Exploring the Driving Forces and Reduction Potential of Industrial Energy-Related CO2 Emissions during 2001–2030: A Case Study for Henan Province, China

Abstract

:1. Introduction

2. Literature Review

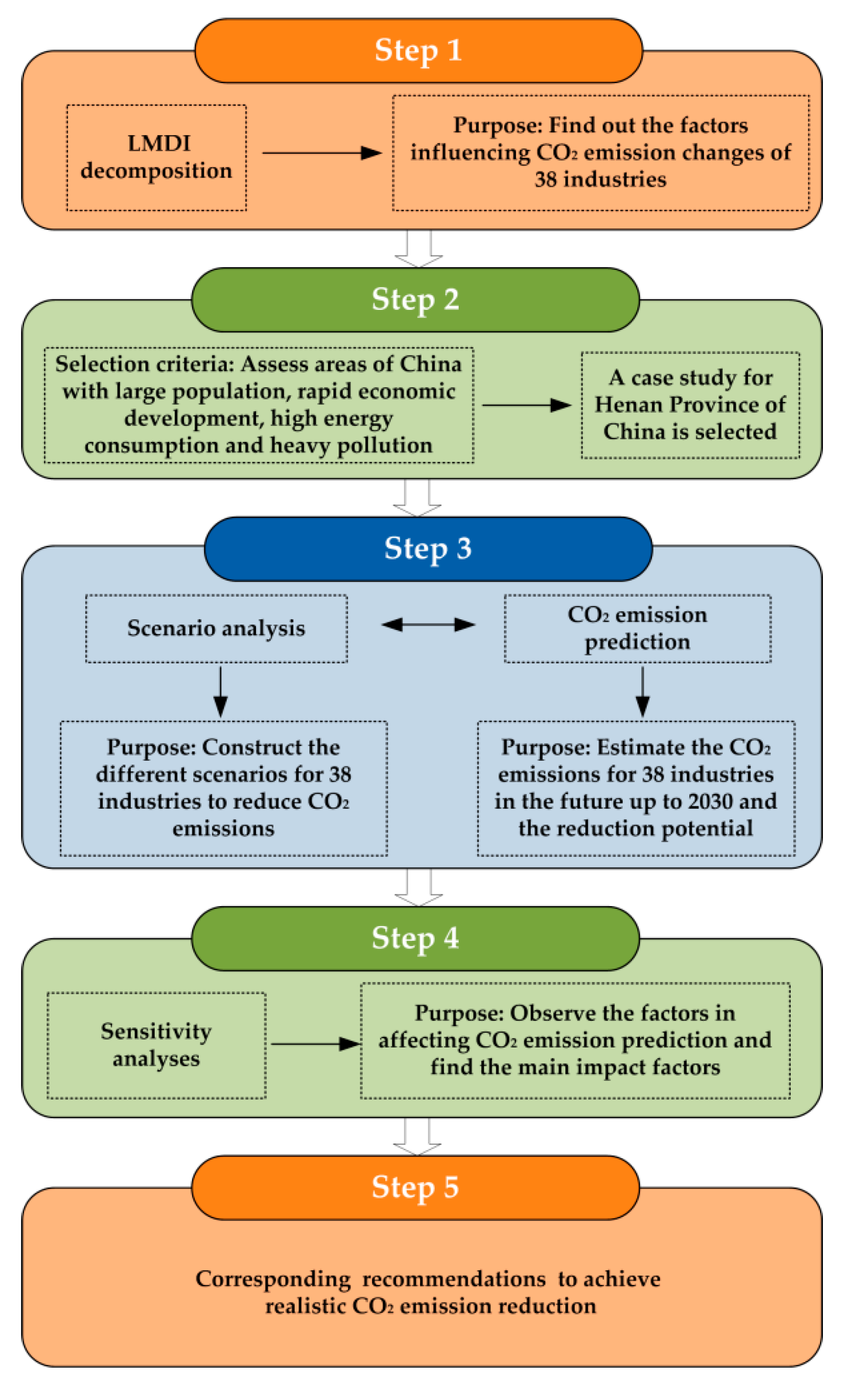

3. Research Methods and Data Sources

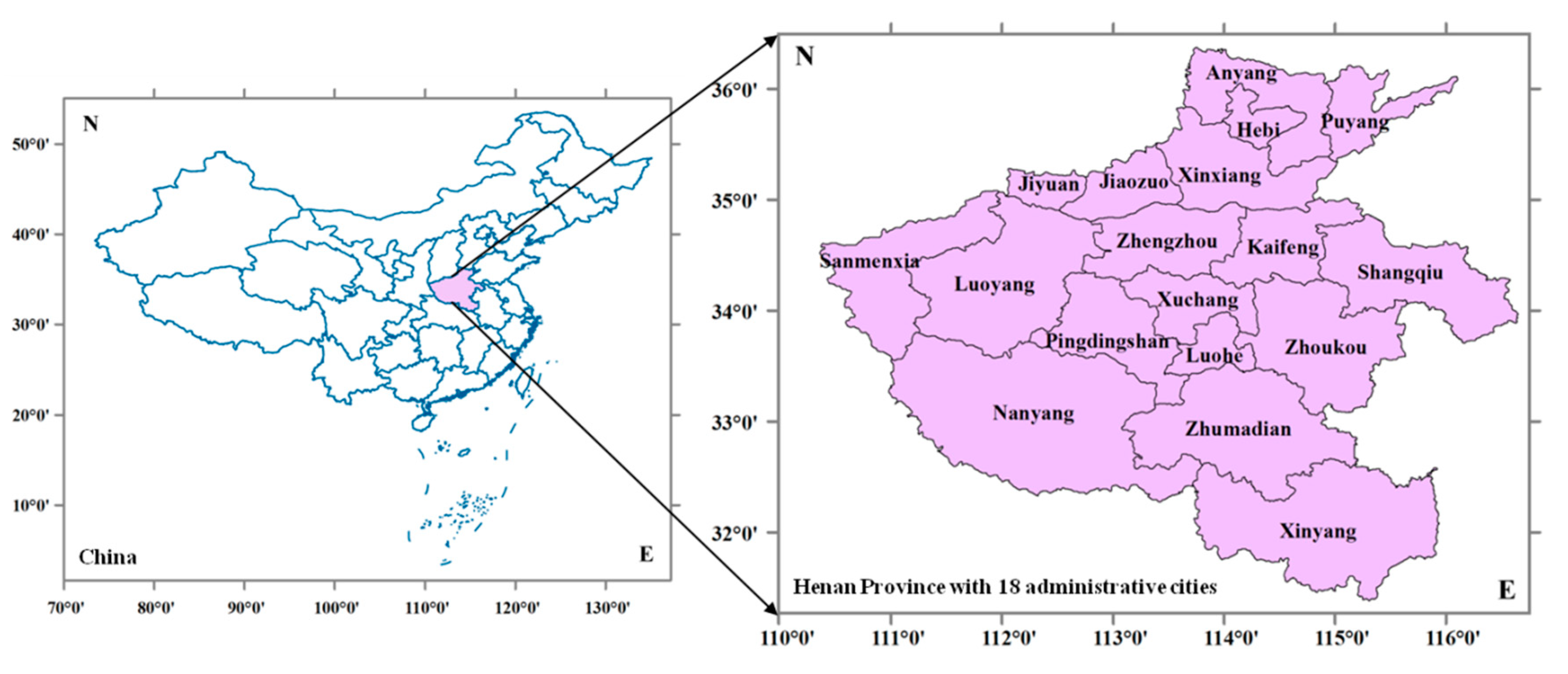

3.1. Study Domain

3.2. Estimation of CO2 Emissions

3.3. LMDI Decomposition

3.4. Prediction of CO2 Emissions

3.5. Data Processing

4. Results and Discussions

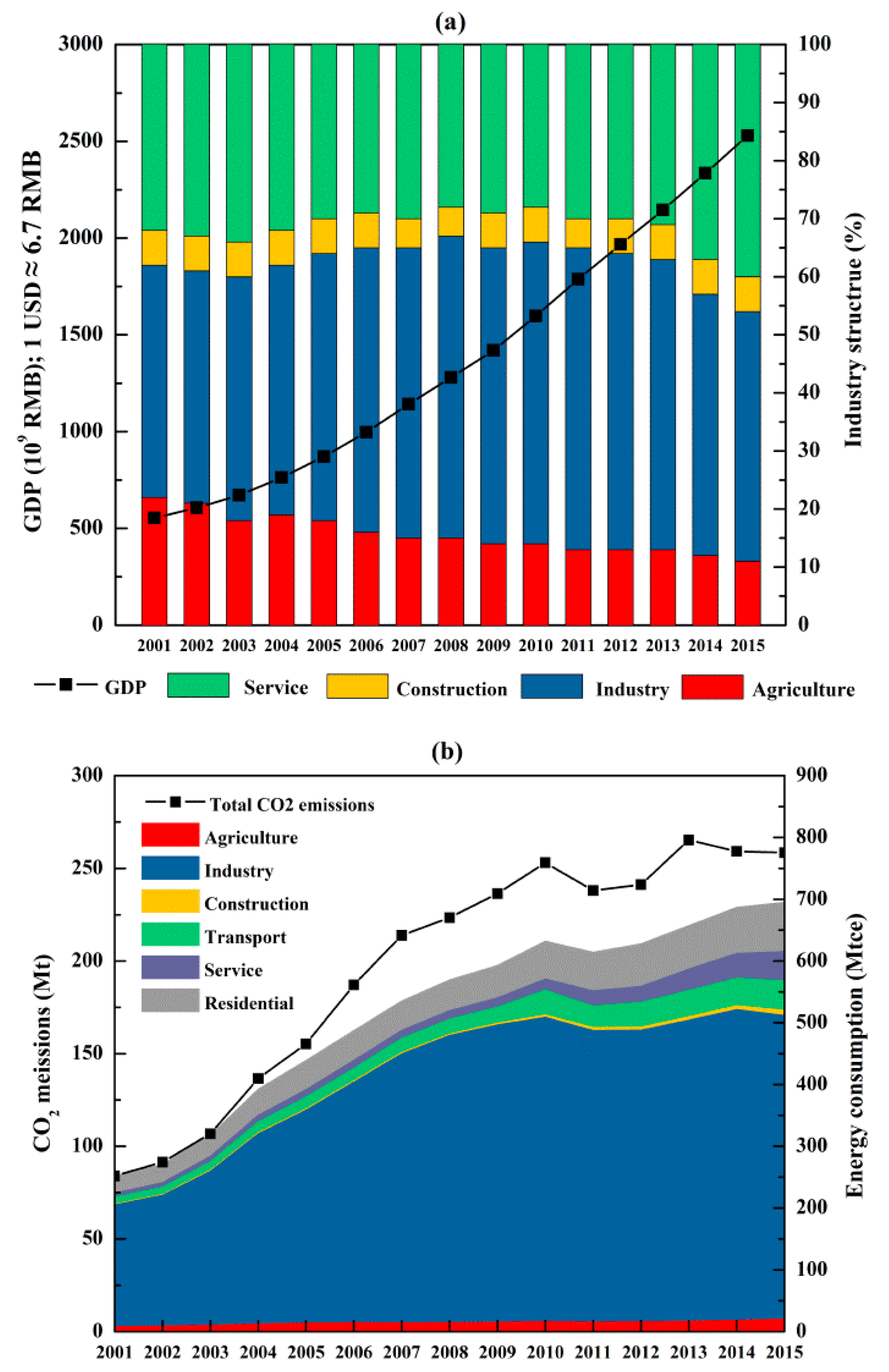

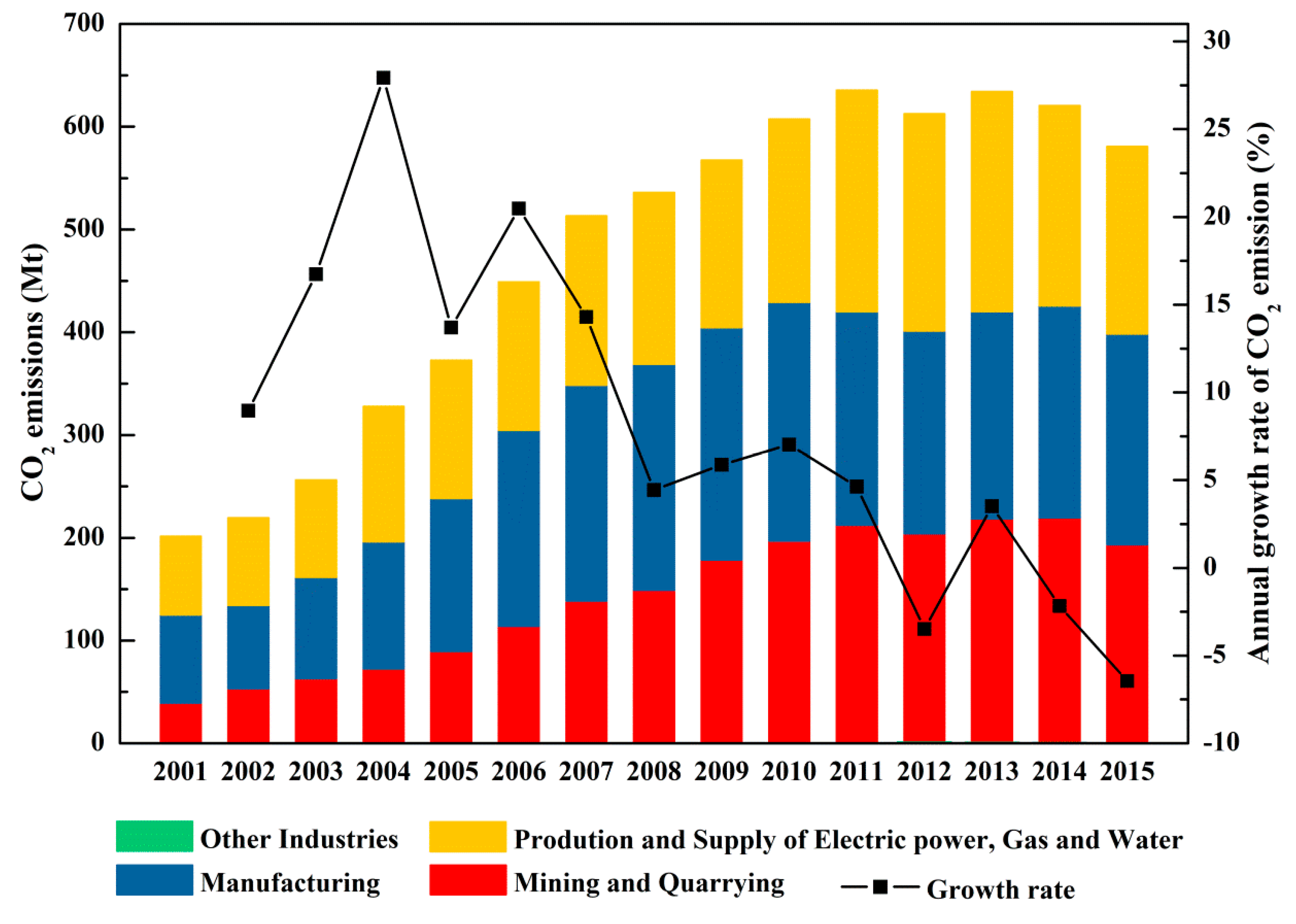

4.1. Analysis of Industrial Energy-Related CO2 Emission Features

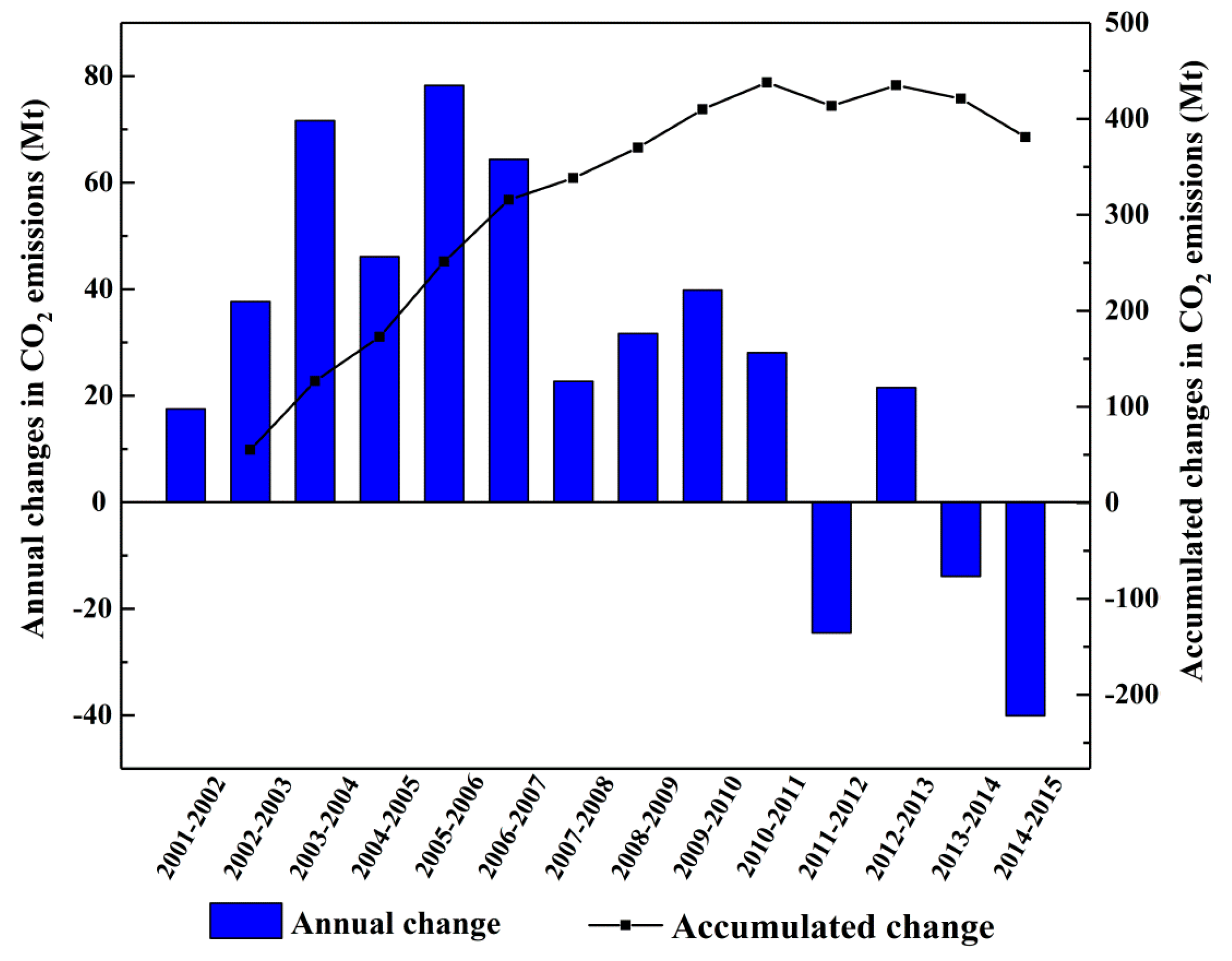

4.2. Analysis of Emission Change Trends and Contributions of Various Factors

4.3. Decomposition Analysis of Driving Factors at Different Stages

4.4. Emissions Reduction Scenario Analysis

4.4.1. Scenario Design

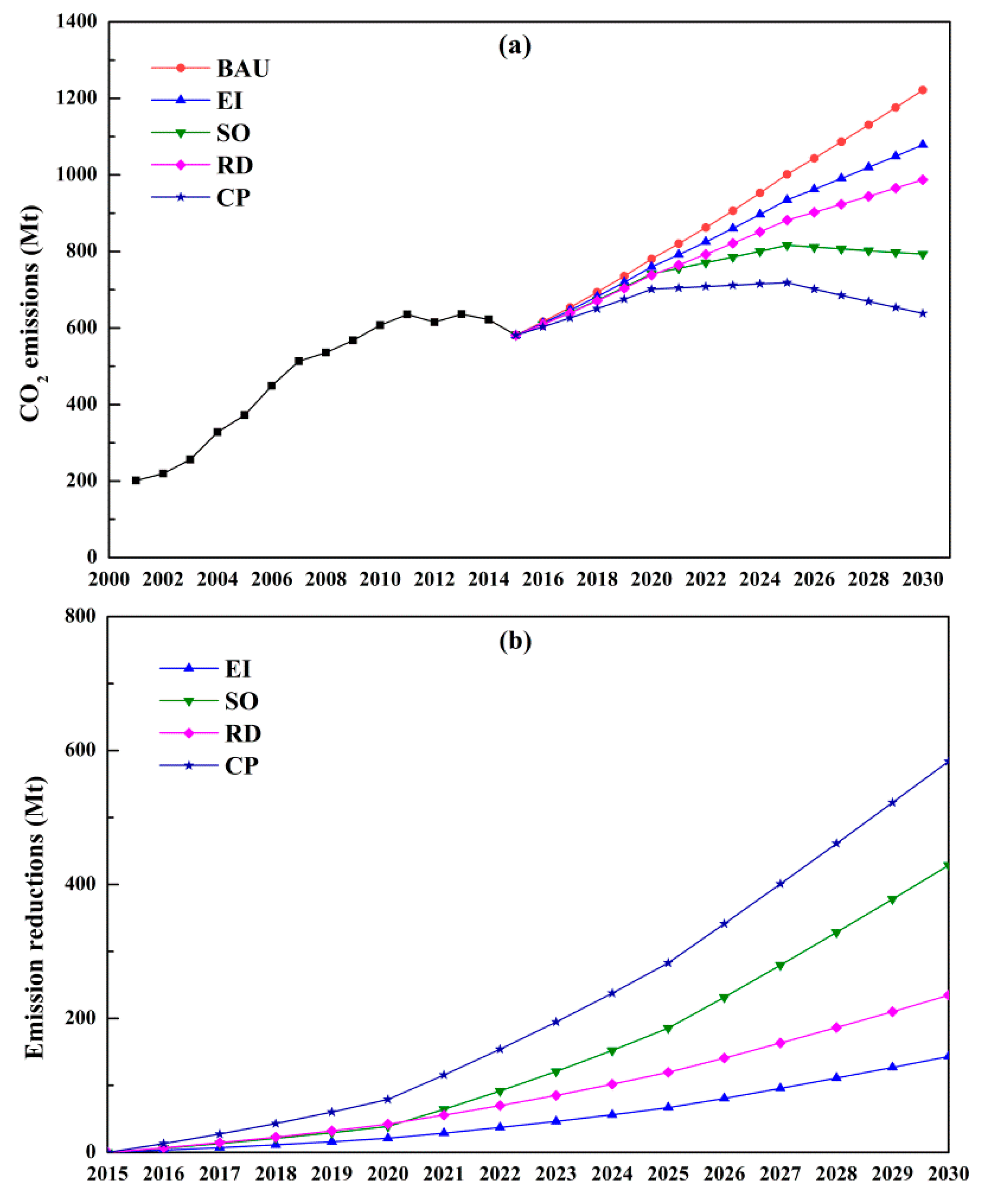

4.4.2. Estimates of the energy-related CO2 emissions and the emission reduction potential

5. Uncertainty and Sensitivity Analysis

5.1. Uncertainty Analysis

5.2. Sensitivity Analysis

6. Conclusions and Policy Implications

Author Contributions

Acknowledgments

Conflicts of Interest

References

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2013: The Physical Science Basis; IPCC: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2007: Synthesis Report; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Yu, S.; Wei, Y.M.; Guo, H.; Ding, L. Carbon emission coefficient measurement of the coal-to-power energy chain in China. Appl. Energy 2014, 114, 290–300. [Google Scholar] [CrossRef]

- Mi, Z.F.; Pan, S.Y.; Yu, H.; Wei, Y.M. Potential impacts of industrial structure on energy consumption and CO2 emission: A case study of Beijing. J. Clean. Prod. 2015, 103, 455–462. [Google Scholar] [CrossRef]

- Guo, Z.Q.; Zhang, X.P.; Zheng, Y.H.; Rao, R. Exploring the impacts of a carbon tax on the Chinese economy using a CGE model with a detailed disaggregation of energy sectors. Energy Econ. 2014, 45, 455–462. [Google Scholar] [CrossRef]

- BP (British Petroleum). Statistical Review of World Energy Full Report; British Petroleum: London, UK, 2015. [Google Scholar]

- Liu, Z. National carbon emissions from the industry process: Production of glass, soda ash, ammonia, calcium carbide and alumina. Appl. Energy 2016, 166, 239–244. [Google Scholar] [CrossRef]

- National State Council (NSC). U.S.-China Joint Announcenment on Climate Change. Available online: http://www.scio.gov.cn/xwfbh/xwbfbh/wqfbh/2015/20151119/xgzc33810/Document/1455884/1455884.htm (accessed on 19 November 2015).

- National Development and Reform Commission (NDRC). Enhanced Actions on Climate Change: China’s Intended Nationally Determined Contributions. Available online: https://www.mfa.gov.cn/ce/cese/eng/zgxw/t1278285.htm (accessed on 3 July 2015).

- Zhou, X.; Zhang, M.; Zhou, M.H.; Zhou, M. A comparative study on decoupling relationship and influence factors between China’s regional economic development and industrial energy-related carbon emissions. J. Clean. Prod. 2017, 142, 783–800. [Google Scholar] [CrossRef]

- Zhu, X.H.; Zou, J.W.; Feng, C. Analysis of industrial energy-related CO2 emissions and the reduciton potential of cities in the Yangtze River Delta region. J. Clean. Prod. 2017, 168, 791–802. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, X.R.; Jiang, Z.J.; Shao, S. How to achieve the 2030 CO2 emission-reduction targets for China’s industrial sector: Retrospective decomposition and prospective trajectories. Global Environ. Chang. 2017, 44, 83–97. [Google Scholar] [CrossRef]

- Xu, S.C.; He, Z.X.; Long, R.Y. Factors that influence carbon emissions due to energy consumption in China: Decomposition analysis using LMDI. Appl. Energy 2014, 127, 182–193. [Google Scholar] [CrossRef]

- Shao, S.; Yang, L.L.; Gan, C.H.; Cao, J.H.; Geng, Y.; Guan, D.B. Using an extended LMDI model to explore techno-economic drivers of energy-related industrial CO2 emission changes: A case study for Shanghai (China). Renew. Sust. Energ. Rev. 2016, 55, 516–536. [Google Scholar] [CrossRef]

- Liu, L.; Wang, S.S.; Wang, K.; Zhang, R.Q.; Tang, X.Y. LMDI decomposition analysis of industry carbon emissions in Henan Province, China: Comparison between different 5-year plans. Nat. Hazards 2016, 80, 997–1014. [Google Scholar] [CrossRef]

- Chong, C.H.; Liu, P.; Ma, L.W.; Li, Z.; Ni, W.D.; Li, X.; Song, S.Z. LMDI decomposition of energy consumption in Guangdong Province, China, based on an energy allocation diagram. Energy 2017, 133, 525–544. [Google Scholar] [CrossRef]

- Rose, A.; Casler, S. Input-output structural decomposition analysis: A critical appraisal. Econ. Syst. Res. 1996, 8, 33–62. [Google Scholar] [CrossRef]

- Chang, Y.F.; Lin, S.J. Structural decomposition of industrial CO2 emission in Taiwan: An input-output approach. Energy Policy 1998, 26, 5–12. [Google Scholar] [CrossRef]

- Zhang, Y.G. Structural decomposition analysis of sources of decarbonizing economic development in China: 1992–2006. Ecol. Econ. 2009, 68, 2399–2405. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhao, H.Y.; Li, L.Y.; Liu, Z.; Liang, S. Carbon dioxide emission drivers for a typical metropolis using input-output structural decomposition analysis. Energy Policy 2013, 58, 312–318. [Google Scholar] [CrossRef]

- Geng, Y.; Zhao, H.Y.; Liu, Z.; Xue, B.; Fujita, T.; Xi, F.M. Exploring driving factors of energy-related CO2 emissions in Chinese provinces: A case of Liaoning. Energy Policy 2013, 60, 820–826. [Google Scholar] [CrossRef]

- Tian, X.; Chang, M.; Tanikawa, H.; Shi, F.; Imura, H. Structural decomposition analysis of the carbonization process in Beijing: A regional explanation of rapid increasing carbon dioxide emission in China. Energy Policy 2013, 53, 279–286. [Google Scholar] [CrossRef]

- Wei, J.; Huang, K.; Yang, S.S.; Li, Y.; Hu, T.T.; Zhang, Y. Driving forces analysis of energy-related carbon dioxide (CO2) emissions in Beijing: An input-output structural decomposition analysis. J. Clean. Prod. 2017, 163, 58–68. [Google Scholar] [CrossRef]

- Mi, Z.F.; Meng, J.; Guan, D.B.; Shan, Y.L.; Song, M.L.; Wei, Y.M.; Liu, Z.; Hubacek, K. Chinese CO2 emission flows have reversed since the global financial crisis. Nat. Commun. 2017, 8, 1712. [Google Scholar] [CrossRef] [PubMed]

- Mi, Z.F.; Meng, J.; Green, F.; Coffman, D.M.; Guan, D.B. China’s “Exported Carbon” Peak: Patterns, Drivers, and Implications. Geophys. Res. Lett. 2018, 45, 4309–4318. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policy making in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Ang, B.W.; Liu, N. Handling zero values in the logarithmic mean Divisia index decomposition approach. Energy Policy 2007, 35, 238–246. [Google Scholar] [CrossRef]

- Hatzigeorgiou, E.; Polatidis, H.; Haralambopoulos, D. CO2 emissions in Greece for 1990-2002: A decomposition analysis and comparison of results using the arithmetic mean Divisia index and logarithmic mean Divisia index techniques. Energy 2008, 33, 492–499. [Google Scholar] [CrossRef]

- Zhao, M.; Tan, L.R.; Zhang, W.G.; Ji, M.H.; Liu, Y.; Yu, L.Z. Decomposing the influencing factors of industrial carbon emissions in Shanghai using the LMDI method. Energy 2010, 35, 2505–2510. [Google Scholar] [CrossRef]

- Akbostancı, E.; Tunç, G.I.; Asık, S.T. CO2 emissions of Turkish manufacturing industry: A decomposition analysis. Appl. Energy 2011, 88, 2273–2278. [Google Scholar] [CrossRef]

- Fernández González, P.; Landajo, M.; Presno, M.J. Multilevel LMDI decomposition of changes in aggregate energy consumption. A cross country analysis in the EU-27. Energy Policy 2014, 68, 576–584. [Google Scholar] [CrossRef]

- Hammond, G.P.; Norman, J.B. Decomposition analysis of energy-related carbon emission from UK manufacturing. Energy 2012, 41, 220–227. [Google Scholar] [CrossRef]

- Freitas, L.C.; Kaneko, S. Decomposition of CO2 emissions change from energy consumption in Brazil: Challenges and policy implications. Energy Policy 2011, 39, 1495–1504. [Google Scholar] [CrossRef]

- Margarita, R.A.; Victor, M. Decomposition analysis and innovative accounting approach for energy-related CO2 (carbon dioxide) emissions intensity over 1996-2009 in Portugal. Energy 2013, 57, 775–787. [Google Scholar]

- Tadhg, O.M. Decomposition of Ireland’s carbon emissions from 1990 to 2010: An extended Kaya identity. Energy Policy 2013, 59, 573–581. [Google Scholar]

- Domingo, G.; Manuel, M. Changes in CO2 emission intensities in the Mexican industry. Energy Policy 2012, 51, 149–163. [Google Scholar]

- Jung, S.; An, K.J.; Dodbiba, G.; Fujita, T. Regional energy-related carbon emission characteristics and potential mitigation in eco-industrial parks in South Korea: Logarithmic mean Divisia index analysis based on the Kaya identity. Energy 2012, 46, 231–241. [Google Scholar] [CrossRef]

- Gao, C.C.; Liu, Y.H.; Jin, J.; Wei, T.Y.; Zhang, J.Y.; Zhu, L.Z. Driving forces in energy-related carbon dioxide emissions in east and south coastal China: Commonality and variations. J. Clean. Prod. 2016, 135, 240–250. [Google Scholar] [CrossRef]

- Xu, S.C.; Han, H.M.; Zhang, W.W.; Zhang, Q.Q.; Long, R.Y.; Chen, H.; He, Z.X. Analysis of regional contributions to the national carbon intensity in China in different Five-Year Plan periods. J. Clean. Prod. 2017, 145, 209–220. [Google Scholar] [CrossRef]

- Zhao, X.R.; Zhang, X.; Li, N.; Shao, S.; Geng, Y. Decoupling economic growth from carbon dioxide emissions in China: A sectoral factor decomposition analysis. J. Clean. Prod. 2017, 142, 3500–3516. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, T.; Wang, Y.N. How to achieve the 2020 and 2030 emissions targets of China: Evidence from high, mid and low energy-consumption industrial sub-sectors. Atmos. Environ. 2016, 145, 280–292. [Google Scholar] [CrossRef]

- Zhang, M.; Song, Y.; Li, P.; Li, H. Study on affecting factors of residential energy consumption in urban and rural Jiangsu. Renew. Sust. Energ. Rev. 2016, 53, 330–337. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Zhou, M.; Mu, H. Decomposition analysis of energy consumption in Chinese transportation sector. Appl. Energy 2011, 88, 2279–2285. [Google Scholar] [CrossRef]

- Lin, B.Q.; Zhang, Z.H. Carbon emissions in China’s cement industry: A sectorand policy analysis. Renew. Sust. Energ. Rev. 2016, 58, 1387–1394. [Google Scholar] [CrossRef]

- Lin, B.Q.; Long, H.Y. Emissions reduction in China’s chemical industry-Based on LMDI. Renew. Sust. Energ. Rev. 2016, 53, 1348–1355. [Google Scholar] [CrossRef]

- Xie, X.; Shao, S.; Lin, B.Q. Exploring the driving forces and mitigation pathways of CO2 emissions in China’s petroleum refining and coking industry: 1995–2031. Appl. Energy 2016, 184, 1004–1015. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Analysis of energy-related CO2 emissions in China’s mining industry: Evidence and policy implications. Resou. Policy 2017, 53, 77–87. [Google Scholar] [CrossRef]

- Lin, B.Q.; Tan, R.P. Sustainable development of China’s energy intensive industries: From theaspect of carbon dioxide emissions reduction. Renew. Sust. Energ. Rev. 2017, 77, 386–394. [Google Scholar] [CrossRef]

- Lin, B.Q.; Ouyang, X.L. Analysis of energy-related CO2 (carbon dioxide) emissionsand reduction potential in the Chinese non-metallic mineral products industry. Energy 2014, 68, 688–697. [Google Scholar] [CrossRef]

- IPCC (Intergovernmental Panel on Climate Change). IPCC Guidelines for National Greenhouse Gas Inventories; United Kingdom Meteorological Office: Bracknell, UK, 2006. [Google Scholar]

- Zhang, Y.J.; Da, Y.B. The decomposition of energy-related carbon emission and its decoupling with economic growth in China. Renew. Sust. Energ. Rev. 2015, 41, 1255–1266. [Google Scholar] [CrossRef]

- Ang, B.W. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Bureau of Statistics of Henan Province. Henan Statistical Yearbook 2002–2016; China Statistics Press: Beijing, China, 2016.

- National Bureau of Statistics of China. China Energy Statistical Yearbook 2015; China Statistics Press: Beijing, China, 2015.

- Wang, C.; Chen, J.; Zou, J. Decomposition of energy-related CO2 emission in China: 1957-2000. Energy 2005, 30, 73–83. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Decomposition of energy-related CO2 emissions in China: An empiricalanalysis based on provincial panel data of three sectors. Appl. Energy 2017, 190, 772–787. [Google Scholar] [CrossRef]

- Liu, L.C.; Fan, Y.; Wu, G.; Wei, Y.M. Using LMDI method to analyze the change of China’s industrial CO2 emissions from final fuel use: An empirical analysis. Energy Policy 2007, 35, 5892–5900. [Google Scholar] [CrossRef]

- Xu, S.C.; He, Z.X.; Long, R.Y.; Chen, H.; Han, H.M.; Zhang, W.W. Comparative analysis of the regional contributions to carbon emissions in China. J. Clean. Prod. 2016, 127, 406–417. [Google Scholar] [CrossRef]

- Wang, S.S.; Zhou, D.Q.; Zhou, P.; Wang, Q.W. CO2 emissions, energy consumption and economic growth in China: A panel data analysis. Energy Policy 2011, 39, 4870–4875. [Google Scholar] [CrossRef]

- Ren, S.G.; Fu, X.; Chen, X.H. Regional variation of energy-related industrial CO2 emissions mitigation in China. China Econ. Rev. 2012, 23, 1134–1145. [Google Scholar] [CrossRef]

- Chen, S.Y. The abatement of carbon dioxide intensity in China: Factors decomposition and policy implications. World Econ. 2011, 34, 1148–1167. [Google Scholar] [CrossRef]

- Fisher-Vanden, K.; Jefferson, G.H.; Ma, J.; Xu, J. Technology development and energy productivity in China. Energy Econ. 2006, 28, 690–705. [Google Scholar] [CrossRef]

- Chiu, T.Y.; Lo, S.L.; Tsai, Y.Y. Establishing an integration-energy-practice model for improving energy performance indicators in ISO 50001 energy management systems. Energies 2012, 5, 5324–5339. [Google Scholar] [CrossRef]

- Feng, T.; Sun, L.; Zhang, Y. The relationship between energy consumption structure, economic structure and energy intensity in China. Energy Policy 2009, 37, 5475–5483. [Google Scholar] [CrossRef]

- Xu, F.; Xiang, N.; Nijkamp, P.; Higano, Y. Dynamic simulation of China’s carbon intensity and energy intensity evaluation focusing on industry and energy structure adjustments by 2020. Environ. Eng. Manag. J. 2013, 12, 1897–1901. [Google Scholar] [CrossRef]

- Yi, B.W.; Xu, J.H.; Fan, Y. Determining factors and diverse scenarios of CO2 emission intensity reduction to achieve the 40-45% target by 2020 in China—A historical and prospective analysis for the period 2005-2020. J. Clean. Prod. 2016, 122, 87–101. [Google Scholar] [CrossRef]

- IEA (International Energy Agency). CO2 Emissions from Fuel Combustion Highlights; IEA: Paris, France, 2016. [Google Scholar]

- Liu, Z.; Guan, D.; Crawford-Brown, D.; Zhang, Q.; He, K.; Liu, J. Energy policy: A low-carbon road map for China. Nature 2013, 500, 143–145. [Google Scholar] [CrossRef] [PubMed]

- Mi, Z.F.; Zhang, Y.K.; Guan, D.B.; Shan, Y.L.; Liu, Z.; Cong, R.G.; Yuan, X.C.; Wei, Y.M. Consumption-based emission accounting for Chinese cities. Appl. Energy 2016, 184, 1073–1081. [Google Scholar] [CrossRef]

- Mi, Z.F.; Meng, J.; Guan, D.B.; Shan, Y.L.; Liu, Z.; Wang, Y.T.; Feng, K.H.; Wei, Y.M. Pattern changes in determinants of Chinese emissions. Environ. Res. Lett. 2017, 12, 074003. [Google Scholar] [CrossRef]

| Variables | Description and Definition | Unit |

|---|---|---|

| Equation (1) | ||

| i | Sector ith of the industrial sector | |

| j | Fuel jth of the energy consumption | |

| EC | Total CO2 emissions of industrial sector | Mt |

| ECij | CO2 emissions of sector ith of fuel jth | Mt |

| Eij | Energy consumption of sector ith of fuel jth | Mtce |

| NCVj | Average net calorific value of fuel jth | TJ/Mtce |

| CCj | Carbon content of fuel jth | t-C/TJ |

| Oj | Carbon oxidation factor of fuel jth | % |

| 44/12 | Ratio of molecular weights of CO2 and C | |

| Equation (2) | ||

| Ei | Energy consumption of sector ith | Mtce |

| Yi | Added value of sector ith | 109 RMB |

| Ri | R&D expenditure of sector ith | 109 RMB |

| Ii | Fixed asset investment of sector ith | 109 RMB |

| Y | Total added value of industrial sector | 109 RMB |

| EFij | CO2 emission per unit of fuel jth in sector ith | t/tce |

| ESij | Share of the fuel jth in final energy consumption of sector ith | Mtce/Mtce |

| EIi | Energy intensity of sector ith | tce/103 RMB |

| REi | Added value per unit of R&D expenditure in sector ith | added value, 109 RMB/R&D expenditure, 109 RMB |

| RIi | Share of R&D expenditure in fixed asset investment of sector ith | R&D expenditure, 109 RMB/fixed asset investment, 109 RMB |

| IIi | Share of fixed asset investment in added value of sector ith | fixed asset investment, 109 RMB/added value, 109 RMB |

| ISi | Share of added value of sector ith in total added value | added value, 109 RMB/added value, 109 RMB |

| Symbol | Industrial Sub-Sector | Symbol | Industrial Sub-Sector |

|---|---|---|---|

| Mining and Quarrying | S20 | Manufacture of medicines | |

| S1 | Mining and washing of coal | S21 | Manufacture of chemical fibers |

| S2 | Extraction of petroleum and natural gas | S22 | Manufacture of rubber and plastics |

| S3 | Mining and processing of ferrous metal ores | S23 | Manufacture of non-metallic mineral products |

| S4 | Mining and processing of non-ferrous metal ores | S24 | Smelting and pressing of ferrous metals |

| S5 | Mining and processing of non-metal ores | S25 | Smelting and pressing of non-ferrous metals |

| Manufacturing | S26 | Manufacture of metal products | |

| S6 | Processing of food from agricultural products | S27 | Manufacture of general purpose machinery |

| S7 | Manufacture of foods | S28 | Manufacture of special purpose machinery |

| S8 | Manufacture of wine, beverage and refined tea | S29 | Manufacture of transport equipment |

| S9 | Manufacture of tobacco | S30 | Manufacture of electrical machinery and equipment |

| S10 | Manufacture of textile | S31 | Manufacture of communication equipment, computers, and other electronic equipment |

| S11 | Manufacture of textile wearing apparel, footwear, and caps | S32 | Manufacture of measuring instruments and machinery for cultural activity and office work |

| S12 | Manufacture of leather, fur, feather, and related products | S33 | Manufacture of other manufacturing |

| S13 | Processing of timber; manufacture of wood, bamboo, rattan, palm, and straw products | S34 | Recycling and disposal of waste |

| S14 | Manufacture of furniture | Production and Supply of Electric Power, Gas and Water | |

| S15 | Manufacture of paper and paper products | S35 | Production and supply of electric power and heat power |

| S16 | Printing, reproduction of recording media | S36 | Production and supply of gas |

| S17 | Manufacture of articles for culture, education, and sport | S37 | Production and supply of water |

| S18 | Processing of petroleum, coking, processing of nuclear fuel | Other Industries | |

| S19 | Manufacture of raw chemical materials and chemical products | S38 | Support activities for mining, Mining of other ores, and Repairing services of metal products, machinery and equipment |

| CO2 Emission Changes (104 t) | Contribution (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Economic Output | Internal Structure | Energy Structure | Energy Intensity | R&D Intensity | R&D Efficiency | Investment Intensity | Total Changes | ηY | ηIS | ηES | ηEI | ηRI | ηRE | ηII | |

| (ΔECY) | (ΔECIS) | (ΔECES) | (ΔECEI) | (ΔECRI) | (ΔECRE) | (ΔECII) | (ΔECtot ) | ||||||||

| 2001–2002 | 2612 | 118 | 2 | −928 | −11621 | 14964 | −3397 | 1750 | 149 | 7 | 0 | −53 | −664 | 855 | −194 |

| 2002–2003 | 4325 | 46 | 16 | −714 | 5743 | −1,4504 | 8855 | 3767 | 115 | 1 | 0 | −19 | 152 | −385 | 235 |

| 2003–2004 | 6150 | 417 | 180 | 409 | −3,5996 | 3088 | 32918 | 7166 | 86 | 6 | 3 | 6 | −502 | 43 | 459 |

| 2004–2005 | 7096 | −1704 | 148 | −1048 | −816 | −8308 | 9241 | 4609 | 154 | −37 | 3 | −23 | −18 | −180 | 200 |

| 2005–2006 | 8553 | −800 | 145 | −144 | 11723 | −12556 | 904 | 7825 | 109 | −10 | 2 | −2 | 150 | −160 | 12 |

| 2006–2007 | 10375 | −1581 | 39 | −2406 | 1125 | −3577 | 2463 | 6438 | 161 | −25 | 1 | −37 | 17 | −56 | 38 |

| 2007–2008 | 8905 | −2901 | 52 | −3782 | 5118 | −47 | −5073 | 2272 | 392 | −128 | 2 | −166 | 225 | −2 | −223 |

| 2008–2009 | 7167 | −1423 | −58 | −2524 | −4693 | −7722 | 12,421 | 3168 | 226 | −45 | −2 | −80 | −148 | −244 | 392 |

| 2009–2010 | 10627 | −4032 | 24 | −2634 | 4,1169 | −27,189 | −13,981 | 3984 | 267 | −101 | 1 | −66 | 1033 | −683 | −351 |

| 2010–2011 | 11747 | −3940 | −168 | −4825 | 9610 | −3603 | −6011 | 2810 | 418 | −140 | −6 | −172 | 342 | −128 | −214 |

| 2011–2012 | 11823 | −9729 | −24 | −4377 | 6204 | −1626 | −4724 | −2453 | 482 | −397 | −1 | −178 | 253 | −66 | −193 |

| 2012–2013 | 8991 | −5180 | −36 | −1613 | −1249 | 1897 | −656 | 2153 | 418 | −241 | −2 | −75 | −58 | 88 | −30 |

| 2013–2014 | 7326 | −4786 | −44 | −3879 | 10961 | −1640 | −9326 | −1387 | 528 | −345 | −3 | −280 | 790 | −118 | −672 |

| 2014–2015 | 6005 | −5653 | 74 | −4439 | −5475 | −1440 | 6920 | −4007 | 150 | −141 | 2 | −111 | −137 | −36 | 173 |

| 2001–2015 | 111,702 | −4,1148 | 350 | −32,903 | 31,802 | −62,263 | 30,553 | 38,094 | 293 | −108 | 1 | −86 | 83 | −163 | 80 |

| Subsector | 2001 (Mt) | 2015 (Mt) | 2001–2015 (Mt) | Increasing Rate (%) |

|---|---|---|---|---|

| Manufacturing | 86 | 205 | 119 (764–645) * | 138 |

| S25: Smelting and Pressing of Non-Ferrous Metals | 7 | 42 | 35 (58–23) * | 500 |

| S19: Manufacture of Raw Chemical Materials and Chemical Products | 16 | 45 | 29 (111–82) * | 181 |

| Mining and Quarrying | 39 | 193 | 154 (594–440) * | 395 |

| S1: Mining and Washing of Coal | 35 | 187 | 152 (197–45) * | 434 |

| Production and Supply of Electric Power, Gas and Water | 76 | 182 | 106 (604–498) * | 139 |

| S35: Production and Supply of Electric Power and Heat Power | 76 | 181 | 105 (438–333) * | 138 |

| Summary | 201 | 580 | 379 | 189 |

| Decomposition Factor | FYP Trend | Annual Average Contribution (%) | ||

|---|---|---|---|---|

| 10th | 11th | 12th | ||

| Economic Output | + | + | + | 19.6 |

| Industrial Internal Structure | − | − | − | −7.2 |

| Energy Structure | + | + | − | 0.1 |

| Energy Intensity | − | − | − | −5.8 |

| R&D Intensity | − | + | + | 5.6 |

| R&D Efficiency | − | − | − | −10.9 |

| Investment Intensity | + | − | − | 5.4 |

| Factors | Historical Trend | Year | Scenario | ||||

|---|---|---|---|---|---|---|---|

| BAU | EI | SO | RD | CP | |||

| Efficiency Improvement Factors | |||||||

| Energy Intensity (EI) θ | −8.9 | 16–20 | −8.9 | −10 | −8.9 | −10.5 | −10.5 |

| 21–25 | −8.9 | −11 | −8.9 | −11.5 | −11.5 | ||

| 26–30 | −8.9 | −12 | −8.9 | −12.5 | −12.5 | ||

| R&D Intensity (RI) ν | −5.3 | 16–20 | −5.3 | −4 | −5.3 | −3 | −3 |

| 21–25 | −5.3 | −3 | −5.3 | −2 | −2 | ||

| 26–30 | −5.3 | −2 | −5.3 | −1 | −1 | ||

| R&D Efficiency (RE) μ | −3 | 16–20 | −3 | −4 | −3 | −5 | −5 |

| 21–25 | −3 | −5 | −3 | −6 | −6 | ||

| 26–30 | −3 | −6 | −3 | −7 | −7 | ||

| Investment Intensity (II) φ | 17.6 | 16–20 | 17.6 | 18 | 17.6 | 18 | 18 |

| 21–25 | 17.6 | 19 | 17.6 | 19 | 19 | ||

| 26–30 | 17.6 | 20 | 17.6 | 20 | 20 | ||

| Structure Adjustment Factors | |||||||

| Industrial Internal Structure (IS) γ | −2.3 | 16–20 | −2.3 | −2.3 | −3 | −2.3 | −3 |

| 21–25 | −2.3 | −2.3 | −4.5 | −2.3 | −4.5 | ||

| 26–30 | −2.3 | −2.3 | −5.5 | −2.3 | −5.5 | ||

| Energy Structure (ES) δ | 0.3 | 16–20 | 0.3 | 0.7 | 0 | 0.3 | 0 |

| 21–25 | 0.3 | 0.7 | −0.5 | 0.3 | −0.5 | ||

| 26–30 | 0.3 | 0.7 | −1 | 0.3 | −1 | ||

| Scenario | Carbon Intensity (t-CO2/104 RMB) | Achieved 2020 Reduction Target or Not (40–45%) | Achieved 2030 Reduction Target or Not (60–65%) | ||

|---|---|---|---|---|---|

| 2005 | 2020 | 2030 | |||

| BAU | 14.24 | 3.56 | 2.47 | Yes | Yes |

| EI | 14.24 | 3.47 | 2.18 | Yes | Yes |

| SO | 14.24 | 3.39 | 1.60 | Yes | Yes |

| RD | 14.24 | 3.37 | 1.99 | Yes | Yes |

| CP | 14.24 | 3.20 | 1.29 | Yes | Yes |

| Parameter | Change Range * | CO2 Emission Uncertainty under CP Scenario, % |

|---|---|---|

| β Economic output (Y) | 10% lower | −12 |

| 10% higher | 13 | |

| γ Industrial internal structure (IS) | 10% lower | −7 |

| 10% higher | 7 | |

| δ Energy structure (ES) | 10% lower | −1 |

| 10% higher | 1 | |

| θ Energy intensity (EI) | 10% lower | −18 |

| 10% higher | 21 | |

| ν R&D intensity (RI) | 10% lower | 3 |

| 10% higher | −3 | |

| μ R&D Efficiency (RE) | 10% lower | −9 |

| 10% higher | 10 | |

| φ Investment intensity (II) | 10% lower | 27 |

| 10% higher | −22 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Wang, K.; Wang, S.; Zhang, R.; Tang, X. Exploring the Driving Forces and Reduction Potential of Industrial Energy-Related CO2 Emissions during 2001–2030: A Case Study for Henan Province, China. Sustainability 2019, 11, 1176. https://doi.org/10.3390/su11041176

Liu L, Wang K, Wang S, Zhang R, Tang X. Exploring the Driving Forces and Reduction Potential of Industrial Energy-Related CO2 Emissions during 2001–2030: A Case Study for Henan Province, China. Sustainability. 2019; 11(4):1176. https://doi.org/10.3390/su11041176

Chicago/Turabian StyleLiu, Lei, Ke Wang, Shanshan Wang, Ruiqin Zhang, and Xiaoyan Tang. 2019. "Exploring the Driving Forces and Reduction Potential of Industrial Energy-Related CO2 Emissions during 2001–2030: A Case Study for Henan Province, China" Sustainability 11, no. 4: 1176. https://doi.org/10.3390/su11041176

APA StyleLiu, L., Wang, K., Wang, S., Zhang, R., & Tang, X. (2019). Exploring the Driving Forces and Reduction Potential of Industrial Energy-Related CO2 Emissions during 2001–2030: A Case Study for Henan Province, China. Sustainability, 11(4), 1176. https://doi.org/10.3390/su11041176