Uncovering Variations, Determinants, and Disparities of Multisector-Level Final Energy Use of Industries Across Cities

Abstract

:1. Introduction

2. Methodology and Data

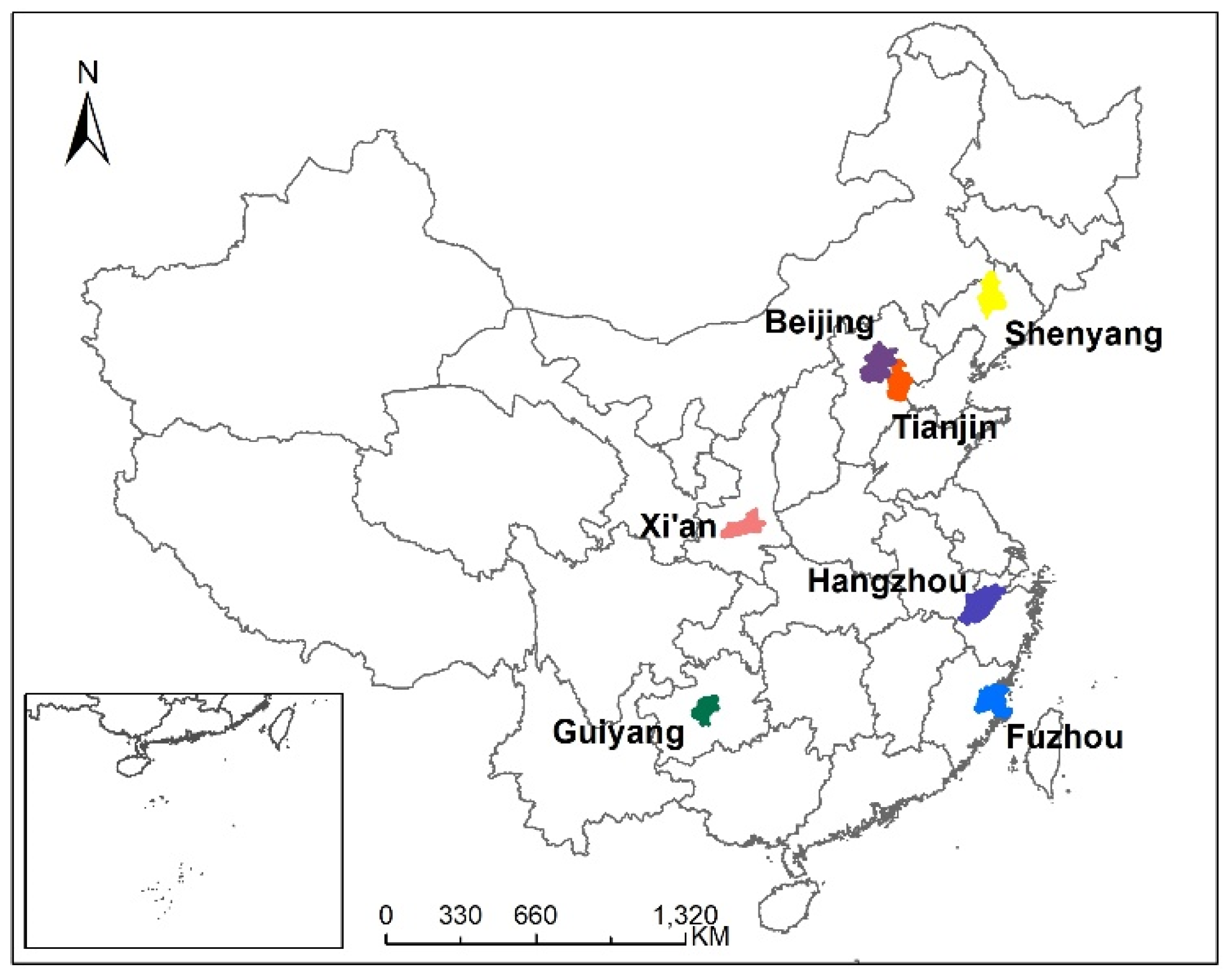

2.1. Target Cities

2.2. LMDI Model Formulation

2.3. Data

3. Results

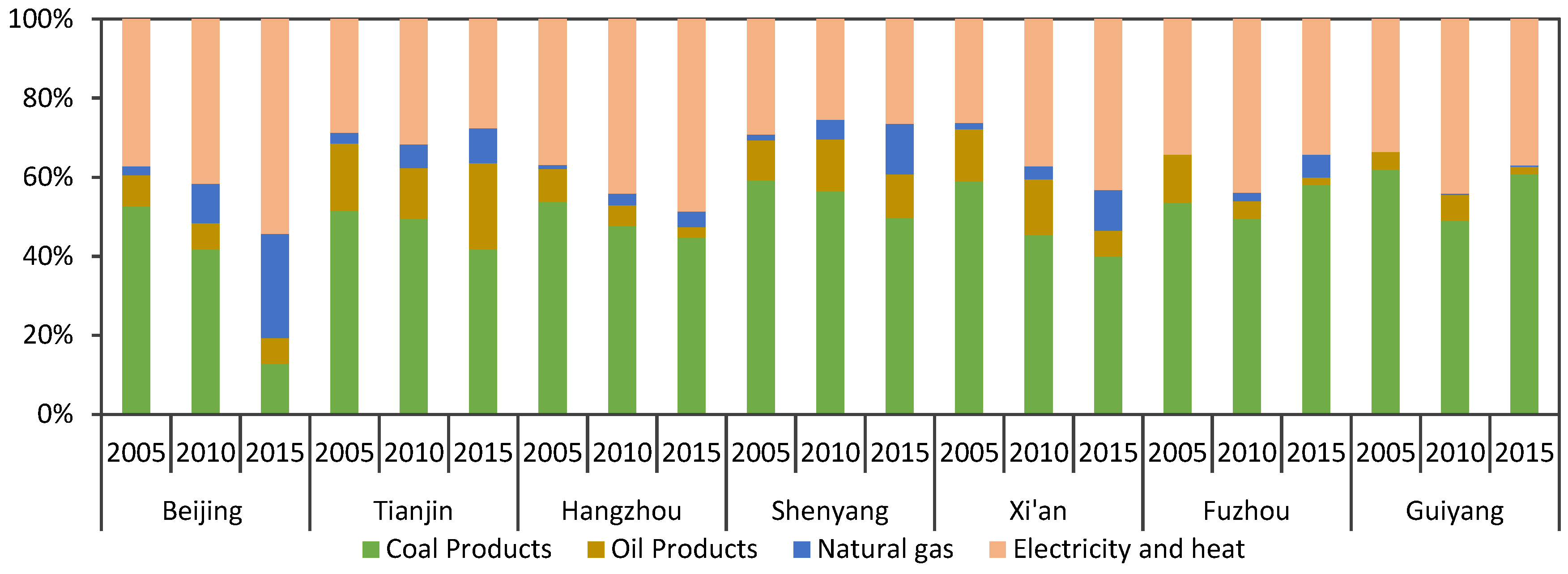

3.1. Changes in Industrial Final Energy Use

3.2. Determinants of Changes in Aggregate Final Energy Use

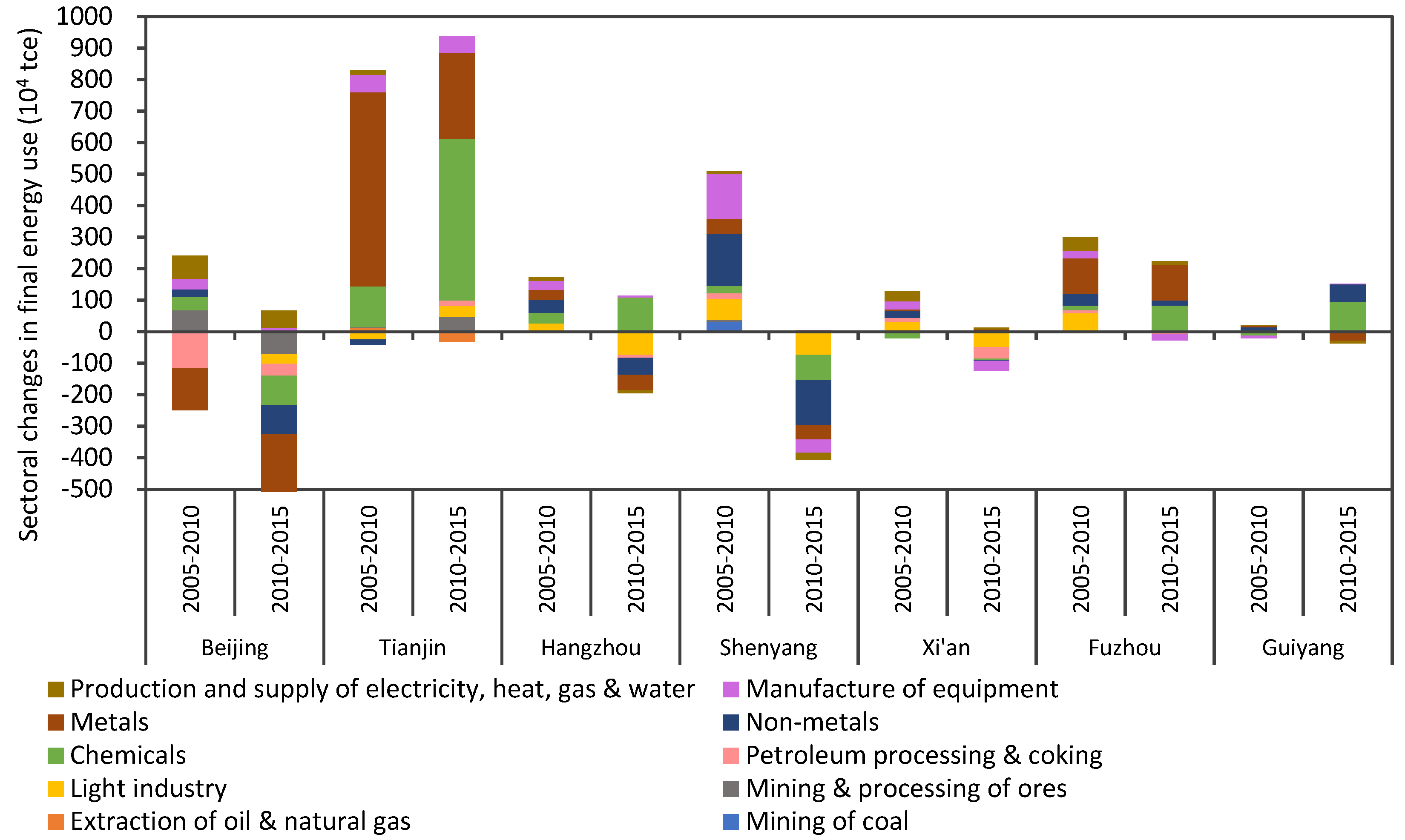

3.3. Determinants of Changes in Sectoral Final Energy Use

4. Discussion and Policy Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, F.; Dong, S.C.; Li, X.; Liang, Q.X.; Yang, W.Z. Energy consumption-economic growth relationship and carbon dioxide emissions in China. Energy Policy 2011, 39, 568–574. [Google Scholar]

- Cantore, N.; Clara, M.; Lavopa, A.; Soare, C. Manufacturing as an engine of growth: Which is the best fuel? Struct. Chang. Econ. Dyn. 2017, 42, 56–66. [Google Scholar] [CrossRef]

- Cansino, J.M.; Sanchez-Braza, A.; Rodriguez-Arevalo, M.L. Driving forces of Spain’s CO2 emissions: A LMDI decomposition approach. Renew. Sustain. Energy Rev. 2015, 48, 749–759. [Google Scholar] [CrossRef]

- Shi, L.; Sun, J.; Lin, J.; Zhao, Y. Factor decomposition of carbon emissions in Chinese megacities. J. Environ. Sci. 2019, 75, 209–215. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Wang, C.; Dong, B.; Gu, G.; Chen, R.; Li, Y.; Zou, H.; Zhang, W.; Li, Q. Carbon emissions from energy consumption in China: Its measurement and driving factors. Sci. Total Environ. 2019, 648, 1411–1420. [Google Scholar] [CrossRef] [PubMed]

- British Petroleum. British Petroleum Statistical Review of World Energy. 2018. Available online: https://www.bp.com/ zh_cn/china/reports-and-publications/_bp_2018-_.html (accessed on 6 February 2019).

- Lin, B.; Ouyang, X. Energy demand in China: Comparison of characteristics between the US and China in rapid urbanization stage. Energy Convers. Manag. 2014, 79, 128–139. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Investigating the drivers of energy-related CO2 emissions in China’s industrial sector: From regional and provincial perspectives. Struct. Chang. Econ. Dyn. 2018, 46, 136–147. [Google Scholar] [CrossRef]

- Ouyang, X.; Lin, B. An analysis of the driving forces of energy-related carbon dioxide emissions in China’s industrial sector. Renew. Sustain. Energy Rev. 2015, 45, 838–849. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, T.; Liu, N.; Kang, J. Changes of energy-related GHG emissions in China: An empirical analysis from sectoral perspective. Appl. Energy 2014, 132, 298–307. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q. A survey of index decomposition analysis in energy and environmental studies. Energy 2000, 25, 1149–1176. [Google Scholar] [CrossRef]

- Ang, B.W.; Huang, H.C.; Mu, A.R. Properties and linkages of some index decomposition analysis methods. Energy Policy 2009, 37, 4624–4632. [Google Scholar] [CrossRef]

- Shao, S.; Liu, J.; Geng, Y.; Miao, Z.; Yang, Y. Uncovering driving factors of carbon emissions from China’s mining sector. Appl. Energy 2016, 166, 220–238. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Decomposition of energy-related CO2 emissions in China: An empirical analysis based on provincial panel data of three sectors. Appl. Energy 2017, 190, 772–787. [Google Scholar] [CrossRef]

- Ang, B.W.; Choi, K.H. Decomposition of aggregate energy and gas emission intensities for industry: A refined Divisia index method. Energy 1997, 18, 59–73. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policymaking in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Ang, B.W. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Mousavi, B.; Lopez, N.S.A.; Manuel Biona, J.B.; Chiu, A.S.F.; Blesl, M. Driving forces of Iran’s CO2 emissions from energy consumption: An LMDI decomposition approach. Appl. Energy 2017, 206, 804–814. [Google Scholar] [CrossRef]

- Du, G.; Sun, C.; Ouyang, X.; Zhang, C. A decomposition analysis of energy-related CO2 emissions in Chinese six high-energy intensive industries. J. Clean Prod. 2018, 184, 1102–1112. [Google Scholar] [CrossRef]

- Ang, B.W.; Xu, X.Y. Tracking industrial energy efficiency trends using index decomposition analysis. Energy Econ. 2013, 40, 1014–1021. [Google Scholar] [CrossRef]

- Fernandez Gonzalez, P.; Landajo, M.; Presno, M.J. Multilevel LMDI decomposition of changes in aggregate energy consumption. A cross country analysis in the EU-27. Energy Policy 2014, 68, 576–584. [Google Scholar] [CrossRef]

- Voigt, S.; De Cian, E.; Schymura, M.; Verdolini, E. Energy intensity developments in 40 major economies: Structural change or technology improvement? Energy Econ. 2014, 41, 47–62. [Google Scholar] [CrossRef]

- Fernandez Gonzalez, P.; Landajo, M.; Presno, M.J. The Divisia real energy intensity indices: Evolution and attribution of percent changes in 20 European countries from 1995 to 2010. Energy 2013, 58, 340–349. [Google Scholar] [CrossRef]

- Cunha, J.; Nunes, M.L.; Lima, F. Discerning the factors explaining the change in energy efficiency. Environ. Dev. Sustain. 2018, 20, 163–179. [Google Scholar] [CrossRef]

- Ediger, V.S.; Huvaz, O. Examining the sectoral energy use in Turkish economy (1980–2000) with the help of decomposition analysis. Energy Convers. Manag. 2006, 47, 732–745. [Google Scholar] [CrossRef]

- Shahiduzzaman, M.; Alam, K. Changes in energy efficiency in Australia: A decomposition of aggregate energy intensity using logarithmic mean Divisia approach. Energy Policy 2013, 56, 341–351. [Google Scholar] [CrossRef]

- Balezentis, A.; Balezentis, T.; Streimikiene, D. The energy intensity in Lithuania during 1995–2009: A LMDI approach. Energy Policy 2011, 39, 7322–7334. [Google Scholar] [CrossRef]

- Inglesi-Lotz, R.; Pouris, A. Energy efficiency in South Africa: A decomposition exercise. Energy 2012, 42, 113–120. [Google Scholar] [CrossRef]

- Bashmakov, I.; Myshak, A. Russian energy efficiency accounting system. Energy Effic. 2014, 7, 743–759. [Google Scholar] [CrossRef]

- Colinet Carmona, M.J.; Roman Collado, R. LMDI decomposition analysis of energy consumption in Andalusia (Spain) during 2003–2012: The energy efficiency policy implications. Energy Effic. 2016, 9, 807–823. [Google Scholar] [CrossRef]

- Cahill, C.J.; Gallachoir, B.P.O. Monitoring energy efficiency trends in European industry: Which top-down method should be used? Energy Policy 2010, 38, 6910–6918. [Google Scholar] [CrossRef]

- Bhattacharyya, S.C.; Ussanarassamee, A. Decomposition of energy and CO2 intensities of Thai industry between 1981 and 2000. Energy Econ. 2004, 26, 765–781. [Google Scholar] [CrossRef]

- Salta, M.; Polatidis, H.; Haralambopoulos, D. Energy use in the Greek manufacturing sector: A methodological framework based on physical indicators with aggregation and decomposition analysis. Energy 2009, 34, 90–111. [Google Scholar] [CrossRef]

- Kim, S. LMDI Decomposition Analysis of Energy Consumption in the Korean Manufacturing Sector. Sustainability 2017, 9, 202. [Google Scholar] [CrossRef]

- Inglesi-Lotz, R.; Blignaut, J.N. South Africa’s electricity consumption: A sectoral decomposition analysis. Appl. Energy 2011, 88, 4779–4784. [Google Scholar] [CrossRef]

- Mairet, N.; Decellas, F. Determinants of energy demand in the French service sector: A decomposition analysis. Energy Policy 2009, 37, 2734–2744. [Google Scholar] [CrossRef]

- Fernandez Gonzalez, P.; Landajo, M.; Presno, M.J. Tracking European Union CO2 emissions through LMDI (logarithmic-mean Divisia index) decomposition. The activity revaluation approach. Energy 2014, 73, 741–750. [Google Scholar] [CrossRef]

- Brizga, J.; Feng, K.; Hubacek, K. Drivers of CO2 emissions in the former Soviet Union: A country level IPAT analysis from 1990 to 2010. Energy 2013, 59, 743–753. [Google Scholar] [CrossRef]

- Bhattacharyya, S.C.; Matsumura, W. Changes in the GHG emission intensity in EU-15: Lessons from a decomposition analysis. Energy 2010, 35, 3315–3322. [Google Scholar] [CrossRef]

- Malla, S. CO2 emissions from electricity generation in seven Asia-Pacific and North American countries: A decomposition analysis. Energy Policy 2009, 37, 1–9. [Google Scholar] [CrossRef]

- Oh, I.; Wehrmeyer, W.; Mulugetta, Y. Decomposition analysis and mitigation strategies of CO2 emissions from energy consumption in South Korea. Energy Policy 2010, 38, 364–377. [Google Scholar] [CrossRef]

- O’ Mahony, T.; Zhou, P.; Sweeney, J. The driving forces of change in energy-related CO2 emissions in Ireland: A multi-sectoral decomposition from 1990 to 2007. Energy Policy 2012, 44, 256–267. [Google Scholar] [CrossRef]

- de Freitas, L.C.; Kaneko, S. Decomposition of CO2 emissions change from energy consumption in Brazil: Challenges and policy implications. Energy Policy 2011, 39, 1495–1504. [Google Scholar] [CrossRef]

- Akbostanci, E.; Tunc, G.I.; Turut-Asik, S. CO2 emissions of Turkish manufacturing industry: A decomposition analysis. Appl. Energy 2011, 88, 2273–2278. [Google Scholar] [CrossRef]

- Hammond, G.P.; Norman, J.B. Decomposition analysis of energy-related carbon emissions from UK manufacturing. Energy 2012, 41, 220–227. [Google Scholar] [CrossRef]

- Jeong, K.; Kim, S. LMDI decomposition analysis of greenhouse gas emissions in the Korean manufacturing sector. Energy Policy 2013, 62, 1245–1253. [Google Scholar] [CrossRef]

- Ma, C.; Stern, D.I. China’s changing energy intensity trend: A decomposition analysis. Energy Econ. 2008, 30, 1037–1053. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, C.; Hong, D. Why did China’s energy intensity increase during 1998–2006: Decomposition and policy analysis. Energy Policy 2010, 38, 1379–1388. [Google Scholar] [CrossRef]

- Nie, H.; Kemp, R. Why did energy intensity fluctuate during 2000–2009? A combination of index decomposition analysis and structural decomposition analysis. Energy Sustain Dev. 2013, 17, 482–488. [Google Scholar] [CrossRef]

- Tan, R.; Lin, B. What factors lead to the decline of energy intensity in China’s energy intensive industries? Energy Econ. 2018, 71, 213–221. [Google Scholar] [CrossRef]

- Chong, C.; Ma, L.; Li, Z.; Ni, W.; Song, S. Logarithmic mean Divisia index (LMDI) decomposition of coal consumption in China based on the energy allocation diagram of coal flows. Energy 2015, 85, 366–378. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Zhou, M.; Mu, H. Decomposition analysis of energy consumption in Chinese transportation sector. Appl. Energy 2011, 88, 2279–2285. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, F. Analysis of rural residential commercial energy consumption in China. Energy 2013, 52, 222–229. [Google Scholar] [CrossRef]

- Xu, S.-C.; He, Z.-X.; Long, R.-Y.; Chen, H. Factors that influence carbon emissions due to energy consumption based on different stages and sectors in China. J. Clean Prod. 2016, 115, 139–148. [Google Scholar] [CrossRef]

- Jiang, R.; Zhou, Y.; Li, R. Moving to a Low-Carbon Economy in China: Decoupling and Decomposition Analysis of Emission and Economy from a Sector Perspective. Sustainability 2018, 10, 978. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Z.; Chen, B. Decomposition Analysis of Energy-Related Industrial CO2 Emissions in China. Energies 2013, 6, 2319–2337. [Google Scholar] [CrossRef]

- Liu, L.-C.; Fan, Y.; Wu, G.; Wei, Y.-M. Using LMDI method to analyzed the change of China’s industrial CO2 emissions from final fuel use: An empirical analysis. Energy Policy 2007, 35, 5892–5900. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R.; Jiang, R. Decoupling and Decomposition Analysis of Carbon Emissions from Industry: A Case Study from China. Sustainability 2016, 8, 1059. [Google Scholar] [CrossRef]

- Lin, B.; Tan, R. Sustainable development of China’s energy intensive industries: From the aspect of carbon dioxide emissions reduction. Renew. Sustain. Energy Rev. 2017, 77, 386–394. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, M.; Zhou, M.; Zhou, M. A comparative study on decoupling relationship and influence factors between China’s regional economic development and industrial energy-related carbon emissions. J. Clean Prod. 2017, 142, 783–800. [Google Scholar] [CrossRef]

- Xu, S.-C.; He, Z.-X.; Long, R.-Y. Factors that influence carbon emissions due to energy consumption in China: Decomposition analysis using LMDI. Appl. Energy 2014, 127, 182–193. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Z. A spatio-temporal decomposition analysis of energy-related CO2 emission growth in China. J. Clean Prod. 2015, 103, 49–60. [Google Scholar] [CrossRef]

- Yang, X.; Wang, S.; Zhang, W.; Li, J.; Zou, Y. Impacts of energy consumption, energy structure, and treatment technology on SO2 emissions: A multi-scale LMDI decomposition analysis in China. Appl. Energy 2016, 184, 714–726. [Google Scholar] [CrossRef]

- Zhao, M.; Tan, L.; Zhang, W.; Ji, M.; Liu, Y.; Yu, L. Decomposing the influencing factors of industrial carbon emissions in Shanghai using the LMDI method. Energy 2010, 35, 2505–2510. [Google Scholar] [CrossRef]

- Zou, J.; Liu, W.; Tang, Z. Analysis of Factors Contributing to Changes in Energy Consumption in Tangshan City between 2007 and 2012. Sustainability 2017, 9, 452. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Zhou, P.; Wei, H. Whole process decomposition of energy-related SO2 in Jiangsu Province, China. Appl. Energy 2017, 194, 679–687. [Google Scholar] [CrossRef]

- Lu, M.; Wang, X.; Cang, Y. Carbon Productivity: Findings from Industry Case Studies in Beijing. Energies 2018, 11, 2796. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Decomposing the change in energy consumption in China’s nonferrous metal industry: An empirical analysis based on the LMDI method. Renew. Sustain. Energy Rev. 2018, 82, 2652–2663. [Google Scholar] [CrossRef]

- Luo, X.; Dong, L.; Dou, Y.; Li, Y.; Liu, K.; Ren, J.; Liang, H.; Mai, X. Factor decomposition analysis and causal mechanism investigation on urban transport CO2 emissions: Comparative study on Shanghai and Tokyo. Energy Policy 2017, 107, 658–668. [Google Scholar] [CrossRef]

- Wang, J.; He, S.; Qiu, Y.; Liu, N.; Li, Y.; Dong, Z. Investigating driving forces of aggregate carbon intensity of electricity generation in China. Energy Policy 2018, 113, 249–257. [Google Scholar] [CrossRef]

- Chontanawat, J.; Wiboonchutikula, P.; Buddhivanich, A. Decomposition analysis of the change of energy intensity of manufacturing industries in Thailand. Energy 2014, 77, 171–182. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X.; Zhang, M.; Song, X. Using a new generalized LMDI (logarithmic mean Divisia index) method to analyze China’s energy consumption. Energy 2014, 67, 617–622. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

| Items | Beijing | Tianjin | Hangzhou | Shenyang | Xi’an | Fuzhou | Guiyang |

|---|---|---|---|---|---|---|---|

| Population (×106) | 21.71 | 15.47 | 7.24 | 8.29 | 8.16 | 6.78 | 4.62 |

| GDP (×109 CNY) a | 2368.57 | 1683.79 | 1005.02 | 727.23 | 580.12 | 561.81 | 289.12 |

| GDP ranking in China | 2 | 5 | 10 | 19 | 26 | 29 | 66 |

| Percentage of industry (% of GDP) | 16.17 | 42.74 | 34.80 | 42.47 | 23.73 | 33.38 | 24.70 |

| Industrial final energy use (×106 tce) b | 8.88 | 34.84 | 15.24 | 6.13 | 2.78 | 8.72 | 5.36 |

| Code | Industrial sectors | Code | Industrial sectors |

|---|---|---|---|

| IS1 | Mining of coal | IS6 | Chemicals |

| IS2 | Extraction of oil & natural gas | IS7 | Nonmetals |

| IS3 | Mining & processing of ores | IS8 | Metals |

| IS4 | Light industry | IS9 | Manufacture of equipment |

| IS5 | Petroleum processing & coking | IS10 | Production and supply of electricity, heat, gas, and water |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, X.; Yang, W.; Wang, Y.; Song, J. Uncovering Variations, Determinants, and Disparities of Multisector-Level Final Energy Use of Industries Across Cities. Sustainability 2019, 11, 1806. https://doi.org/10.3390/su11061806

Liao X, Yang W, Wang Y, Song J. Uncovering Variations, Determinants, and Disparities of Multisector-Level Final Energy Use of Industries Across Cities. Sustainability. 2019; 11(6):1806. https://doi.org/10.3390/su11061806

Chicago/Turabian StyleLiao, Xianrui, Wei Yang, Yichen Wang, and Junnian Song. 2019. "Uncovering Variations, Determinants, and Disparities of Multisector-Level Final Energy Use of Industries Across Cities" Sustainability 11, no. 6: 1806. https://doi.org/10.3390/su11061806

APA StyleLiao, X., Yang, W., Wang, Y., & Song, J. (2019). Uncovering Variations, Determinants, and Disparities of Multisector-Level Final Energy Use of Industries Across Cities. Sustainability, 11(6), 1806. https://doi.org/10.3390/su11061806