Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation

Abstract

:1. Introduction

- Extension of existing reservoirs is the first choice for reservoir construction to avoid building a new one and increasing additional excavations. Engineering geology issues must be prevented. Friendly terrain is better for transporting and arranging giant machines. The water inlet of the lower reservoir should not be selected in the sea area with high silt or sand content.

- Regarding the regions that have the insistent demands of the power supply but cannot address the requirements for upper reservoir construction, digging underground caverns as the lower reservoir will probably be an informed decision.

- It is necessary to use covers that are made from special materials on the upper reservoir surface. The covers can prevent seawater leakage and adapt temperature variation. Many sensors buried under the covers are used to monitor and control the pump operation in the case of seawater leakage.

- As a new-style power plant, it should not apply for an oversize installed capacity of SPSP. The head of SPSP should be greater than 100 meters to ensure the sufficient generator head and the smaller scale of the upper reservoir. In order to minimize the investment and energy losses, the horizontal distance between the reservoirs should be as short as possible. The ratio of horizontal distance to hydraulic head is within the allowable limit of 10.

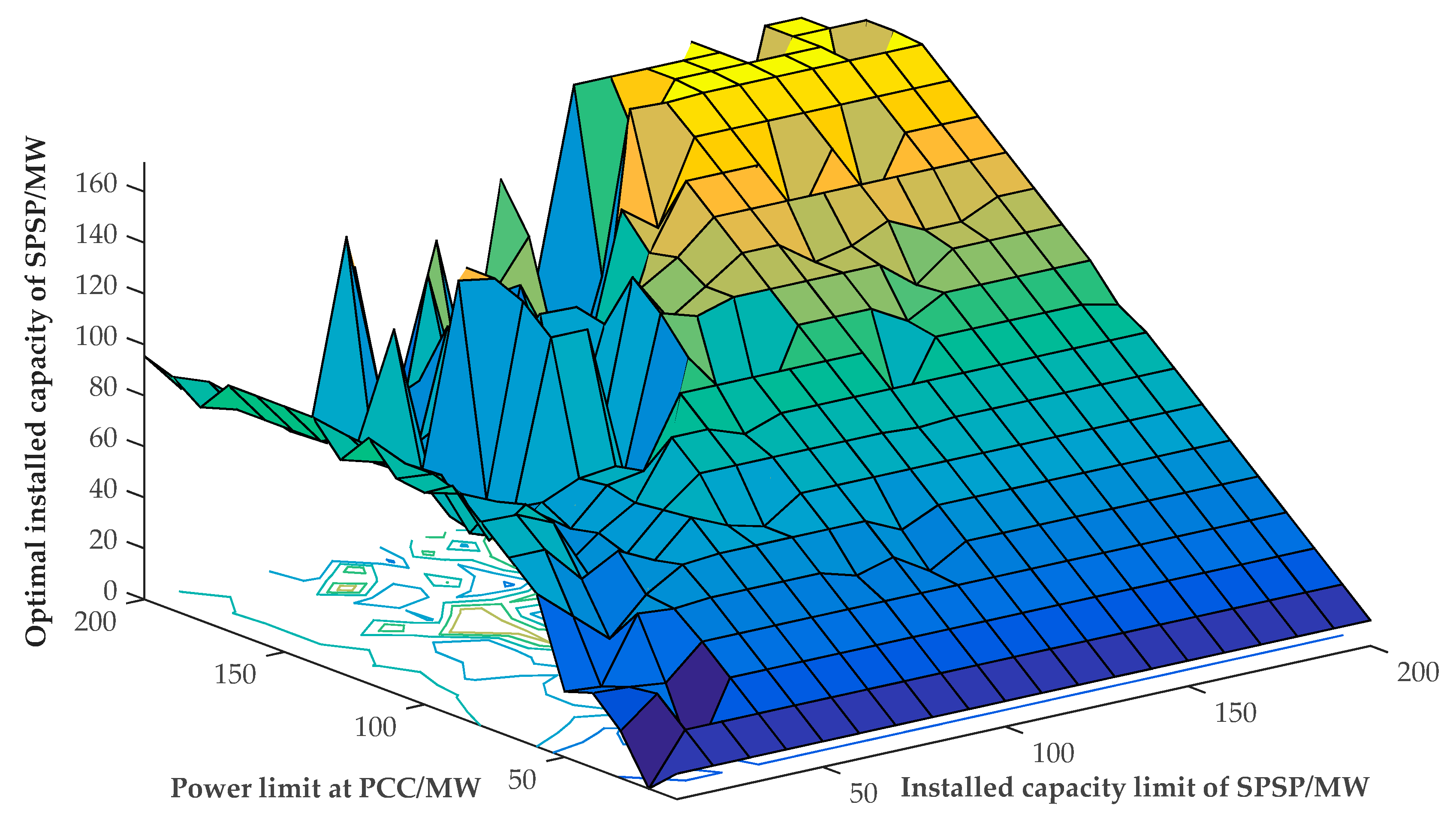

- An optimal sizing method of SPSP with variable-speed units in connected mode on an islanded microgrid is proposed.

- A simplified modeling method of variable-speed units is proposed and applied for the optimal sizing of SPSP.

- The contributing factors to the revenue of SPSP are discussed.

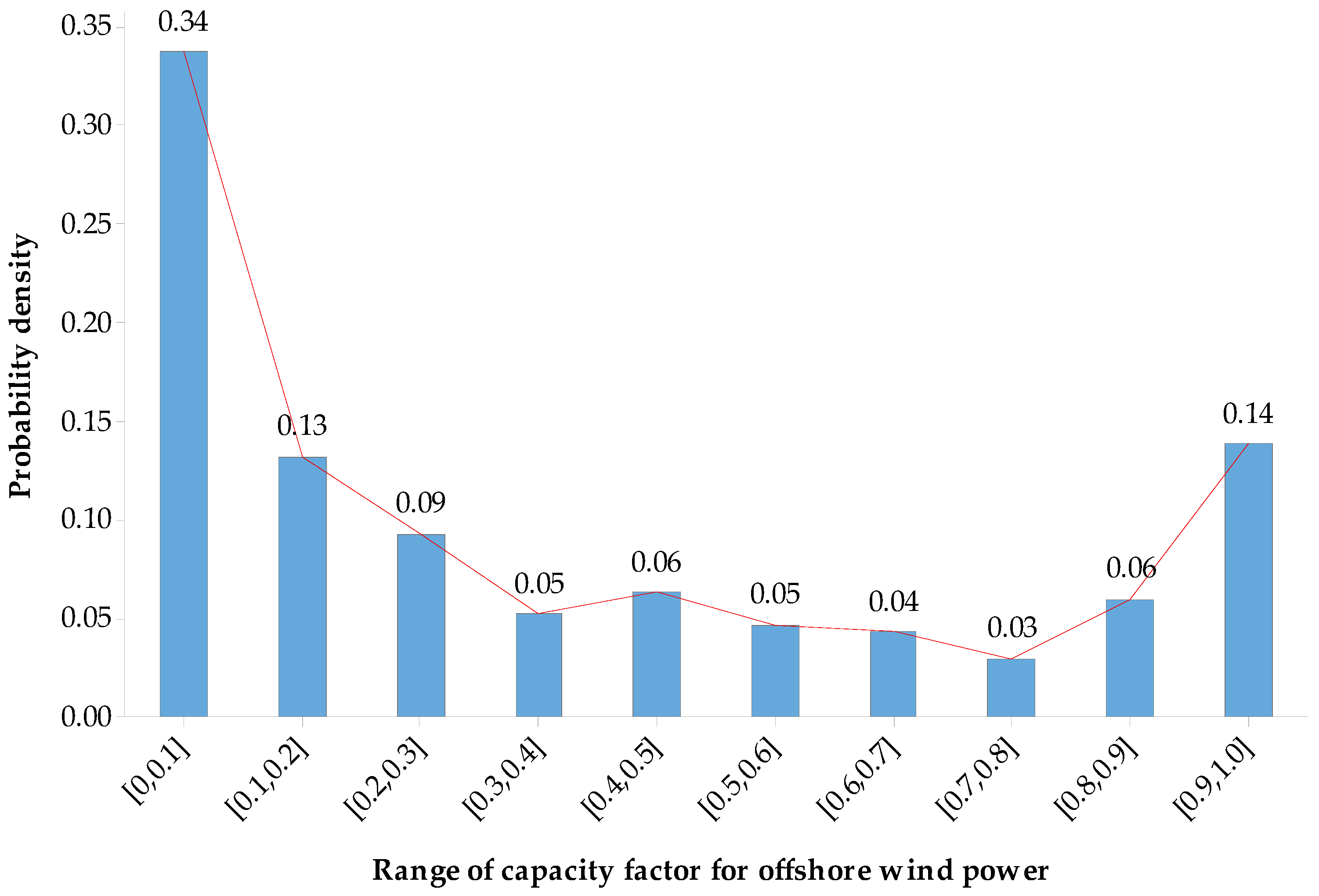

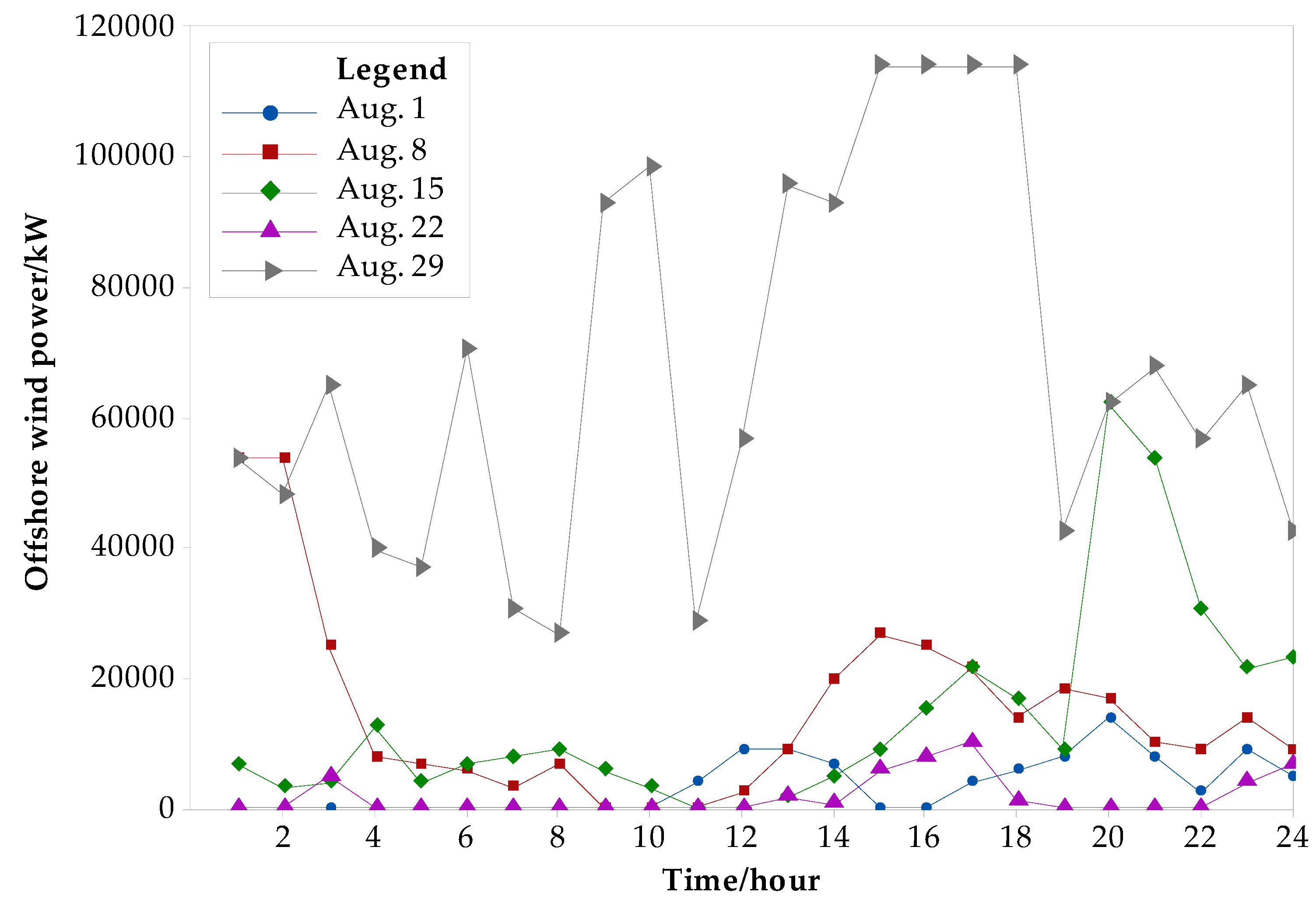

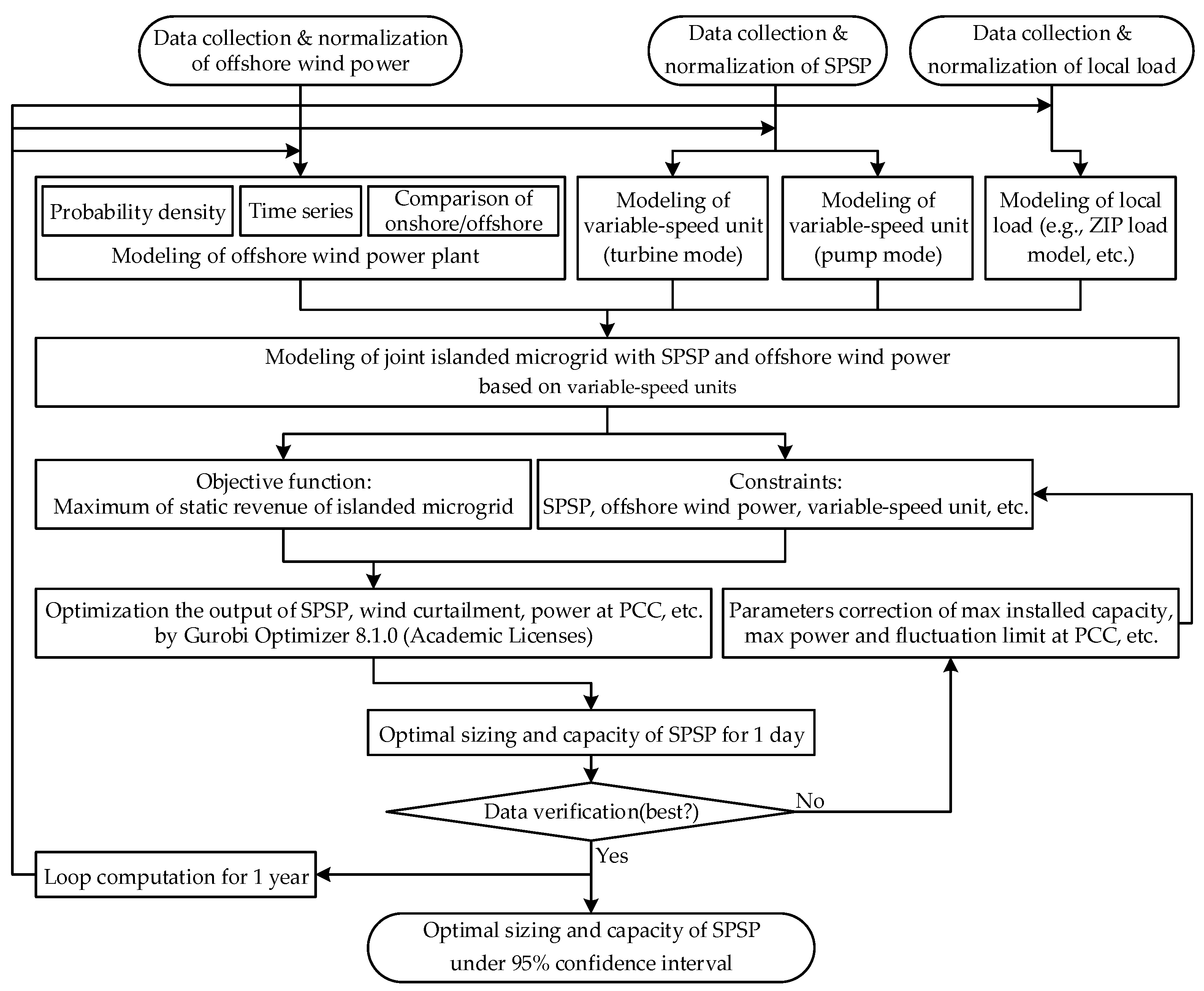

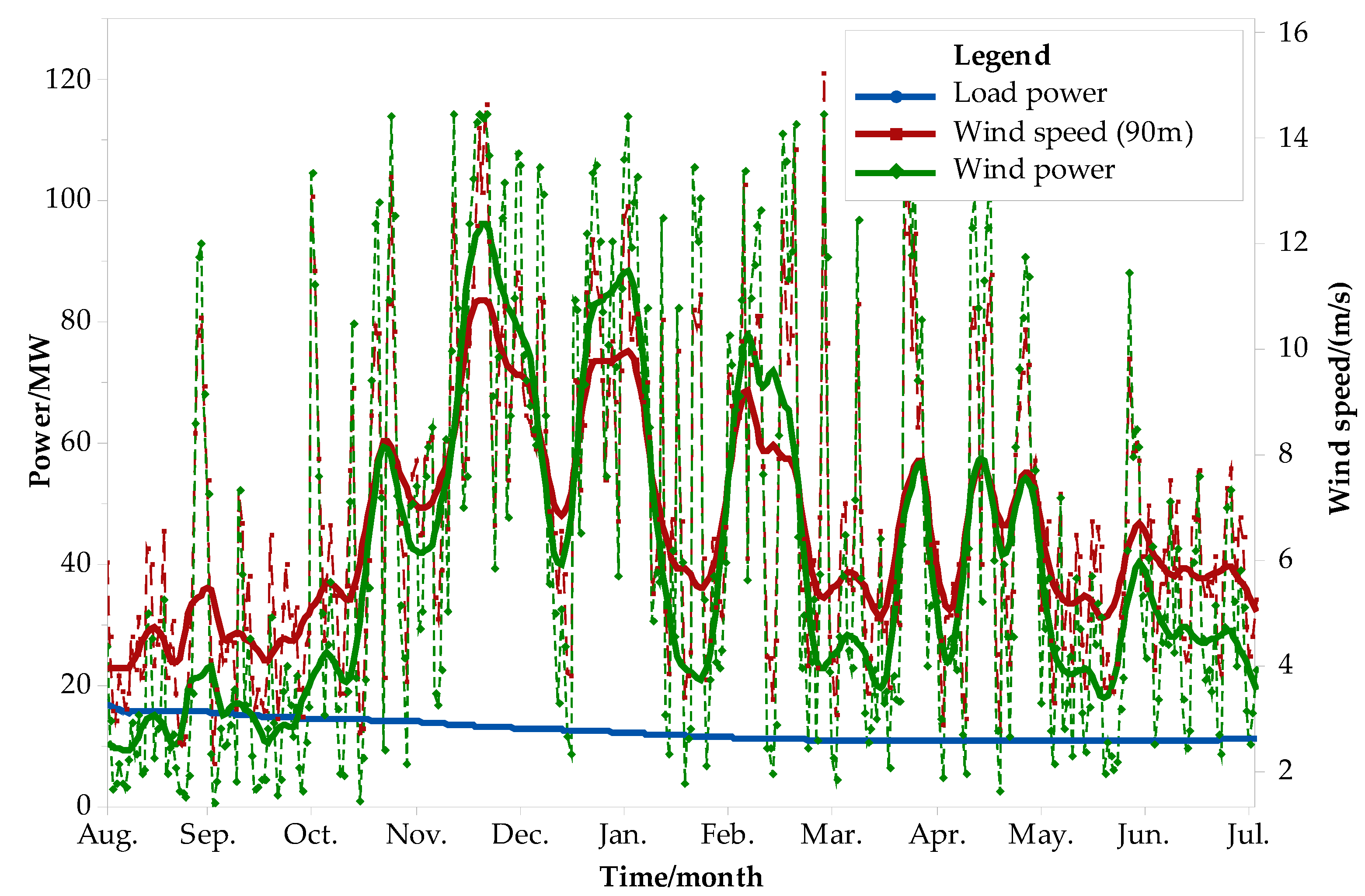

2. Output Characteristics of Offshore Wind Power

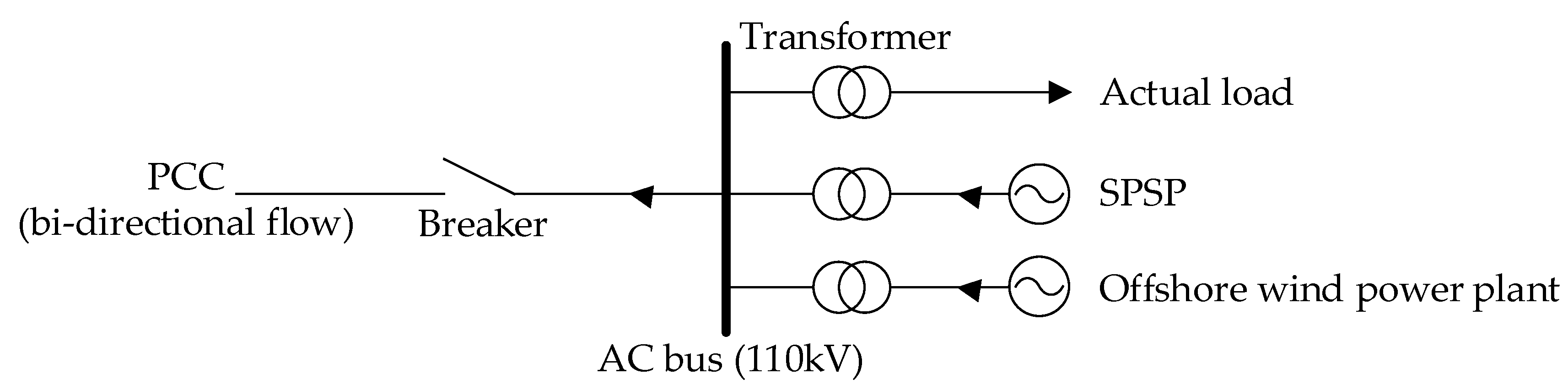

3. Optimal Sizing of SPSP

3.1. Objective Function

3.2. Constraints

3.2.1. Power Balance Constraints of Islanded Microgrid

3.2.2. Output Power Constraints of Offshore Wind Power Plant

3.2.3. Output Power Constraints of SPSP

3.2.4. Electrical Energy Limit Constraints of SPSP

3.2.5. Electrical Energy Balance Constraints of the SPSP

3.2.6. Life Cycle Constraints of SPSP

3.2.7. Ramp Rate Constraints of Variable-Speed Units

4. Equivalent Modeling and Constraint Correction of SPSP

4.1. Output Power Characteristics of Variable-Speed Units

4.1.1. Generator Operating Mode

4.1.2. Pump Operating Mode

4.2. Constraint Correction of SPSP

4.2.1. Equivalent SOC of SPSP

4.2.2. Equivalent Self-Discharge of SPSP

4.3. Power and Fluctuation Limit Constraints at PCC

5. Case Study

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature (In Order of Appearance)

| capacity revenue of the SPSP (CNY) | |

| electrical energy revenue settled through PCC (incl. sales income and purchasing cost) (CNY) | |

| capital cost of the SPSP (CNY) | |

| energy losses cost of the SPSP (CNY) | |

| operating cost of the SPSP (CNY) | |

| peaking regulation cost of the SPSP (CNY) | |

| capacity tariff(price) of the SPSP (CNY/kW) | |

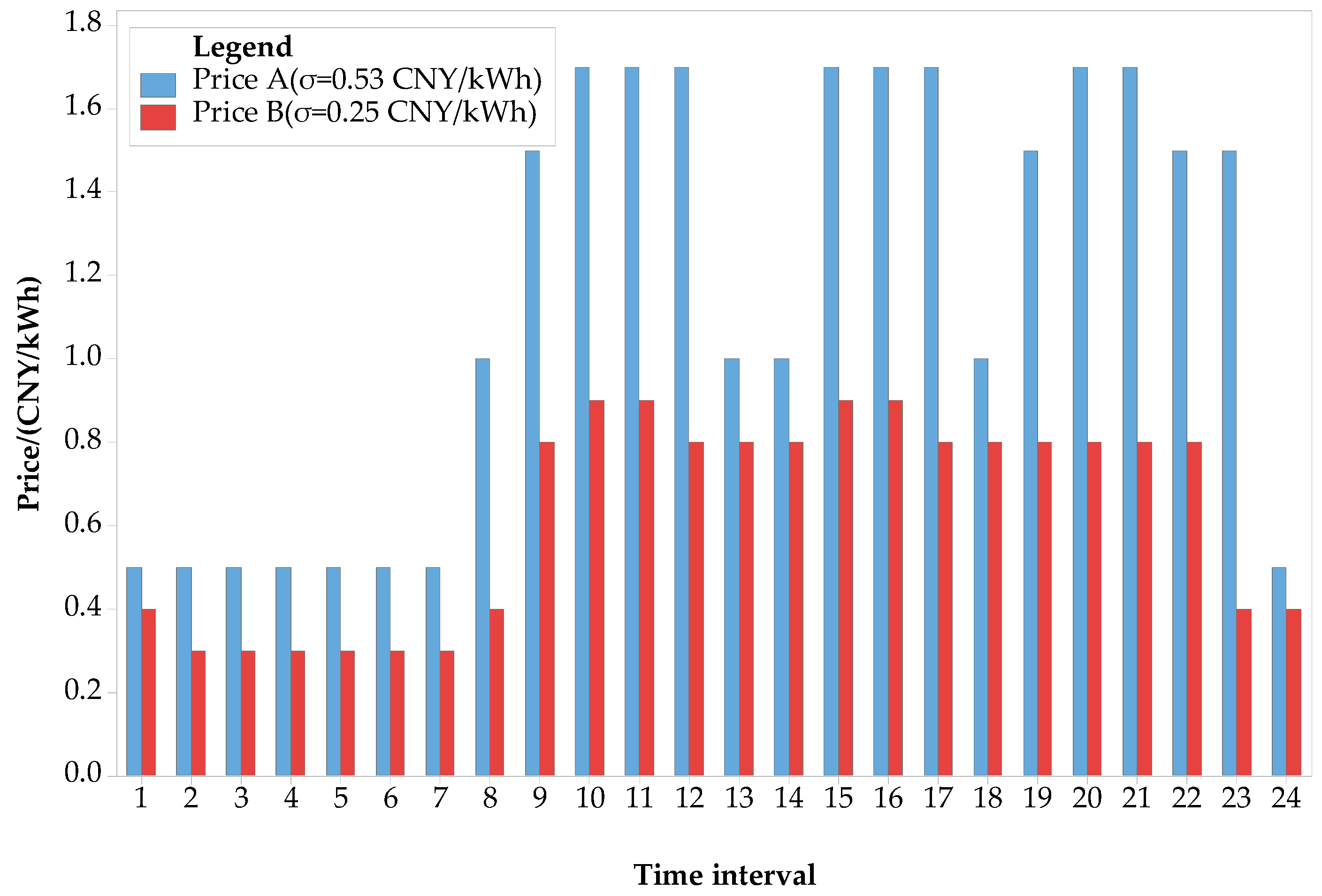

| time-of-use tariffs for generating at time t (CNY/kWh) | |

| time-of-use tariffs for pumping at time t (CNY/kWh) | |

| power at PCC at time t (positive or negative) (kW) | |

| output power of the SPSP at time t (positive or negative) (kW) | |

| output power of the SPSP at time t in turbine mode (kW) | |

| input power of the SPSP at time t in pump mode (kW) | |

| minimum and maximum output power of the SPSP at time t in turbine mode (kW) | |

| minimum and maximum input power of the SPSP at time t in pump mode (kW) | |

| installed capacity of the SPSP (kW) | |

| offshore wind power at time t (kW) | |

| predicted value of offshore wind power at time t (kW) | |

| actual load at time t (kW) | |

| peaking cost factor (CNY/kWh) | |

| boolean value (unitless) | |

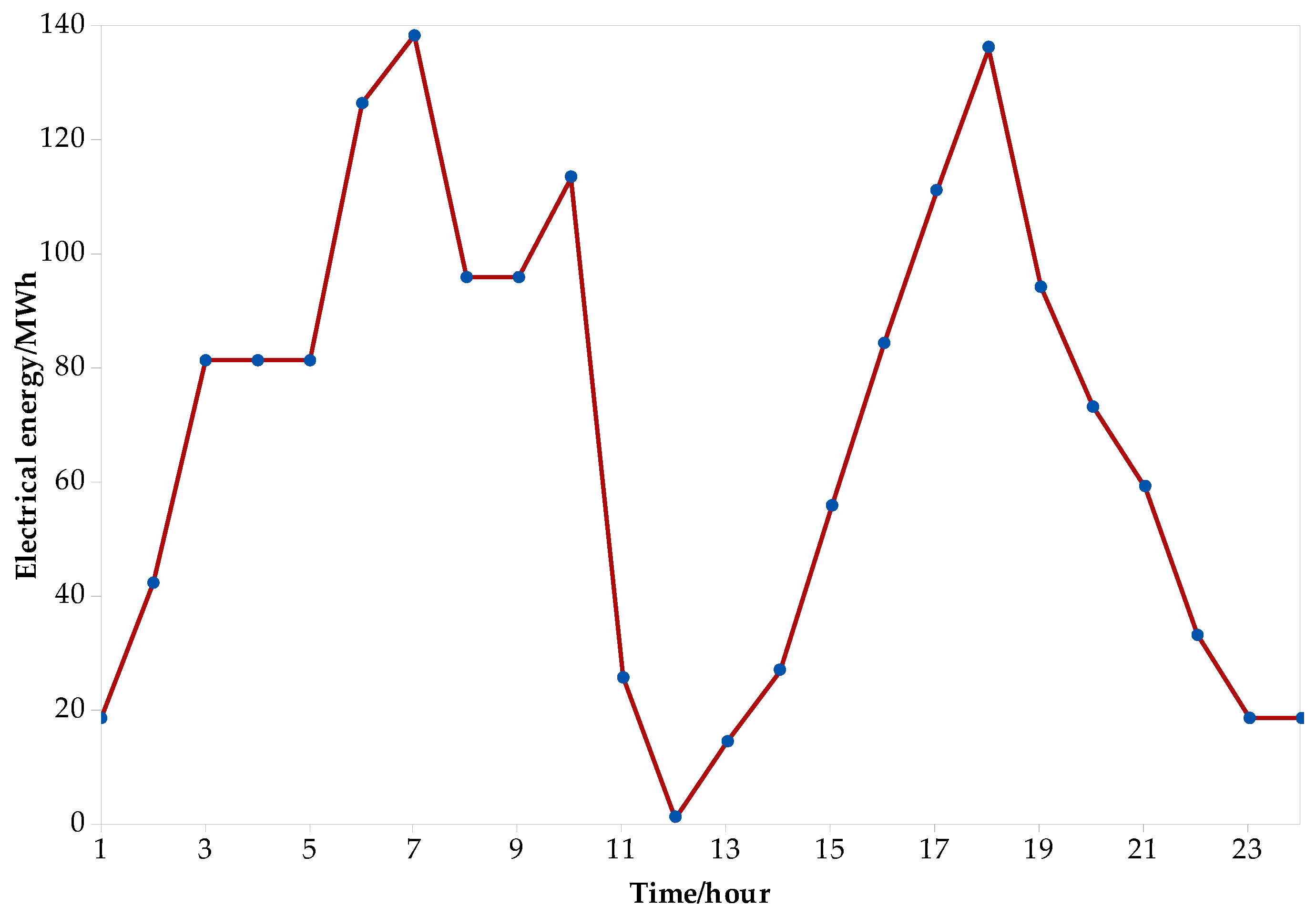

| electrical energy of the upper reservoir at time t (kW) | |

| minimum and maximum electrical energy of the upper reservoir (MWh) | |

| electrical energy generated and consumed during a scheduling period (e.g., 24 h) (MWh) | |

| energy conversion efficiency of the SPSP in turbine and pump modes (unitless) | |

| life cycle, maximum service life (times) | |

| ramp rate of the variable-speed units at time t in turbine and pump mode (MW/h) | |

| maximum ramp rate of the variable-speed units at time t in turbine and pump mode (MW/h) | |

| density of seawater (1.05×103 kg/m3) | |

| active head of gravity (9.81 m/s2) | |

| hydraulic head and pump head (m) | |

| hydraulic head and pump head (pu) | |

| turbine flow and pump flow (m3/s) | |

| turbine flow and pump flow (pu) | |

| mechanical speed (pu) | |

| relative deviation of mechanical speed (pu) | |

| reference power (pu) | |

| polynomial fitting coefficients (unitless) | |

| residual electrical energy rate of the upper reservoir at time t (MWh) | |

| minimum and maximum residual electrical energy rate of the upper reservoir (MWh) | |

| volume of upper reservoir at time t (m3) | |

| maximum volume of upper reservoir at time t (m3) | |

| fitting function of the sectional area about head (m2) | |

| energy loss rate (unitless) | |

| thermal stability power at PCC (associated with rated short-time withstand current) (kW) | |

| sample standard deviation of power at PCC (kW) | |

| evaluation index for power fluctuation at PCC (unitless) | |

| parameter values of σpcc (unitless) |

References

- Kook, K.; McKenzie, K.; Liu, Y.; Atcitty, S. A study on applications of energy storage for the wind power operation in power systems. In Proceedings of the IEEE PES General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- Vatu, R.; Ceaki, O.; Mancasi, M.; Porumb, R.; Seritan, G. Power quality issues produced by embedded storage technologies in smart grid environment. In Proceedings of the 50th International Universities Power Engineering Conference (UPEC), Stoke on Trent, UK, 1–4 September 2015. [Google Scholar]

- Golovanov, N.; Lazaroiu, G.; Porumb, R. Wind generation assessment proposal by experimental harmonic and distortion factor analysis. In Proceedings of the 48th International Universities’ Power Engineering Conference (UPEC), Dublin, Ireland, 2–5 September 2013. [Google Scholar]

- Vatu, R.; Ceaki, O.; Golovanov, N.; Porumb, R.; Seritan, G. Analysis of storage technologies with smart grid framework. In Proceedings of the 49th International Universities Power Engineering Conference (UPEC), Cluj-Napoca, Romania, 2–5 September 2014. [Google Scholar]

- Akhil, A.; Huff, G.; Currier, A.; Kaun, B.; Rastler, D.; Chen, S.; Cotter, A.; Bradshaw, D.; Gauntlett, W. DOE/EPRI 2013 Electricity Storage Handbook in Collaboration with NRECA. Sandia National Lab; Report SAND2013-5131; 2013. Available online: https://www.sandia.gov/ess-ssl/publications/SAND2013-5131.pdf (accessed on 14 March 2019).

- McLean, E.; Kearney, D. An evaluation of seawater pumped hydro storage for regulating the export of renewable energy to the national grid. Energy Procedia 2014, 46, 152–160. [Google Scholar] [CrossRef]

- Karampelas, K.; Ekonomu, L. Electricity Distribution-Intelligent Solutions for Electricity Transmission and Distribution Networks, 1st ed.; Springer: Berlin, Germany, 2016; pp. 27–61. [Google Scholar]

- Xu, F.; Chen, L.; Jin, H.; Liu, Z. Modeling and application analysis of optimal joint operation of pumped storage power station and wind power. Autom. Electr. Power Syst. 2013, 37, 149–154. [Google Scholar]

- Jiang, R.; Wang, J.; Guan, Y. Robust unit commitment with wind power and pumped storage hydro. IEEE Trans. Power Syst. 2012, 27, 800–810. [Google Scholar] [CrossRef]

- Gill, S.; Ault, G.; Kockar, I. The optimal operation of energy storage in a wind power curtailment scheme. In Proceedings of the IEEE PES General Meeting, San Diego, CA, USA, 22–26 July 2012. [Google Scholar]

- Pan, W.; Fan, Y.; Zhu, L.; Gao, A. The optimal sizing for pumped storage system in wind farm. Trans. China Electrotech. Soc. 2008, 23, 120–124. [Google Scholar]

- Katsaprakakis, D.; Christakis, D.; Stefanakis, I.; Spanos, P.; Stefanakis, N. Technical details regarding the design, the construction and the operation of seawater pumped storage system. Energy 2013, 55, 619–630. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; He, J.; Chai, Q. Offshore wind energy development in China: Current status and future perspective. Renew. Sustain. Energy Rev. 2011, 15, 4673–4684. [Google Scholar] [CrossRef]

- Portero, U.; Velázquez, S.; Carta, J. Sizing of a wind-hydro system using a reversible hydraulic facility with seawater. A case study in the Canary Islands. Energy Convers. Manag. 2015, 106, 1251–1263. [Google Scholar] [CrossRef]

- Suul, J.; Uhlen, K.; Undeland, T. Variable speed pumped storage hydropower for integration of wind energy in isolated grids-case description and control strategies. In Proceedings of the IEEE International Conference on Sustainable Energy Technologies, Espoo, Finland, 24–27 November 2008. [Google Scholar]

- Zhu, S.; Zhang, Y.; Chowdhury, A. Capacity credit of wind generation based on minimum resource adequacy procurement. IEEE Trans. Ind. Appl. 2012, 48, 730–735. [Google Scholar] [CrossRef]

- Fujihara, T.; Imano, H.; Oshima, K. Development of Pump Turbine for Seawater Pumped Storage Power Plant. Hitachi Rev. 1998, 47, 199–202. [Google Scholar]

- Rehman, S.; Al-Hadhrami, L.; Alam, M. Pumped hydro energy storage system: A technological review. Renew. Sust. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Geth, F.; Brijs, T.; Kathan, J.; Driesen, J.; Belmans, R. An overview of large-scale stationary electricity storage plants in Europe: Current status and new developments. Renew. Sust. Energy Rev. 2015, 52, 1212–1227. [Google Scholar] [CrossRef]

- Pina, A.; Ioakimidis, C.; Ferrão, P. Economic modeling of a seawater pumped-storage system in the context of São Miguel. In Proceedings of the IEEE International Conference on Sustainable Energy Technologies, Singapore, 24–27 November 2008. [Google Scholar]

- Xu, Q.; Kang, C.; Zhang, N.; Fan, Y.; Zhu, H. A discussion on offshore wind power output characteristics and its accommodation. Autom. Electr. Power Syst. 2011, 35, 54–59. [Google Scholar]

- Ioakimidis, C.; Genikomsakis, K. Integration of Seawater Pumped-Storage in the Energy System of the Island of São Miguel (Azores). Sustainability 2018, 10, 3438. [Google Scholar] [CrossRef]

- Sinden, G. Characteristics of the UK wind resource: Long-term patterns and relationship to electricity demand. Energy Policy 2007, 35, 112–127. [Google Scholar] [CrossRef]

- Castronuovo, E.; Lopes, J. On the optimization of the daily operation of a wind-hydro power plant. IEEE Trans. Power Syst. 2004, 19, 1599–1606. [Google Scholar] [CrossRef]

- Tewari, S.; Mohan, N. Value of NAS Energy Storage toward Integrating Wind: Results from the Wind to Battery Project. IEEE Trans. Power Syst. 2013, 532–541. [Google Scholar] [CrossRef]

- Muljadi, E.; Singh, M.; Gevorgian, V.; Mohanpurkar, M.; Hovsapian, R.; Koritarov, V. Dynamic modeling of adjustable-speed pumped storage hydropower plant. In Proceedings of the IEEE PES General Meeting, Denver, CO, USA, 26–30 July 2015. [Google Scholar]

- Koritarov, V.; Guzowski, L.; Feltes, J.; Kazachkov, Y.; Gong, B.; Trouille, B.; Donalek, P. Modeling Adjustable Speed Pumped Storage Hydro Units Employing Doubly-Fed Induction Machines; Report ANL/DIS-13/06; Argonne National Lab: Lemont, IL, USA, 2013. Available online: https://ceeesa.es.anl.gov/projects/psh/ANL_DIS-13_06_Modeling_AS_PSH.pdf (accessed on 26 February 2019).

- Liang, J.; Harley, R. Pumped storage hydro-plant models for system transient and long-term dynamic studies. In Proceedings of the IEEE PES General Meeting, Providence, RI, USA, 25–29 July 2010. [Google Scholar]

- Scherer, L.; Pfister, S. Global water footprint assessment of hydropower. Renew. Energy 2016, 99, 711–720. [Google Scholar] [CrossRef]

- Kuwabara, T.; Shibuya, A.; Furuta, H.; Kita, E.; Mitsuhashi, K. Design and dynamic response characteristics of 400 MW adjustable speed pumped storage unit for Ohkawachi power station. IEEE Trans. Energy Convers. 1996, 11, 376–384. [Google Scholar] [CrossRef]

- Sivakumar, N.; Das, D.; Padhy, N. Variable speed operation of reversible pump-turbines at Kadamparai pumped storage plant-A case study. Energy Convers. Manag. 2014, 78, 96–104. [Google Scholar] [CrossRef]

- He, Y.; Hu, J.; Yan, Z.; Shang, J. Compensation mechanism for ancillary service cost of grid-integration of large-scale wind farms. Power Syst. Technol. 2013, 37, 3552–3557. [Google Scholar]

- Juan, I.; Alejandro, P.; José, R. Optimal short-term operation and sizing of pumped-storage power plants in systems with high penetration of wind energy. In Proceedings of the 7th International Conference on the European Energy Market (EMM), Madrid, Spain, 23–25 June 2010. [Google Scholar]

| Country | Region | Research Organizations | Installed Capacity |

|---|---|---|---|

| Greece | Lesvos, Crete, Kasos | TEI of Crete, TEI of Piraeus, National Technical University of Athens | ~70 MW |

| Australia | Spencer Gulf | EnergyAustralia, Arup Group, University of Melbourne | 225 MW |

| Portugal | São Miguel | University of Mons Technical University of Lisbon | ~10 MW |

| Ireland | Glinsk | Organic Power, RSE S.p.A | 480 MW |

| United Kingdom | Dundrum | Dublin Institute of Technology | 100 MW |

| Belgium | iLand Project | Belgian Government | 550 MW |

| Estonia | Muuga Harbour | Energiasalv OÜ, Estivo-Nomine Consult | 500 MW |

| Indonesia | East Java | PT Pertamina, J-POWER | 800 MW |

| United States | Lanai Island | Gridflex Energy | 300 MW |

| Italy | Foxi Murdegu | U.S. Department of Energy, RSE S.p.A | ~150 MW |

| Chile | Iquique | Espejo de Tarapacá (Valhalla) | 300 MW |

| Saudi Arabia | Magna, Tabuk | SNC-Lavalin, KFUPM | 1000 MW |

| Cape Verde | Santiago | Gesto Energy, Cape Verde Government | 150 MW |

| Onshore/Offshore Wind Power Plant | Probability (Output Power > 80% of Rated Power) | Probability (Output Power < 35% of Rated Power) |

|---|---|---|

| An onshore wind power plant in Gansu, China | 3% | 76% |

| An offshore wind power plant in the South China Sea | 20% | 56% |

| Upper Reservoir Levels | Value | Volume | Value |

|---|---|---|---|

| Normal water levels | 124.2 m | Normal reservoir | 6.1×105 m3 |

| Dead water levels | 98 m | Dead reservoir | 1×104 m3 |

| Description | Value | Description | Value |

|---|---|---|---|

| Annual operating cost | 40 CNY/kW | Combined efficiency | 75% |

| Capital cost | 17,000 CNY/kW | Peaking cost factor | 0.062 CNY/kWh |

| Maximum service life | 30 Year | Capacity price | 1000 CNY/kW |

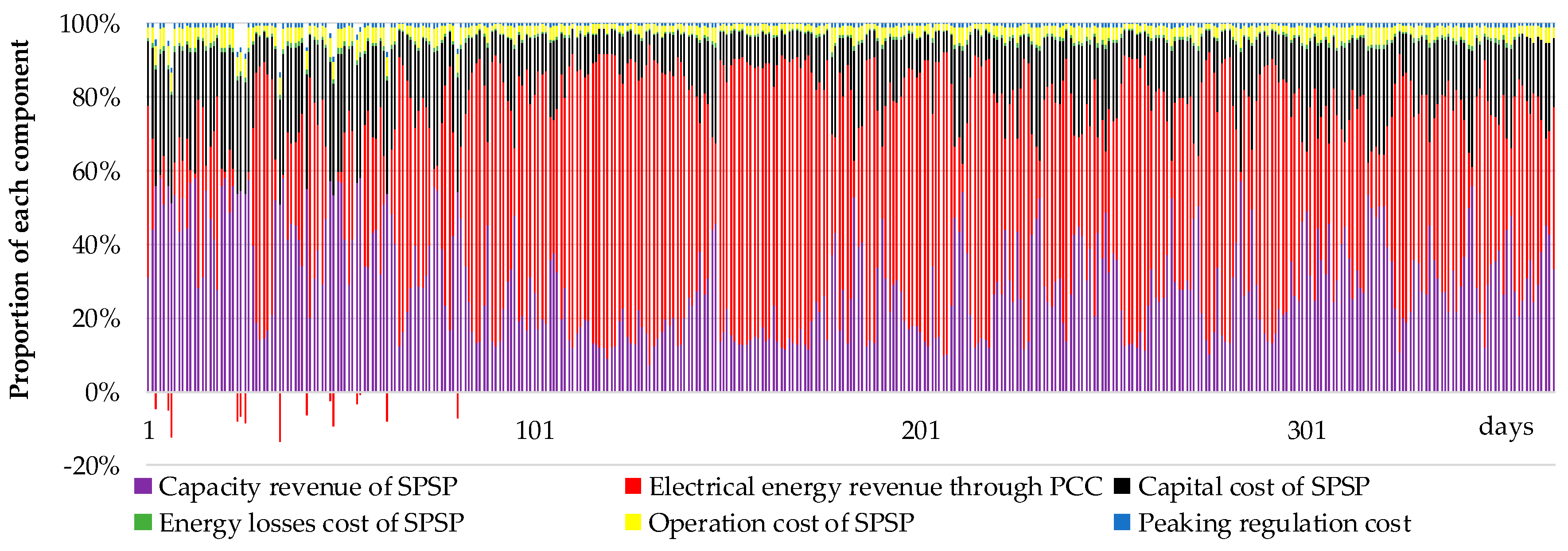

| Description | Revenue (CNY/day) |

|---|---|

| Total revenue of investment entity | 1,750,000 |

| Capacity revenue of SPSP | 220,000 |

| Electrical energy revenue through PCC (incl. wind power) | 1,730,000 |

| Capital cost of SPSP | 120,000 |

| Energy losses cost of SPSP | 10,000 |

| Operating cost of SPSP | 60,000 |

| Peaking regulation cost | 10,000 |

| Description | Value |

|---|---|

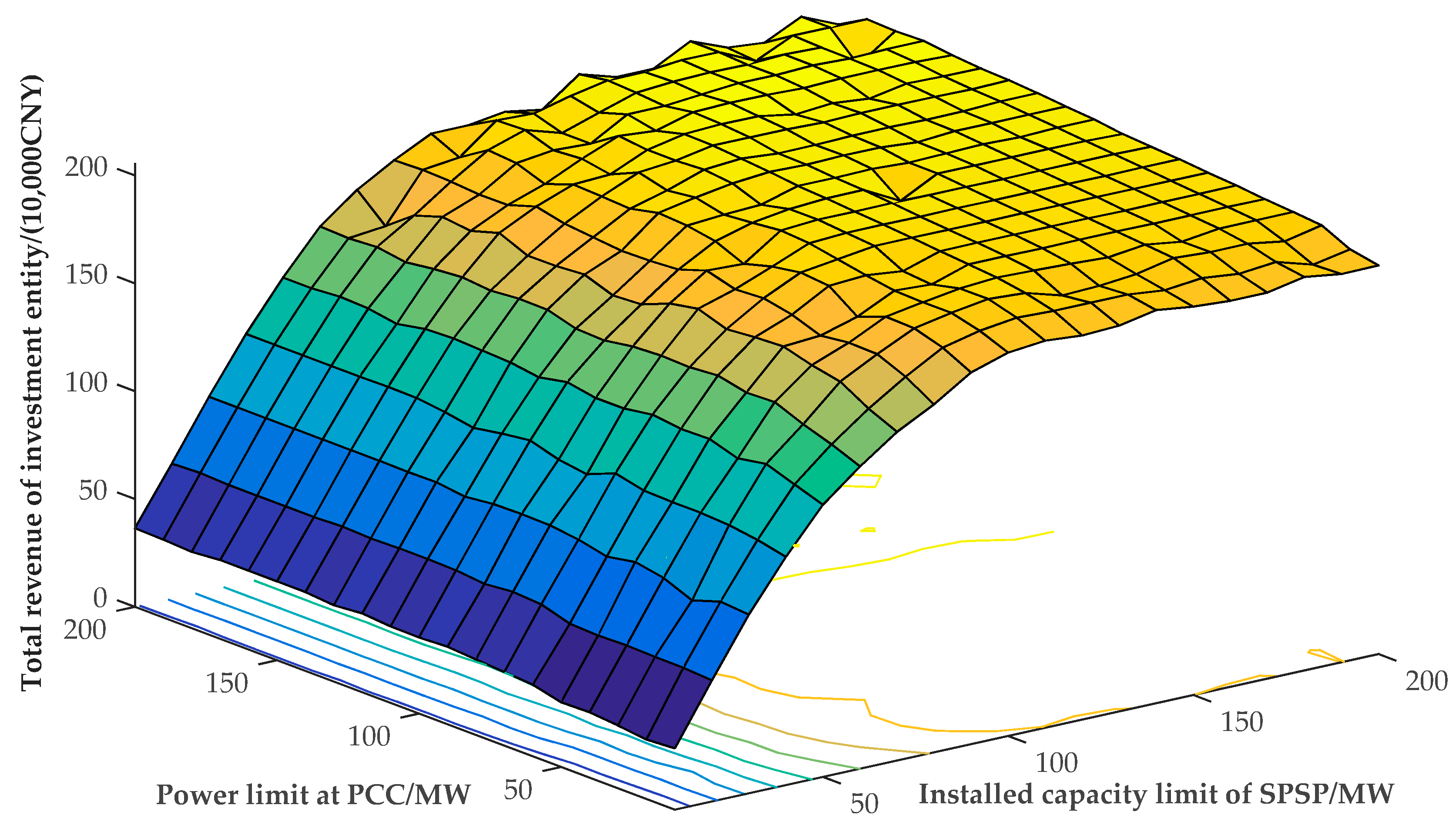

| Optimal installed capacity of SPSP | [76, 81] 1 MW |

| Excess static revenue | 53,810,000 CNY |

| Wind curtailment energy | 51,607 MWh |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, W.; Deng, C.; Li, D.; Chen, M.; Peng, P.; Zhang, H. Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation. Sustainability 2019, 11, 1939. https://doi.org/10.3390/su11071939

Yao W, Deng C, Li D, Chen M, Peng P, Zhang H. Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation. Sustainability. 2019; 11(7):1939. https://doi.org/10.3390/su11071939

Chicago/Turabian StyleYao, Weiwei, Changhong Deng, Dinglin Li, Man Chen, Peng Peng, and Hao Zhang. 2019. "Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation" Sustainability 11, no. 7: 1939. https://doi.org/10.3390/su11071939

APA StyleYao, W., Deng, C., Li, D., Chen, M., Peng, P., & Zhang, H. (2019). Optimal Sizing of Seawater Pumped Storage Plant with Variable-Speed Units Considering Offshore Wind Power Accommodation. Sustainability, 11(7), 1939. https://doi.org/10.3390/su11071939