Life Cycle Cost, Energy and Carbon Assessments of Beijing-Shanghai High-Speed Railway

Abstract

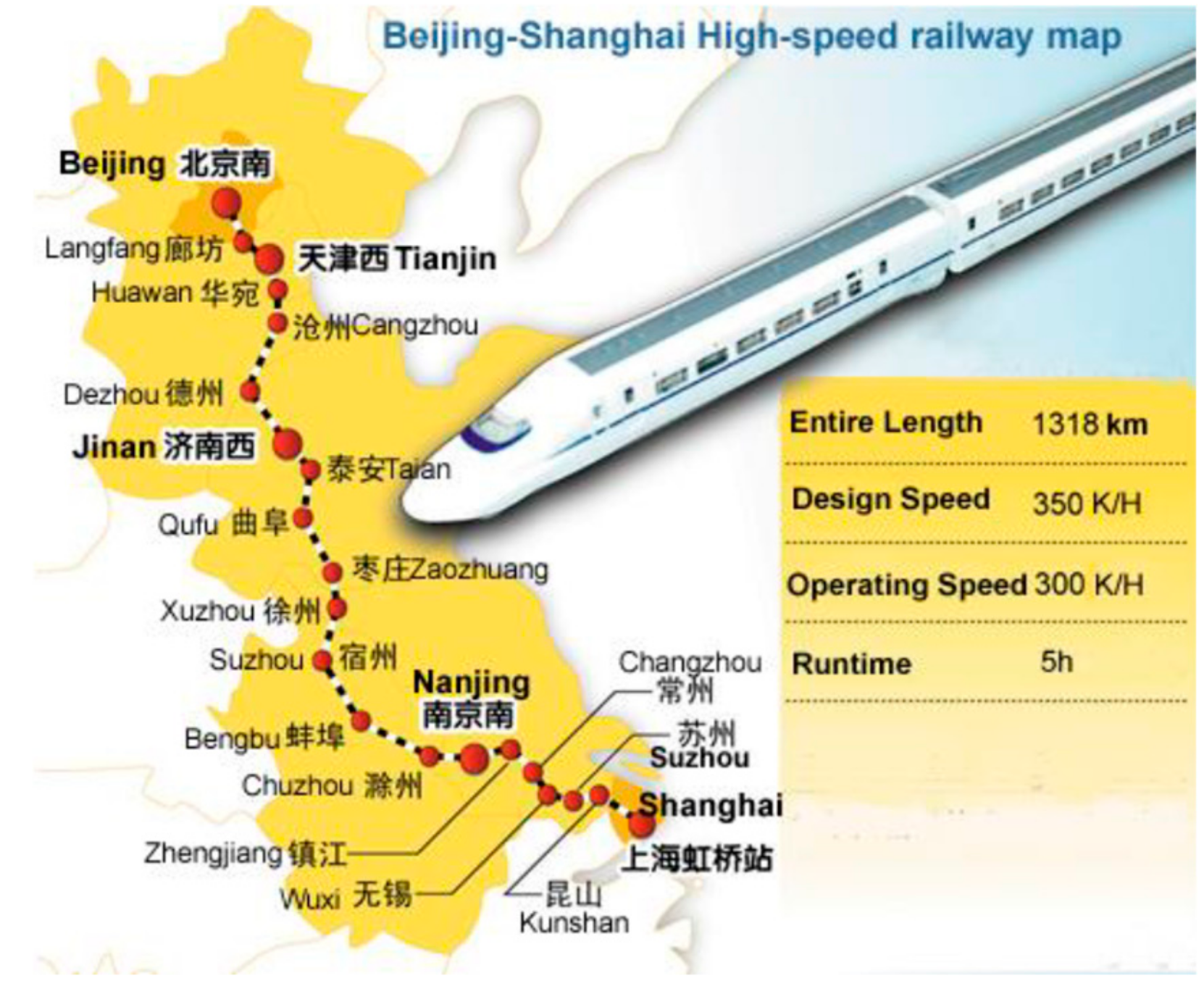

:1. Introduction

2. Literature Review

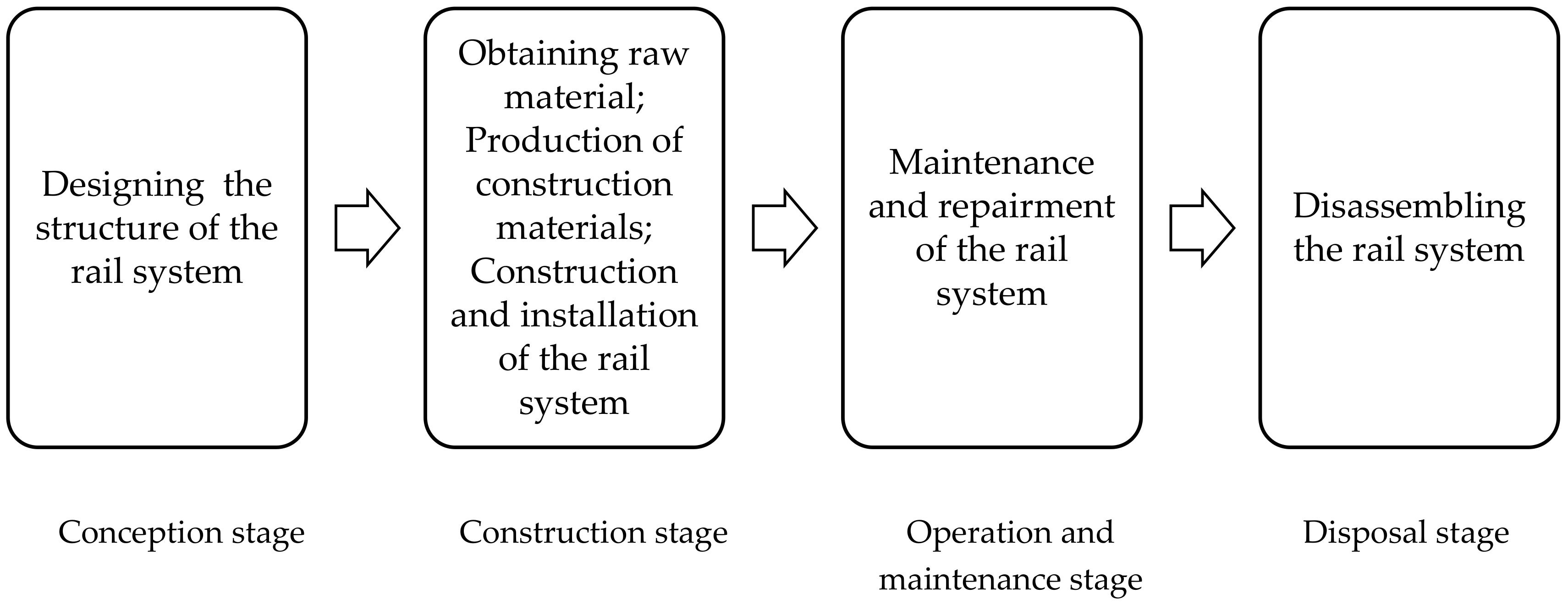

3. Methodology

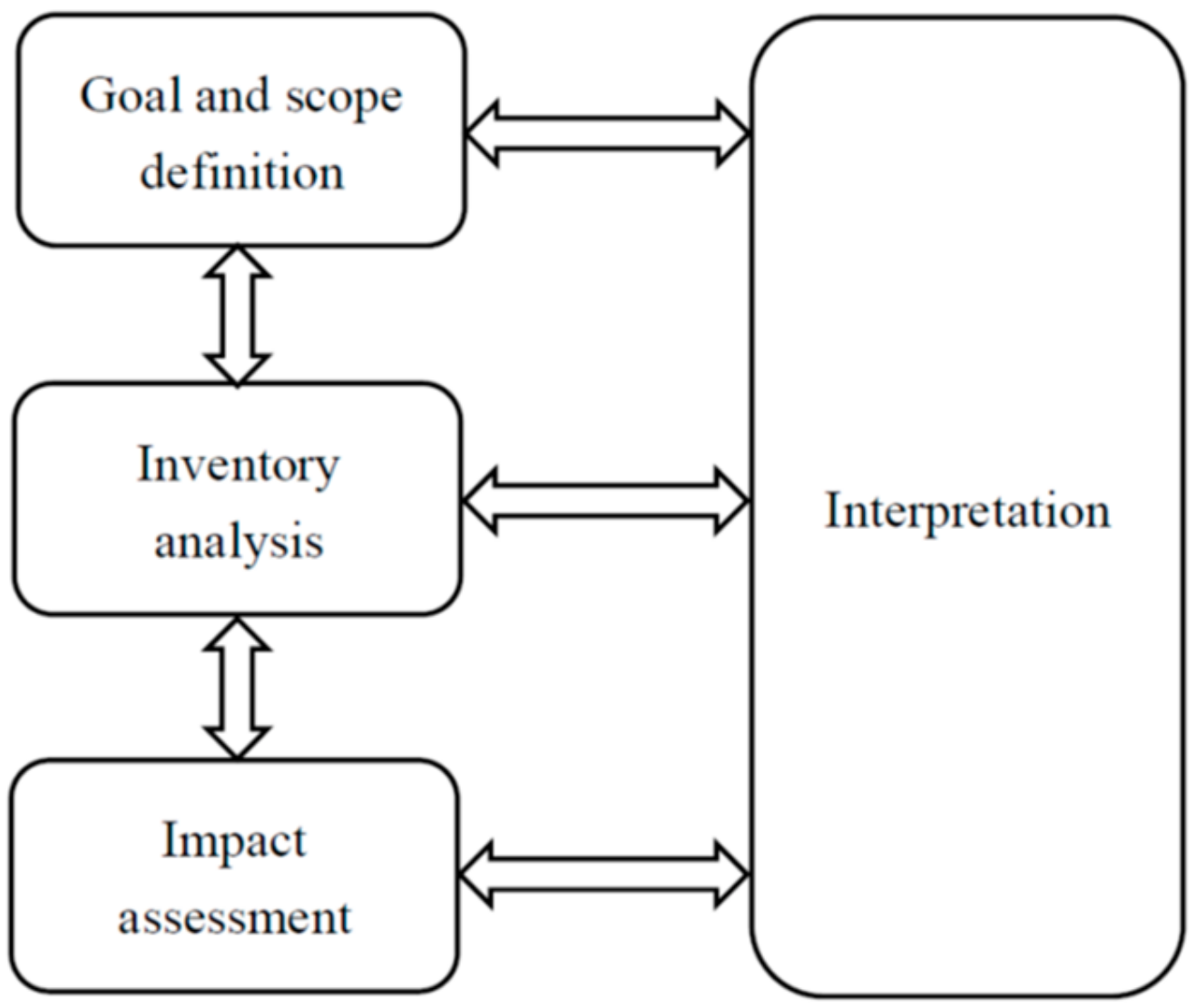

3.1. Life Cycle Assessment

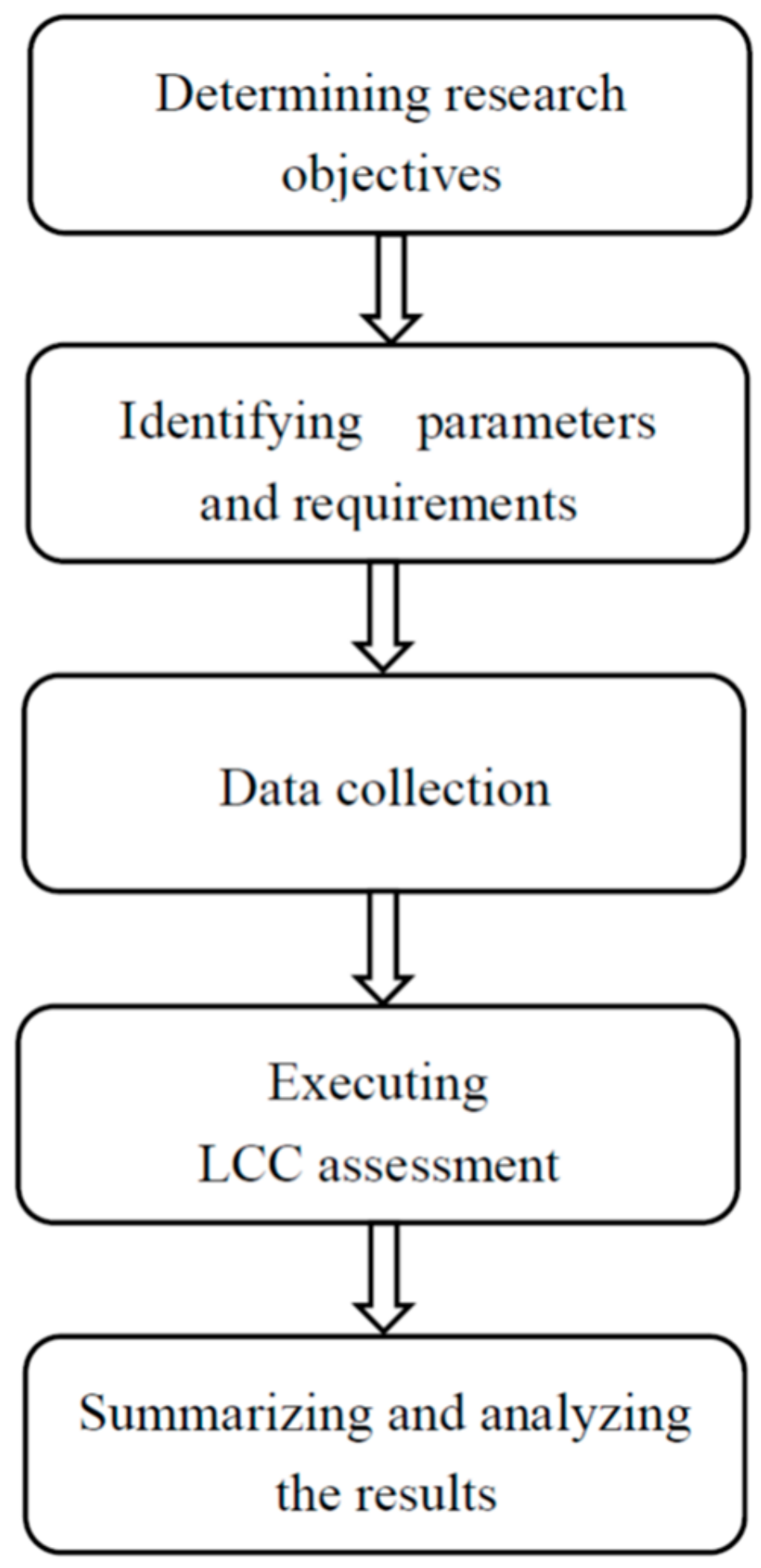

3.2. Life Cycle Cost

4. Results

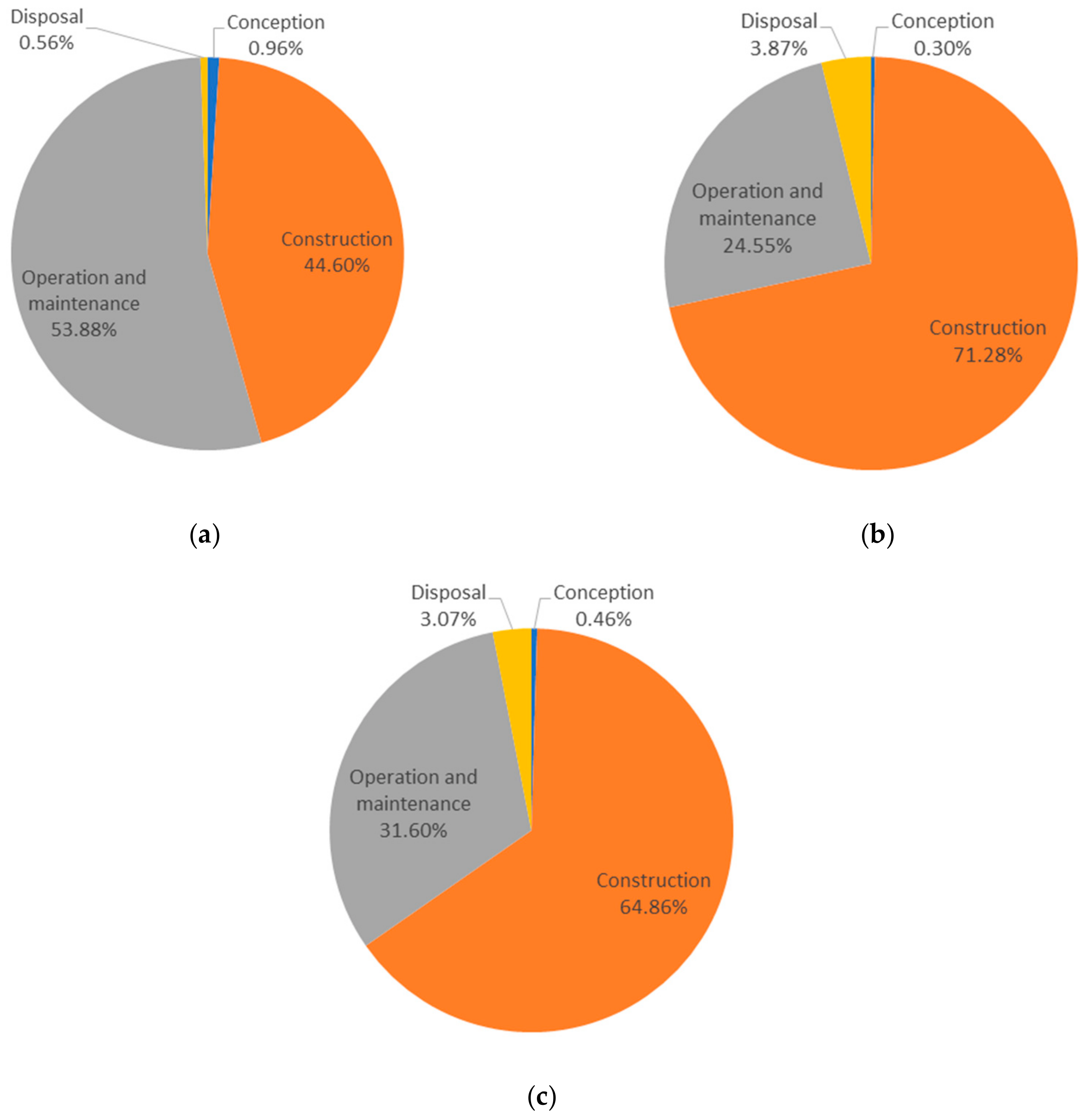

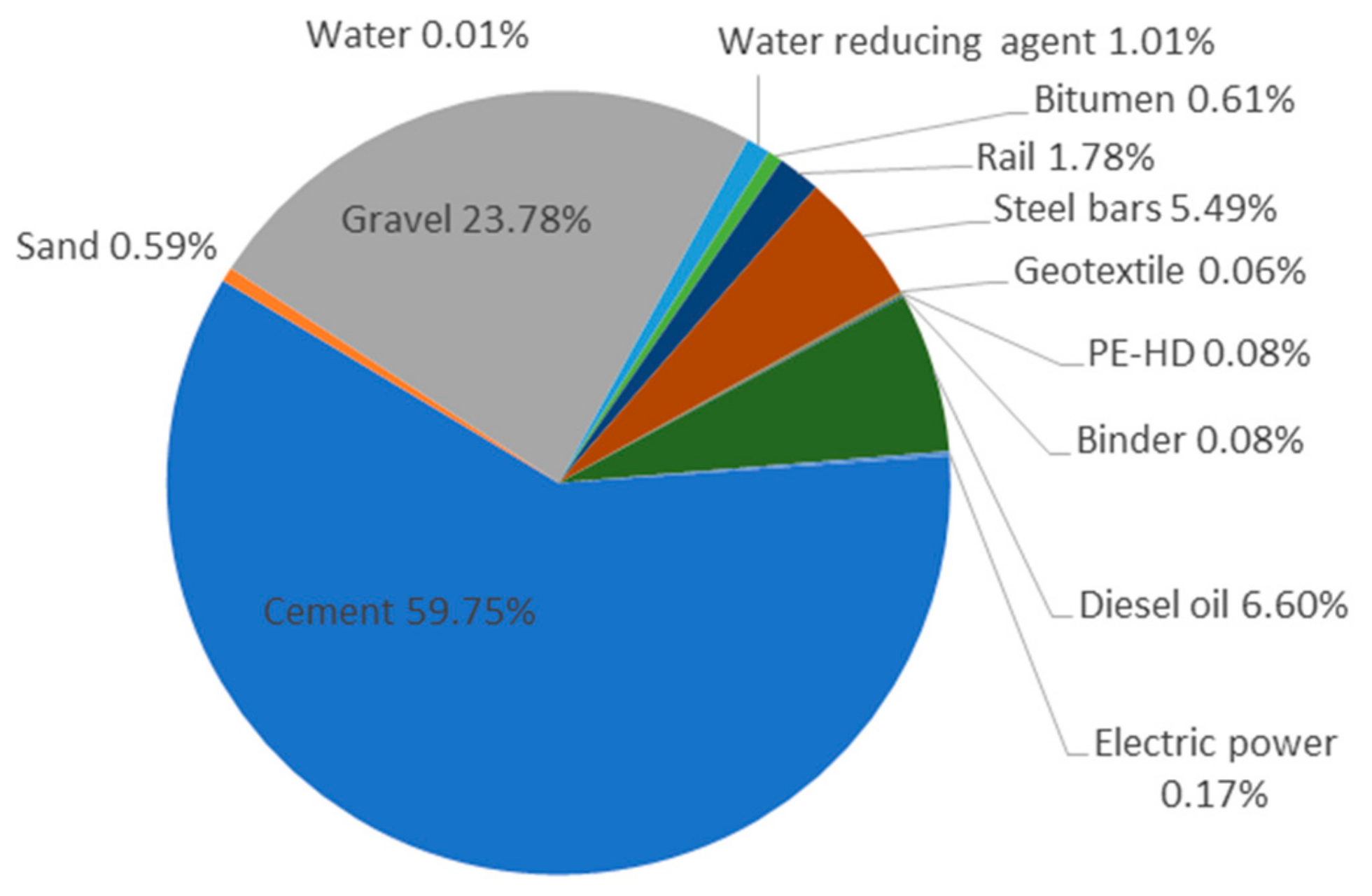

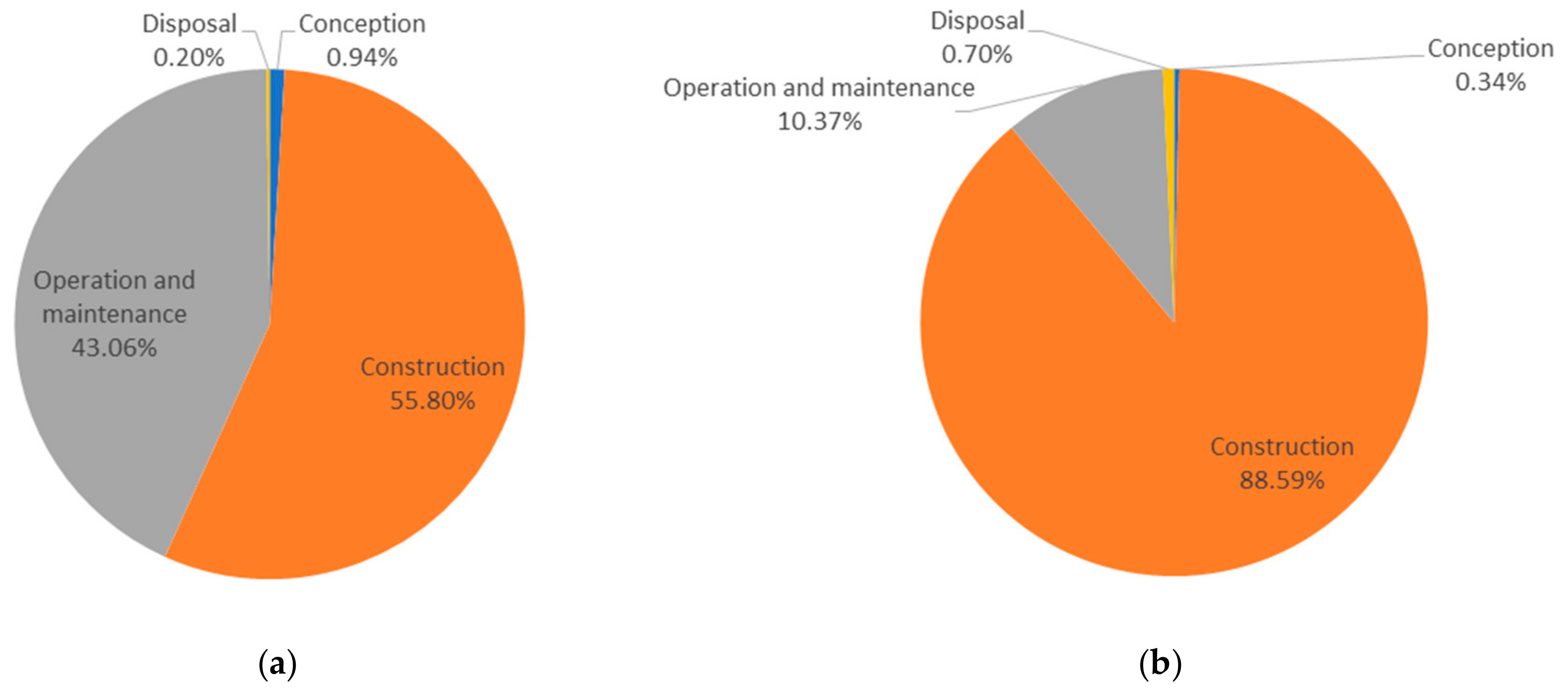

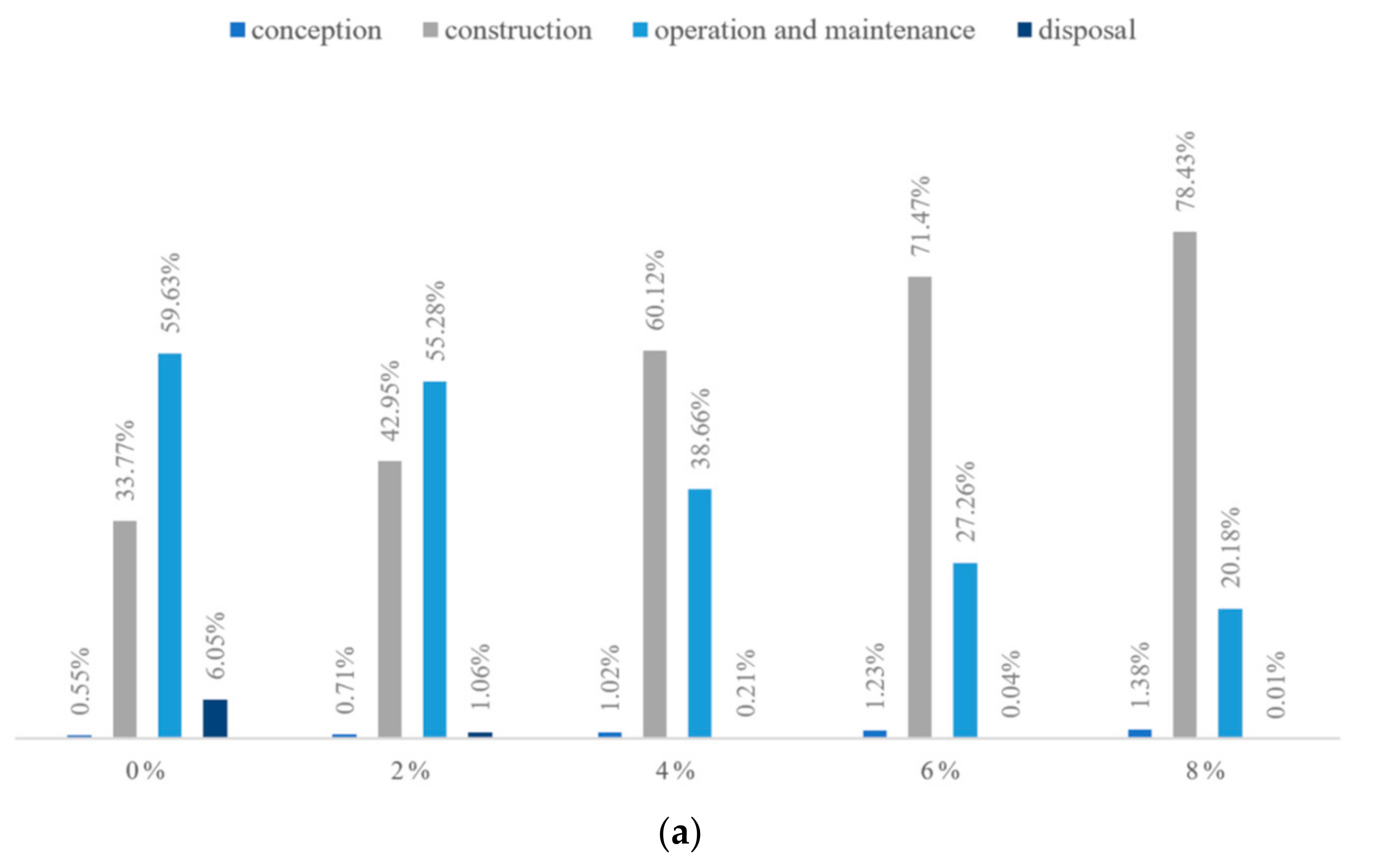

4.1. Results of Life Cycle Assessment

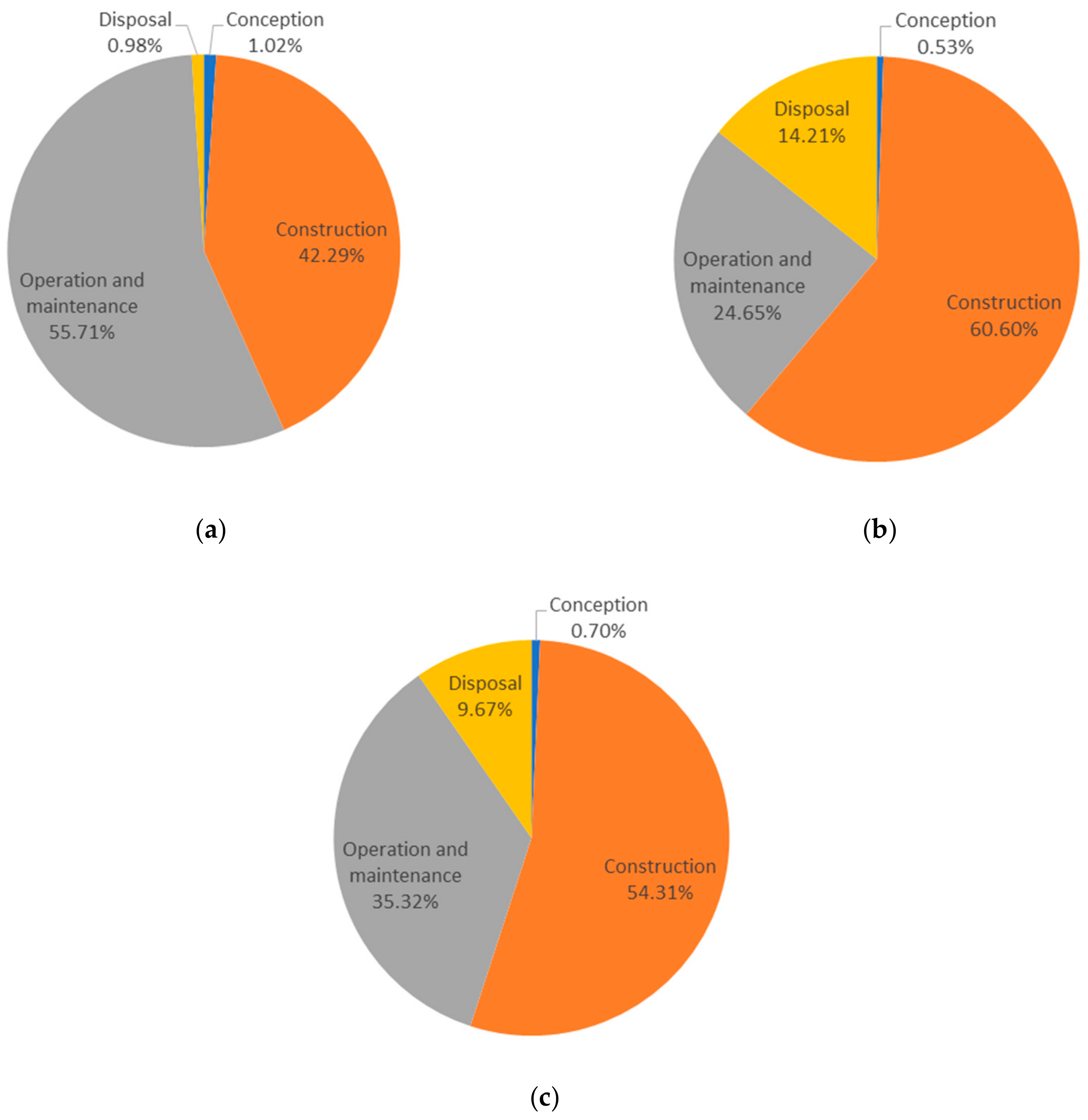

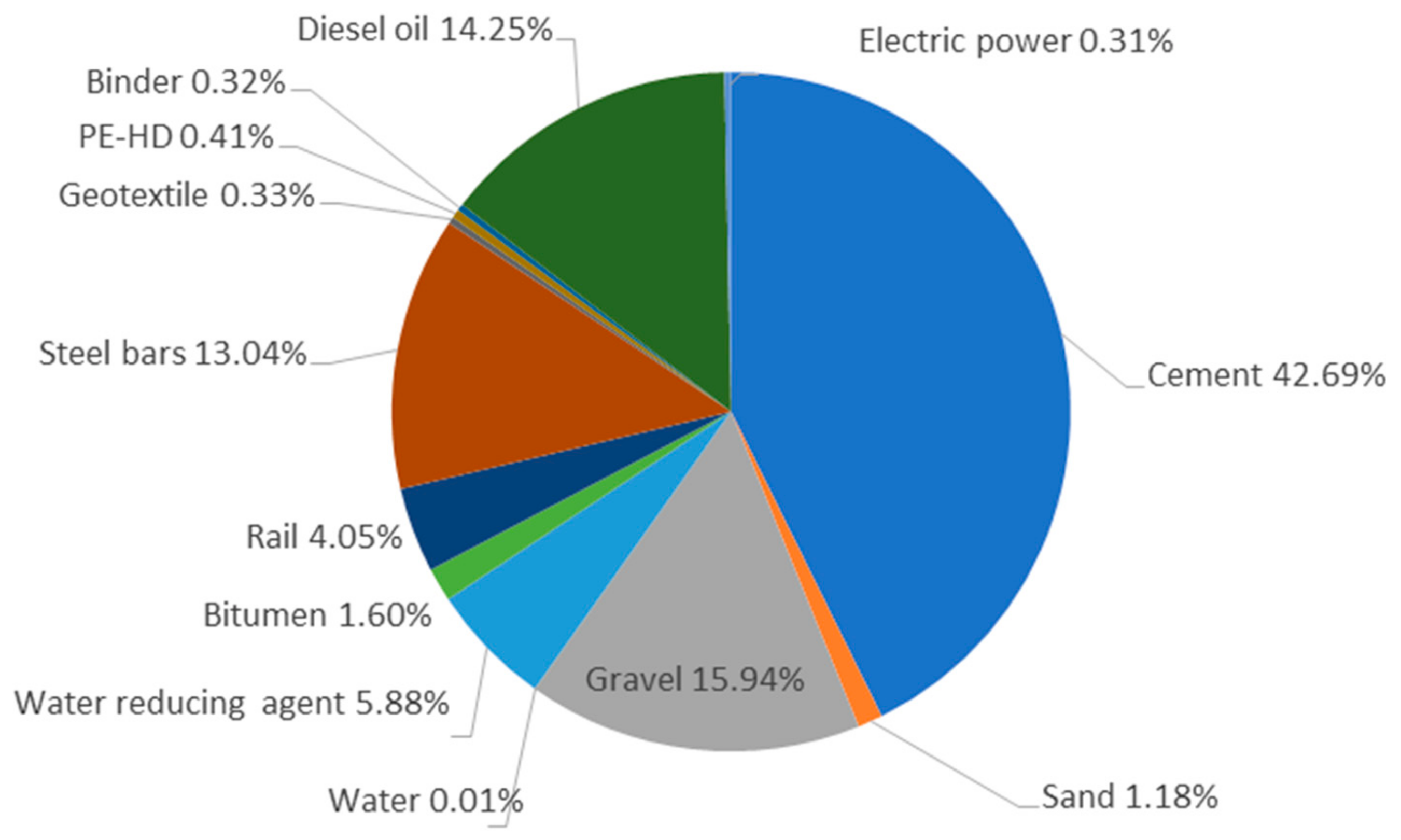

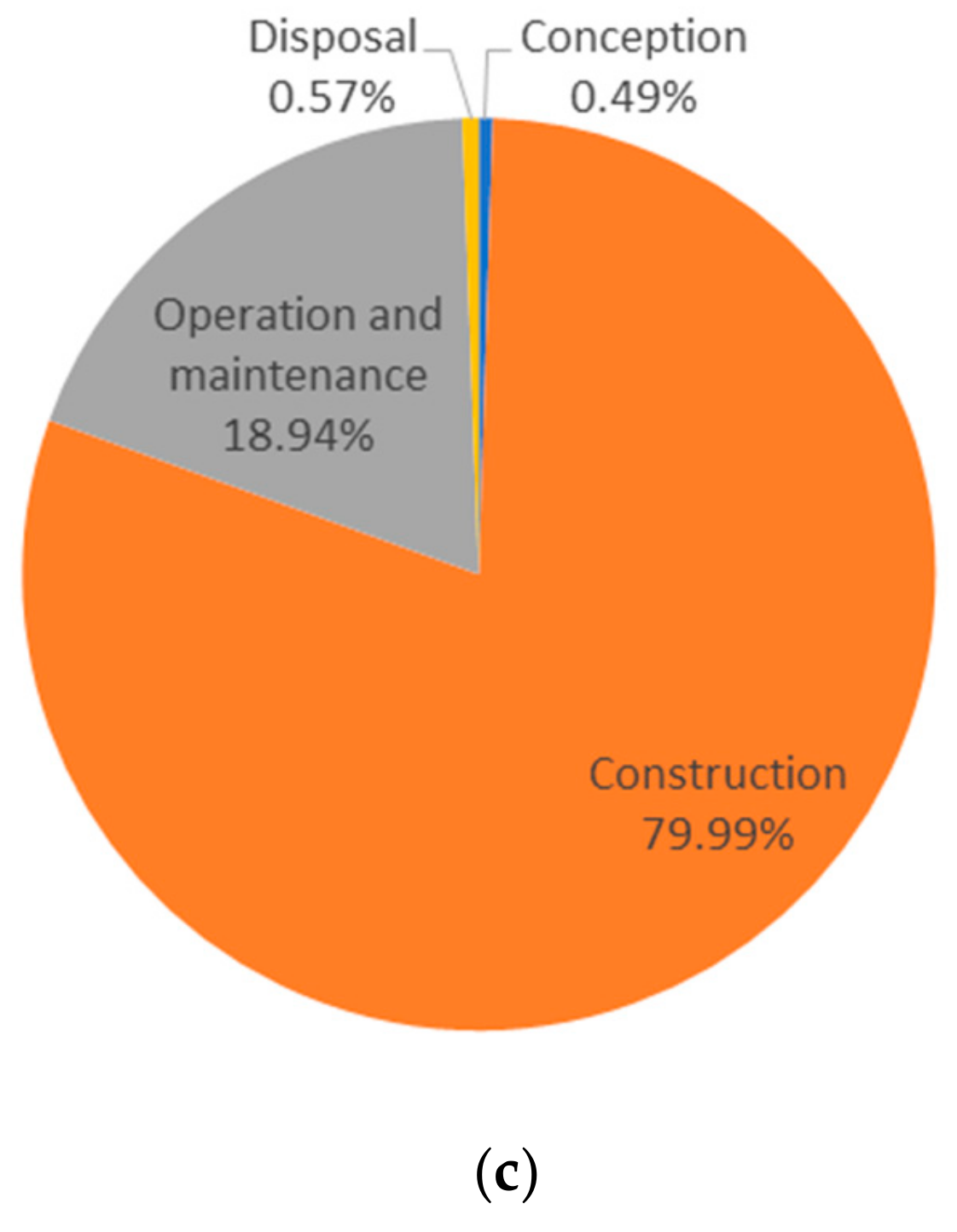

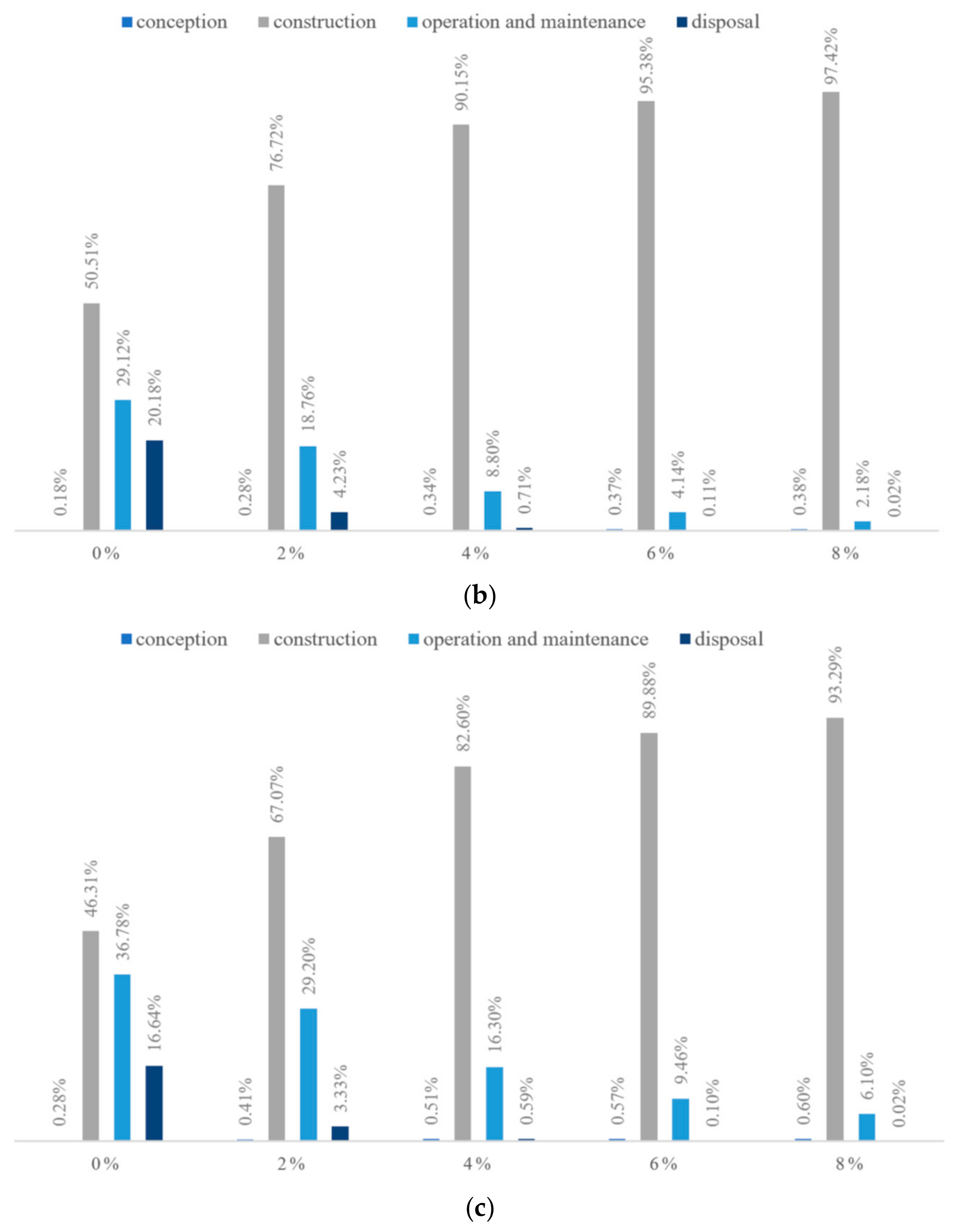

4.2. Results of Life Cycle Cost

5. Discussion

5.1. Results Analysis and Recommendation

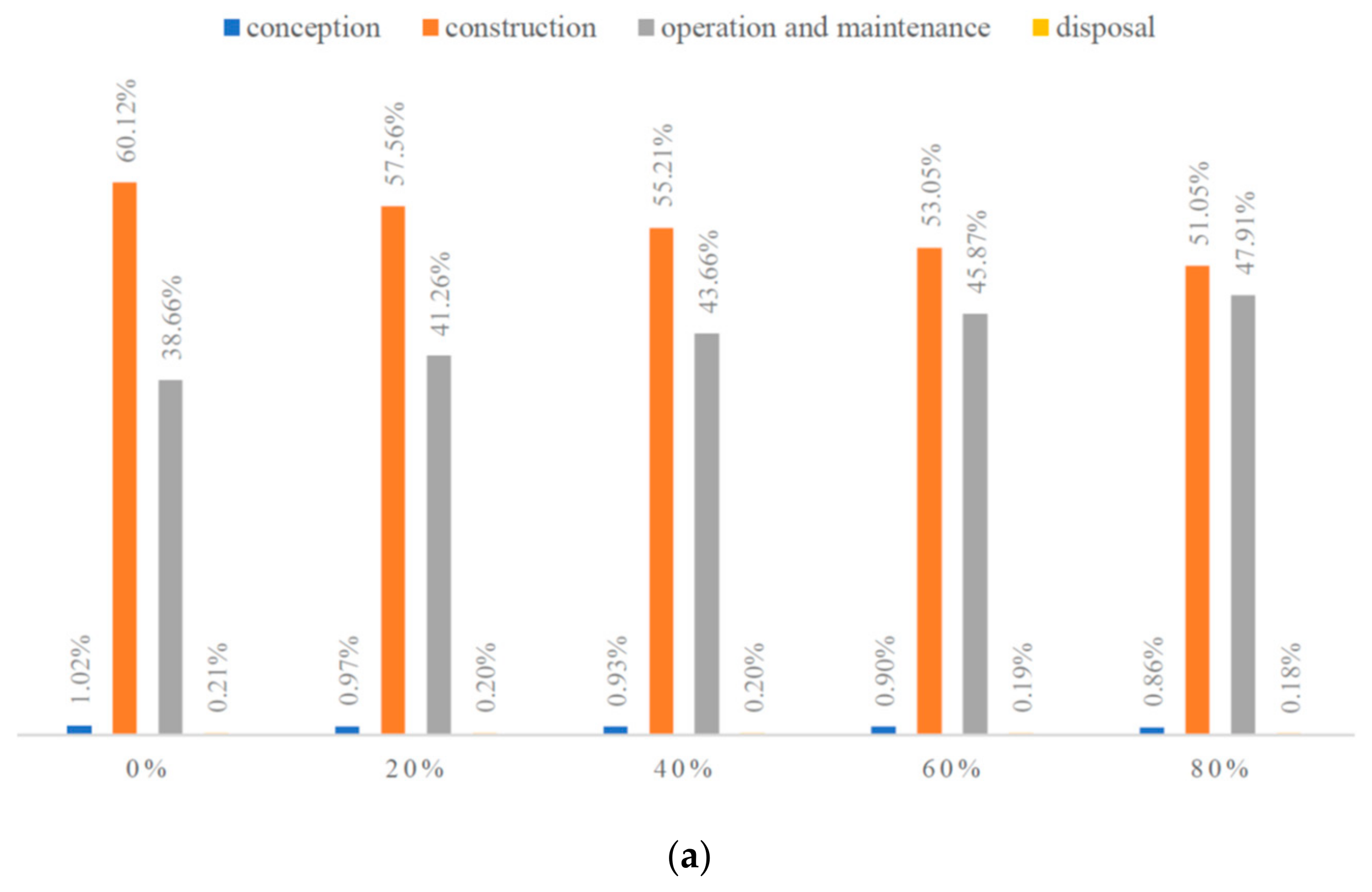

5.2. Sensitive Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chinese Railways. Overview of Beijing-Shanghai High-speed Railway Construction. 2008. Available online: http://www.cnki.net (accessed on 10 July 2019).

- Brautigam, D. The Real Cost of Chinese Railway Construction in Nigeria; Johns Hopkins University: Baltimore, MD, USA, 2010. [Google Scholar]

- The World Bank. Cost of High Speed Rail in China One Third Lower than in Other Countries. 2014. Available online: https://www.worldbank.org/en/news/press-release/2014/07/10/cost-of-high-speed-rail-in-china-one-third-lower-than-in-other-countries (accessed on 29 November 2019).

- Yang, J.; Wang, H.; Zhou, J. Life cycle assessment of Chinese railway transportation. Res. Environ. Sci. 2013, 26, 1029–1034. [Google Scholar]

- Ma, X.; Shi, F.; Liu, P.; Bai, J.; Li, Q. Introduction and Using Analysis of Life Cycle Cost Management. Henan Electr. Power 2006, 4, 18–21. [Google Scholar]

- ChinaTouristMaps. Detailed Map of Beijing-Shanghai High-Speed Railway. 2019. Available online: http://www.chinatouristmaps.com/current/beijing-shanghai-high-speed-railway/beijing-shanghai-high-speed-railway-map.html. (accessed on 25 December 2019).

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef]

- Chester, M.; Horvath, A. Life-cycle assessment of high-speed rail: The case of California. Environ. Res. Lett. 2010, 5, 014003. [Google Scholar] [CrossRef]

- Chang, B.; Kendall, A. Life cycle greenhouse gas assessment of infrastructure construction for California’s high-speed rail system. Transp. Res. Part D Transp. Environ. 2011, 16, 429–434. [Google Scholar] [CrossRef]

- Sárik, V. Decision-Making Model for Track System of High-Speed Rail Lines: Ballasted Track, Ballastless Track or Both? KTH Royal Institute of Technology: Stockholm, Sweden, 2018. [Google Scholar]

- Von Rozycki, C.; Koeser, H.; Schwarz, H. Ecology profile of the German high-speed rail passenger transport system, ICE. The Int. J. Life Cycle Assess. 2003, 8, 83–91. [Google Scholar] [CrossRef]

- Åkerman, J. The role of high-speed rail in mitigating climate change–The Swedish case Europabanan from a life cycle perspective. Transp. Res. Part D Transp. Environ. 2011, 16, 208–217. [Google Scholar] [CrossRef]

- Jones, H.; Moura, F.; Domingos, T. Life cycle assessment of high-speed rail: A case study in Portugal. Int. J. Life Cycle Assess. 2017, 22, 410–422. [Google Scholar] [CrossRef]

- Wang, L. Re-discussion on reduction of CO2 emission in China′s cement industry. China Cem. 2008, 2, 36–39. [Google Scholar]

- Yue, Y.; Wang, T.; Liang, S.; Yang, J.; Hou, P.; Qu, S.; Zhou, J.; Jia, X.; Wang, H.; Xu, M. Life cycle assessment of high speed rail in China. Transp. Res. Part D Transp. Environ. 2015, 41, 367–376. [Google Scholar] [CrossRef]

- Zoeteman, A.; Esveld, C. Evaluating Track Structures: Life Cycle Cost Analysis as a Structured Approach; World Congress on Railway Research: Tokyo, Japan, 1999. [Google Scholar]

- Zoeteman, A. Life cycle cost analysis for managing rail infrastructure. Eur. J. Transp. Infrastruct. Res. 2001, 1, 4. [Google Scholar]

- Chen, J.; Huang, R. Evaluation of Advantages and Comparative Efficiency of TRA Ballastless Track; National Taiwan Ocean University: Keelung, Taiwan, 2003. [Google Scholar]

- Wu, Y. Economy analysis of ballastless track of passenger dedicated line based on life cycle cost. Sichuan Archit. 2010, 30, 270–272. [Google Scholar]

- Lin, J.; Li, H.; Huang, W.; Xu, W.; Cheng, X. A Carbon Footprint of High-Speed Railways in China: A Case Study of the Beijing-Shanghai Line. J. Ind. Ecol. 2018, 23, 869–878. [Google Scholar] [CrossRef]

- National Railway Administration. Code for Design of High Speed Railway TB10620-2014; National Railway Administration of People’s Republic of China (NRA): Beijng, China, 2014.

- Sftool.gov. Life Cycle Assessment (LCA) Overview, GSA Sustainable Facilites Tool. 2019. Available online: https://sftool.gov/plan/400/life-cycle-assessment-lca-overview (accessed on 17 July 2019).

- Environmental Management: Life Cycle Assessment; Principles and Framework; International Organization for Standardization: London, UK, 2006.

- Infield, D.; Freris, L. Renewable Energy in Power Systems, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Zou, T. Analysis on Technical and Economic Indicators of Beijing-Shanghai High Railway Base and Bridge Engineering. Railw. Surv. Des. 2008, 8, 77–79. [Google Scholar]

- Cheng, Z. The Application of CRTS-II Slab Ballastless Track in Passenger Oriented Track. Railw. Constr. Technol. 2011, 7, 120–123. [Google Scholar]

- Zhao, Y. The key equipment of laying CRST II ballastless tracks. Constr. Tech. 2011, 8, 45–48. [Google Scholar]

- Huang, J. Application of CFG pile in Wenfu Railway. Railw. Constr. Technol. 2006, 8, 71–73. [Google Scholar]

- Ma, D. Research on Economy of Ballastless Track of High-Speed Railway in China; Southwest Jiaotong University: Chengdu, China, 2009. [Google Scholar]

- Fu, B. Study on Energy Consumption and Carbon Emission Life Cycle of High Speed Rill; Shijjazhuang Tiedao University: Shaoxing, China, 2017. [Google Scholar]

- Ke, J.; Zheng, N.; Fridley, D.; Price, L.; Zhou, N. Potential energy savings and CO2 emissions reduction of China′s cement industry. Energy Policy 2012, 45, 739–751. [Google Scholar] [CrossRef] [Green Version]

- Chappat, M.; Bilal, A.J. Sustainable Development—The Environmental Road of the Future: Life Cycle Analysis. 2003. Available online: https://www.colas.com/sites/default/files/publications/route-future-english_1.pdf (accessed on 10 July 2019).

- Feng, X. Modeling Life Cycle Energy Consumption and Greenhouse Gas Emissions for High-Speed Railways; Beijing Jiaotong University: Beijing, China, 2014. [Google Scholar]

- World Steel in Figures; World Steel Association: Brussels, Belgium, 2011.

- Yan, X.; Crookes, R.J. Life cycle analysis of energy use and greenhouse gas emissions for road transportation fuels in China. Renew. Sustain. Energy Rev. 2009, 13, 2505–2514. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, S.; Peng, T.; Ou, X. Life Cycle Energy Consumption and Greenhouse Gas Emissions Analysis of Natural Gas-Based Distributed Generation Projects in China. Energies 2017, 10, 1515. [Google Scholar]

- Li, H. Economic Appraisal Research on Ballastless Track of High-Speed Railway Based on Life Cycle Cost; Southwest Jiaotong University: Chendu, China, 2014. [Google Scholar]

- Qi, G. Construction Organization and Costs Analysis of CRTS II Type Plate Ballastless Track. Railway. Railw. Eng. Cost Manag. 2013, 28, 11–14. [Google Scholar]

- You, L. Economic Analysis of Life Cycle of Ballastless Track Structure of High Speed Railway. Sichuan Cem. 2016, 8, 42–43. [Google Scholar]

- European Commission. Assessment of Unit Costs (Standard Prices) of Rail Projects (CAPital EXpenditure); Directorate-General for Regional and Urban Policy: Brussels, Belgium, 2018. [Google Scholar]

- Wang, Y. Discussion on economy evaluation of ballastless track in China by LCC analysis. Acad. Trends 2007, 1, 10–14. [Google Scholar]

- Net Present Value (NPV); Investopedia: New York, NY, USA, 2019.

- Seo, M.-S.; Kim, T.; Hong, G.; Kim, H. On-site measurements of CO2 emissions during the construction phase of a building complex. Energies 2016, 9, 599. [Google Scholar] [CrossRef]

- World Cement. GGBS: How We Can Produce Sustainable Concrete. 2009. Available online: https://www.worldcement.com/europecis/01102009/ggbs_the_worlds_most_sustainable_building_material/ (accessed on 15 August 2019).

- Kaewunruen, S.; Sussman, J.M.; Matsumoto, A. Grand challenges in transportation and transit systems. Front. Built Environ. 2016, 2, 4. [Google Scholar] [CrossRef] [Green Version]

| Materials | Quantity of Work (ton/km) | Amount for the Track (t) | Amount for the Earthwork (t) | |

|---|---|---|---|---|

| Track | Earthwork | |||

| Sand | 1841.82 | 15,879.40 | 2,427,515.97 | 20,929,049.20 |

| Gravel | 1505.31 | 178,256.50 | 1,983,995.31 | 234,942,067.00 |

| Water | 317.60 | 3147.90 | 418,590.21 | 4,148,932.20 |

| Bitumen | 207.32 | - | 273,241.17 | - |

| Rail | 120.00 | - | 158,160.00 | - |

| Steel bar | 409.00 | - | 539,062.00 | - |

| Geotextile | 1.47 | - | 1941.41 | - |

| PE-HD | 2.34 | - | 3089.39 | - |

| Binder | 1.60 | - | 2102.21 | - |

| Electric power | 11.86 | - | 15,638.07 | - |

| Construction Equipment | Track | Earthwork | ||||

|---|---|---|---|---|---|---|

| Working Time (h) | Rated Power (kW) | Energy (MJ) | Working Time (h) | Rated Power (kW) | Energy (MJ) | |

| Concrete distributor | 45.6 | 22.0 | 3612 | — | — | — |

| Concrete mixing plant | 45.6 | 160.0 | 26,266 | 219.9 | 160.0 | 126,662 |

| CNC grinding machine | 45.6 | 260.0 | 42,682 | — | — | — |

| Gantry crane | 113.0 | 86.5 | 35,188 | — | — | — |

| Two-way transporter | 34.5 | 110.0 | 13,662 | — | — | — |

| CA mortar truck | 27.7 | 90.0 | 8975 | — | — | — |

| Track laying machine | 6.0 | 396.0 | 8554 | — | — | — |

| Spiral drilling machine | — | — | — | 311.2 | 90.0 | 100,829 |

| Excavator | — | — | — | 5889.0 | 125.0 | 2,650,050 |

| Loading machine | — | — | — | 2944.5 | 162.0 | 1,717,232 |

| Concrete pump | — | — | — | 439.8 | 115.0 | 182,077 |

| Stages | Track | Earthwork | Entire Rail System | |||

|---|---|---|---|---|---|---|

| CO2 (kt) | Energy (TJ) | CO2 (kt) | Energy (TJ) | CO2 (kt) | Energy (TJ) | |

| Conception | 35.59 | 382.22 | 35.59 | 382.22 | 71.18 | 764.44 |

| Construction | 1647.50 | 15,908.26 | 8317.33 | 43,546.72 | 9964.83 | 59,454.98 |

| Operation and Maintenance | 1990.18 | 20,956.20 | 2864.48 | 17,713.92 | 4854.66 | 38,670.12 |

| Disposal | 20.75 | 369.04 | 451.29 | 10,214.50 | 472.04 | 10,583.54 |

| Sum | 3694.02 | 37,615.72 | 11,668.68 | 71,857.36 | 15,362.70 | 109,473.08 |

| Stages | Track (million US$) | Earthwork (million US$) | Entire Rail System (million US$) |

|---|---|---|---|

| Conception | 14.27 | 14.27 | 14.27 |

| Construction | 844.15 | 3769.86 | 4614.01 |

| Operation and maintenance | 651.37 | 441.36 | 910.61 |

| Disposal | 2.99 | 29.77 | 32.75 |

| Sum | 1512.78 | 4255.26 | 5585.92 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaewunruen, S.; Sresakoolchai, J.; Peng, J. Life Cycle Cost, Energy and Carbon Assessments of Beijing-Shanghai High-Speed Railway. Sustainability 2020, 12, 206. https://doi.org/10.3390/su12010206

Kaewunruen S, Sresakoolchai J, Peng J. Life Cycle Cost, Energy and Carbon Assessments of Beijing-Shanghai High-Speed Railway. Sustainability. 2020; 12(1):206. https://doi.org/10.3390/su12010206

Chicago/Turabian StyleKaewunruen, Sakdirat, Jessada Sresakoolchai, and Junying Peng. 2020. "Life Cycle Cost, Energy and Carbon Assessments of Beijing-Shanghai High-Speed Railway" Sustainability 12, no. 1: 206. https://doi.org/10.3390/su12010206

APA StyleKaewunruen, S., Sresakoolchai, J., & Peng, J. (2020). Life Cycle Cost, Energy and Carbon Assessments of Beijing-Shanghai High-Speed Railway. Sustainability, 12(1), 206. https://doi.org/10.3390/su12010206