3.1. Identification of Lean Design Management Practices from the Literature

Affinity methods are used in design thinking to help in making sense of the information when data come from diverse sources/contexts, such as facts, ethnographic research, brainstorming results, users’ opinions and needs, insights, and design issues [

29]. Considering the exploratory nature of this study and the mixed nature of the data collected, affinity methods were selected for information classification. From the literature review, 19 lean design management practices were identified and grouped into three categories using the affinity method [

30,

31]: stakeholder management, project planning and control, and problem solving and decision making. Below, the practices of each of the categories are presented; for each one of the practices, its supporting references are presented by category.

The management of stakeholders (category 1) is one of the most important elements in the management of any type of project [

32,

33]. As an example of its relevance, the project management body of knowledge (PMBOK) as proposed by the Project Management Institute (PMI) added stakeholder management as the tenth area of knowledge to be considered by project managers [

1]. Within this category, requirement management is usually one of the critical elements for the management of construction projects [

33], where the identification and management must be conducted not only with external clients but also with all stakeholders of the project, while also considering internal clients [

1,

32]. To correctly manage requirements, the systematic participation of a client as a feedback agent of the proposition generated by designers is fundamental [

14,

23,

34]. Additionally, the early involvement of specialist designers and builders will generate a design with a comprehensive value proposal; furthermore, the design will consider the knowledge and experience of these actors as internal clients, allowing them to anticipate potential incompatibility problems among designers and even consider an optimal design for future construction [

6,

35,

36].

Table 5 provides a summary of the main references found in the literature about lean management practices associated with stakeholder management.

The planning and monitoring (category 2) of projects are activities that require more time when managing a project; in the latest version of the PMBOK [

1], 73.47% of the proposed processes for project management belonged to the planning and monitoring categories [

1]. In the AEC industry, there are certain standardized tools and practices that are commonly used for planning and control, specifically during the construction phase, such as the earned value method [

49,

50] or LPS

® [

22,

51,

52]. However, during the design phase, there are no common tools and practices for design teams [

51]; currently, there have been reports and case studies about the application of certain management tools, such as the design structure matrix and LPS

® [

53]. Most of the practices compiled are related to the use of LPS

® [

16,

52].

Table 6 provides a summary of the main references encountered in the literature about lean management practices associated with project planning and control.

During the design phase, there are many iterations associated with both the creative process of design and the existence of problems of a different nature, such as incompatibilities between specialties, regulatory constraints, economic constraints, and ill-defined requirements, among others [

34]. Therefore, these creative or problem iterations will generate instances of decision making and problem solving (category 3), which can be addressed individually and centralized, collaboratively and decentralized [

60], or intuitively with defined and standardized action protocols [

23,

61]. The lean theory proposes collaborative, continuous, and standardized management as appropriate practices to solve problems, make decisions, and use the resulting information as lessons learned [

35,

43,

57].

Table 7 provides a summary of the main references encountered in the literature about lean management practices associated with problem solving and decision making.

3.2. The Relationship between Lean Design Management Practices and Lean Principles

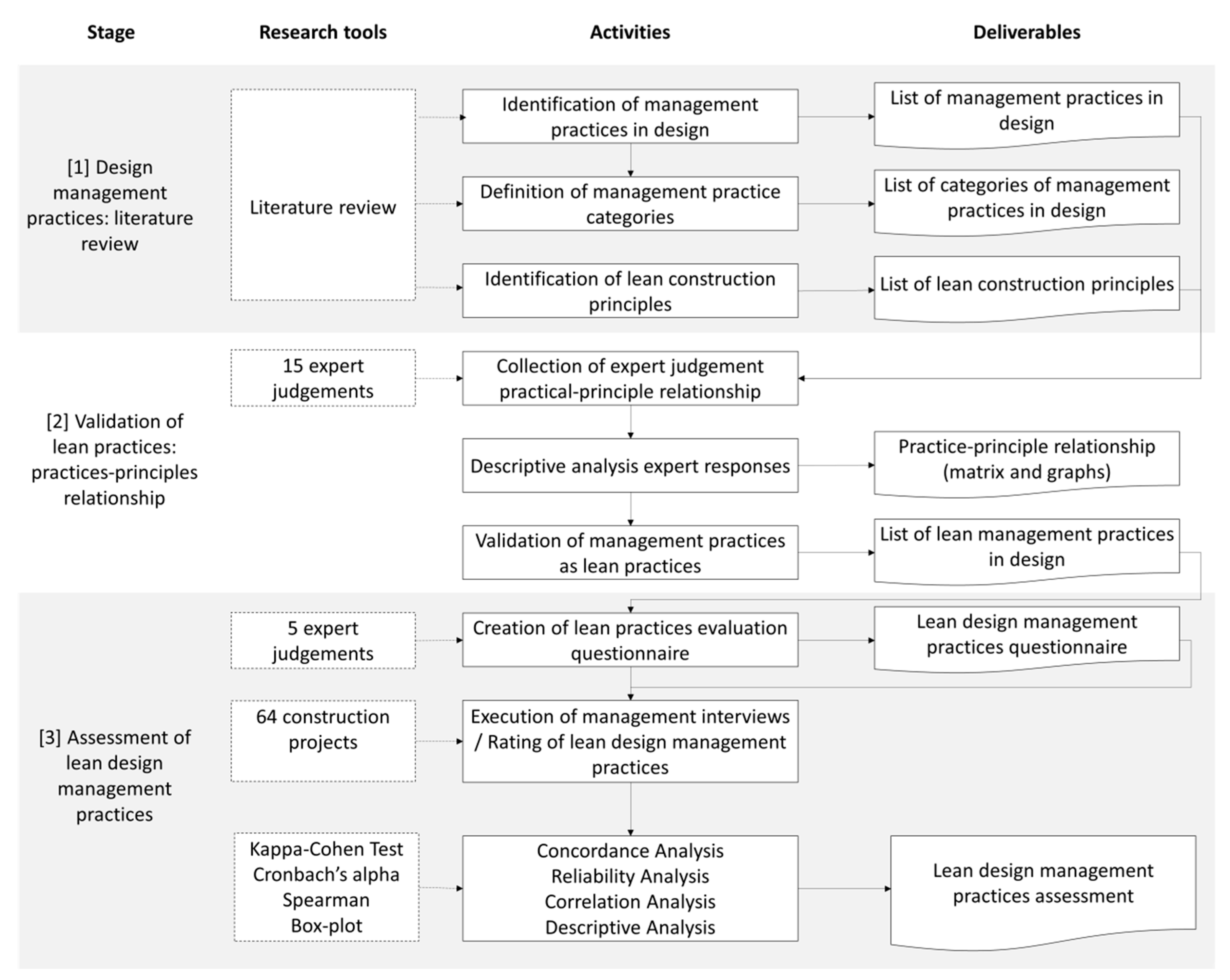

To validate the 19 lean design management practices, their relationships with the 11 principles of lean construction were investigated. The judgment of 15 experts was used to consider whether the practical–principle relationship was nonexistent (0), a partial relationship (1), or a complete relationship (2). As each expert provided their judgment on each of the 209 possible practice–principle relationships, the median value of the experts′ answers was used. All of the relationships were presented in a matrix of practical–principle relationships (

Table 8), which could be visualized more compactly as a node diagram. In the node diagram, the nodes represented the principles and practices, while the edges represented relationships between the nodes (

Figure 2).

Figure 2 depicts the network diagrams, where the white nodes represent the principles, and the black nodes are the practices associated with the various categories of stakeholder management, planning and monitoring, and problem solving and decision making. The size of the practice nodes remained constant; however, the size of the principle nodes increased as additional practices contributed to each principle. The connections, represented by arrows, were continuous lines when complete relationships existed and dotted lines when connections were partial.

Figure 2 allows visualization of the management practices that contributed to each principle; therefore, the visualization of management practices could serve as a guide for organizations to decide which practices have higher priorities than others.

The 11 lean construction principles were linked by at least three practices and, at most, 17 of the 19 lean design management practices; that is, all of the lean construction principles were considered in the practices documented in this study. The principles that were most reinforced in the design phase of construction projects were as follows: increasing the output value through systematic consideration of customer requirements, reducing the amount of non-value-adding activities, reducing the process variability, reducing the cycle times, increasing the process transparency, and continuously improving processes. This was a predictable result, since during the design phase, clients are provided with a first approximation of the final product that they expect to receive. The principles that were least reinforced were increasing the output flexibility, balancing the flow improvement with conversion improvement, and benchmarking. The standard deviation of the number of practices connected to each principle was 4.68 practices; however, if the three least reinforced principles were not considered in the calculation, the standard deviation was 1.48; that is, without accounting for these three principles, a greater level of homogeneity existed among the remaining eight principles, which was altered when considering the eleven lean construction principles.

On average, each principle was connected with 12 of the 19 lean design management practices, which demonstrated a suitable level of compatibility between lean design management practices and lean construction principles. The number of total connections between practices and principles was 138 (including partial and complete relationships), which accounted for 66.03% of all potential relationships. However, of the total number of connections, 19.57% were complete relationships and 80.43% were partial relationships, which indicated that when applying lean construction principles during the design phase, there were, on average, two practices that would directly impact the management and application of these principles during the design phase. On average, there were six practices that only partially impacted the management and application of lean construction principles.

In addition, all practices were connected to each other through at least one principle; therefore, the implementation of lean practices in the design phase could be simple and gradual if the design team was clear about the lean construction principles that were being considered for implementation in the management process. However, each implementation process should be carried out gradually; therefore, it was important to identify which practices contributed to a greater number of lean construction principles. The identification would enable organizations to determine the rate at which practices would be gradually implemented.

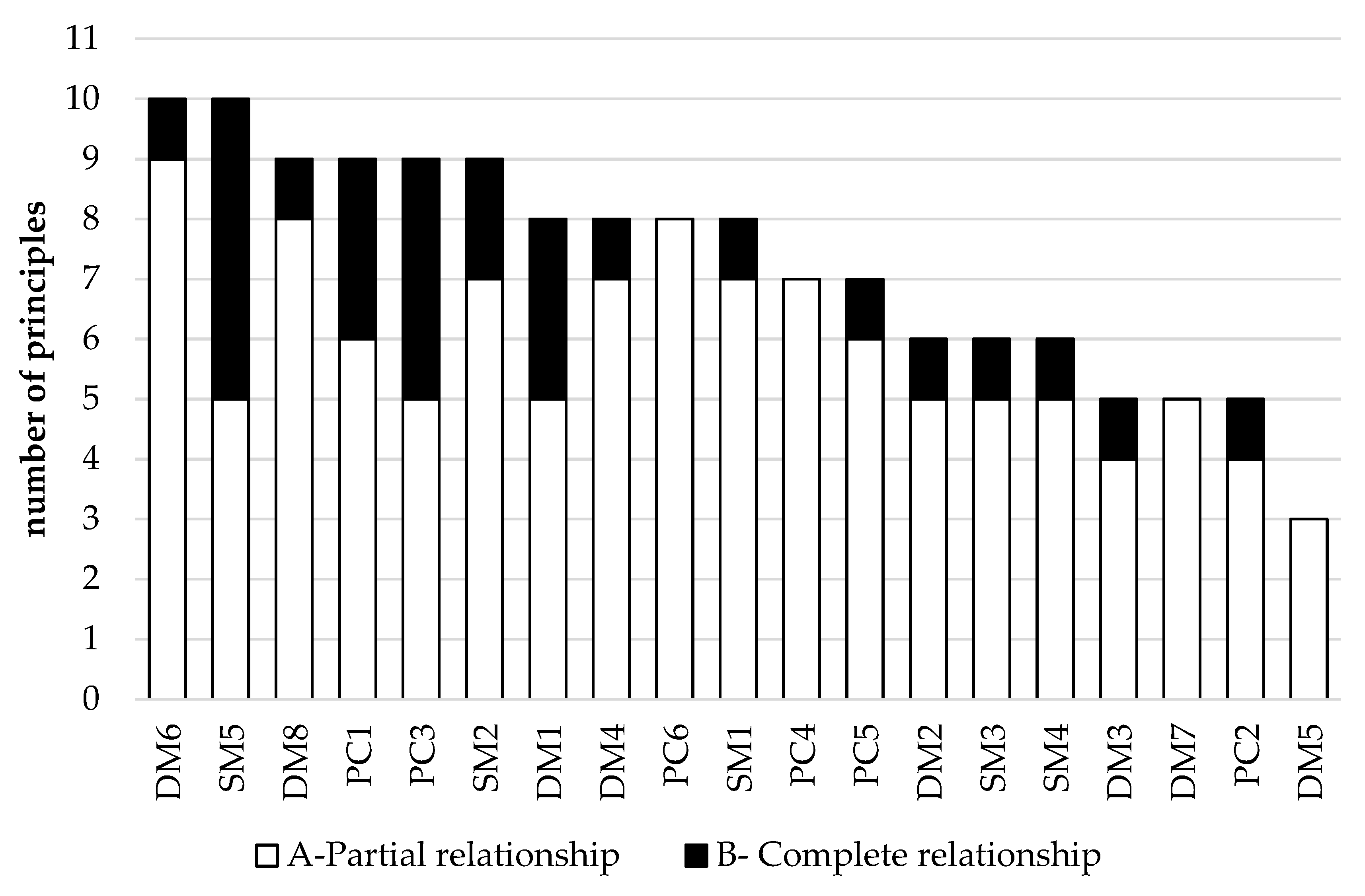

Figure 3 shows the number of principles that each of the practices contributed to: (A) partially and (B) completely.

The 19 defined lean design management practices were subject to at least three principles and a maximum of 10 out of 11 lean construction principles proposed by Koskela. The practices that contributed to a larger number of principles were the simultaneous design of the product and construction process, use of benchmarking information to make decisions, definition of activities, milestones and control points, and collaborative planning. Several of the aforementioned practices belonged to the planning and control category, which was in agreement with the literature review of lean construction principles in the design phase; most of the case studies in the literature reflected the implementation of LPS® during the design phase of construction projects.

The practices that contributed to fewer principles were the making of decisions at the last responsible moment, plan–do–check–act (PDCA) problem solving, multicriteria decision making, and benchmarking to obtain information for planning. Three of these four practices corresponded to the problem-solving and decision-making category; therefore, there would be a knowledge gap associated with the approach of this type of implementation of the lean construction principles. It is important to mention that the number of lean construction principles related to a practice does not imply that this practice is more or less important in the process of implementing a lean design process.

On average, each practice contributed to 7.26 principles. Distinguishing this information by category, practices of the stakeholder management, planning and control, and problem solving and decision-making categories contributed to, on average, 7.80, 7.50, and 6.75 principles, respectively; therefore, none of the categories dominated over the others, although it was again observed that the problem solving and decision making category was the least related to the principles of lean construction.

3.3. Assessment of Lean Design Management Practices in Construction Projects

Bloom and Van Reenen′s [

65] developed a method to measure and explain management practices across firms and countries, which uses open-ended questions. This approach fits better to the current research than absolute scoring grids, and it is a proven model that is highly cited in the literature. Based on the list of lean design management practices, a project management questionnaire was created that contained five levels [

65]. For each practice, the collaborative team of experts (

Table 3) proposed a description was defined for scores 1, 3, and 5, while scores 2 and 4 were defined as an intermediate point between 1–3 and 3–5, respectively:

Score 1: a traditional management practice,

Score 3: an initial lean design management practice,

Score 5: a developed lean design management practice.

The researchers assessed 64 projects in the design phase; each project was independently assessed by two researchers, and then the final score was collaboratively defined. To evaluate the degree of agreement between the two researchers, the Cohen′s kappa test [

28] was used, where the null hypothesis (H0) was defined as no agreement between the two researchers, and the alternative hypothesis (H1) was defined as agreement between the two researchers. The test considered a level of significance of 5%. When applying Cohen’s kappa test, a percentage of agreement of 75% was obtained, with a Cohen’s kappa value of 0.65 and

p-value of 0.03. Since the

p-value was less than 0.05, the null hypothesis could be rejected, while the alternative hypothesis that there existed agreement between the two researchers could not be rejected [

66]. When performing the Cohen’s kappa test considering the collaborative decision of the two independent researchers, Cohen’s kappa values of 0.81 and 0.82 were obtained, which indicated a high degree of agreement [

66].

Then, the researcher analyzed the internal consistency of the questionnaire measuring scale using Cronbach’s alpha coefficient. For the questionnaire of 19 items and 64 test projects, a Cronbach’s alpha coefficient calculated was 0.918. Hence, the element of the tool assesses the same characteristics for a project for each lean design management practices. From the high level of internal consistency (reliability) and the high level of agreement between the researchers, it is concluded that the questionnaire is an objective and consistent tool for evaluating the levels of lean design management practices in construction projects.

In addition, hypothesis tests were conducted to identify significant differences according to the characteristic of the evaluated projects. Nonparametric hypothesis tests were applied with a significance level of 95% since the variables of each evaluation of the 19 lean design management practice are ordinal qualitative. The Mann–Whitney U test was used to compare pairs of samples (building and infrastructure projects), and the Krustal–Wallis test was used to compare three samples (Colombia, Chile, and Spain). Concerning the type of project, the p-value was not lower than 0.05; therefore, the authors do not have enough information to reject the hypothesis that building and infrastructure projects have significant differences in their lean design management practices. About the difference by country of project design, when performing the test, it was observed that there were significant differences (p-value < 0.05) in the lean design management practices SM1 and SM2, which correspond to the early incorporation of specialist designers and builders. This difference was generated specifically between the projects evaluated in Chile and Colombia, where the latter had a better development of these lean design management practices. In the other 17 practices, there were no significant differences among countries (p-value > 0.05); therefore, the projects can be compared between them.

Then, in order to verify whether there was a correlation at the performance level between the 19 lean design management practices, the authors built a Spearman correlation matrix (

Table 9), in which the researchers calculated the Spearman’s rho coefficient and the level of correlation significance between each pair of lean design management practices. In the matrix, it can be observed that the magnitudes of the correlations were moderate (around 0.5); however, 74.85% of the correlations were significant (

p-value < 0.05). This highlights the connection that exists between the lean design management practices, given that the joint realization of these practices is a contribution to the fulfillment of the principles of lean construction.

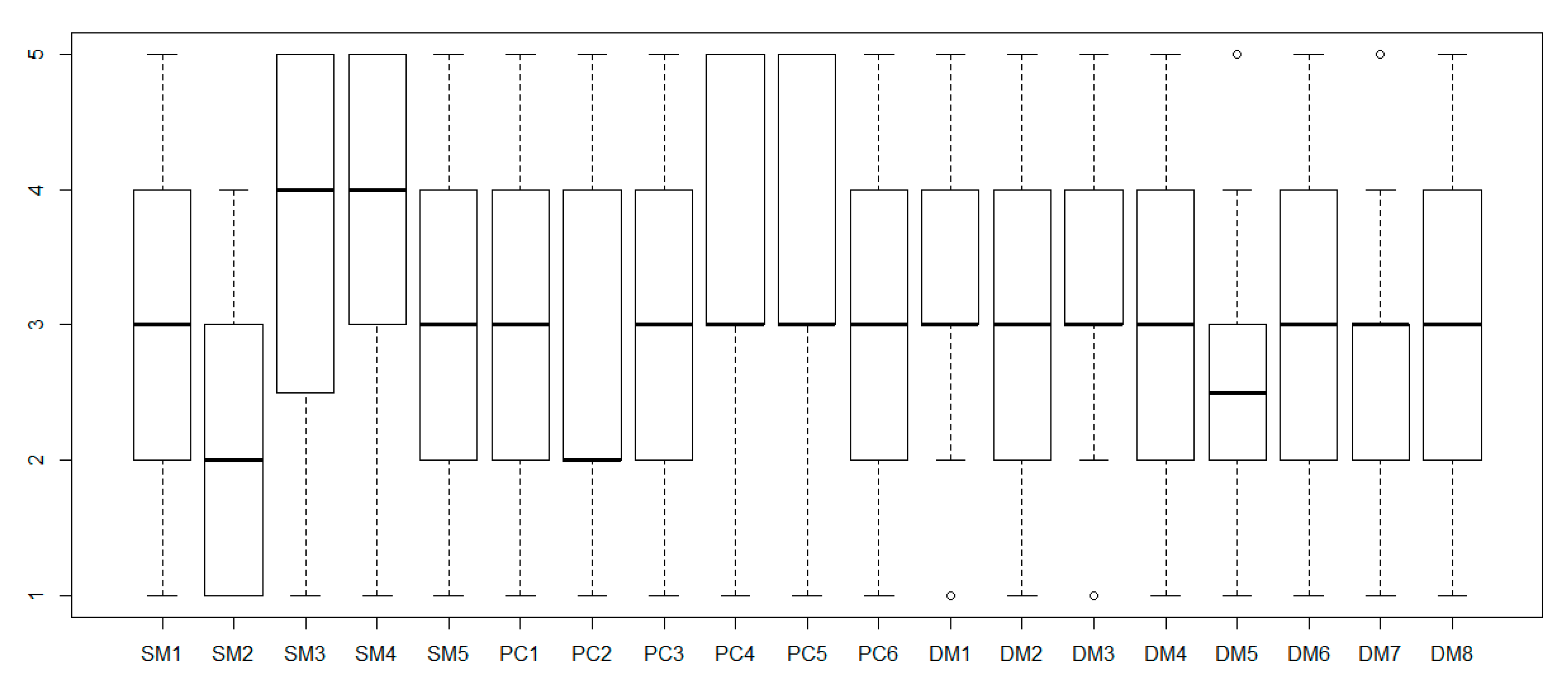

Using the 64 evaluated projects, a descriptive analysis was conducted to determine the distribution of the levels for each lean design management practice (

Figure 4). According to this figure, the practices with the highest level of implementation were “requirements management (identification of constraints, technical specifications, and special requirements)” and “client systematic participation and support during meetings concerning decision making and resolution of problems”; these are the only practices where there was a higher level than that of the initially implemented lean design management practices. Additionally, 75% of the projects were beginning to apply lean design with the practices “planning in different levels” and “constrains management visualization”, however, even at initial levels. The same happened with the lean design management practices “collaborative solving problems” and “PDCA problem solving”. The practices with the lowest level of implementation were “builders in early stages”, “decision-making until the last responsible moment”, and “multicriteria decision-making”, where lean implementation levels were practically nonexistent in about 75% of the evaluated projects. In addition, high ranges of variability can be observed in

Figure 4, since in most lean design management practices (15 of 19) there is a two-level difference between the 75th percentile and the 25th percentile. This variability reflects that lean design practices are not yet a standard in management at this stage of the project.

Finally, from

Figure 4 it can also be seen that the practices that contribute most to the development of lean construction principles (

Figure 3) had normal behaviors in the range defined for each of the practices (DM

6, SM

5, DM

8, PC

1, PC

3), that is, the minimum value at level 1, the 25th percentile at level 2, the median at level 3, the 75th percentile at level 4, and the maximum value at level 5. Therefore, the variability of lean design management practice assessment is transferred to fulfillment of the lean construction principles.