. [101] | Shipping Operation | Create a model to support LNG strategic planning. | Stochastic MILP |

| Berle et al. [102] | Shipping Operation | Address a vulnerability in a maritime transportation system. | Monte Carlo simulation |

| Halvorsen-Weare et al. [103] | Shipping Operation | Consider uncertainty to create robust routes and schedules for the vessel fleet. | Single objective MIP Optimisation method |

| Urciuoli et al. [104] | Delivery and Consumption | Build resilience energy supply chains against exogenous security threats. | Data collection |

| Li and Barton [109] | Overall supply chain | Integrate the design and operation of energy systems with the consideration of uncertainties. | MINLP |

| Stage | Stage Inputs | Stage Outputs | Sustainability/Resilience | KPI’s |

|---|---|---|---|---|

| Offshore operation |

| Gas to onshore operation for liquefaction | Sustainability |

|

| Onshore operation & storage |

| LNG production | Sustainability |

|

| Shipping operation |

| Deliver the cargo to the customer | Sustainability Resilience |

|

| Delivery and consumption |

| Demand needs | Resilience |

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Haidous, S.; Al-Ansari, T. Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models. Sustainability 2020, 12, 243. https://doi.org/10.3390/su12010243

Al-Haidous S, Al-Ansari T. Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models. Sustainability. 2020; 12(1):243. https://doi.org/10.3390/su12010243

Chicago/Turabian StyleAl-Haidous, Sara, and Tareq Al-Ansari. 2020. "Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models" Sustainability 12, no. 1: 243. https://doi.org/10.3390/su12010243

APA StyleAl-Haidous, S., & Al-Ansari, T. (2020). Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models. Sustainability, 12(1), 243. https://doi.org/10.3390/su12010243