Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy

Abstract

:1. Introduction

- Define the typological and technological characteristics of reference buildings;

- Define the measures/packages/technological variants of energy efficiency;

- Assess the final and primary energy consumption of buildings;

- Assess the costs of the measures/packages/technological variants;

- Generate a consumption-cost curve.

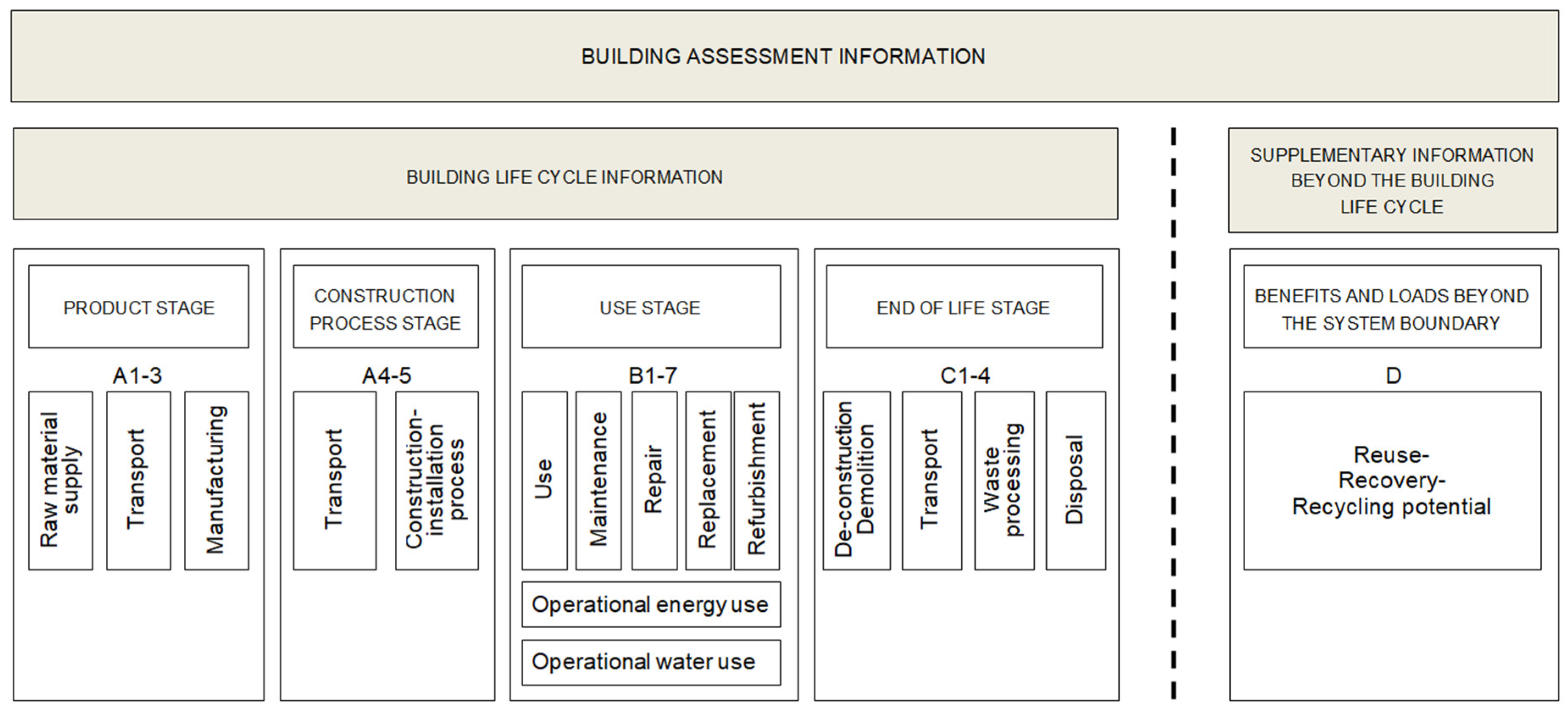

2. Life Cycle Cost Methodology

3. Case Study Analysis

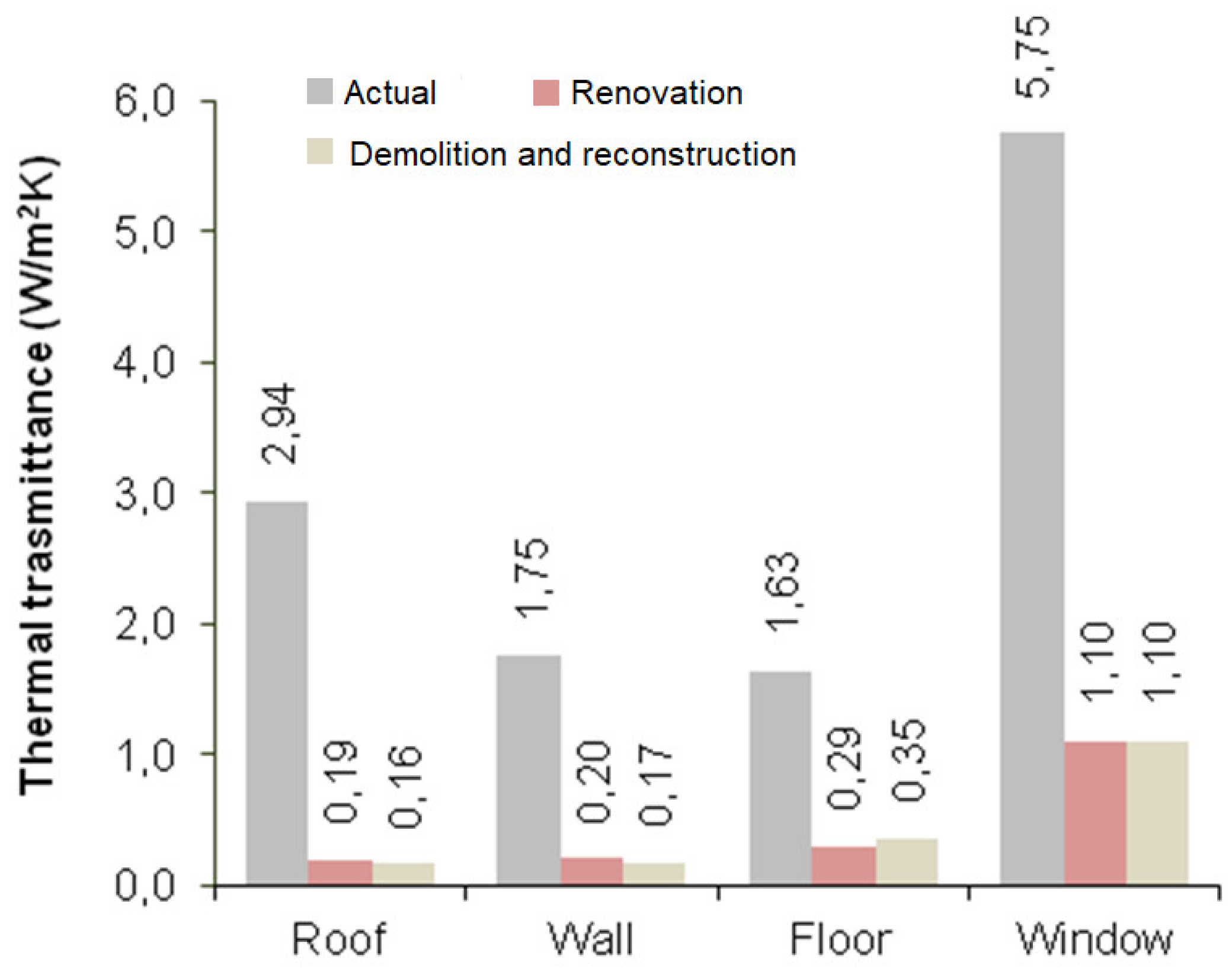

3.1. Description of Two Alternative Solutions for the Case Study Renovation

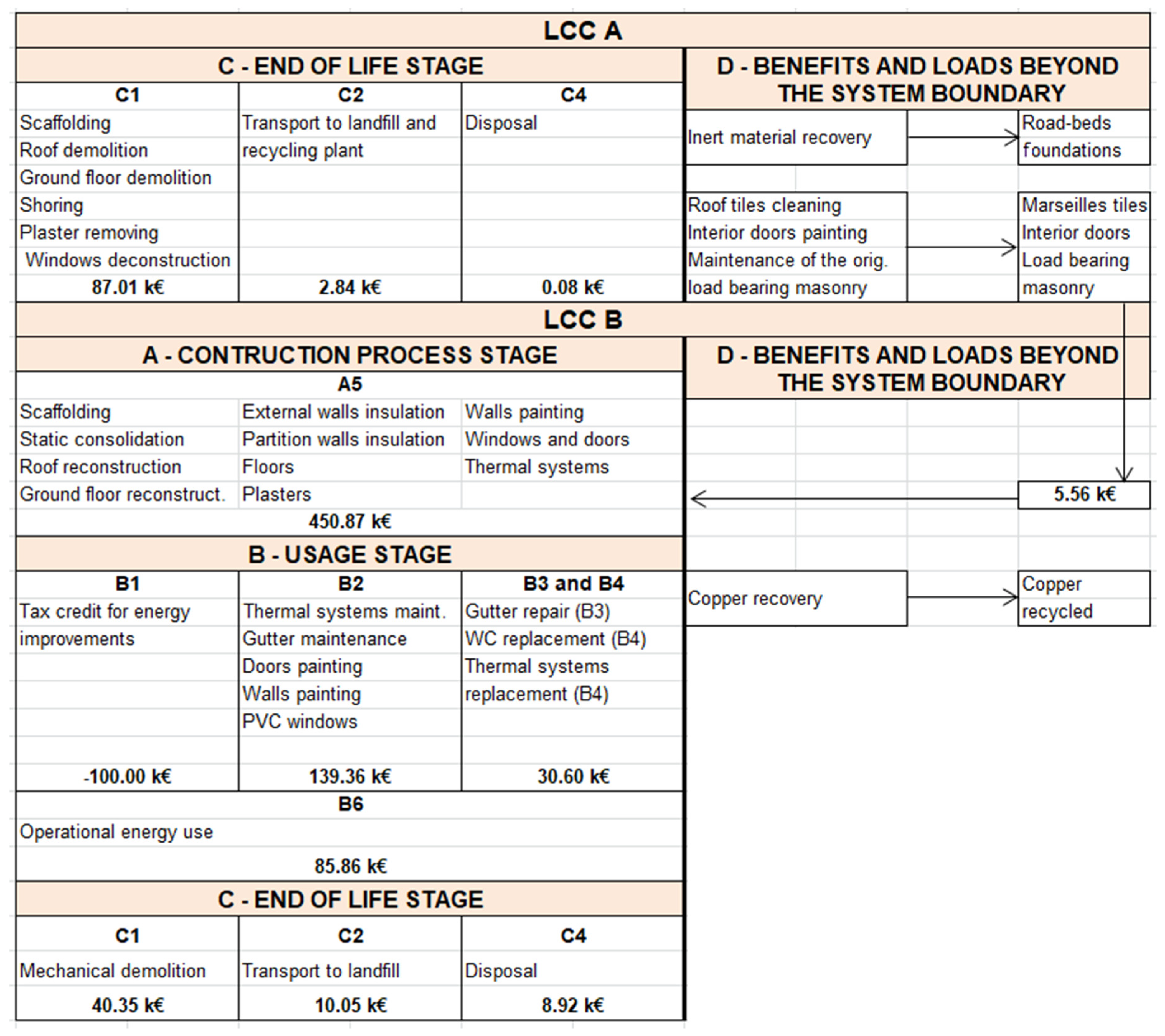

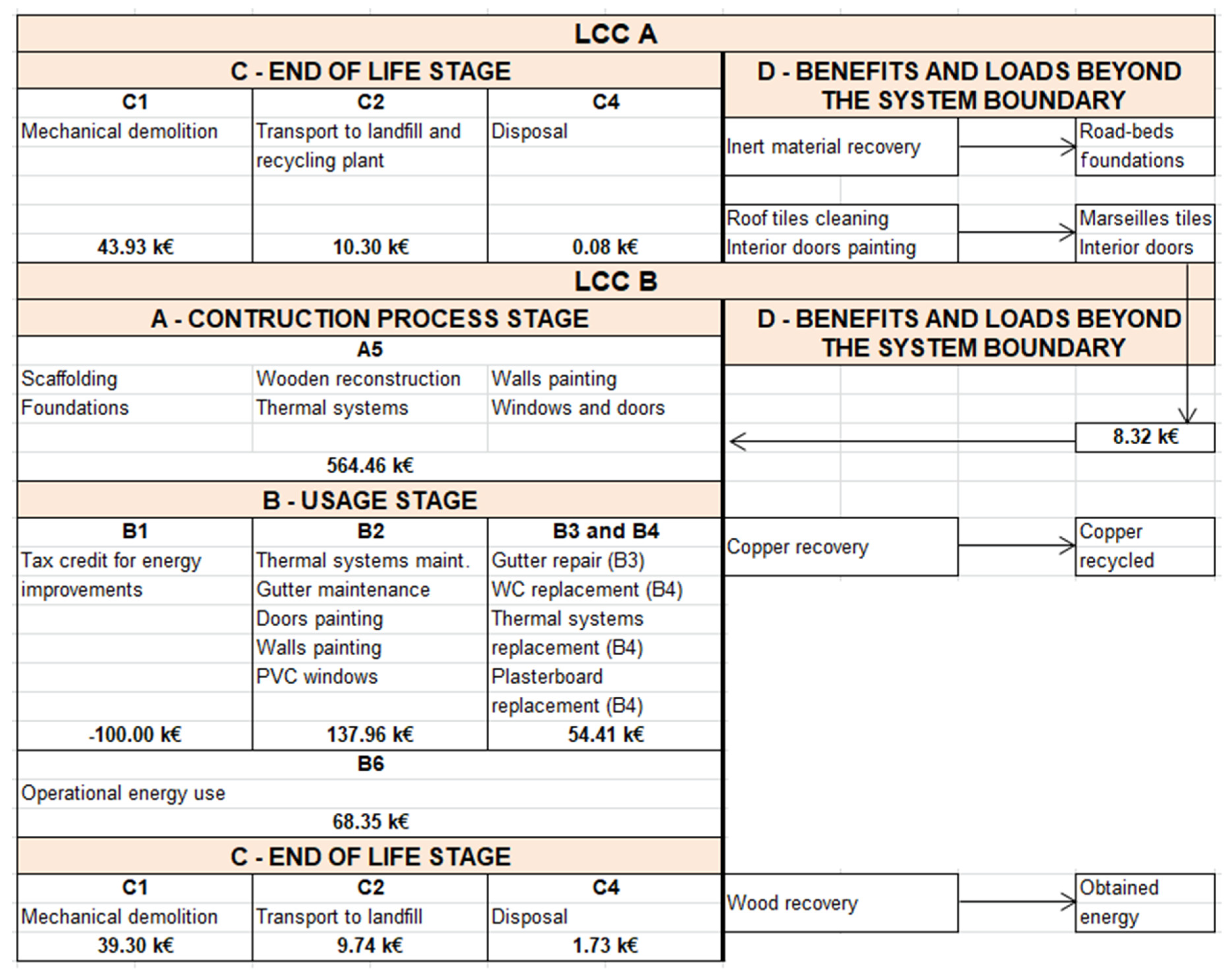

3.2. Application of the LCC to the Case Study

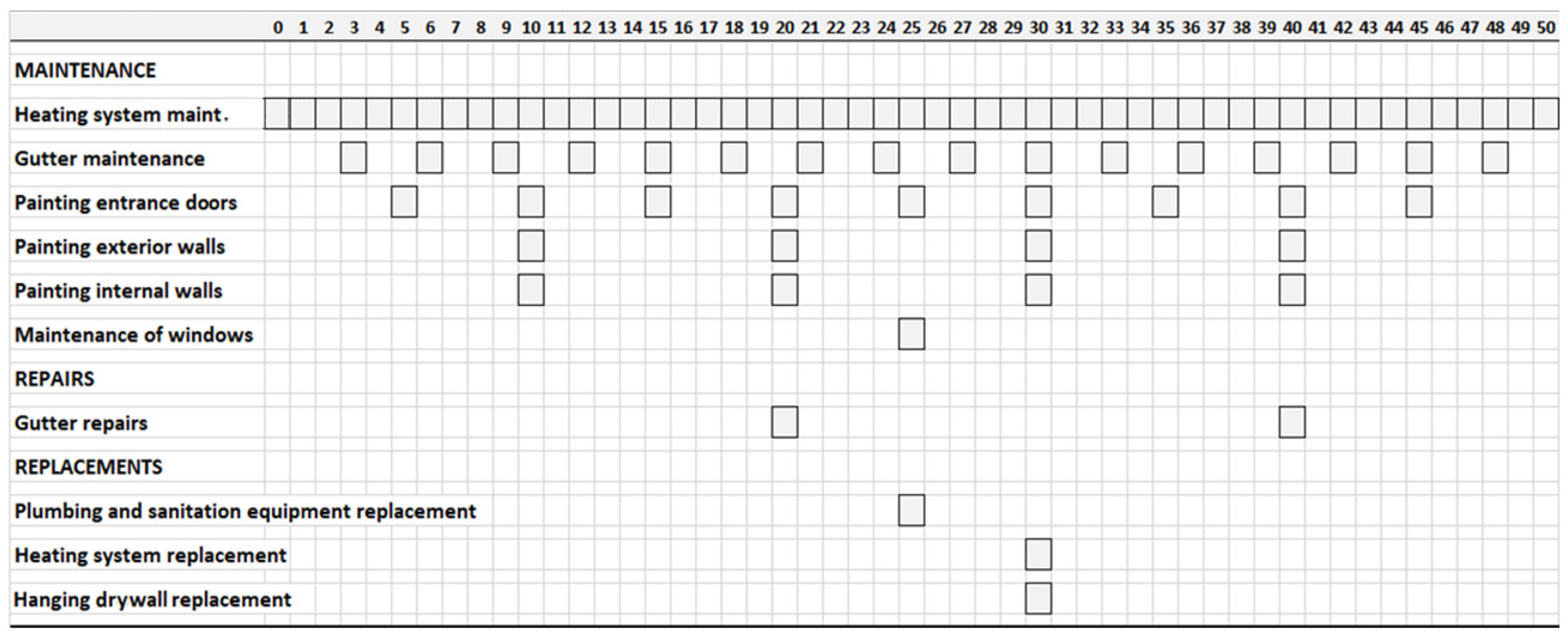

- A scientific approach, based on the knowledge of degradation phenomena and their actions on materials to define obsolescence models;

- An experimental approach, based on the monitoring over time of buildings or building elements, observing the evolution of degradation phenomena from their first appearance and deriving, from the observed data, effective models of obsolescence;

- A qualitative approach proposed by ISO 15686 [33]. According to Reference [33], the declared RSL value (or the RSL value evaluated by one of the previous approaches) is weighted by opportune correction coefficients to calculate the actual RSL value. Correction coefficients are established for the quality of the components, the design and execution of the works, the specific conditions of the internal and external environment, and the level of use and maintenance. This approach is the most widespread.

- For Module A (construction processes stage), costs were determined on the basis of the project schedule;

- For Module B1, costs were determined on the basis of the current regulatory framework—all the benefits of any tax relief for interventions aimed at energy conservation were considered;

- For Modules B2, B3, and B4, costs were determined on the basis of the maintenance and replacement plan;

- For Module B6, costs were determined on the basis of the energy consumption for heating and the domestic hot water production during the RSL. The use of cold water and electricity were neglected in the economic assessment, because they are not influenced by the two alternatives analyzed and are, therefore, considered the same for both solutions;

- For Module C, costs were determined on the basis of the project schedule.

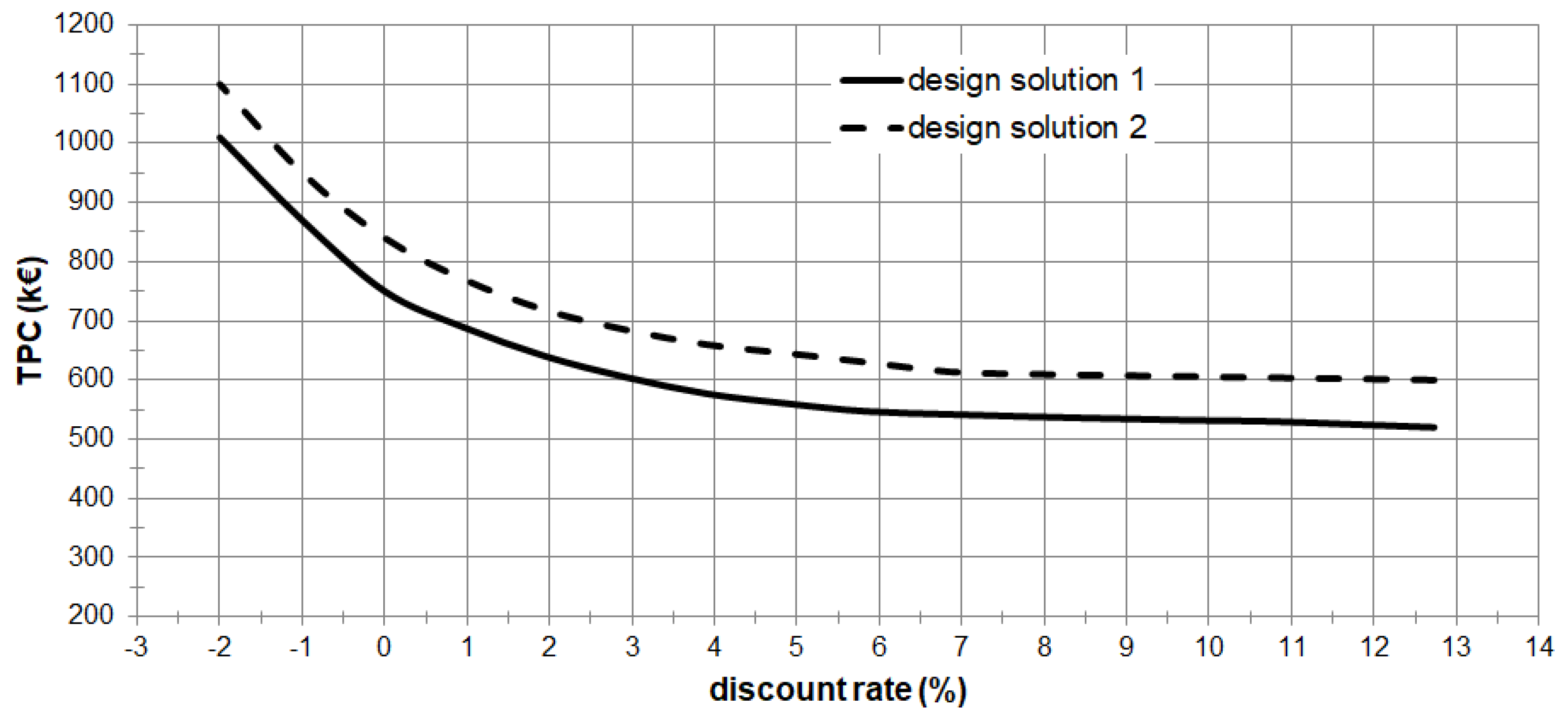

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References and Notes

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=celex%3A32010L0031 (accessed on 6 March 2019).

- Commission Delegated Regulation (EU) No 244/2012 of 16 January 2012 Supplementing Directive 2010/31/EU of the European Parliament and of the Council on the energy performance of buildings by Establishing a Comparative Methodology Framework for Calculating Cost-Optimal Levels of Minimum Energy Performance Requirements for Buildings and Building Elements Text with EEA Relevance. Available online: https://publications.europa.eu/en/publication-detail/-/publication/40347d51-cd2d-4935-9ae1-293171ba12d2/language-en (accessed on 6 March 2019).

- Italian Energy Efficiency Action Plan 2018. Italian Ministry of Economic Development. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/energy-efficiency-directive/national-energy-efficiency-action-plans (accessed on 6 March 2019).

- Armani, R.; Pietrobon, M.; Pagliano, L. Definizione dei Parametri per L’ottimizzazione di Interventi di Riqualificazione in Considerazione del Fattore Costi/Benefici; Report RdS/PAR2013/114; Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA): Rome, Italy, 2014; Available online: http://www.enea.it/it/Ricerca_sviluppo/documenti/ricerca-di-sistema-elettrico/edifici-pa/2013/rds-par2013-114.pdf/view (accessed on 6 March 2019).

- Kapsalaki, M.; Leal, V.; Santamouris, M. A methodology for economic efficient design of Net Zero Energy Buildings. Energy Build. 2012, 55, 765–778. [Google Scholar] [CrossRef]

- Han, G.; Srebric, J.; Enache-Pommer, E. Variability of optimal solutions for building components based on comprehensive life cycle cost analysis. Energy Build. 2014, 79, 223–231. [Google Scholar] [CrossRef]

- Moschetti, R.; Brattebø, H. Combining Life Cycle Environmental and Economic Assessments in Building Energy Renovation Projects. Energies 2017, 10, 1851. [Google Scholar] [CrossRef]

- Monteiro, C.S.; Causone, F.; Cunha, S.; Pina, A.; Erba, S. Addressing the challenges of public housing retrofits. In Proceedings of the Ninth KES International Conference on Energy Procedia, Sustainability in Energy and Buildings 2017, Chania, Greece, 5–7 July 2017; Volume 134, pp. 442–451. [Google Scholar] [CrossRef]

- DellaValle, N.; Bisello, A.; Balest, J. In search of behavioural and social levers for effective social housing retrofit programs. Energy Build. 2018, 172, 517–524. [Google Scholar] [CrossRef]

- Islam, H.; Jollands, M.; Setunge, S. Life cycle assessment and life cycle cost implication of residential buildings—A review. Renew. Sustain. Energy Rev. 2015, 42, 129–140. [Google Scholar] [CrossRef]

- Finnegan, S.; Jones, C.; Sharples, S. The embodied CO2e of sustainable energy technologies used in buildings: A review article. Energy Build. 2018, 181, 50–61. [Google Scholar] [CrossRef]

- Ingrao, C.; Messineo, A.; Beltramo, R.; Yigitcanlar, T.; Ioppolo, G. How can life cycle thinking support sustainability of buildings? Investigating life cycle assessment applications for energy efficiency and environmental performance. J. Clean. Prod. 2018, 201, 556–569. [Google Scholar] [CrossRef]

- Hossain, M.U.; Thomas Ng, S. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Balocco, C.; Colaianni, A. Assessment of Energy Sustainable Operations on a Historical Building. The Dante Alighieri High School in Florence. Sustainability 2018, 10, 2054. [Google Scholar] [CrossRef]

- Fantozzi, F.; Le Bail, L.; Leccese, F.; Rocca, M.; Salvadori, G. General Lighting in Office Buildings: Techno-economic Considerations on the Fluorescent Tubes Replacement with LED Tubes. Int. J. Eng. Technol. Innov. 2016, 7, 143–156. [Google Scholar]

- Fantozzi, F.; Leccese, F.; Salvadori, G.; Rocca, M.; Garofalo, M. LED Lighting for Indoor Sports Facilities: Can Its Use Be Considered as Sustainable Solution from a Techno-Economic Standpoint? Sustainability 2016, 8, 618. [Google Scholar] [CrossRef]

- Bellia, L.; Borrelli, M.; De Masi, R.F.; Ruggiero, S.; Vanoli, G.P. University building: Energy diagnosis and refurbishment design with cost-optimal approach. Discussion about the effect of numerical modelling assumptions. J. Build. Eng. 2018, 18, 1–18. [Google Scholar] [CrossRef]

- Corrado, V.; Ballarini, I.; Paduos, S.; Tulipano, L. A new procedure of energy audit and cost analysis for the transformation of a school into a nearly zero-energy building. Energy Procedia 2017, 140, 325–338. [Google Scholar] [CrossRef]

- Carpino, C.; Bruno, R.; Arcuri, N. Social housing refurbishment in Mediterranean climate: Cost-optimal analysis towards the n-ZEB target. Energy Build. 2018, 174, 642–656. [Google Scholar] [CrossRef]

- Biserni, C.; Valdiserri, P.; D’Orazio, D.; Garai, M. Energy Retrofitting Strategies and Economic Assessments: The Case Study of a Residential Complex Using Utility Bills. Energies 2018, 11, 2055. [Google Scholar] [CrossRef]

- Sharif, S.A.; Hammad, A. Simulation-Based Multi-Objective Optimization of Institutional Building Renovation Considering Energy Consumption, Life-Cycle Cost and Life-Cycle Assessment. J. Build. Eng. 2018. [Google Scholar] [CrossRef]

- Stokes, E.; Akram, S. Project Management in Construction; McGraw-Hill: New York, NY, USA, 2008; ISBN1 8389780615. ISBN2 9788389780614. [Google Scholar]

- CEN/TC 350 WI 017:2013 Sustainability of Construction Works—Assessment of Buildings—Calculation Methods.

- EN 15643-4:2012 Sustainability of Construction Works—Assessment of Buildings—Framework for the Assessment of Economic Performance.

- Scuderi, G. Retrofit of Residential Buildings in Europe. Designs 2019, 3, 8. [Google Scholar] [CrossRef]

- Filogamo, L.; Peri, G.; Rizzo, G.; Giaccone, A. On the classification of large residential buildings stocks by sample typologies for energy planning purposes. Appl. Energy 2014, 135, 825–835. [Google Scholar] [CrossRef]

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.156.01.0075.01.ENG (accessed on 6 March 2019).

- Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=celex%3A32012L0027 (accessed on 6 March 2019).

- Fantozzi, F.; Leccese, F.; Salvadori, G.; Tuoni, G. Energy demand analysis and energy labelling of new residential buildings in Tuscany (Italy). WIT Trans. Ecol. Environ. 2009, 122, 217–229. [Google Scholar] [CrossRef]

- EN 1990:2002+A1:2005 Eurocode—Basis of Strucutral Desing.

- Gargari, C.; Palumbo, E. Progettare la Durabilità: Confronto tra Soluzioni in Laterizio e in Legno; Costruire in Laterizio: Milan, Italy, 2011. (In Italian) [Google Scholar]

- ISO/TS 15686-9:2008, Buildings and Constructed Assets—Service-Life Planning—Guidance on Assessment of Service-Life Data.

- EN 15978:2011 Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation.

- European Commission. Development and Implementation of Initiatives Fostering Investment and Innovation in construction And Demolition Waste Recycling Infrastructure; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-68097-7. [Google Scholar]

| Conservative Renovation | Demolition and Reconstruction |

|---|---|

| end of life stage | |

| Selective demolition | Mechanical demolition |

| construction process stage | |

| Static consolidation | Excavation |

| Roof replacement and insulation | Substructure |

| Ground floor replacement and insulation | Rebuilding with Platform Frame method |

| External wall insulation | Condensing boiler installation |

| Partition wall insulation | Radiator installation |

| Window and door replacement | |

| Condensing boiler installation | |

| Radiator installation | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fantozzi, F.; Gargari, C.; Rovai, M.; Salvadori, G. Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy. Sustainability 2019, 11, 1452. https://doi.org/10.3390/su11051452

Fantozzi F, Gargari C, Rovai M, Salvadori G. Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy. Sustainability. 2019; 11(5):1452. https://doi.org/10.3390/su11051452

Chicago/Turabian StyleFantozzi, Fabio, Caterina Gargari, Massimo Rovai, and Giacomo Salvadori. 2019. "Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy" Sustainability 11, no. 5: 1452. https://doi.org/10.3390/su11051452

APA StyleFantozzi, F., Gargari, C., Rovai, M., & Salvadori, G. (2019). Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy. Sustainability, 11(5), 1452. https://doi.org/10.3390/su11051452