Life Cycle Assessment Contribution in the Product Development Process: Case Study of Wood Aluminum-Laminated Panel

Abstract

1. Introduction

2. Methodology: Life Cycle Assessment (LCA)

2.1. Goal and Scope of the Study

2.1.1. Functional Unit (FU)

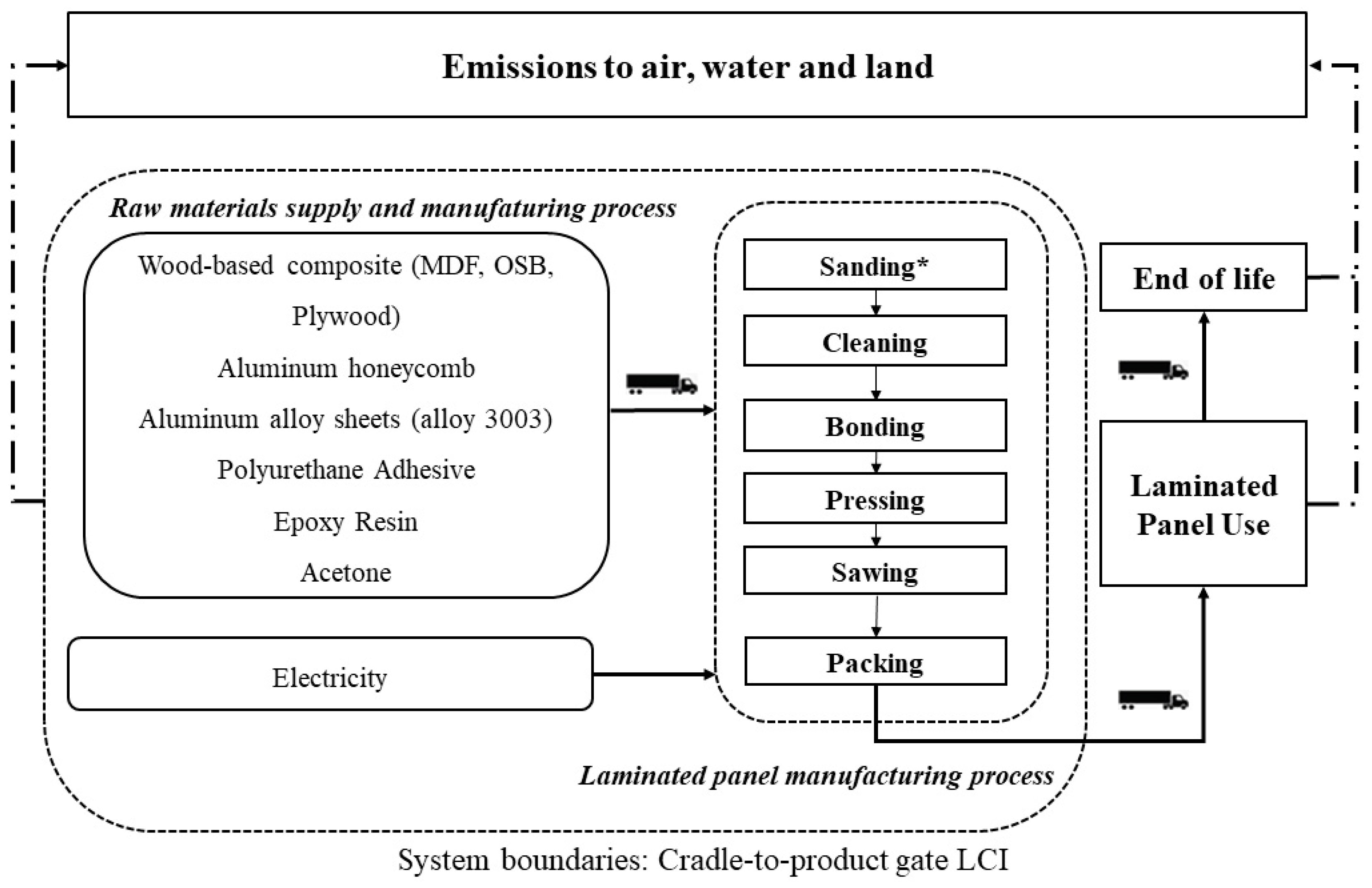

2.1.2. Definition of System Boundary from Cradle-to-Gate

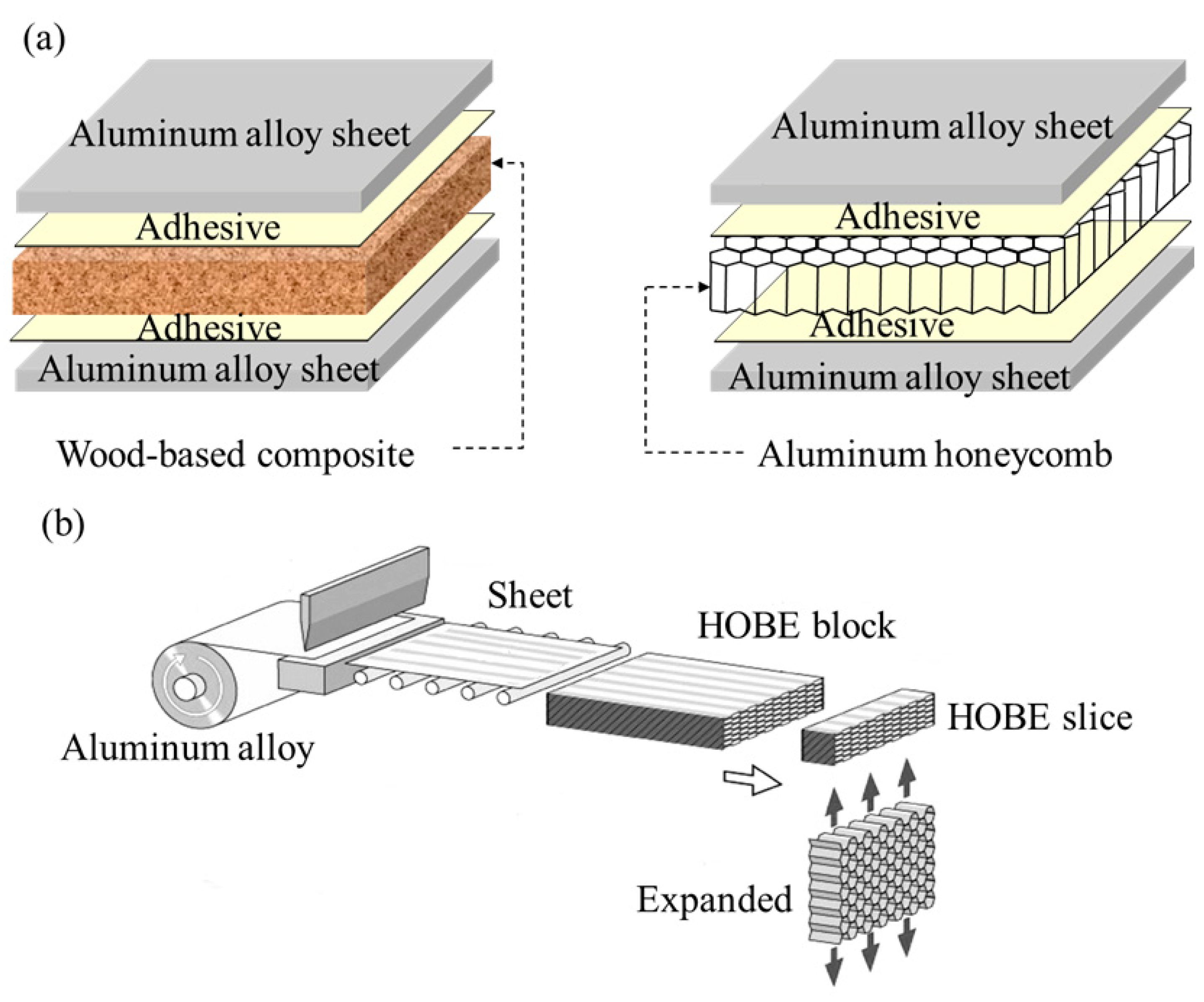

2.1.3. Description of the Studied Panels

2.1.4. Description of Manufacturing Process of the Wood Aluminum-Laminated Panel

2.1.5. Description of Manufacturing of the Aluminum Honeycomb Panel

2.1.6. Assumption and Limitation

- The packing stage has been excluded of assessment of environmental impacts because they are considered identical for the four types of laminated panels.

- All data for the WAL panel manufacturing process was obtained from laboratory tests and adapted in the modeling to reflect the industrial context.

2.2. Life Cycle Inventory

2.3. Life Cycle Impact Assessment Method (LCIA)

3. Results and Discussion

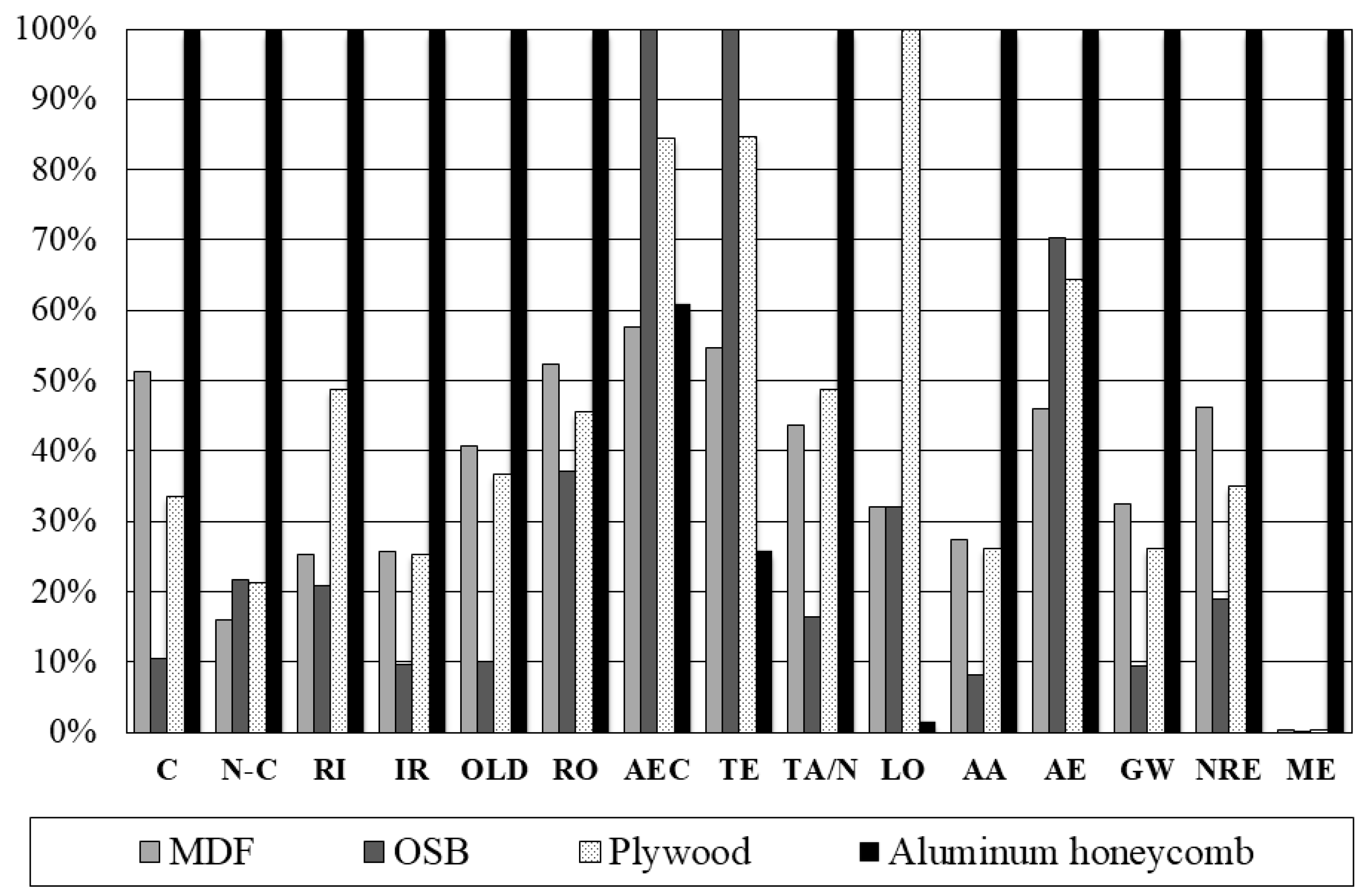

3.1. Analysis of Manufacturing Processes of Wood-Based Composite and of Aluminum Honeycomb Panels Without Lamination.

- Carcinogens category (C): Adhesive production (MUF, UF and PF resins) was the main contributor to negative impact, which represented 66–78% of total contributing emissions for wood-based composites. The 100% of contributions to this impact category was associated with epoxy resin for aluminum honeycomb.

- Non-carcinogens (N-C): Majority of emissions contributing to this impact category were associated with the treatment of wood ash mixture for MDF (52%) and OSB (91%), while heat production from hardwood chips was the main contributor for plywood (84%). For aluminum honeycomb, treatment of red mud from bauxite digestion represented more than 88% of total contributing emissions.

- Respiratory inorganics (RI): MUF and UF resins (55%), OSB production (70%), and heat production from hardwood chips (68%) were the main contributors to negative impact for MDF, OSB and plywood respectively. For aluminum honeycomb, 13% and 12% of contributions to this impact category were associated with transport (transoceanic ship) of bauxite and aluminum production respectively.

- Ionizing radiation (IR): Electricity was the main contributor to IR, which represented 39%, 45% and 57% for MDF, OSB and aluminum honeycomb respectively, while melamine formaldehyde resin was the main contributor for plywood manufacturing (43%).

- Ozone layer depletion (OLD): MUF and UF resins (72%), pulpwood hardwood production (41%) and MUF resin (75%) were the main contributor for MDF, OSB and plywood respectively. Heat production from petroleum (39%) was the main contributor for aluminum honeycomb manufacturing.

- Respiratory organics (RO): 55%, 41% and 41% of contributions to this impact category were associated with the MDF production, PF resin (OSB), and sawlog and veneer log production (plywood) respectively. 48% of contributions to this category were associated with aluminum primary liquid production for aluminum honeycomb.

- Aquatic ecotoxicity (AEC): Treatment of wood ash mixture was the main contributor to this category for MDF (72%) and OSB (98%), while heat production from hardwood chips for plywood (93%). For aluminum honeycomb, treatment of red mud from bauxite digestion represented more than 49% of total contributing emissions.

- Terrestrial ecotoxicity (TE): Treatment of wood ash mixture was the main contributor to this category for MDF (75%) and OSB (98%), while heat production from hardwood chips was the main contributor for plywood (95%). 43% of contributions to this category was associated with bauxite mine operation for aluminum honeycomb.

- Terrestrial acid/nutri (TA/N): 36%, 45% and 52% of contributions to this category were associated with MUF and UF resins (MDF), OSB production (OSB) and MUF resin (plywood) respectively. For aluminum honeycomb, 26% of contributions to this impact category were associated with transport of bauxite (transoceanic ship).

- Land occupation (LO): Wood production (softwood, hardwood and veneer log) was the most effective contributor to LO for MDF (99%), OSB (100%) and plywood (78%).

- Aquatic acidification (AA): Adhesive production was the main contributor to AA, which represented 63%, 35% and 64% for MDF, OSB and plywood respectively. Aluminum production and transport of bauxite were the main contributor with 19% and 16% respectively, for aluminum honeycomb.

- Aquatic eutrophication (AE): Treatment of wood ash mixture was the main contributor to this category for MDF (47%) and OSB (72%), while heat production from hardwood chips was the main contributor for plywood (73%). For aluminum honeycomb, Aluminum primary liquid production represented more than 52% of total contributing emissions.

- Global warming (GW): Once again, adhesive production was the main contributor to this category (64%, 59% and 76% for MDF, OSB and plywood respectively). 30% of contributions to this category was associated with aluminum production (aluminum primary liquid production).

- Non-renewable energy (NRE): Adhesive production was also the main contributor to this category (67%, 65% and 43% for MDF, OSB and plywood respectively). For aluminum honeycomb, hard coal (mine operation) for aluminum production (14%) was the main contributor to this category.

- Mineral extraction (ME): Adhesive production was also the main contributor to this category (87%, 72% and 80% for MDF, OSB and plywood respectively). 98% of contributions to this category were associated with bauxite mine operation for aluminum honeycomb.

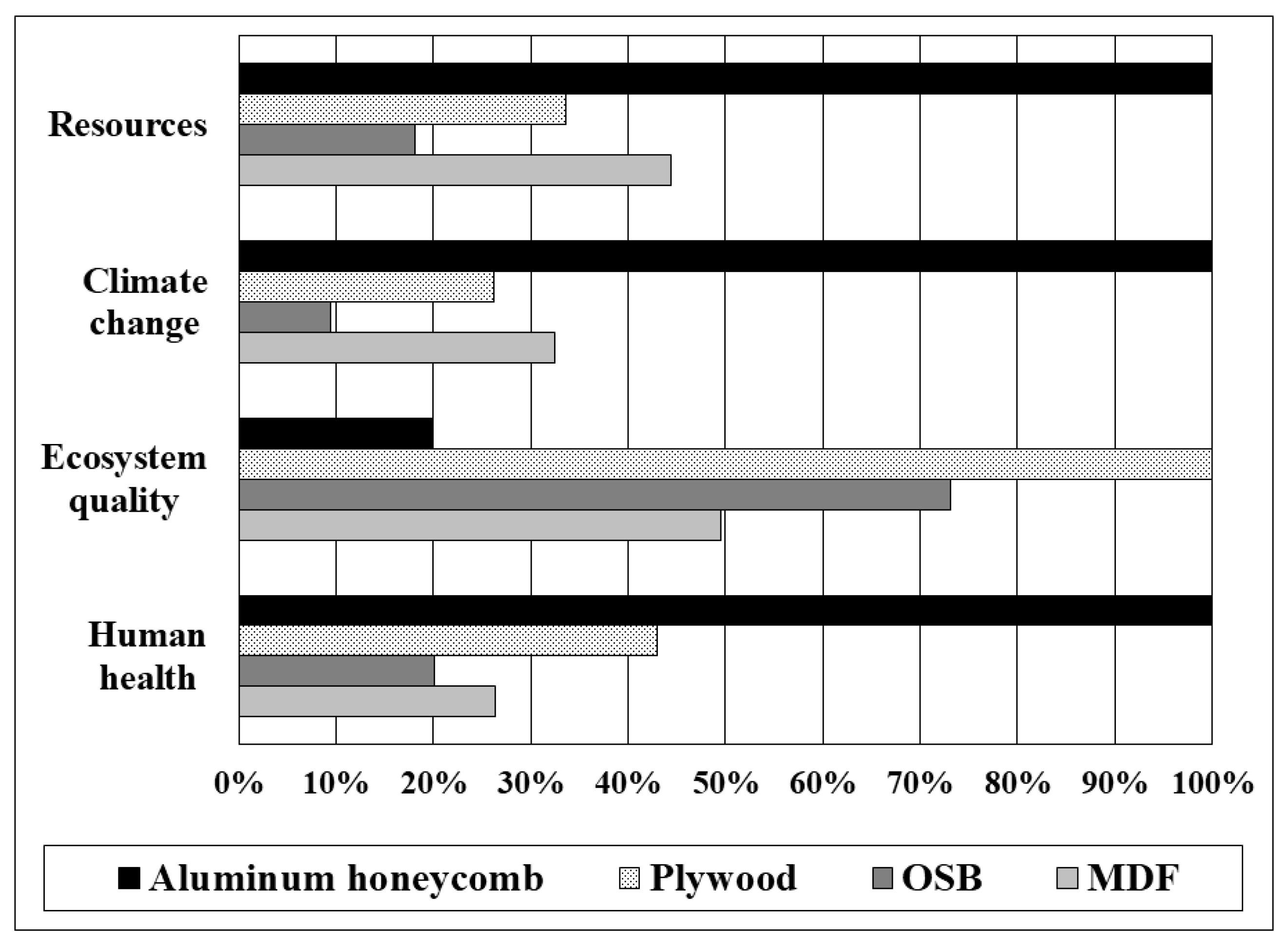

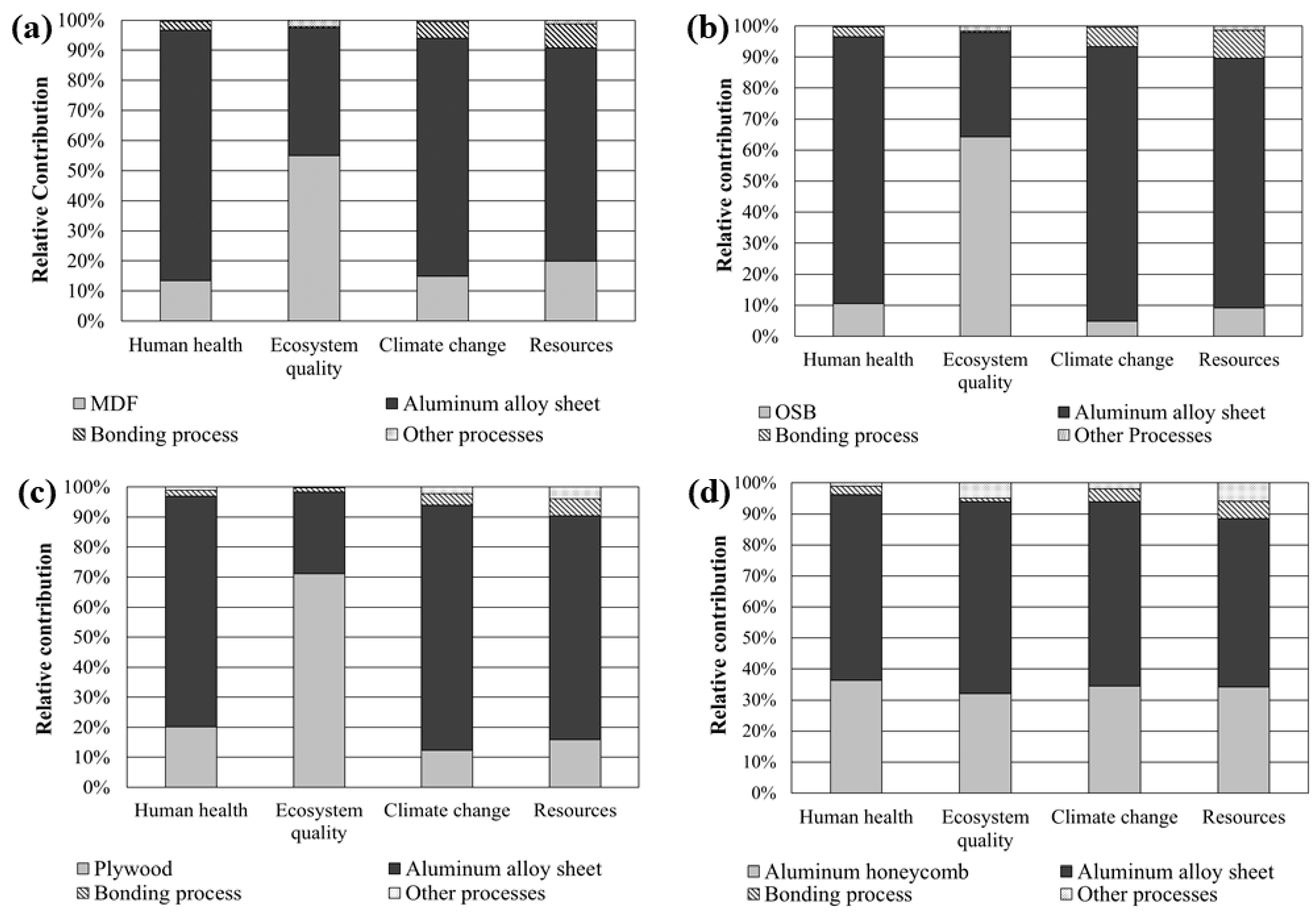

3.2. Analysis of Manufacturing Process of WAL Panels and AHP

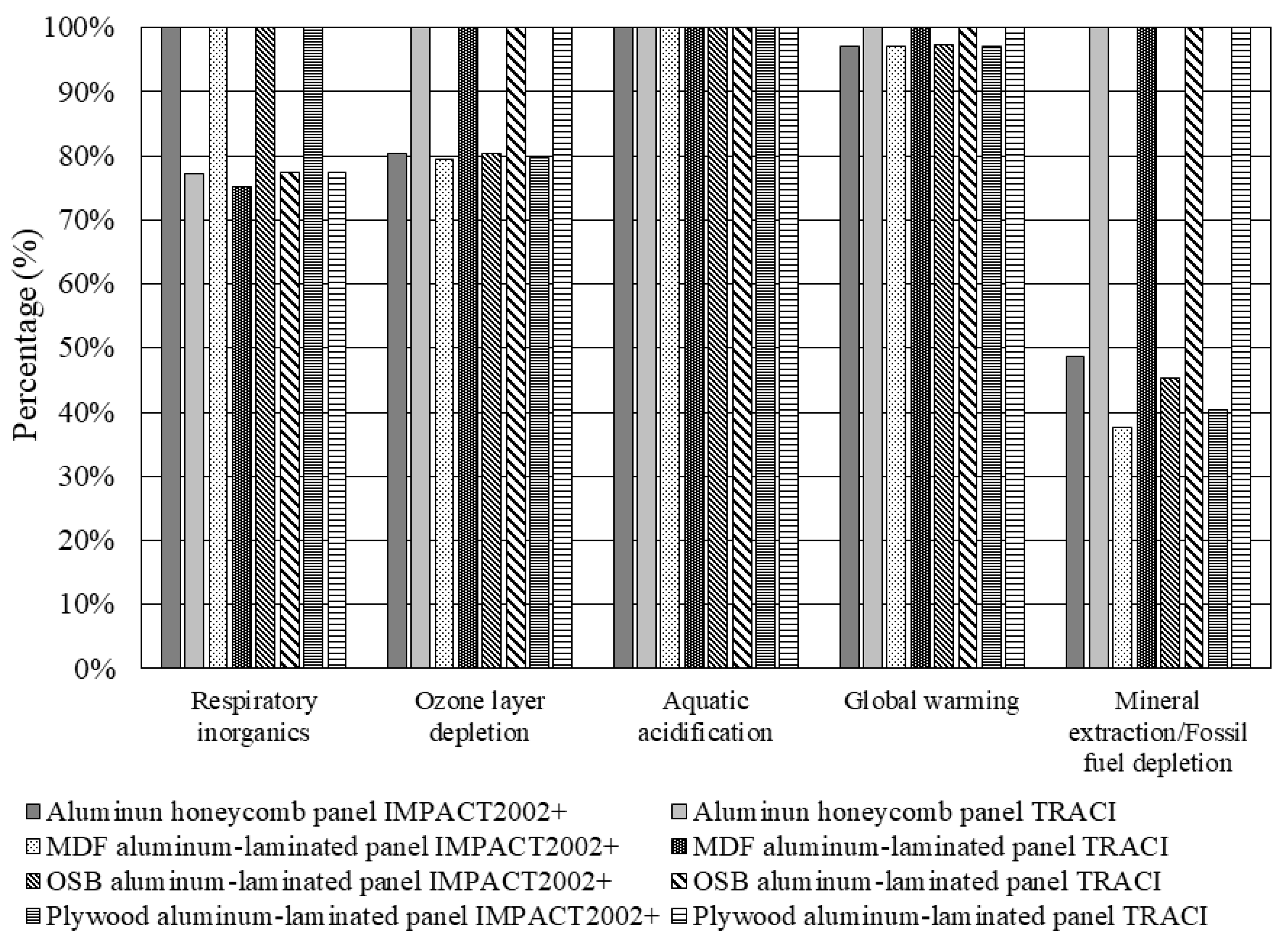

3.3. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nielsen, P.H.; Wenzel, H. Integration of environmental aspects in product development: A stepwise procedure based on qualitative life cycle assessment. J. Clean. Prod. 2002, 10, 247–257. [Google Scholar] [CrossRef]

- Chang, D.; Lee, C.K.M.; Chen, C.-H. Review of life cycle assessment towards sustainable product development. J. Clean. Prod. 2014, 83, 48–60. [Google Scholar] [CrossRef]

- La Rosa, A.; Cicala, G. LCA of fibre-reinforced composites. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing Series in Textiles: Catania, Italy, 2015; Volume 172, 377p. [Google Scholar]

- Bovea, M.D.; Vidal, R. Increasing product value by integrating environmental impacts, costs and customer valuation. J. Resour. Conserv. Recycl. 2004, 41, 133–145. [Google Scholar] [CrossRef]

- González-García, S.; Feijoo, G.; Widsten, P.; Kandelbauer, A.; Zikulnig-Rusch, E.; Moreira, M. Environmental performance assessment of hardboard manufacture. Int. J. Life Assess. 2009, 14, 456–466. [Google Scholar] [CrossRef]

- Puettmann, M.; Oneil, E.; Kline, E.; Johnson, L. Cradle to Gate Life Cycle Assessment of Oriented Strandboard Production from the Southeast; University of Washington: Seattle, WA, USA, 2013; 35p. [Google Scholar]

- Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Puettmann, M.; Oneil, E.; Wilson, J. Cradle to Gate Life Cycle Assessment of U.S. Medium Density Fiberboard Production; University of Washington: Seattle, WA, USA, 2013; 26p. [Google Scholar]

- Rivela, B.; Moreira, M.T.; Feijoo, G. Life cycle inventory of Medium Density Fibreboard. Int. J. LCA 2007, 12, 143–150. [Google Scholar] [CrossRef]

- Wilson, J. Medium Density Fiberboard (MDF): A Life-cycle Inventory of Manufacturing Panels from Resource through Product; Corrim: Phase II. Final Report; Oregon State University: Corvallis, OR, USA, 2008; 50p, Available online: https://corrim.org/wp-content/uploads/2018/03/lci-medium-density-fiberboard-panels-resource-through-product.pdf (accessed on 13 March 2017).

- Zeller, V.; Richard, A.; Degrez, M.; Thyssen, N.; De Boever, L. Life Cycle Assessment of Medium Density Fibreboard LCA at Product Level; Project Report 3.4 v.2; ENECOBOIS: Brussels, Belgium, 2015; 38p. [Google Scholar]

- Moro Piekarski, C.; de Francisco, A.C.; Mendes da Luz, L.; Kovaleski, J.L.; Lopes Silva, D.A. Life cycle assessment of medium-density fiberboard (MDF) manufacturing process in Brazil. Sci. Total Environ. 2017, 575, 103–111. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Yang, H. Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China. Int. J. Environ. Res. Public Health 2017, 15, 2060. [Google Scholar] [CrossRef] [PubMed]

- Kline, E. Gate-to-gate life-cycle inventory of oriented strandboard production. Wood Fiber Sci. 2005, 37, 74–84. [Google Scholar]

- Ferro, F.S.; Silva, D.A.; Lahr, F.A.; Argenton, M.; González-García, S. Environmental aspects of oriented strand boards production. A Brazilian case study. J. Clean. Prod. 2018, 183, 710–719. [Google Scholar] [CrossRef]

- Puettmann, M.; Oneil, E.; Wilson, J.; Johnson, L. Cradle to Gate Life Cycle Assessment of Softwood Plywood Production from from the Southeast; University of Washington: Seattle, WA, USA, 2013; 35p. [Google Scholar]

- Puettmann, M.; Oneil, E.; Wilson, J.; Johnson, L. Cradle to Gate Life Cycle Assessment of Softwood Plywood Production from the Pacific Northwest; University of Washington: Seattle, WA, USA, 2013; 34p. [Google Scholar]

- EPA. Framework for Assessing Biogenic CO2 Emissions from Stationary Sources: U.S. Environmental Protection Agency, Office of Air and Radiation Office of Atmospheric Programs, Climate Change Division. 2014. Available online: https://www.epa.gov/climatechange/november-2014-revised-framework-assessing-biogenic-co2-emissions-stationary-sources (accessed on 20 October 2017).

- Beauregard, R.; Bernier, P.; Bouthillier, L.; Levasseur, A.; Paré, D.; St-Laurent-Samuel, A.; Thiffault, E. The Use of Biomass to Reduce Greenhouse Gaz Emissions in Quebec; Scientific advisory report; the Ministry of Natural Resources of Québec: Quebec City, QC, Canada, 2012; 19p. Available online: https://cfs.nrcan.gc.ca/publications?id=34300 (accessed on 15 January 2017).

- Dos Santos, M.F.N.; Battistelle, R.A.G.; Bezerra, B.S.; Varum, H.S. Comparative study of the life cycle assessment of particleboards made of residues from sugarcane bagasse (Saccharum spp.) and pine wood shavings (Pinus elliottii). J. Clean. Prod. 2014, 64, 345–355. [Google Scholar] [CrossRef]

- Wilson, J. Life-cycle inventory of formaldehyde-based resins used in wood composites in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 125–143. [Google Scholar]

- Silva, D.A.L.; Rocco Lahr, F.A.; Varanda, L.D.; Christoforo, A.L.; Ometto, A.R. Environmental performance assessment of the melamine-urea-formaldehyde (MUF) resin manufacture: A case study in Brazil. J. Clean. Prod. 2015, 96, 299–307. [Google Scholar] [CrossRef]

- Batouli, S.; Zhua, Y.; Narb, M.; D’Souza, N. Environmental performance of kenaf-fiber reinforced polyurethane: A life cycle assessment approach. J. Clean. Prod. 2014, 66, 164–173. [Google Scholar] [CrossRef]

- La Rosa, A.; Reccab, G.; Summerscalesc, J.; Latteria, A.; Cozzoa, G.; Cicalaa, G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J. Clean. Prod. 2014, 74, 135–144. [Google Scholar] [CrossRef]

- Song, Y.; Youn, J.; Gutowski, T. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Umair, S. Environmental Impacts of Fiber Composite Materials. Study on Life Cycle Assessment of Materials used for Ship Superstructure. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2006; 63p. [Google Scholar]

- Xun, X.; Jayaramana, K.; Morin, C.; Pecqueux, N. Life cycle assessment of wood-fibre-reinforced polypropylene composites. J. Mater. Process. Technol. 2008, 198, 168–177. [Google Scholar]

- Liu, G.; Muller, D. Addressing sustainability in the aluminum industry: A critical review of life cycle assessments. J. Clean. Prod. 2012, 35, 108–117. [Google Scholar] [CrossRef]

- Hong, J.; Zhou, J.; Hong, J.; Xu, X. Environmental and economic life cycle assessment of aluminum-silicon alloys production: a case study in China. J. Clean. Prod. 2012, 24, 11–19. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [Google Scholar] [CrossRef]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Environmental consequences of recycling aluminum old scrap in a global market. Resour. Conserv. Recycl. 2014, 89, 94–103. [Google Scholar] [CrossRef]

- Tan, R.B.H.; Khoo, H.H. An LCA study of a primary aluminum supply chain. J. Clean. Prod. 2005, 13, 607–618. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.; Hong, J.; Han, X.; He, J.; Shi, W.; Li, X. Environmental footprint of aluminum production in China. J. Clean. Prod. 2016, 133, 1242–1251. [Google Scholar] [CrossRef]

- Aluminum Association Inc. The Environmental Footprint of Semi-Finished Aluminum Products in North America; A Life Cycle Assessment Report; Aluminum Association. Inc.: Arlington County, VA, USA, 2013; 123p. [Google Scholar]

- Segovia, F.; Blanchet, P.; Barbuta, C.; Beauregard, R. Aluminum-laminated panels: Physical and mechanical properties. BioResources 2015, 10, 4751–4767. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006; Standard 14040. [Google Scholar]

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006; Standard 14044. [Google Scholar]

- Ecoinvent Centre. Ecoinvent Database. Swiss Centre for Life Cycle Inventories. 2018. Available online: https://www.ecoinvent.org/database/ecoinvent-35/ecoinvent-35.html (accessed on 15 March 2019).

- American Society for Testing and Materials. Standard Test Methods for Evaluating Properties of Wood-Based Fiber and Particle Panel Materials; ASTM D1037; ASTM International: West Conhohocken, PA, USA, 2012. [Google Scholar]

- Stark, N.; Cai, Z.; Carll, C. Woo-based Composite Materials. Panel products, Glued-Laminated Timber, Structural Composite Lumber, and Wood-Nonwood Composite Materials. In Wood Handbook Wood as an Engineering Material; General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; 508p. [Google Scholar]

- Beaulieu, D. Les Caractéristiques de L’aluminium Structural, 2nd ed.; Les Presses de l’aluminium: Saguenay, QC, Canada, 2013; 132p. [Google Scholar]

- Bitzer, T. Honeycomb Technology: Materials, Desing, Manufacturing, Applications and Testing; Chapman & Hall: London, UK, 1997; 233p. [Google Scholar]

- Jolliet, O.; Saadé, M.; Crettaz, P. Analyse du Cycle de Vie: Comprendre et Realiser un Écobilan; Presses Polytechniques et Universitaires Romandes.Lausanne: Lausanne, Suisse, 2010; 242p. [Google Scholar]

- Bare, J.C. TRACI 2.0—The Tool for the Reduction and Assessment of Chemical and other environmental Impacts. In Clean Technologies and Environmental Policy; Springer: New York, NY, USA, 2011; Volume 13, pp. 687–696. [Google Scholar]

| Main Features | Wood Aluminum-Laminated Panels | Aluminum Honeycomb Panel | ||

| Core material | MDF | OSB | Plywood | Aluminum Honeycomb |

| Thickness (mm) | 10.89 | 11.47 | 10.15 | 10.00 |

| Face sheet thickness (mm) | 0.6 | 0.6 | 0.6 | 0.6 |

| Physical Properties | ||||

| Areal Weight (kg/m2) | 10.50 | 11.47 | 10.15 | 4.60 |

| Thickness swelling (%) (24-h water soaking) | 16.17 | 2.46 | 1.65 | --- |

| Water absorption (%) (24-h water soaking) | 19.70 | 11.37 | 12.73 | --- |

| Mechanical Properties | ||||

| Module of elasticity (MPa) | 18,267 | 17,354 | 19,323 | 19,570 |

| Module of rupture (MPa) | 90 | 61 | 125 | 102 |

| Laminated Panels Manufacturing | Based on Process | Quantity | Source of Data |

|---|---|---|---|

| Wood Aluminum-Laminated Panels | |||

| Raw Materials Supply | |||

| MDF | Medium-density fibreboard {RoW}| medium-density fibre board production, uncoated | Alloc Rec, U | 1 m2 | Ecoinvent 3.5 * |

| OSB | Oriented strand board {CA-QC}| production | Alloc Rec, U | 1 m2 | Ecoinvent 3.5 |

| Plywood | Plywood, for outdoor use {CA-QC}| production | Alloc Rec, U | 1 m2 | Ecoinvent 3.5 |

| Aluminum alloy sheets | Aluminum alloy, AlMg3 {CA-QC}| production | Alloc Rec, U | 3.280 kg | Ecoinvent 3.5 * |

| Sheet rolling, aluminum {CA-QC}| processing | Alloc Rec, U | Ecoinvent 3.5 | ||

| Polyurethane | Polyurethane, flexible foam {RoW}| production | Alloc Rec, U | 0.130 kg | Ecoinvent 3.5 * |

| Processes | |||

| Degreasing | Degreasing, metal part in alkaline bath {RoW}| processing | Alloc Rec, U | 2 m2 | Ecoinvent 3.5 |

| Electricity (All processes) | Electricity, medium voltage {CA-QC}| market for | Alloc Rec, U | 6.95 kwh | Ecoinvent 3.5 |

| Aluminum Honeycomb Panel | |||

| Raw Materials Supply | |||

| Aluminum Honeycomb | 1 m2 | Built | |

| Aluminum alloy sheets | Aluminum alloy, AlMg3 {CA-QC}| production | Alloc Rec, U | 1.549 kg | Ecoinvent 3.5 * |

| Sheet rolling, aluminum {CA-QC}| processing | Alloc Rec, U | Ecoinvent 3.5 | ||

| Epoxy resin | Adhesive, for metal {RoW}| production | Alloc Rec, U | 0.132 kg | Ecoinvent 3.5 |

| Aluminum alloy sheets | Aluminum alloy, AlMg3 {CA-QC}| production | Alloc Rec, U | 3.280 kg | Ecoinvent 3.5 * |

| Sheet rolling, aluminum {CA-QC}| processing | Alloc Rec, U | Ecoinvent 3.5 | ||

| Epoxy resin | Adhesive, for metal {RoW}| production | Alloc Rec, U | 0.200 kg | Ecoinvent 3.5 |

| Processes | |||

| Degreasing | Degreasing, metal part in alkaline bath {RoW}| processing | Alloc Rec, U | 2 m2 | Ecoinvent 3.5 |

| Electricity (All processes) | Electricity, medium voltage {CA-QC}| market for | Alloc Rec, U | 65.23 kwh | Ecoinvent 3.5 |

| Impact Category | Hotspots | |||

|---|---|---|---|---|

| MDF | OSB | Plywood | Aluminum Honeycomb | |

| Carcinogens | Adhesive production (MUF, UF and PF resins) | Epoxy resin | ||

| Non-carcinogens | Treatment of wood ash mixture, pure, landfarming | Treatment of wood ash mixture, pure, landfarming | Heat production from hardwood chips | Treatment of red mud from bauxite digestion |

| Respiratory inorganics | MUF and UF resins | OSB production | Heat production from hardwood chips | Transport (transoceanic) |

| Ionizing radiation | Electricity | Electricity | MUF resin | Electricity (Pressing) |

| Ozone layer depletion | MUF and UF resins | Pulpwood hardwood production | MUF resin | Petroleum and gas production (heat production) |

| Respiratory organics | MDF production | PF resin | Sawlog and veneer log production | Coke (aluminum primary liquid production) |

| Aquatic ecotoxicity | Treatment of wood ash mixture, pure, landfarming | Treatment of wood ash mixture, pure, landfarming | Heat production from hardwood chips | Treatment of red mud from bauxite digestion |

| Terrestrial ecotoxicity | Treatment of wood ash mixture, pure, landfarming | Treatment of wood ash mixture, pure, landfarming | Heat production from hardwood chips | Bauxite mine operation |

| Terrestrial acid/nutri | MUF and UF resins | OSB production | MUF resin | Transport (transoceanic) |

| Land occupation | Pulpwood softwood production | Pulpwood hardwood production | Sawlog and veneer log production | Hard coal (mine operation) |

| Aquatic acidification | Adhesive production (MUF, UF and PF resins) | Aluminum primary liquid production | ||

| Aquatic eutrophication | Treatment of wood ash mixture, pure, landfarming | Treatment of wood ash mixture, pure, landfarming | Heat production from hardwood chips | aluminum primary liquid production |

| Global warning | Adhesive production (MUF, UF and PF resins) | Aluminum primary liquid production | ||

| Non-renewable energy | Adhesive production (MUF, UF and PF resins) | Hard coal (mine operation) | ||

| Mineral extraction | Adhesive production (MUF, UF and PF resins) | Bauxite mine operation | ||

| Category | LAMINATED PANELS | |||

|---|---|---|---|---|

| MDF Aluminum-Laminated Panel | OSB Aluminum-Laminated Panel | Plywood Aluminum-Laminated Panel | Aluminum Honeycomb Panel | |

| Human Health (DALY) | 4.78 × 10−5 | 4.62 × 10−5 | 5.18 × 10−5 | 6.65 × 10−5 |

| Ecosystem quality (PDF*m2*yr) | 10.40 | 13.10 | 16.20 | 7.13 |

| Climate change (kg CO2 eq) | 31.20 | 27.90 | 30.30 | 41.50 |

| Resources (MJ primary) | 4.81 × 102 | 4.24 × 102 | 4.58 × 102 | 6.29 × 102 |

| Materials/Processes | CO2 Emissions in kg by Laminated Panels | |||

|---|---|---|---|---|

| MDF Aluminum-Laminated Panel | OSB Aluminum-Laminated Panel | Plywood Aluminum-Laminated Panel | Aluminum Honeycomb Panel | |

| Core manufacturing | 4.46 | 1.25 | 3.55 | 13.30 |

| Aluminum alloy sheet manufacturing | 22.90 | 22.90 | 22.90 | 22.90 |

| Bonding process | 1.05 | 1.05 | 1.05 | 1.59 |

| Other processes | 2.16 | 2.10 | 2.10 | 0.61 |

| Total | 30.60 | 27.30 | 29.60 | 38.40 |

| Category | Adhesive Production | |||

|---|---|---|---|---|

| Epoxy Resin | Main Substances | Polyurethane Adhesive | Main Substances | |

| Human Health (DALY) | 9.21 × 10−7 | NOx, SO2 | 4.86 × 10−7 | NOx, Particules ˂ 2.5um |

| Ecosystem quality (PDF*m2*yr) | 0.0435 | NOx, Zinc | 0.0185 | NOx, Zinc |

| Climate change (kg CO2 eq) | 0.84 | CO2, CH4 | 0.573 | CO2, CH4 |

| Resources (MJ primary) | 17.4 | Gas natural | 12.8 | Gas natural |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segovia, F.; Blanchet, P.; Amor, B.; Barbuta, C.; Beauregard, R. Life Cycle Assessment Contribution in the Product Development Process: Case Study of Wood Aluminum-Laminated Panel. Sustainability 2019, 11, 2258. https://doi.org/10.3390/su11082258

Segovia F, Blanchet P, Amor B, Barbuta C, Beauregard R. Life Cycle Assessment Contribution in the Product Development Process: Case Study of Wood Aluminum-Laminated Panel. Sustainability. 2019; 11(8):2258. https://doi.org/10.3390/su11082258

Chicago/Turabian StyleSegovia, Franz, Pierre Blanchet, Ben Amor, Costel Barbuta, and Robert Beauregard. 2019. "Life Cycle Assessment Contribution in the Product Development Process: Case Study of Wood Aluminum-Laminated Panel" Sustainability 11, no. 8: 2258. https://doi.org/10.3390/su11082258

APA StyleSegovia, F., Blanchet, P., Amor, B., Barbuta, C., & Beauregard, R. (2019). Life Cycle Assessment Contribution in the Product Development Process: Case Study of Wood Aluminum-Laminated Panel. Sustainability, 11(8), 2258. https://doi.org/10.3390/su11082258